Bottle blowing machine

A bottle blowing machine and frame technology, which is applied to other household appliances, household appliances, applications, etc., can solve the problems of high cost, unfavorable operation, complex structure, etc., and achieve the effects of convenient operation, improved efficiency and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The present invention will be further described below in conjunction with accompanying drawing and embodiment:

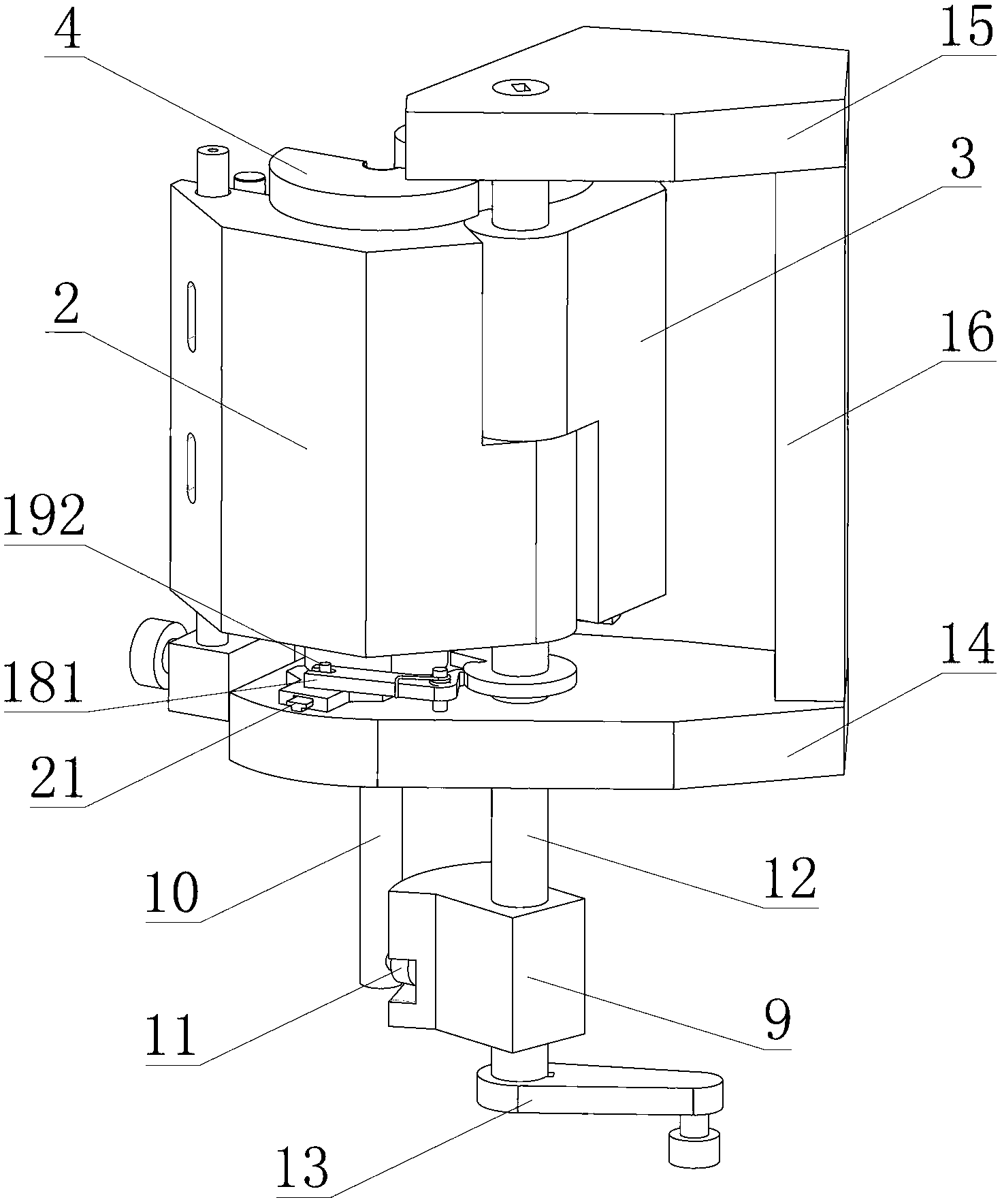

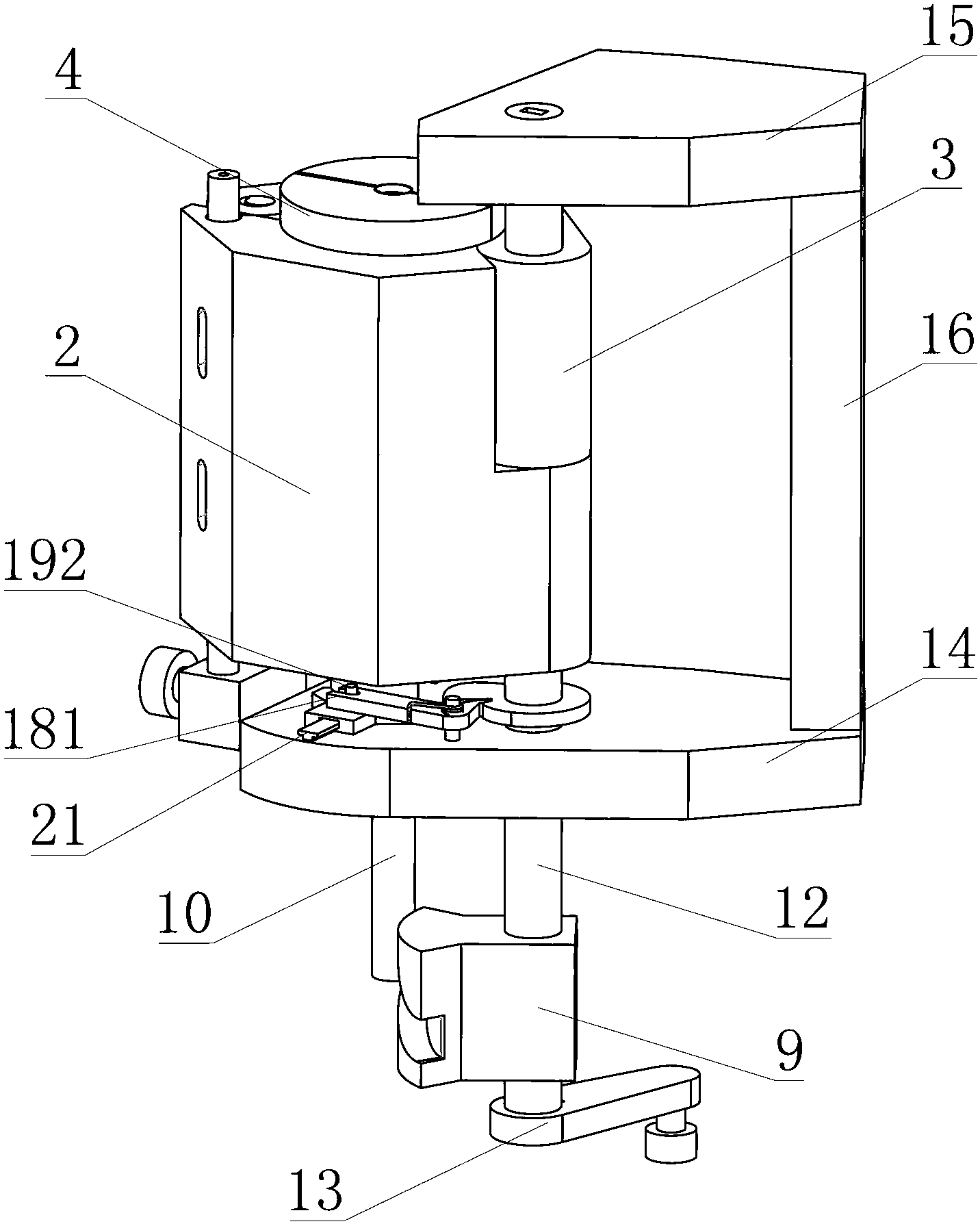

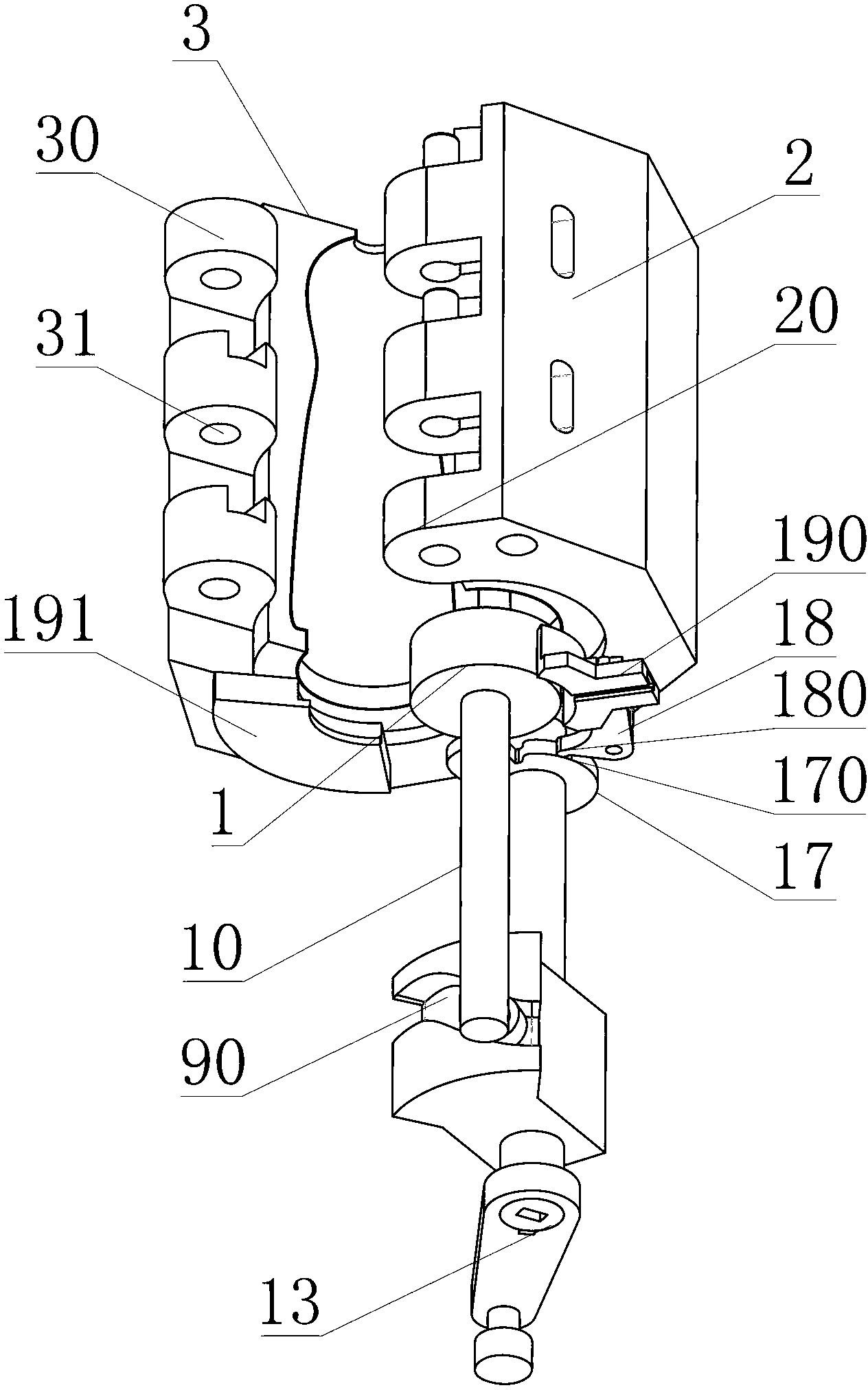

[0028] Such as Figure 1-4 The blow molding machine shown includes a frame, an opening and closing mold assembly arranged on the frame, a lifting assembly, a bottom mold locking assembly and a driving assembly for driving the above-mentioned various assemblies. The following specifically describes each component in detail:

[0029] The frame includes a support 14 , a top frame 15 above the support 14 and a support frame 16 fixedly connected between the support 14 and the top frame 15 .

[0030] The mold opening and closing assembly includes a bottom mold 1, a fixed template 2 arranged on the frame, and a movable template 3 matched with the fixed template 2. The opening and closing mold assembly has a mold opening state and a mold closing state. When it is in the film closing state, the bottom mold 1, the fixed platen 2 and the movable platen 3 enclo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com