Imvite/natural rubber composite and preparation method thereof

A technology of natural rubber and composite materials, which is applied in the field of montmorillonite/natural rubber composite materials and their preparation, can solve problems such as reducing the performance of composite materials, achieve the effects of reducing production costs, expanding the scope of use, and simple and efficient preparation methods

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

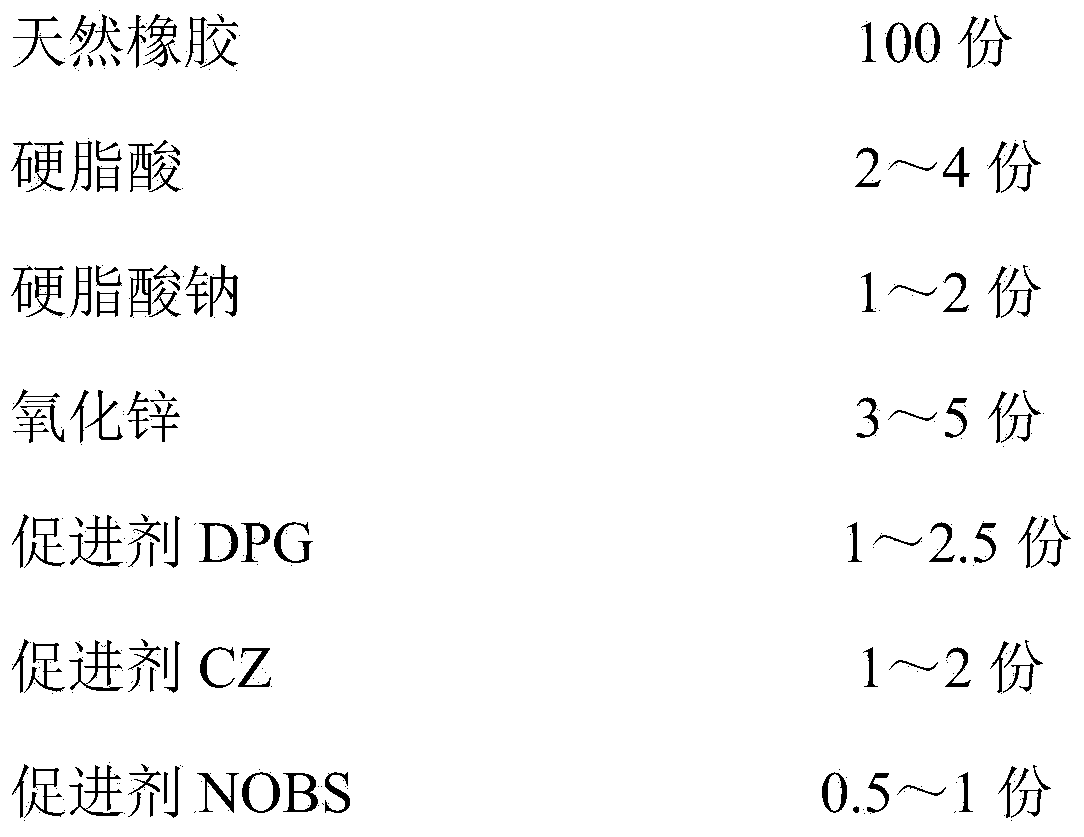

[0039] formula:

[0040]

[0041] Described natural rubber is natural latex, and weight solid content is 60%;

[0042] (1) Add 50 g of 10% weight concentration of graphene oxide solution to 500 g of 20% weight concentration of alkylammonium salt (octadecyltrimethylammonium chloride) modified montmorillonite suspension, At the same time, 0.5 g of Si-69 coupling agent was added, and stirred at 60° C. for 10 hours. The modified montmorillonite suspension can be obtained.

[0043] (2) Add distilled water to the natural rubber latex with a weight concentration of 60% to dilute it to a weight concentration of 10%, then add sodium stearate, add the modified montmorillonite suspension in step (1) while stirring, and keep the temperature constant The tank was raised to 60°C, and after 4 hours of reaction, the emulsion was poured out, and about 10% of CaCl was added dropwise. 2 The aqueous solution is demulsified. After it is completely demulsified into a co-precipitated gel, it i...

Embodiment 2

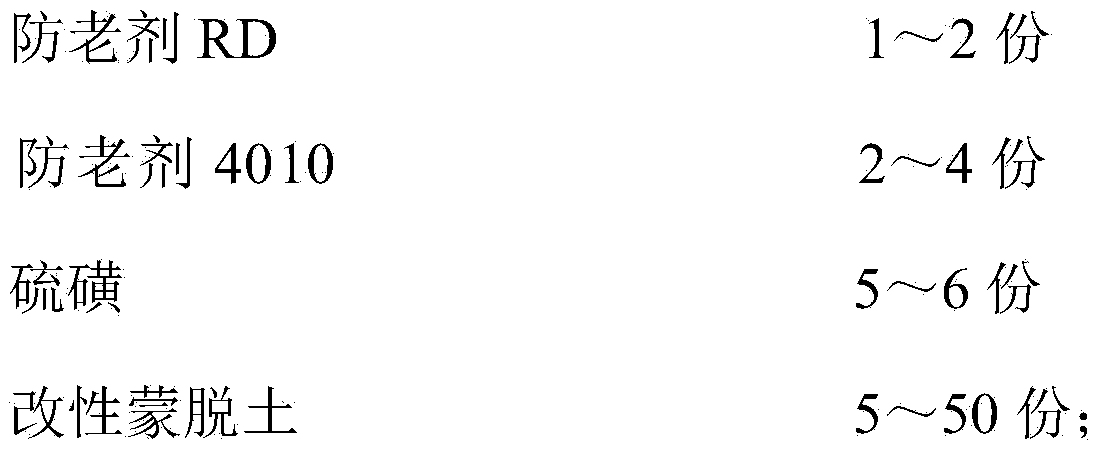

[0048] formula:

[0049]

[0050]

[0051] Described natural rubber is natural latex, and weight solid content is 60%;

[0052] (1) Add 10 g of 10% weight concentration of graphene solution to 25 g of 20% weight concentration of amino acid (α-amino acid) modified montmorillonite suspension, and add fatty acid coupling agent in an amount of 0.1 g The joint agent was stirred for 6 hours at a temperature of 90°C. The modified montmorillonite suspension can be obtained.

[0053] (2) Add distilled water to the natural rubber latex with a weight concentration of 60% to dilute it to a weight concentration of 11%, then add sodium stearate, add the modified montmorillonite suspension in step (1) while stirring, and keep the temperature constant The tank was raised to 62°C, and after 5 hours of reaction, the emulsion was poured out, and about 11% of CaCl was added dropwise.2 The aqueous solution is demulsified. After it is completely demulsified into a co-precipitated gel, it is...

Embodiment 3

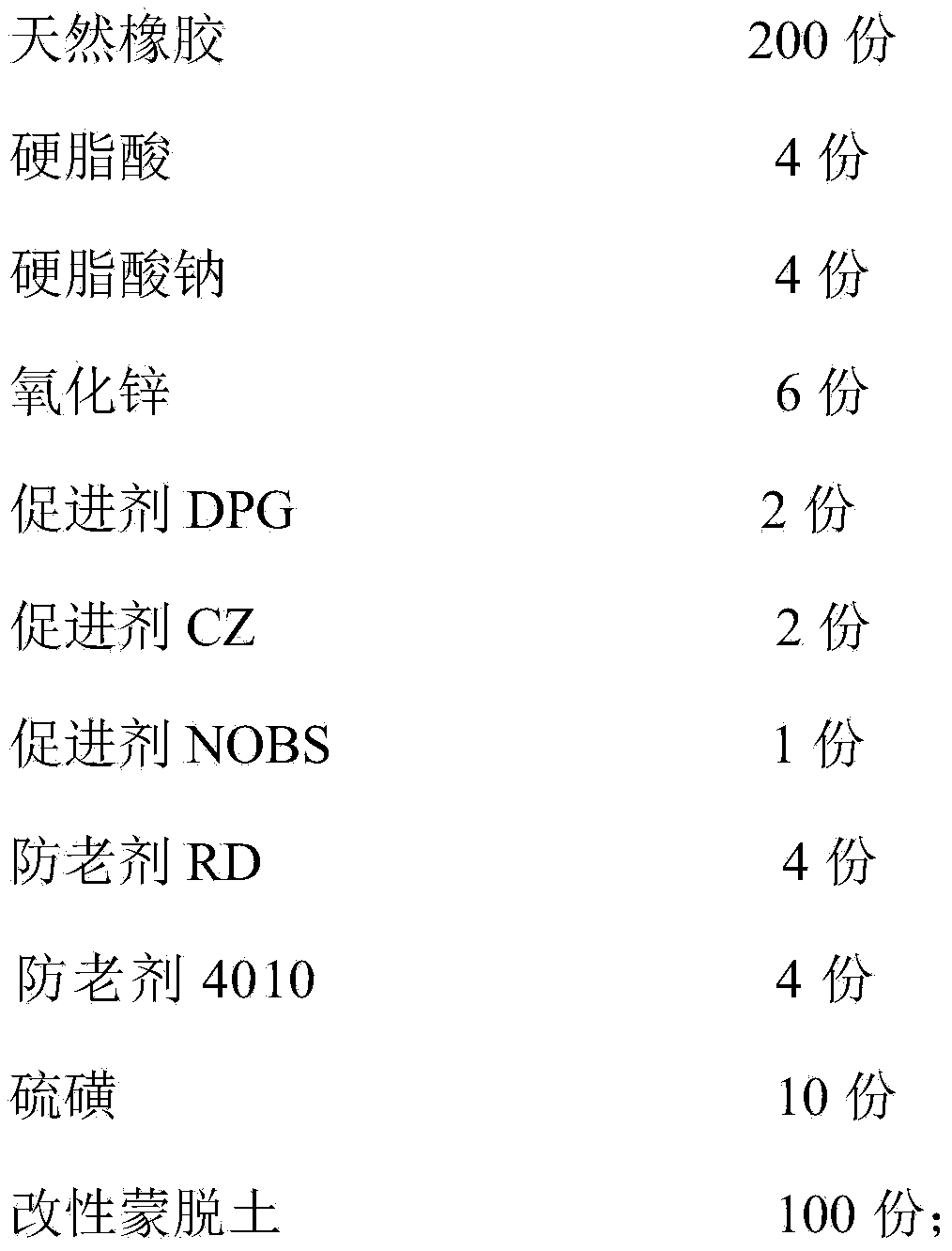

[0058] formula:

[0059]

[0060] Described natural rubber is natural latex, and weight solid content is 60%;

[0061] (1) Add 15g of 10% weight concentration graphene solution and 5g 10% weight concentration graphene oxide solution to 100g weight concentration 20% aspartic acid modified montmorillonite suspension, while Add titanate coupling agent in an amount of 0.2 g, and stir at 80° C. for 8 hours. The modified montmorillonite suspension can be obtained.

[0062] (2) Add distilled water to the natural rubber latex with a weight concentration of 60% to dilute it to a weight concentration of 9%, then add sodium stearate, add the modified montmorillonite suspension in step (1) while stirring, and keep the temperature constant The tank was raised to 60°C, and after 4 hours of reaction, the emulsion was poured out, and about 9% CaCl was added dropwise. 2 The aqueous solution is demulsified. After it is completely demulsified into a co-precipitated gel, it is washed severa...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com