Bottle blank autorotation device of blowing bottle blank heating system

A technology of heating system and autorotation device is applied in the field of equipment combining blow molding and parison manufacturing, and can solve the problems of poor stability, high noise, complex transmission structure, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

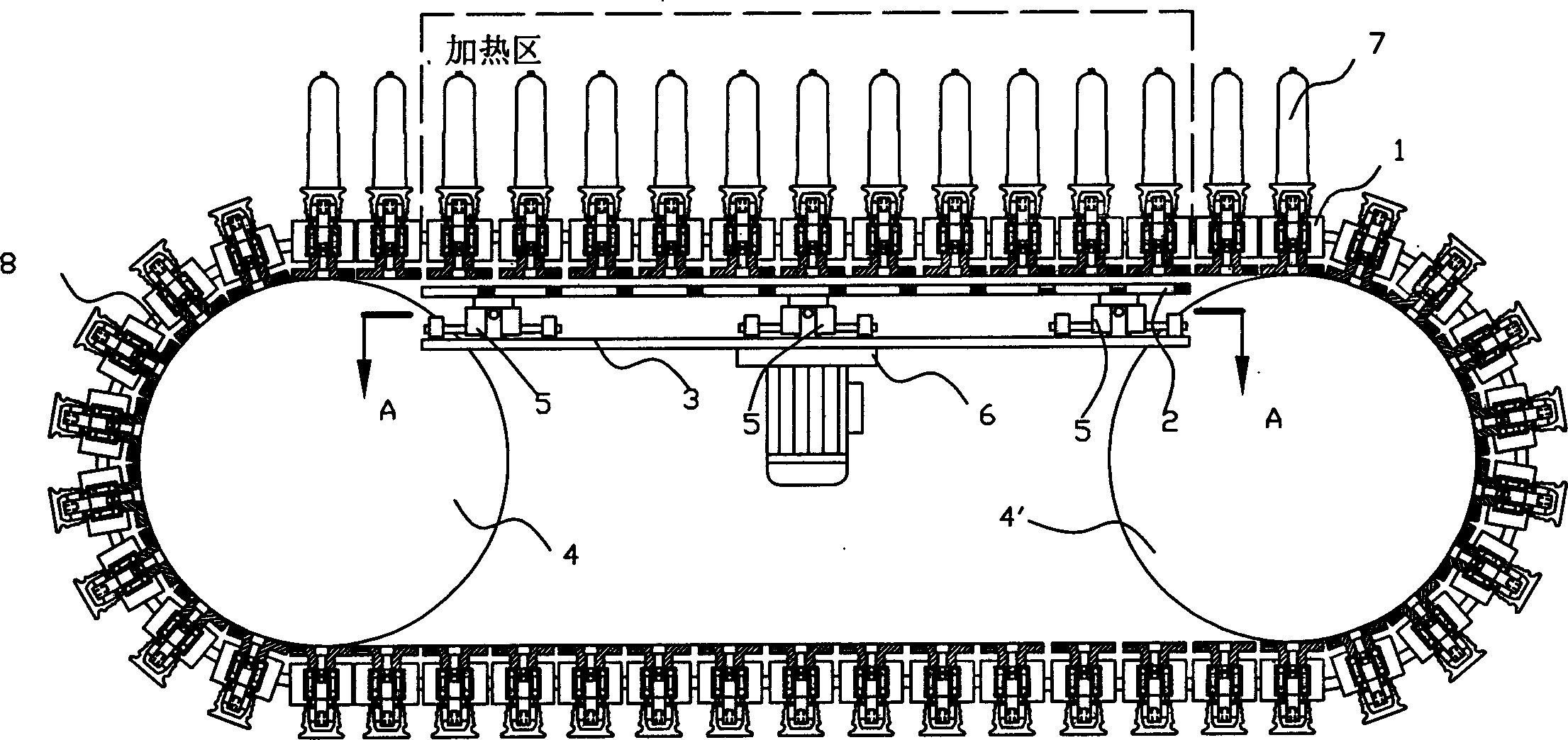

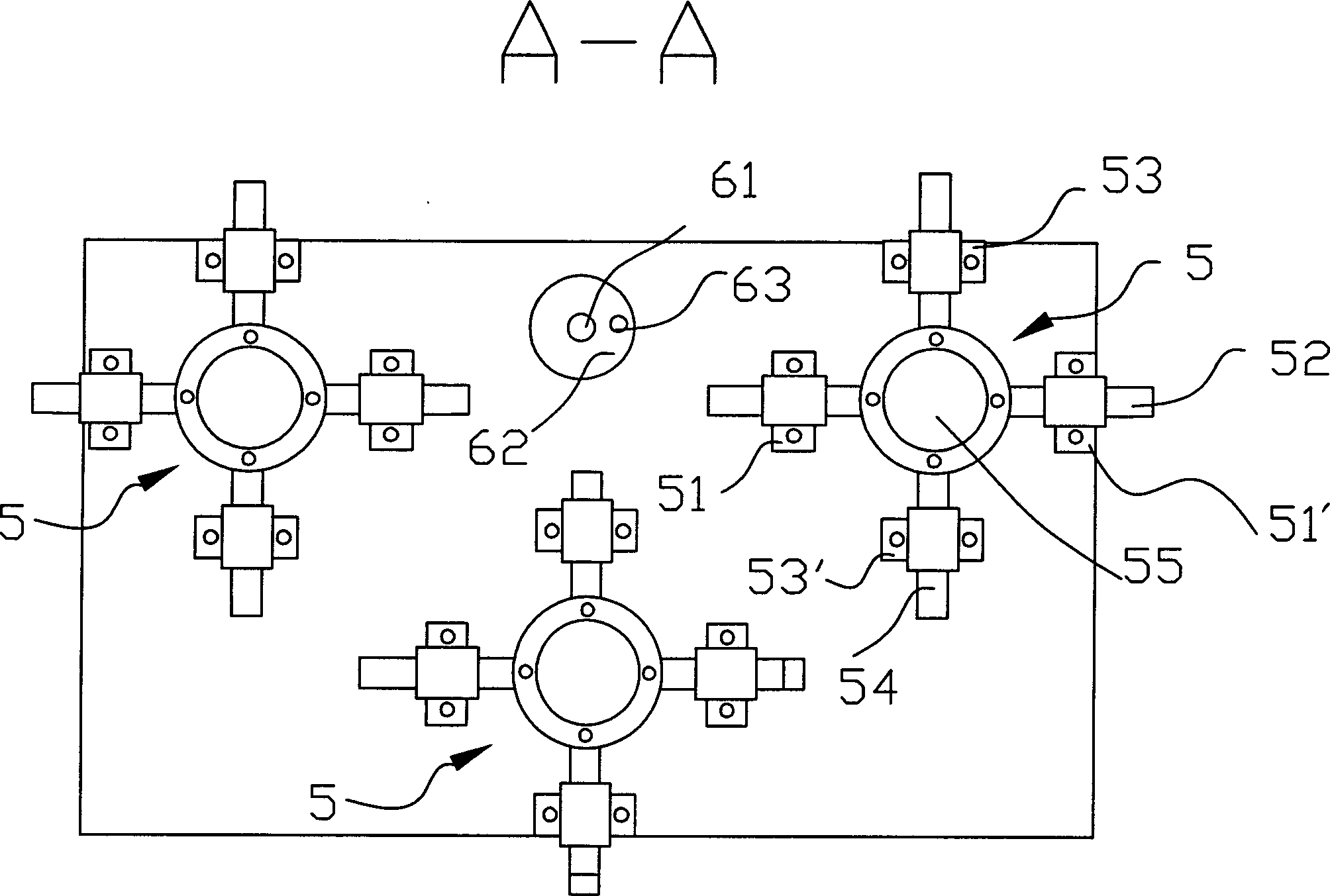

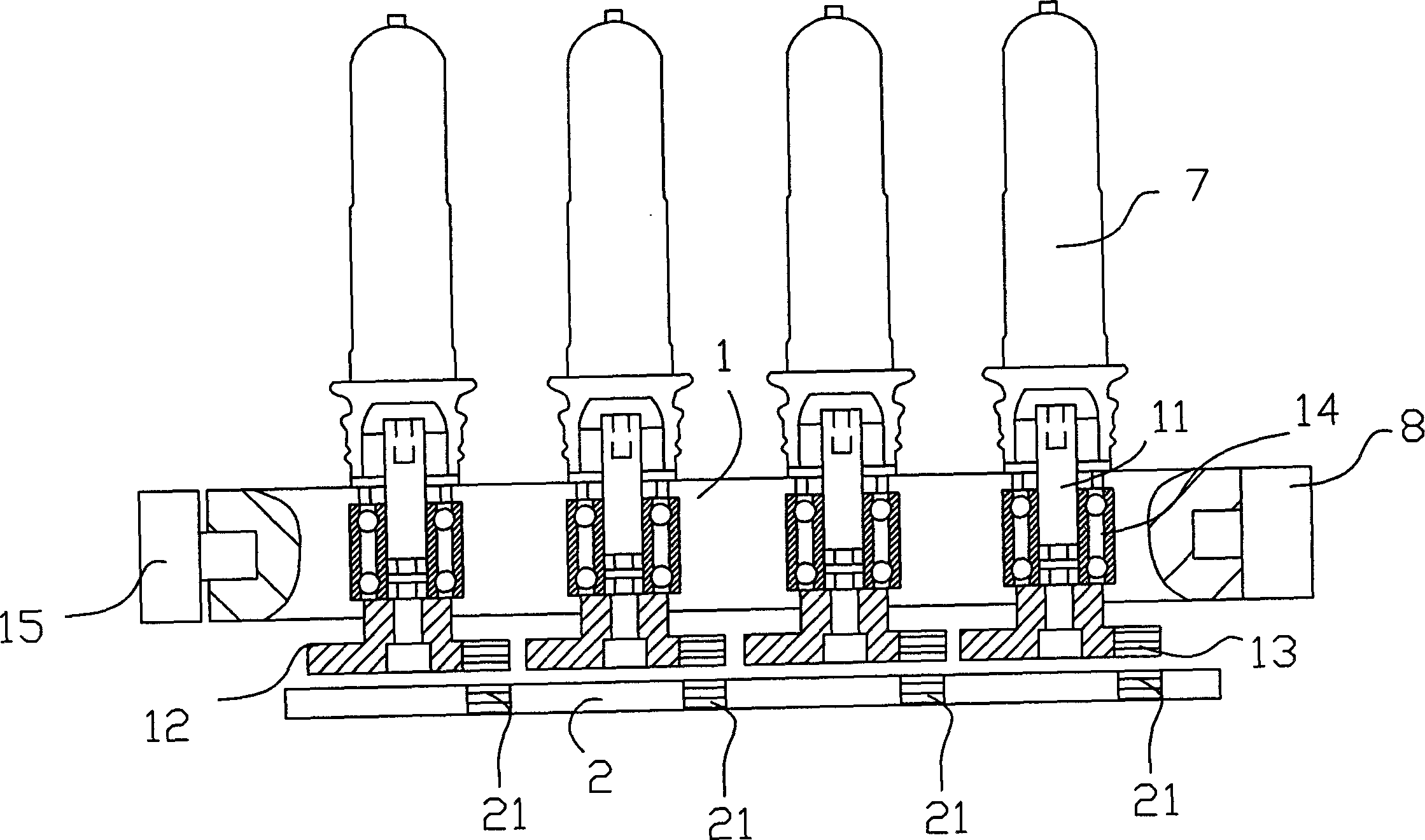

[0015] The structure of an embodiment of the bottle blank rotation device of the blow molding bottle blank heating system of the present invention, as Figure 1-3 shown. The preform rotation device of the blow molding preform heating system is integrally installed on a frame. The frame is located below the preform heating zone. A driving sprocket 4 and a driven sprocket 4' are respectively installed at the two ends of the frame rear side. The driving sprocket 4 is driven by a stepping motor. A conveyor chain 8 is connected between the driving sprocket 4 and the driven sprocket 4'. Each group of outer chain plates of the conveying chain 8 is fixedly connected with the rear end of an aluminum strip flat plate 1 . There is a horizontal guide rail at the upper end of the frame front side, which corresponds to the horizontal section on the conveyor chain 8 and accommodates the guide wheels 15 at the front ends of each bar-shaped flat plate 1 . In this way, the strip-shaped fla...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com