Recovered gas recycling system for full-automatic rotary bottle blowing machine

A technology for recovering gas and bottle blowing machines, which is applied in applications, household appliances, and other household appliances, and can solve problems such as energy waste, environmental pollution, and water consumption.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0011] The present invention will be further described below in conjunction with the accompanying drawings and specific examples.

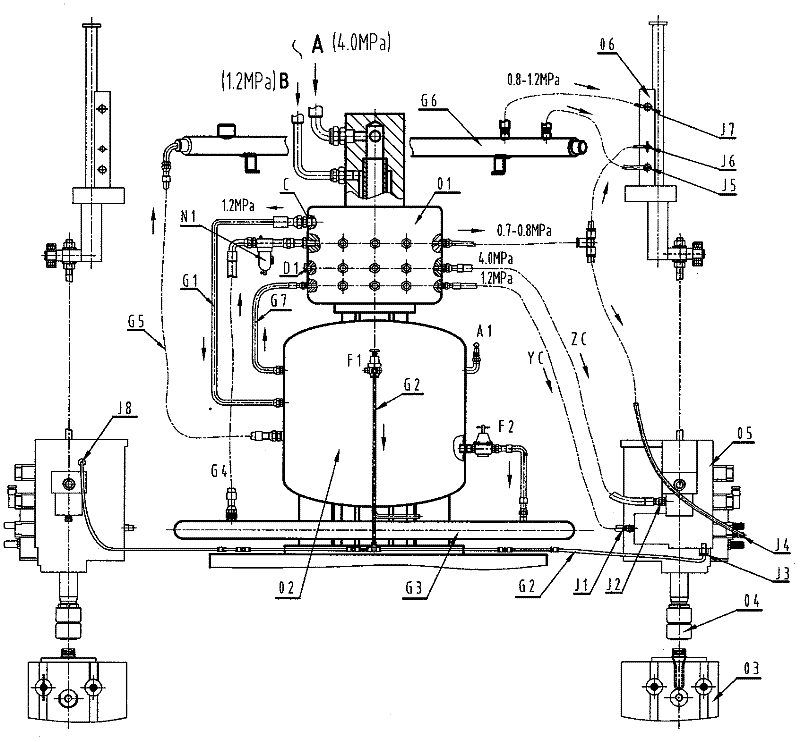

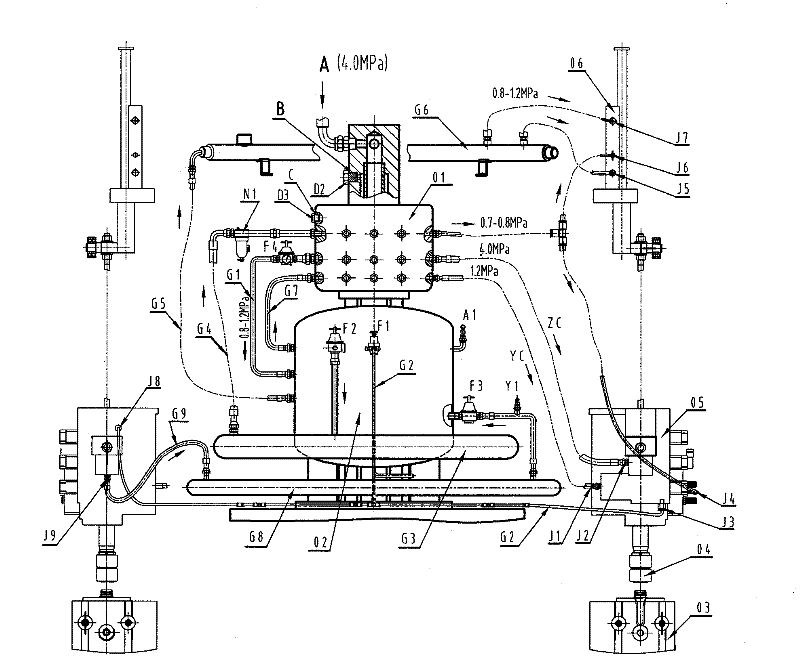

[0012] see figure 1 , image 3 , the high-pressure recovery gas recovery system of the automatic rotary blow molding machine of the present invention is composed of many parts and components, which are fixed on the upper part of the main body of the blow molding machine with bolts, wherein the gas distributor 01 is installed on the top of the gas storage tank 02 Above; the inlet end of the pressure reducing valve F4 is connected to a high-pressure air outlet on the distributor 01, and the other end is connected to the air storage tank 02 through the medium-pressure air pipe G1; the air inlet end of the pressure reducing valve F1 is connected to the air storage tank 02, and the air One end of the pressure reducing valve F2 is connected to the air tank 02, and the outlet end is connected to the low-pressure pipe G3; one end of the low-pressure air ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com