Production method for increasing strength of streamlined drinking bottle and streamlined drinking bottle

A production method and streamlined technology, applied in the direction of the bottle, etc., can solve the problems of inability to calculate the length of the vacuum plate, the balance between the quantity and the change of internal pressure, the influence of product canning, and the imbalance of the bottle body, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

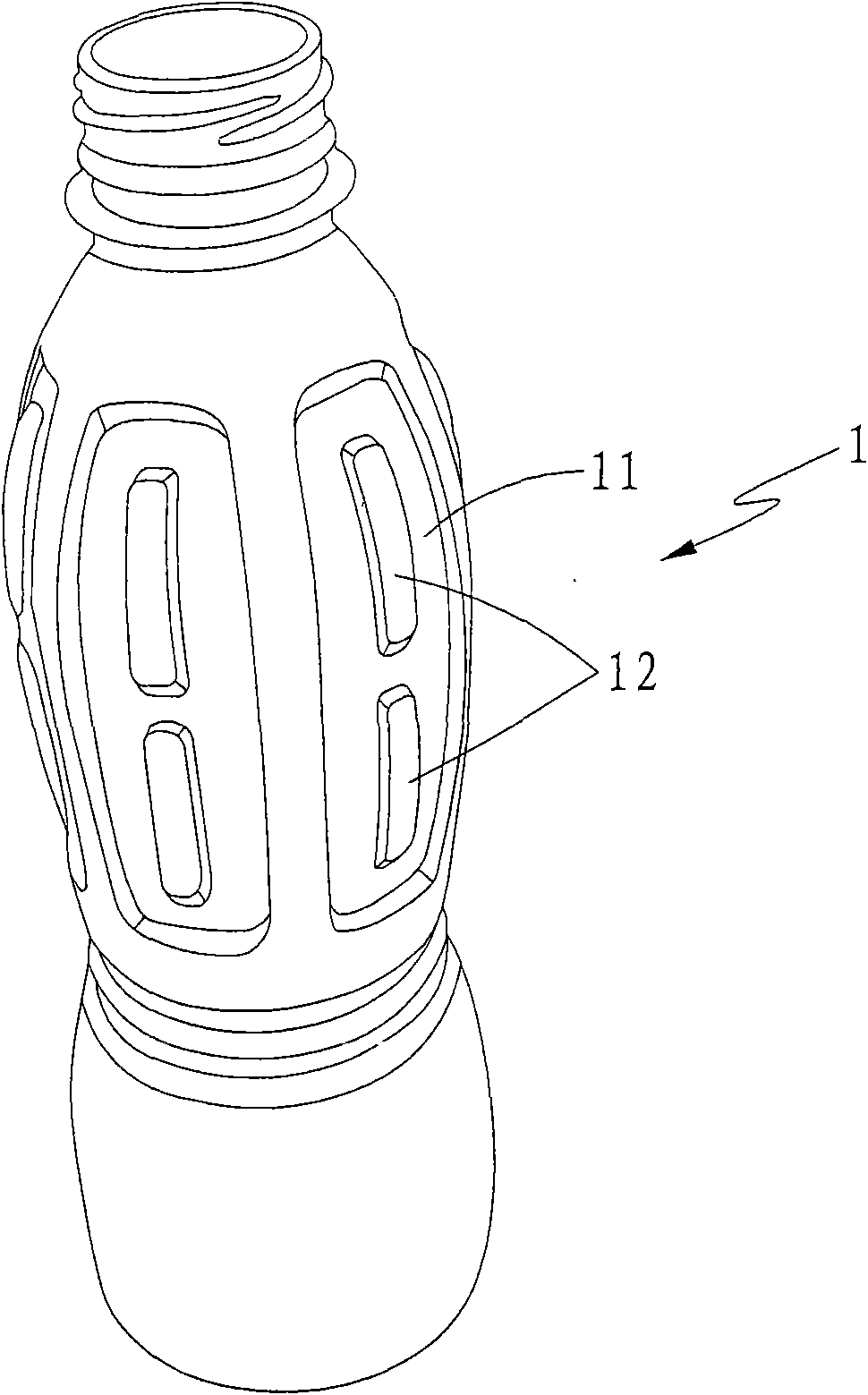

[0019] The production method of increasing streamlined beverage bottle intensity of the present invention, its concrete steps are:

[0020] First, pre-set several vacuum plate templates on the bottle blowing mold corresponding to the curved body of the streamlined bottle, and appropriately increase the diameter of the bottle body of the mold, and then perform pre-blowing;

[0021] Secondly, conduct capacity, deformation, pressure resistance and drop tests on the pre-blown bottles, and correct the radian, length, quantity and bottle diameter of the vacuum plate template on the mold according to the obtained test data, and then blow the bottle;

[0022] Furthermore, the pre-blown bottle is subjected to the aforementioned test, and then the mold is revised according to the data until a bottle meeting the corresponding standard is obtained.

[0023] In this production method, since the vacuum board is installed on the curved bottle body of the streamlined bottle to solve the probl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com