Blow-molding mechanism for handle assembly snapping grooves in container with handle

A mold mechanism and handle technology, which is applied in the field of blow molding mechanism, can solve the problems of high wear rate of parts, permanent deformation of spring, failure of reset of stuck mold, etc., and achieve the effect of reducing wear

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The technical solution of the present invention will be further described below in conjunction with the accompanying drawings.

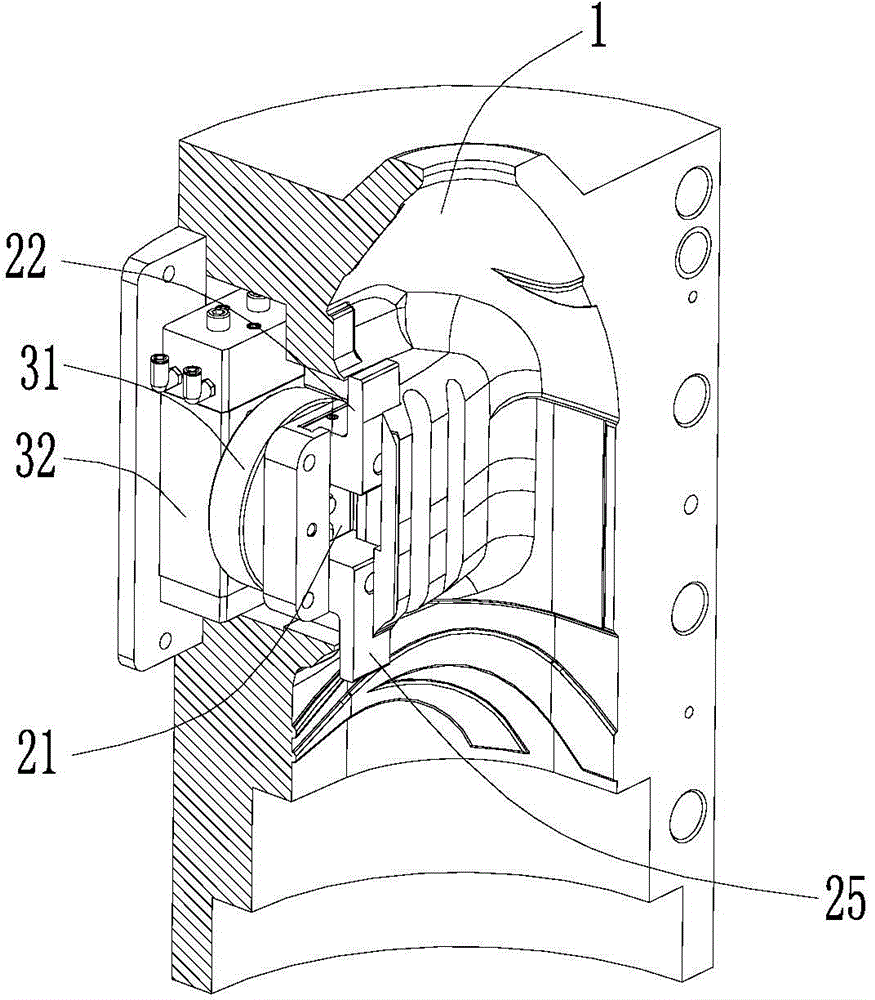

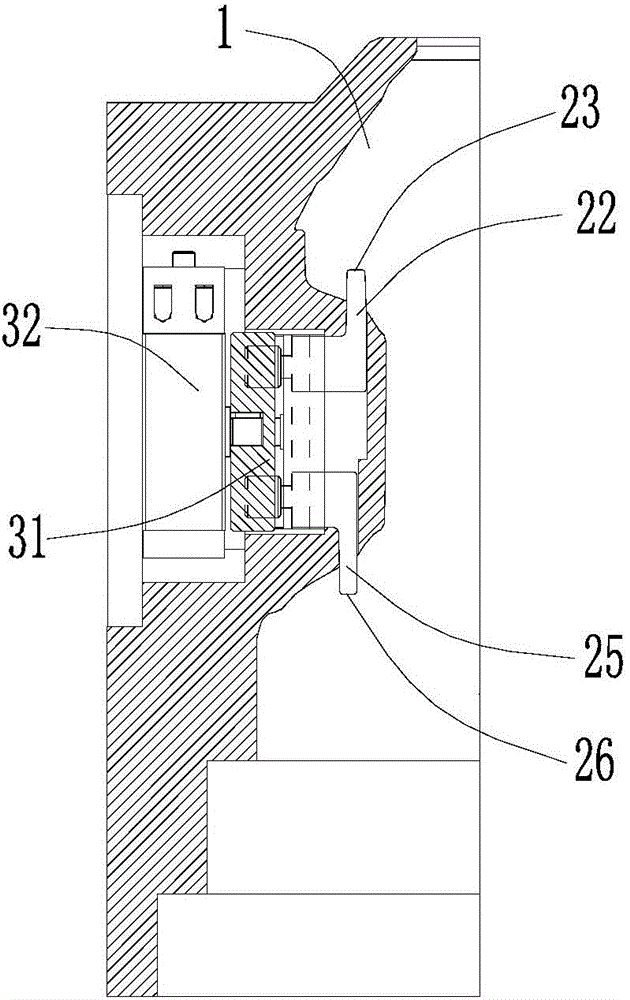

[0023] see Figure 1-3 As shown, the above-mentioned blow molding mechanism for assembling the handle on the container with a handle is set on the frame, and is used to form two upper and lower parts in the blowing mold 1 when the bottle blowing machine blows the container. Card slot molds for blown card slots.

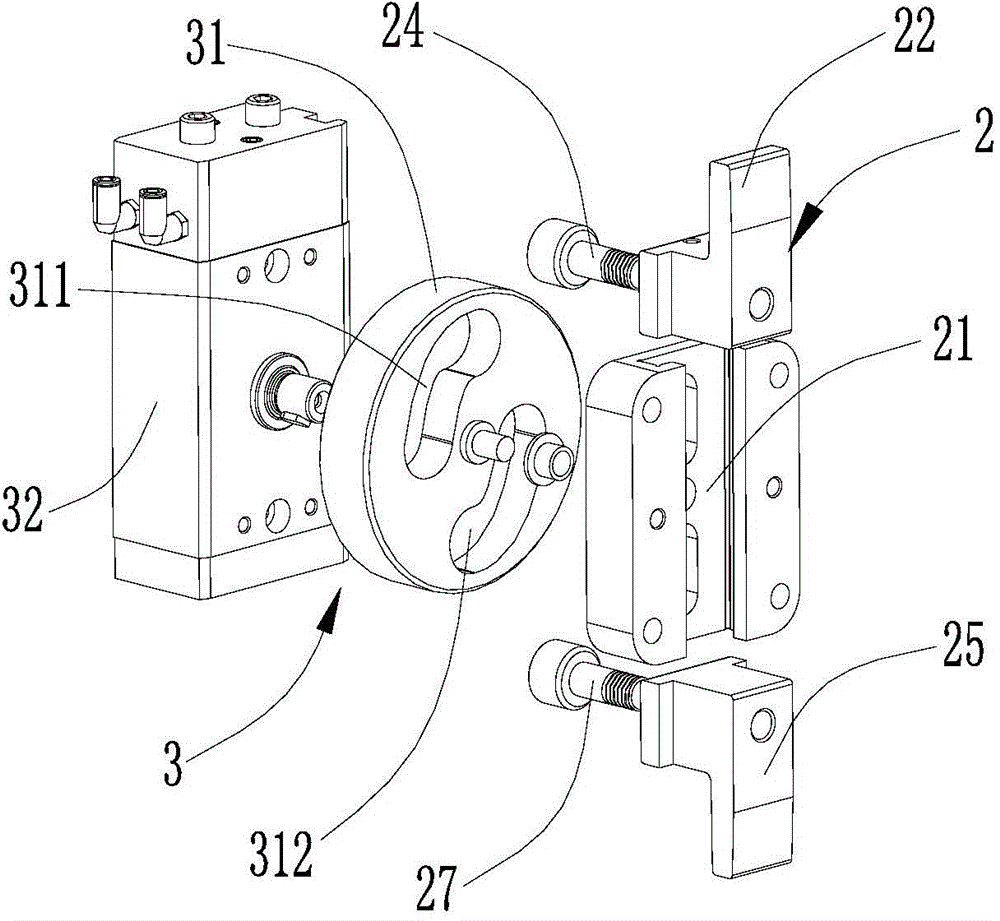

[0024] The above-mentioned blow molding mechanism includes a sliding mold mechanism 2 arranged on the frame for forming the groove mold, and a driving mechanism 3 for driving the mold mechanism 2 to slide on the frame.

[0025] The above-mentioned mold mechanism 2 includes a chute 21 fixed on the frame and distributed along the vertical direction, and a first slot 23 which is provided in the chute 21 and is used to be blown in the blowing mold 1 and slides up and down. The first sliding block 22, the second sliding block 25 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com