Polylactic resin composition for blowing transparent heat-resisting bottle

A technology of polylactic acid resin and composition, applied in the field of polylactic acid resin composition, can solve the problems of affecting the light transmittance of materials, polylactic acid is not suitable for bottle blowing process, application limitation, etc., and achieves high heat resistance and high crystallinity. degree requirements and the effect of increasing compatibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

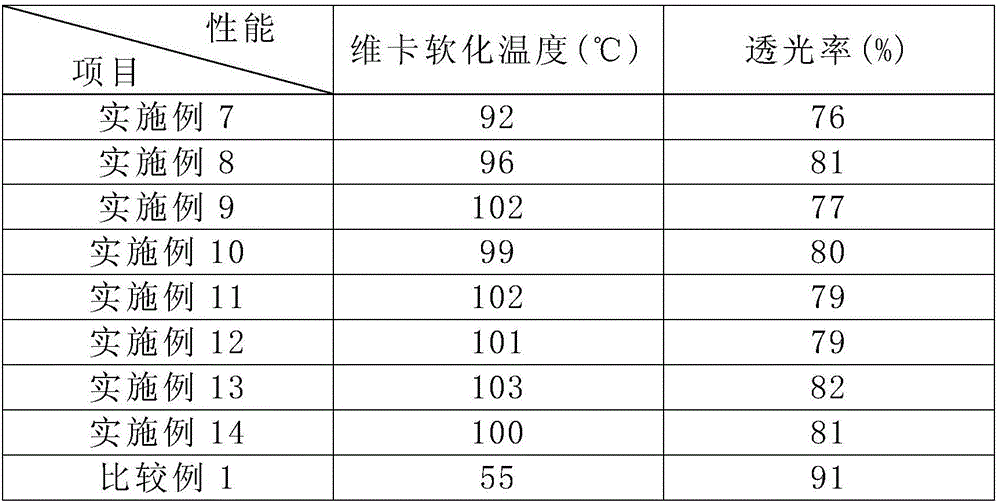

Examples

Embodiment 1

[0020] Styrene-butadiene-styrene block copolymer (SBS) is dropped into the twin-screw extruder, wherein, in SBS, the B segment content is 50mol%, and then, 5wt% glycidyl methacrylate (GMA ), 0.5wt% initiator dicumyl peroxide and 0.1wt% crosslinking agent triallyl isocyanurate (TAIC) are mixed and dropped into the twin-screw extruder, and the temperature is controlled to be 200°C Extrude for granulation; then, put the product and 5wt% poly D-lactic acid into another twin-screw extruder again and control the temperature at 220°C to extrude and granulate to obtain the corresponding elastomer with core-shell structure , that is, the corresponding toughening modifier T1.

Embodiment 2

[0022] Styrene-isoprene-styrene block copolymer (SIS) is dropped into twin-screw extruder, wherein, in SIS, the content of stage I is 80mol%, and then, 1wt% glycidyl methacrylate ( GMA), 0.1wt% initiator dicumyl peroxide and 3.0wt% crosslinking agent triallyl isocyanuric acid ester (TAIC) are mixed and dropped into the twin-screw extruder, and the control temperature is 160 ℃ Then, put the product and 30wt% poly D-lactic acid into another twin-screw extruder again and control the temperature at 180°C to extrude and pelletize to obtain the corresponding elastic core-shell structure. body, that is, the corresponding toughening modifier T2.

Embodiment 3

[0024] Styrene-butadiene-styrene block copolymer (SBS) is dropped into the twin-screw extruder, wherein, the B segment content is 70mol% in the SBS, and then, 3wt% glycidyl methacrylate (GMA ), 0.3wt% initiator dicumyl peroxide and 1.0wt% crosslinking agent triallyl isocyanurate (TAIC) are mixed and dropped into the twin-screw extruder, and the temperature is controlled to be 180°C Extrude for granulation; then, put the product and 10wt% poly D-lactic acid into another twin-screw extruder again and control the temperature at 220°C to extrude and granulate to obtain the corresponding elastomer with core-shell structure , that is, the corresponding toughening modifier T3.

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com