Patents

Literature

271 results about "Blowing bottles" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

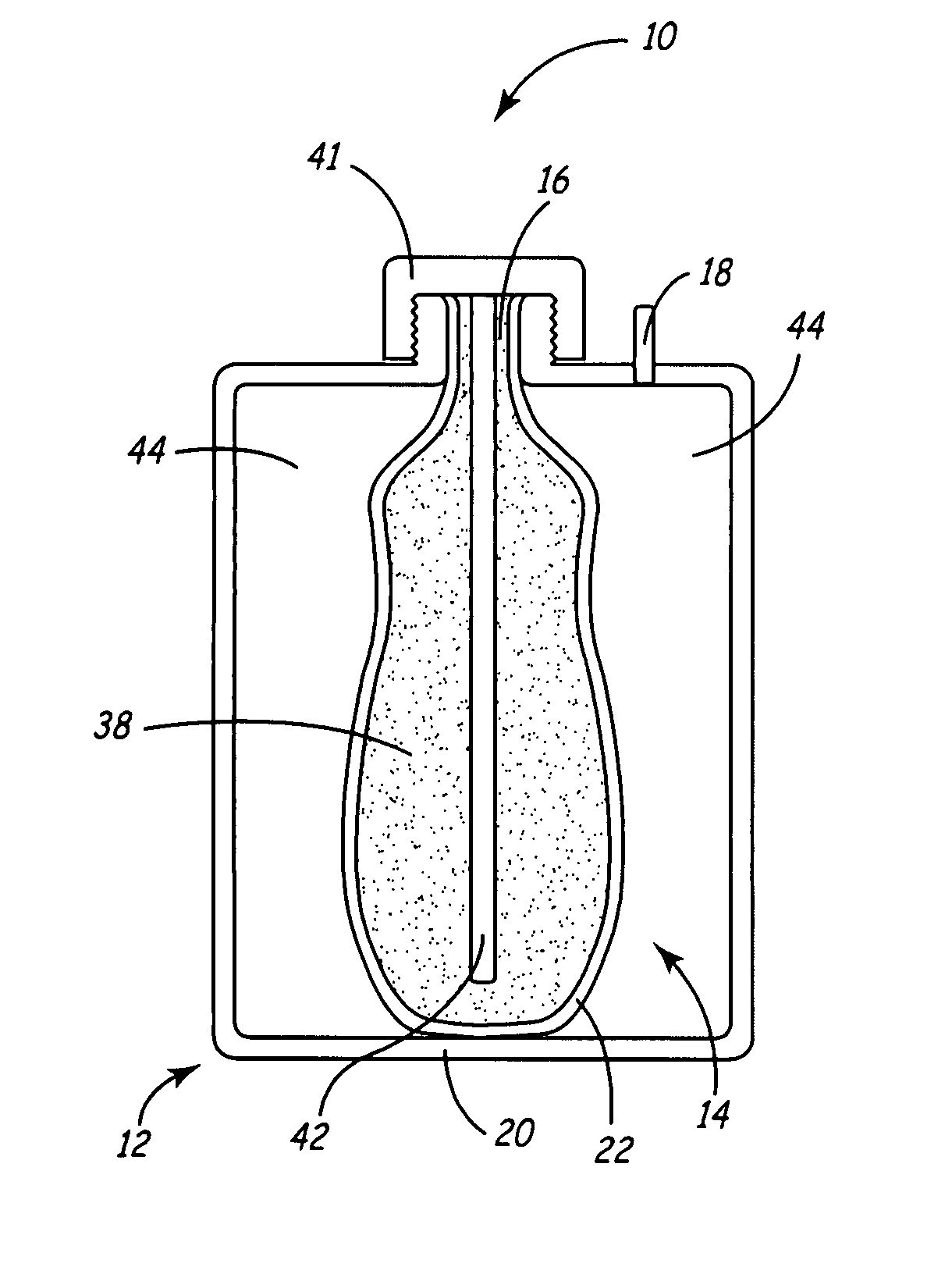

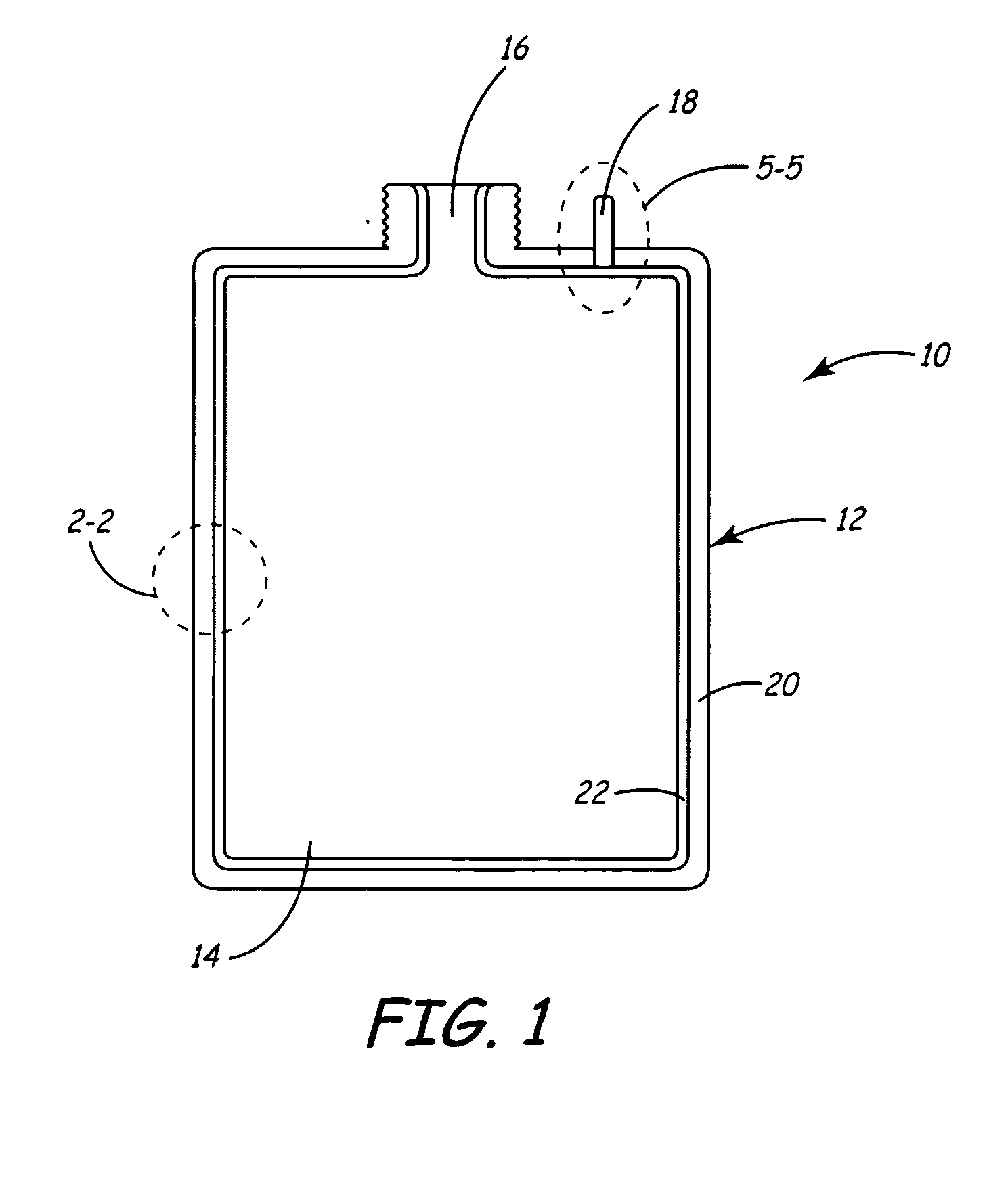

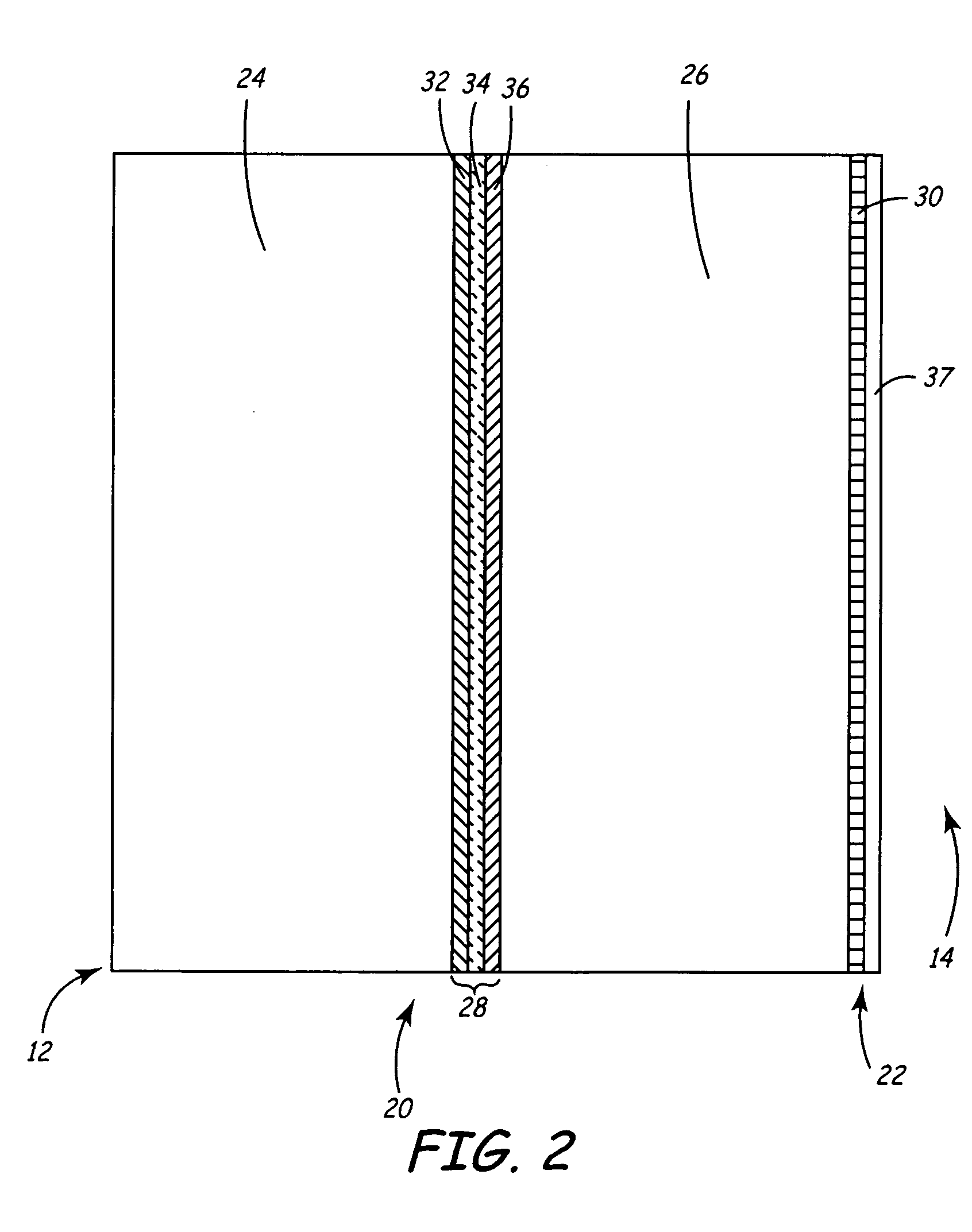

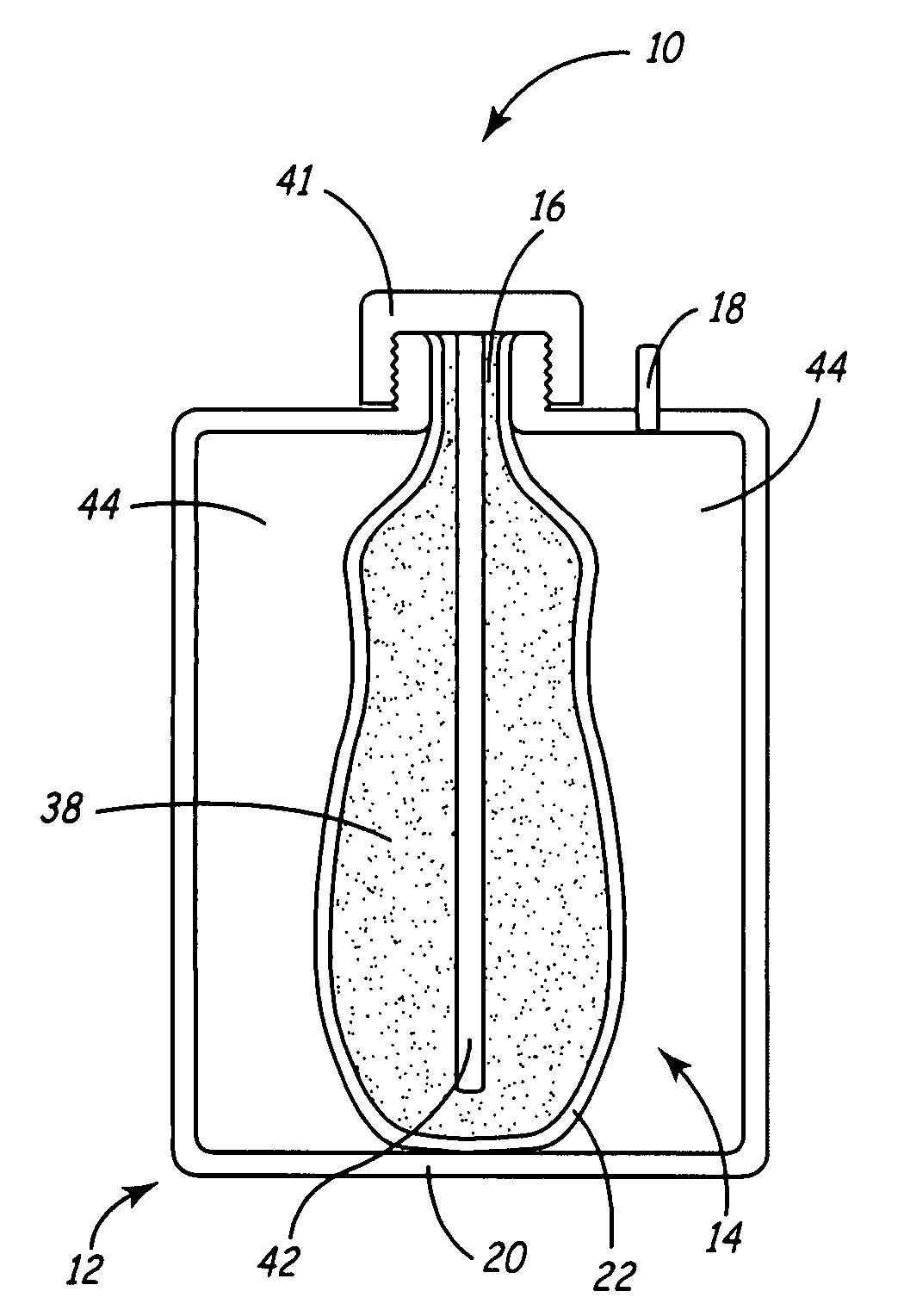

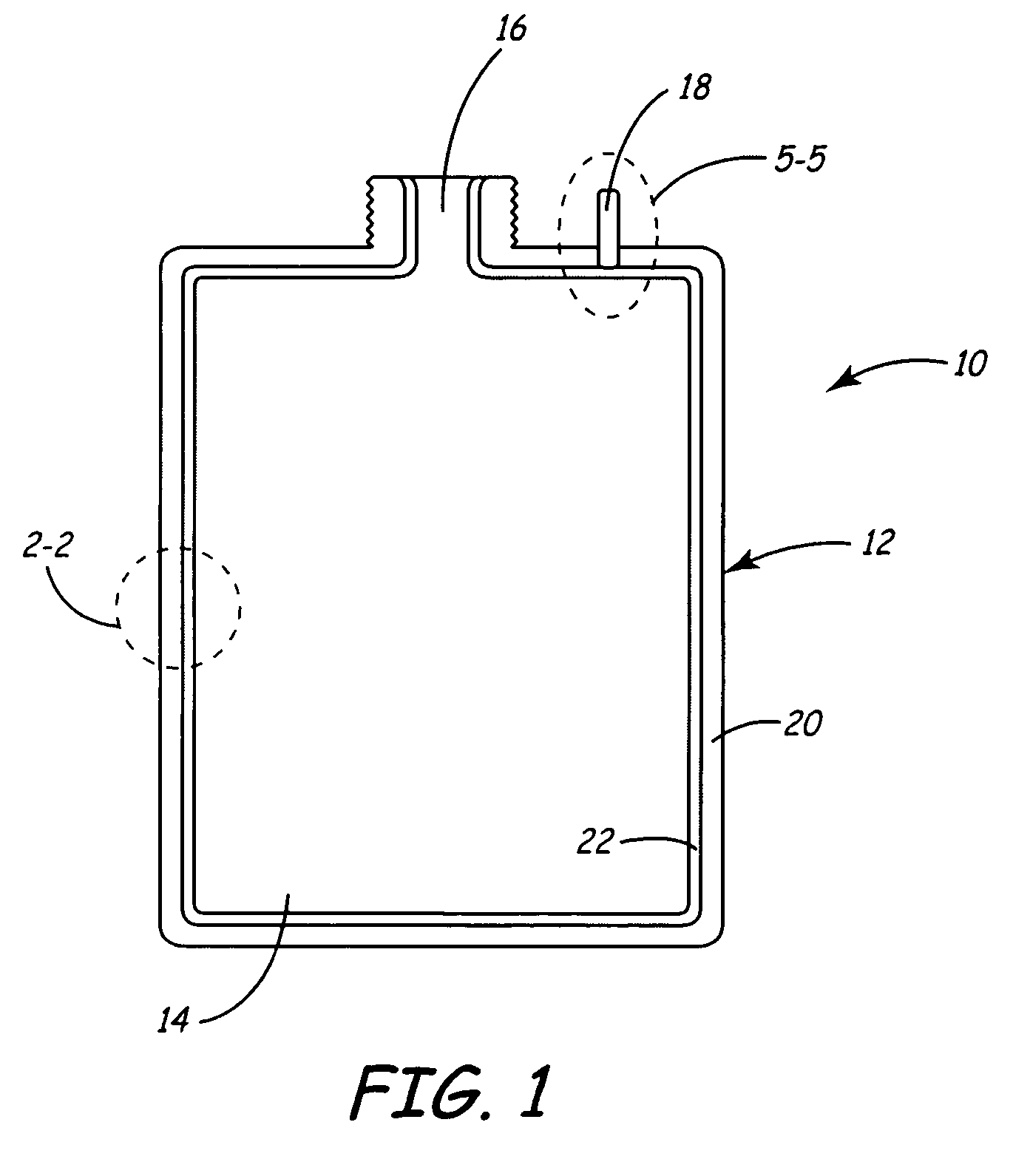

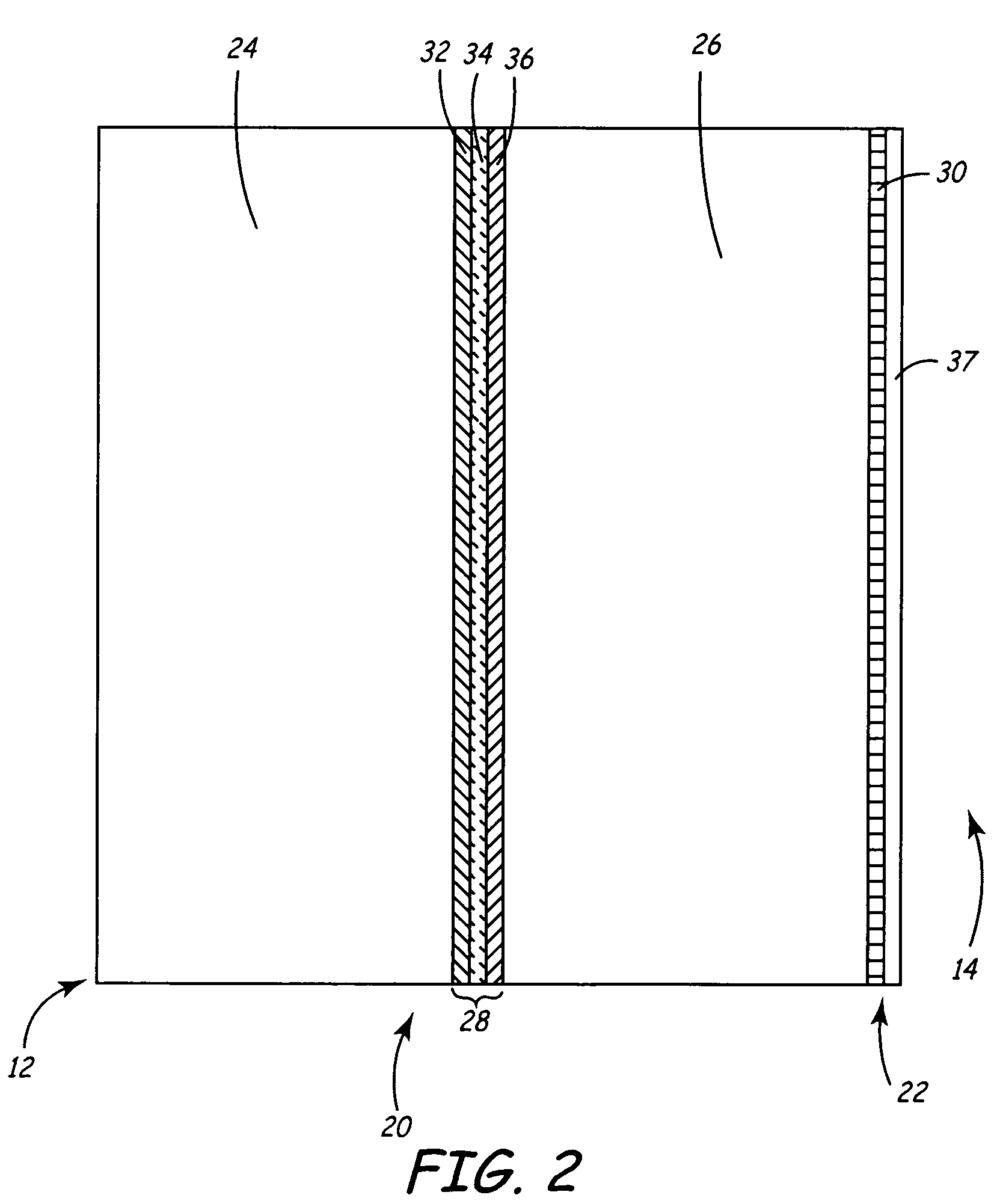

Blown bottle with intrinsic liner

InactiveUS20050103802A1Differing bond strengthOpening closed containersBottle/container closureEngineeringBlowing bottles

A container for holding and dispensing liquid having a container wall comprising a rigid portion that dimensionally defines the container, a liner portion disposed within the container adjacent to the rigid portion, and an adhesive layer disposed between the rigid portion and the liner portion. The adhesive layer removably secures the liner portion to the rigid portion such that the liner portion is capable of being separated from the rigid portion and collapsed within the container, for dispensing the liquid.

Owner:ADVANCED TECH MATERIALS INC

Blown bottle with intrinsic liner

InactiveUS7308991B2Differing bond strengthOpening closed containersBottle/container closureEngineeringBlowing bottles

A container for holding and dispensing liquid having a container wall comprising a rigid portion that dimensionally defines the container, a liner portion disposed within the container adjacent to the rigid portion, and an adhesive layer disposed between the rigid portion and the liner portion. The adhesive layer removably secures the liner portion to the rigid portion such that the liner portion is capable of being separated from the rigid portion and collapsed within the container, for dispensing the liquid.

Owner:ADVANCED TECH MATERIALS INC

Multi-layered biaxial stretch blow molded bottle and method for production thereof

InactiveUS7666486B2Improve propertiesExcellent oxygen barrier propertiesEnvelopes/bags making machinerySynthetic resin layered productsBlow moldingEngineering

A multi-layer biaxially stretched blow bottle having a 3-layer structure of PET / nylon MXD6 / PET or a 5-layer structure of PET / nylon MXD6 / PET / nylon MXD6 / PET, wherein the oxygen gas transmission coefficient of the nylon MXD6 layer is at most 6.0×10−14 cm3·cm / cm2·sec·cmHg as measured under conditions of a temperature of 23° C. and a relative humidity of 80%, and a production process of the bottle by biaxial stretch blow molding at a low stretching temperature and high draw ratios.

Owner:KUREHA KAGAKU KOGYO KK

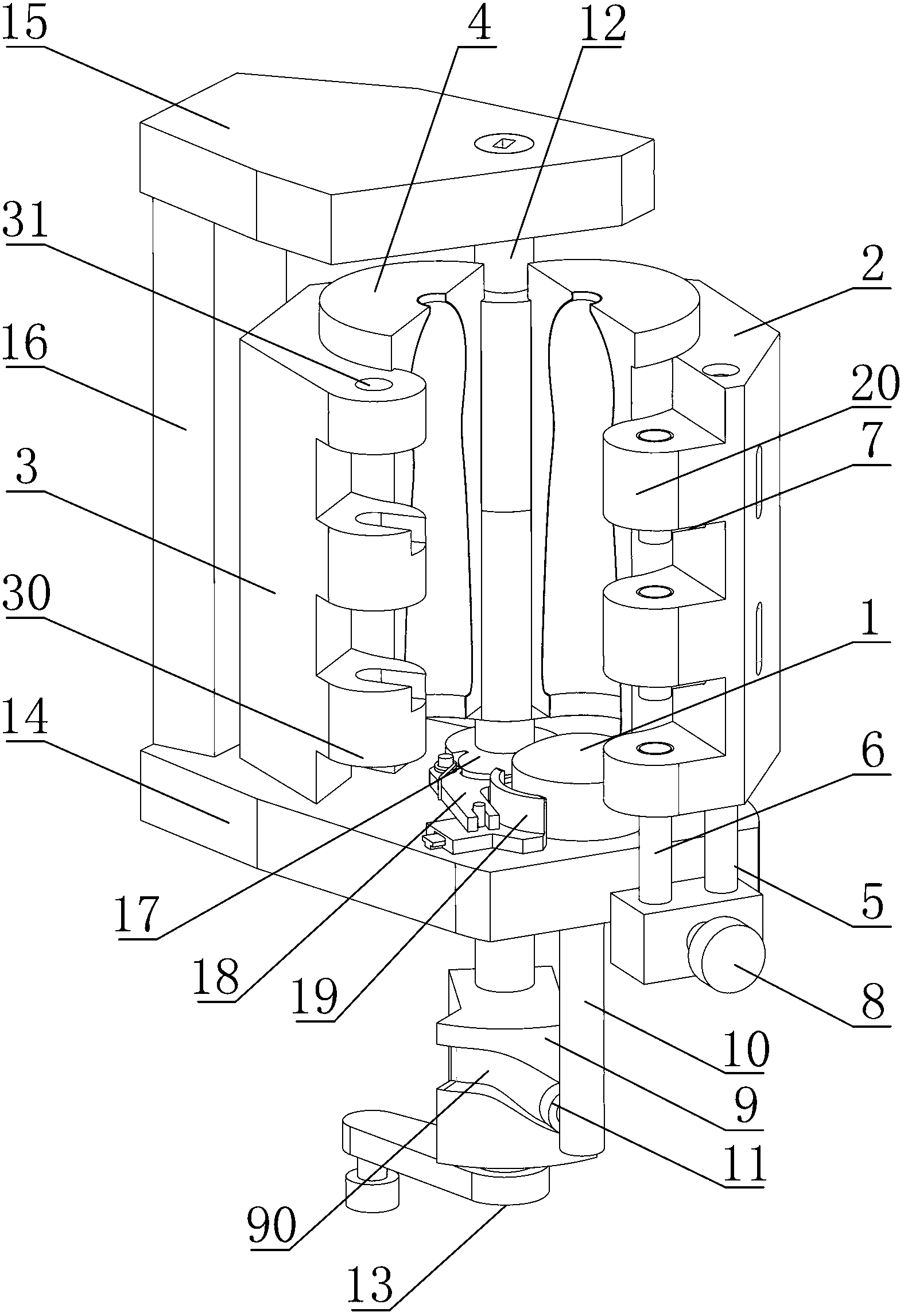

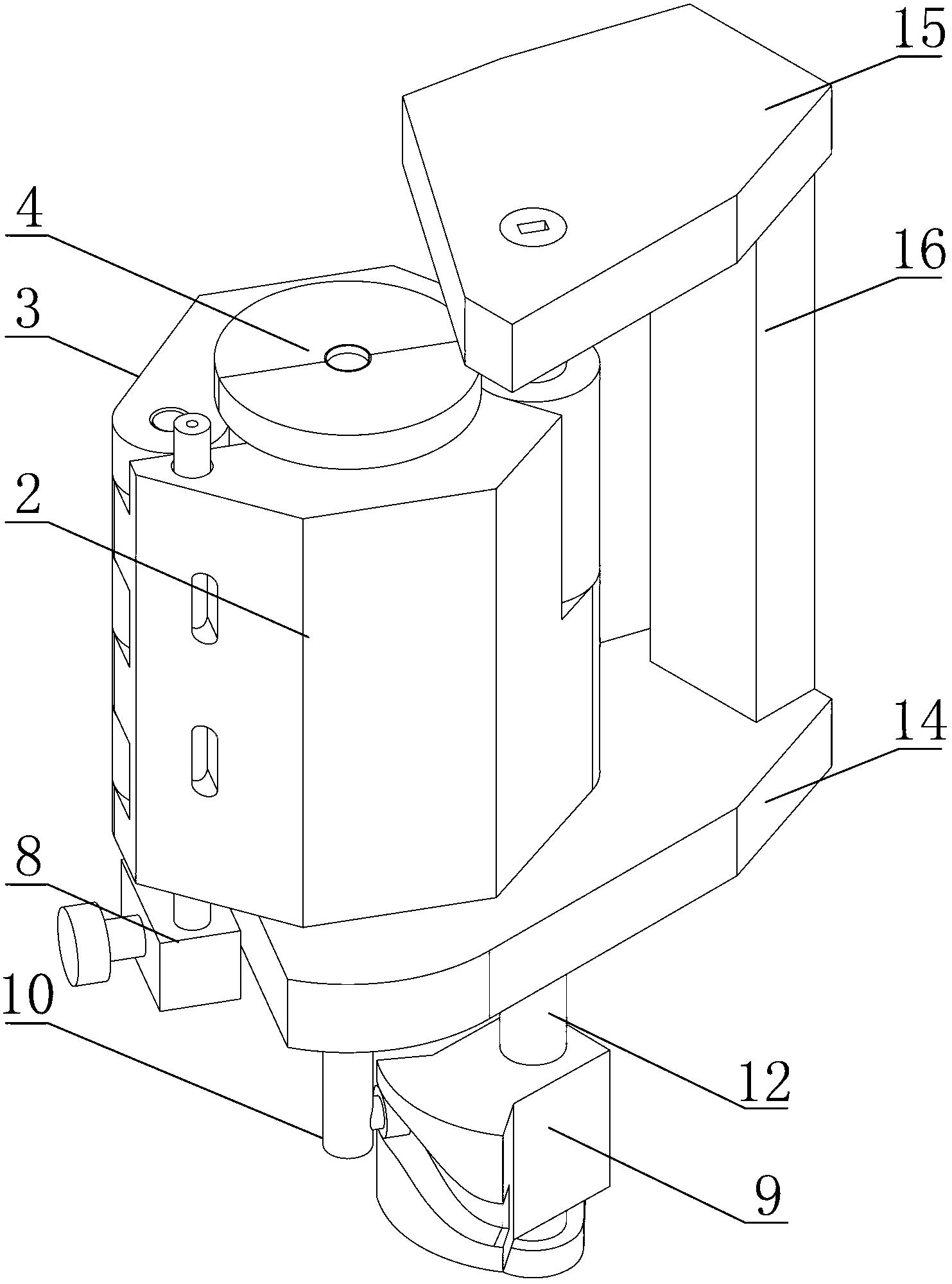

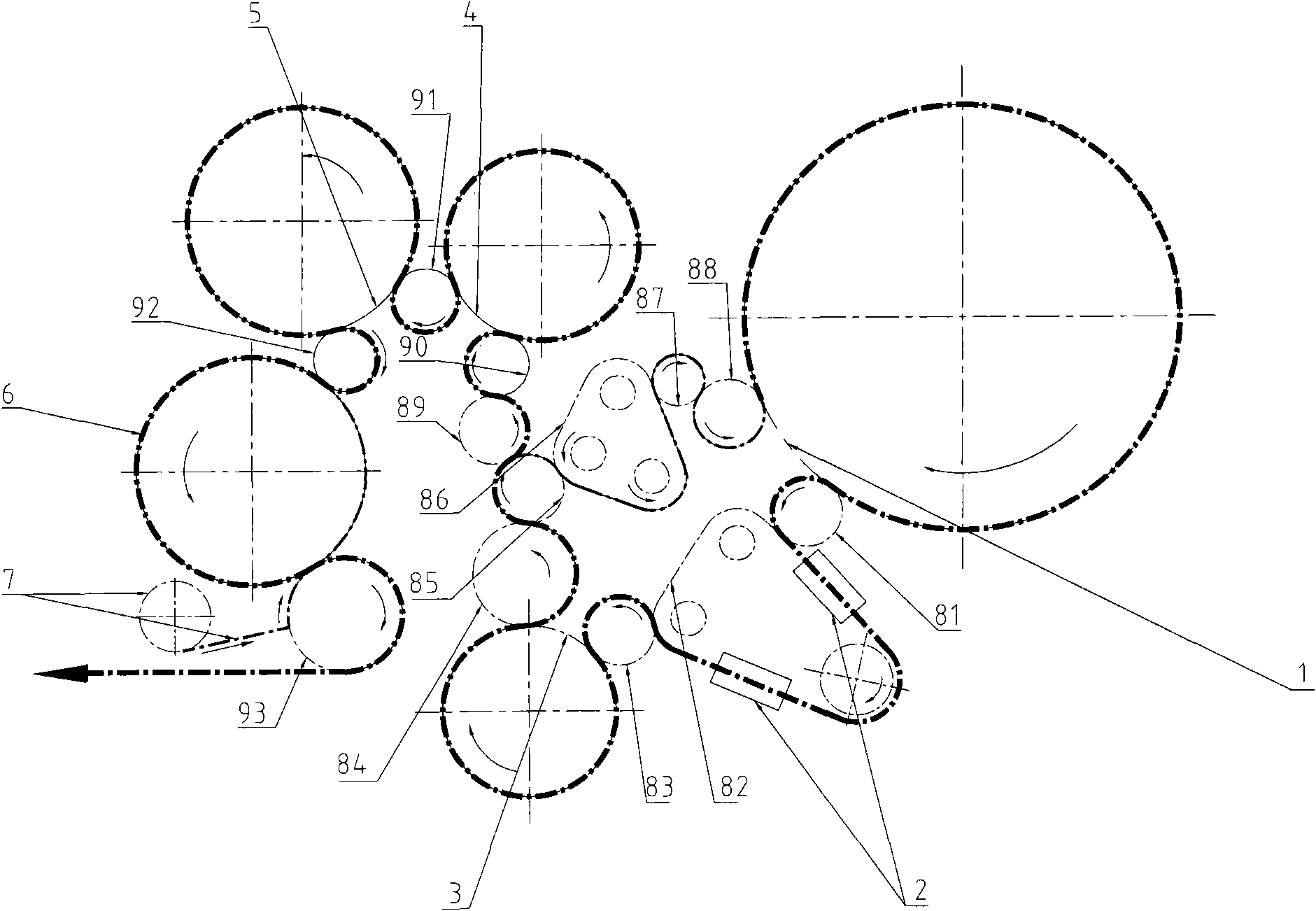

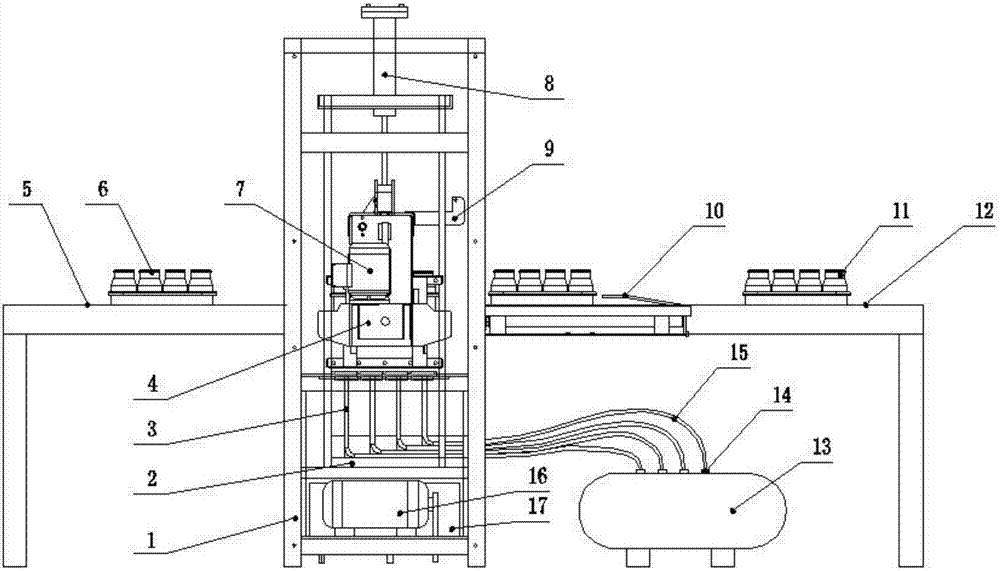

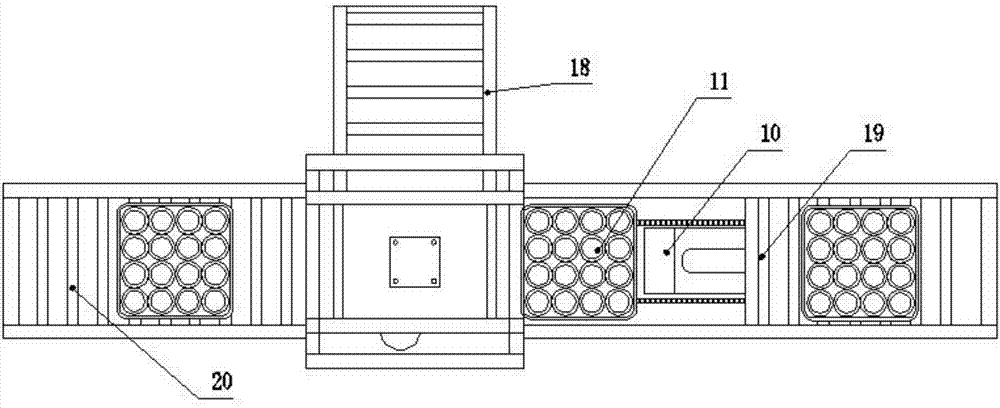

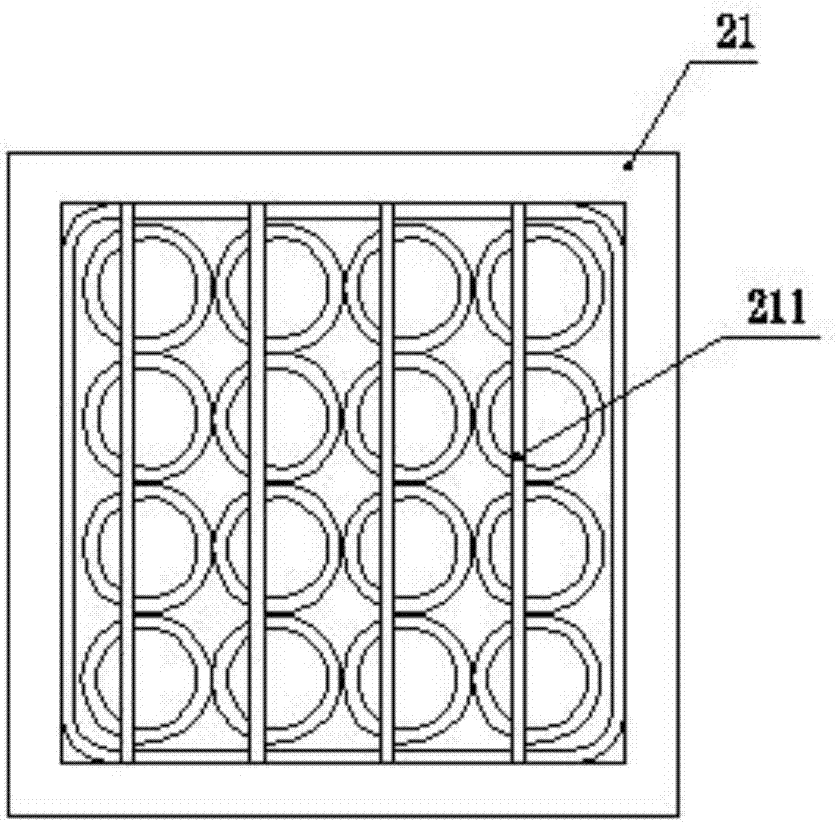

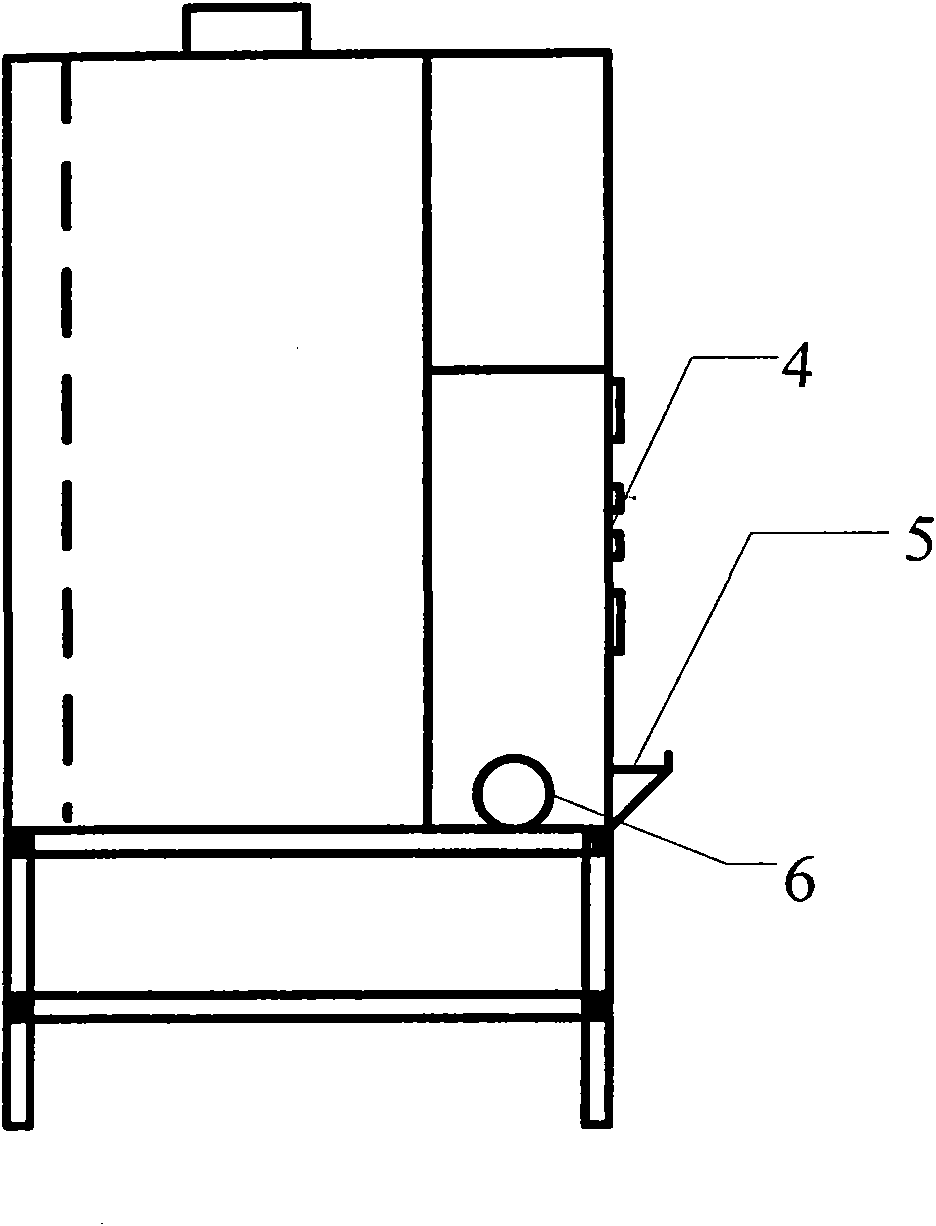

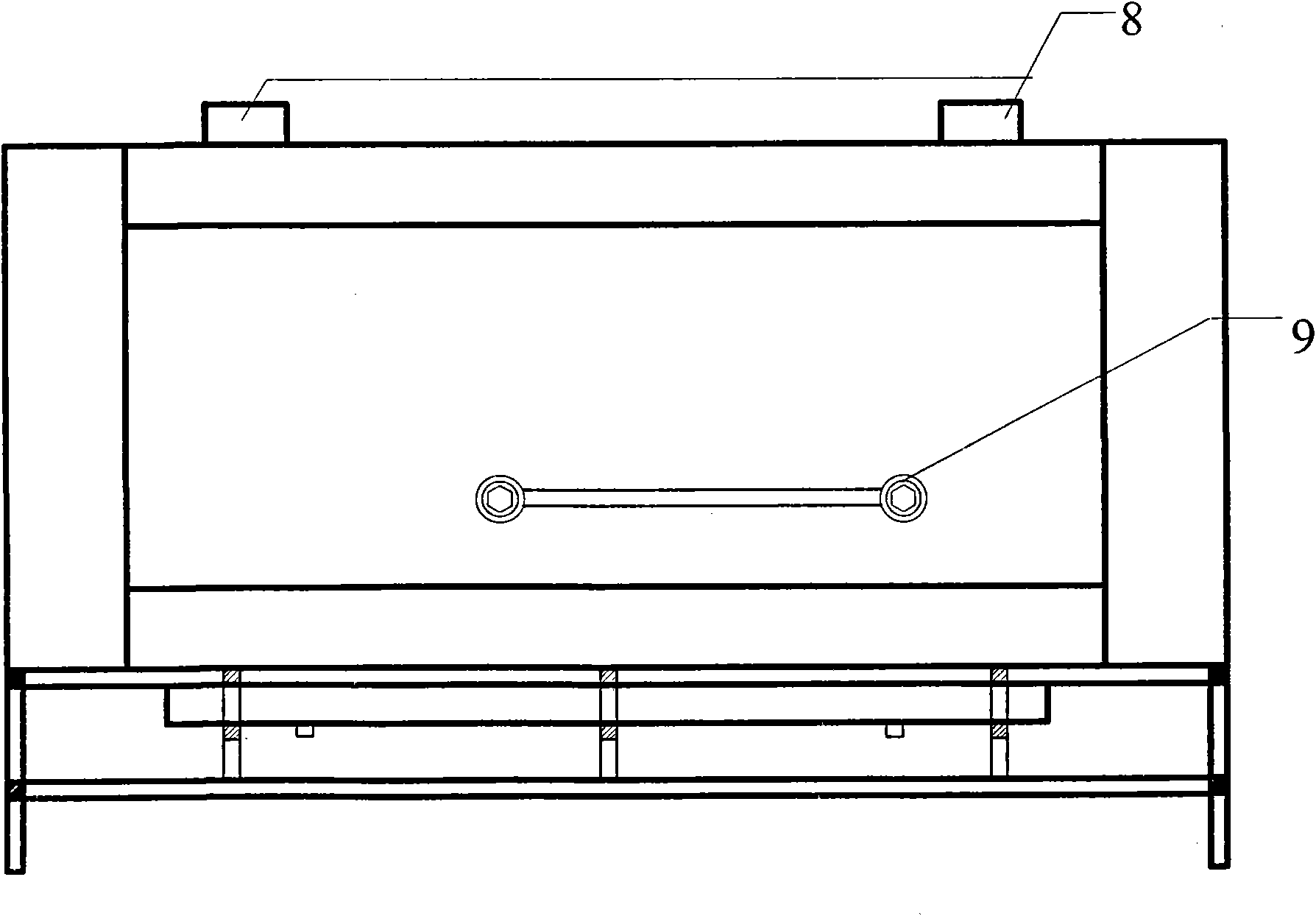

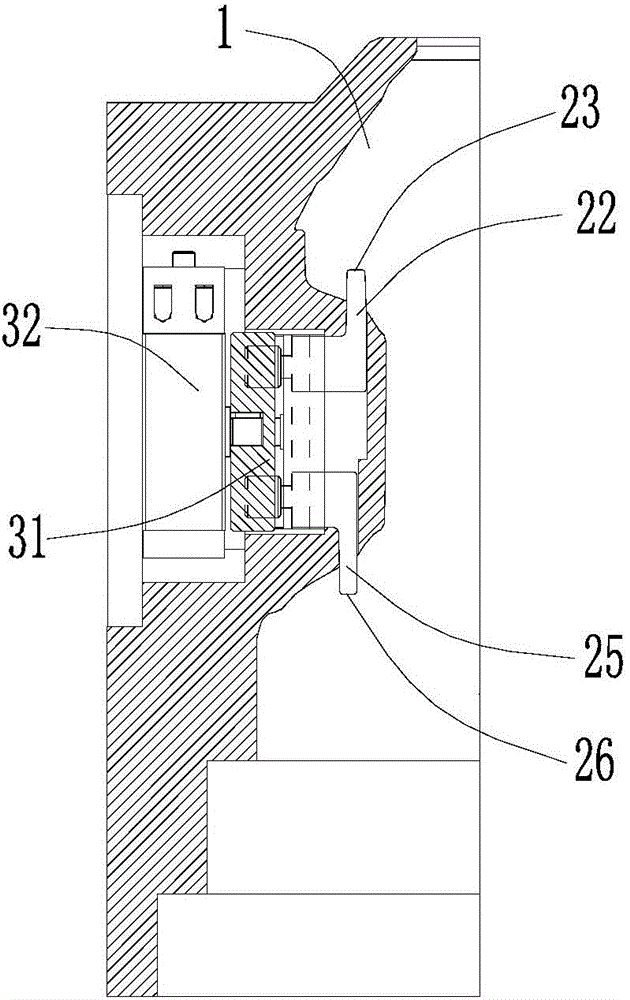

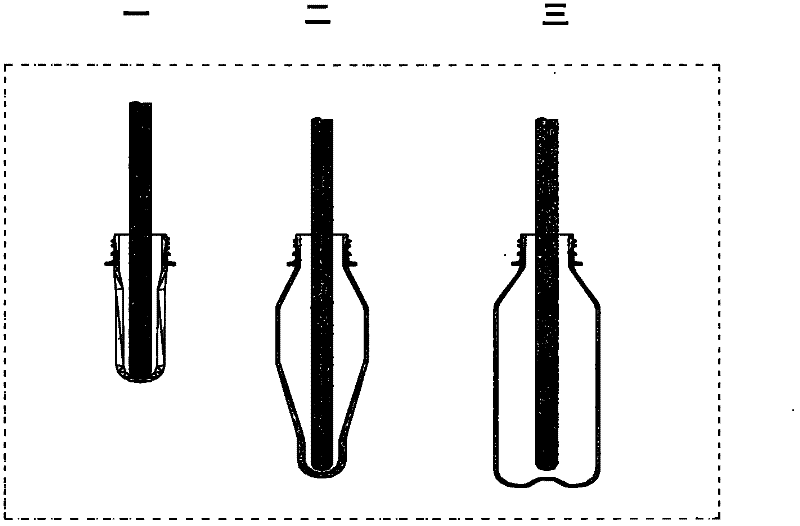

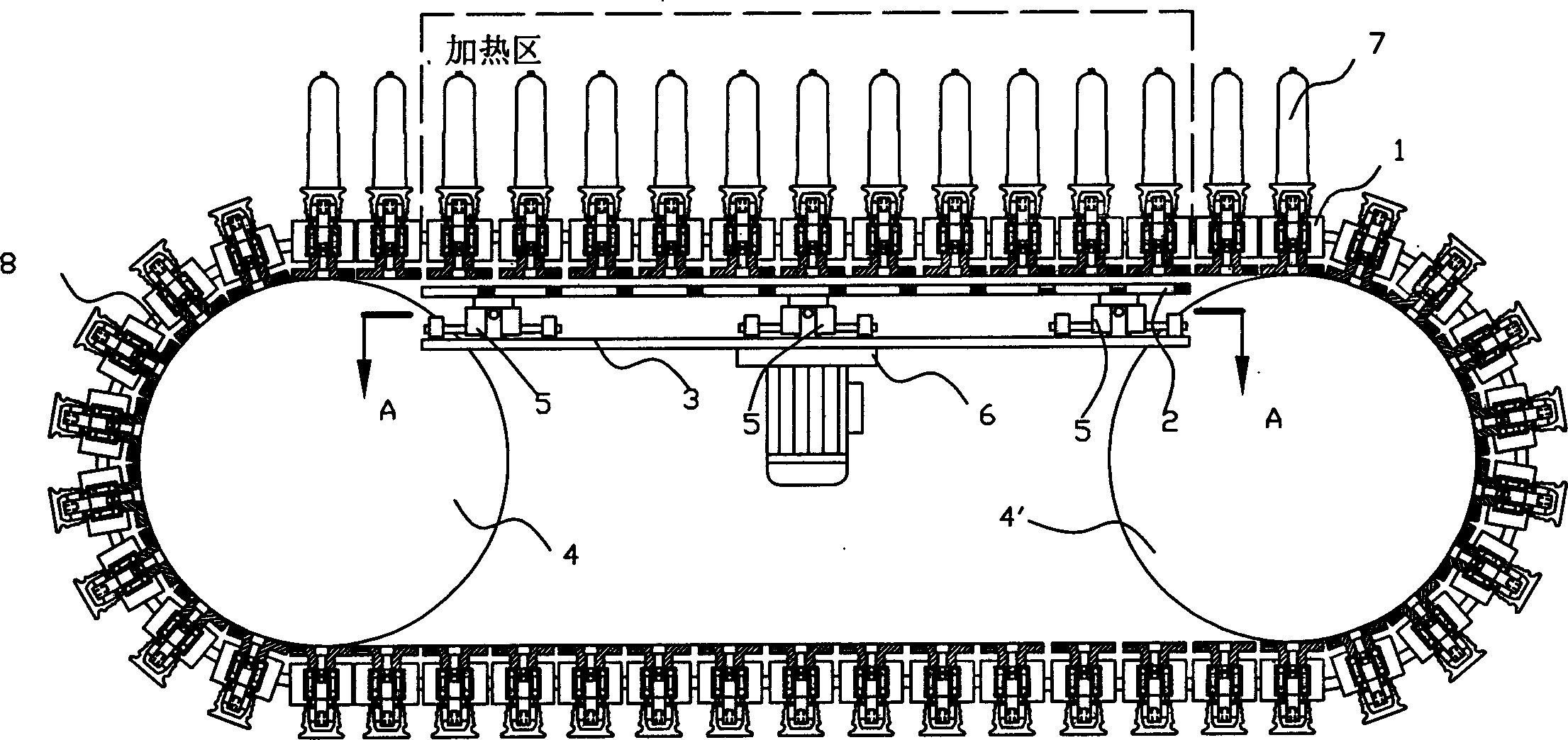

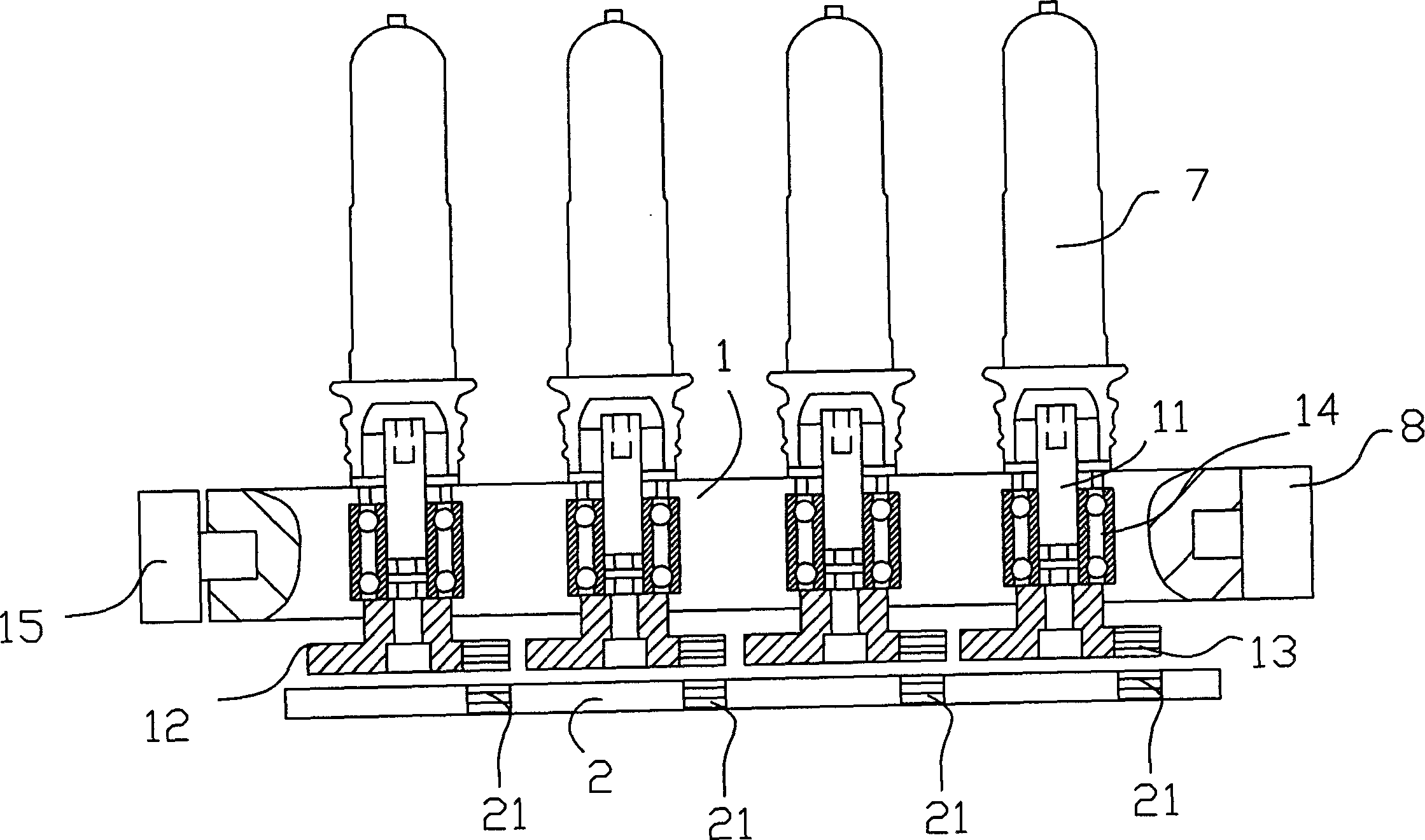

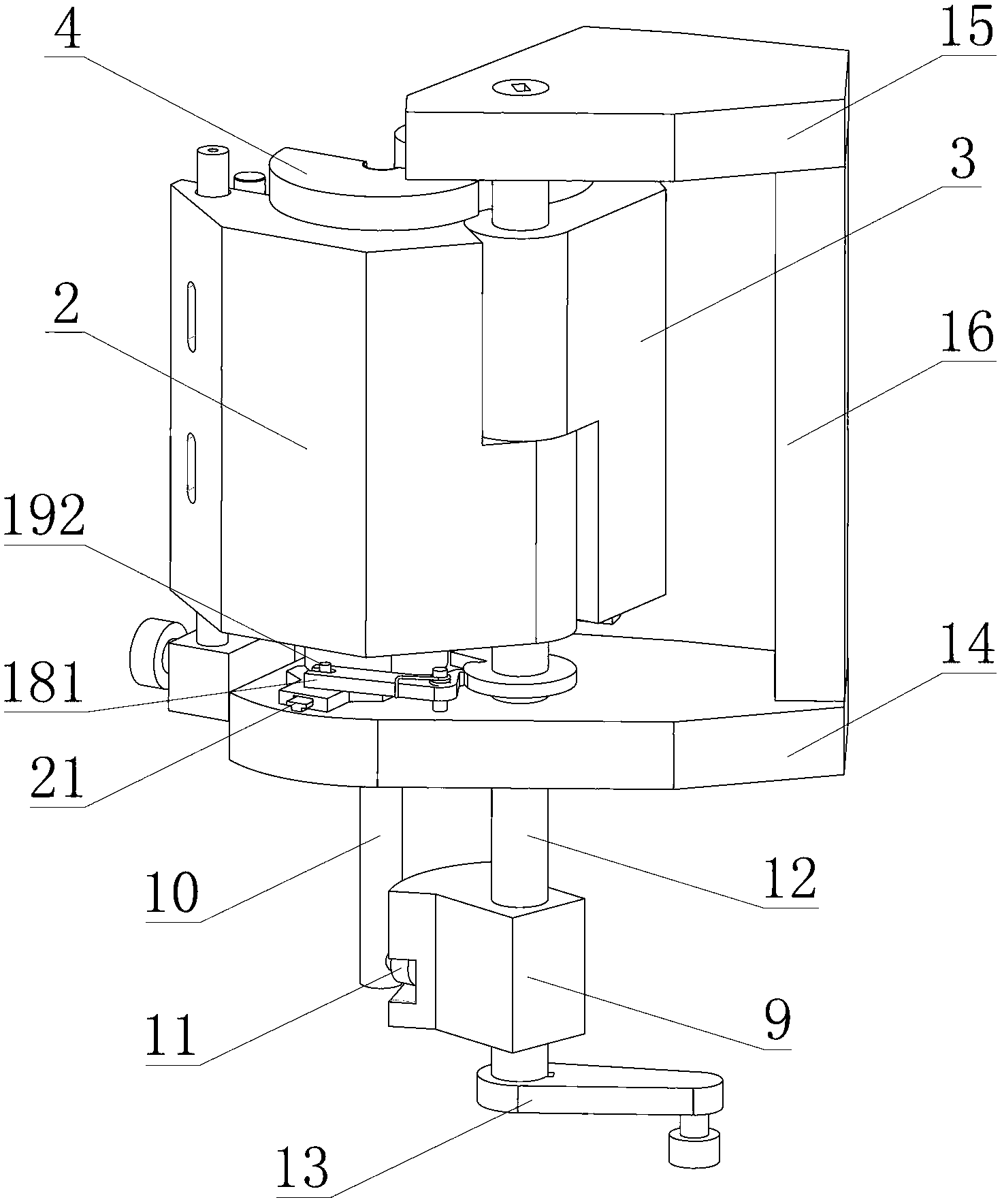

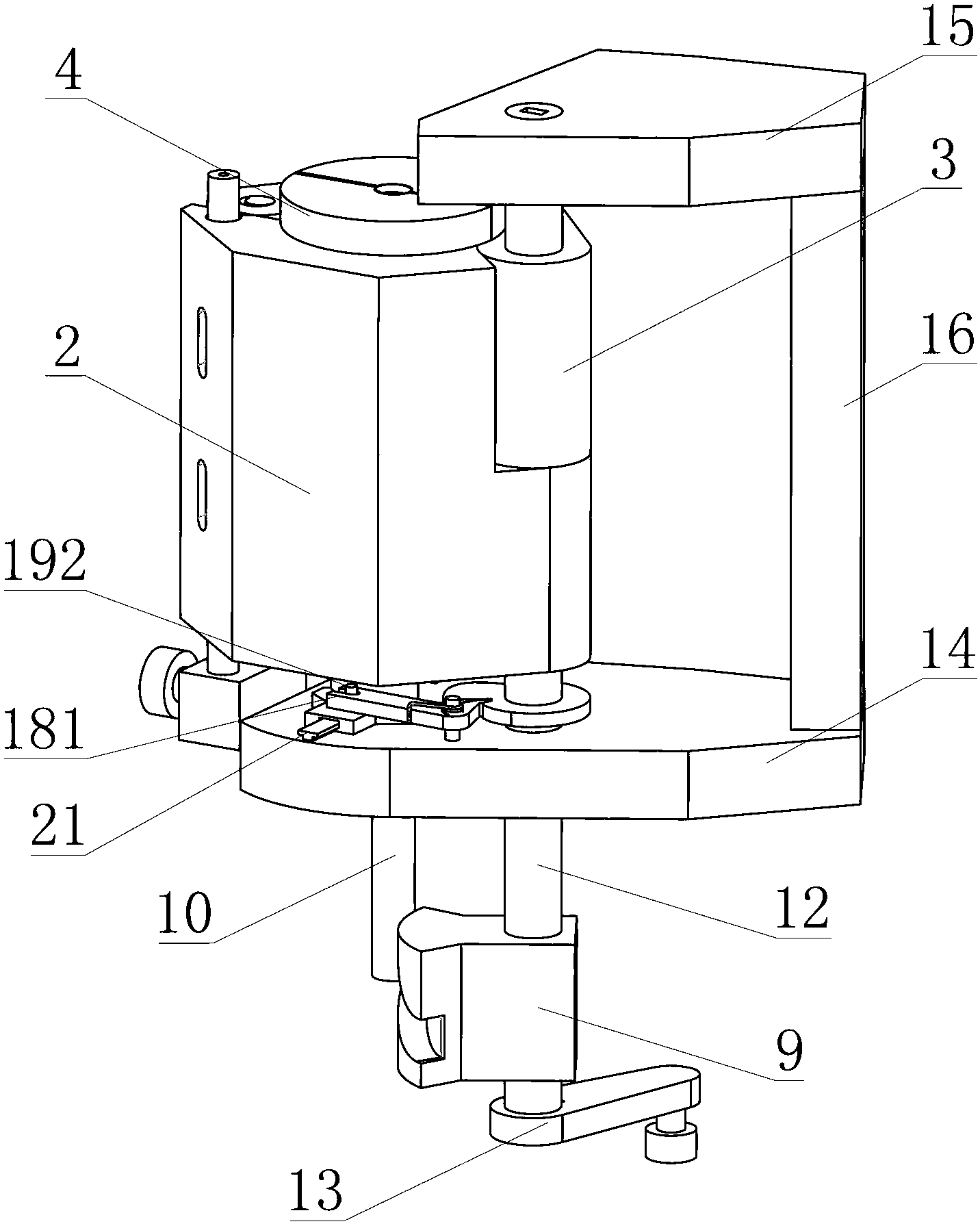

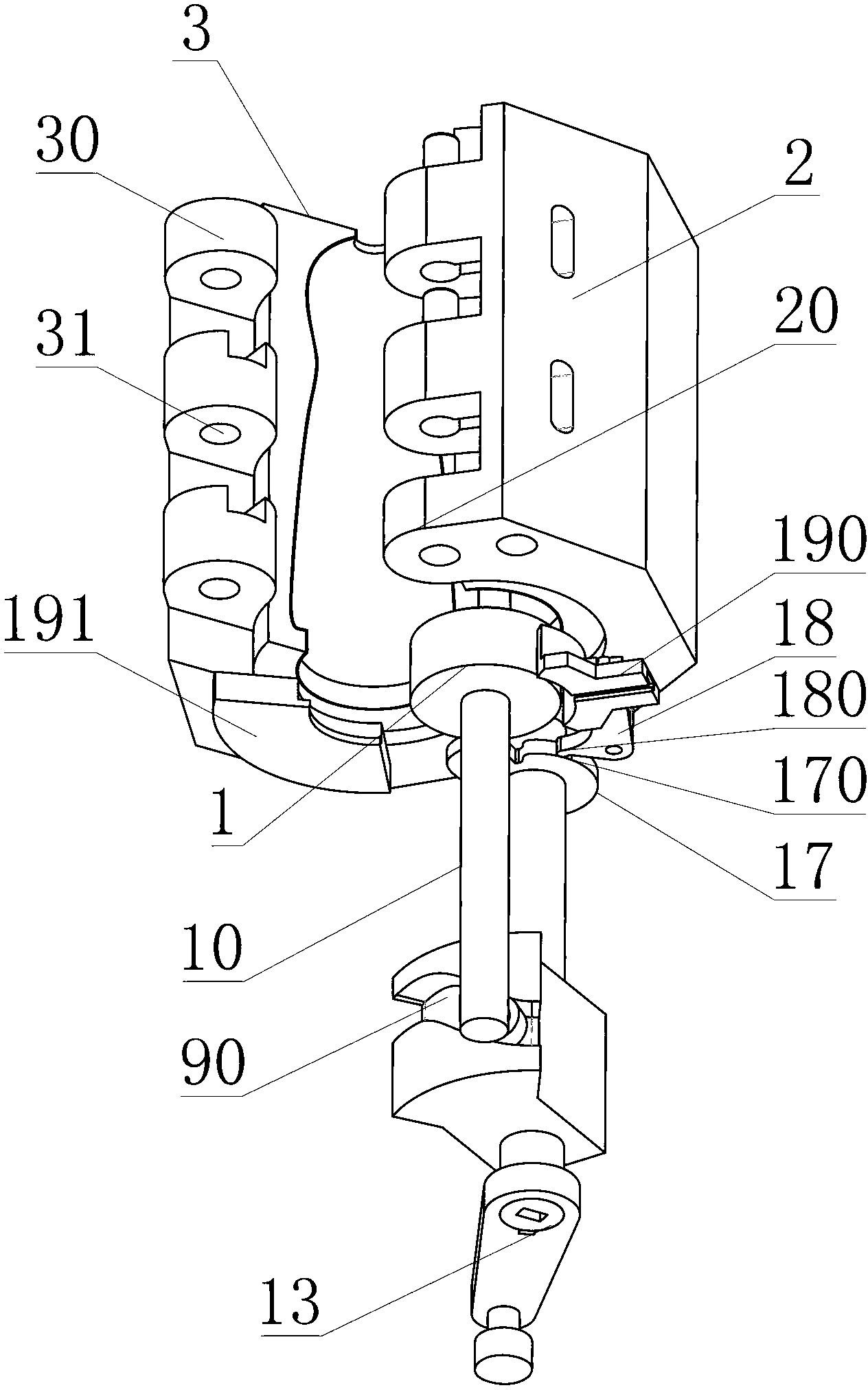

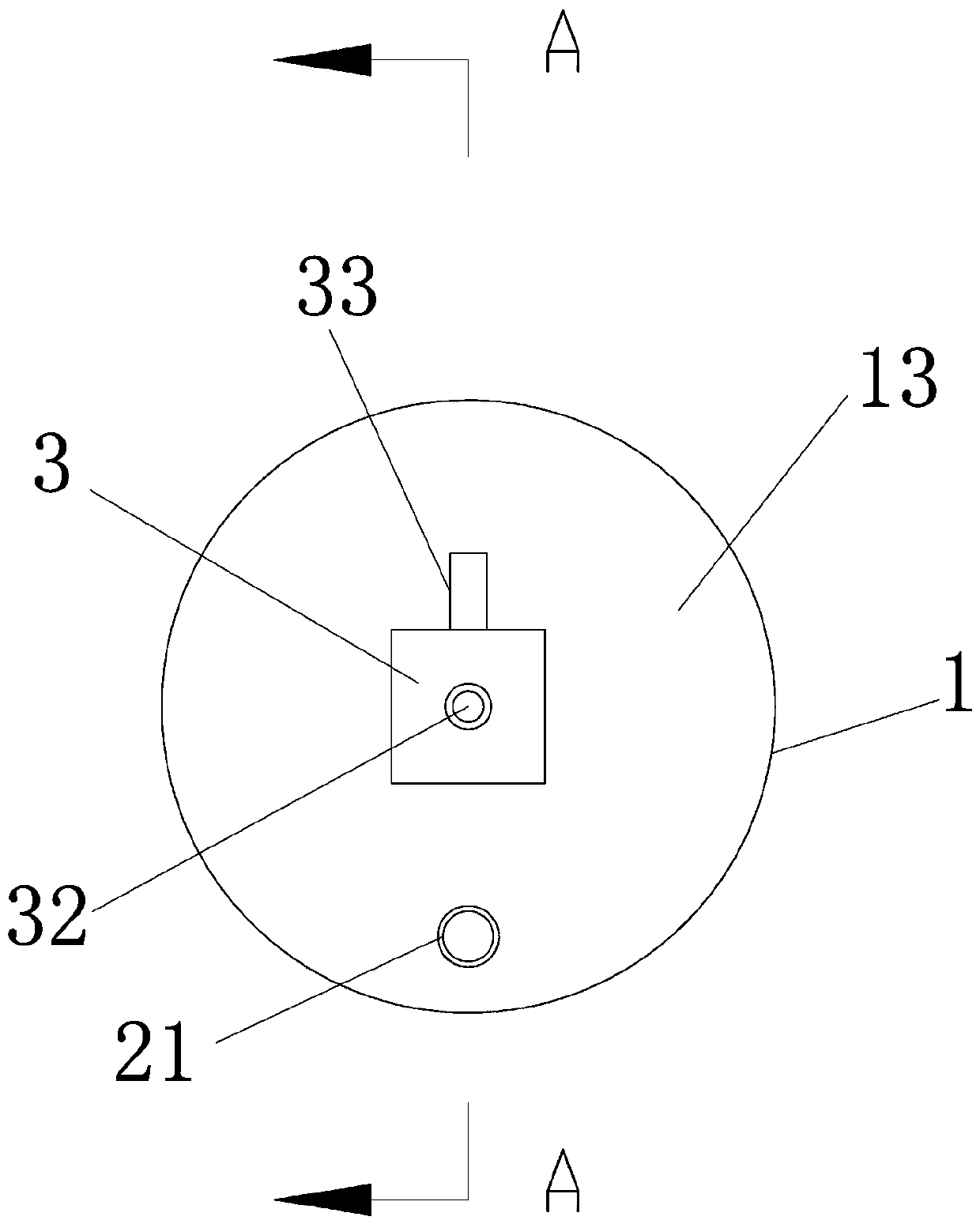

Bottle blowing machine

ActiveCN103171126AImprove efficiencySimple structureDomestic articlesHollow articlesCamBlowing bottles

The invention relates to a bottle blowing machine. The machine comprises a frame, a die opening and closing assembly, a lift assembly, a bottom die locking assembly and a driving assembly, wherein the die opening and closing assembly comprises a bottom die, a fixed template and a movable template; the lift assembly comprises a cam, a lift rod and a pulley, a runner is formed in the cam, the pulley is slidably arranged in the runner, and the bottom die is fixed on the upper end part of the lift rod; the bottom die locking assembly comprises a driving connection block, a driven connection block and a slide block, and the slide block is arranged on the frame; the driving assembly comprises a rotating shaft, and a power source which is used for driving the rotating shaft to rotate; the movable template, the cam and the driving connection block are fixedly connected with a rotating shaft at the same time; and when the rotating shaft rotates, a die is closed by the fixed template and the movable template, and the lift rod drives the bottom die to rise, and the slide block slides between the frame and the bottom die. The bottle blowing machine can be used for driving the three assemblies to act at the same time through only one rotating shaft, and completing die closing, lifting and locking steps, and is simple in structure and convenient to operate, so that the efficiency of bottle blowing process can be improved.

Owner:JIANGSU NEWAMSTAR PACKAGING MACHINERY

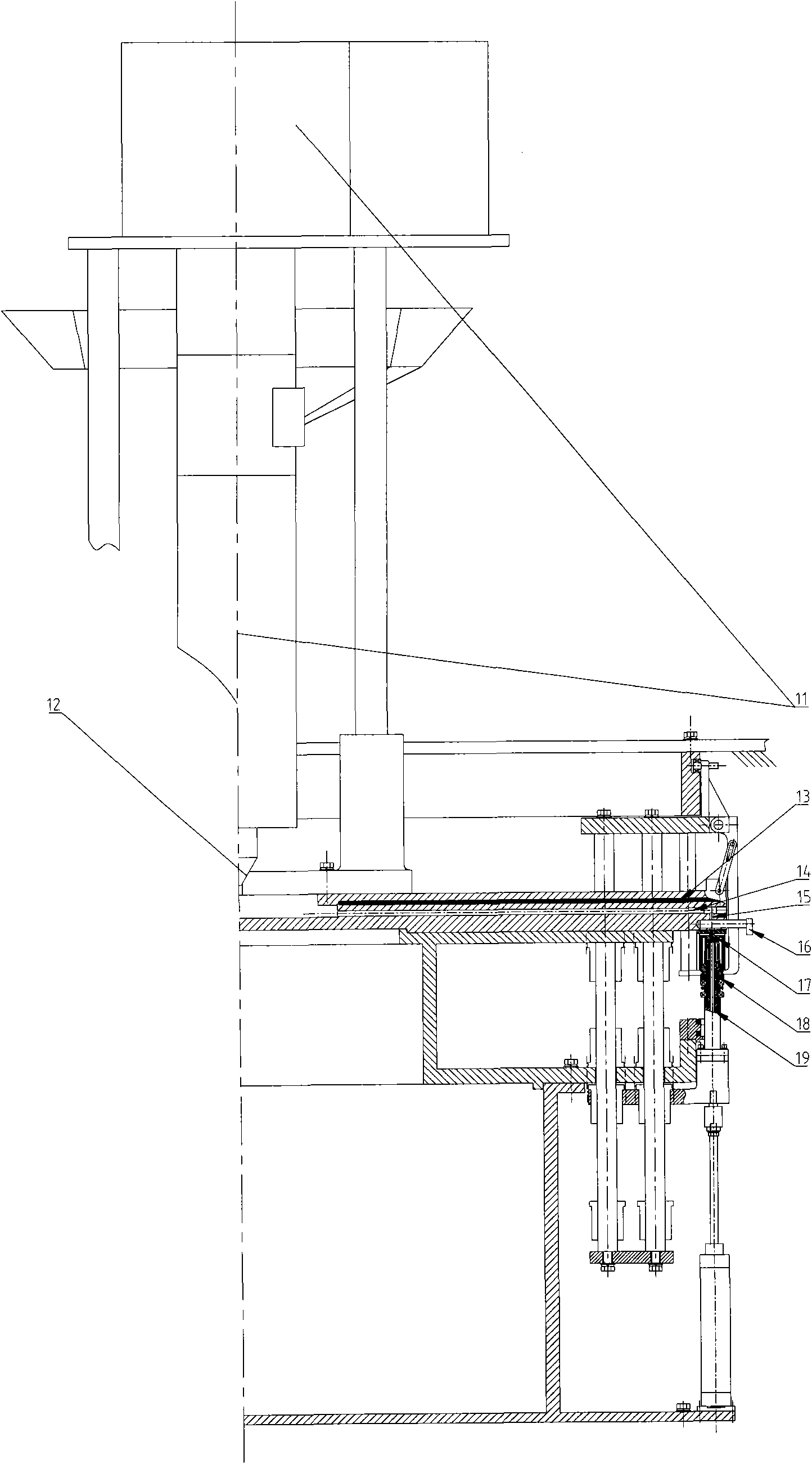

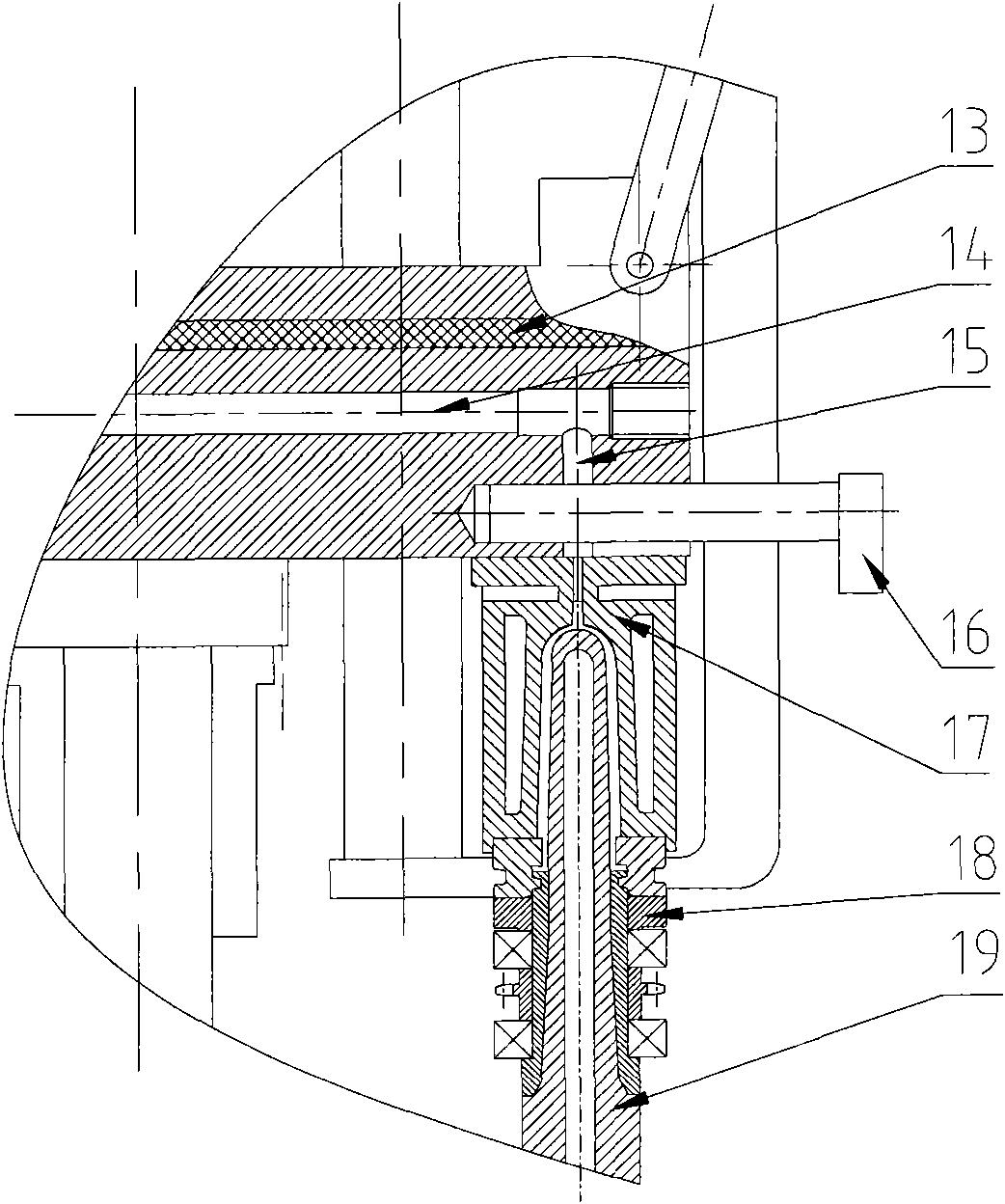

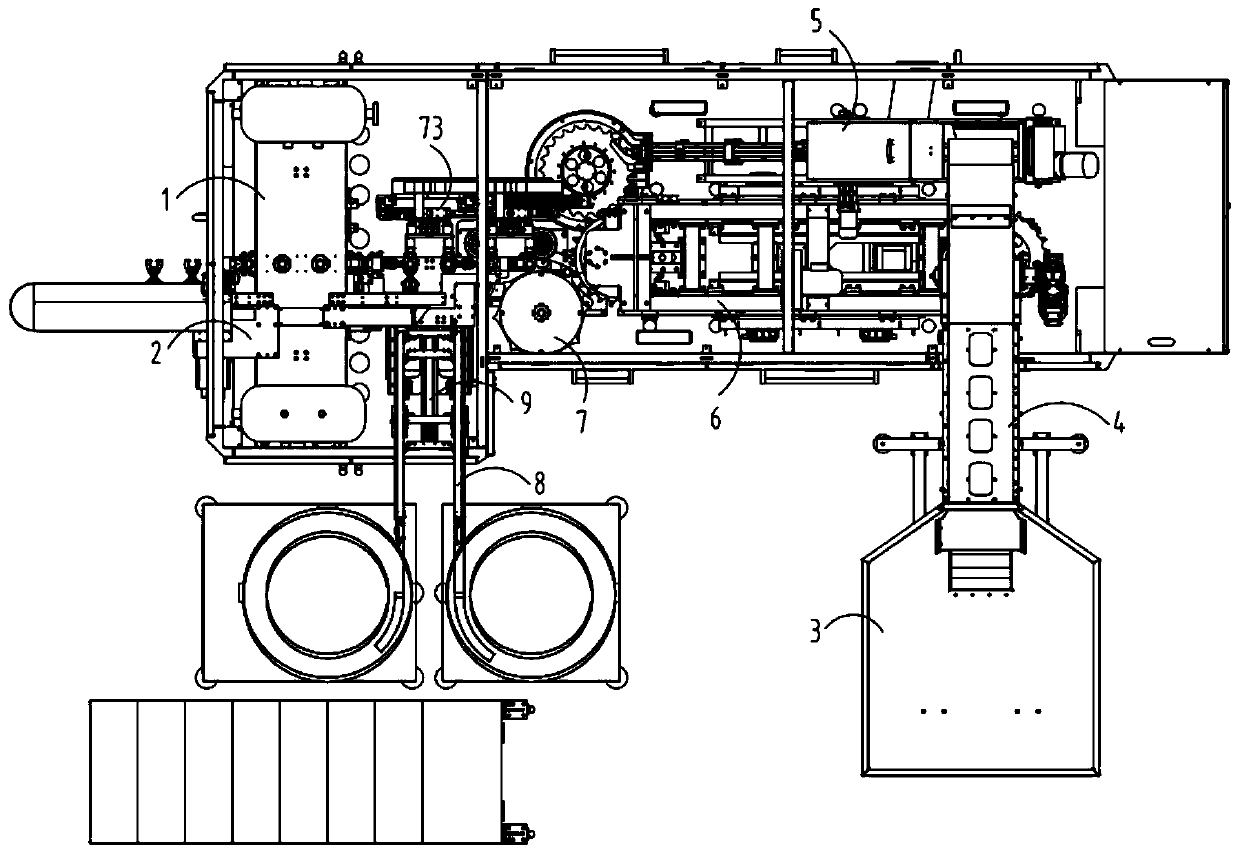

Filling machine integrated with blanking, bottle blowing, cleaning, filling and sealing

ActiveCN101664995AAchieve a clean effectBottle-handling machinesLiquid bottlingBiochemical engineeringCovering system

The invention provides a filling machine integrated with blanking, bottle blowing, cleaning, filling and sealing, comprising a blanking system, a heating system, a bottle blowing system, a cleaning system, a filling system, a sealing system, a covering system and a delivery system wich connects the blanking system, the heating system, the bottle blowing system, the cleaning system, the filling system, the sealing system and the covering system sequentially together; by adopting the filling machine integrated with blanking, bottle blowing, cleaning, filling and sealing, the problem that when the bottle blowing system is used, compression air for blowing bottle can be mixed with particles to pollute the bottle by using the blanking-bottle blowing-filling-sealing four-in-one machine manufactured by Hunan CHINASUN pharmaceutical machinery Co.,Ltd. is solved, thereby achieving the effect that the manufactured bottle is clean.

Owner:HUNAN CHINASUN PHARMA MASCH CO LTD

Polyester Blends

InactiveUS20100044266A1Ready-for-oven doughsSynthetic resin layered productsPolyesterPolyethylene terephthalate

Disclosed are molded articles comprising a thermoplastic polymer composition comprising, consisting essentially of, or prepared from (a) about 30% to about 99 weight % based on the combination of (a) and (b) of a poly(ethylene terephthalate) homopolymer or copolymer; and (b) about 1 to about 70% weight % based on the combination of (a) and (b) of a poly(trimethylene terephthalate) homopolymer or copolymer. Specific embodiments include injection-molded preforms and blown bottles.

Owner:EI DU PONT DE NEMOURS & CO

Containers incorporating polyester-containing multilayer structures

InactiveUS20060029822A1Good interlayer adhesion characteristicSolve the lack of adhesionBottlesSynthetic resin layered productsPolyesterPolymer science

Disclosed are injection molded hollow articles used as bottle preforms and blown bottles, comprising a coextruded or coinjected multilayer structure comprising at least one interior core layer adhered to at least one exterior layer and further comprising a polyester composition comprising from 0.005 to 7 mole % of a sulfonic acid comonomer or a salt thereof. The bottles are particularly useful for packaging liquids such as carbonated beverages, beer, juices, isotonic beverages, milk and other dairy products, and the like.

Owner:EI DU PONT DE NEMOURS & CO

Plastic bottle blowing process

The invention relates to a plastic bottle blowing process. The plastic bottle blowing process comprises the following steps of (1) manufacturing a bottle preform mold, putting a raw material into a charging barrel, heating the raw material in the charging barrel, injecting the raw material into an injection mold and taking out the raw material in the injection mold after the raw material is cooledand solidified to obtain plastic bottle preforms; (2) conducting blow molding, specifically, taking out heated pipe blanks in sequence, putting the first pair of pipe blanks into bottle mold clamp mouths to be clamped stably and pressing a start button; (3) bottle blowing, wherein the bottle blowing process comprises mold closing, mouth sealing, rod dropping, air blowing, air discharging, mouth opening, rod rising, mold opening and program stopping; and (4) taking out blown bottles, detecting whether the blown bottles are qualified or not, putting the second pair of heated pipe blanks into the mold, pressing the start button to conduct second circulating production. Through the plastic bottle blowing process provided by the invention, the processing bottles are uniform in wall thickness and free of flashes and postprocessing. The bottoms of plastic parts do not have joint seams. The strength is high, and the production efficiency is high.

Owner:平湖市浩鑫塑胶股份有限公司

Multi-Layered Biaxial Stretch Blow Molded Bottle and Method for Production Thereof

InactiveUS20070224375A1Excellent oxygen barrier propertiesImprove propertiesSynthetic resin layered productsAmpoulesBlow moldingEngineering

A multi-layer biaxially stretched blow bottle having a 3-layer structure of PET / nylon MXD6 / PET or a 5-layer structure of PET / nylon MXD6 / PET / nylon MXD6 / PET, wherein the oxygen gas transmission coefficient of the nylon MXD6 layer is at most 6.0×10−14 cm3·cm / cm2·sec·cmHg as measured under conditions of a temperature of 23° C. and a relative humidity of 80%, and a production process of the bottle by biaxial stretch blow molding at a low stretching temperature and high draw ratios.

Owner:KUREHA KAGAKU KOGYO KK

Gas barrier easy-demolding fully biodegradable beverage bottle production method

ActiveCN106366588AImprove oxygen resistanceHigh barrierBio-packagingBottlesPlasticizerBlowing bottles

The invention provides a gas barrier easy-demolding fully biodegradable beverage bottle production method which includes the steps: raw material modification: adding plastic additives into fully biodegradable materials, mixing the plastic additives and the fully biodegradable materials according to a certain proportion, and performing granulation for the mixture; processing plastic master batches: uniformly mixing the mixture, and processing the mixture into the plastic master batches; blowing bottles; performing surface treatment of the bottles. The plastic additives are at least one in chain extenders, nucleating agents, plasticizers and plastic expansion microspheres, the fully biodegradable materials include powder biodegradable materials which are at least four in PLA (polylactic acid), PBS (poly butylene succinate), PHA (polyhydroxyalkanoate), PBSA poly(butylene succinate adipate), PBAT (poly butylene adipate-co-terephthalate) and starch, and blowing bottles include blowing the bottles by extrusion and blowing the bottles by injection molding.

Owner:ZHEJIANG BILI PACKAGING

Method for preventing deformation of polypropylene transfusion bottle during sterilization

ActiveCN102161464ANo deformation problemsQuality improvementBottle-handling machinesWater bathsMedicine

The invention belongs to the technical field of medicaments and in particular relates to a method for preventing deformation of a polypropylene transfusion bottle during sterilization. The invention aims to solve the problems of deformation of the bottle and influence on medicament quality when the polypropylene transfusion bottle is used for accommodating medicinal liquid. The method for preventing deformation of the polypropylene transfusion bottle during sterilization comprises the following steps of: 1) injecting blanks, namely setting certain parameters by using a computer injection molding machine, preserving pressure when the whole stroke reaches 95 percent and injecting polypropylene particles into bottle blanks; 2) blowing bottles, namely heating internal part and external part of each bottle blank respectively to different temperatures by rotating the bottle blank and blowing the bottle blank by using air with a certain pressure into a polypropylene bottle; 3) washing the bottle, namely washing the polypropylene bottle by an ion wind washing technique and according to the conventional method; 4) performing encapsulation; 5) sealing; and 6) performing sterilization, namely performing sterilization by using a water bath sterilizer, and then performing light detection, labeling and packaging. During sterilization, the transfusion bottle is not deformed, so that quality stability of the medicinal liquid is guaranteed.

Owner:SHANXI NUOCHENG PHARMA

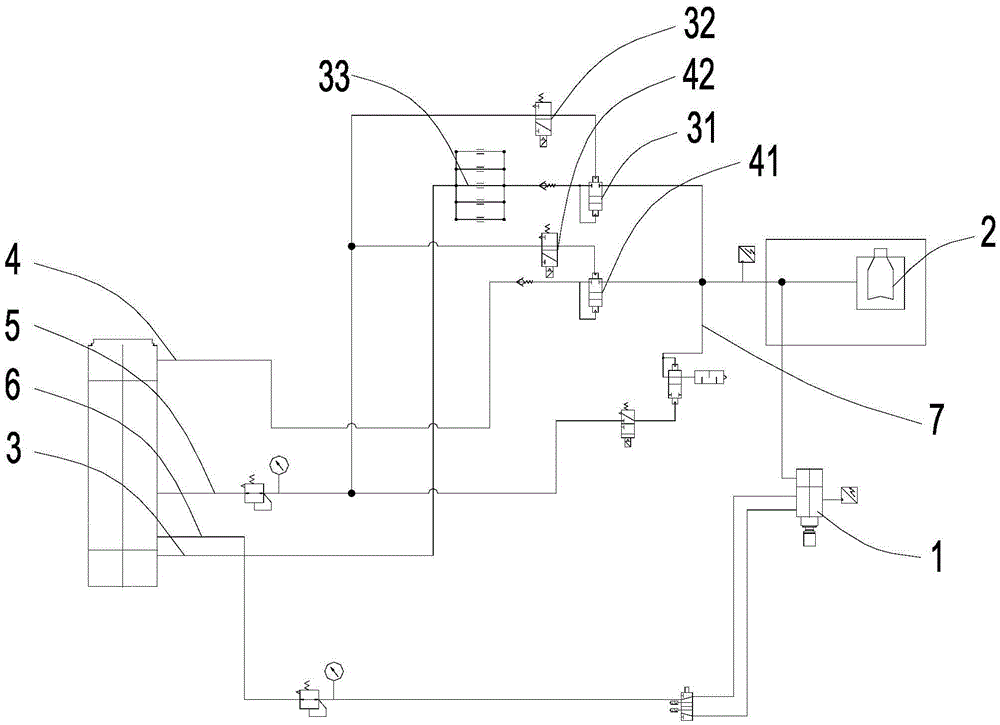

Pneumatic bottle taking system for edible fungi cultivation

InactiveCN107041234AAvoid destructionReduce breakage rateCultivating equipmentsMushroom cultivationEngineeringHigh pressure

The invention discloses a pneumatic bottle removal system for edible fungus cultivation, which comprises a frame, a bottle frame input line, a bottle frame output line, a hydraulic system, a turning mechanism, an air charging mechanism and a PLC controller, and the frame is arranged between the bottle frame input line and the bottle frame output line. Between the output lines of the bottle frame, the lower part of the frame is provided with an inflatable mechanism, and the upper part of the inflatable mechanism is provided with a turning mechanism at the corresponding position, and the pressing frame plate used in conjunction with the turning bracket is set above the turning bracket; The locking device of the frame plate; the lifting of the turning mechanism and the fixed platform of the inflatable tube are controlled by the hydraulic system, and the PLC controller controls the work of the relevant components of the whole system. The invention adopts high-pressure gas to blow out the waste culture materials in the bacteria cultivation bottle, which greatly reduces the damage rate of the bacteria bottle. When the bacteria bottle is cleaned, high-pressure gas purge is performed on multiple bacteria bottles at the same time, which greatly improves the working efficiency of the bacteria bottle cleaning. Through intelligent operation control, the labor intensity of workers is reduced.

Owner:深圳市达利时实业有限公司

Blowing corrosion machine and method for corrosion and cleaning

The invention relates to a blowing corrosion machine and a method for corrosion and cleaning. The blowing corrosion machine is characterized in that an air inlet valve is connected with an air inlet pipe; one end of the air inlet pipe is connected with a coil cylinder, and the other end is communicated with an air chamber A; in processing, wafers are placed to the bottom of a blow bottle and provided with a screen with a cover; the blow bottle is installed on the air chamber A and connected with an air chamber A in a corrosive solution tank through quick-sealing threads; a terminal of a water purifier is connected with one end of a water inlet pipe through a water inlet valve; the other end of the water inlet pipe is communicated with an air chamber B; a waste pipe is connected with an overflow hole on a pure water tank; a steam pipe is connected with an exhaust hole; and a monitoring system is arranged on a control cabinet. The invention has the advantages that during corrosion and cleaning operation, compressed air is controlled through flow, and dispersion of the wafers can not cause lamination and defective products with corrosion marks; because a corrosion bottle is connected with the air chamber through the quick threads, the installation and disassembly operation is convenient and fast; the quantity of loading wafers in a single bottle is increased by 3000pcs than that of a cradle, and the production efficiency is high; and the structure is simple without control of a servo motor.

Owner:菲特晶(南京)电子有限公司

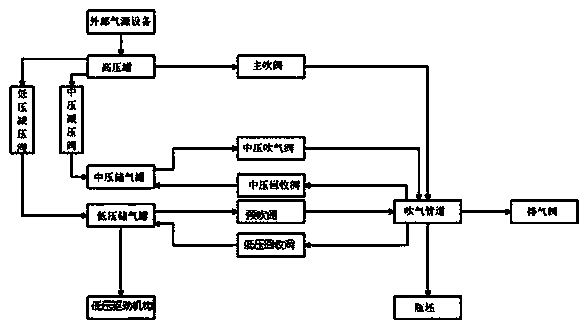

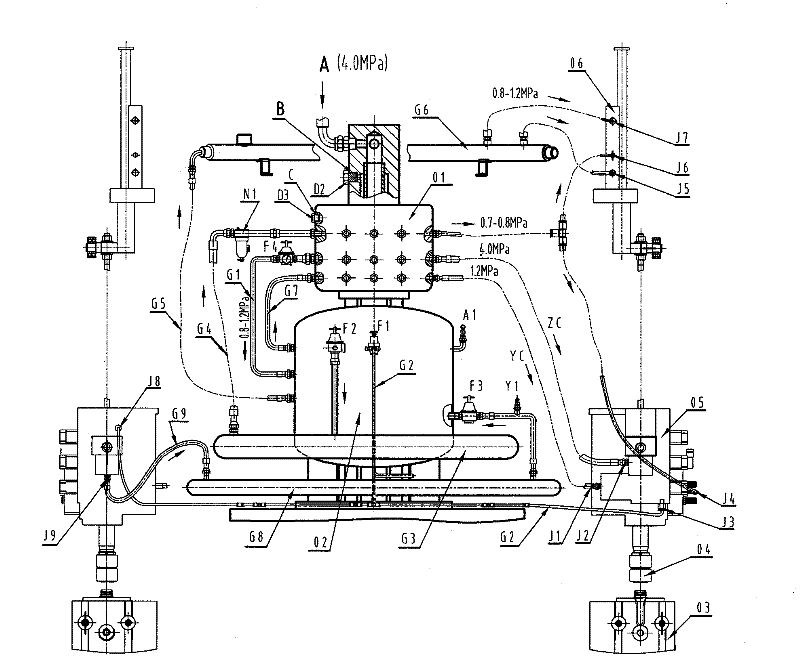

Bottle blowing structure and method

InactiveCN104228042AReduce supplyReduce consumptionHollow articlesProcess engineeringEnergy consumption

The invention discloses a bottle blowing structure and method. By adopting the bottle blowing structure, gases in a container during the periods of primary bottle blowing and secondary bottle blowing are recycled, and the recycled low-pressure gases are applied to the next bottle blowing process, so that supply of low-pressure gases from an external gas source can be reduced, consumption of a high-pressure gas is further reduced, the utilization rate of energy sources is increased, energy consumption of compressed air supplied to a container blower by external gas source equipment and the machining cost of the container blower are reduced, and energy conservation and environment protection are achieved.

Owner:GUANGZHOU TECH LONG PACKAGING MACHINERY CO LTD

Method for controlling blowing bottle of automatic bottle blowing machine with dual-station

ActiveCN1623761AProcess requirements to ensure independent formingTo achieve the purpose of automatic balance on both sidesEngineeringBlowing bottles

A method for controlling the automatic bottle blower with dual working positions is disclosed. Said automatic bottle blower is composed of an extruder and two individual mould holders with moulds (one for one). Said two mould holders are working consistently according to such steps as lifting up mould holder, closing mould, cutting material, lowering down mould holder, inserting tube, blowing, releasing air, opening mould, and withdrawing tube up. Said steps are controlled by computer.

Owner:GUANGDONG LESHAN INTELLIGENT EQUIP CORP LTD

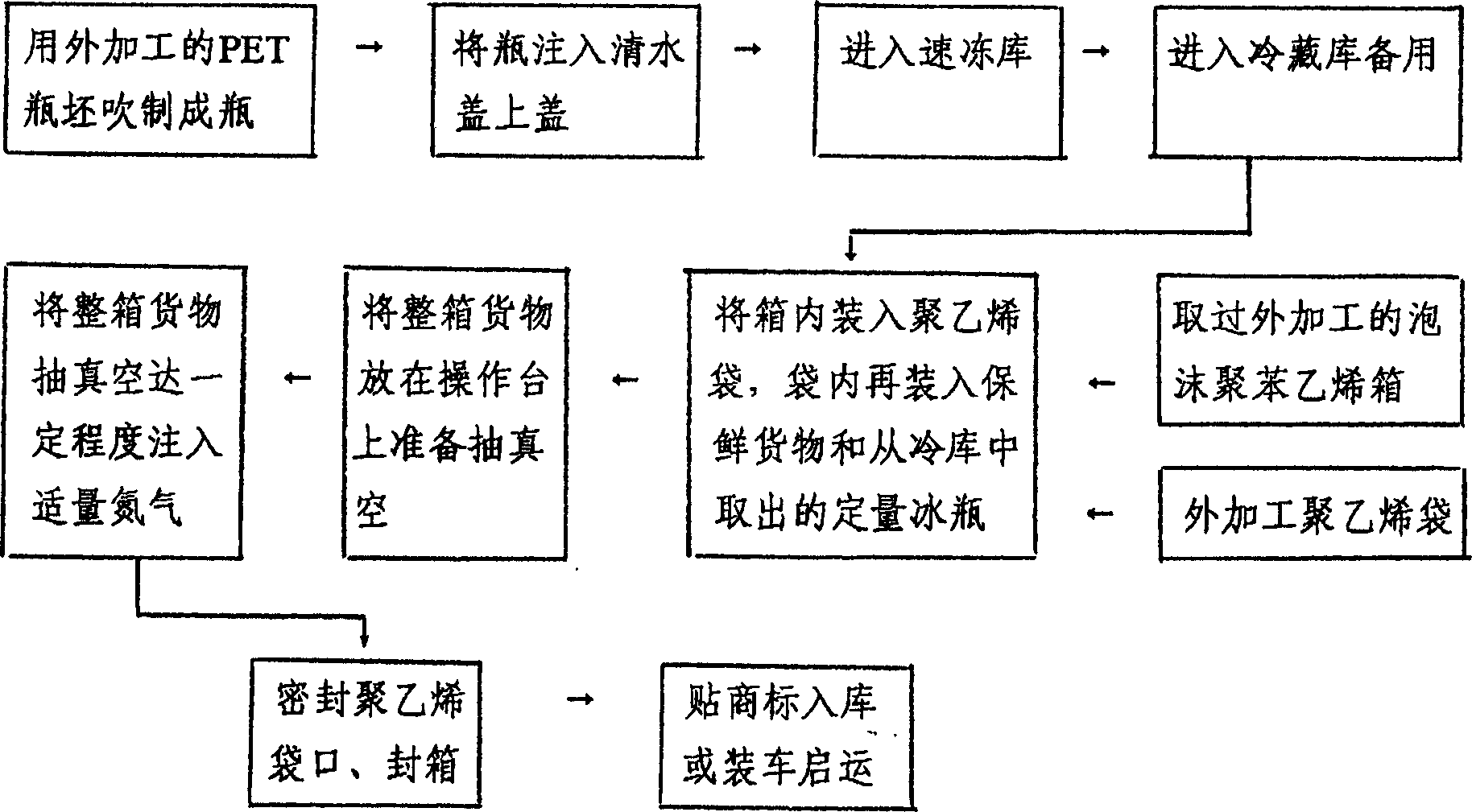

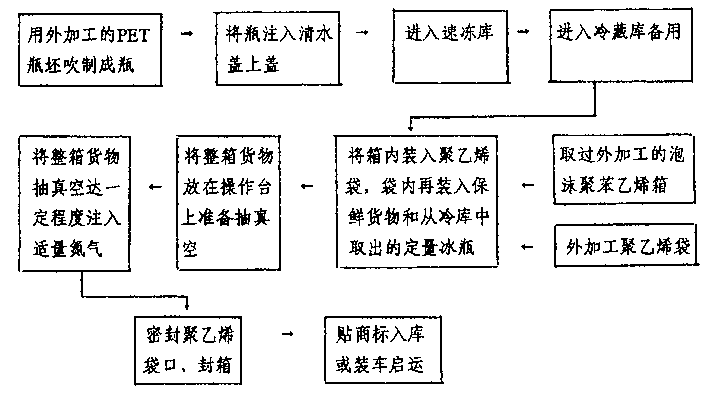

Vacuum, gas conditioning, nitrogen filling temp-controlled method for fruit, flower, vegetable, etc. freshness-retaining container

InactiveCN1420067AReduce manufacturing costImmediate economic effectLarge containersPackaging under vacuum/special atmosphereNitrogenEngineering

An antistaling method for the container of fruit, vegetables, fresh flower and agricultural by-products includes such steps as blowing bottles, filling water in the bottles, quickly freezing to become ice bottles, loading the products and said ice bottles in bags, vacuumizing it while filling nitrogen gas, sealing and loading the bags in container. Its advantages are long antistaling time (30-60 days), and easy operation.

Owner:张繁荣

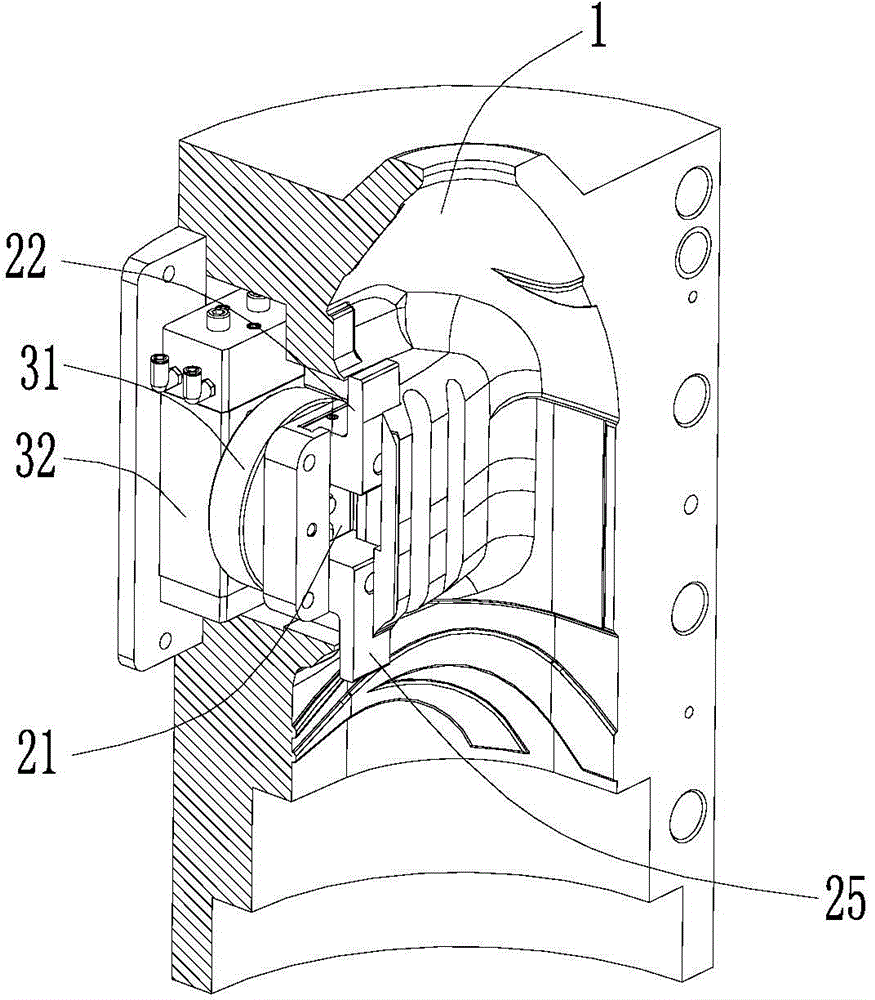

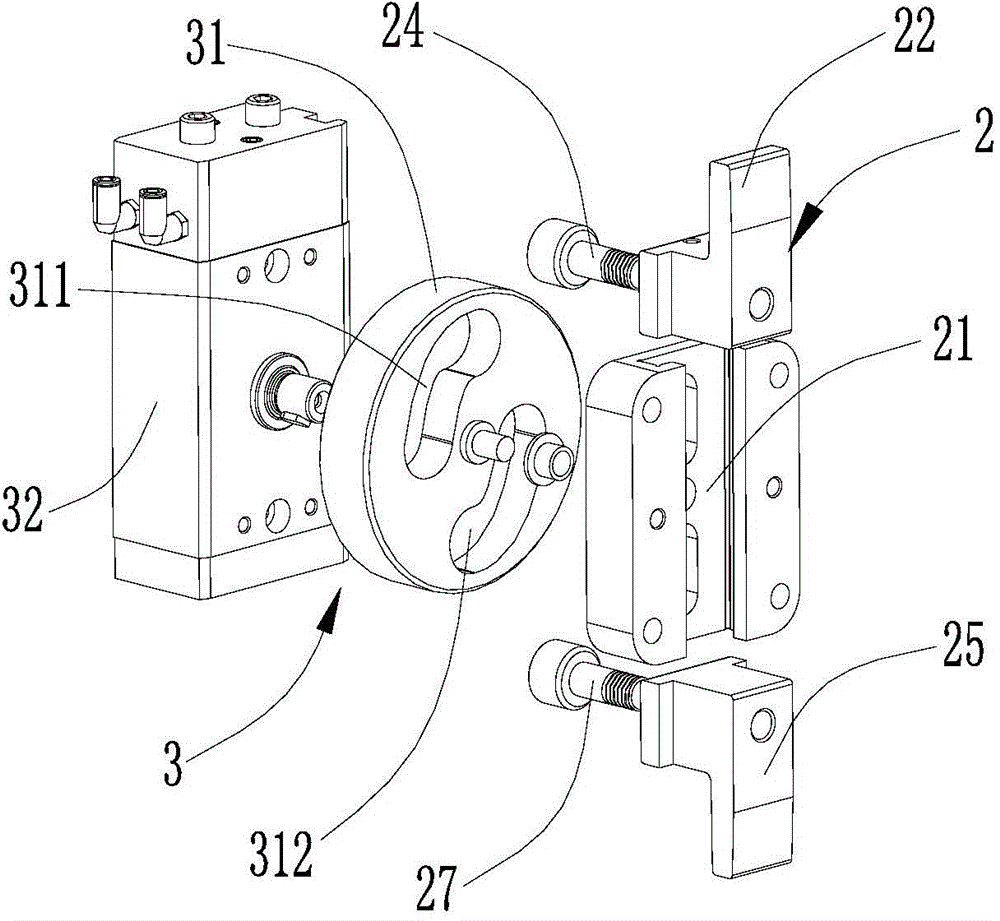

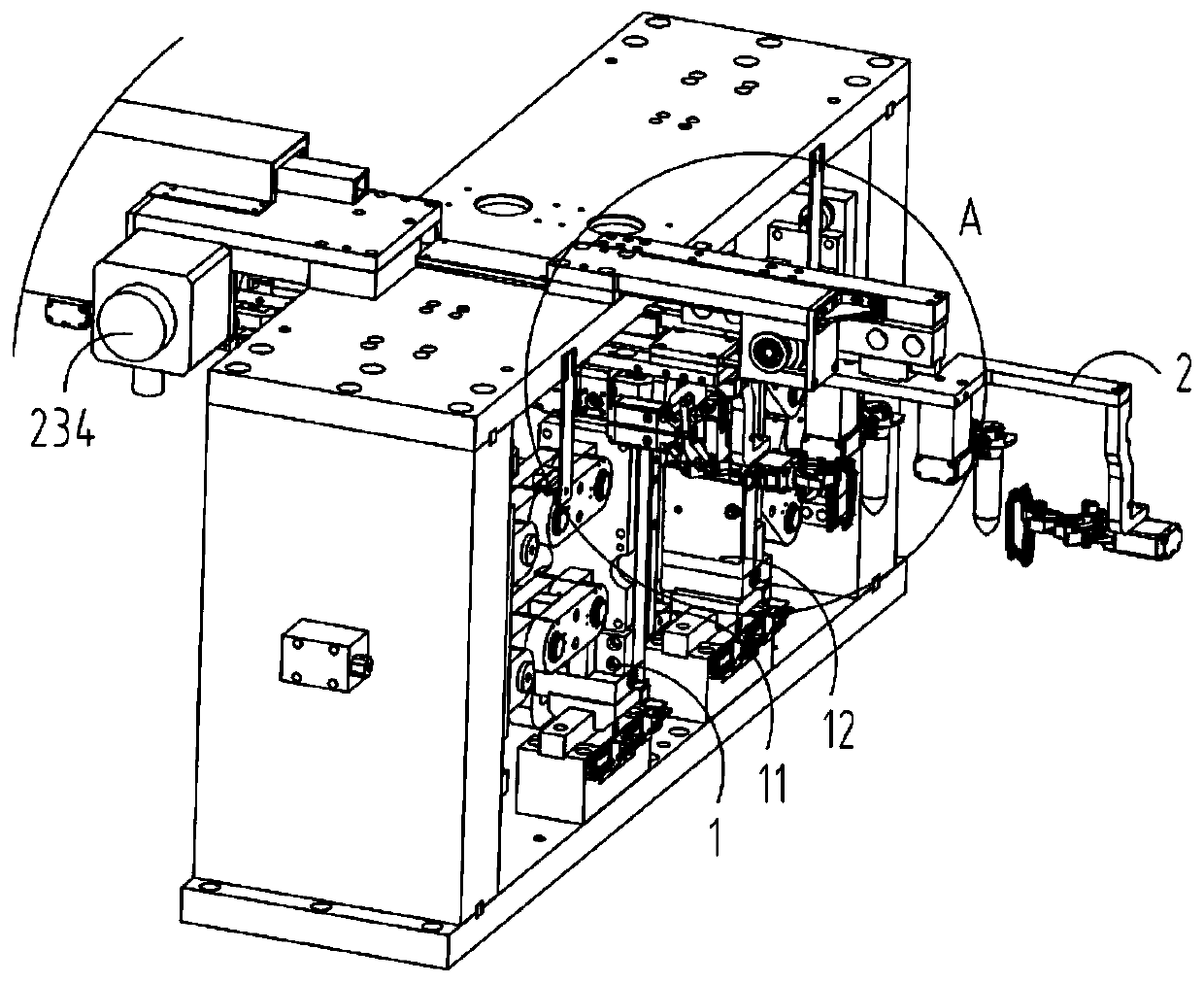

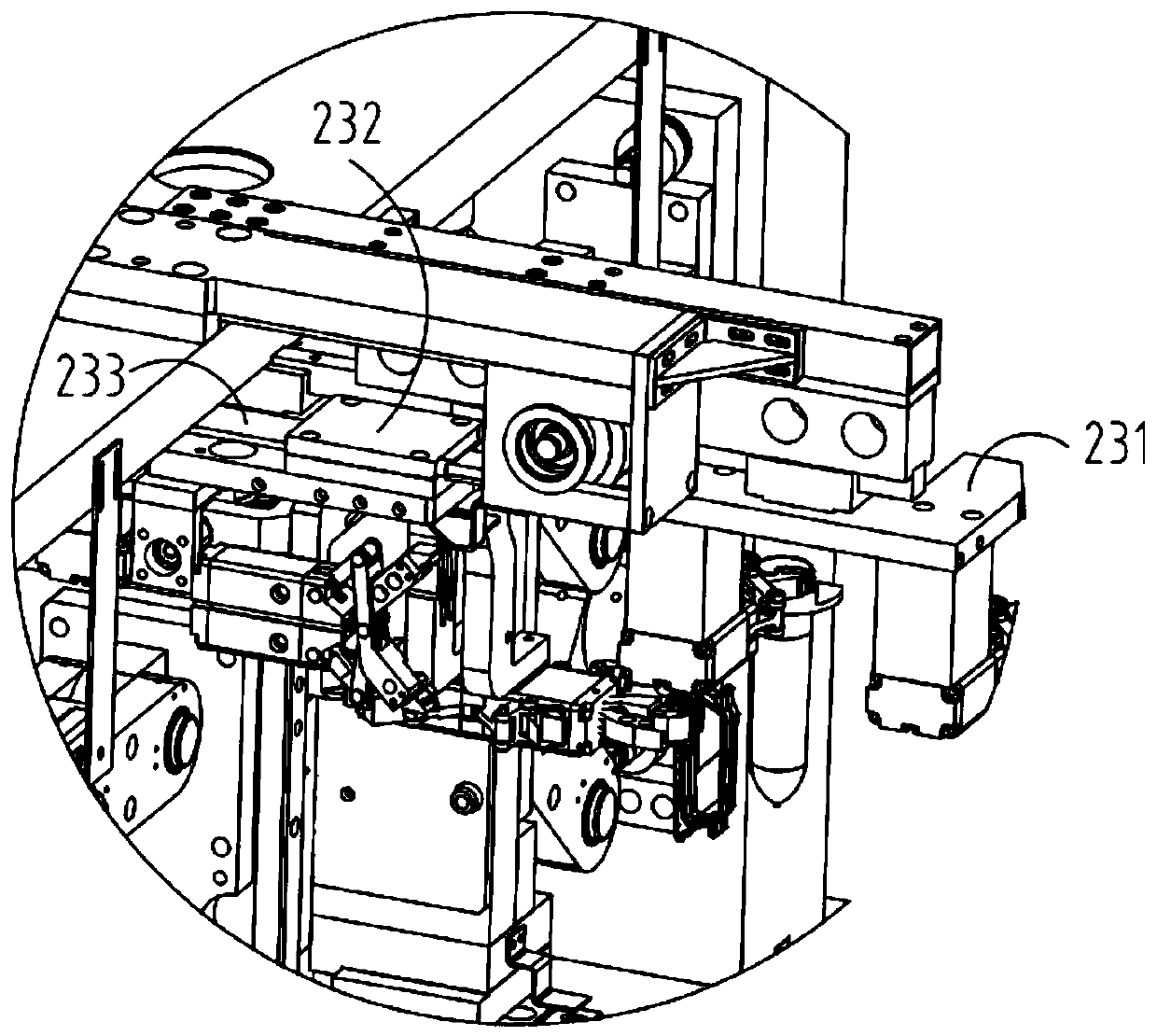

Blow-molding mechanism for handle assembly snapping grooves in container with handle

The invention discloses a blow-molding mechanism for handle assembly snapping grooves in a container with a handle. The blow-molding mechanism is arranged on a machine frame and is used for forming a snapping groove mold for blow-molding the snapping grooves in a bottle blowing mold when the container is subjected to blow-molding by a bottle blowing machine; the blow-molding mechanism comprises a mold mechanism and a driving mechanism, wherein the mold mechanism is slidably arranged on the machine frame, and the driving mechanism is arranged on the machine frame and is used for driving the mold mechanism to extend into the bottle blowing mold so as to form the snapping groove mold; the driving mechanism is also used for driving the mold mechanism to slide out of blow-molded containers. According to the blow-molding mechanism for the handle assembly snapping grooves in the container with the handle, disclosed by the invention, an oscillating cylinder is arranged to drive a cam to rotate, and the cam drives two sliding blocks to be close to each other or far away from each other, so that the problem that the sliding blocks cannot reset is avoided; the original sliding friction is changed into rolling friction, so that the wear among parts is effectively reduced; the oscillating cylinder is driven through low-pressure gas, so that the blow-molding mechanism is more energy-saving.

Owner:JIANGSU NEWAMSTAR PACKAGING MACHINERY

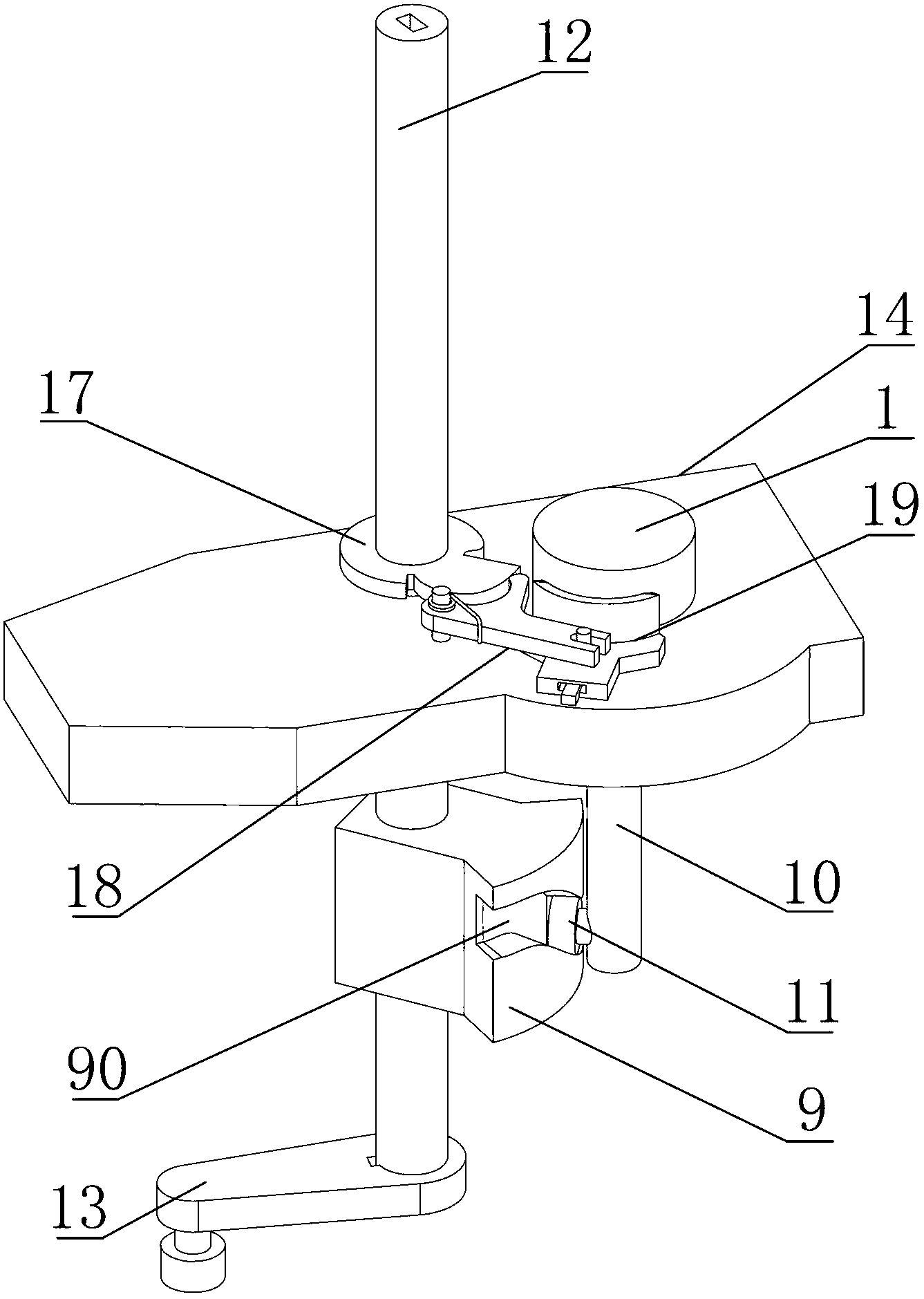

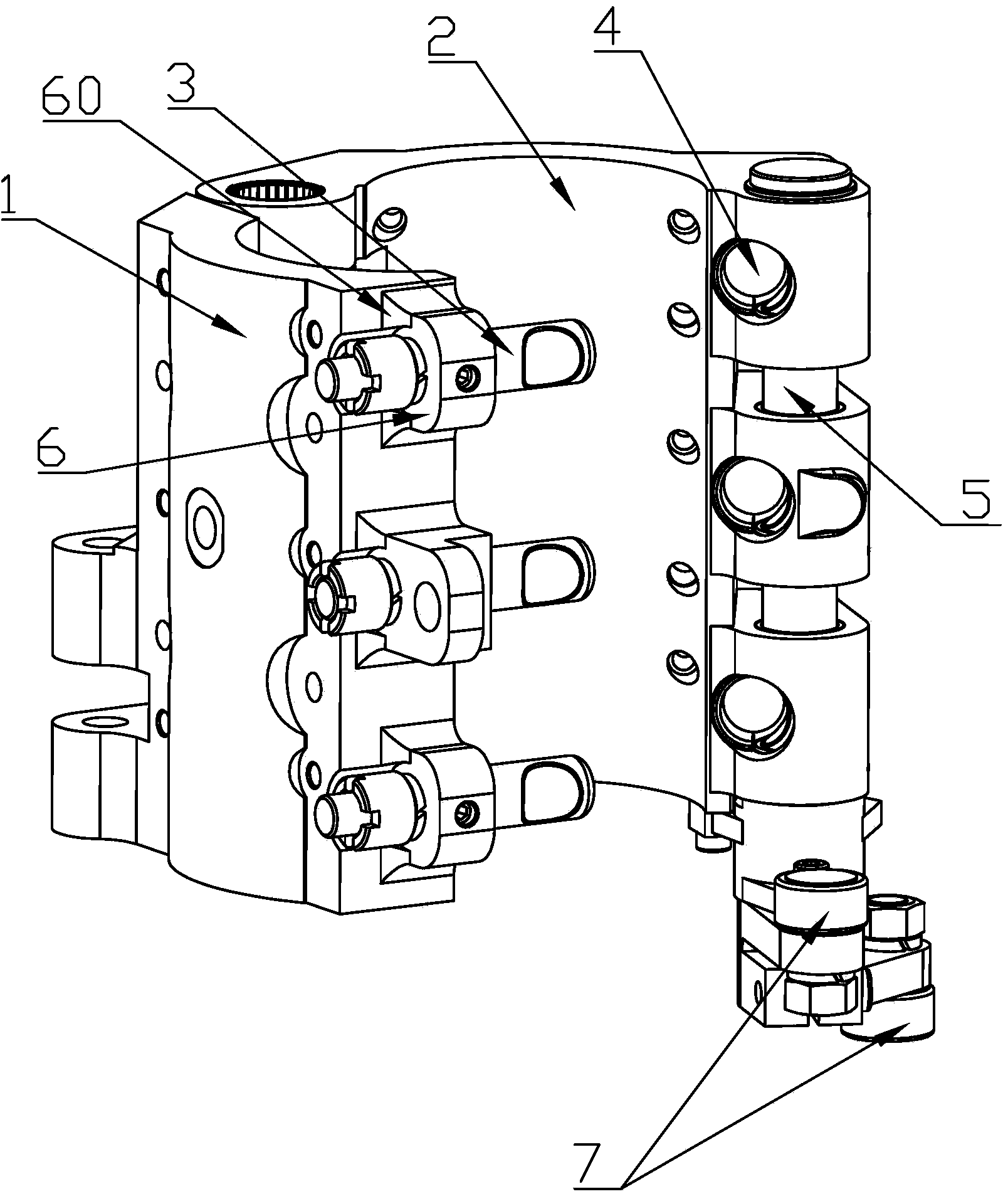

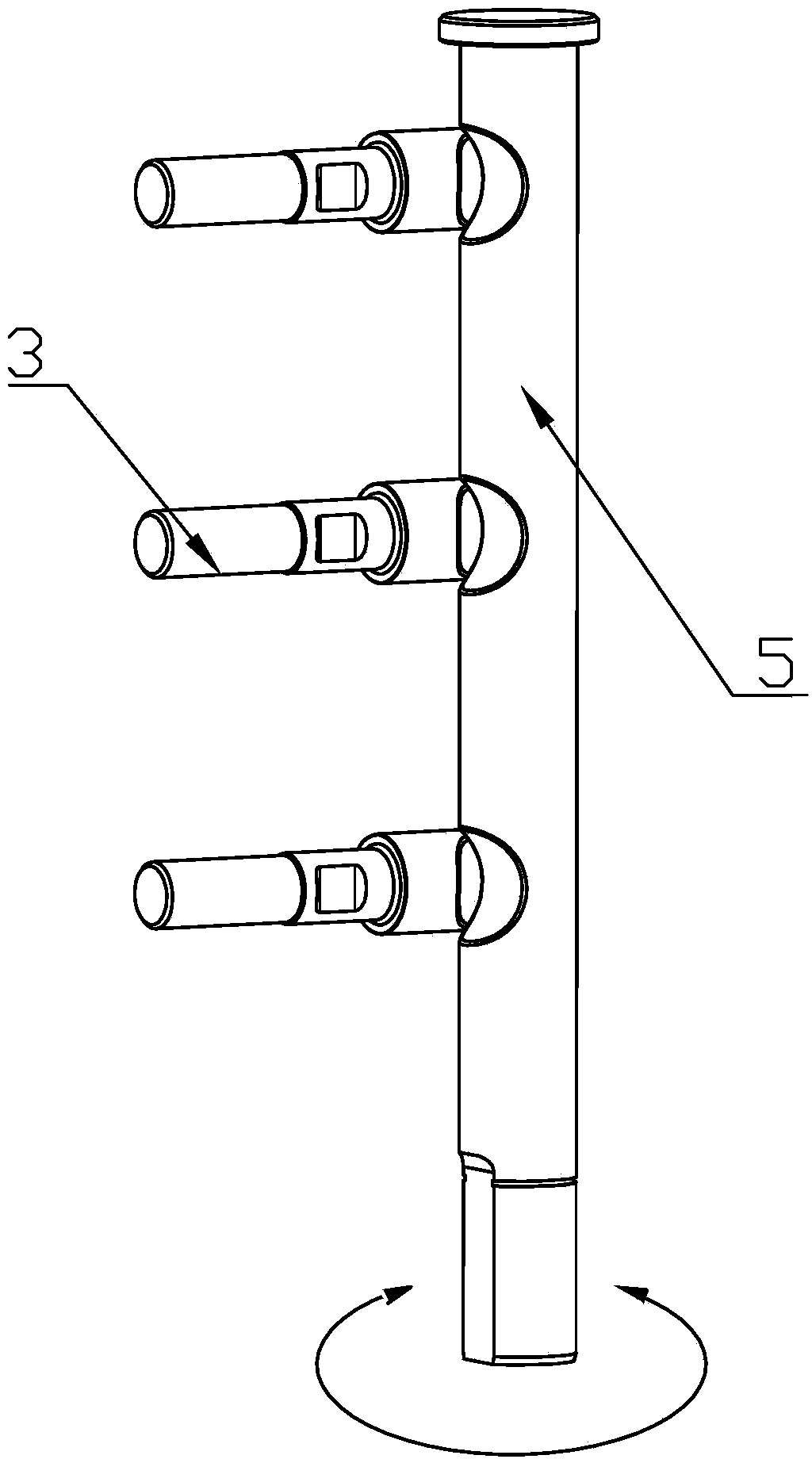

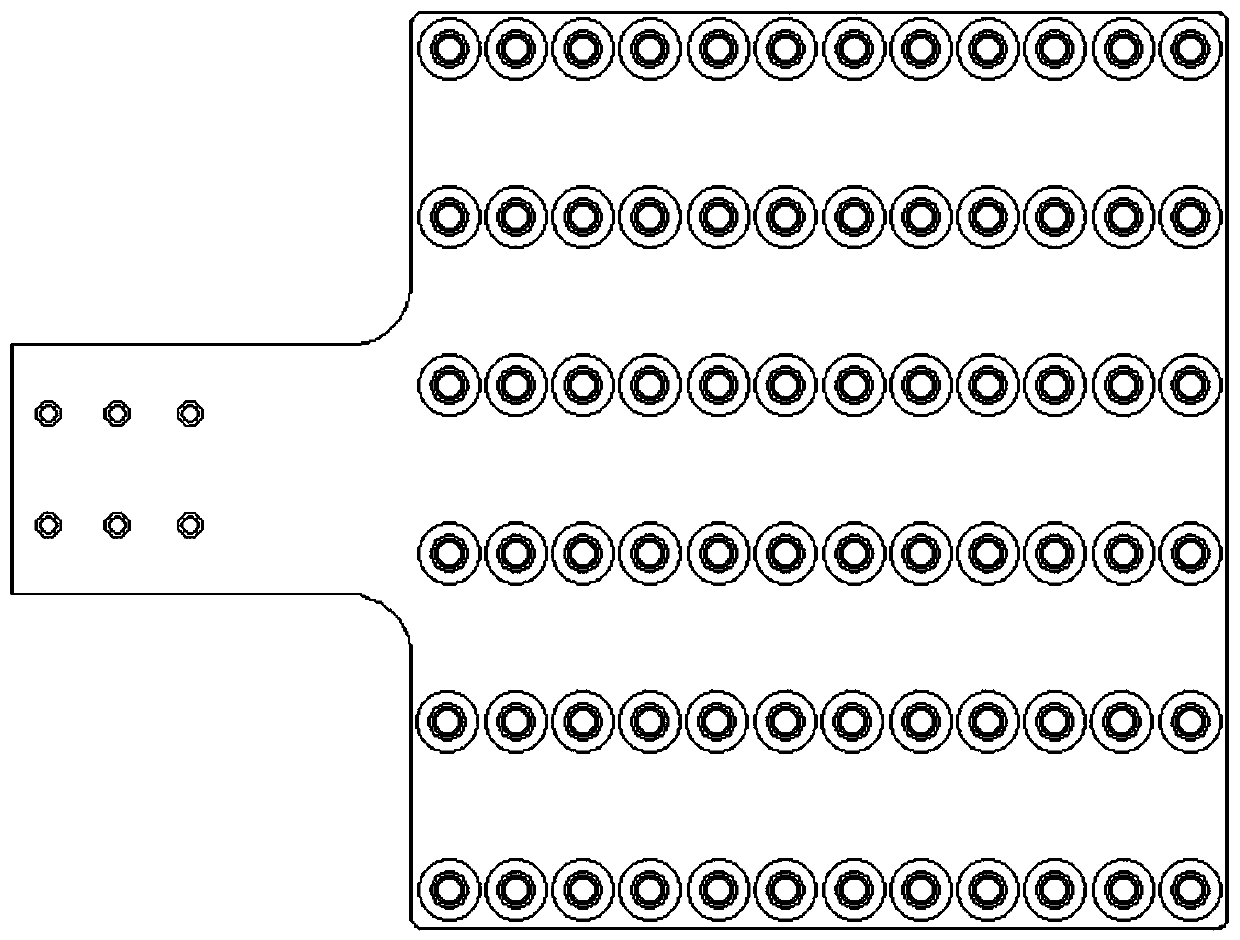

Rotation type mold locking mechanism

The invention discloses a rotation type mold locking mechanism. The rotation type mold locking mechanism comprises a fixed mold frame and a movable mold frame, wherein the movable mold frame is provided with a plurality of mold locking rods, the fixed mold frame is provided with a plurality of positioning holes, a locking device is arranged between the mold locking rods and the positioning holes, and the movable mold frame and the fixed mold frame are locked or unlocked due to the cooperation of the mold locking rods, the positioning holes and the locking devices so as to clamp or release blow bottles; the locking device comprises rod gaps or rod bulges in or on the mold locking rods and a rotating shaft, shaft gaps are formed in the parts, coinciding with the positioning holes, of the rotating shaft, and a rotating mechanism for driving the rotating shaft to rotate is arranged at the lower end of the rotating shaft. According to the rotation type mold locking mechanism, the unlocking and locking between the fixed mold frame and the movable mold frame are realized by controlling the rotation angle position of the rotating shaft and by virtue of the rotating shaft on the fixed mold frame and the mold locking rods on the movable mold frame; a mold is directly locked by virtue of the shaft gaps or shaft bulges in or on the rotating shaft as well as the rod gaps in the mold locking rods, so that the transition power transfer is reduced, linear motion is replaced by rotary motion, and the rotation type mold locking mechanism can stably and reliably work.

Owner:广州西力机械有限公司

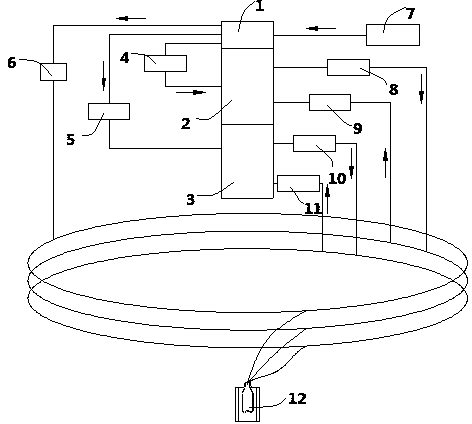

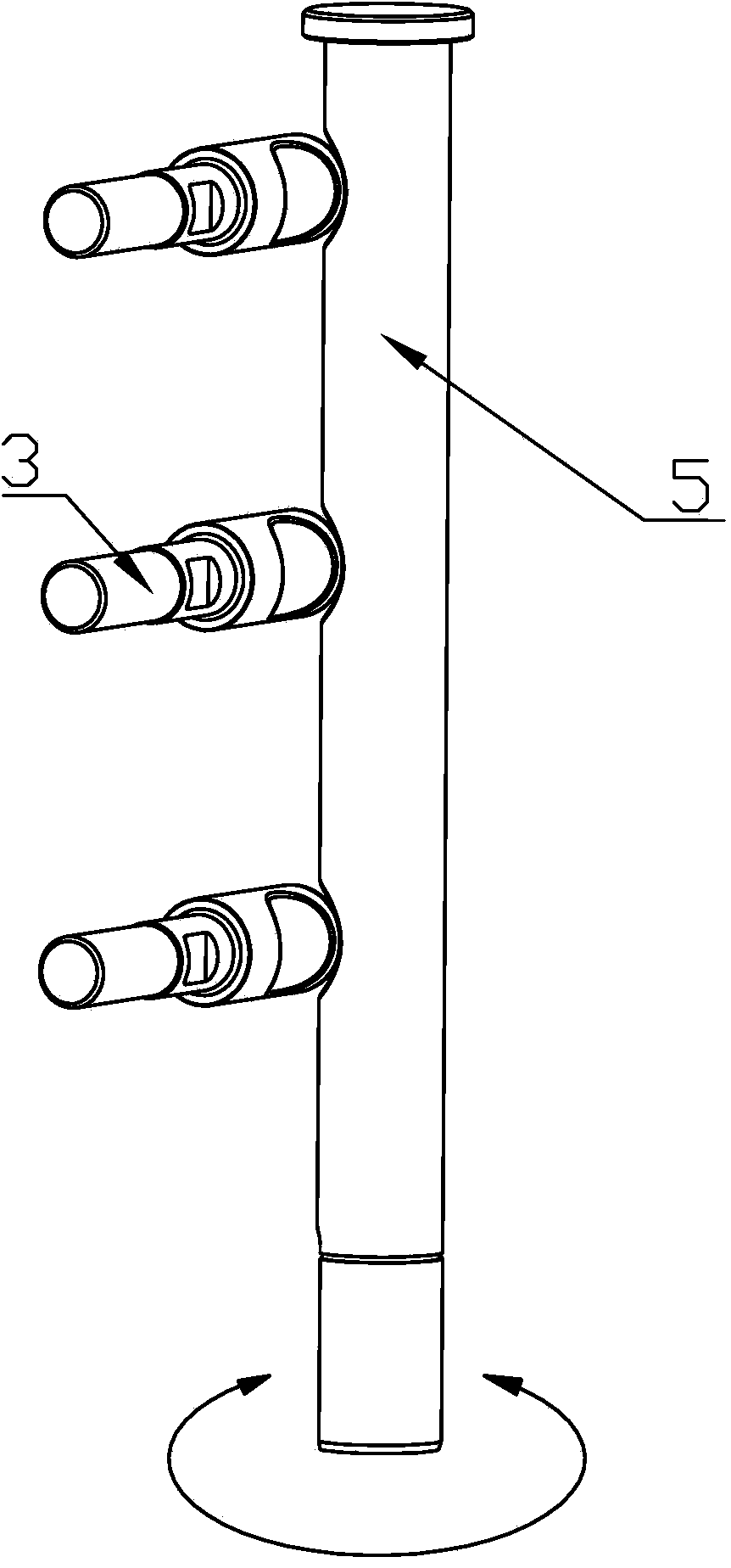

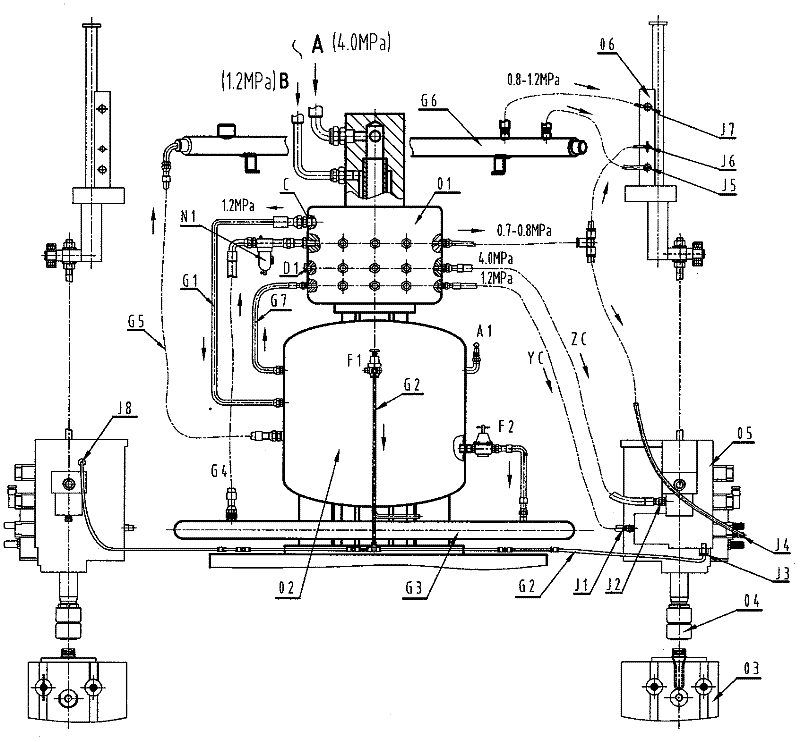

Recovered gas recycling system for full-automatic rotary bottle blowing machine

InactiveCN102452164ALow costImprove performanceHollow articlesGas collecting tubeProcess engineering

The invention discloses a structure of a recovered gas recycling system for a full-automatic rotary bottle blowing machine and a working method thereof. The system comprises a gas distributor, a gas storage tank, a reducing valve, an overflow valve, a safety valve, a recovered gas collecting tube, a recovered gas gathering tube, a high-pressure gas tube, a medium-pressure gas tube, a low-pressure gas tube, a medium-pressure through tube and a low-pressure through tube, wherein high-pressure gas blown through a bottle is collected into the recovered gas gathering tube through the recovered gas collecting tube and is introduced into the gas storage tank after being reducing into medium-pressure gas through the reducing valve, the medium-pressure gas is conveyed to the medium-pressure through tube through the medium-pressure gas tube, one part of the medium-pressure gas is distributed to each stretching cylinder through the medium-pressure through tube for driving a cylinder piston to work, and the other part of medium-pressure gas is distributed to each mold by through the gas distributor for pre-blowing onto a bottle blank, so that a large amount of medium and low-pressure gas can be saved. Due to the adoption of the recovered gas recycling system, on the premise of ensuring the sanitary quality of a blown bottle and a very high yield, a large amount of energy is saved, and the noise pollution of bottle blowing can be lowered. The recovered gas recycling system belongs to an energy-saving and emission-reducing technology which benefits the nation and the people.

Owner:GUANGZHOU TECH LONG PACKAGING MACHINERY CO LTD

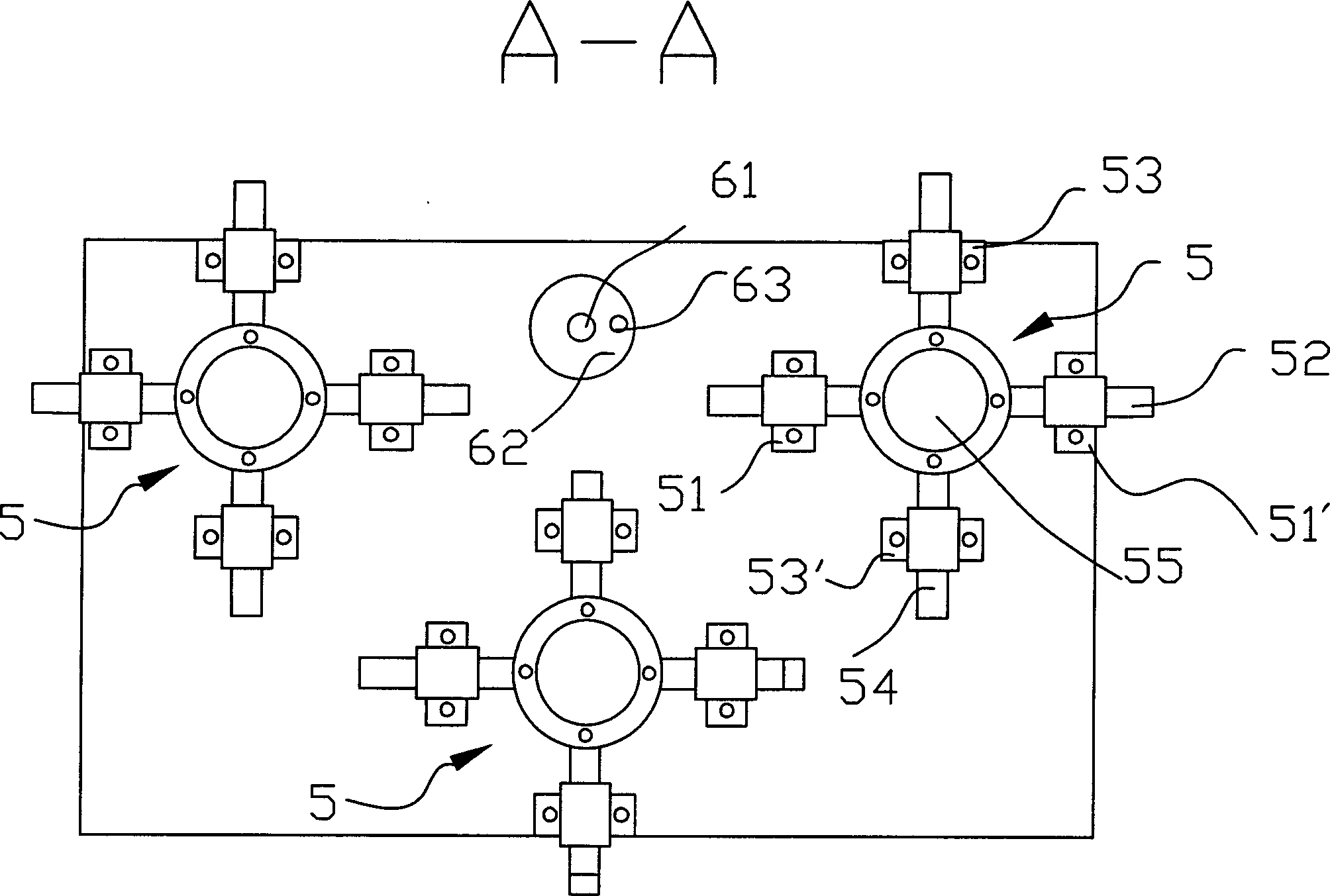

Bottle blank autorotation device of blowing bottle blank heating system

A bottle blank rotating apparatus for the heating system of blowing bottle blanks is composed of a plane plate, multiple bottle blank holders installed on said plate in rotary mode, multiple magnets installed eccentrically to said bottle blank holders (one for one), and an active plate with multiple magnets relative to the magnets on bottle blank holders. When said active plate and plane plate is parallelly swinging along a circular tracing, the bottle blank holders and their bottle blanks are rotating under the action of magnetic attraction.

Owner:厦门市立精实业有限公司

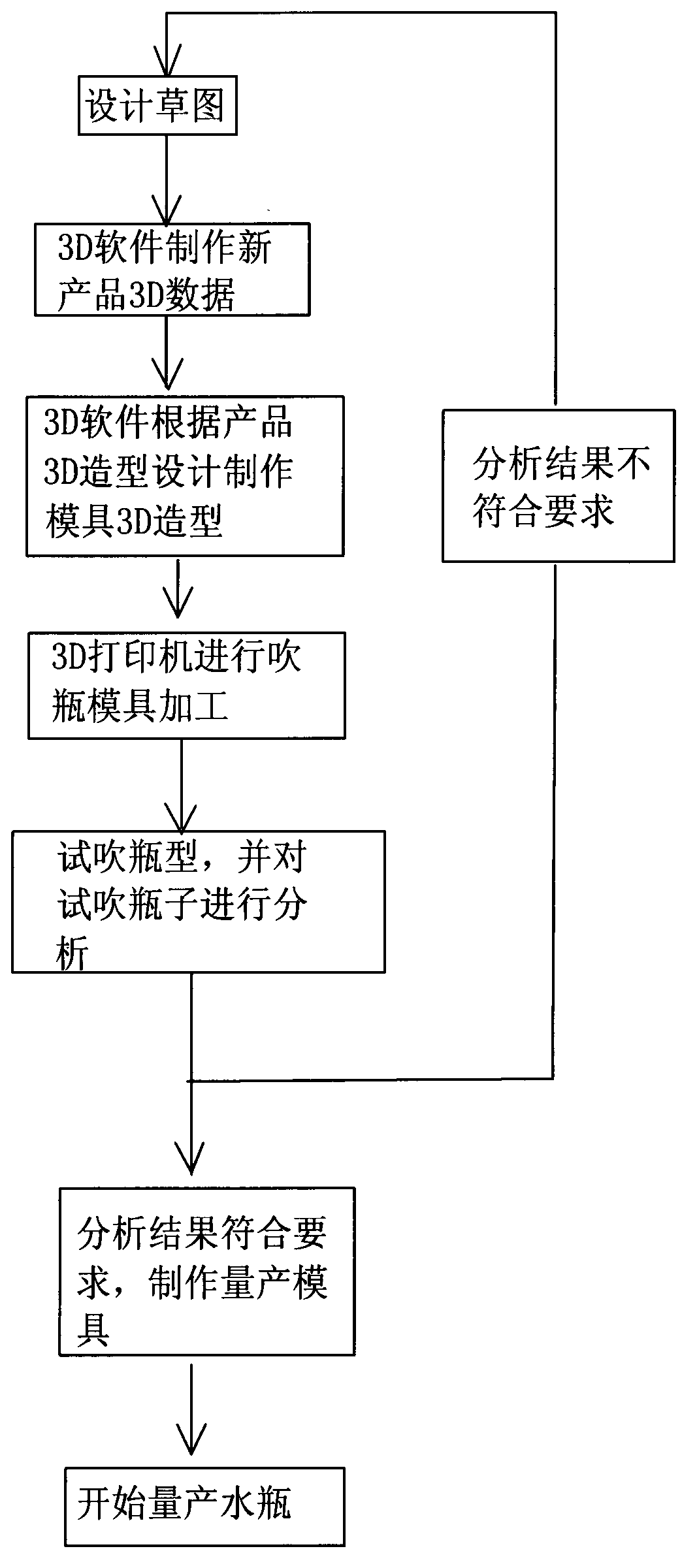

Water bottle manufacturing technology

InactiveCN103056997AShorten production timeReduce manufacturing costManufacturing technologyPlastic materials

The invention provides a water bottle manufacturing technology which comprises the specific technology steps of designing a rough plan; producing novel product 3D (three-dimensional) data by 3D software; designing and manufacturing a mold 3D model by 3D software according product 3D models; machining a blow bottle mold by a 3D printer; trying to blow bottle molds, and analyzing bottles tried to be blown; if the analysis result corresponds to requirements, manufacturing mass production molds (steel molds or aluminum molds); and beginning to produce water bottles in mass. According to the invention, molds are machined by utilizing plastic materials through a 3D printer, although the price of the raw materials is not low, the raw materials are very good from the aspect of environment-friendliness; and the most important is that time is saved, which is extremely important for newly designed products.

Owner:ALTECH NEW MATERIALS SUZHOU CO LTD

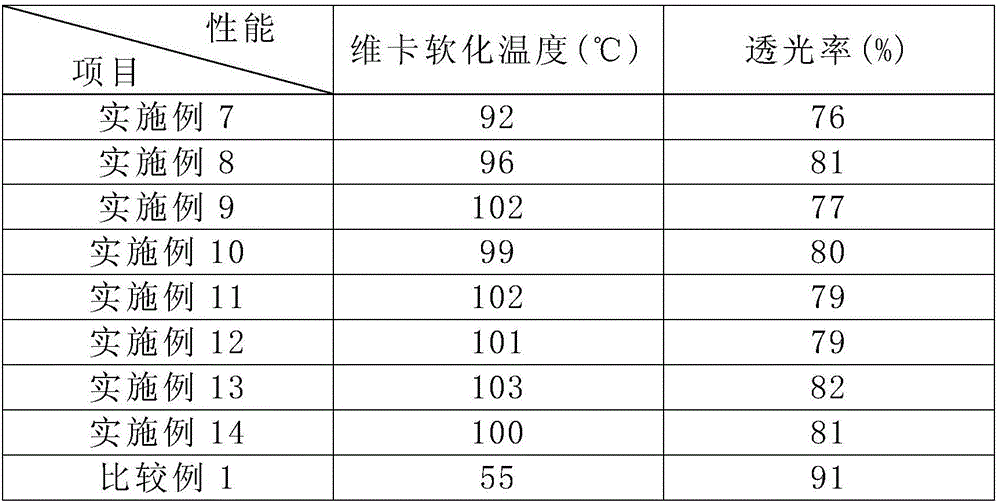

Polylactic resin composition for blowing transparent heat-resisting bottle

The invention relates to a polylactic resin composition for blowing a transparent heat-resisting bottle and belongs to the technical field of high molecular materials. Aiming at solving the problems of an existing process of blowing a bottle by utilizing polylactic acid that rapid crystallization cannot be realized and the strength is poor, the invention provides the polylactic resin composition for blowing the transparent heat-resisting bottle; the composition is prepared from the following components in parts by weight: 94 to 98 parts of polyL-lactic acid, 0.1 to 1.0 part of inorganic filling and 1.0 to 5.0 parts of a toughening modifier; the toughening modifier is an elastomer with a core-shell structure; a core layer is polybutadiene or polyisoprene; a shell layer is polystyrene or polyD-lactic acid. The polylactic resin composition provided by the invention can guarantee relatively high crystallization degree requirements and realizes high heat resistance; the polylactic resin composition can be applied to products of a bottle blowing process; the polylactic resin composition also has the performance of high light transmittance.

Owner:ZHEJIANG HISUN BIOMATERIALS

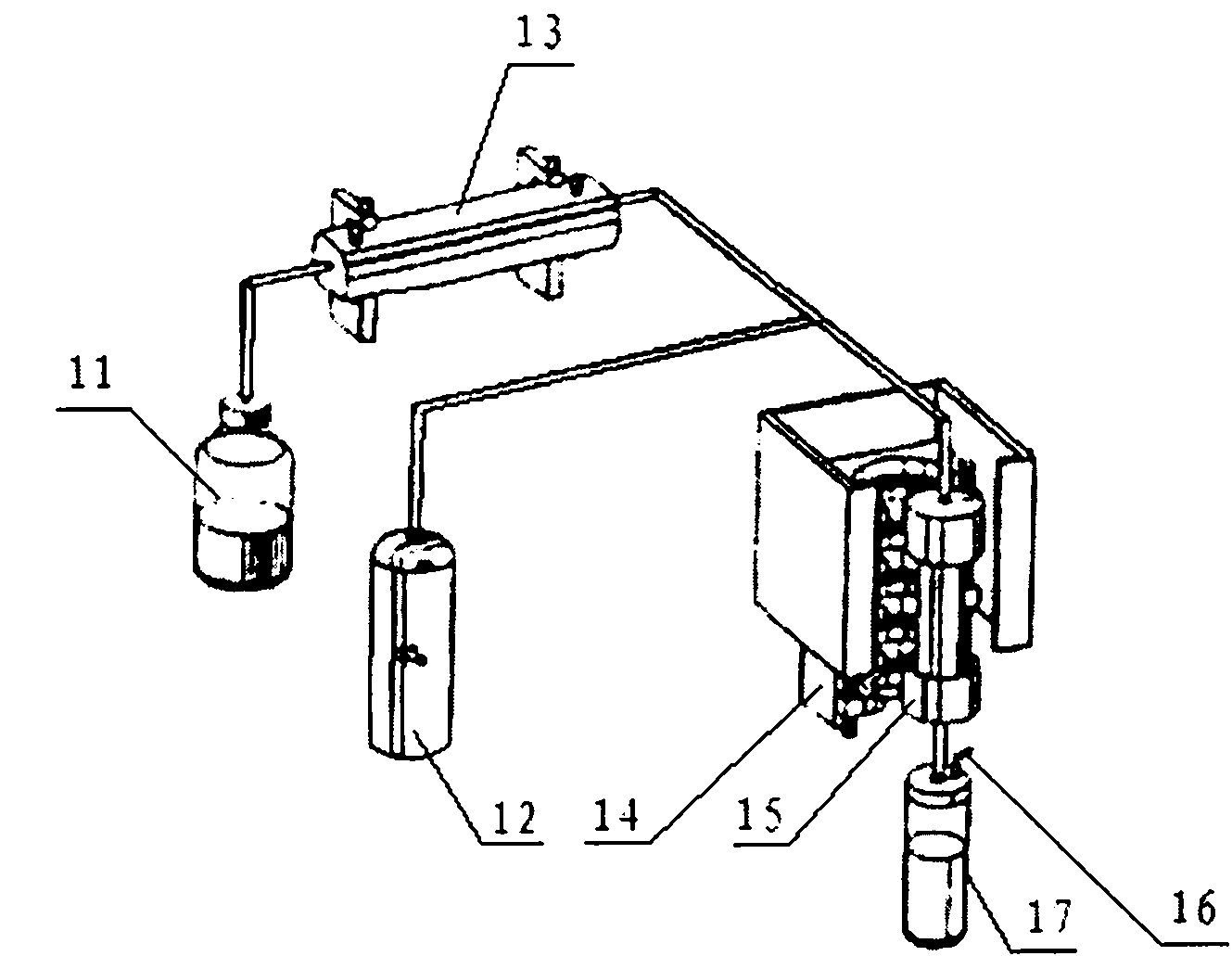

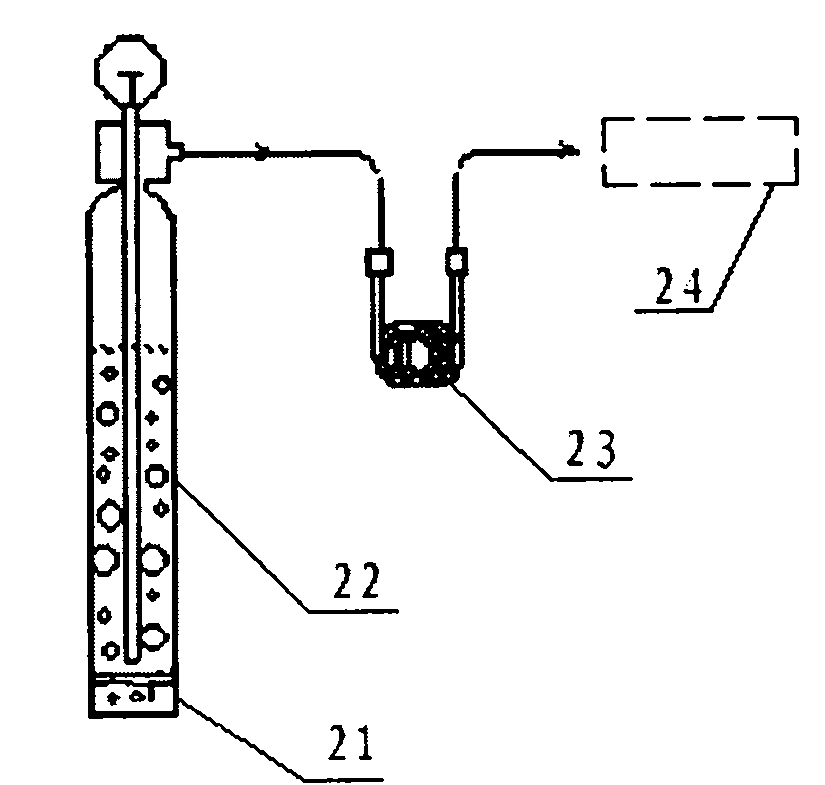

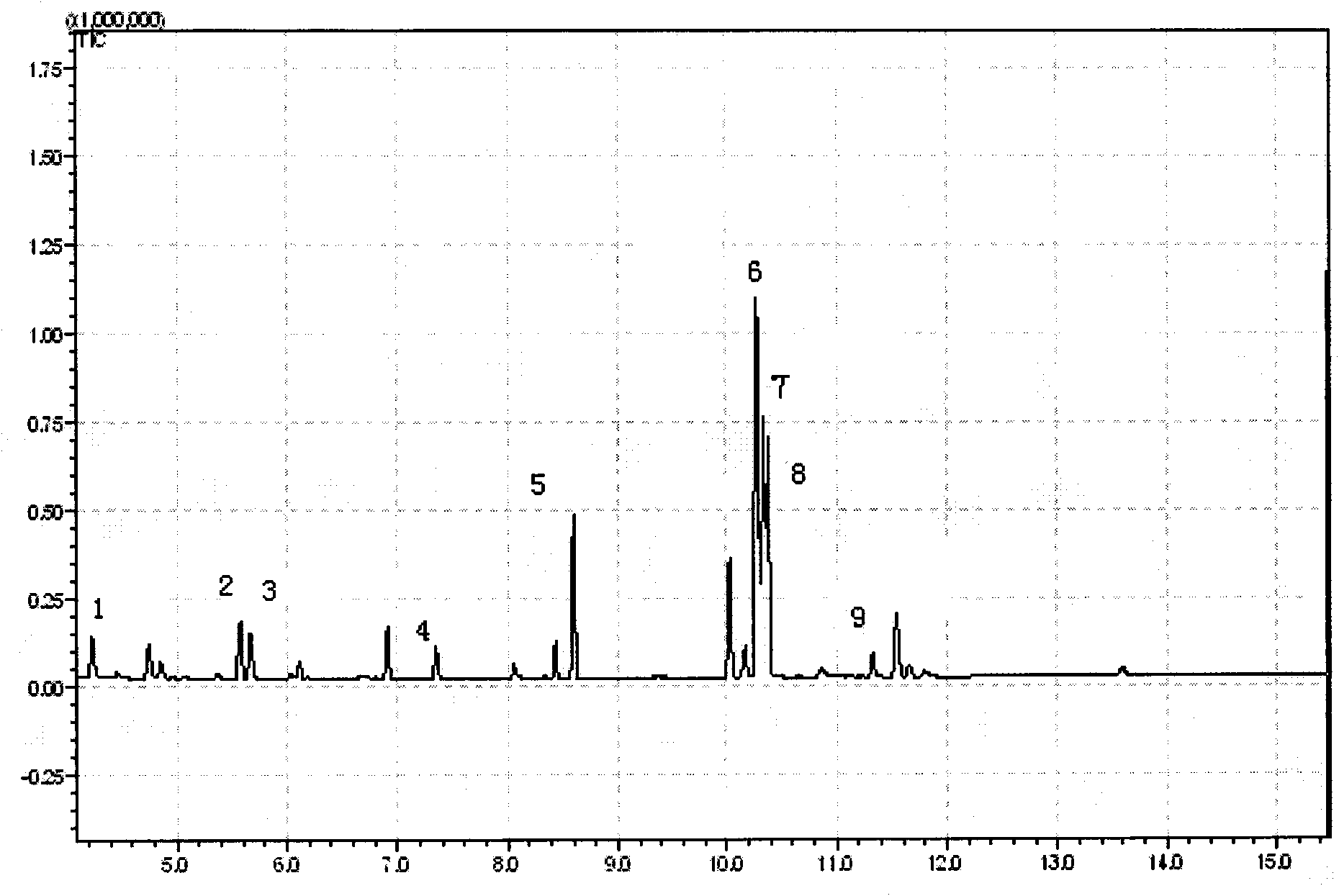

Method for rapidly sampling and identifying essential oil in chestnut flowers

The invention discloses a method for rapidly extracting and identifying essential oil in chestnut flowers. The method comprises the following steps of: (A) rapidly extracting the essential oil in chestnut flowers, loading mounting a filter membrane, quartz sand and crushed chestnut flowers into an extraction pool, opening a nitrogen cylinder bottle, setting pressure to be 100 Psi and starting to statically and circularly extract once to twice at the extraction pool with the temperature of 80-130 DEG C under the extraction pressure of 1200-1800 Psi for 10-20 min by using pure water as a solvent and nitrogen as a carrier gas to obtain extraction liquid, wherein static extraction is carried out for 10-20 min and circulation extraction is carried out once or twice; and (B) rapidly identifying the essential oil in the chestnut flowers, putting the extraction liquid obtained in the last step into a blowing bottle, blowing by adopting a soil-blowing mode on a blowing and trapping device to blow with 40 ml / min of nitrogen, continuously stirring for 10-15 min with a magnetic rotor under the driving of magnetic force, continuing for 10-15 min, absorbing the essential oil content in the extraction liquid onto a collecting trap, heating adding the collecting trap to 220 DEG C and resolving analyzing the essential oil content onto a combined gas phase chromatography-mass spectrometer connected with the collecting trap for identification. The invention extracts the essential oil in the chestnut flowers by utilizing an accelerated solvent extraction technology, directly analyzes extracts the extraction liquid by utilizing a blowing and trapping technology and has less sample consumption and greatly accelerated increased identification speed.

Owner:HEBEI UNIVERSITY OF SCIENCE AND TECHNOLOGY

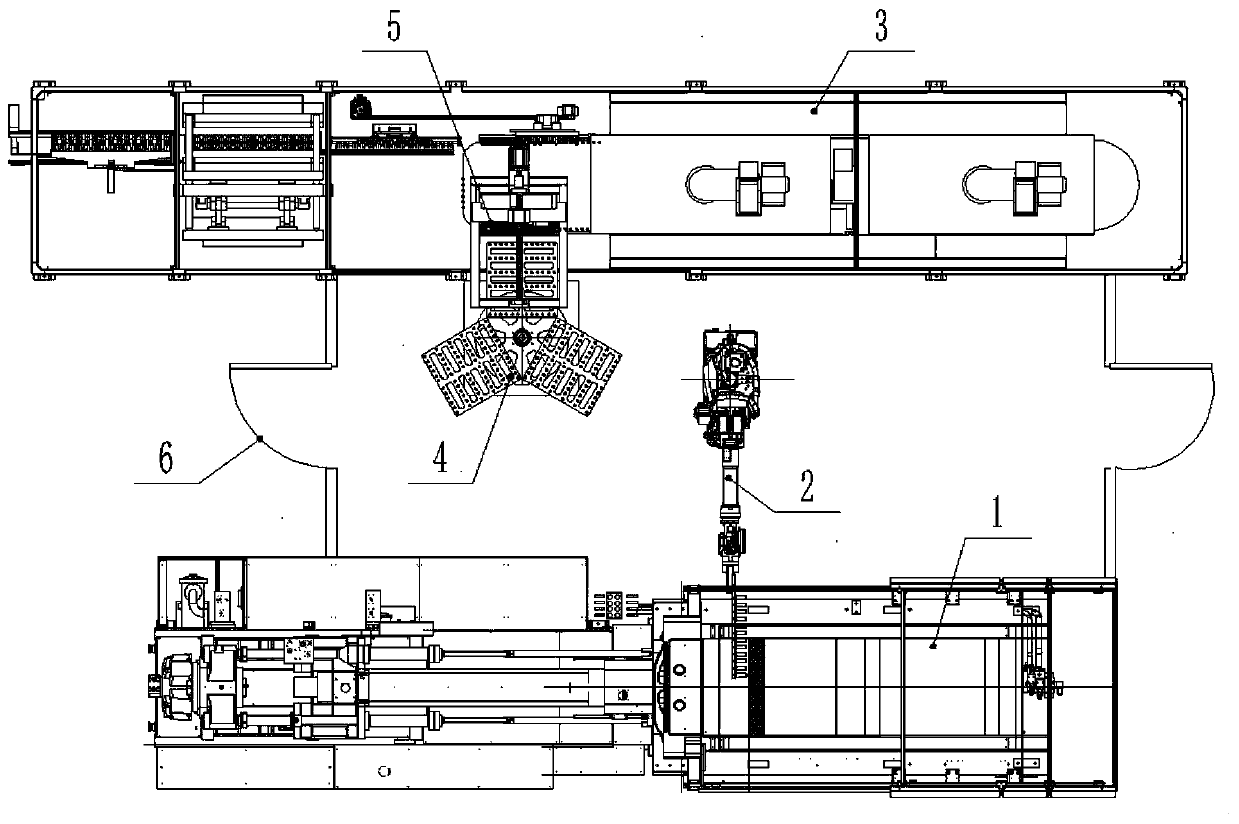

Automatic device used for blowing making of bottle blank of vertical type transfusion bag

PendingCN111409249AResolve collisionSimple processDomestic articlesHollow articlesForeign matterQuality control

The invention discloses an automatic device used for blowing making of a bottle blank of a vertical type transfusion bag and belongs to the technical field of bottle blank conveying. The automatic device comprises a bottle blowing device and an injection molding device, and is characterized in that the bottle blowing device and the injection molding device are arranged in parallel, and a bottle blank transferring system is installed between the bottle blowing device and the injection molding device; and the bottle blank transferring system comprises a discharging mechanical device used for taking out the bottle blank after being subjected to injection molding in the injection molding device, a circulating disk used for temporarily storing the bottle blank, and a feeding mechanical device used for conveying the bottle blank on the circulating disk to the bottle blowing device, and the feeding mechanical device is on a large chain following clamp. Multiple devices are integrated, high automation is achieved from injection molding to bottle blowing, and no manual intervention exists in the whole process. The whole transferring process of the bottle blank is free of mutual collision, ordered arranging and conveying is achieved, the risk that foreign matter is introduced in the bottle blank transferring process is reduced, and the quality control is guaranteed in the product production process.

Owner:SICHUAN KELUN PHARMA CO LTD

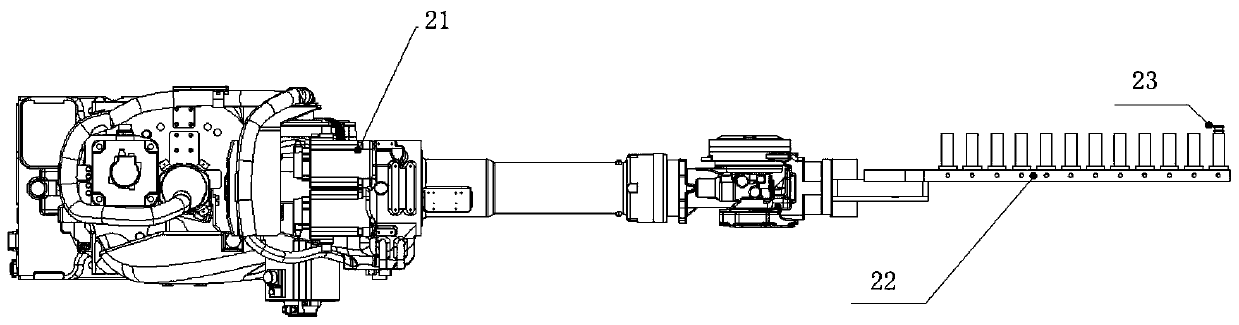

Automatic bottle blowing system and method for handle bottle

ActiveCN111216340ASimplify the front processIncrease productivityDomestic articlesBlow moldingProcess engineering

The invention provides an automatic bottle blowing system and method for a handle bottle. The system comprises an automatic bottle blowing module, an automatic bottle blank sorting module and an automatic handle sorting module. An integrated clamping mechanism which simultaneously comprises a bottle blank clamping assembly and a handle clamping assembly is arranged in the automatic bottle blowingmodule, the bottle blank clamping assembly clamps bottle blanks sorted and output by the automatic bottle blank sorting module, meanwhile, after the handle clamping assembly clamps handles sorted andoutput by the automatic handle sorting module, the clamping mechanism integrally moves into a bottle blowing mold to carry out a subsequent blow molding process, blank feeding and handle feeding processes are synchronously carried out, the previous process is simplified, the production efficiency is improved, and the technical problems that the previous process is complex and the production efficiency is low in the prior art are solved.

Owner:DEMARK (CHANGXING) INJECTION SYST CO LTD

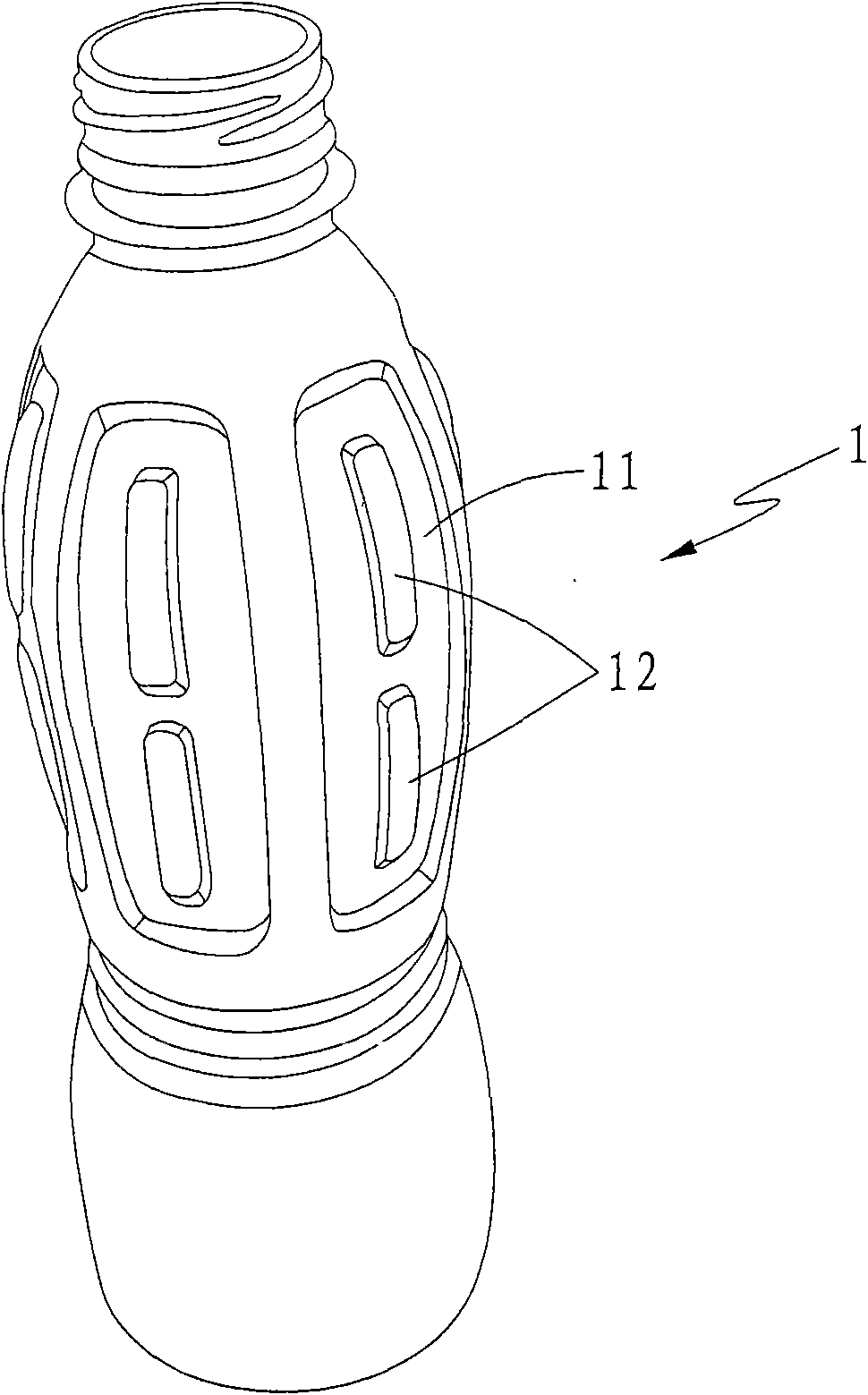

Production method for increasing strength of streamlined drinking bottle and streamlined drinking bottle

The invention discloses a method for increasing strength of streamlined beverage bottle and obtained drinking bottle using the method, arcuated bottle body is equipped with vacuum boards, after repeat tests, the vacuum boards are in an even distribution on the bottle body, moreover the number and length of the vacuum board are adapting with inner pressure variation of bottle by adjusting position and length of vacuum board on the mold when blowing bottle.

Owner:XIAMEN YINLU FOOD GROUP

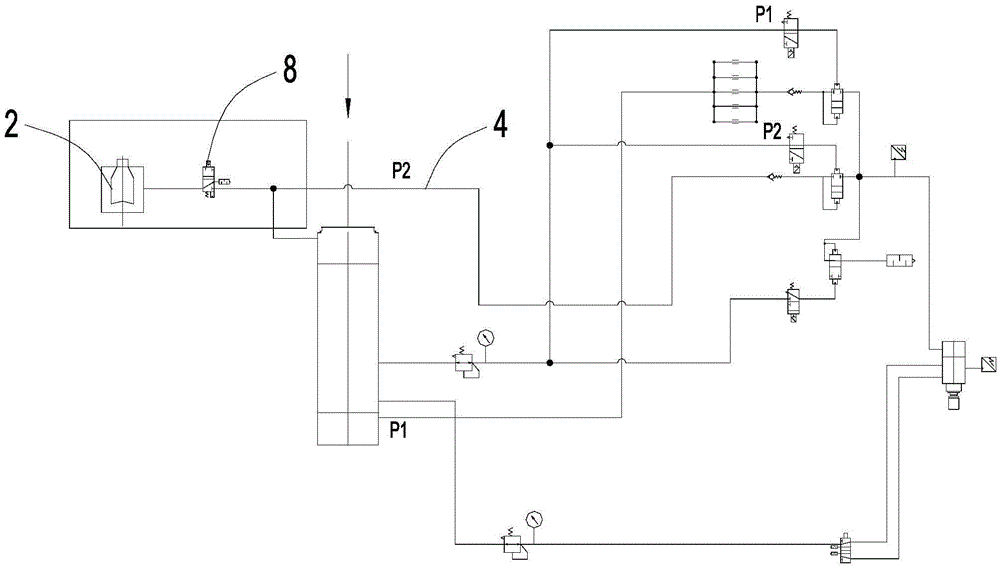

Complemental air circuit for bottle blowing machine

The invention discloses a complemental air circuit for a bottle blowing machine. Air is blown into a bottle blank through a sealing cylinder; the bottle blank is located in a mold; the sealing cylinder comprises an air inlet valve and an air release valve; the complemental air circuit for the bottle blowing machine comprises a gas output device, a bottle blowing air pipeline and a complemental air pipeline; the bottle blowing air pipeline is used for blowing air into the bottle blank; the complemental air pipeline is used for blowing air into the mold; both the bottle blowing air pipeline and the complemental air pipeline are connected onto the air release valve; the gas output device comprises a first air blowing pipeline and a second air blowing pipeline; the first air blowing pipeline is used for outputting the first circuit of high-pressure gas and the second air blowing pipeline is used for outputting the second circuit of high-pressure gas; and both the first air blowing pipeline and the second air blowing pipeline are connected onto the air inlet valve. According to the complemental air circuit for the bottle blowing machine, both the bottle blowing air pipeline used for blowing the bottle blank and the complemental air pipeline used for compensating the mold are connected to the air release valve of the sealing cylinder; and air is supplied to the bottle blowing air pipeline and the complemental air pipeline alternately through the first air blowing pipeline and the second air blowing pipeline which are connected onto the air inlet valve of the sealing cylinder, so that an air circuit system of the bottle blowing machine is simplified, and the cost is reduced.

Owner:JIANGSU NEWAMSTAR PACKAGING MACHINERY

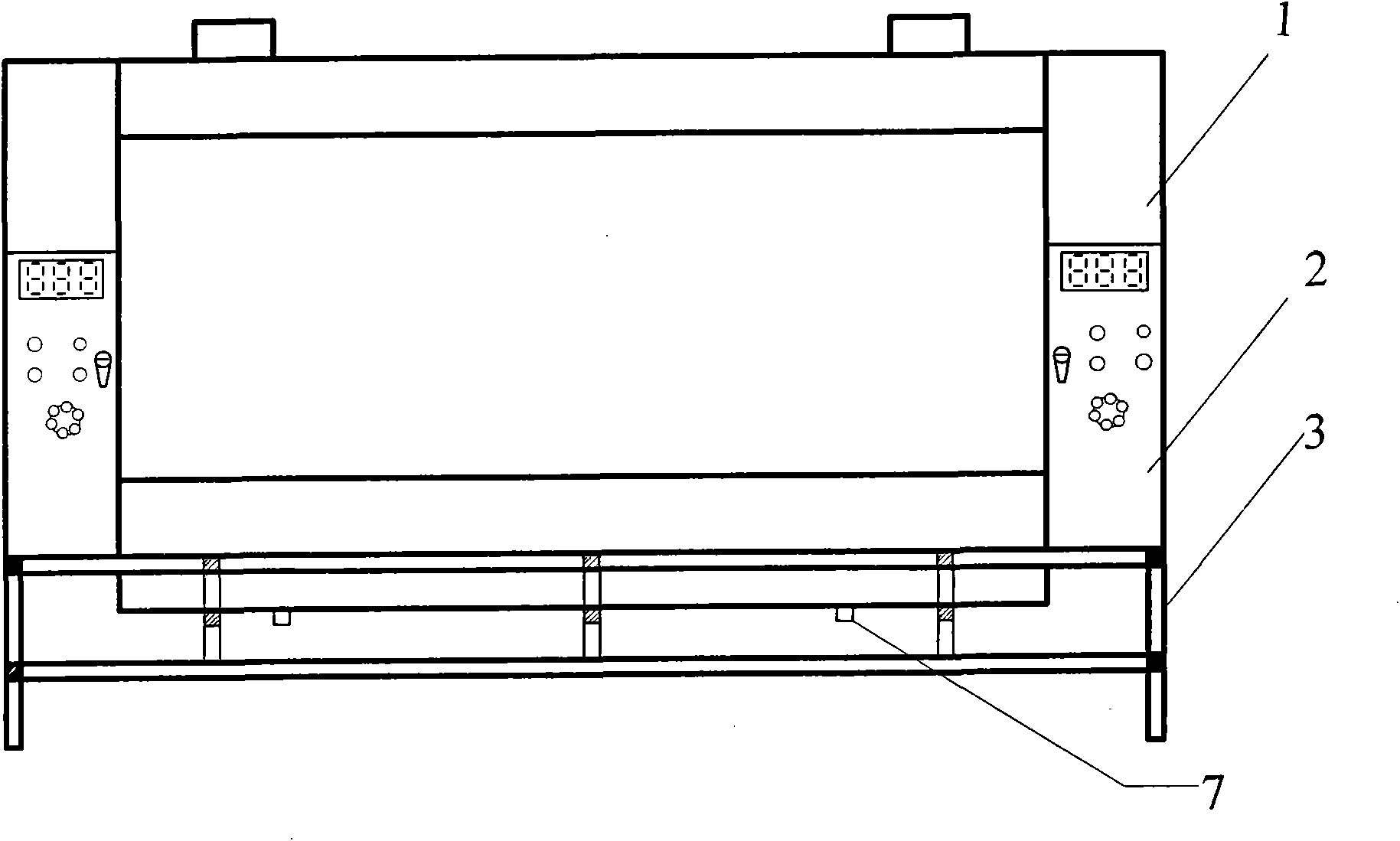

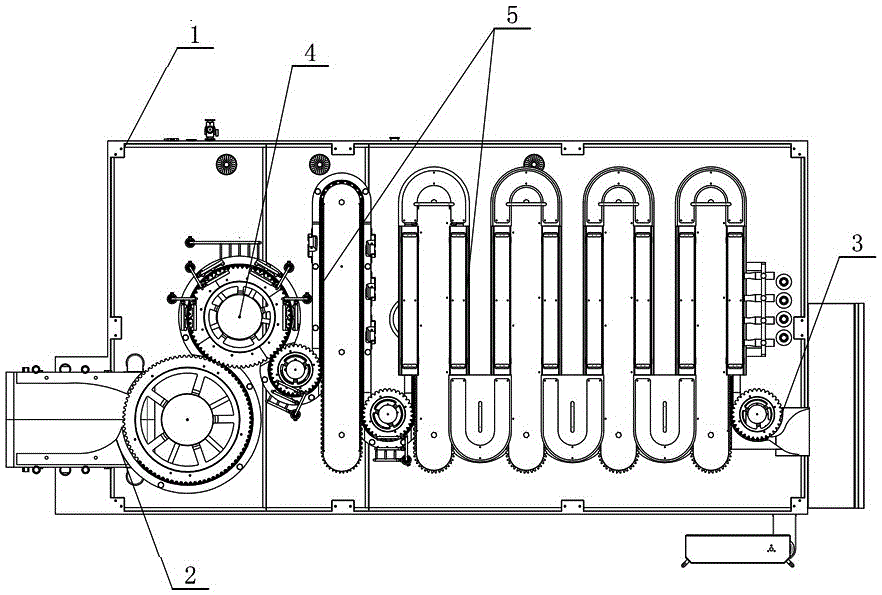

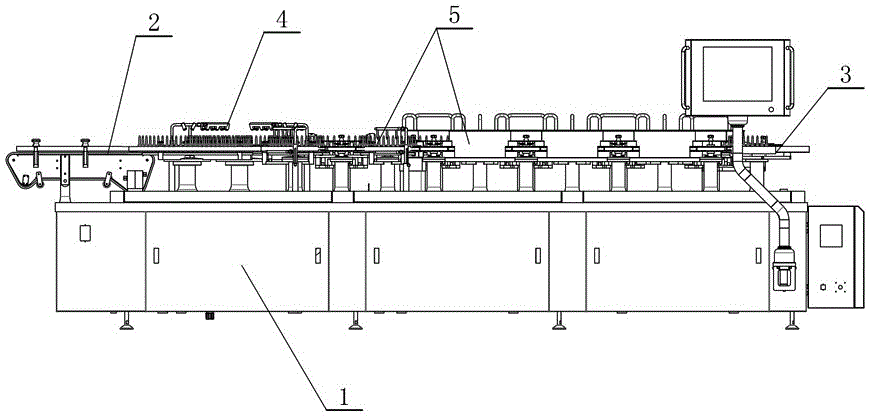

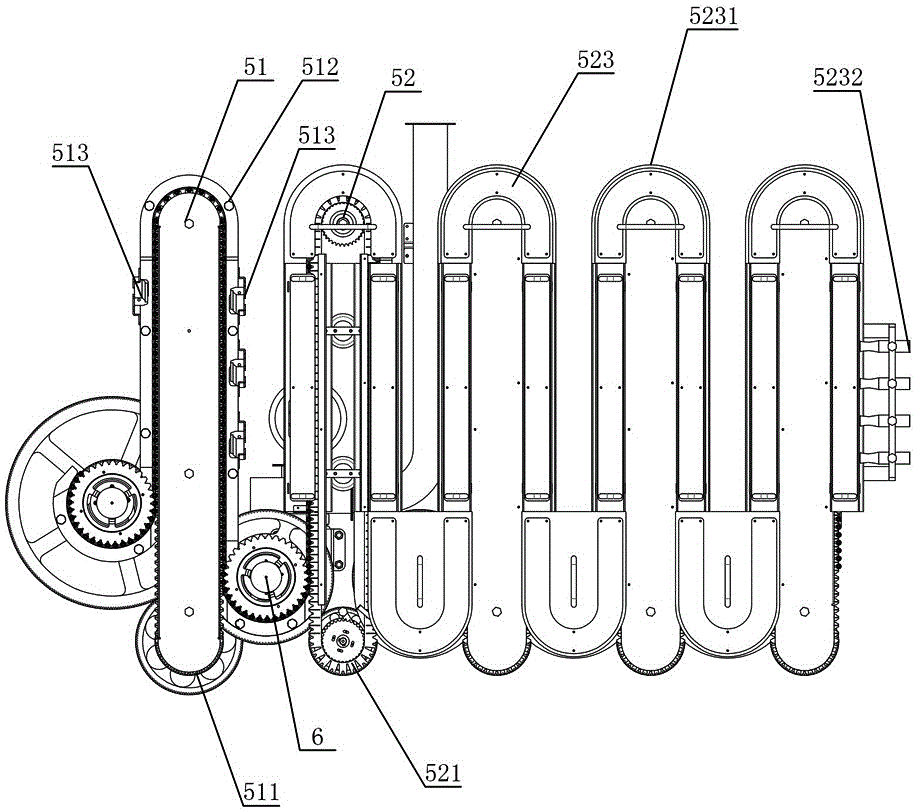

Cleaning machine

ActiveCN106166557AExtension of timeImprove drying effectHollow article cleaningDrying gas arrangementsButt jointEngineering

The invention discloses a cleaning machine comprising a rack. A bottle feeding mechanism and a bottle discharging mechanism are installed to head and tail sections of the rack respectively, a cleaning mechanism in butt joint with the bottle feeding mechanism is arranged between the bottle feeding mechanism and the bottle discharging mechanism on the rack, and a blown bottle conveying mechanism with an S-shaped bottle conveying path is in butt joint with the position between the cleaning mechanism and the bottle discharging mechanism on the rack. The cleaning machine has the advantages of simple and compact structure, and capabilities of improving blow-drying effect and capacity and reducing whole machine occupied area.

Owner:TRUKING TECH LTD

Bottle blowing machine

The invention relates to a bottle blowing machine. The machine comprises a frame, a die opening and closing assembly, a lift assembly, a bottom die locking assembly and a drive assembly, wherein the die opening and closing assembly comprises a bottom die, a fixed template and a movable template; the lift assembly comprises a cam, a lift rod and a pulley, a runner is formed on the cam, the pulley is slidably arranged in the runner, and the bottom die is fixed on the lift rod; the bottom die locking assembly comprises a driving connection block, a driven connection block, a first slide block and a second slide block, the first slide block is slidably arranged on the frame, and the second slide block is fixed on the movable template; the drive assembly comprises a rotating shaft and a power source; the movable template, the cam and the driving connection block are fixedly connected with the rotating shaft at the same time; and when the rotating shaft is rotated, a die is closed by the fixed and movable templates, and the bottom die rises and the first and second slide blocks slide between the frame and the bottom die. The bottle blowing machine can be used for driving the three assemblies to act at the same time through only one rotating shaft, and completing die closing, lifting and locking steps, and is simple in structure and convenient to operate, so that the efficiency of bottle blowing process can be improved.

Owner:JIANGSU NEWAMSTAR PACKAGING MACHINERY

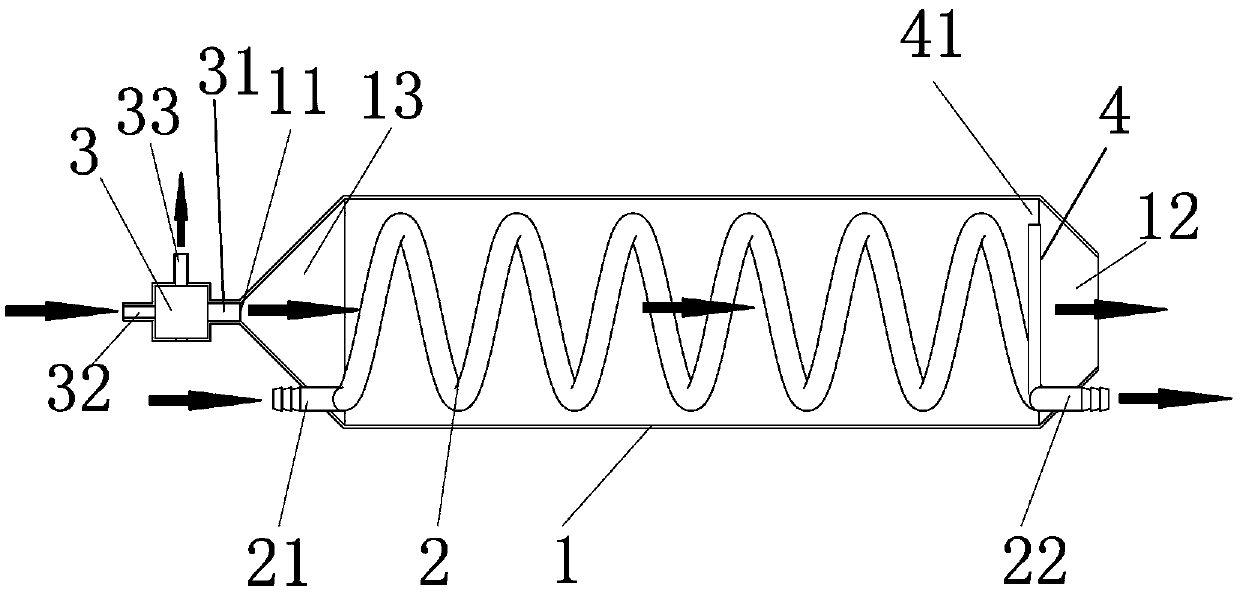

Bottle blowing machine cooling gas cooling device

The invention discloses a bottle blowing machine cooling gas cooling device which is characterized in that the bottle blowing machine cooling gas cooling device comprises a pressure tank and a coolingpipe arranged in the pressure tank; an inlet of the cooling pipe is connected with a compressor; an outlet of the cooling pipe is connected with a bottle blowing needle of a bottle blowing machine; the cooling pipe is spirally wound and arranged in the pressure tank; an air inlet is formed in one end of the pressure tank; an air outlet is formed in the other end of the pressure tank; the air inlet is connected with the cold air end of an air cooler; an air inlet of the air cooler is connected with the compressor; and the hot air end of the air cooler is connected with a silencer. The bottle blowing machine cooling gas cooling device has the beneficial effects that 1, the bottle blowing machine cooling gas cooling device is simple in structure and low in production cost and the market competitiveness is improved; 2, a vortex cooler is used for cooling compressed air, so that the temperature difference between the compressed air and a product in the bottle blowing machine is increased,the heat exchange speed is raised and the cooling of the product is accelerated; and 3, the vortex cooler is simple in structure and convenient to use, the vortex cooler can refrigerate simply by communicating with the compressed air, and a huge and complicated compressor refrigeration system is not required.

Owner:GUANGDONG LESHAN INTELLIGENT EQUIP CORP LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com