Automatic bottle blowing system and method for handle bottle

A handle, automatic technology, applied to other household appliances, household components, household appliances and other directions, can solve the problems of complex front process, low production efficiency, etc., to solve the complex front process, high production efficiency, clamping exchange structure Cleverly designed effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

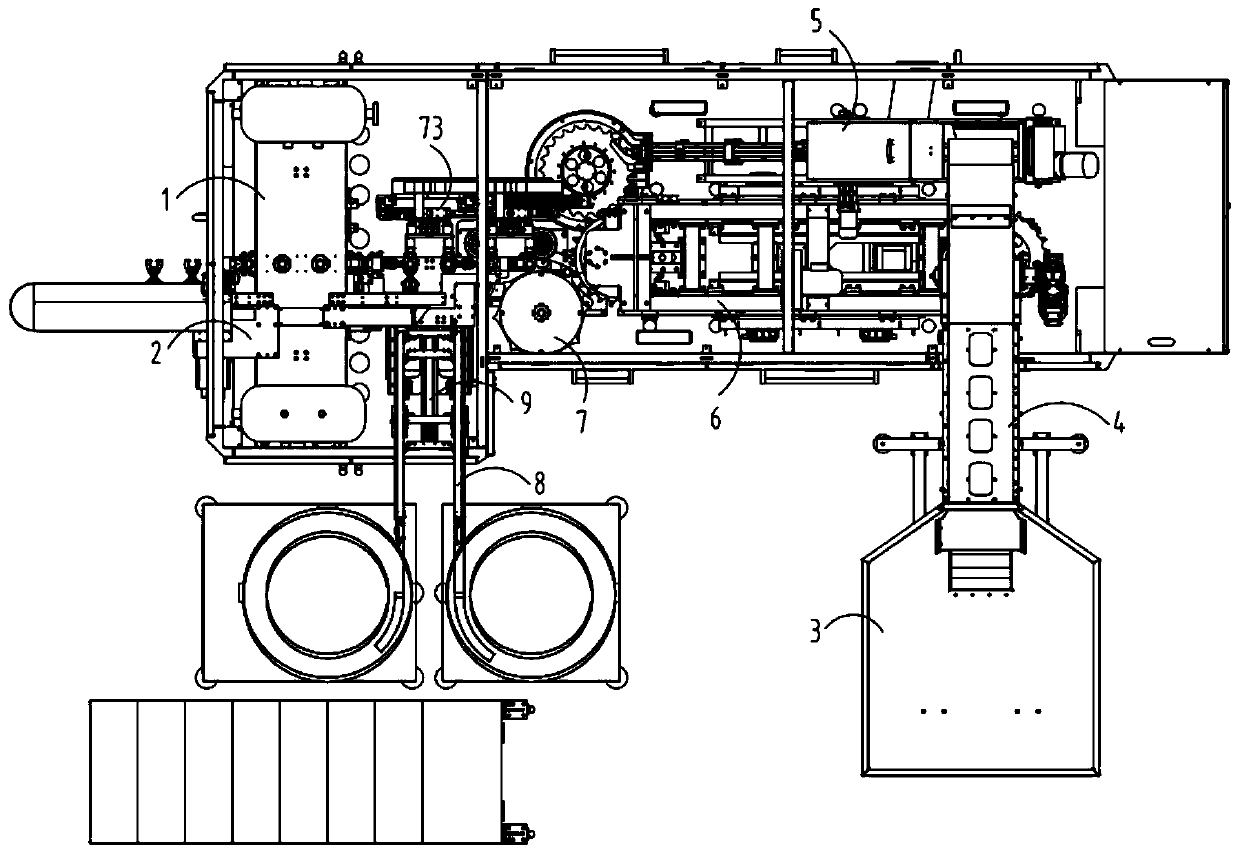

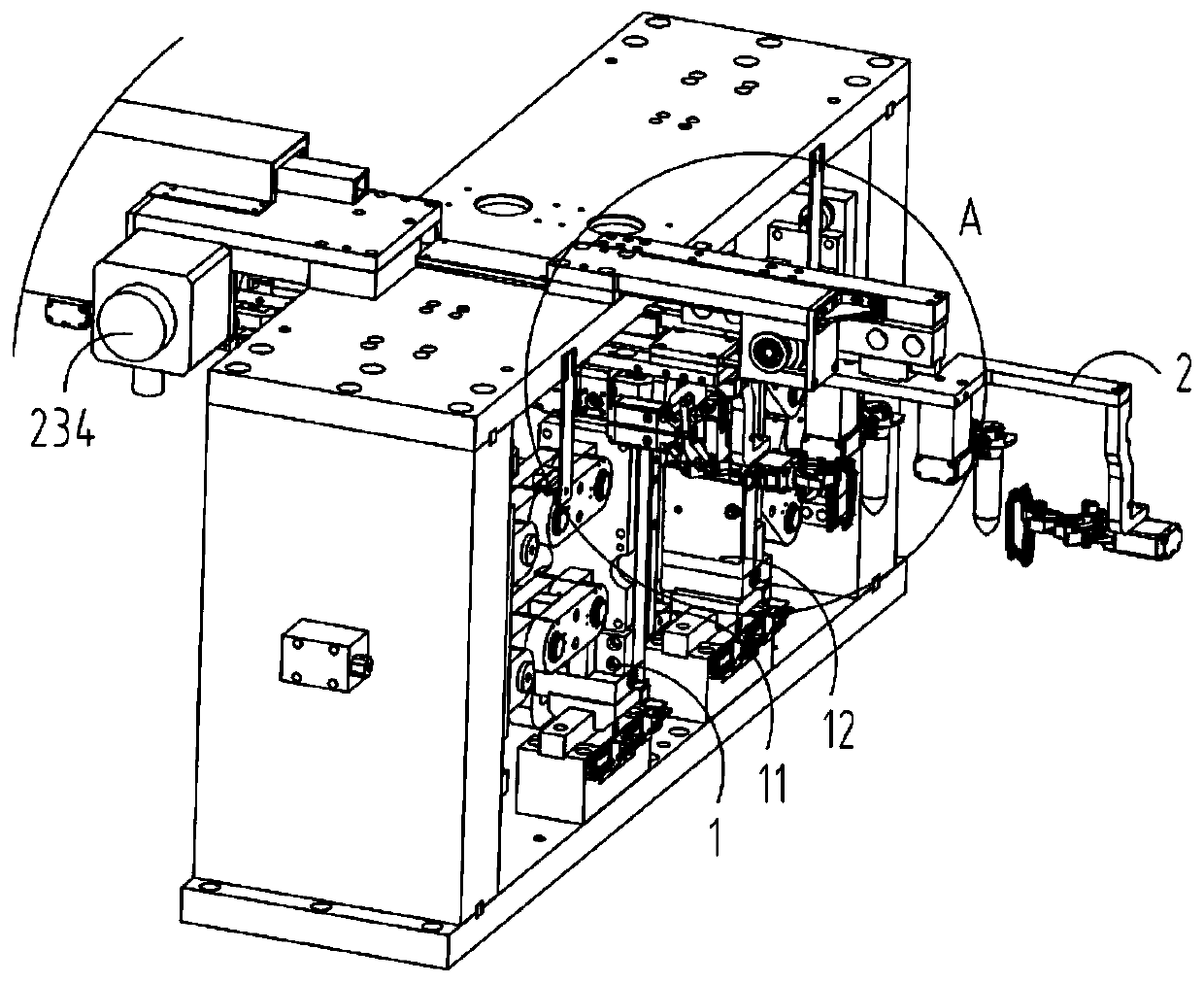

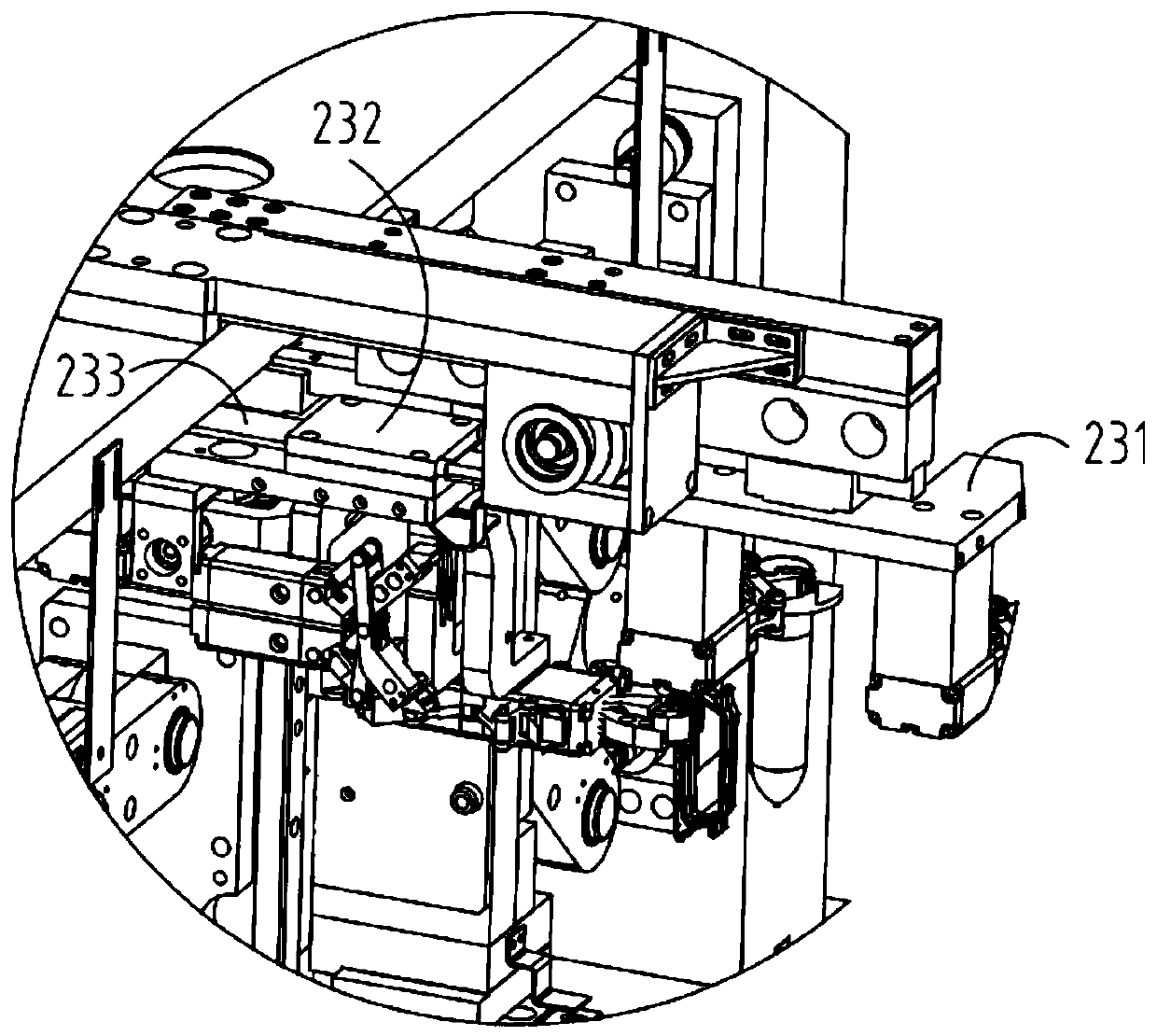

[0043] Such as figure 1 , 2 As shown in 6 and 6, an automatic bottle blowing system for handle bottles includes an automatic bottle blowing module, the automatic bottle blowing module includes a bottle blowing mold 1, and a clamping mechanism 2 is slidably arranged above the bottle blowing mold 1, and the clamping mechanism 2 The holding mechanism 2 includes a translation assembly 23 and a preform clamping assembly 21 and a handle clamping assembly 22 arranged on the translation assembly 23, and the translation assembly 23 drives the preform clamping assembly 21 and the handle clamping assembly 22 Together with a group of clamped preforms 10 and a group of handles 20 corresponding to the group of preforms 10, they are translated into the bottle blowing mold 1 at the same time.

[0044] In the present invention, by setting an integrated clamping mechanism 2 including a preform clamping component 21 and a handle clamping component 22, the preform clamping component 21 clamps th...

Embodiment 2

[0067] According to the manual attached Figure 11 Describe a kind of handle bottle automatic bottle blowing method in this embodiment.

[0068] A method for automatic bottle blowing of handle bottles, comprising the following steps:

[0069] (a) The handles are automatically sorted, and the handles 20 are manually poured into the handle vibration sorting mechanism in batches for vibration sorting, and the handles 20 that have completed the vibration sorting are arranged in sequence and are transported to the bottom by the handle conveying track 8;

[0070] (b) Handle clamping transfer, the handle sliding clamping mechanism 9 clamps the handle 20 at the bottom of the handle conveying track 8 and translates to directly below the handle clamping assembly 22, and the handle 20 is clamped and exchanged by the handle clamping assembly 22 telescopically ;

[0071] (c) Automatic arrangement of preforms, which is carried out simultaneously with the above step (a) and step (b). After...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com