Method for quickly preparing zinc oxide nanobelt under air atmosphere

A zinc oxide nanotechnology, air atmosphere technology, applied in zinc oxide/zinc hydroxide, nanotechnology and other directions, can solve the problems of long generation cycle, small output, limited number of nanobelts, etc., to reduce the reaction time and simplify the gas circuit system Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

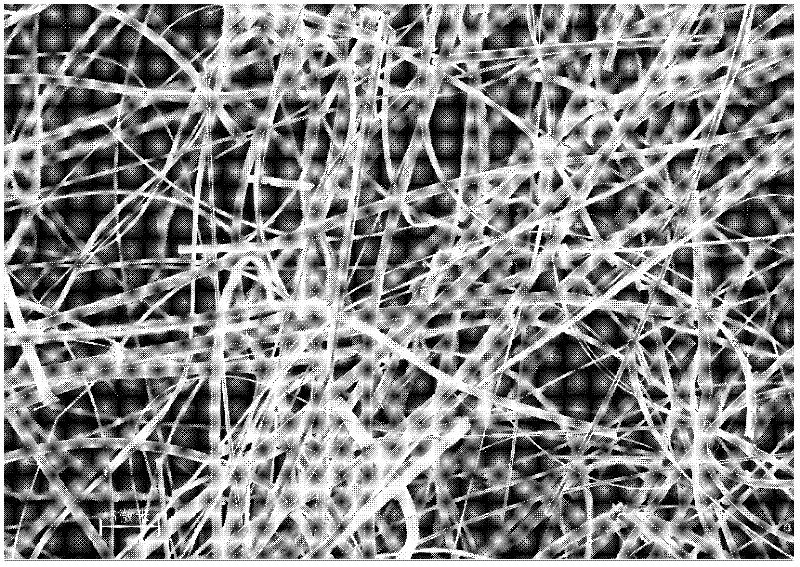

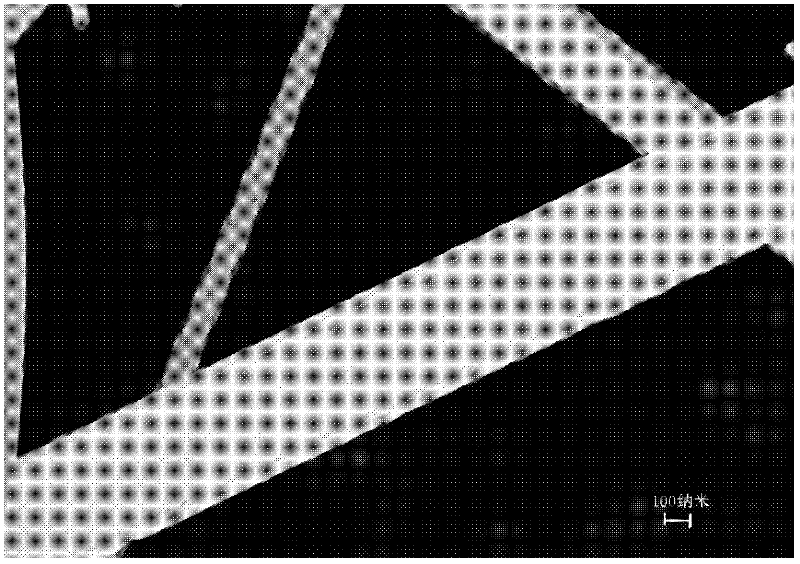

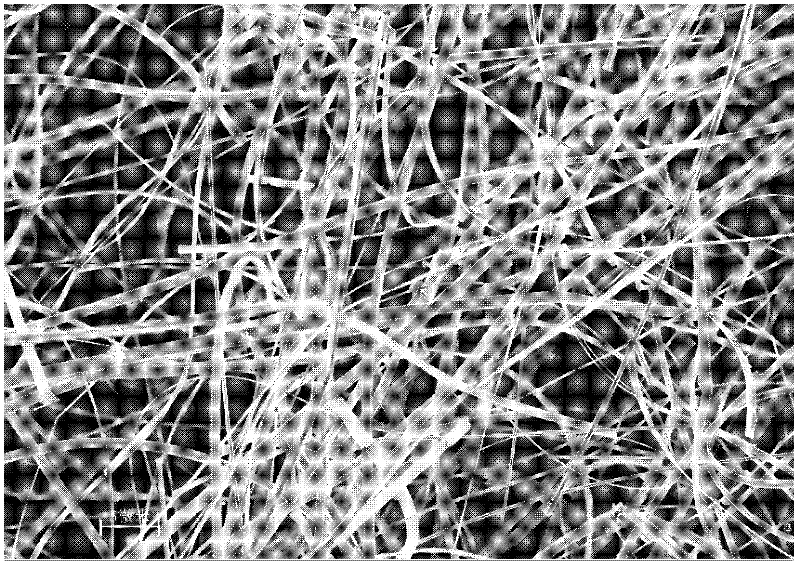

Image

Examples

Embodiment 1

[0026] (1) Take an appropriate amount of zinc oxide powder and coke powder with a balance, and the mass ratio is 7: 1 to 1: 1. In this embodiment, 5 grams of zinc oxide powder and 5 grams of coke powder are weighed, and they are evenly mixed with a mortar ;

[0027] (2) The mixed raw material is placed in a hollow graphite tube. The specification of the graphite tube is 12 centimeters long, 30 millimeters in outer diameter, and 24 millimeters in inner diameter. One end is closed, and one end is open. The graphite tube is placed in a horizontal quartz tube, and placed Within the range of action of the high-frequency coil;

[0028] (3) Turn on the cooling water of the high-frequency equipment, turn on the heating power of the equipment, the temperature in the graphite tube rises rapidly, and within about 2 minutes, the temperature in the graphite tube rises to about 1200 degrees Celsius, and the air continues to flow in, and a large amount of white smoke appears in the quartz tu...

Embodiment 2

[0032] A method for rapidly preparing zinc oxide nanoribbons under an air atmosphere, using air as the atmosphere environment, using a mixture of zinc oxide powder and carbonaceous material powder as a raw material, using high-frequency induction heating equipment to heat the mixture, and collecting white cotton flocculent oxide The zinc nanobelt specifically comprises the following steps:

[0033] (1) take zinc oxide powder and graphite powder as raw material, the mass ratio of zinc oxide powder and graphite powder is 3: 1, guarantee that graphite powder is suitably excessive, it is mixed homogeneously;

[0034] (2) mixed raw material is placed in hollow graphite tube, and the specification of hollow graphite tube is external diameter 30 millimeters, inner diameter 24 millimeters, length 12 centimeters, one end is closed, and the other end is open, and hollow graphite tube is placed in horizontal quartz tube, And put it within the range of high-frequency equipment;

[0035] ...

Embodiment 3

[0039] A method for rapidly preparing zinc oxide nanoribbons under an air atmosphere, using air as the atmosphere environment, using a mixture of zinc oxide powder and carbonaceous material powder as a raw material, using high-frequency induction heating equipment to heat the mixture, and collecting white cotton flocculent oxide The zinc nanobelt specifically comprises the following steps:

[0040] (1) Using zinc oxide powder and activated carbon as raw materials, the mass ratio of zinc oxide powder and activated carbon is 4: 1, ensuring that the activated carbon is properly excessive and mixed evenly;

[0041] (2) mixed raw material is placed in hollow graphite tube, and the specification of hollow graphite tube is external diameter 30 millimeters, inner diameter 24 millimeters, length 12 centimeters, one end is closed, and the other end is open, and hollow graphite tube is placed in horizontal quartz tube, And put it within the range of high-frequency equipment;

[0042] (3...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com