Complemental air circuit for bottle blowing machine

A bottle blowing machine and compensation gas technology, which is applied in the field of compensation gas path of bottle blowing machine, can solve the problems of affecting the quality of blown bottles and enlargement of the clamping seam, and achieves the effects of compact structure, simplified gas path system and cost reduction.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

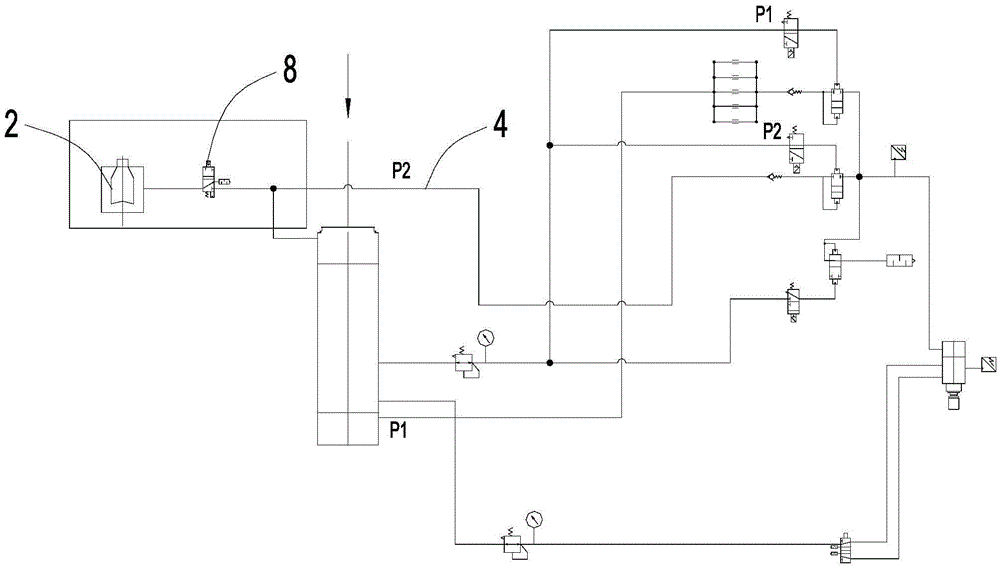

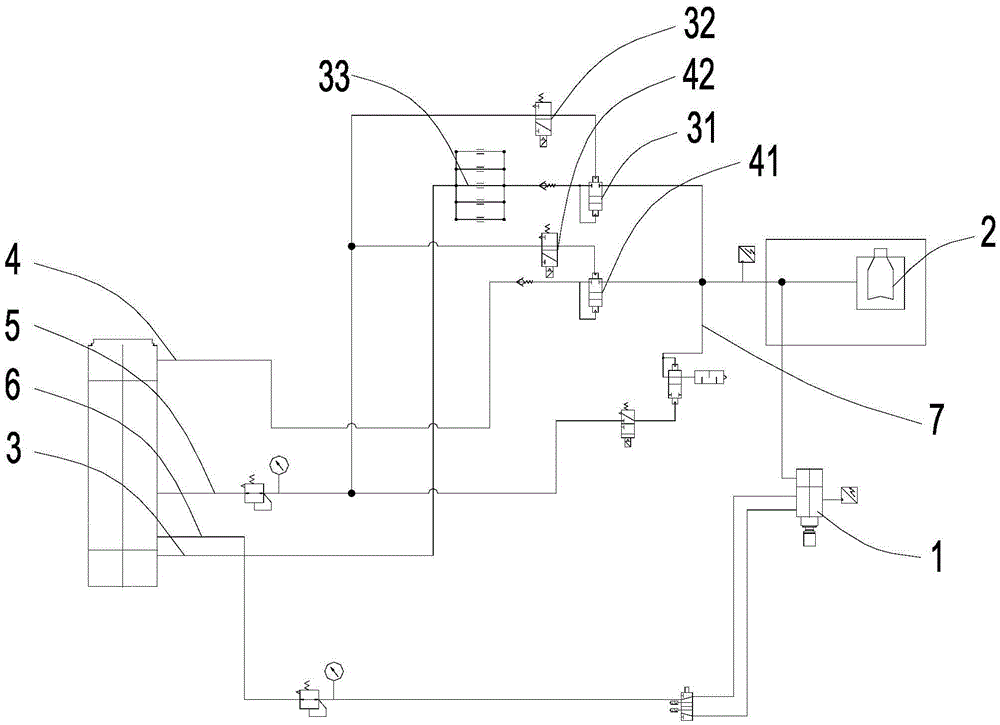

[0020] The technical solution of the present invention will be further described below in conjunction with the accompanying drawings.

[0021] see figure 2 As shown, the compensation air path of the above-mentioned blow molding machine uses the sealing cylinder 1 that moves up and down to seal the preform and then blows it. The preform is located in the mold 2. The sealing cylinder 1 includes an air inlet valve and an exhaust valve. valve.

[0022] The compensation gas circuit of the bottle blowing machine includes a gas output device, a blowing gas pipeline for blowing the preform, and a compensation gas pipeline for blowing the mold 2. The blowing gas pipeline and the compensation gas pipeline are both It is connected to the exhaust valve, and the blowing gas pipeline and the compensation gas pipeline are simultaneously fed into the blowing gas pipeline through the exhaust valve.

[0023] The gas output device includes a first blowing pipeline 3 for outputting a f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com