Patents

Literature

824results about How to "Uniform tension" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

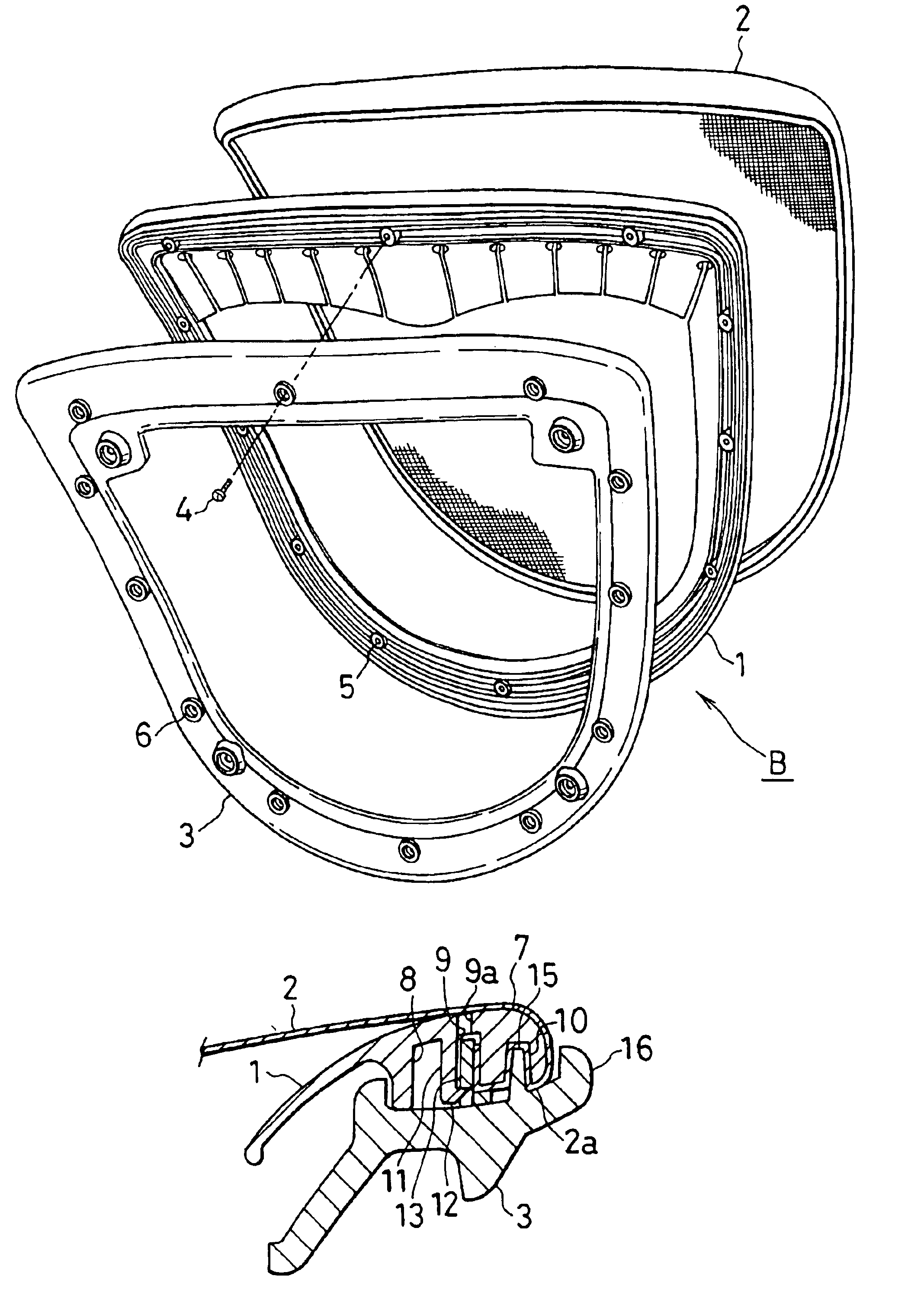

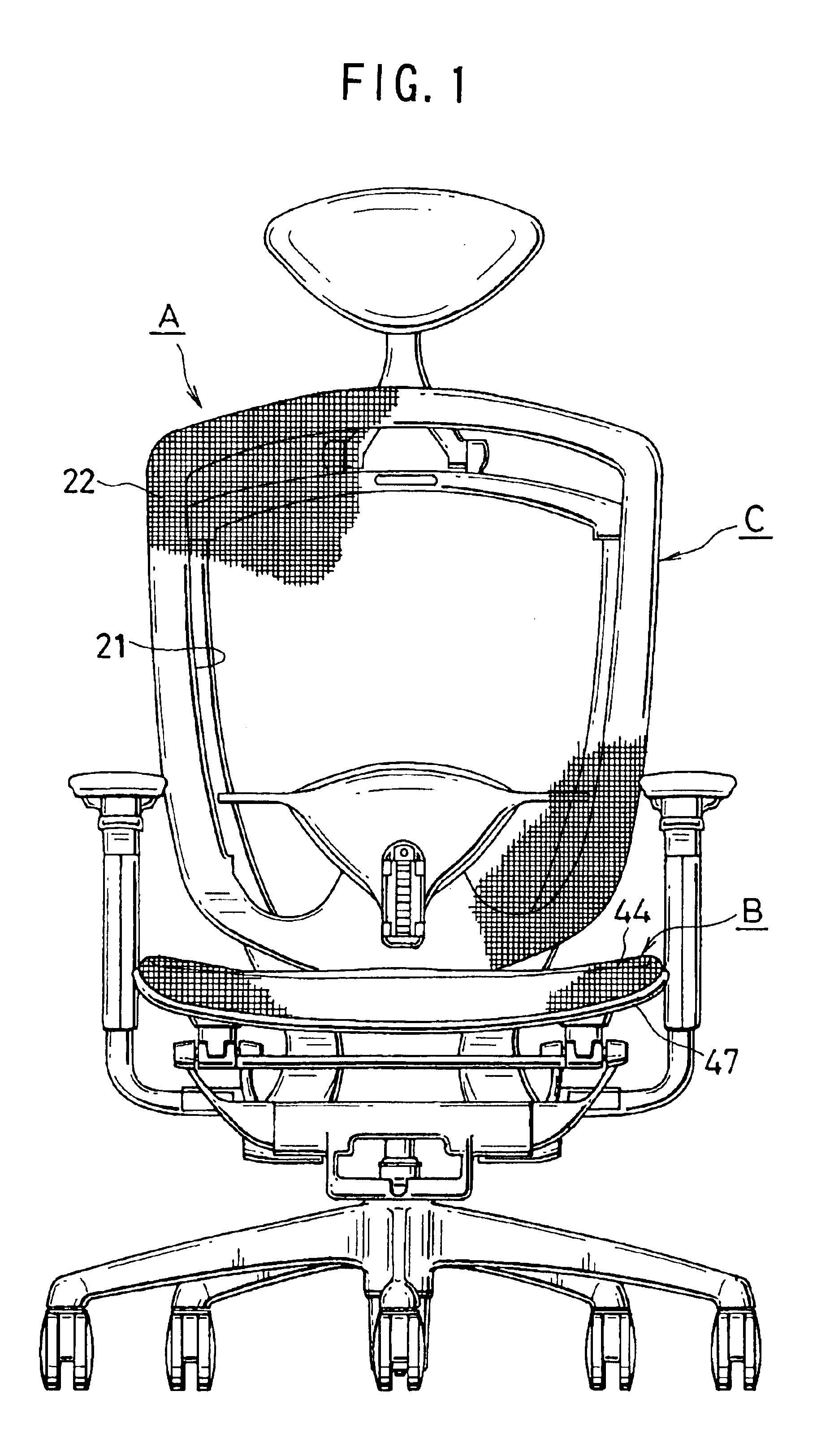

Structure for mounting a net member to a frame for a seat or backrest of a chair

InactiveUS6942300B2Simple low uniform tensile forceSuitable comfortStuffed mattressesSpring mattressesYarnEngineering

Owner:OKAMURA CORP

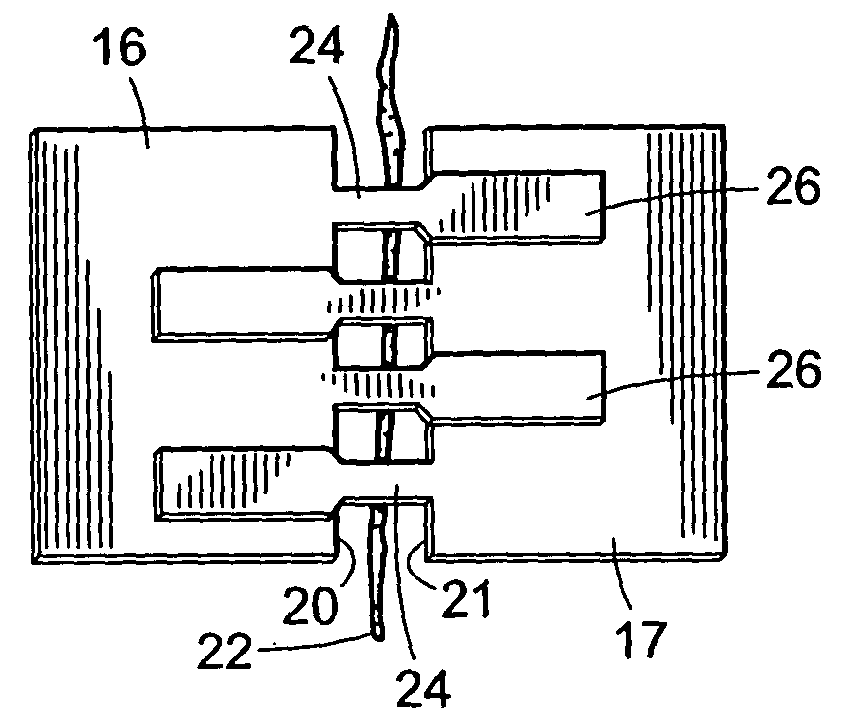

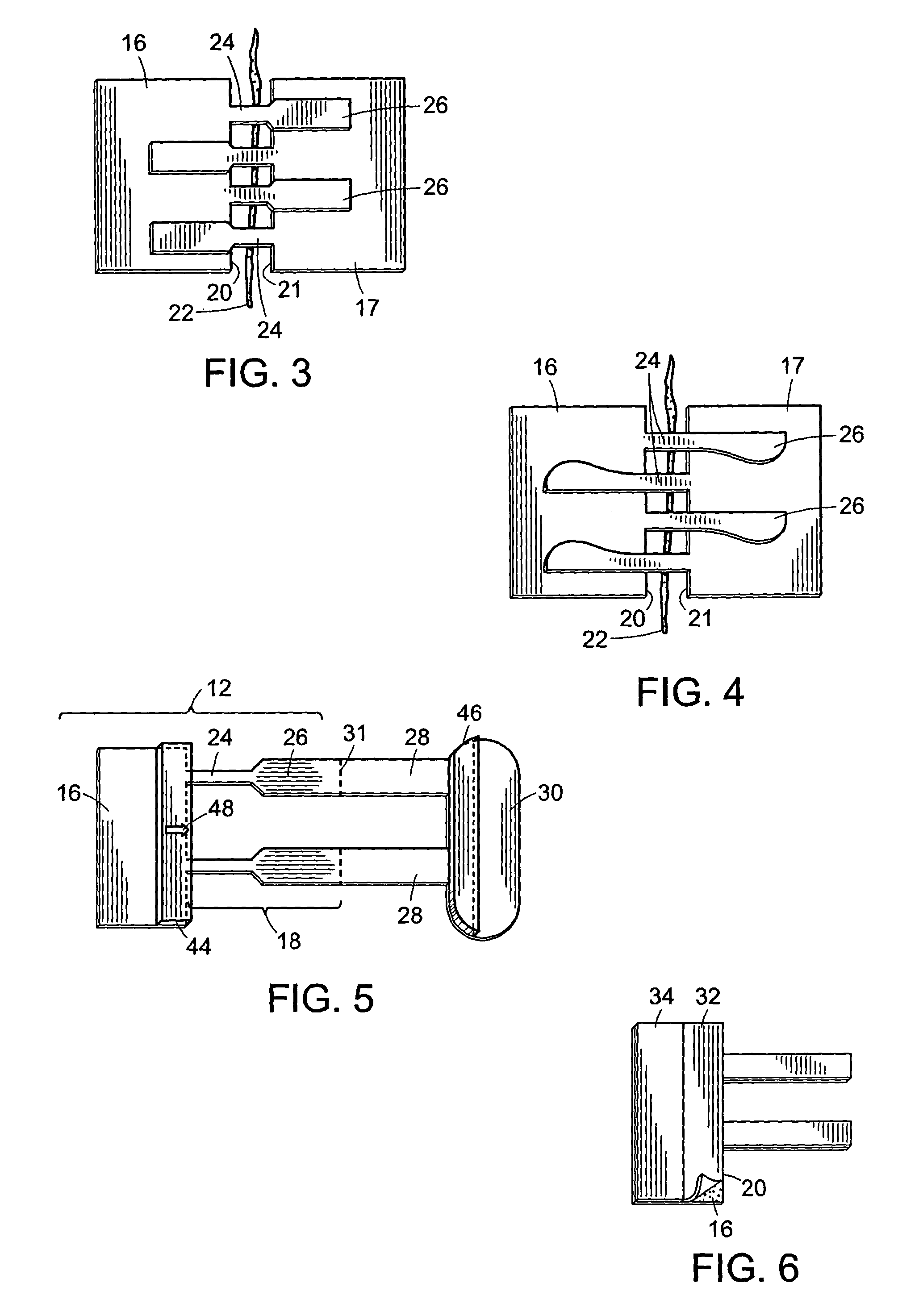

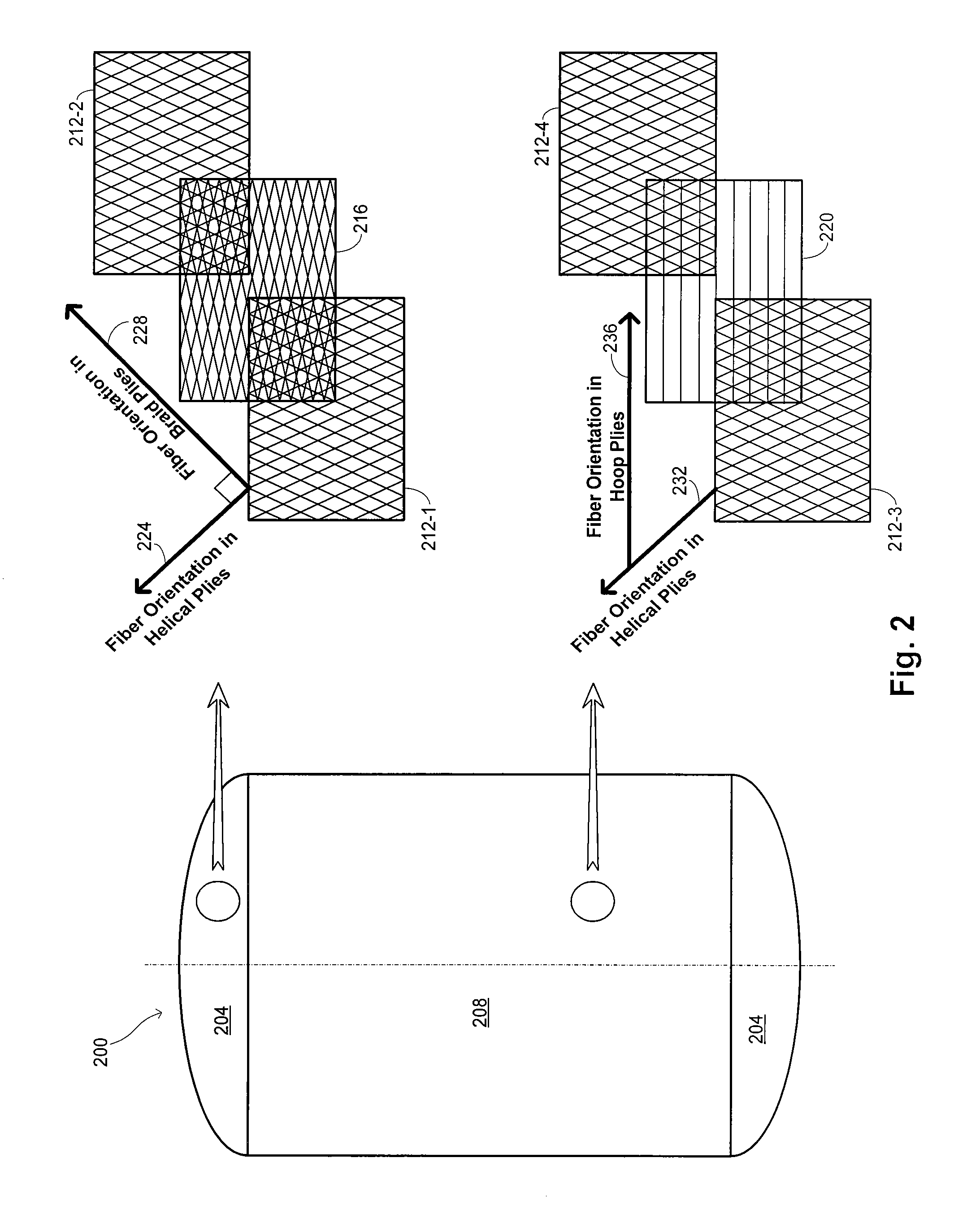

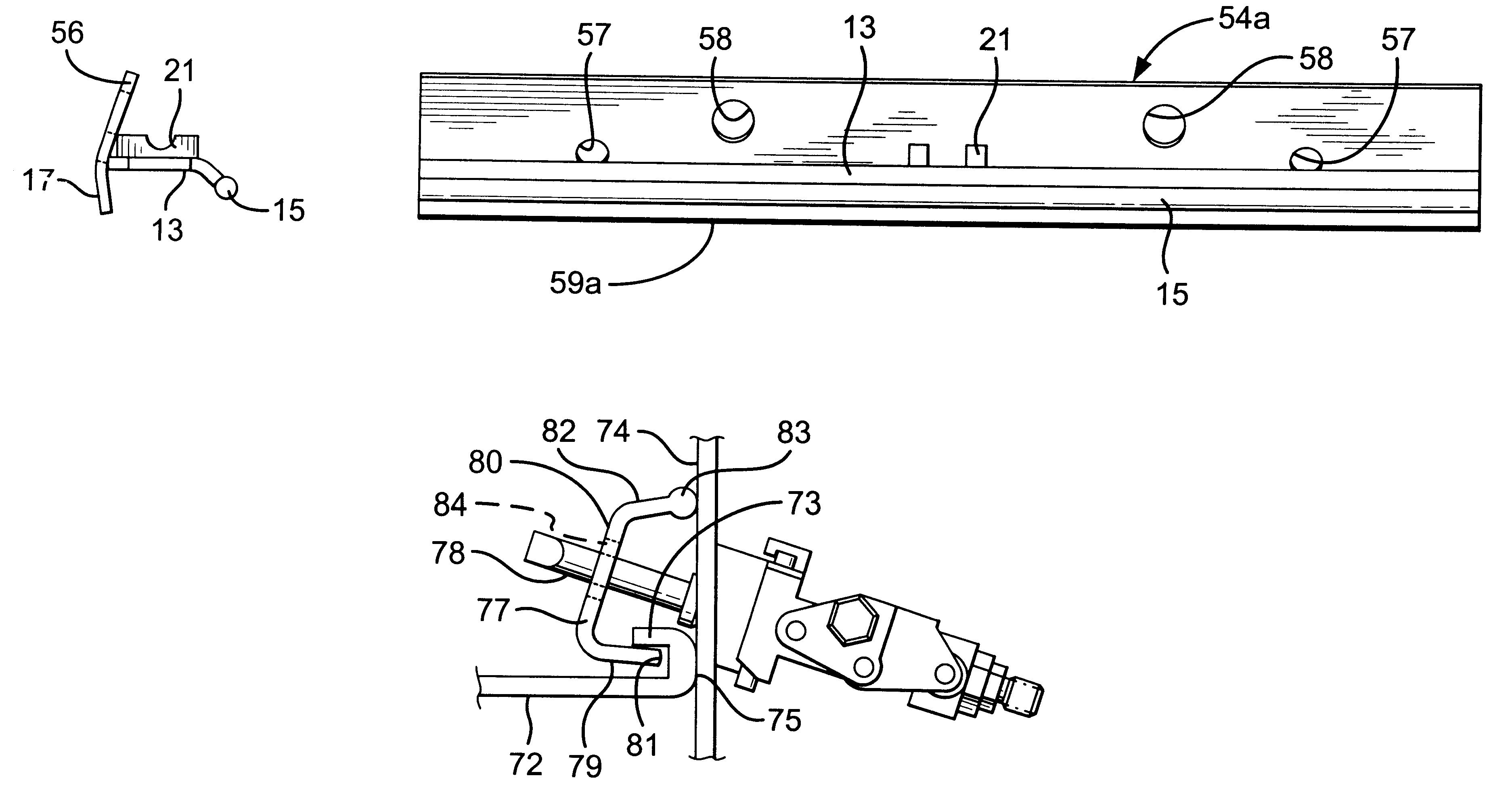

Ribbon feeder and printer

InactiveCN1914045AEliminate wrinklesUniform tensionPrinting mechanismsInking apparatusConductor CoilMechanical engineering

The invention relates to a ribbon feeder of printer. Ribbon tension detecting means (20, 21) each consisting of a plate-like lever body (35) are disposed upstream and downstream, respectively, of a ribbon path from a platen (7). The plate-like lever body (35) has first and second rollers (47, 48) disposed upstream and downstream of the ribbon path and swings around the axis of the rotary shaft of the second roller (48) according to the tension on the ribbon traveling as guided by these rollers (47, 48). When the amount of swing is above or below a fixed vale, a ribbon feed motor (18) or a ribbon winding motor (19) is driven. Further, the ribbon tension detecting means (20, 21) are each provided with a wrinkle eliminating member adapted to contact an ink ribbon (13) so as to eliminate wrinkles formed in the ink ribbon (13).

Owner:CITIZEN WATCH CO LTD

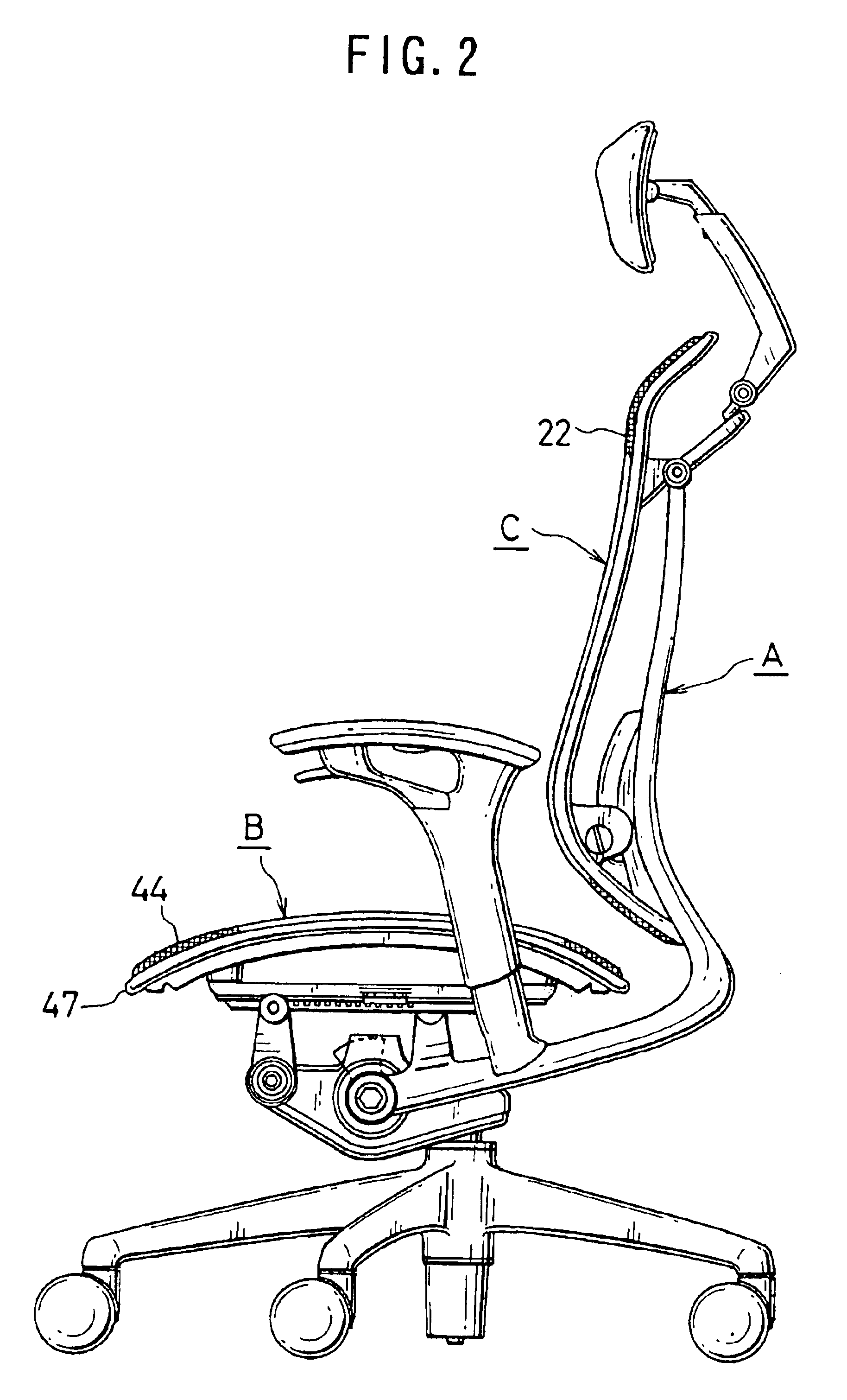

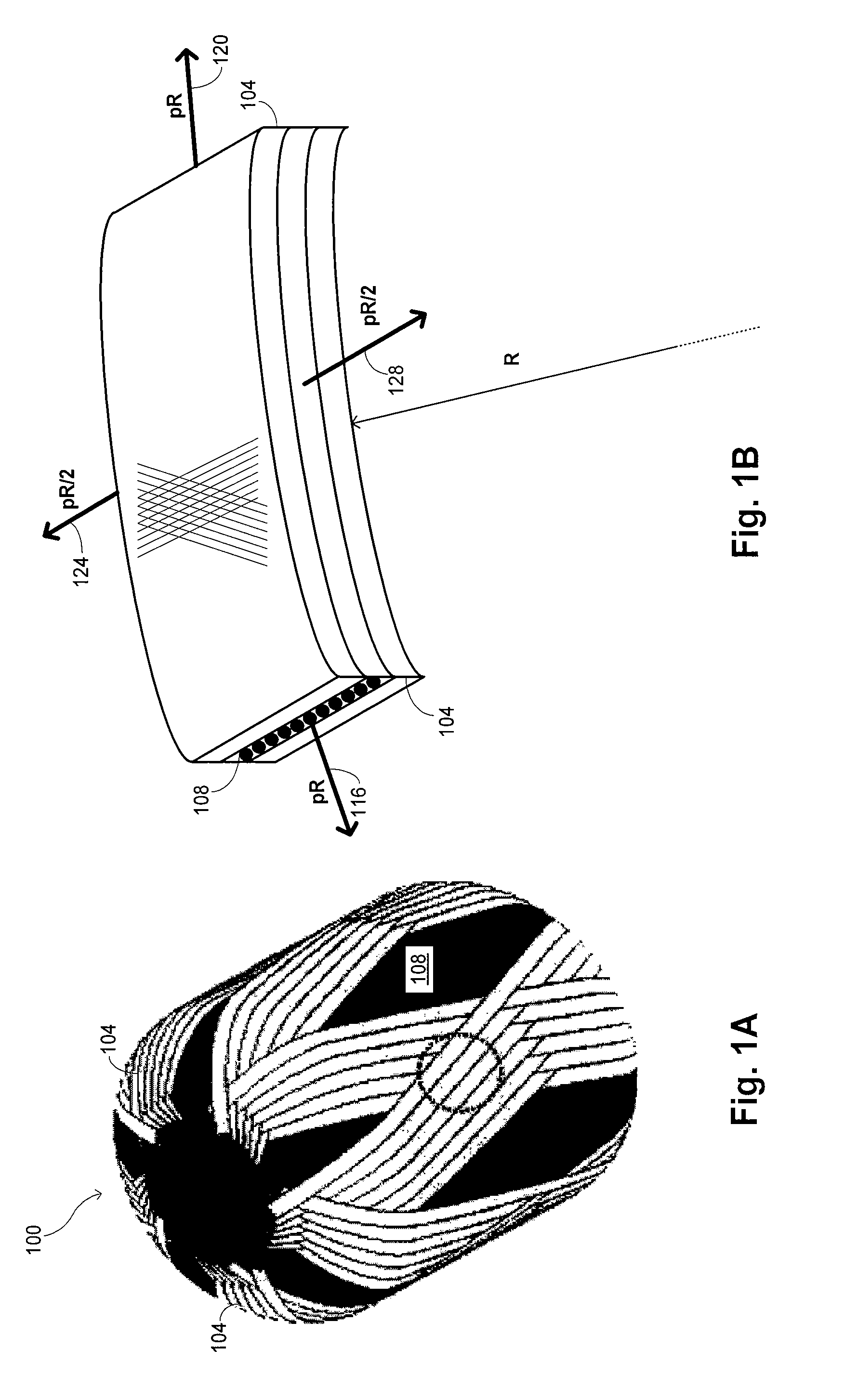

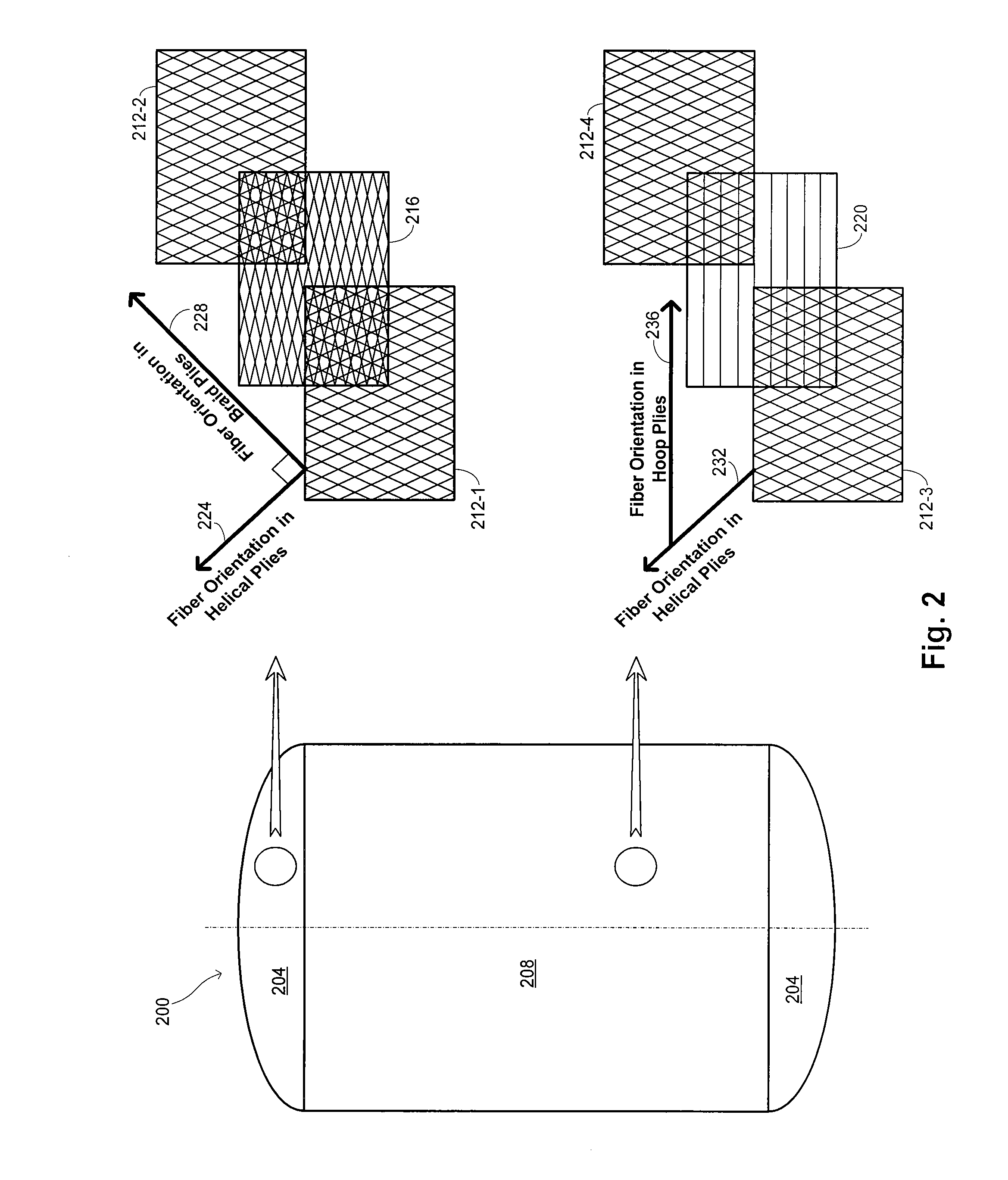

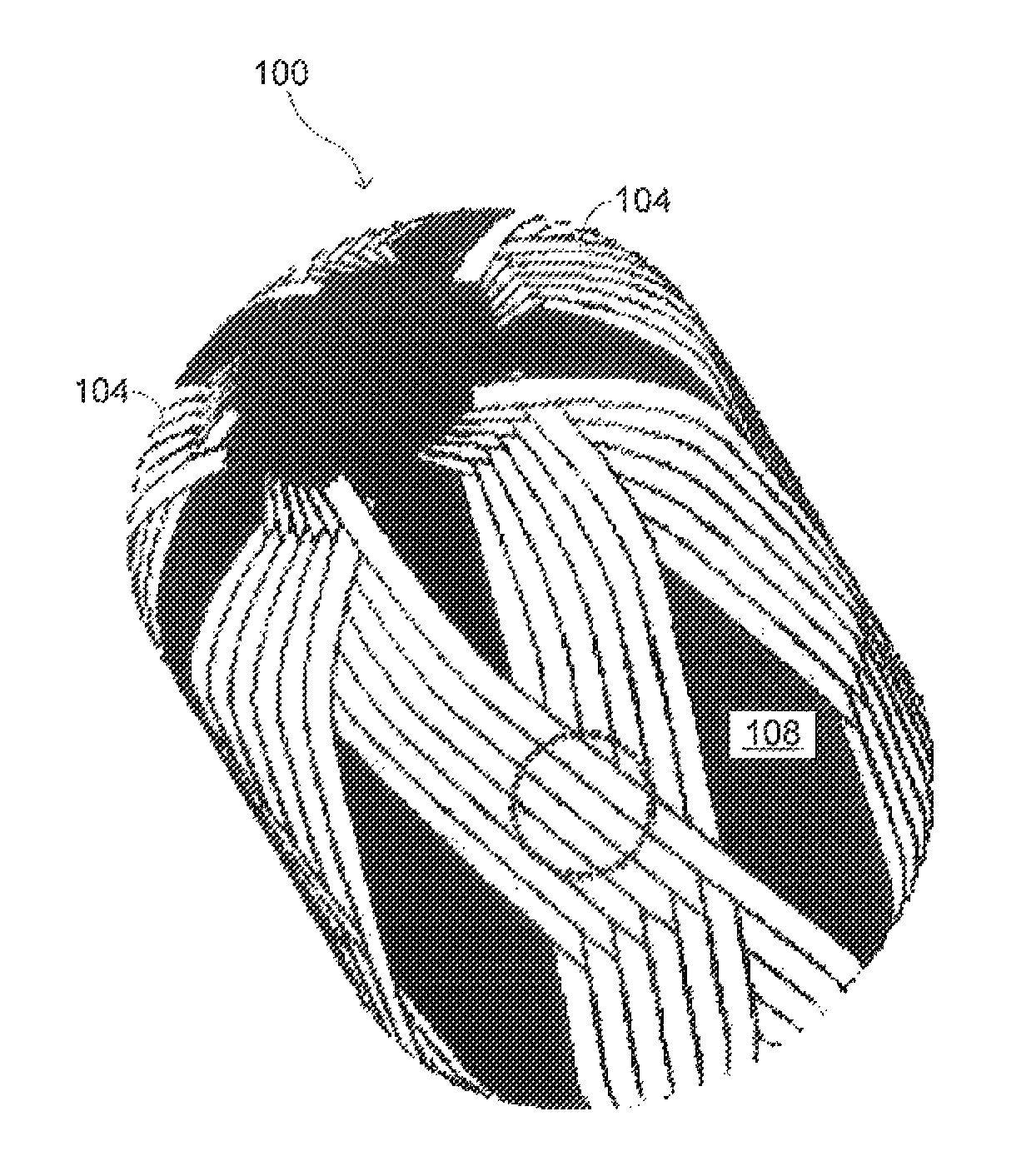

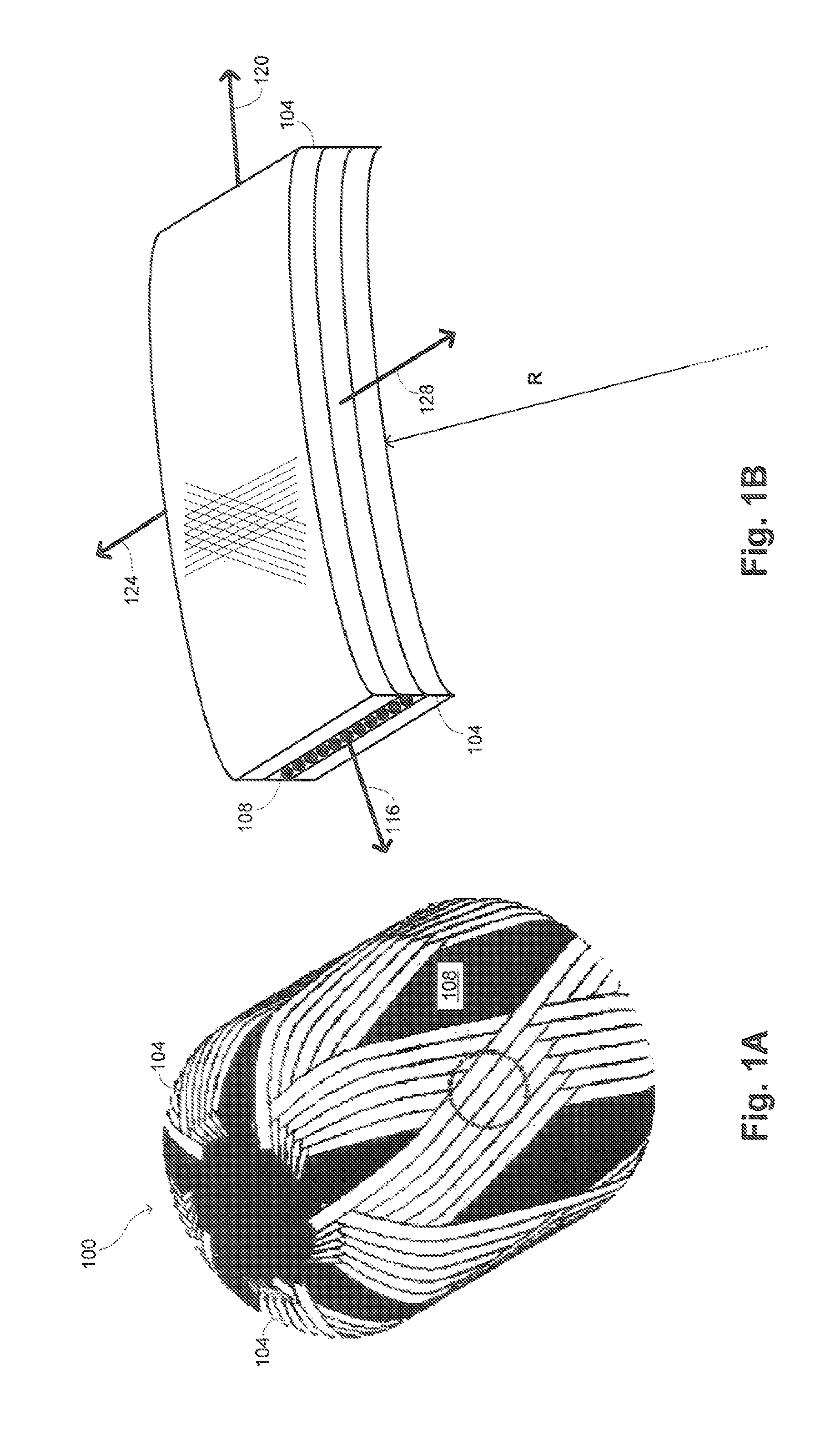

Damage and leakage barrier in all-composite pressure vessels and storage tanks

ActiveUS20090314785A1Superior barrier against leakageStrengthAdhesive processesGas handling applicationsFiberAxis of symmetry

A linerless tank structure has a body that defines an enclosed interior volume. The body has a cylindrical section having an axis of symmetry and a dome section coupled with the cylindrical section. The construction of the pressure vessel includes multiple fiber plies. At least one of the fiber plies is a helical ply having fibers traversing the dome helically about the axis of symmetry. At least a second of the fiber plies is a braided or woven ply.

Owner:COMPOSITE TECH DEV

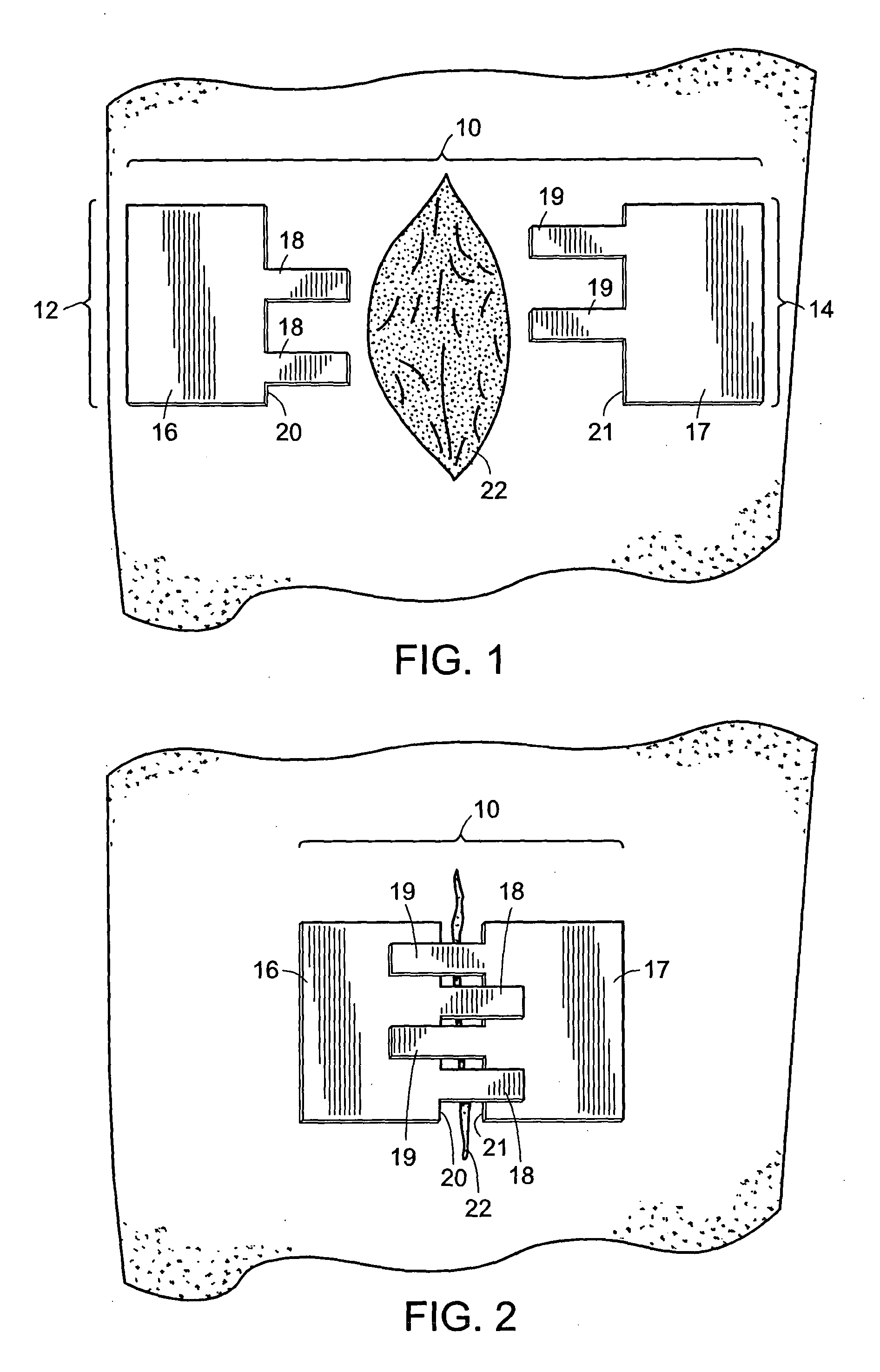

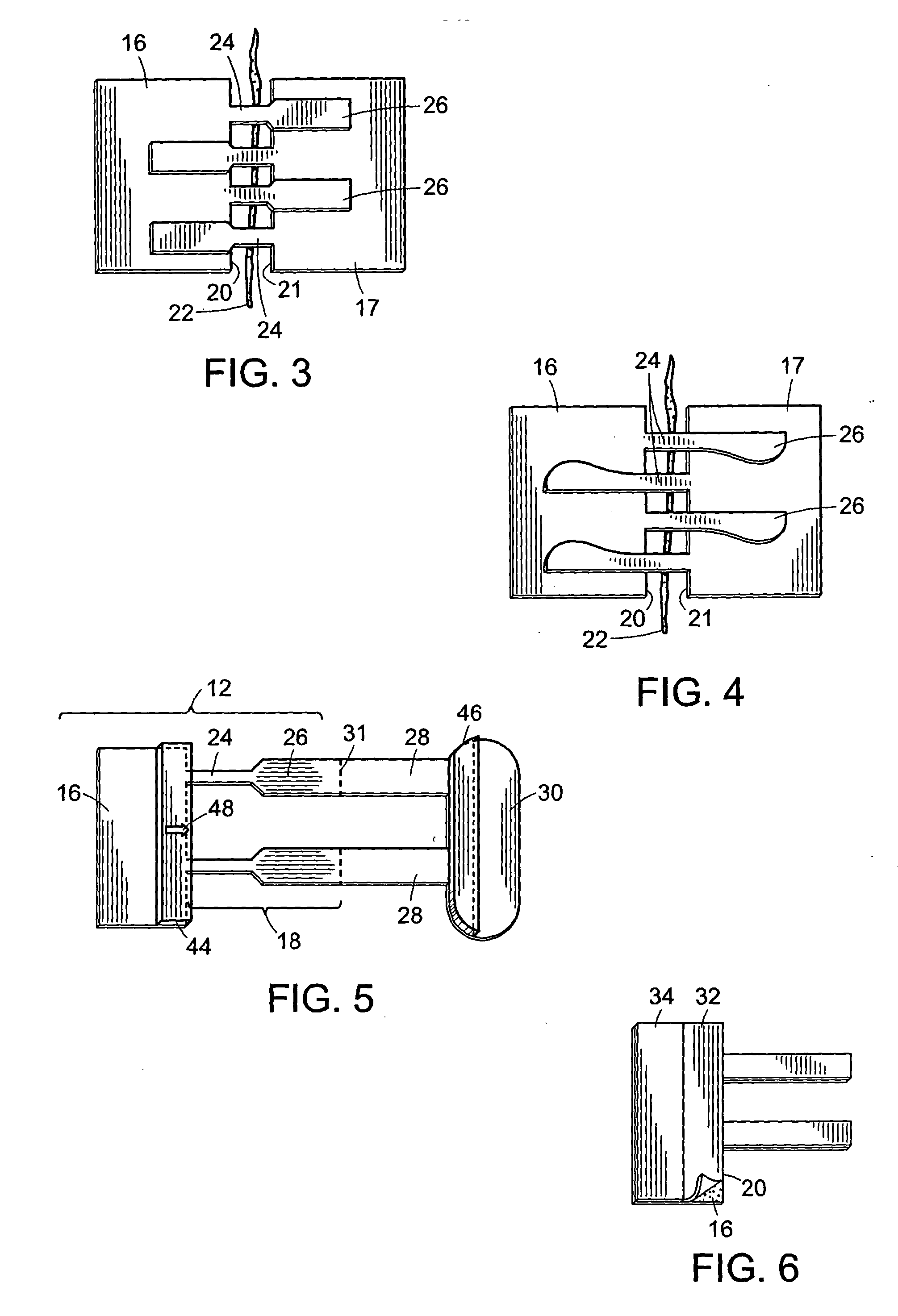

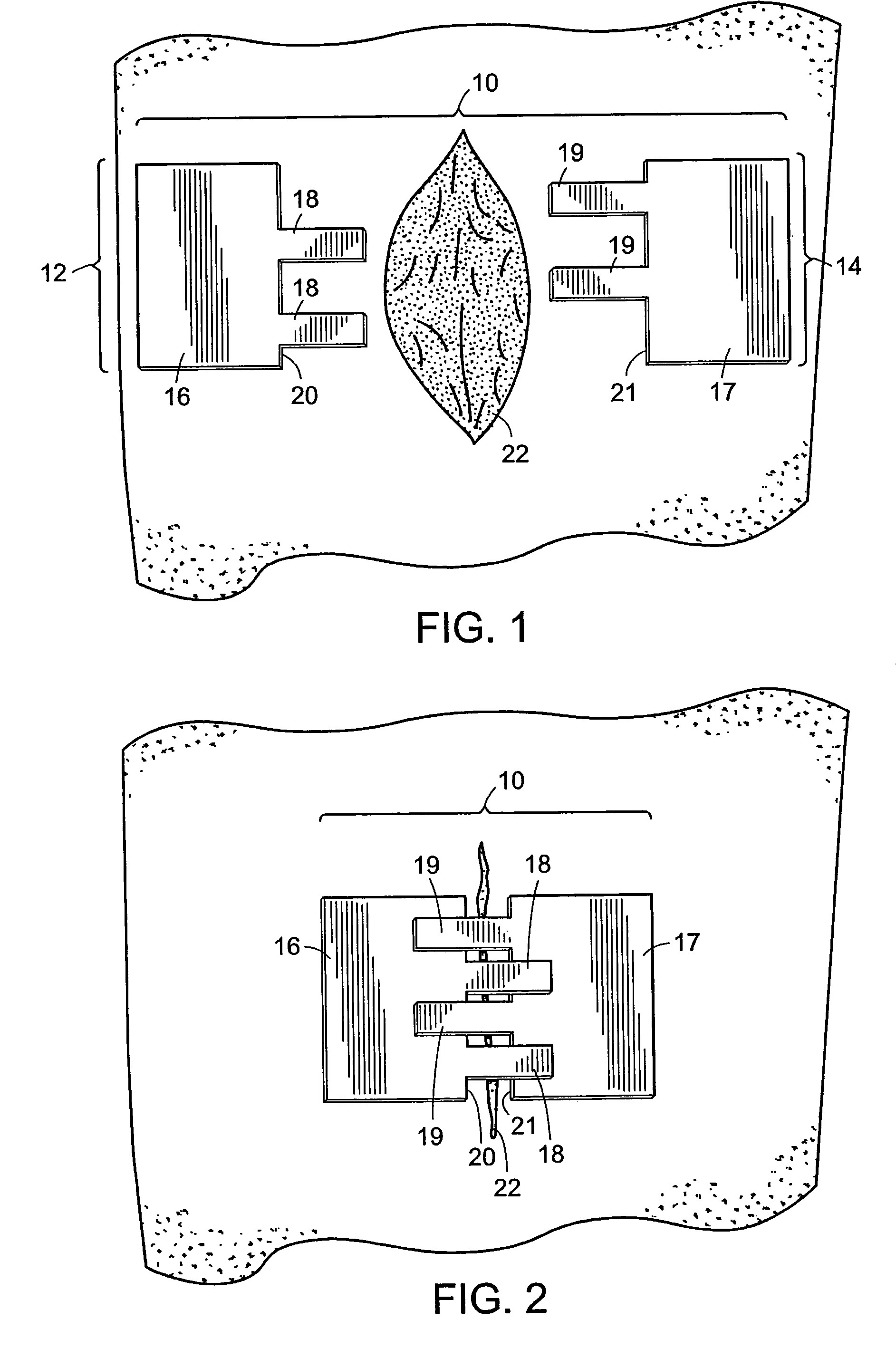

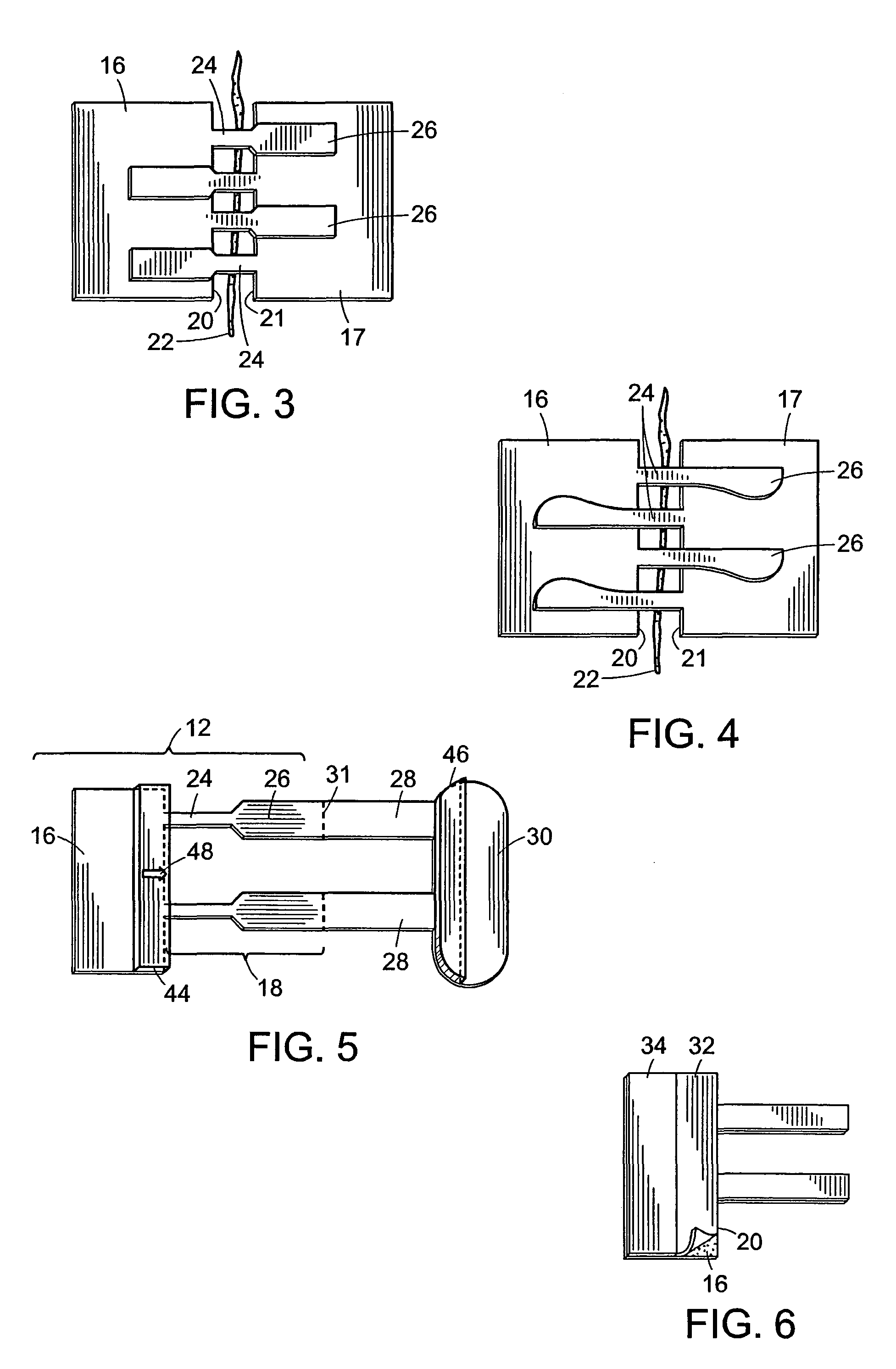

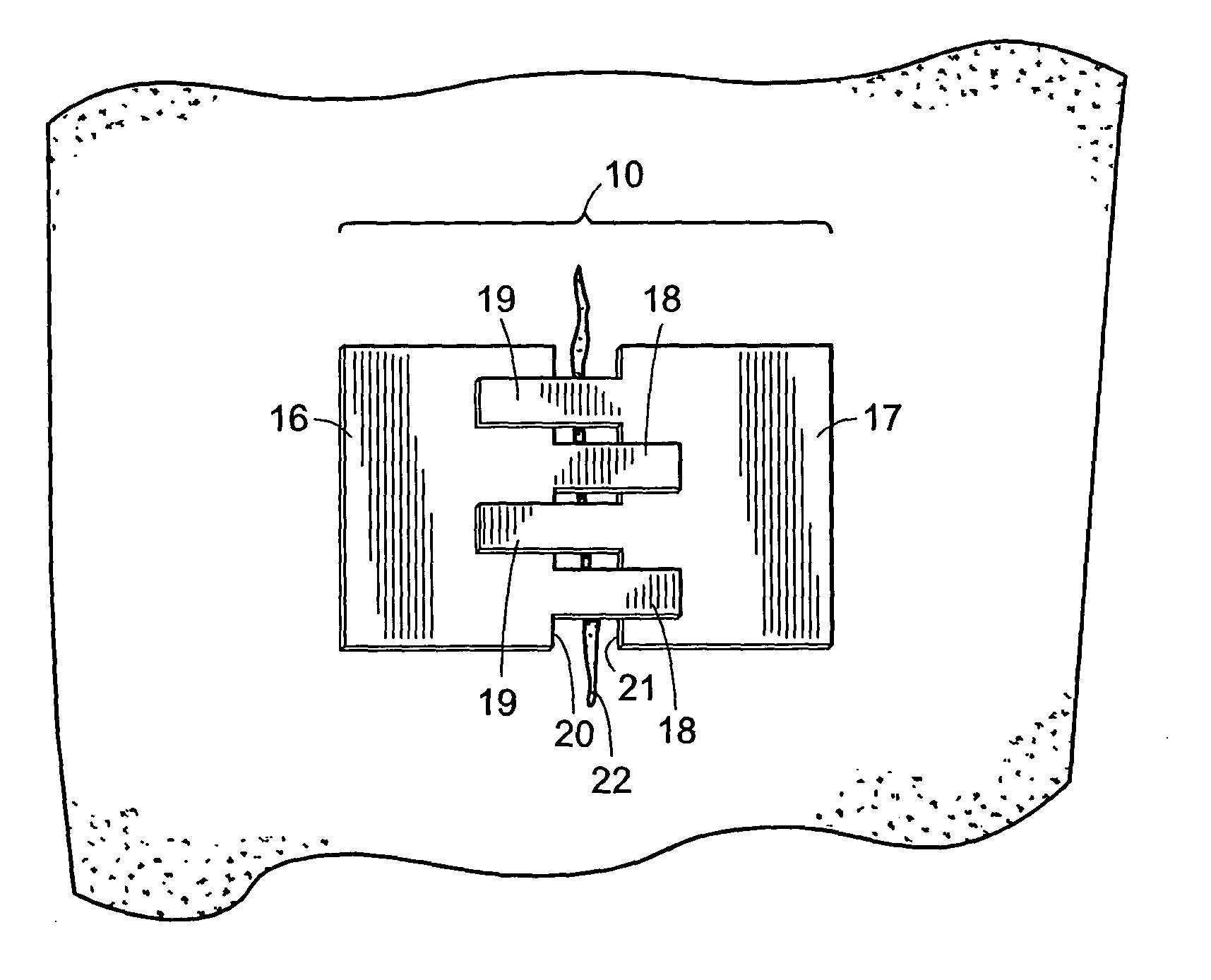

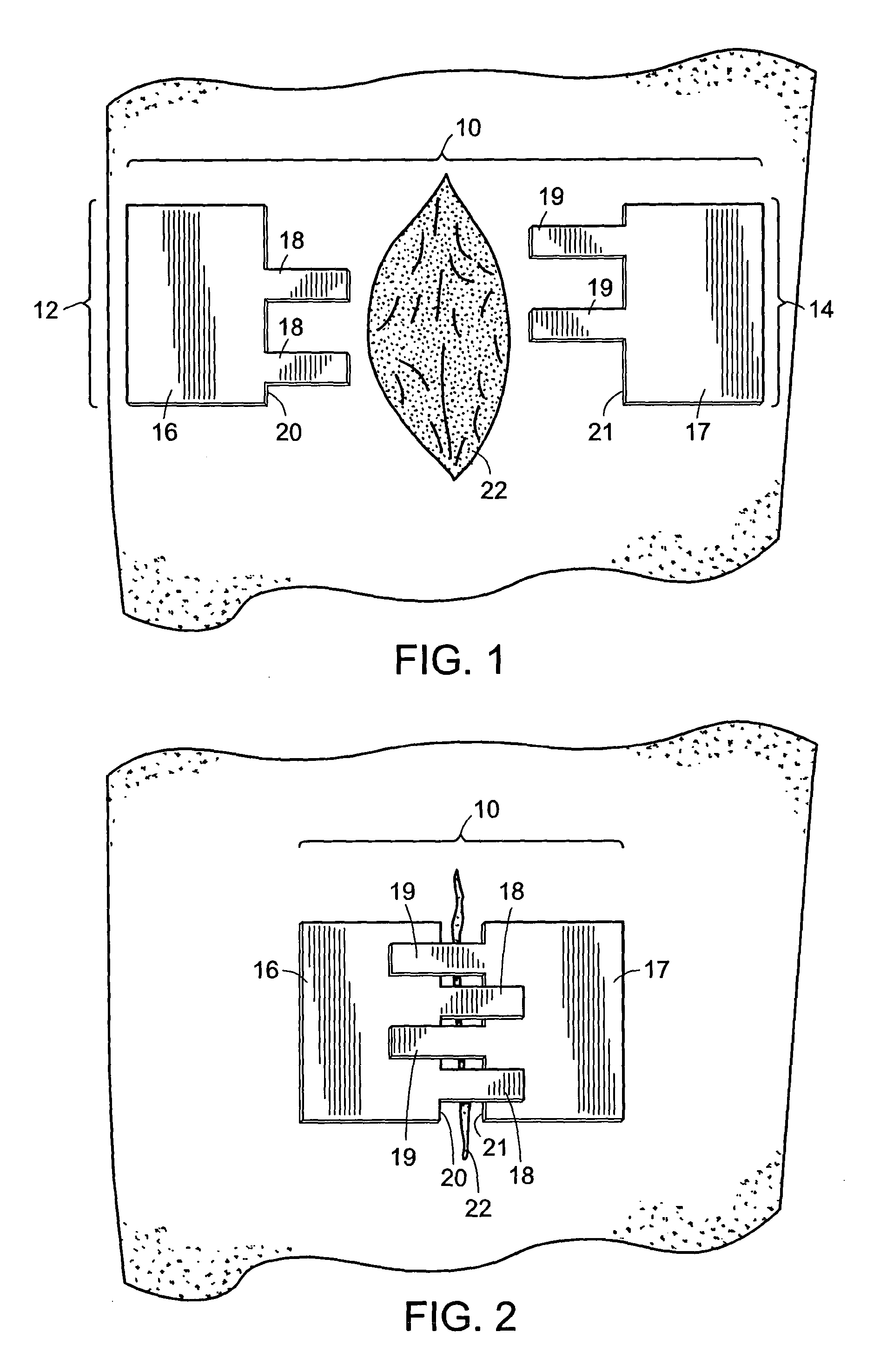

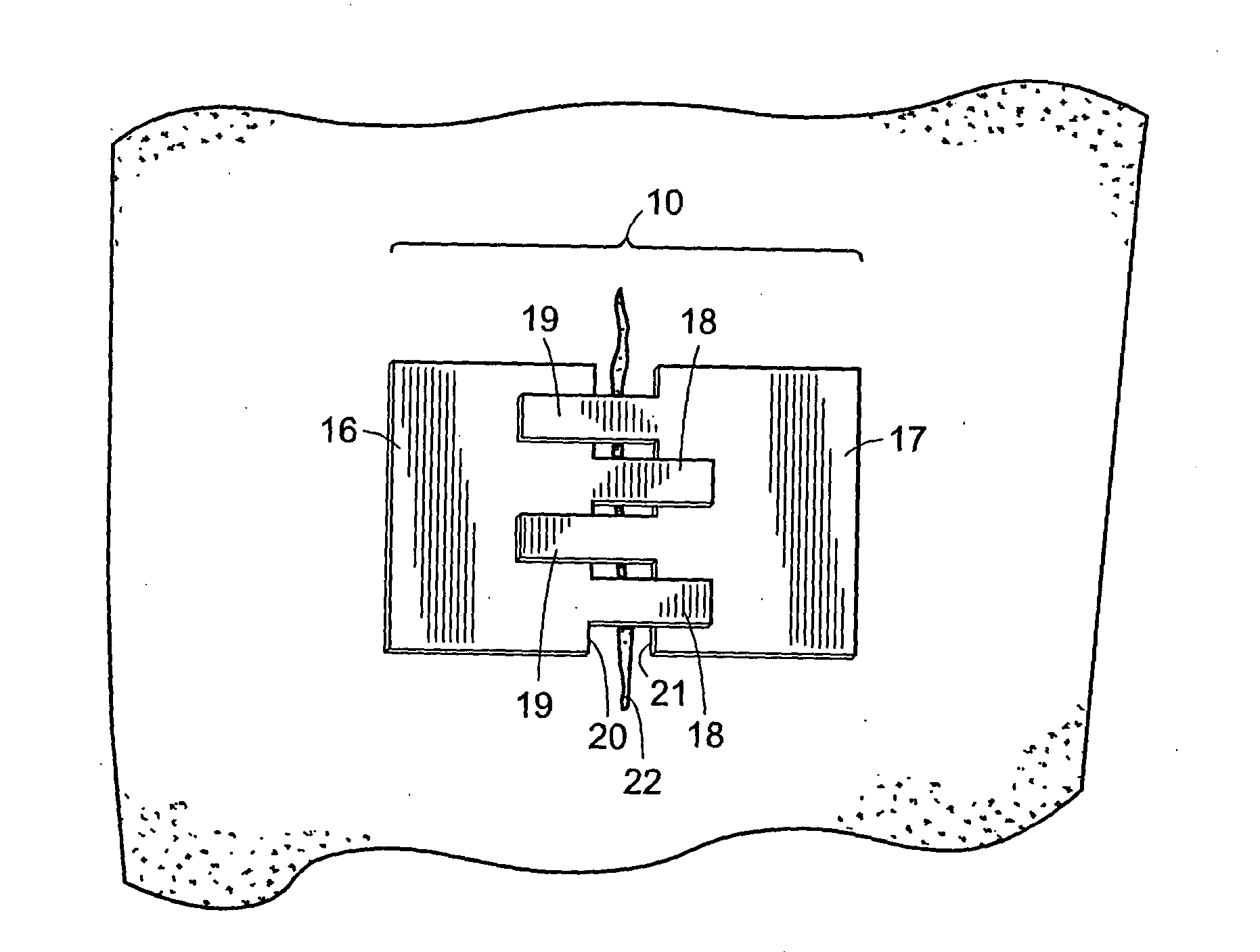

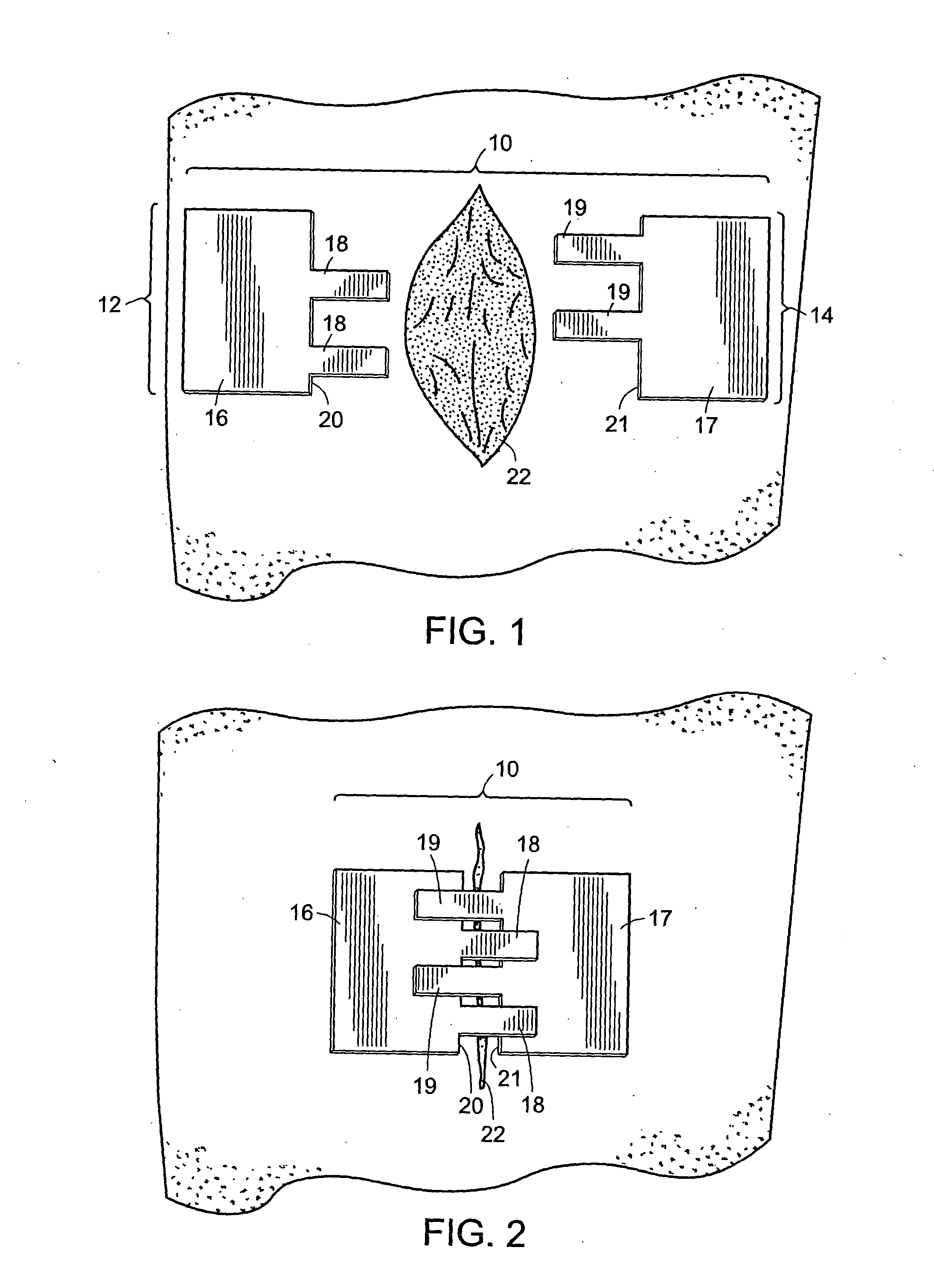

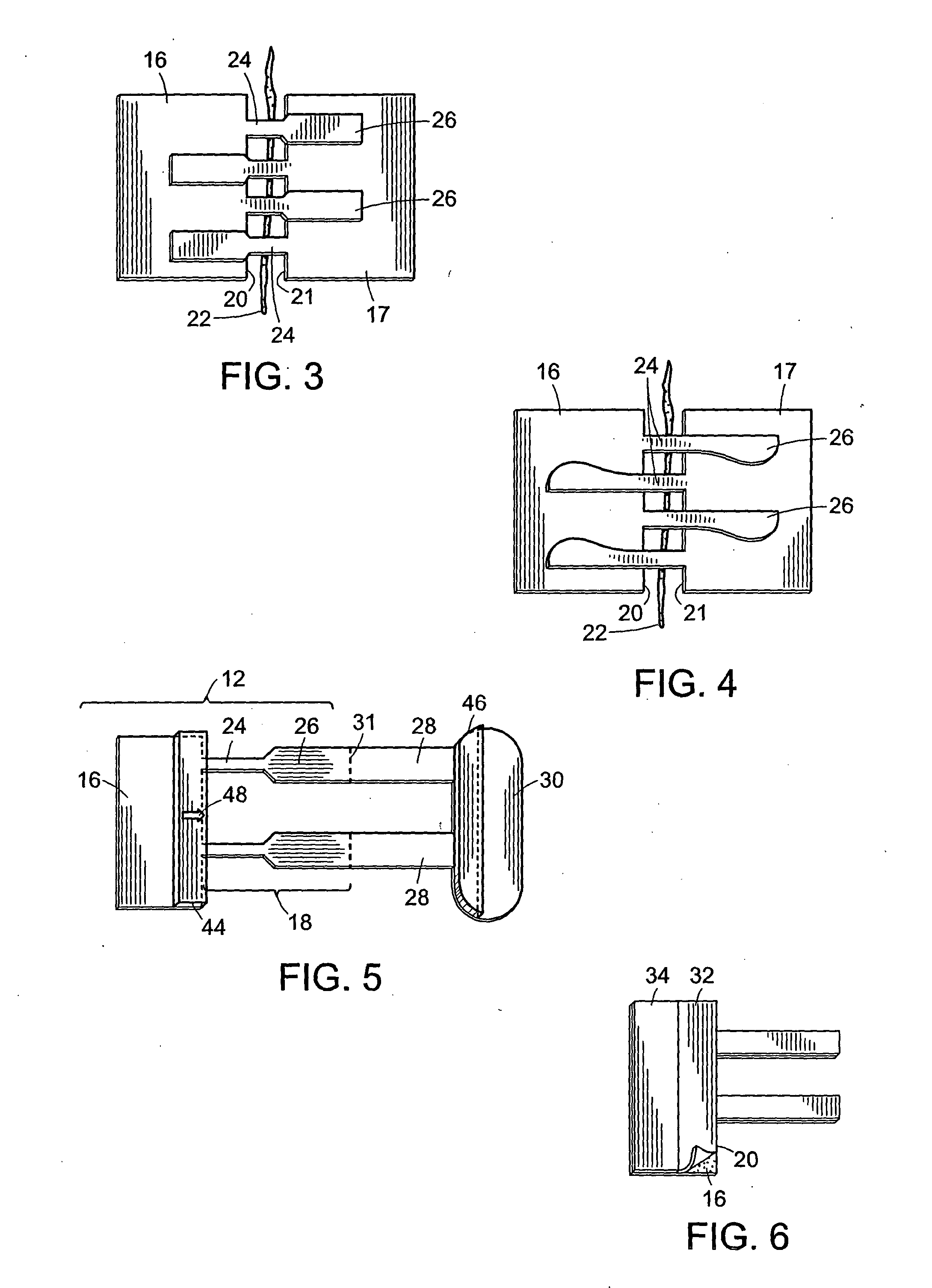

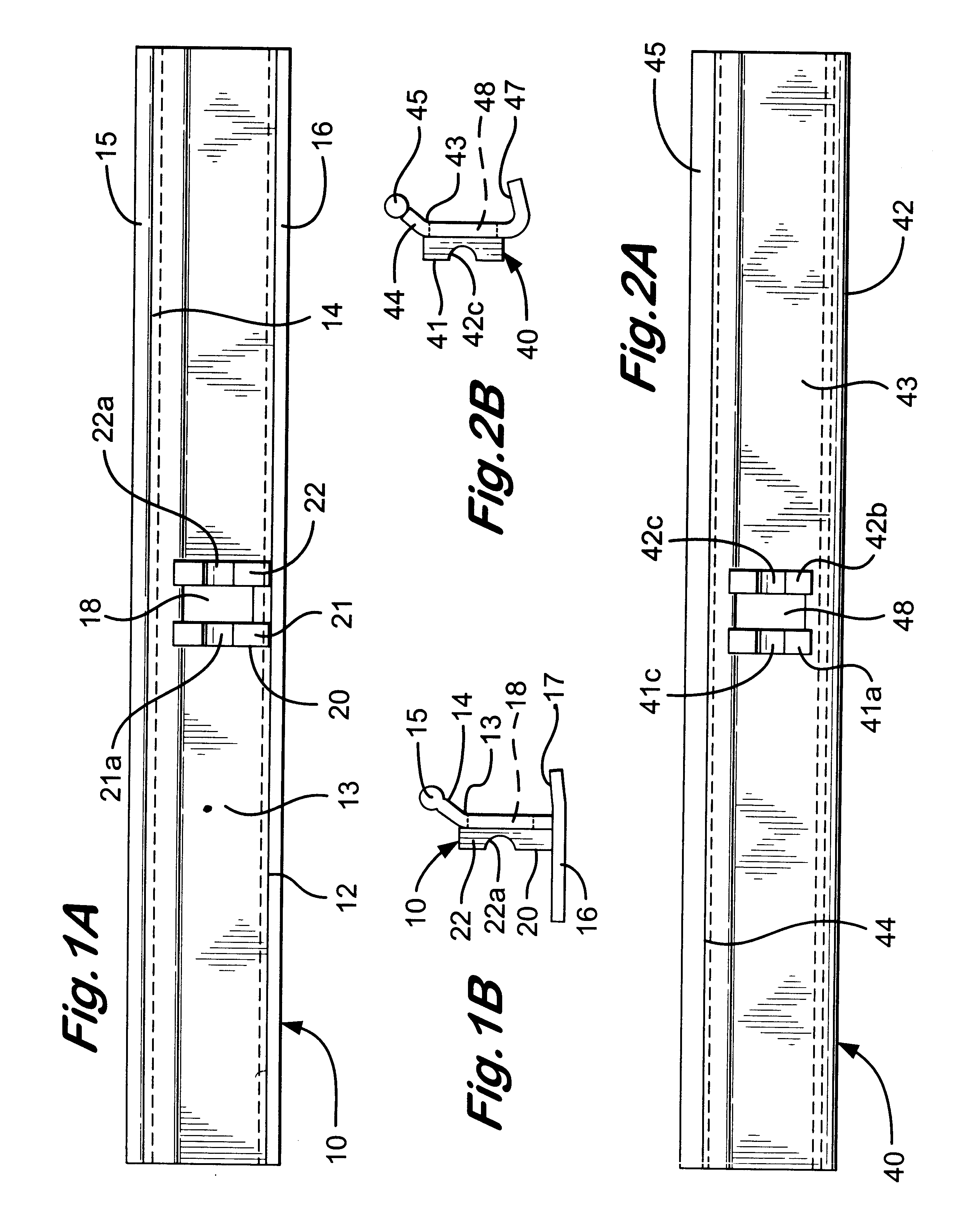

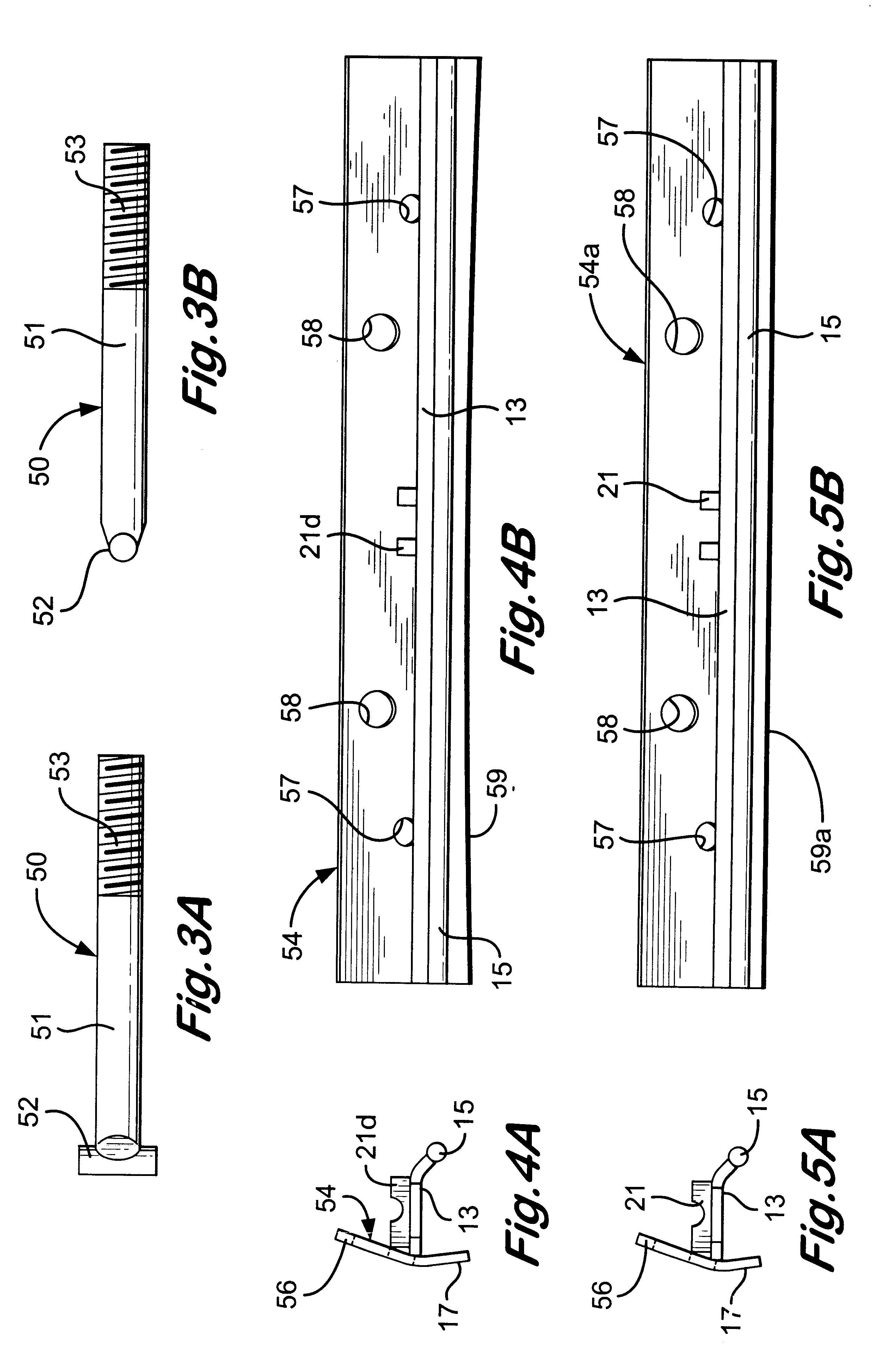

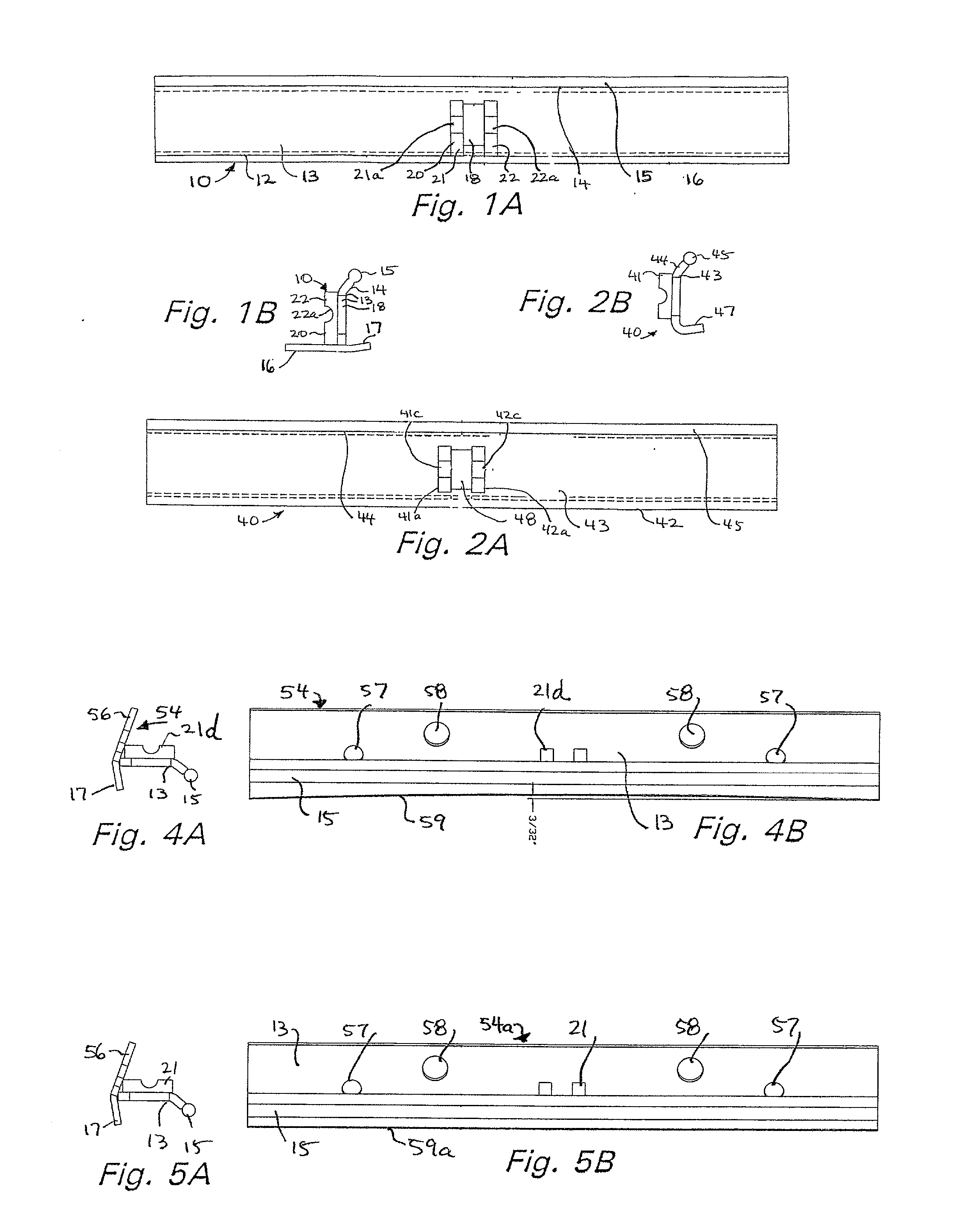

Device for laceration or incision closure

ActiveUS20050020956A1Improve comfortEasy to processSuture equipmentsPlastersAdhesiveBiomedical engineering

Disclosed is a two-component device for closing a laceration or incision. The device includes a first component comprising a first adhesive-backed anchoring member and one or more first connecting members extending from one edge thereof in a first direction. Also included is a second component comprising a second adhesive-backed anchoring member and one or more second connecting members extending from one edge thereof in a second direction generally opposite to the first direction. Means for attaching the one or more first connecting members to the second anchoring member and means for attaching the one or more second connecting members to the first anchoring member is also provided. The attachment of the connecting members to the anchoring members forms attached and bridging portions of the one or more connecting members, the attached portions being attached to an anchoring member, and the bridging portions spanning the over-laceration area between the first and second anchoring members. The first and second components disclosed are transparent, so that visual inspection of the laceration can be achieved subsequent to application of the device. Methods of use are also disclosed.

Owner:CLOZEX MEDICAL LLC

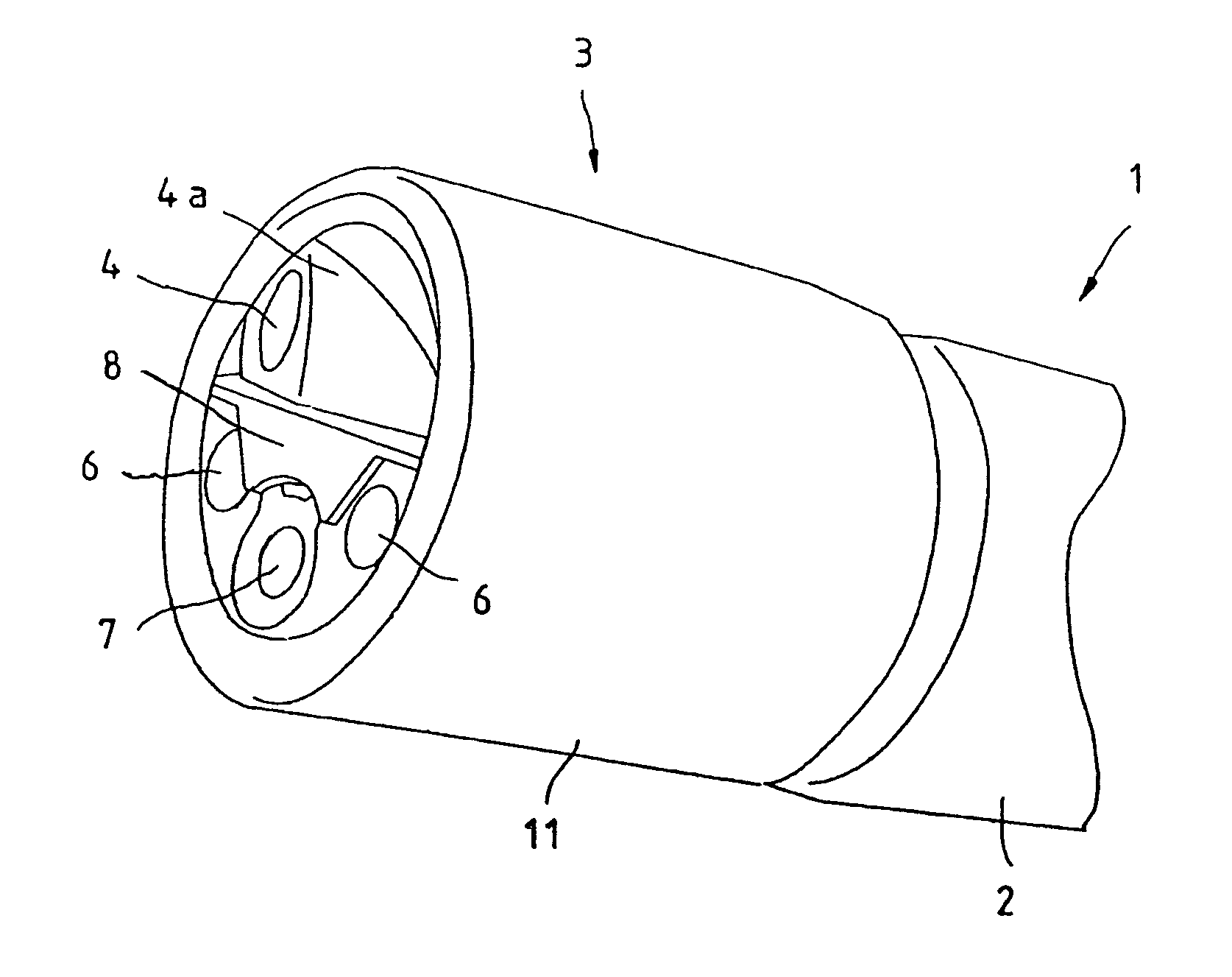

Endoscope

ActiveUS7846090B2Constant uniform depth of insertionUniform tensionElectrically conductive connectionsSurgeryBowden cableEndoscope

The invention relates to an endoscope having a shaft in which at least one working channel is positioned and having on the distal end of the shaft an endoscope head, such that the part of the working channel contained in the endoscope head can be rotated with respect to the related working channel by a Bowden cable that is mounted on a control handle on the proximal end by a collet. To configure an endoscope in such a manner that it ensures simple construction as well as a constantly even tension of the Bowden cable, it is proposed with the invention that the depth of insertion of a cable cord of the Bowden cable into the collet can be limited by a pressure element acting on the cable cord and collet.

Owner:STORZ ENDOSKOP PROD GMBH

Method and apparatus for making intraluminal implants and construction particularly useful in such method and apparatus

InactiveUS20040254633A1Reduce the possibilityUniform tensionStentsBlood vesselsBiomedical engineeringBraid

A method of and an apparatus for making a braided intraluminal implant, by providing a mandrel having at least one small-diameter section joined at least at one end to a large-diameter section; interweaving a plurality of filaments to form a tubular braid enclosing at least a part of the small-diameter section and at least a part of the large-diameter section; and cutting the tubular braid to produce a tubular braid segment having outwardly flared ends at its opposite ends. One flared end is produced by the large-diameter section of the mandrel, and the opposite outwardly flared end may be produced either by another large-diameter section of the mandrel, or by cutting the tubular braid at a portion formed by the small-diameter section of the mandrel but at a location wherein the release of stresses in the filaments inherently produces an outward flaring of the braid at that end.

Owner:STRYKER CORP +1

Device for laceration or incision closure

InactiveUS7354446B2Improve comfortEasy to processSurgical veterinaryWound clampsSystem protectionBiomedical engineering

Disclosed is a two-component device for closing a laceration or incision. The device includes a first component comprising a first adhesive-backed anchoring member and one or more first connecting members extending from one edge thereof in a first direction. The first adhesive-backed anchoring member is protected by a two-stage release liner system which includes: 1) a release liner with a bottom surface covering the adhesive-backed surface of the first anchoring member; and 2) a semi-rigid tab attached to a portion of the top surface of the release liner. The semi-rigid tab includes a first and a second edge. The first edge is oriented generally parallel to the wound edge of the first anchoring member and attached to the release liner at a position intermediate in the release liner between the portion of the release liner protecting the wound edge and the portion of the release liner protecting the edge of the first anchoring member generally opposite the wound edge. The second edge extends unattached beyond the wound edge. The device also includes a second component with substantially similar structural features as those described for the first component. Also provided is a means for attaching the one or more first connecting members to the second anchoring member and means for attaching the one or more second connecting members to the first anchoring member. The attachment of the connecting members to the anchoring members forms attached and bridging portions of the one or more connecting members. The attached portions are attached to an anchoring member, and the bridging portions span the over-laceration area between the first and second anchoring members. Also disclosed is a two-stage release liner system which is not associated with a specific device. Methods of use are also disclosed.

Owner:CLOZEX MEDICAL LLC

Device for laceration or incision closure

ActiveUS7414168B2Improve comfortEasy to processSuture equipmentsPlastersAdhesiveBiomedical engineering

Disclosed is a two-component device for closing a laceration or incision. The device includes a first component comprising a first adhesive-backed anchoring member and one or more first connecting members extending from one edge thereof in a first direction. Also included is a second component comprising a second adhesive-backed anchoring member and one or more second connecting members extending from one edge thereof in a second direction generally opposite to the first direction. Means for attaching the one or more first connecting members to the second anchoring member and means for attaching the one or more second connecting members to the first anchoring member is also provided. The attachment of the connecting members to the anchoring members forms attached and bridging portions of the one or more connecting members, the attached portions being attached to an anchoring member, and the bridging portions spanning the over-laceration area between the first and second anchoring members. The first and second components disclosed are transparent, so that visual inspection of the laceration can be achieved subsequent to application of the device. Methods of use are also disclosed.

Owner:CLOZEX MEDICAL LLC

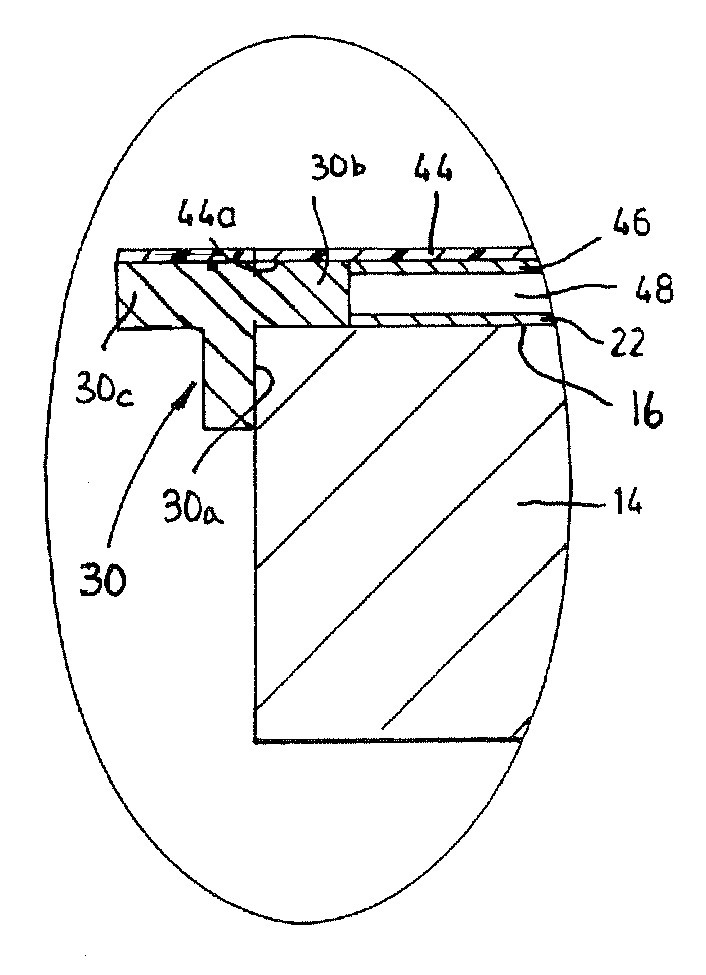

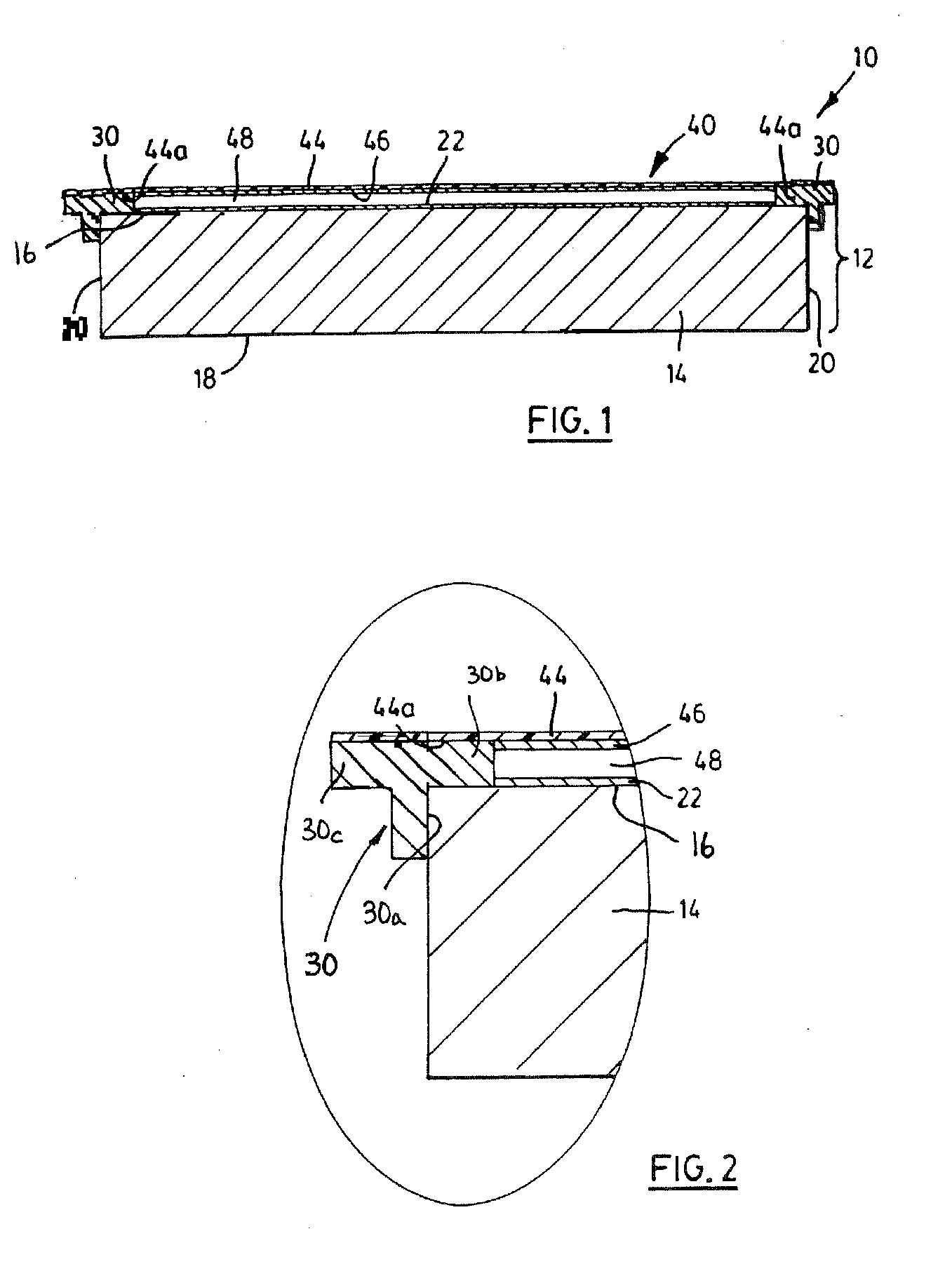

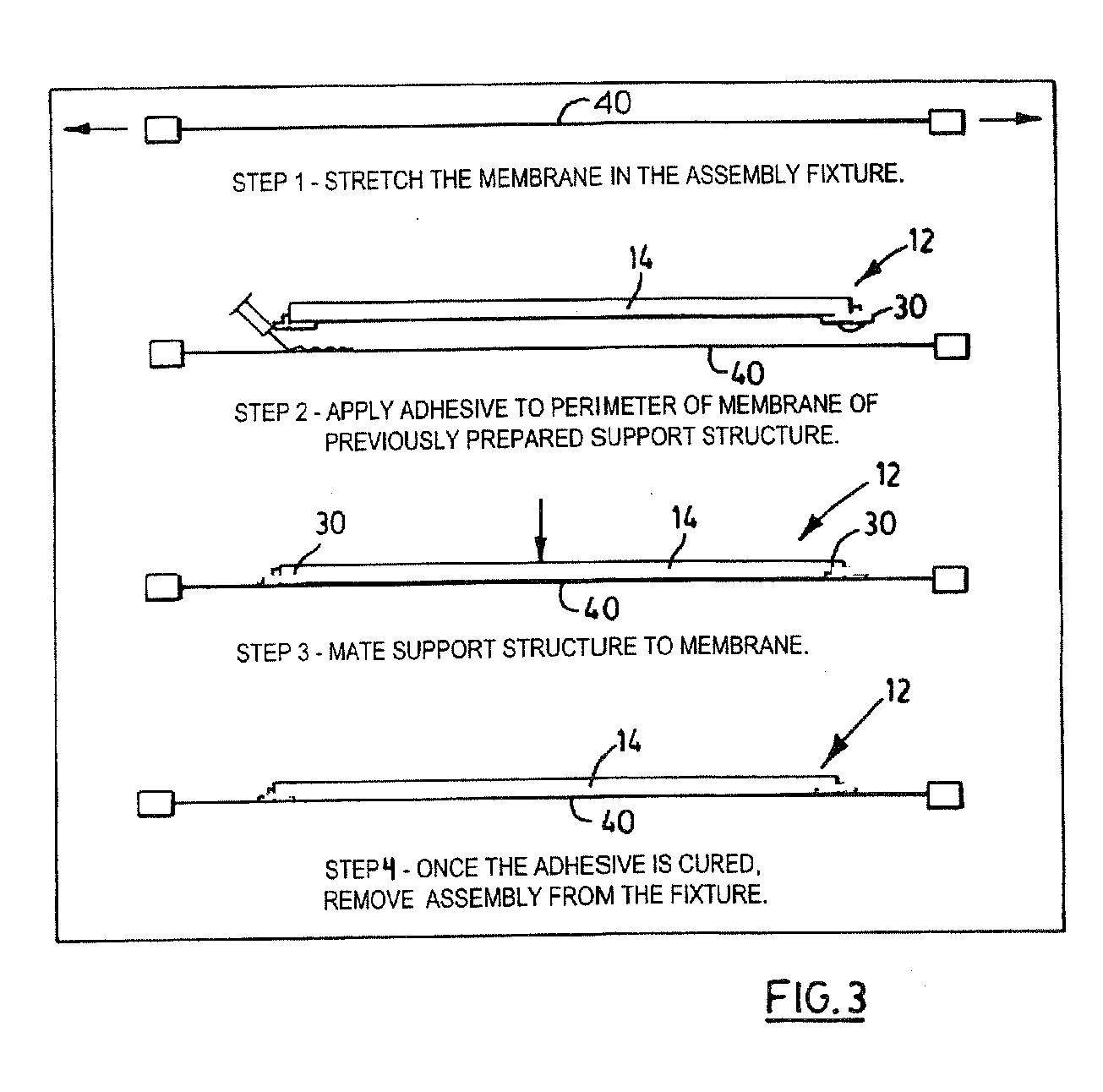

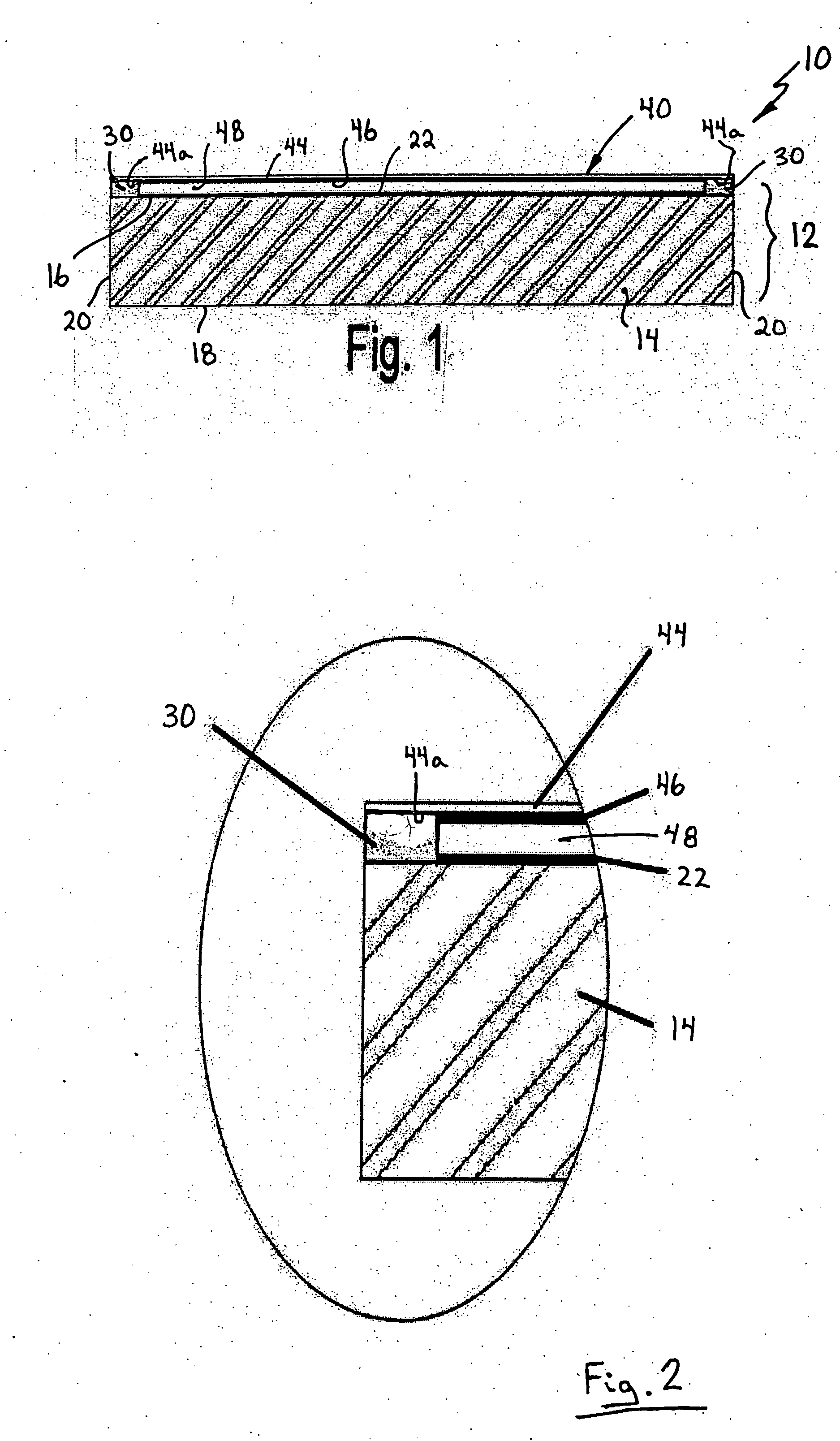

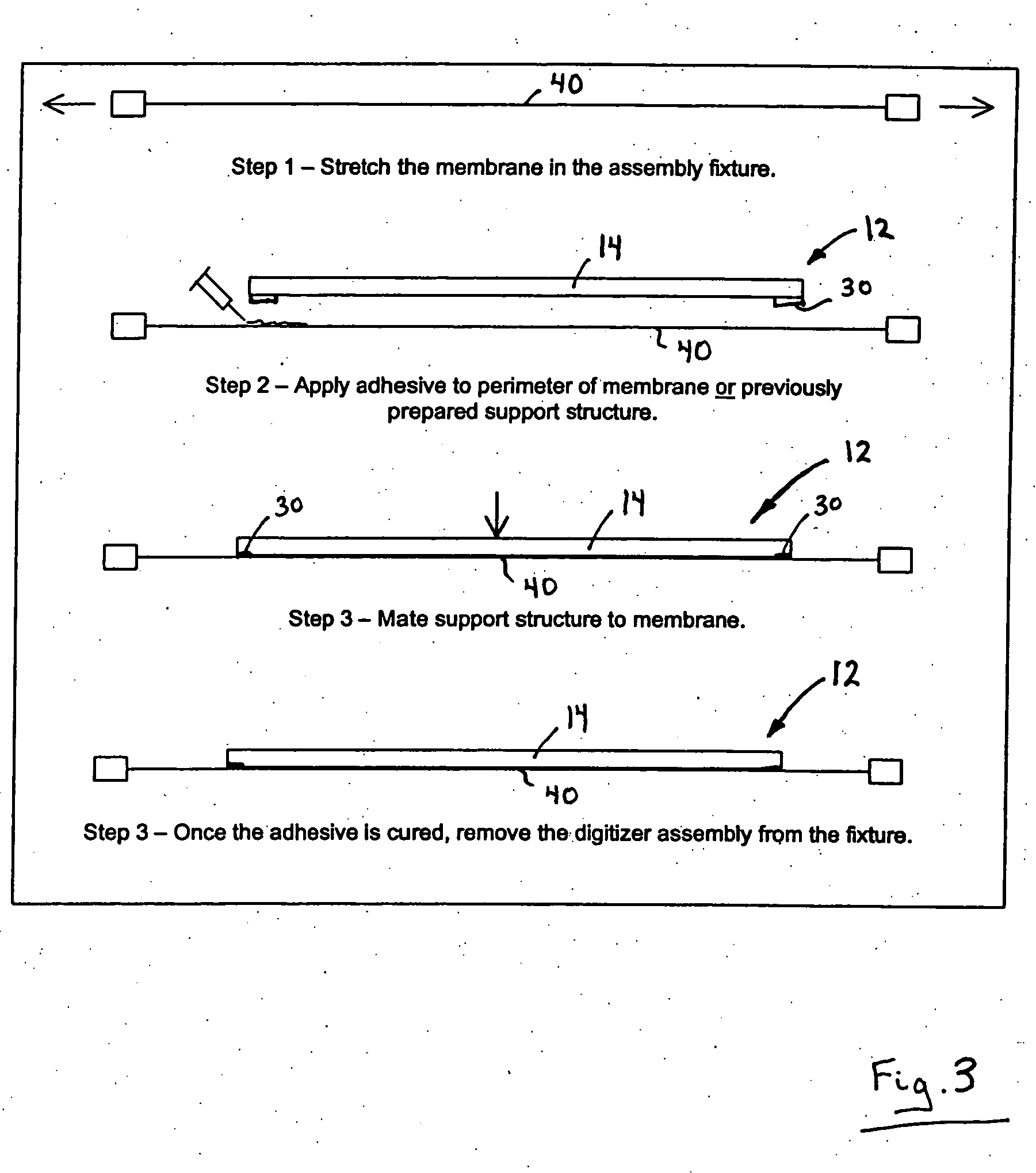

Tensioned touch panel and method of making same

ActiveUS20080083602A1Reducing manufacturing and labour costUniform tensionContact materialsLine/current collector detailsTouchscreenTouch panel

A tensioned touch panel includes a support structure having a substrate with a generally planer conductive surface disposed thereon and an insulating spacer generally about the periphery of the substrate. A pretensioned conductive member overlies the support structure. The spacer separates the conductive membrane and the conductive surface thereby to define an air gap therebetween. A conductive membrane is secured to the support structure under sufficient tension to inhibit slack from developing in the conductive membrane as a result of changes in environmental conditions. A method of assembling a tensioned touch panel is also provided.

Owner:SMART TECH INC (CA)

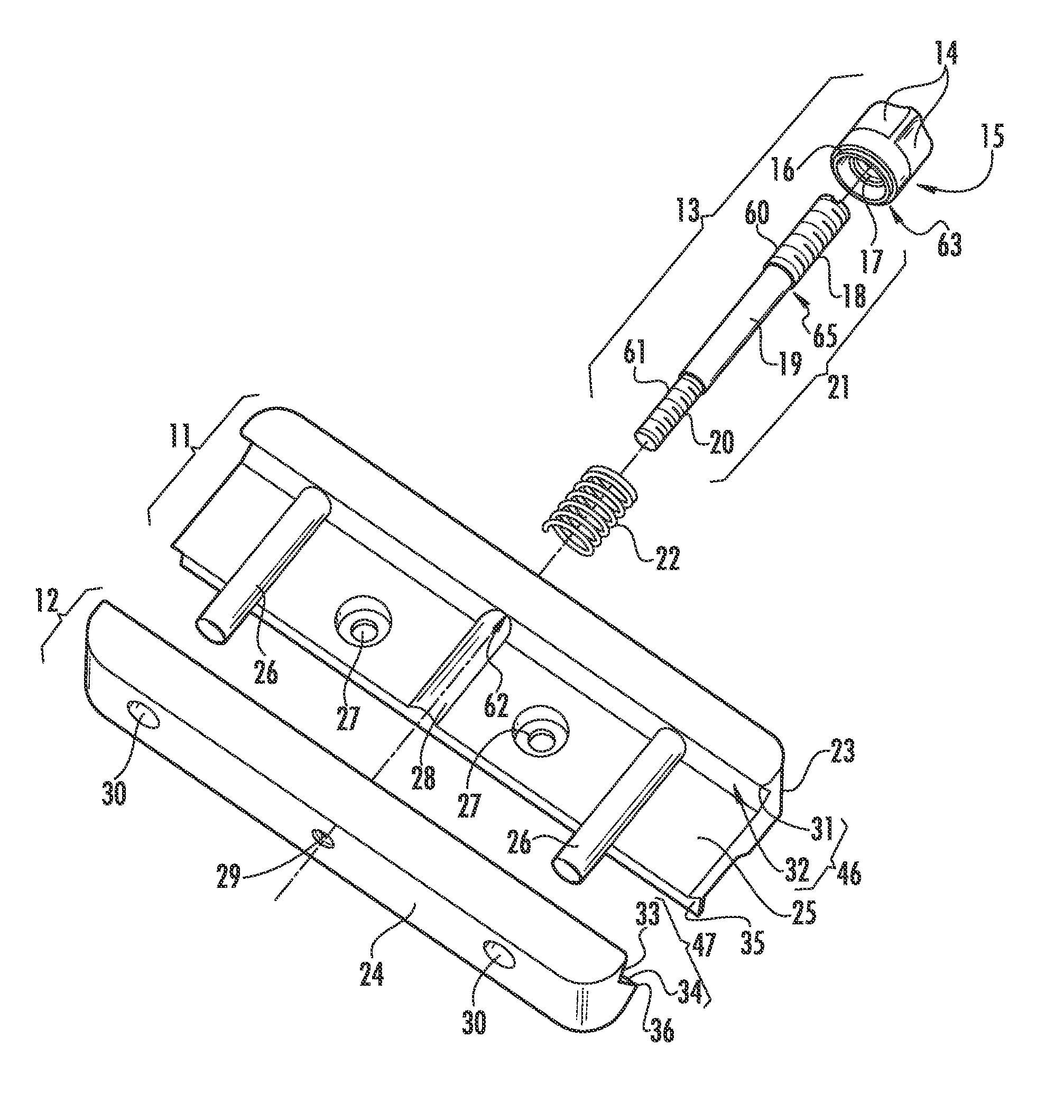

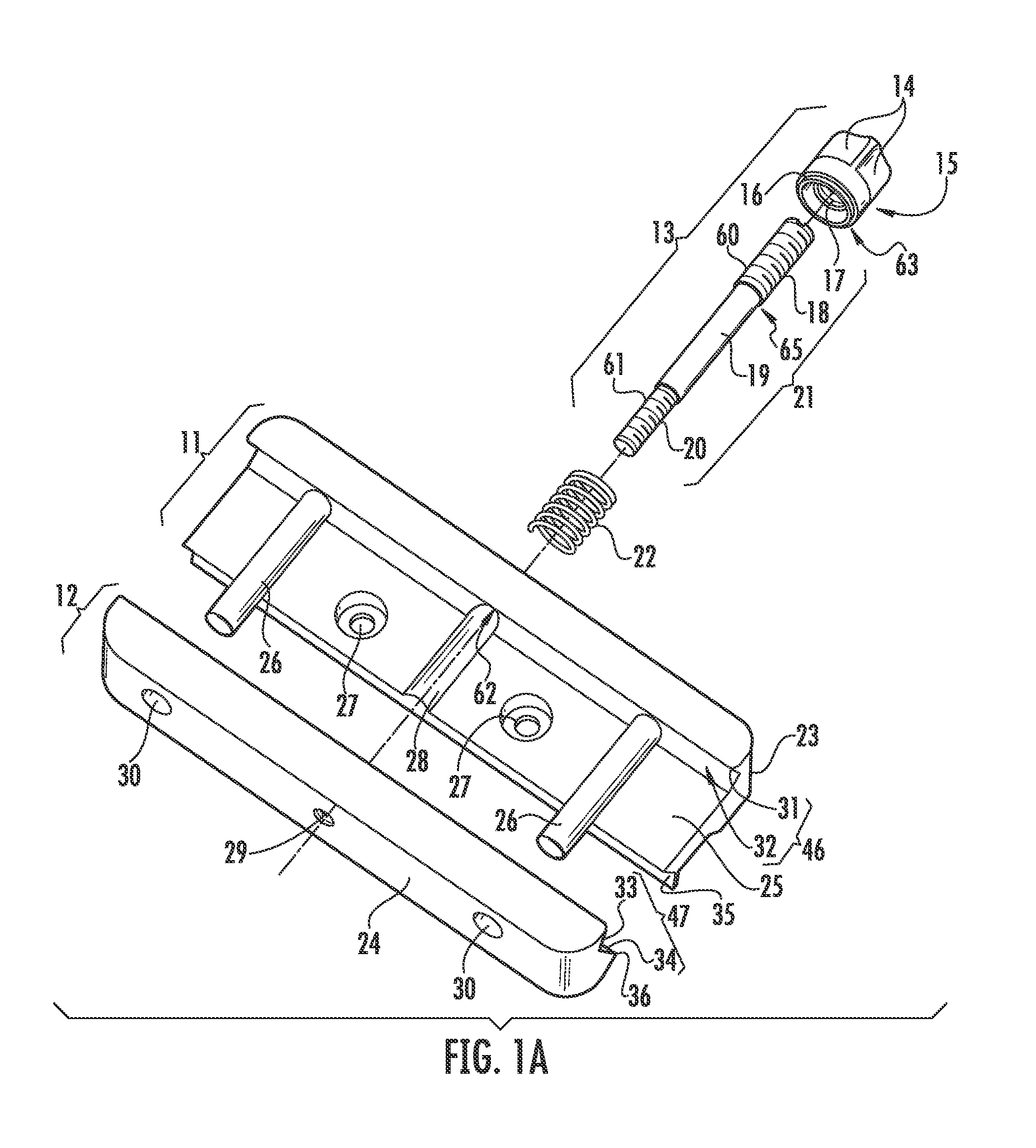

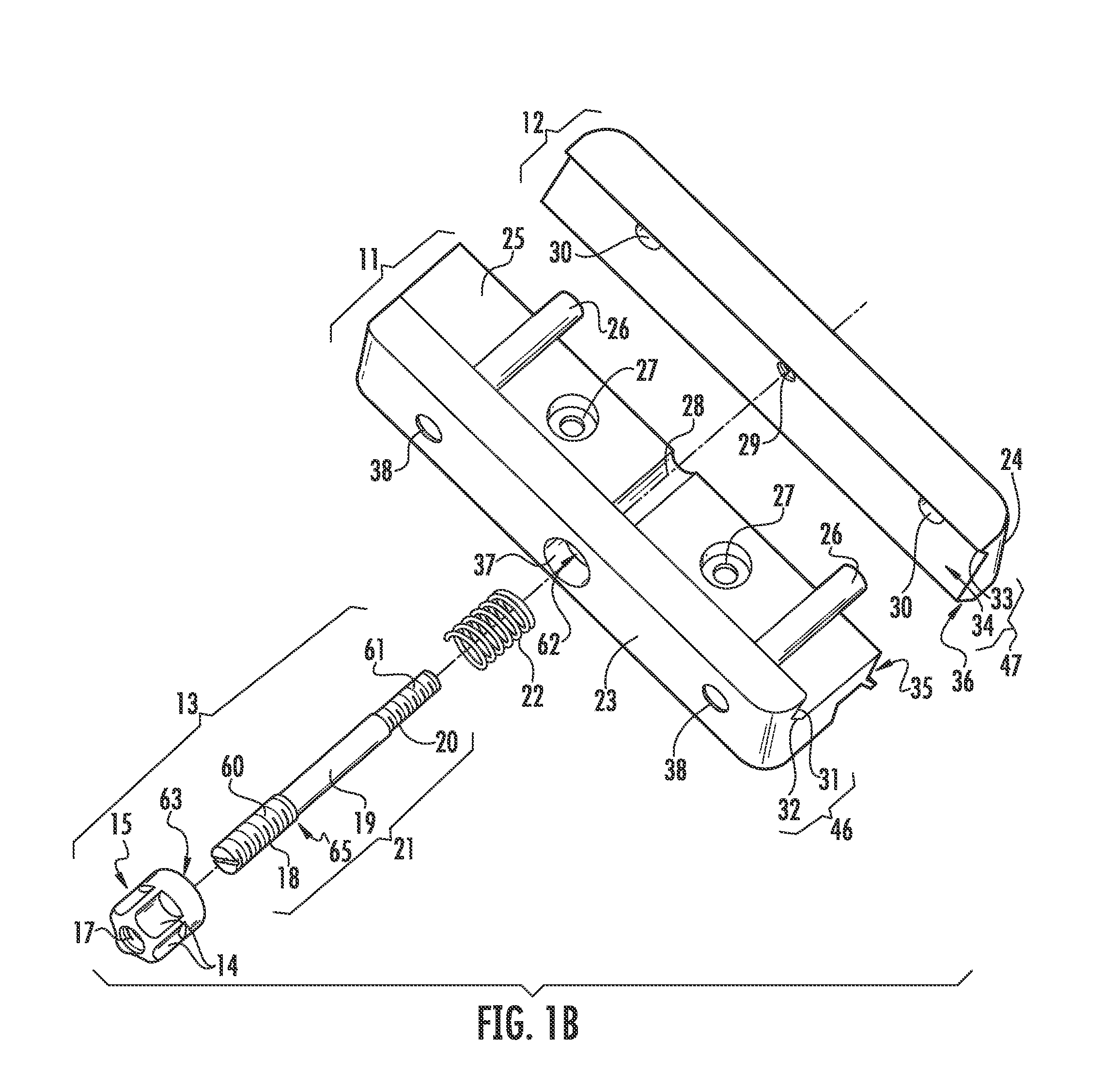

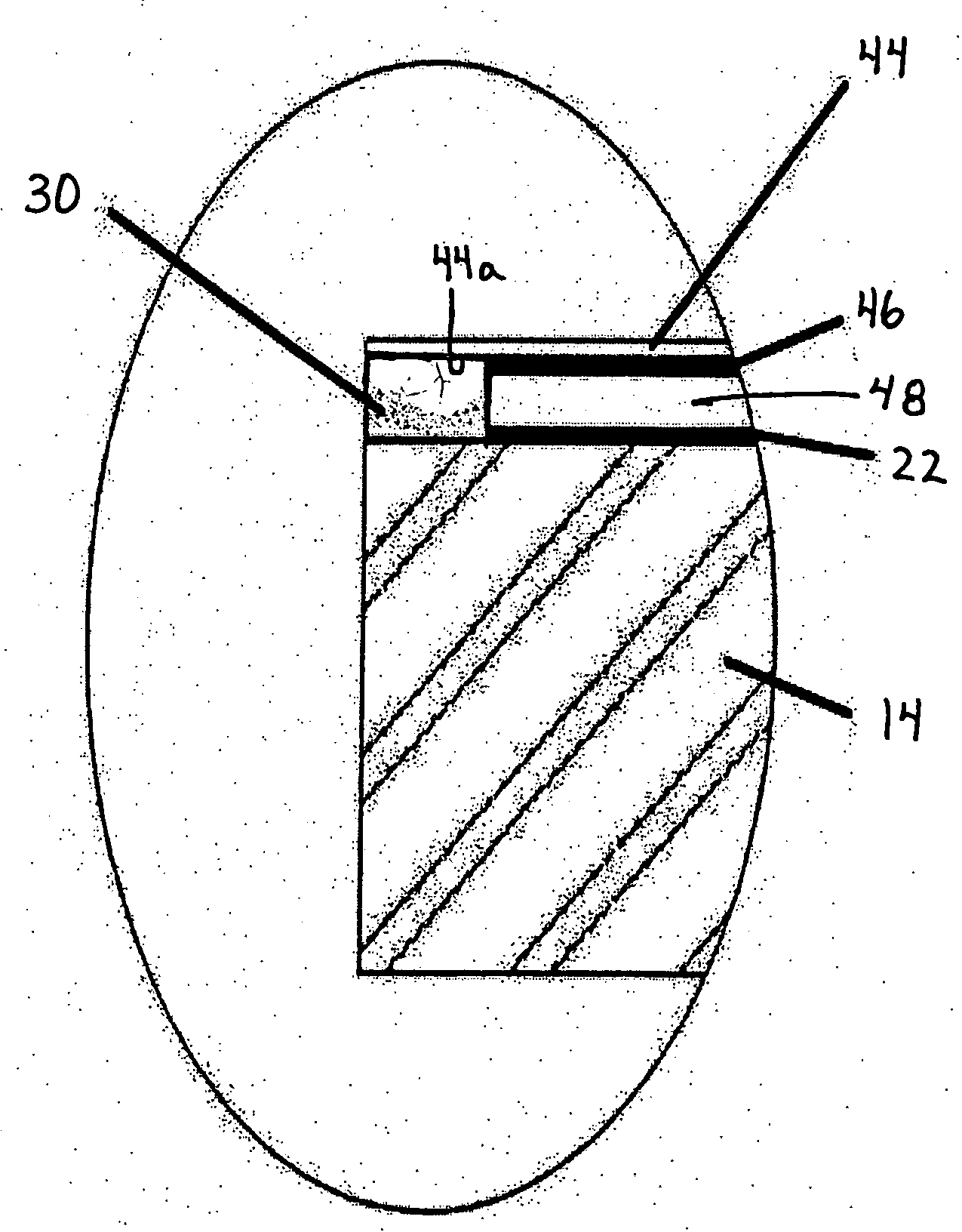

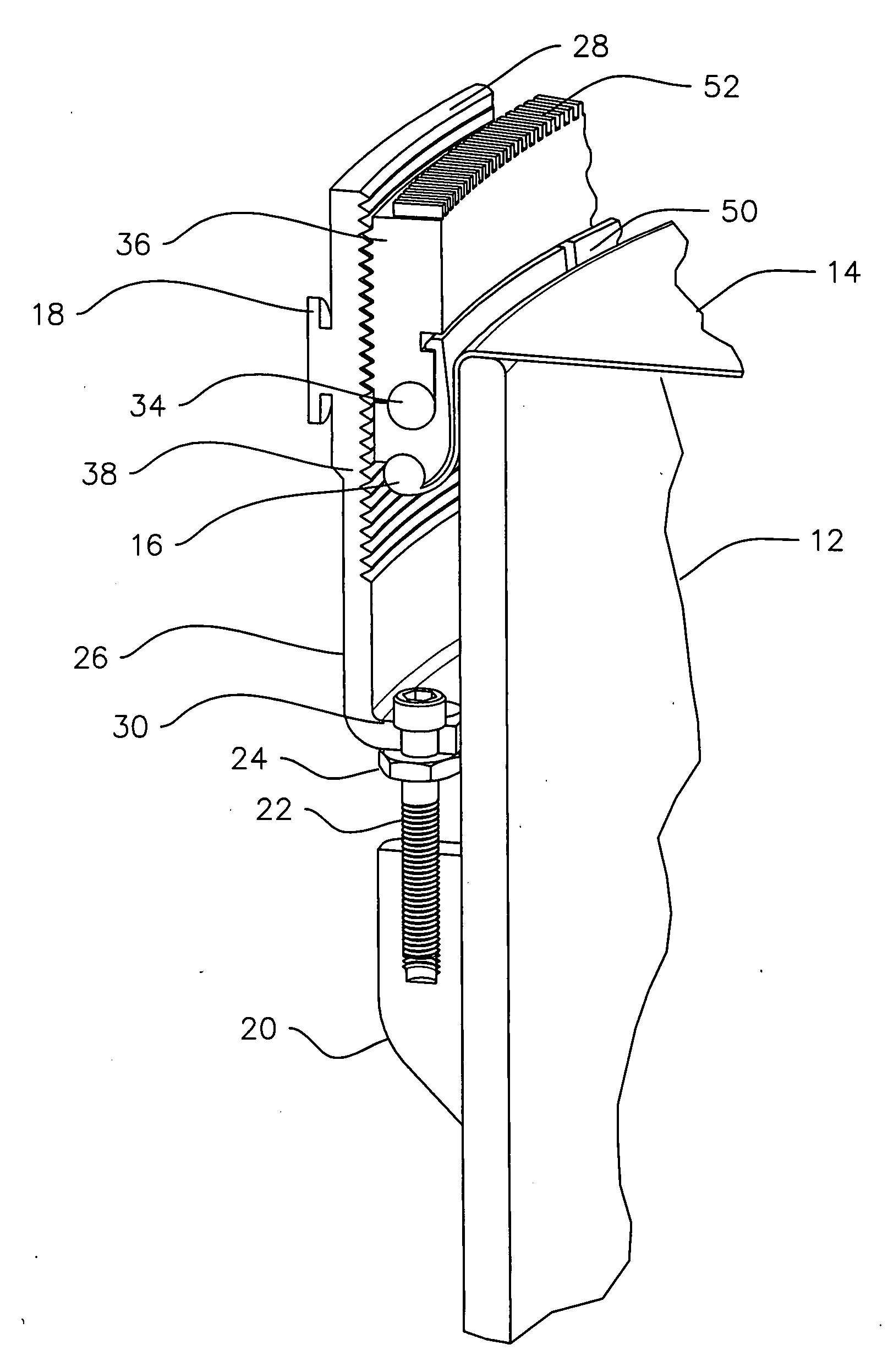

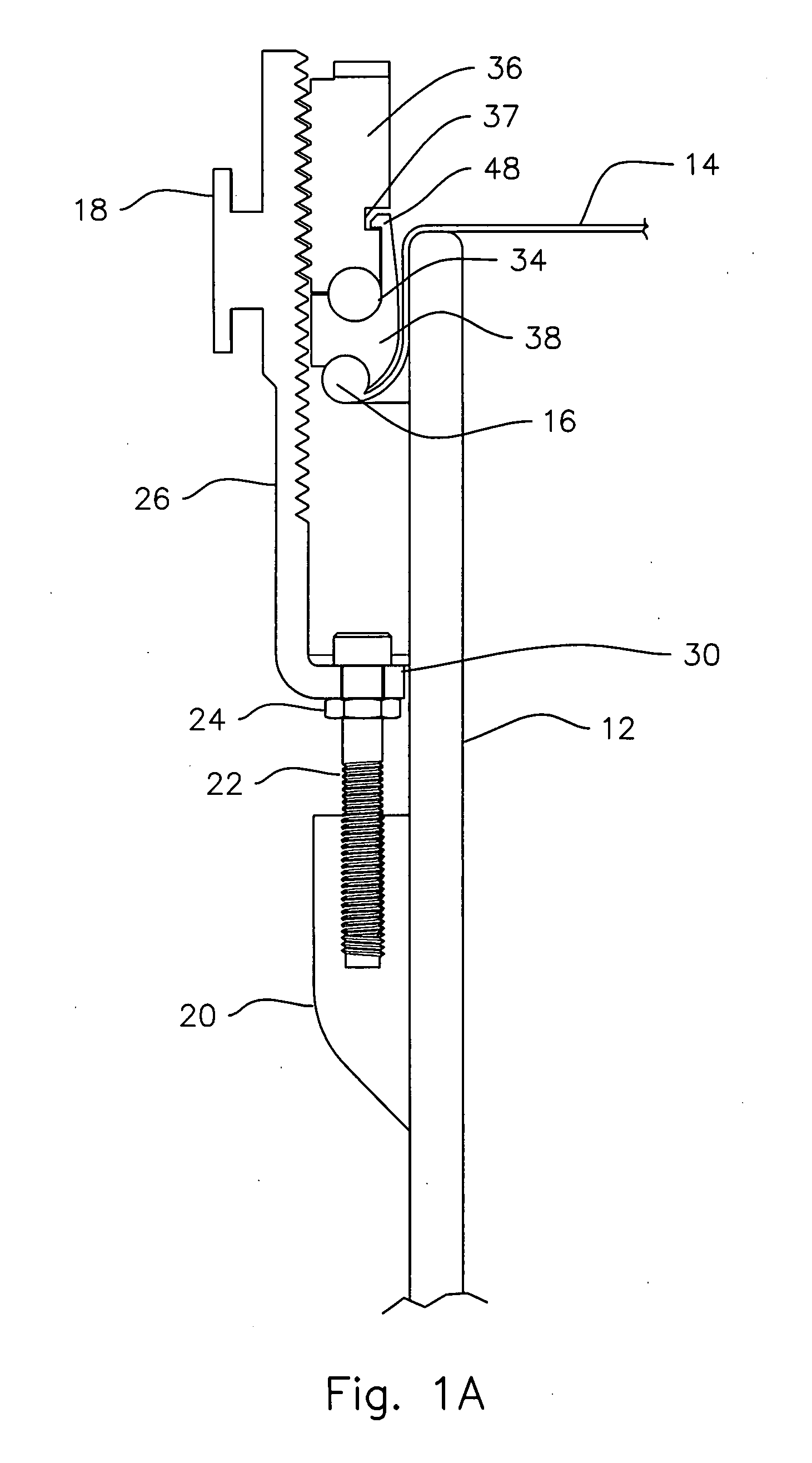

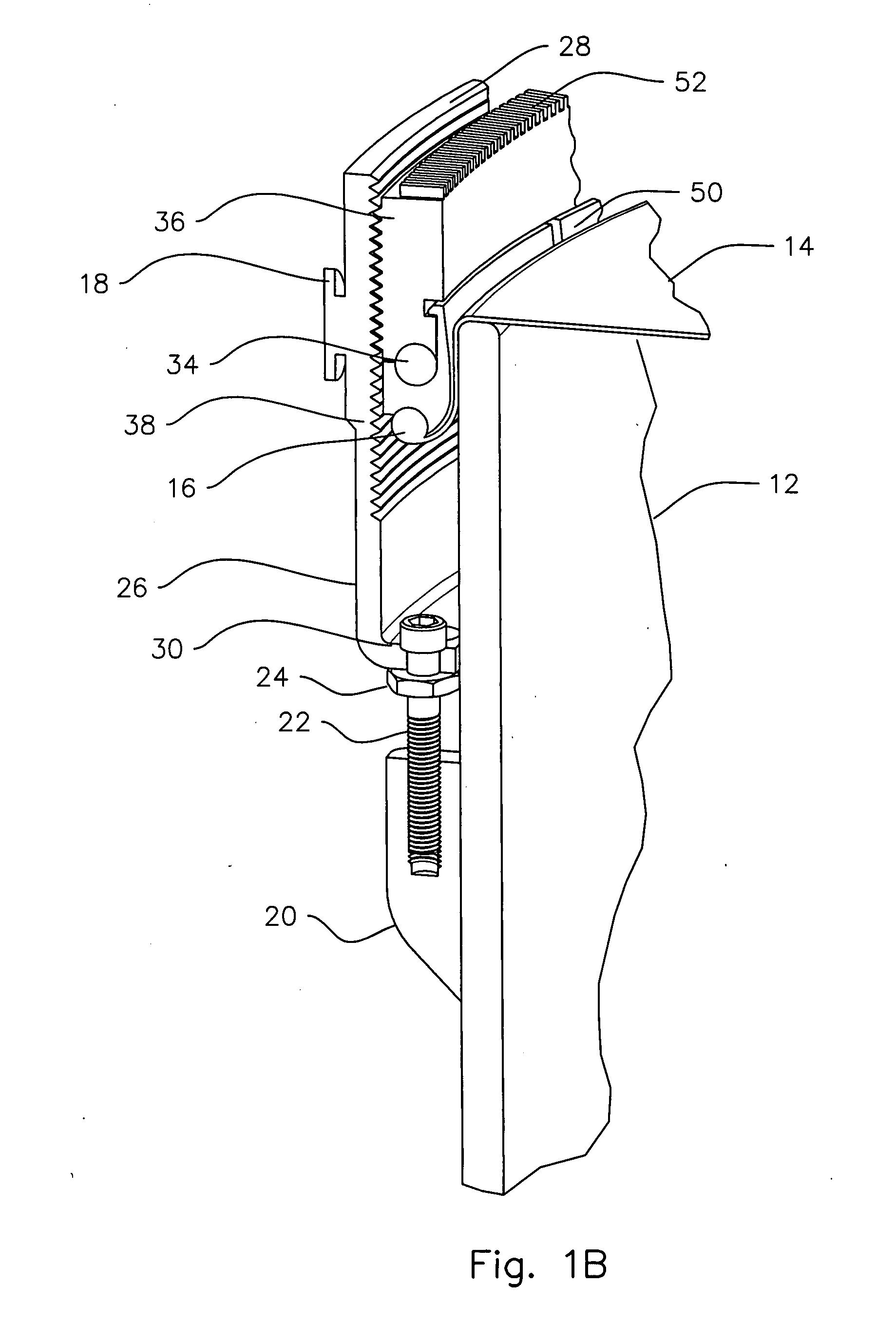

Mount adapter device utilizing a push system

ActiveUS8276307B2High strengthQuick unlockCartridge extractorsSighting devicesEngineeringMechanical engineering

A mount adapter device utilizing a spring-loaded push system for quickly and securely attaching accessories to weapon accessory rails is disclosed. The mount adapter device generally includes a first base member, a second base member, a push rod member, and a resilient member. The push rod member connects the first base member and the second base member. The first base member is linearly slidable into engagement with the second base member in a first direction, and the second base member is linearly slidable into engagement with the first base member in a second direction which is opposite the first direction. The first base member includes a first clamping member for engaging a first edge of the weapon accessory rail. The second base member includes a second clamping member for engaging a second edge of the rail. The resilient member provides a spring force and is arranged to force the first clamping member to move in the first direction into locking engagement with the first edge of the rail while simultaneously forcing the second clamping member to move in the second direction into locking engagement with the second edge of the rail.

Owner:SAMAK ENTERPRISES

Tensioned touch panel and method of making same

ActiveUS20050241929A1Lower manufacturing requirementsReduce labor costsContact materialsContact surface shape/structureTouchscreenTouch panel

A tensioned touch panel includes a support structure having a substrate with a generally planer conductive surface disposed thereon and an insulating spacer generally about the periphery of the substrate. A pretensioned conductive member overlies the support structure. The spacer separates the conductive membrane and the conductive surface thereby to define an air gap therebetween. A conductive membrane is secured to the support structure under sufficient tension to inhibit slack from developing in the conductive membrane as a result of changes in environmental conditions. A method of assembling a tensioned touch panel is also provided.

Owner:SMART TECH INC (CA)

Device for laceration or incision closure

InactiveUS20050021081A1Eliminate stretchHigh strengthDiagnosticsSurgical veterinaryAdhesiveEngineering

Disclosed is a two-component device for closing a laceration or incision. The device includes a first component comprising a first adhesive-backed anchoring member and one or more first connecting members extending from one edge thereof in a first direction. Also included is a second component comprising a second adhesive-backed anchoring member and one or more second connecting members extending from one edge thereof in a second direction generally opposite to the first direction. Adhesive is provided for attaching the one or more first connecting members to the second anchoring member and for attaching the one or more second connecting members to the first anchoring member. The attachment of the connecting members to the anchoring members forms attached and bridging portions of the one or more connecting members, the attached portions being attached to an anchoring member, and the bridging portions spanning the over-laceration area between the first and second anchoring members. Adhesive is applied to at least a portion of a lower surface of the connecting members, and the lower surface of the bridging portion contains less adhesive than the attached portion. In preferred embodiments, the lower surface of the bridging portion is substantially free of adhesive. Methods of use are also disclosed.

Owner:CLOZEX MEDICAL LLC

Damage and leakage barrier in all-composite pressure vessels and storage tanks

ActiveUS8074826B2StrengthImprove leakageAdhesive processesGas handling applicationsFiberAxis of symmetry

Owner:COMPOSITE TECH DEV

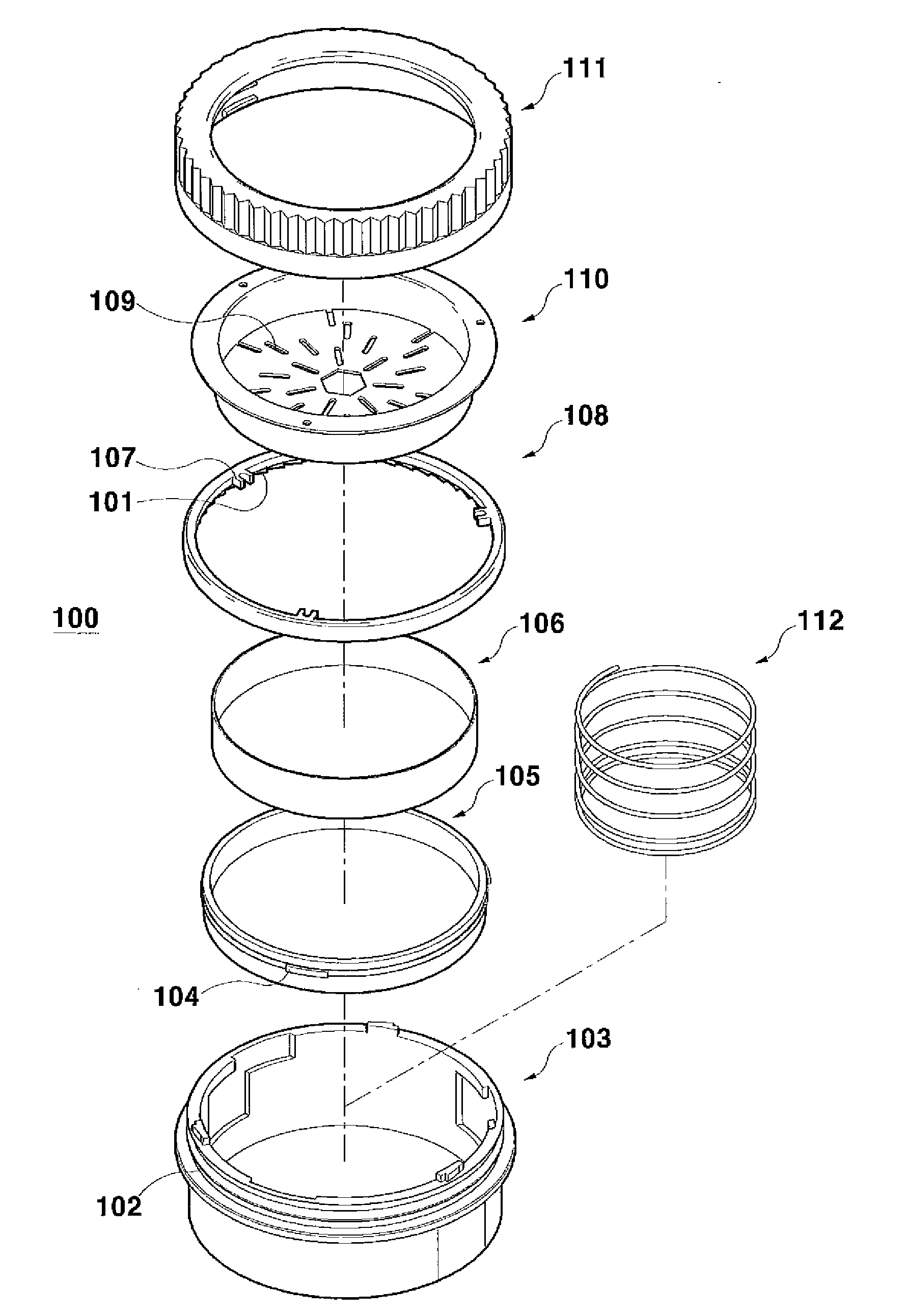

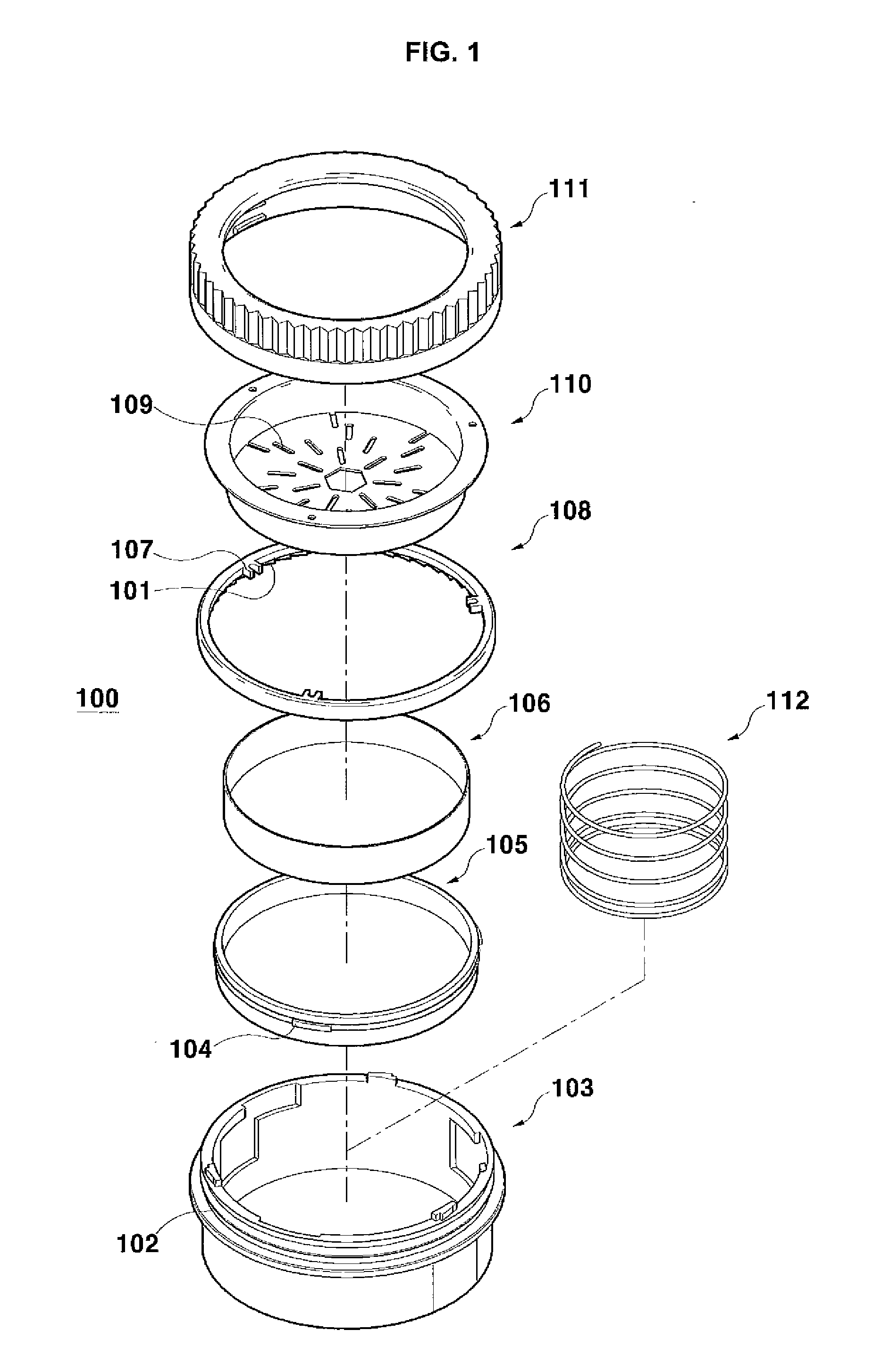

Cosmetics case

ActiveUS20080276956A1Avoid dischargeEasy to GrindPackaging toiletriesPackaging cosmeticsCouplingEngineering

The present invention relates to a cosmetics case including a cover having a lock protrusion and a hinge protrusion; a base case to which the cover is pivotally connected; an intermediate case installed in the base case and in which a button and a spring are installed; a powder case receiving solid powder therein, installed in the intermediate case and supported by the spring; and a grinding member rotatably installed in a coupling groove of the intermediate case to grind the surface of the solid powder received in the powder case. The present invention provides the cosmetics case capable of rotating in both directions, in which rotation in one direction permits grinding of the solid powder and rotation in the other direction permits pressing down of the surface of the solid powder, thereby preventing the ground powder from being discharged outwards, and after use, the cover is closed to prevent impurities from being put into the solid powder.

Owner:CHO KYU SUK

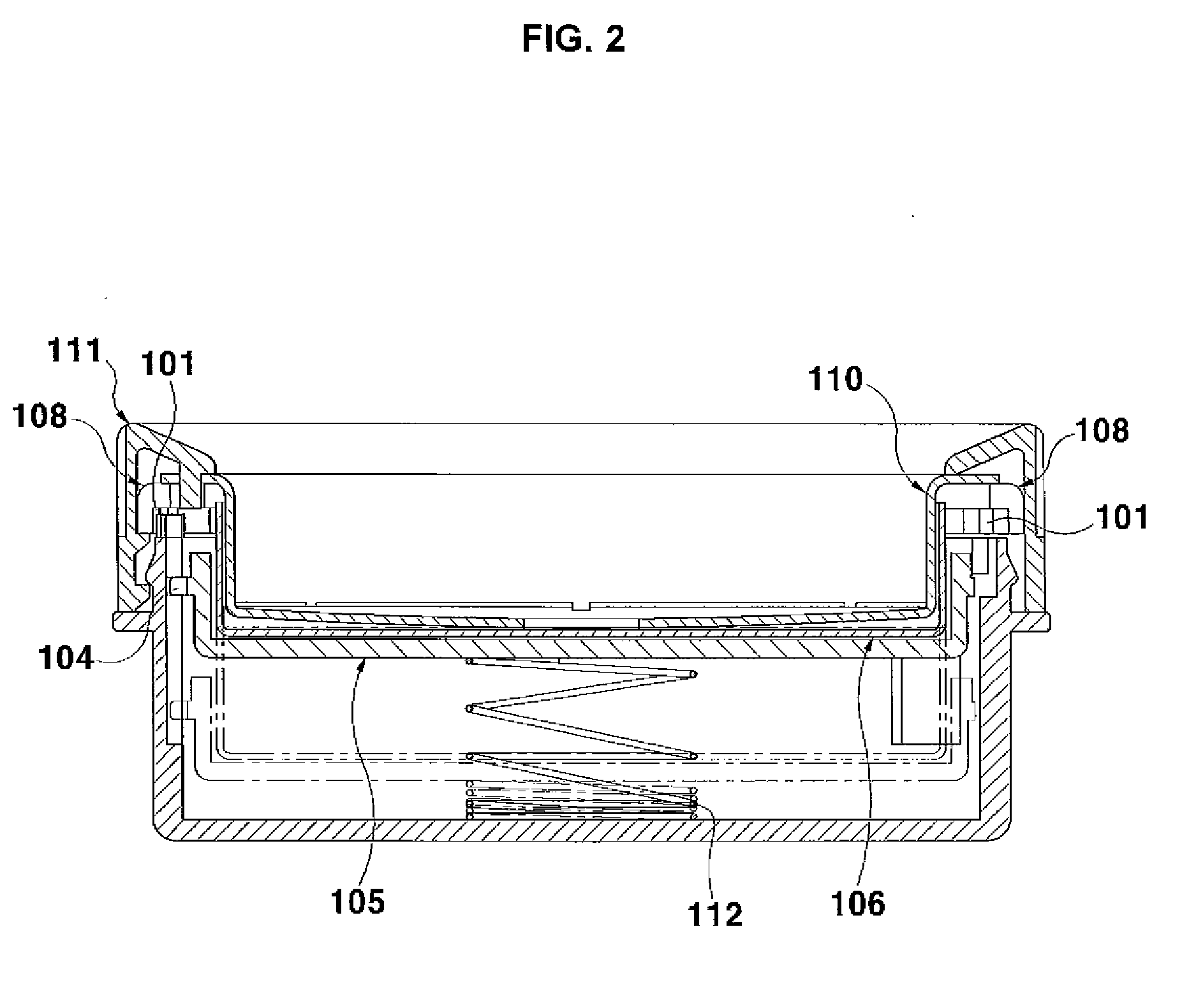

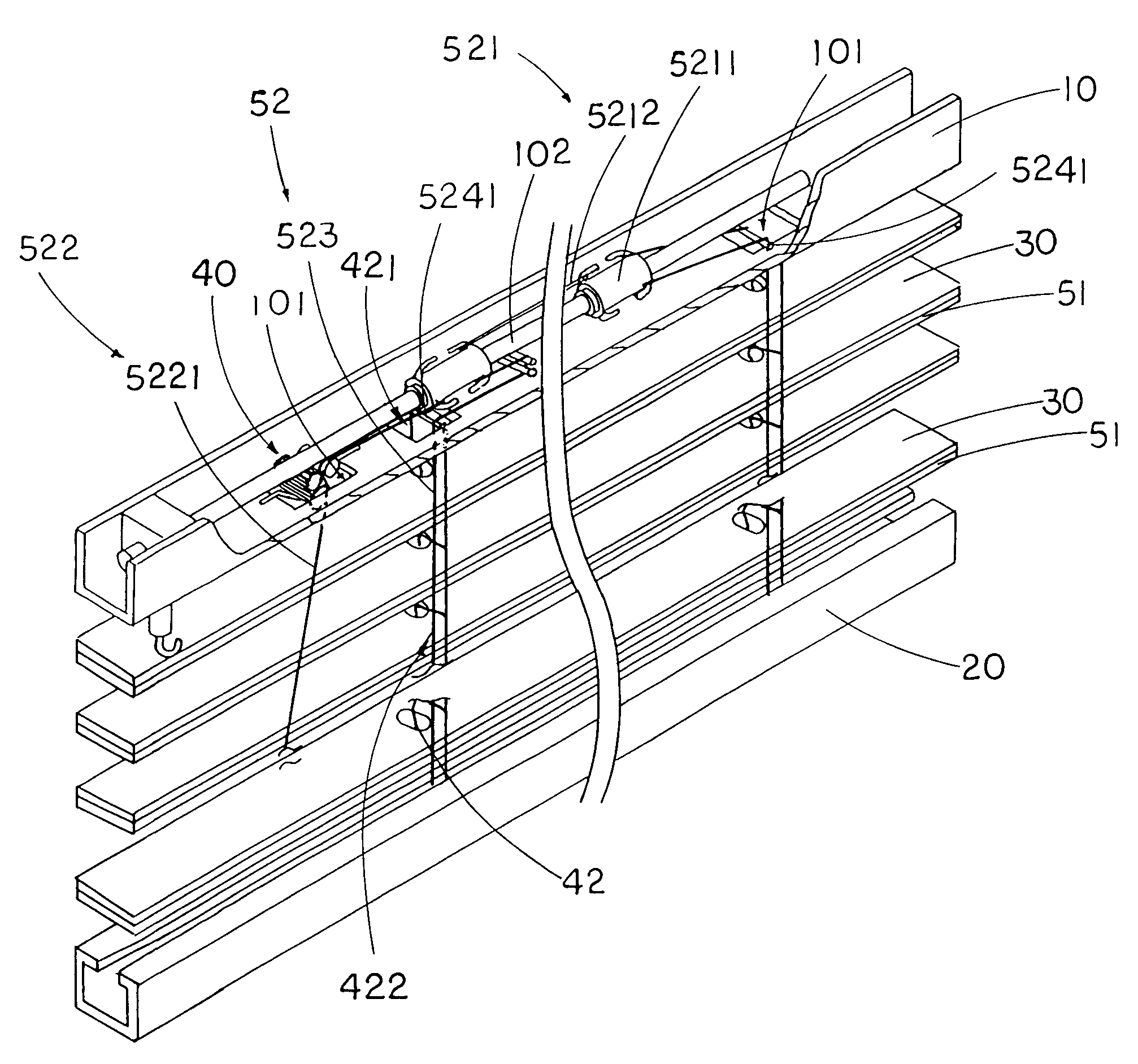

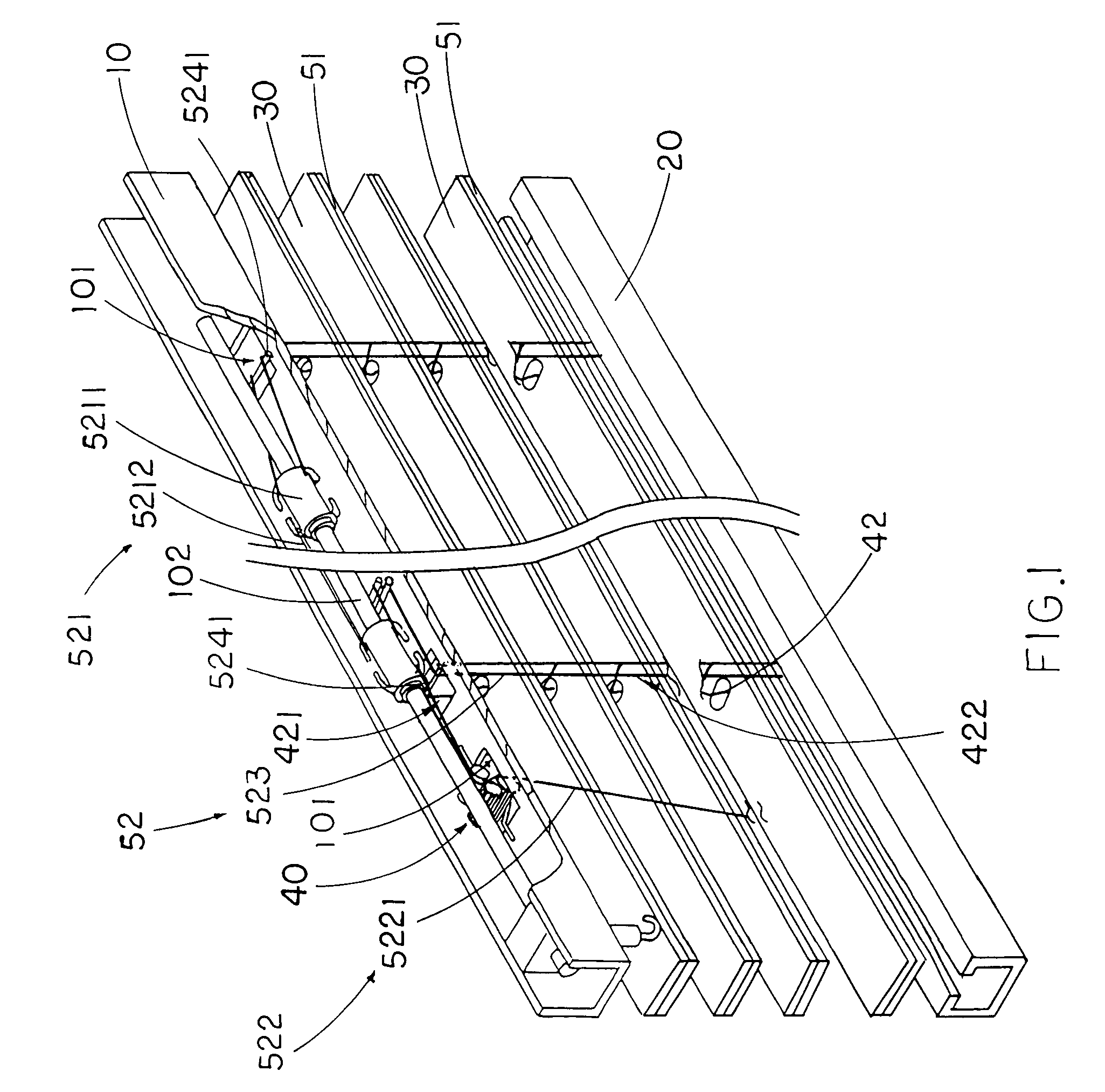

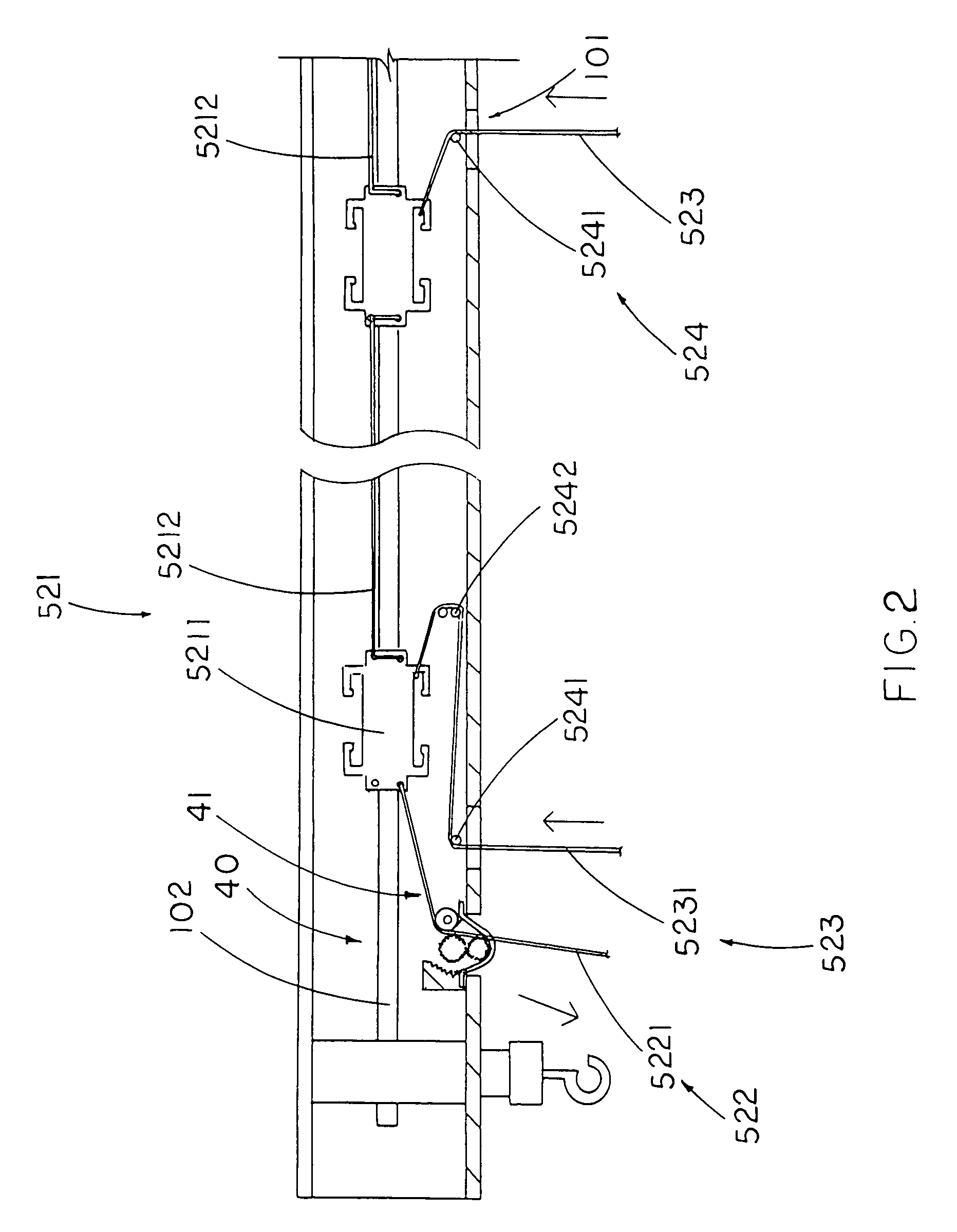

Window blind

A supplement blind enhancement for a window blind includes a plurality of enhancing blades positioned between every two adjacent slats of the window blind, a control system having a control slider, a blade controller extended from the control slider to slidably shift the control slider between a light shading position and a light enhancing position, and an elongated element extended from the control slider to engage with the enhancing blades. At the light shading position, the control slider is driven to slide the enhancing blades suspendedly disposed between the slats in an alternating manner for substantially blocking sunlight passing through a gap between each two slats, and at the light enhancing position, the control slider is driven to slide that each of the enhancing blades to overlap with the respective slat for allowing the sunlight passing through the gap between each two slats.

Owner:LAI TONY

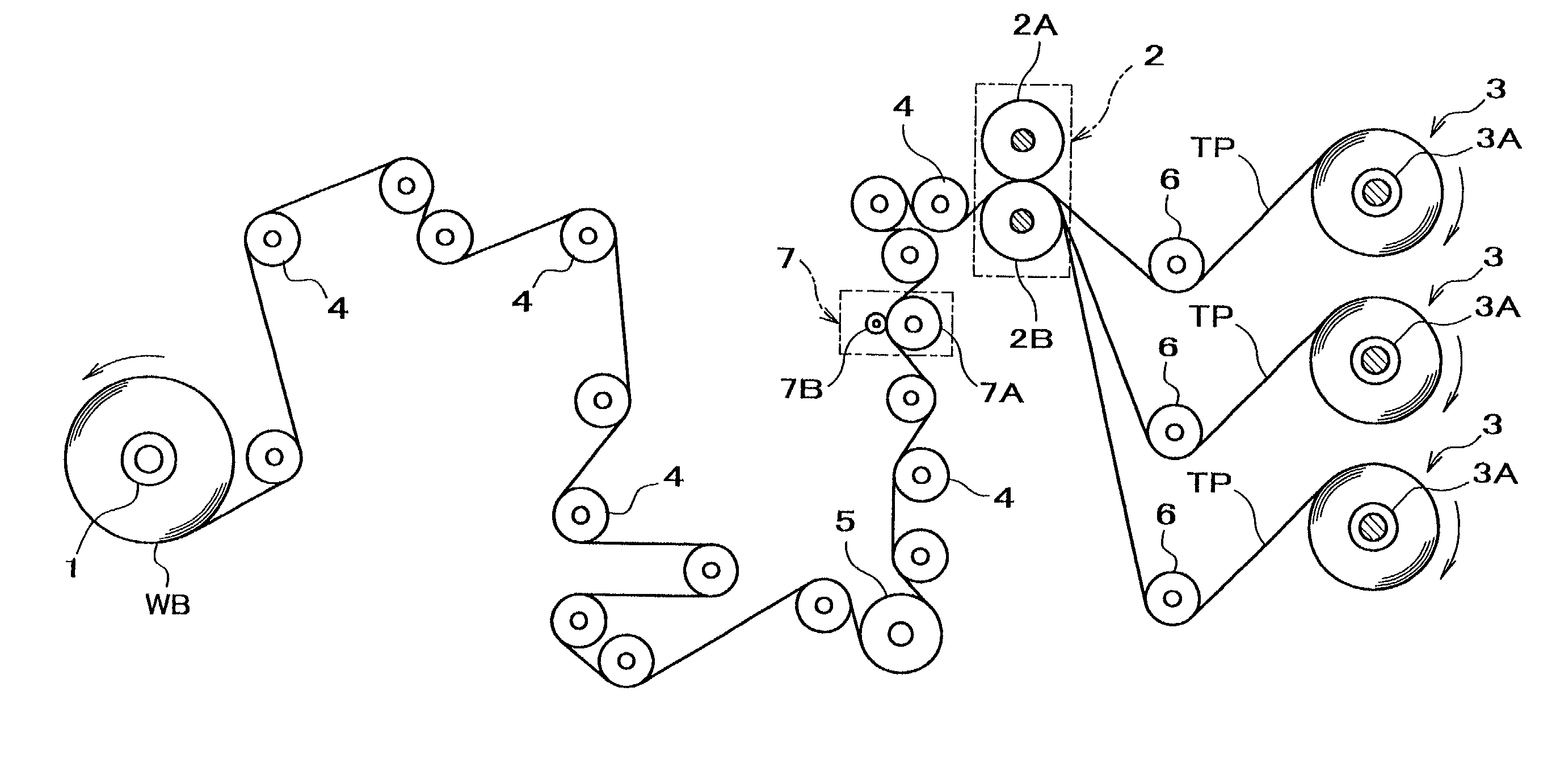

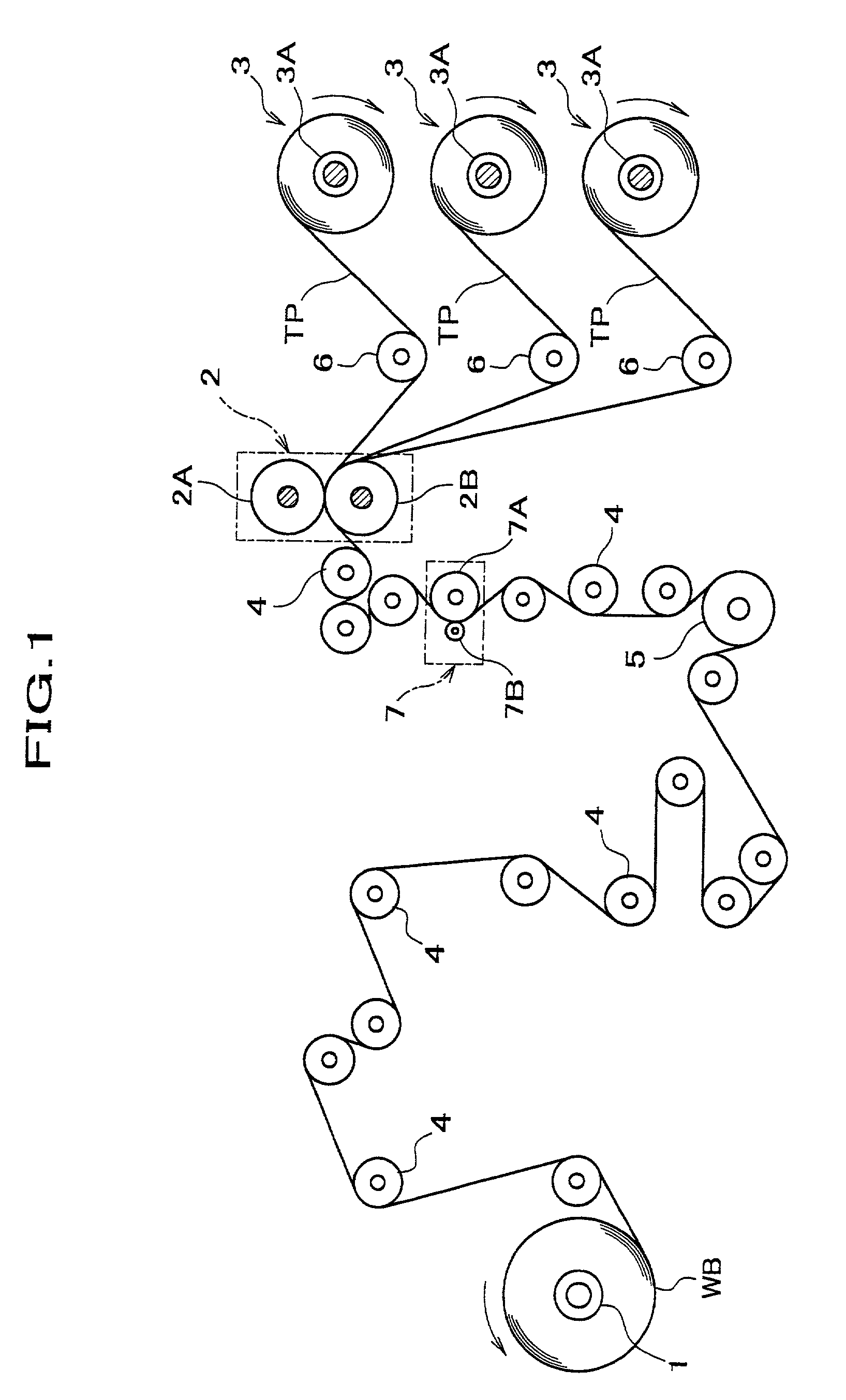

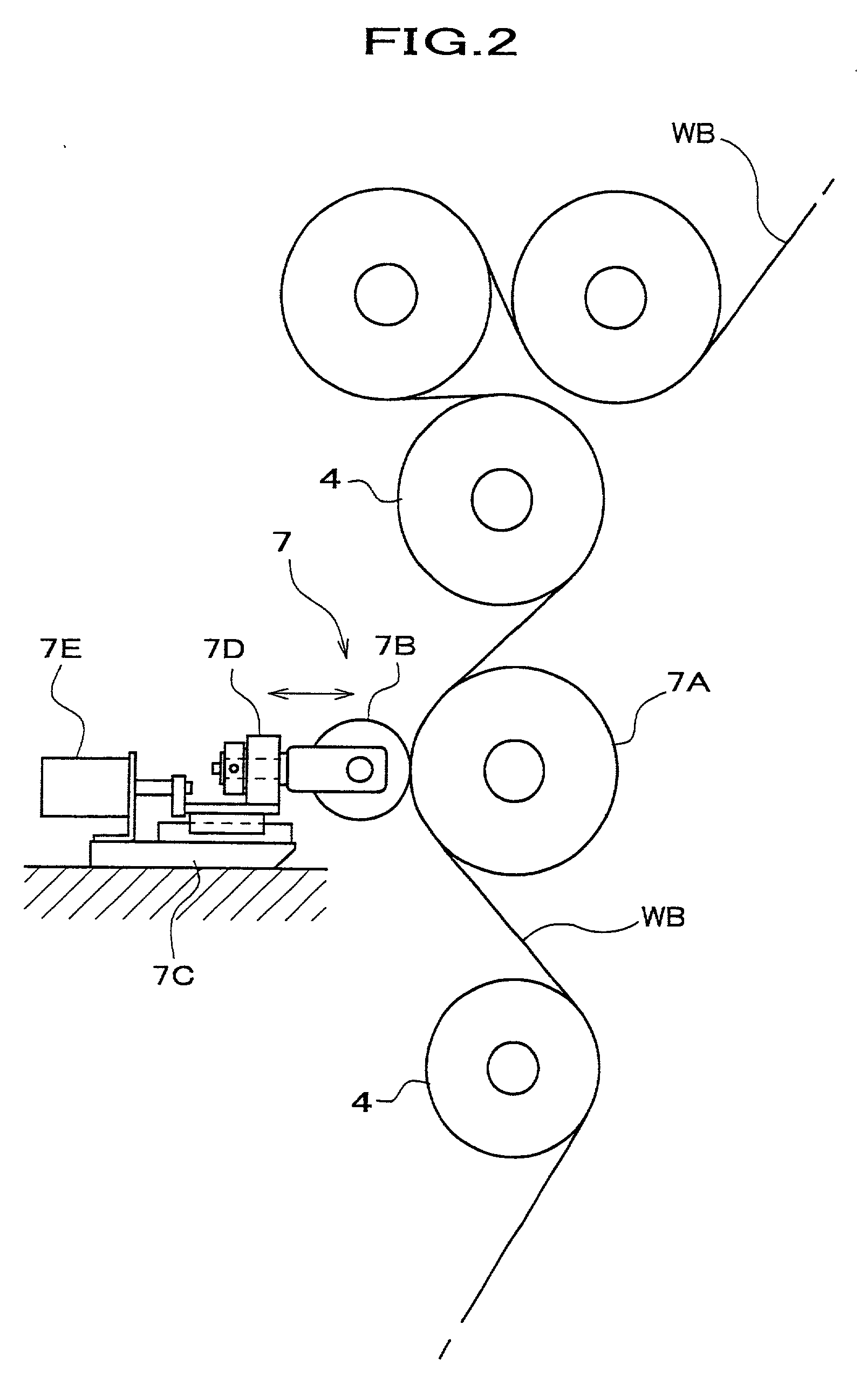

Process for producing magnetic tape

InactiveUS20020149866A1Reduce tensionUniform tensionCarrier editingRecord information storageMagnetic tapeEngineering

A process for producing a magnetic tape is provided, in which a web is extended in the width direction immediately before it is cut by a slitter when the web is supplied to the slitter to be cut into several magnetic tapes. The extension of the web is performed by an extension roller apparatus comprises a backup roller for rolling the web and a pair of horizontally disposed extension rollers which elastically push the web WB at portions near both sides thereof to allow the web for extending in the width direction.

Owner:FUJIFILM CORP +1

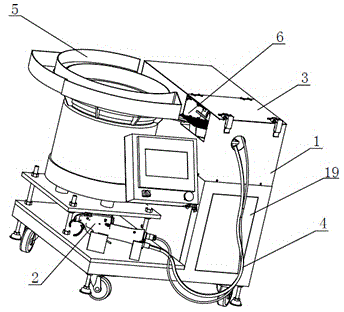

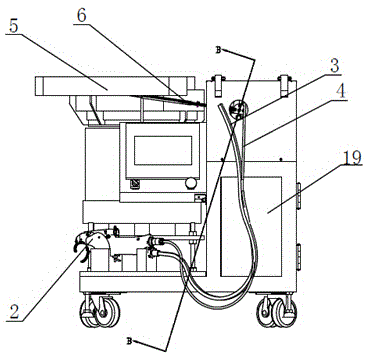

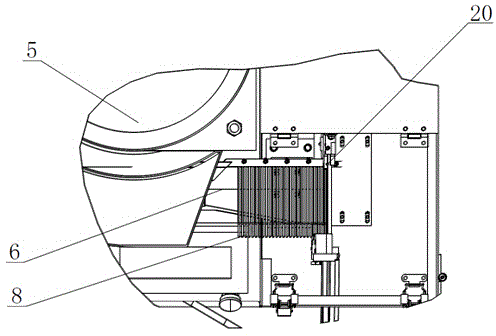

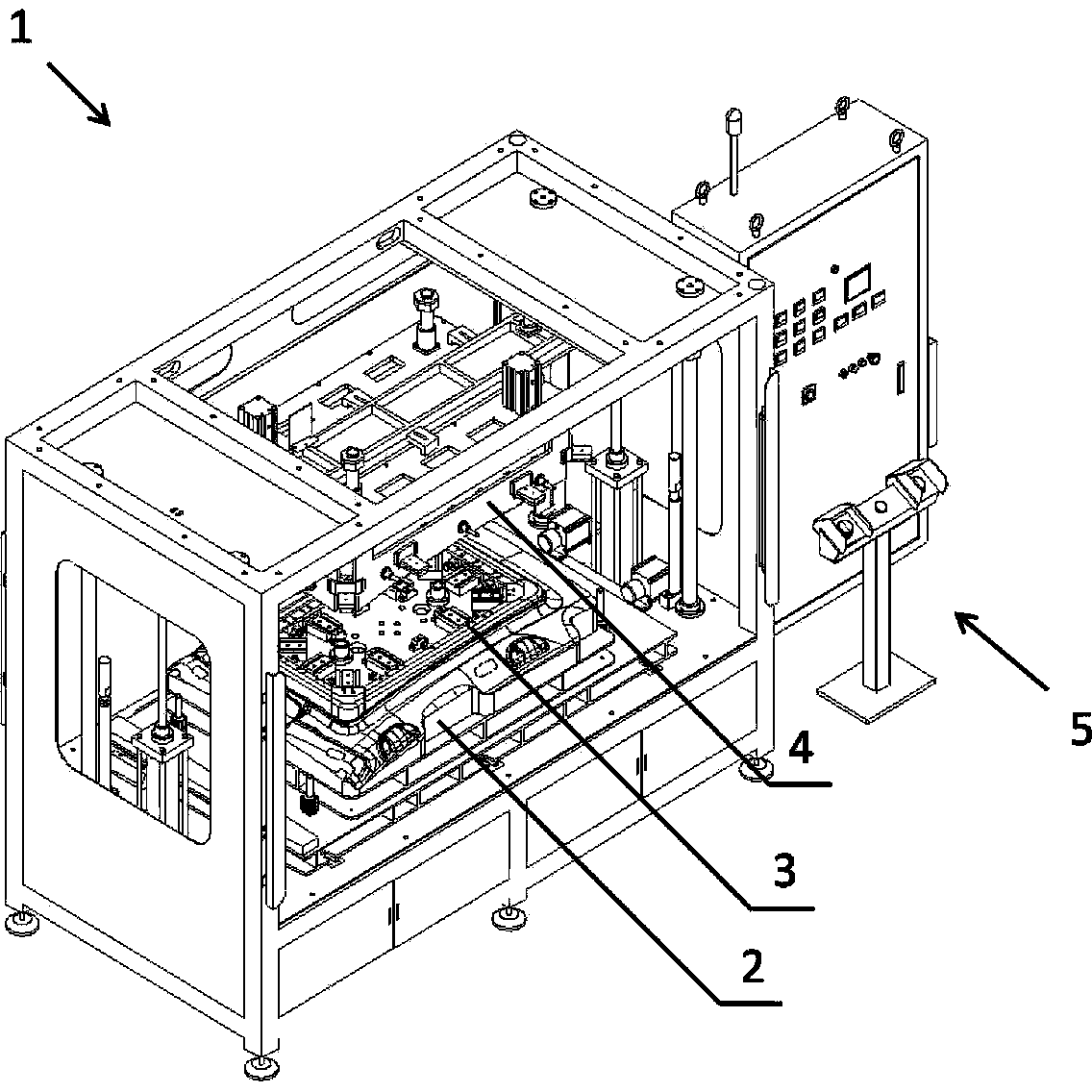

Hand-held automatic binding tool

ActiveCN104150006AImprove the efficiency of strapping operationsUniform tensionBinding material applicationBundling machine detailsHand heldEngineering

The invention provides a hand-held automatic binding tool which comprises a main machine, a gun head, a feeding pipe and a data line. The main machine is connected with the gun head through the feeding pipe and the data line. The hand-held automatic binding tool further comprises a vibrating plate and straight vibrator. The vibrating plate is located on the left side of the main machine. The straight vibrator is connected to the right side of the vibrating plate. The straight vibrator is connected with a pushing chamber. The vibrating plate screens and sorts bulk binding bands. When an optical fiber sensor detects that the front-most binding band is in position, an air cylinder pushes the front-most binding band into the feeding pipe, a trigger is pulled to allow compressed air to feed the binding band into the gun head, and the gun head completes winding, perforating, tightening and cutting off. The hand-held automatic binding tool has the advantages that binding efficiency is increased greatly, binding can be completed while hands are not in contact with the binding bands, labor intensity of workers is relieved greatly, the gun head is small in size and lightweight, and the gun head is connected with main machine through the flexible pipeline.

Owner:SHENZHEN SWIFT AUTOMATION TECH CO LTD

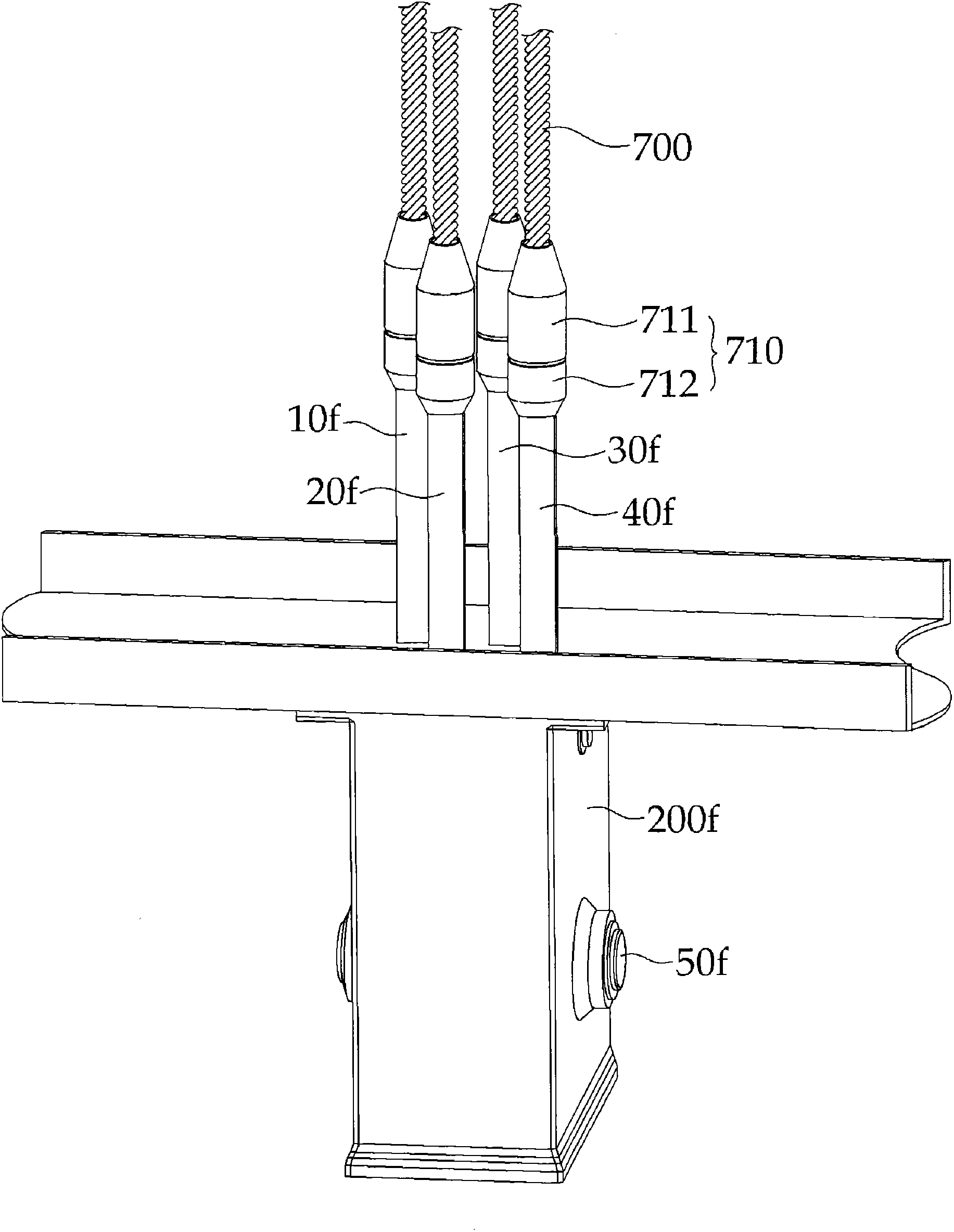

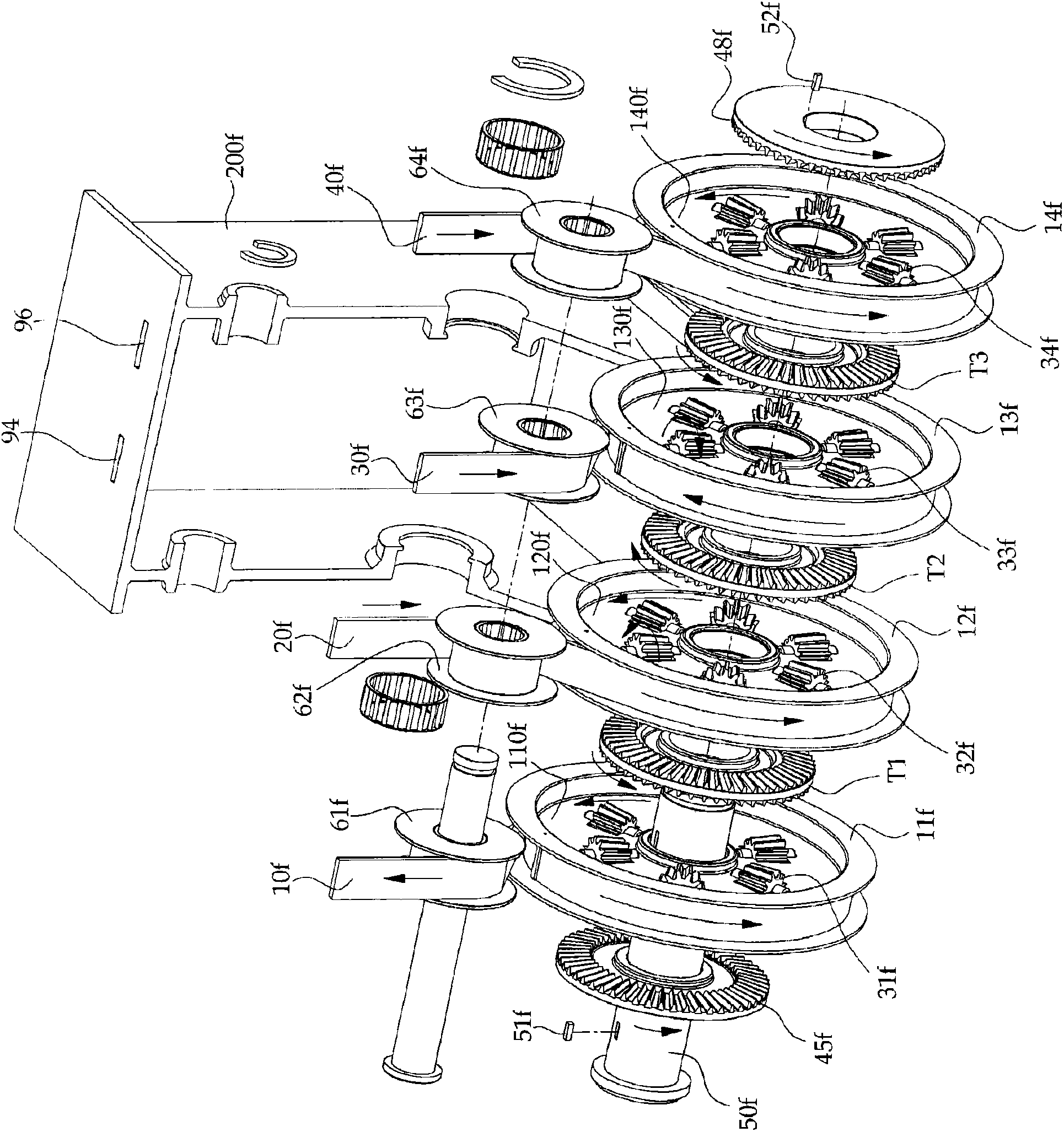

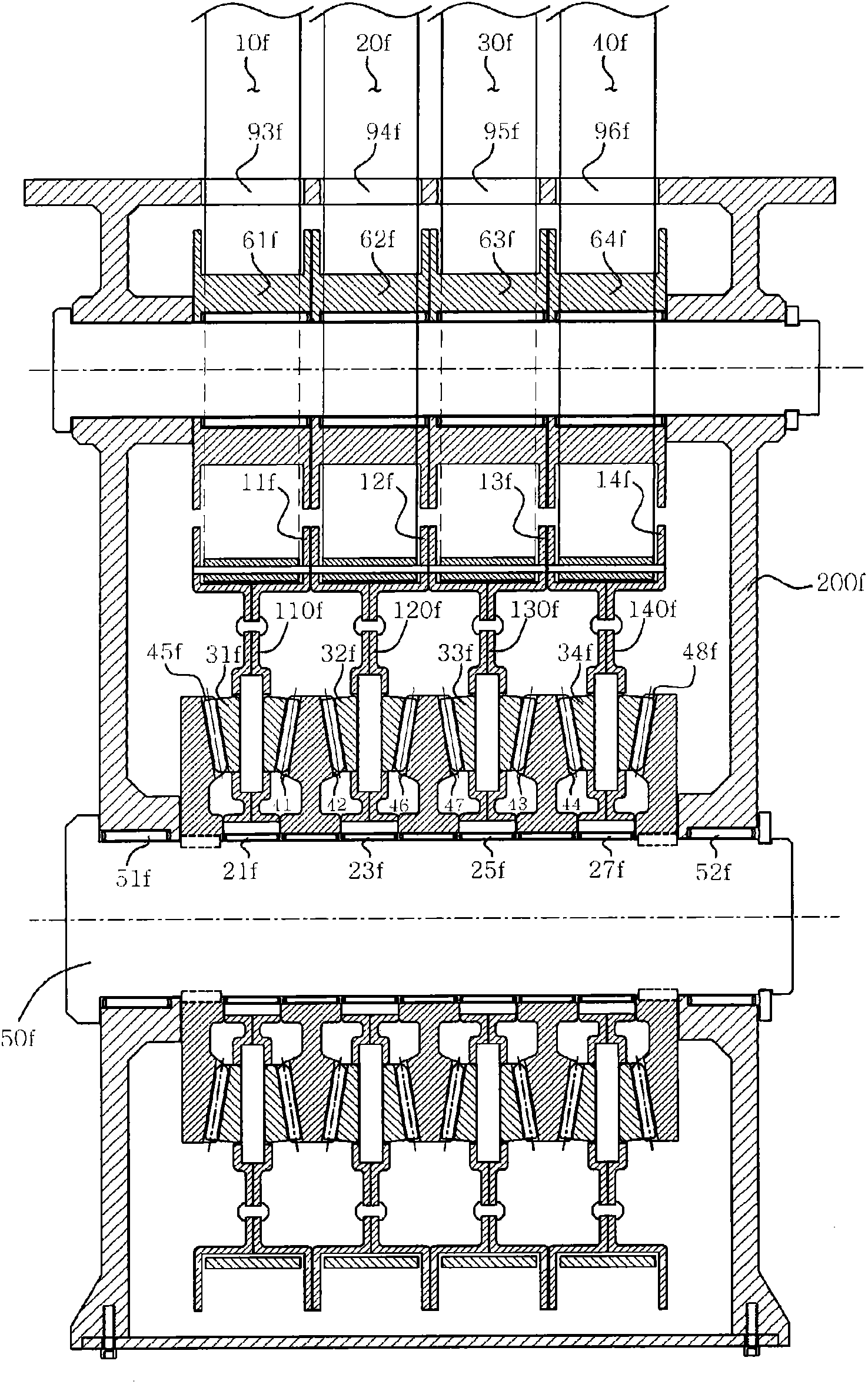

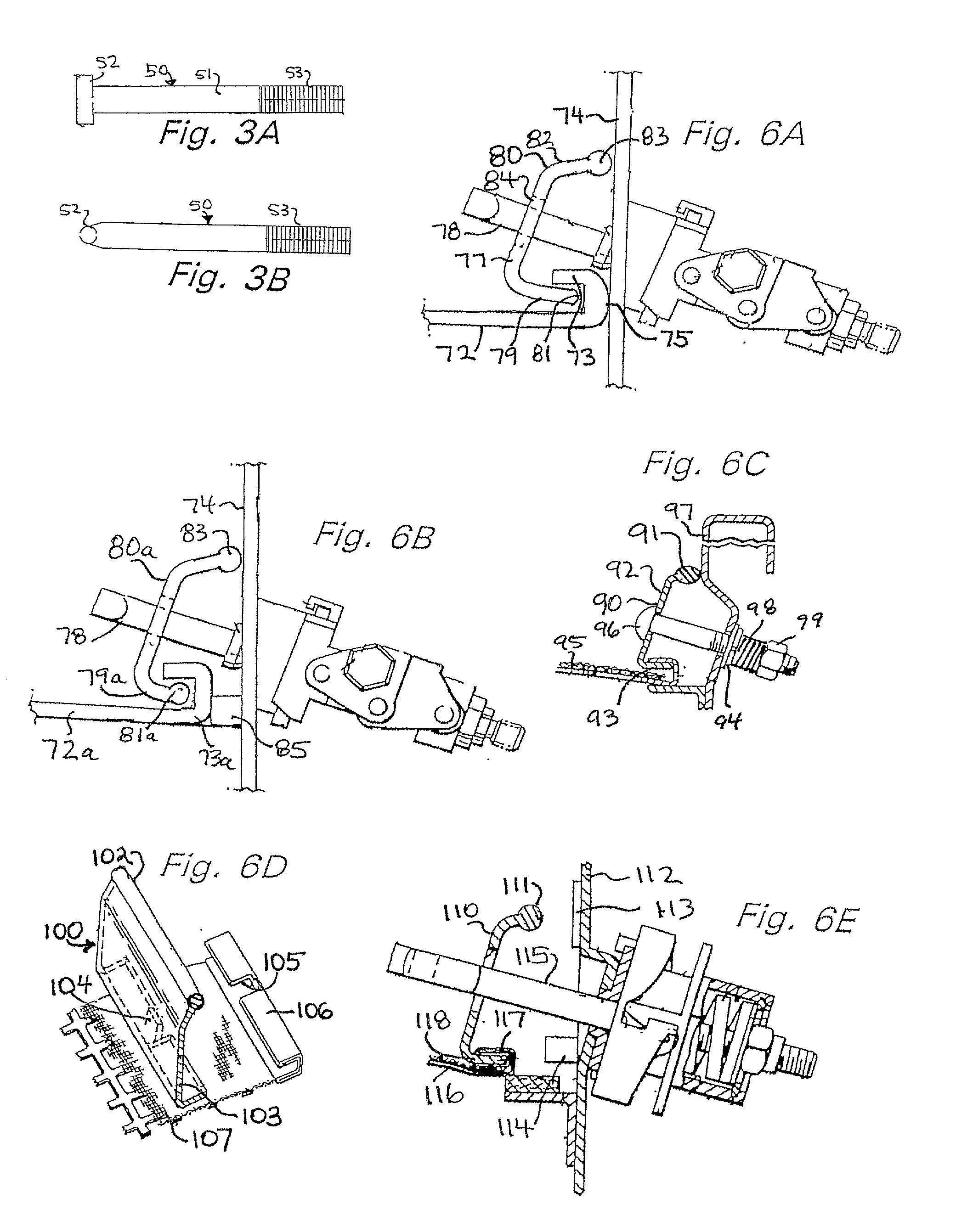

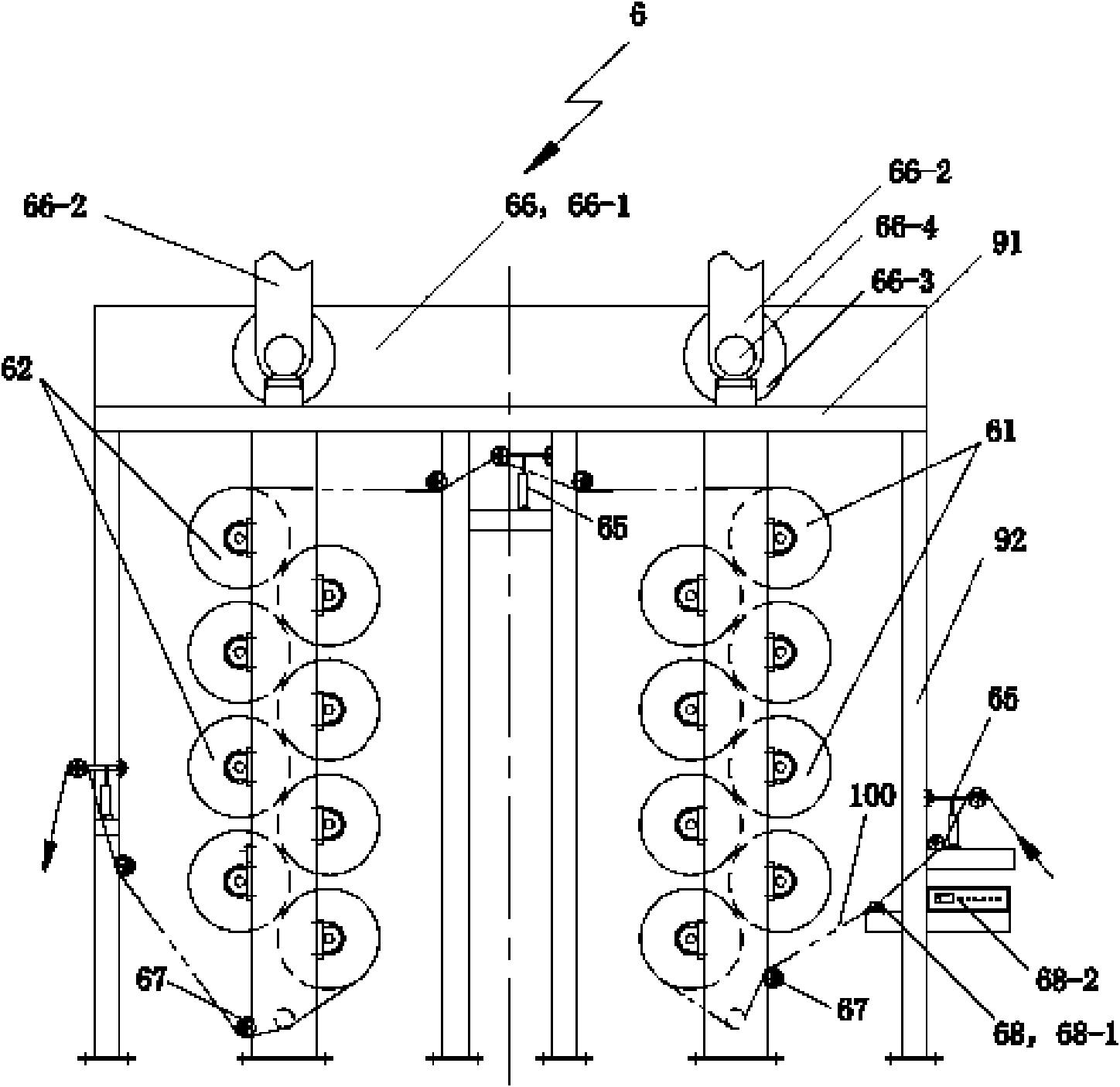

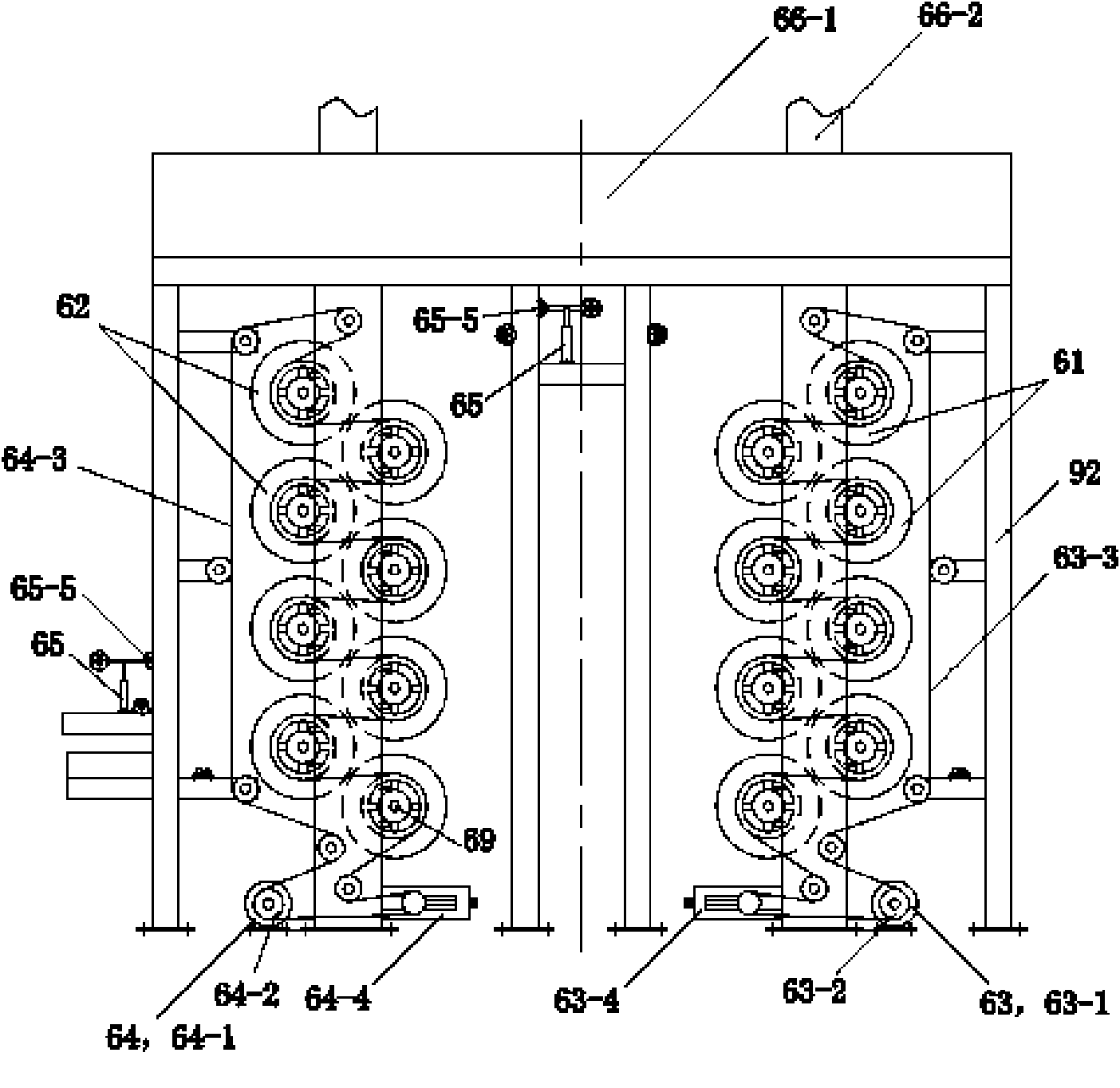

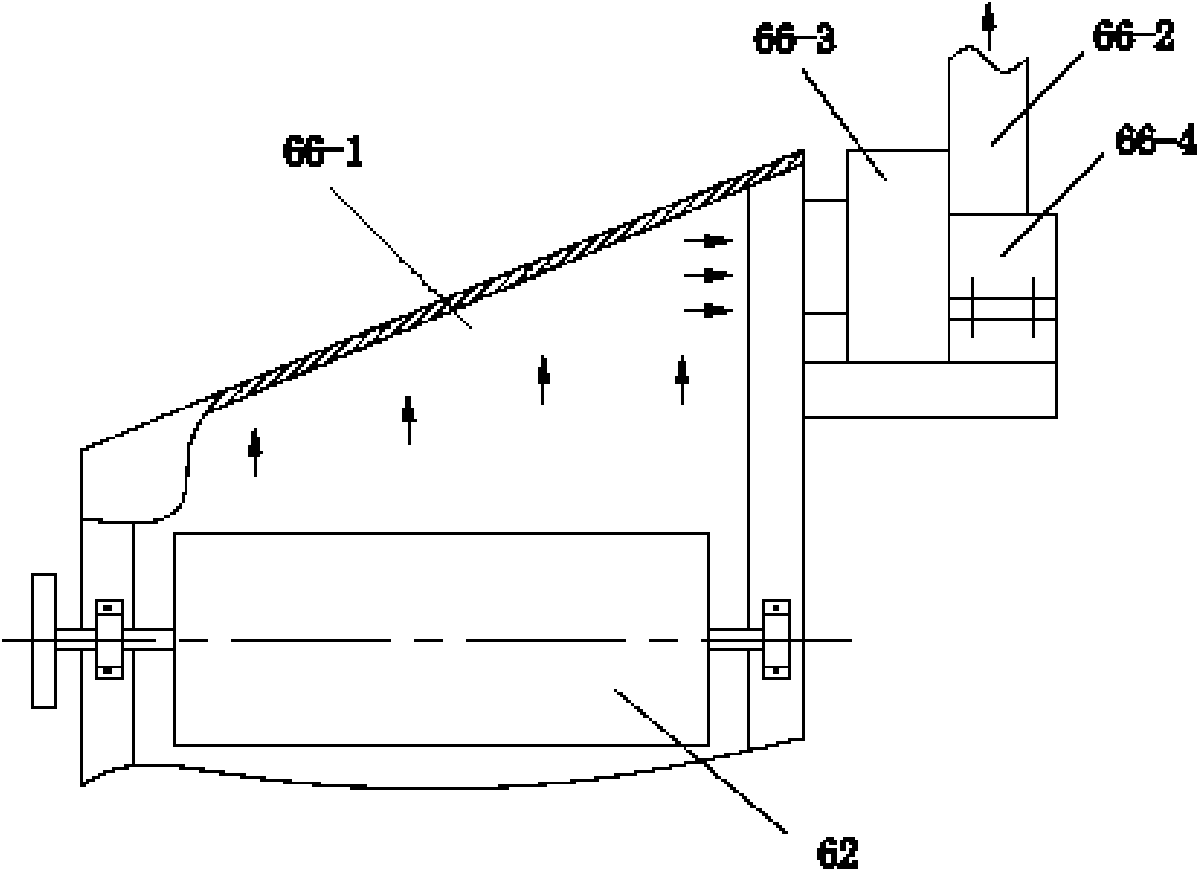

Apparatus for equalizing the tensions among elevator wire ropes

The present invention relates to an apparatus for equalizing tensions among elevator wire ropes, which immediately eliminates imbalance and equalizes the tensions among elevator wire ropes in the event of differences in the lengths of elevator wire ropes, to thereby improve safety, durability and reliability. The apparatus of the present invention automatically corrects imbalance caused by changes in the lengths of a plurality of elevator wire ropes (700) to maintain a balance in the tensions of elevator wire ropes, and comprises: a main body (200f), the interior of which has an accommodation space; tension adjustment means coupled to a plurality of belts (10f, 20f, 30f, 40f) connected to the elevator wire ropes (700), respectively, and arranged in the main body (200f); a main rotary shaft (50f) which penetrates through the tension adjustment means and which is rotatably coupled to the main body (200f); and first and second external gears (45f, 48f) which are fixed at the main rotary shaft (50f) such that the gears (45f, 48f) are rotatable, and which are coupled to the front and rear surfaces of the tension adjustment means to transmit rotating forces.

Owner:全秉寿

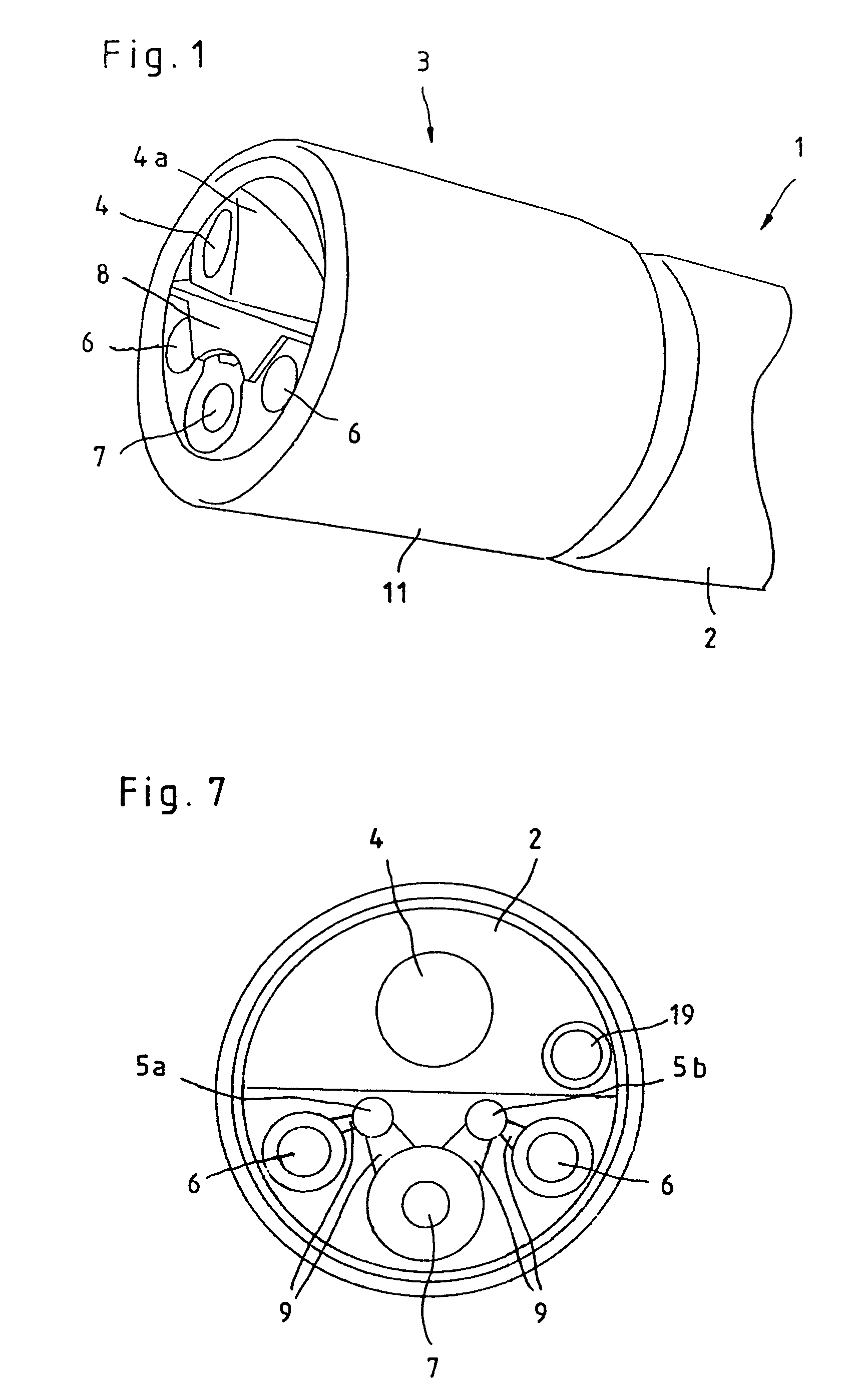

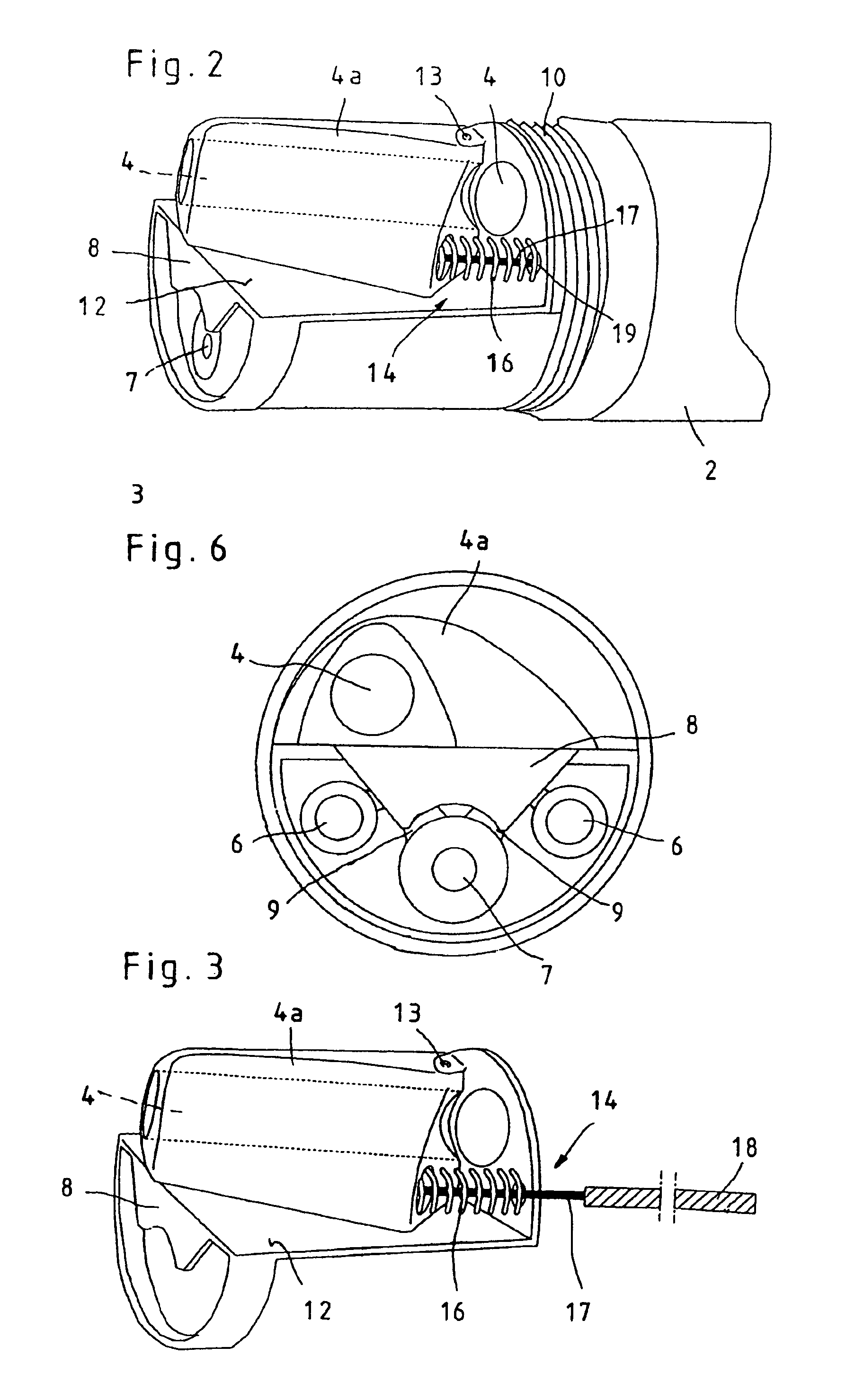

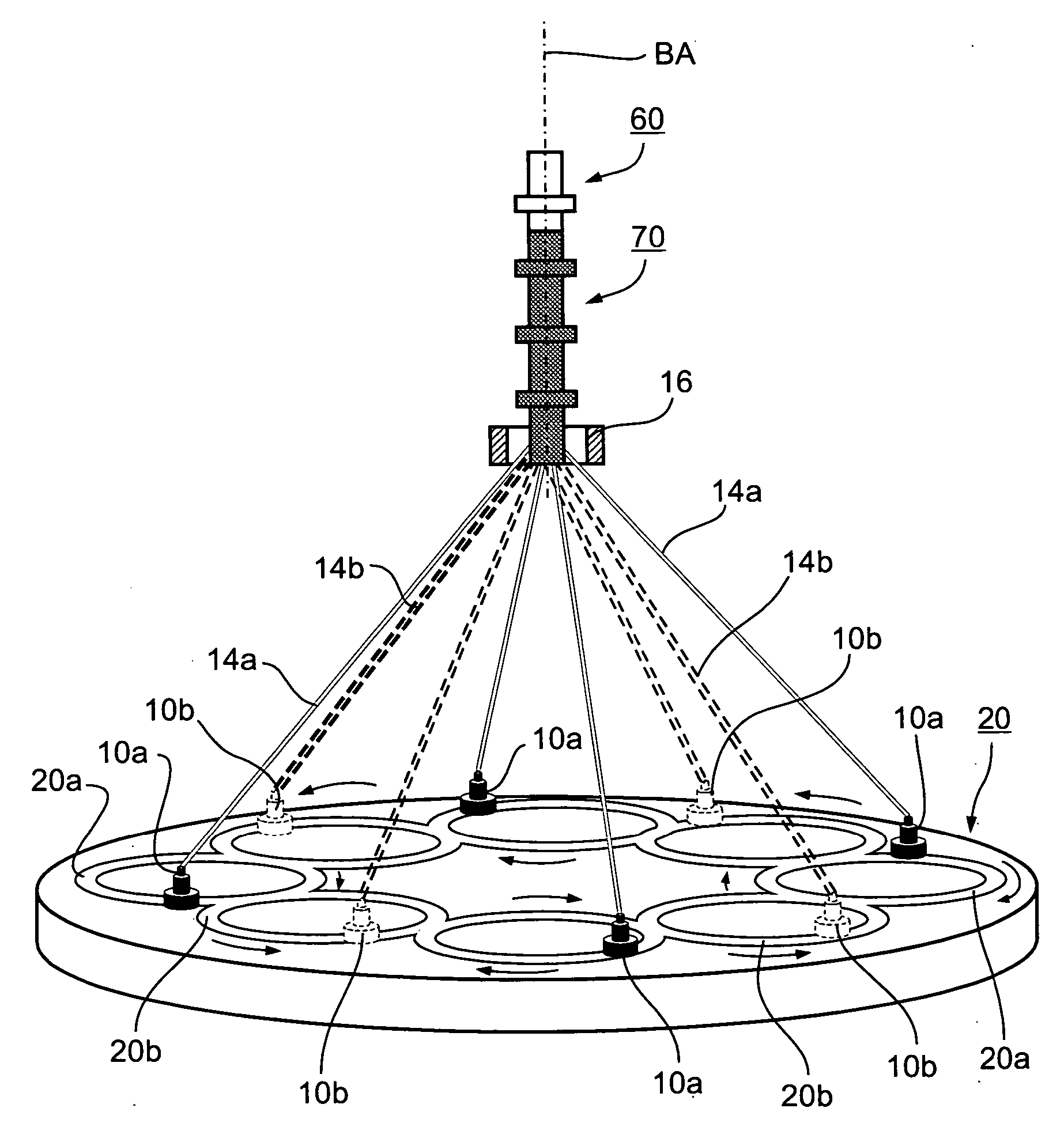

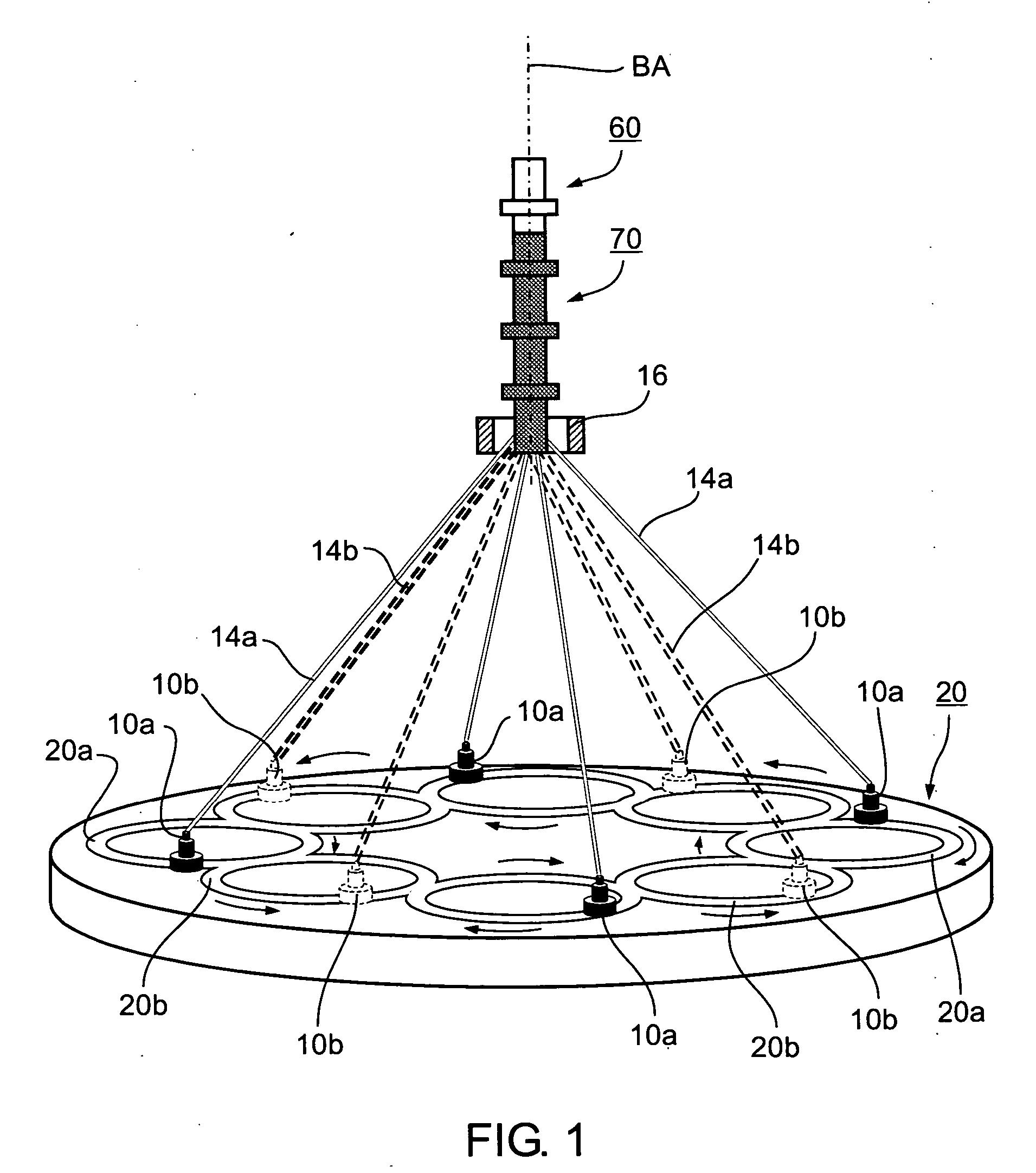

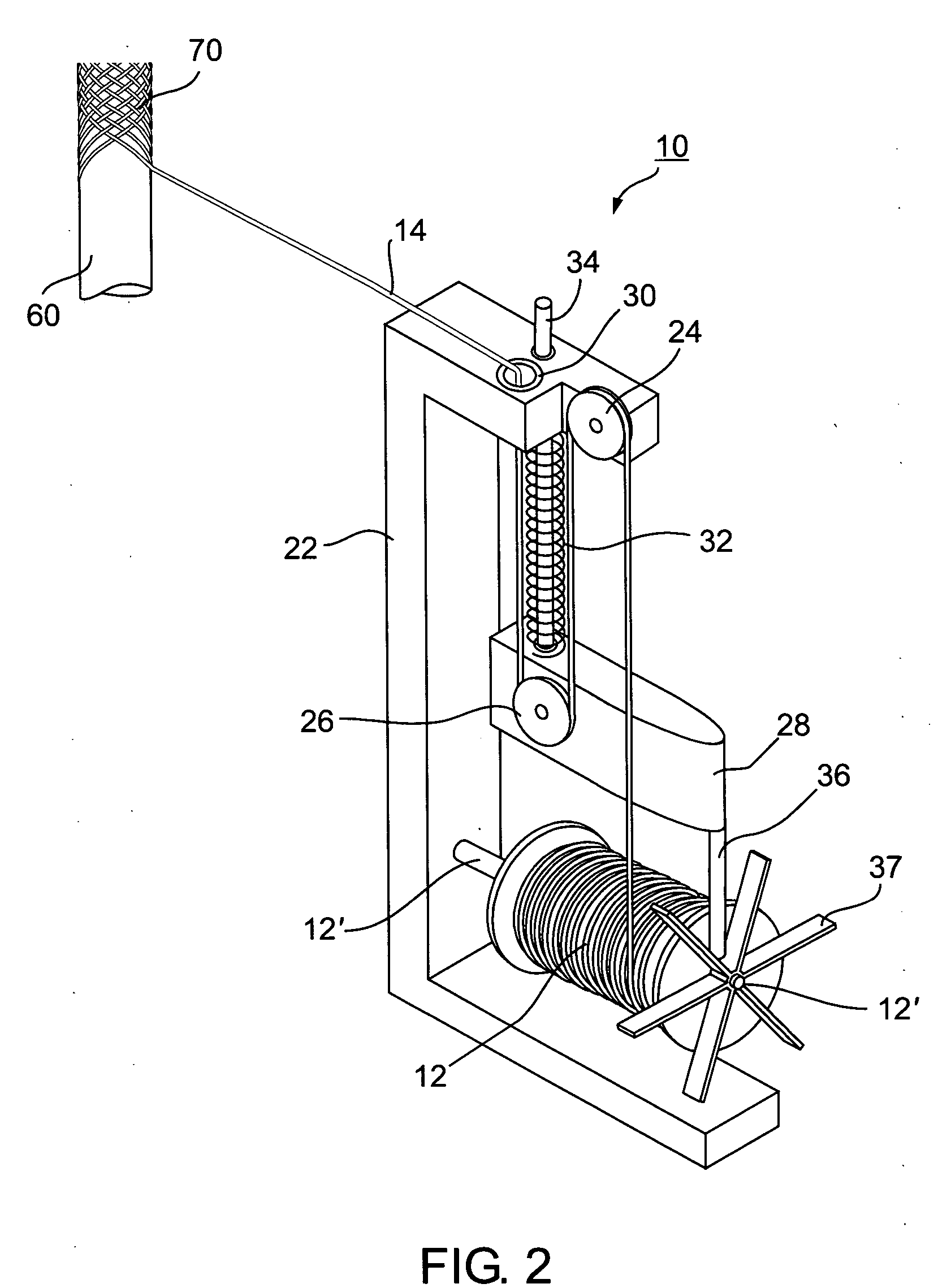

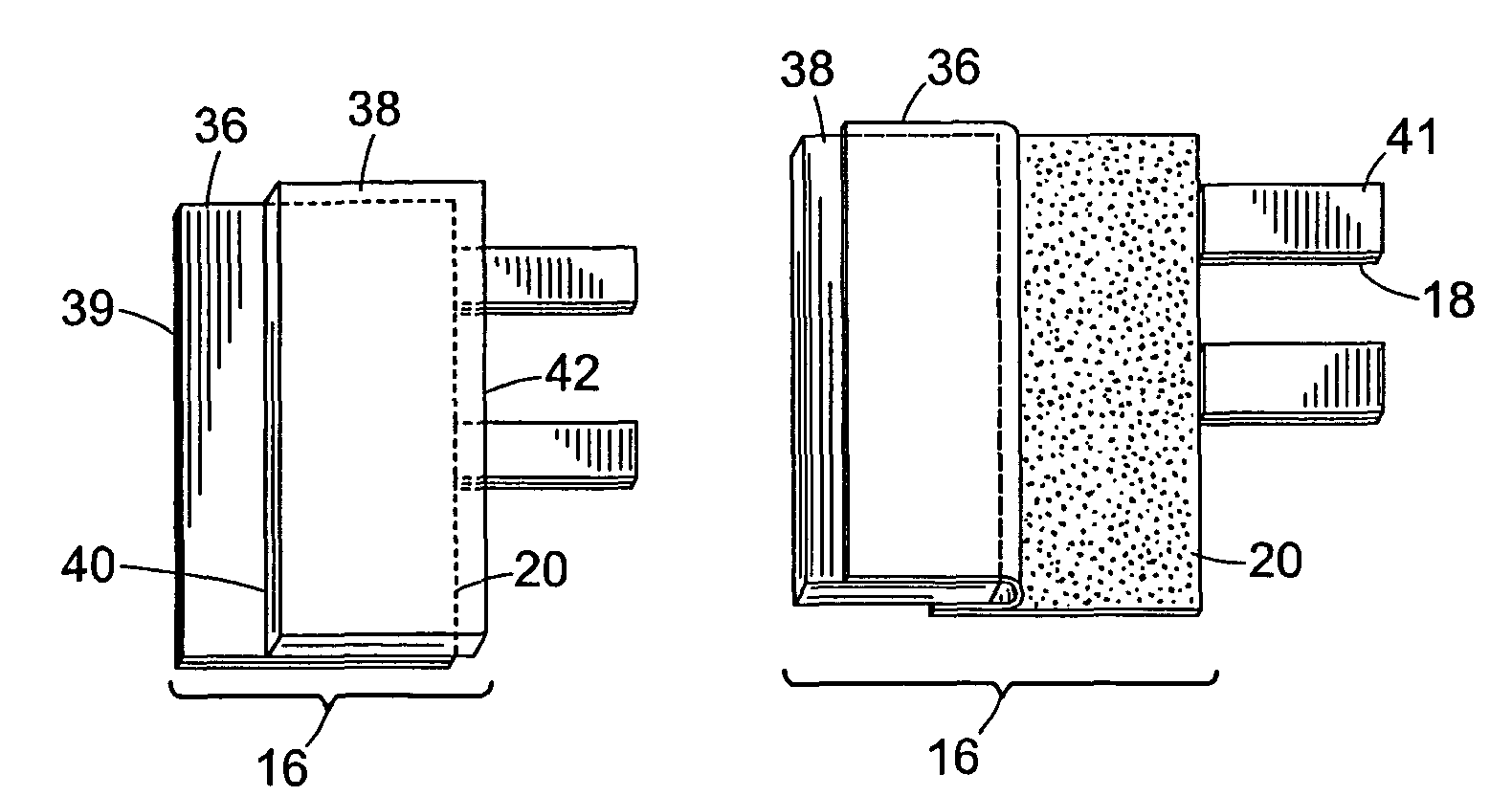

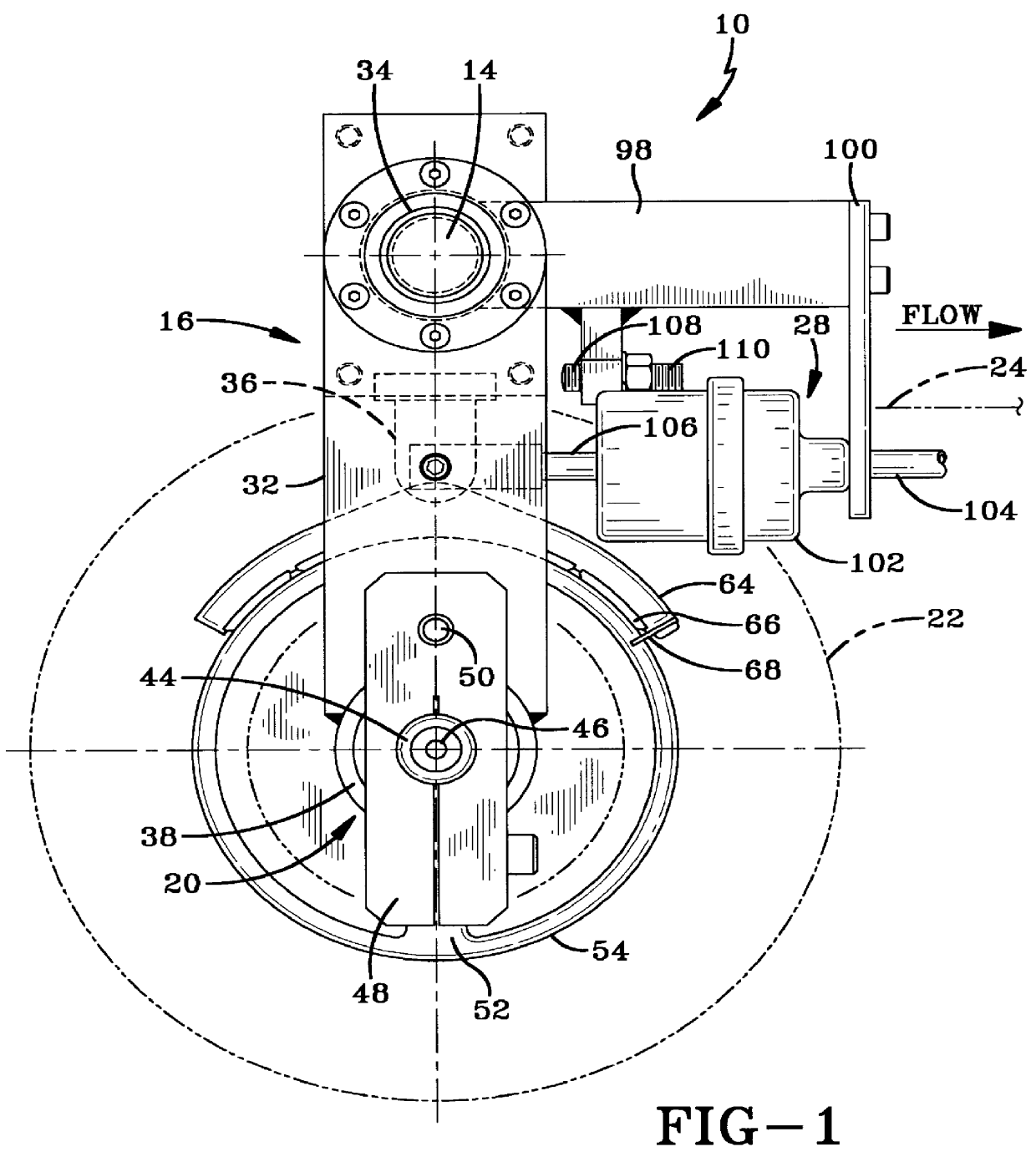

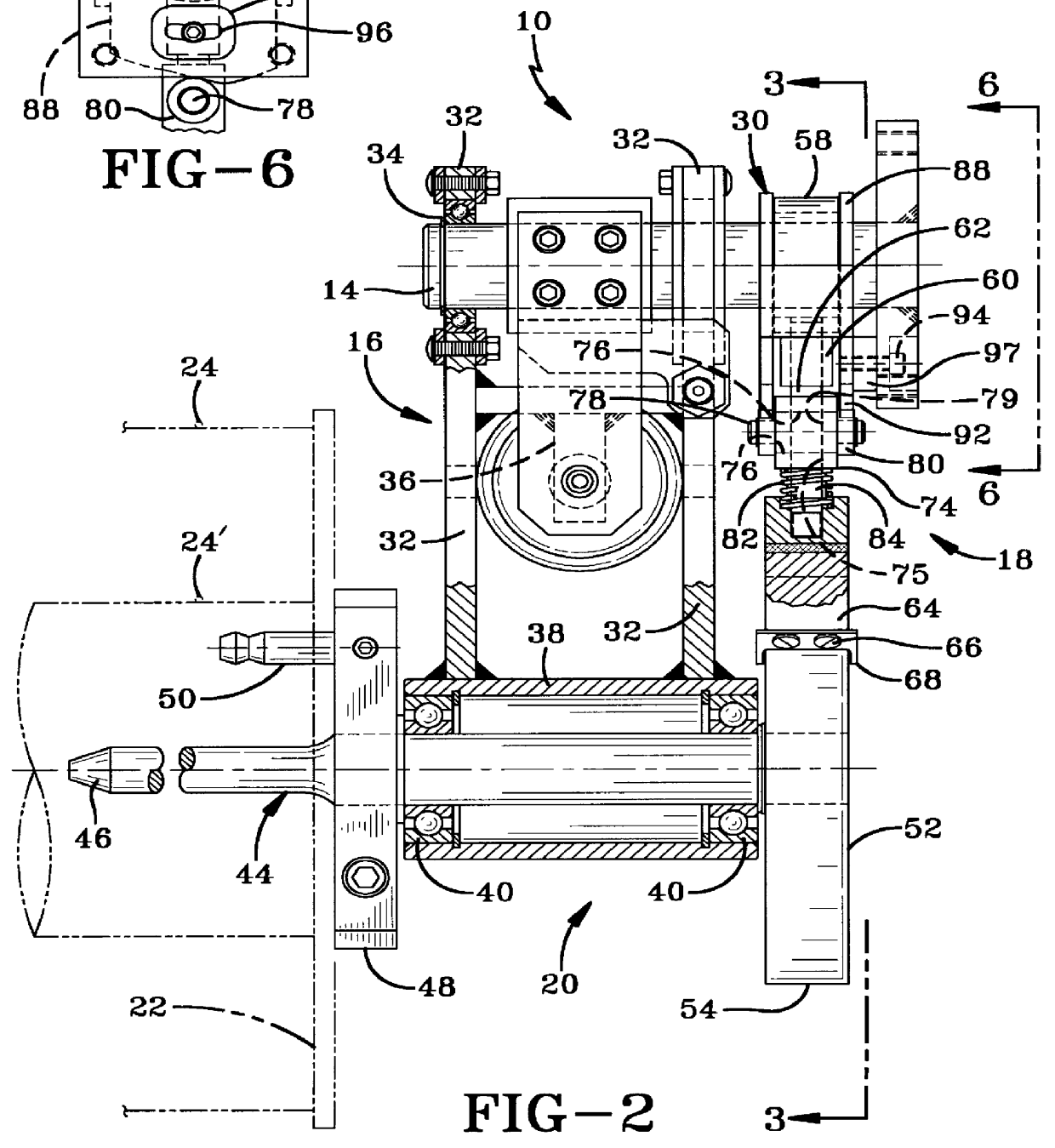

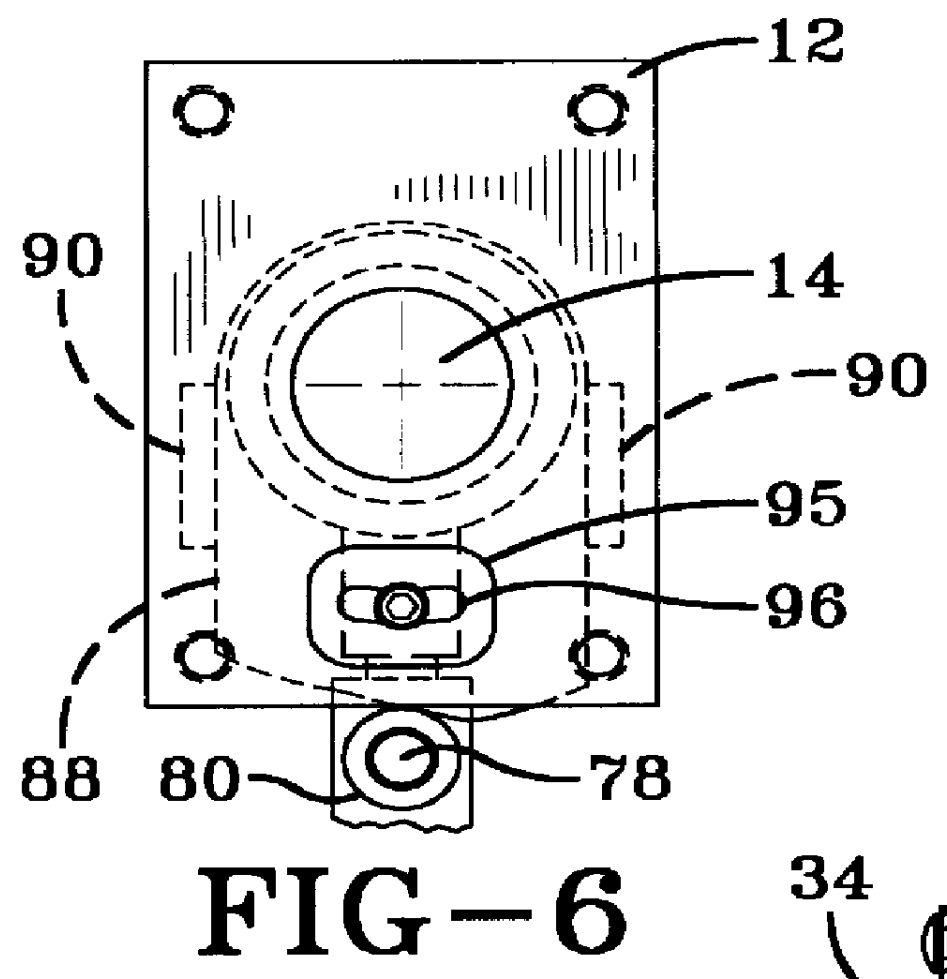

Self-compensating filament tension control device

InactiveUS6098910AEasy to adjustUniform tensionFilament handlingDrum brakesEngineeringTension control

A tension control device (10) for regulating the payout of filamentary material (24) from a spool (22) includes a fixed support (12, 14), a swing frame assembly (16) pivotably mounted on the fixed support and predisposed to a holding position, and a spindle assembly (20) carried by the swing frame assembly. The spindle assembly (20) carries the spool (22) and rotates with the spool as the filament is pulled off the spool. A braking assembly (18) is pivotably mounted on the fixed support (14) and is movable with the swing frame assembly (16). A cam (30) is fixably mounted on the fixed support and bears against the braking assembly (18) and forces the braking assembly to control the rotation of the spindle assembly. A pull-off force applied by filamentary material causes the swing frame assembly to move away from the holding position and allows rotation of the spindle assembly. A loading assembly fixably mounted on the fixed support positions the swing frame assembly and the braking assembly to a holding position that must be overcome by tension applied by the filament in order for the spool to begin rotation.

Owner:RJS

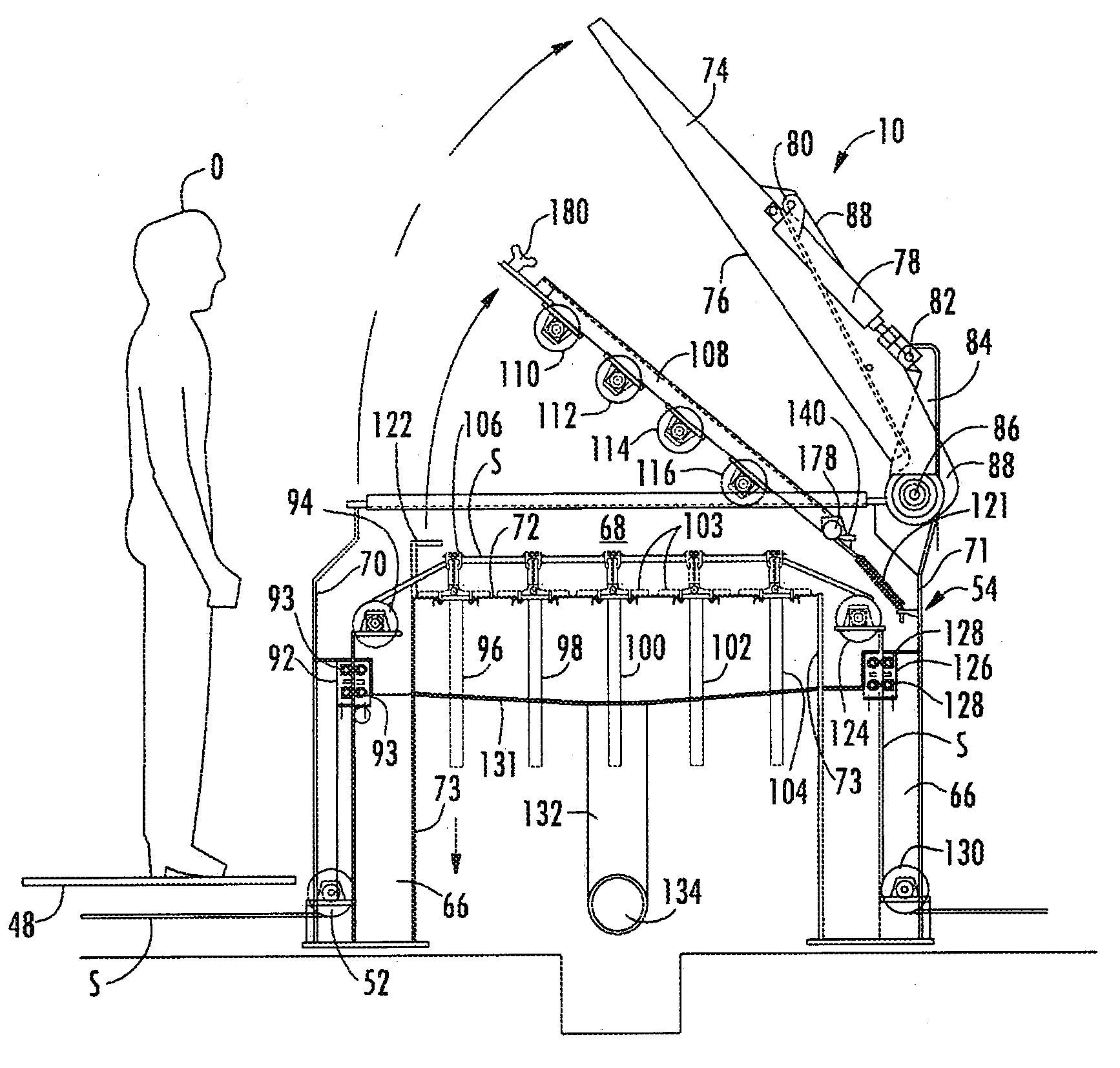

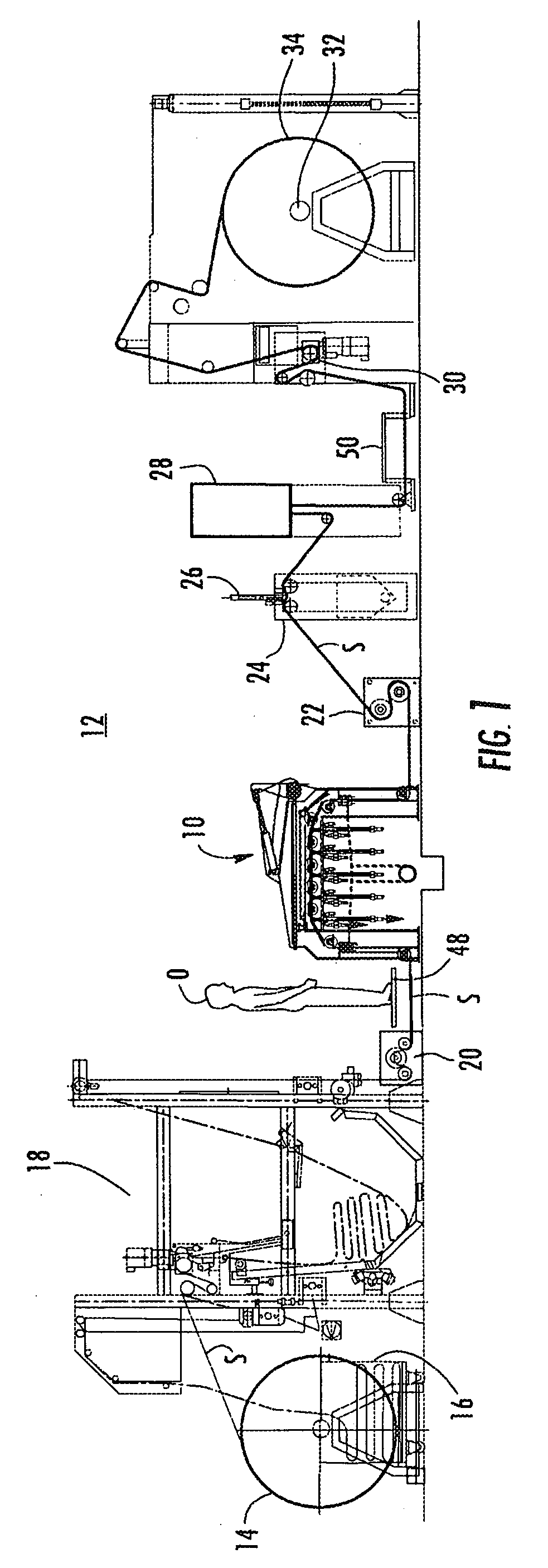

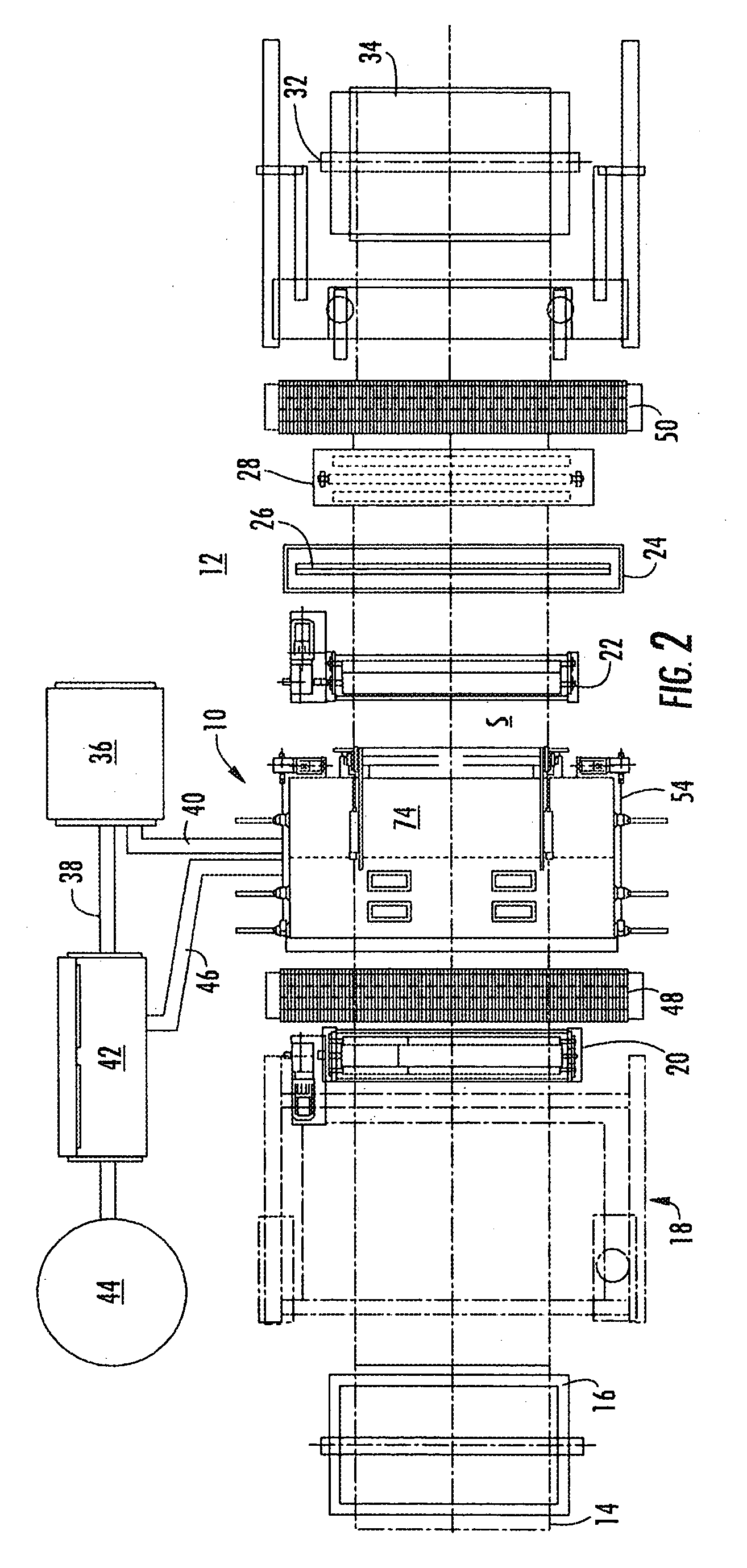

Drawbar and screen system

Owner:VARCO I P INC

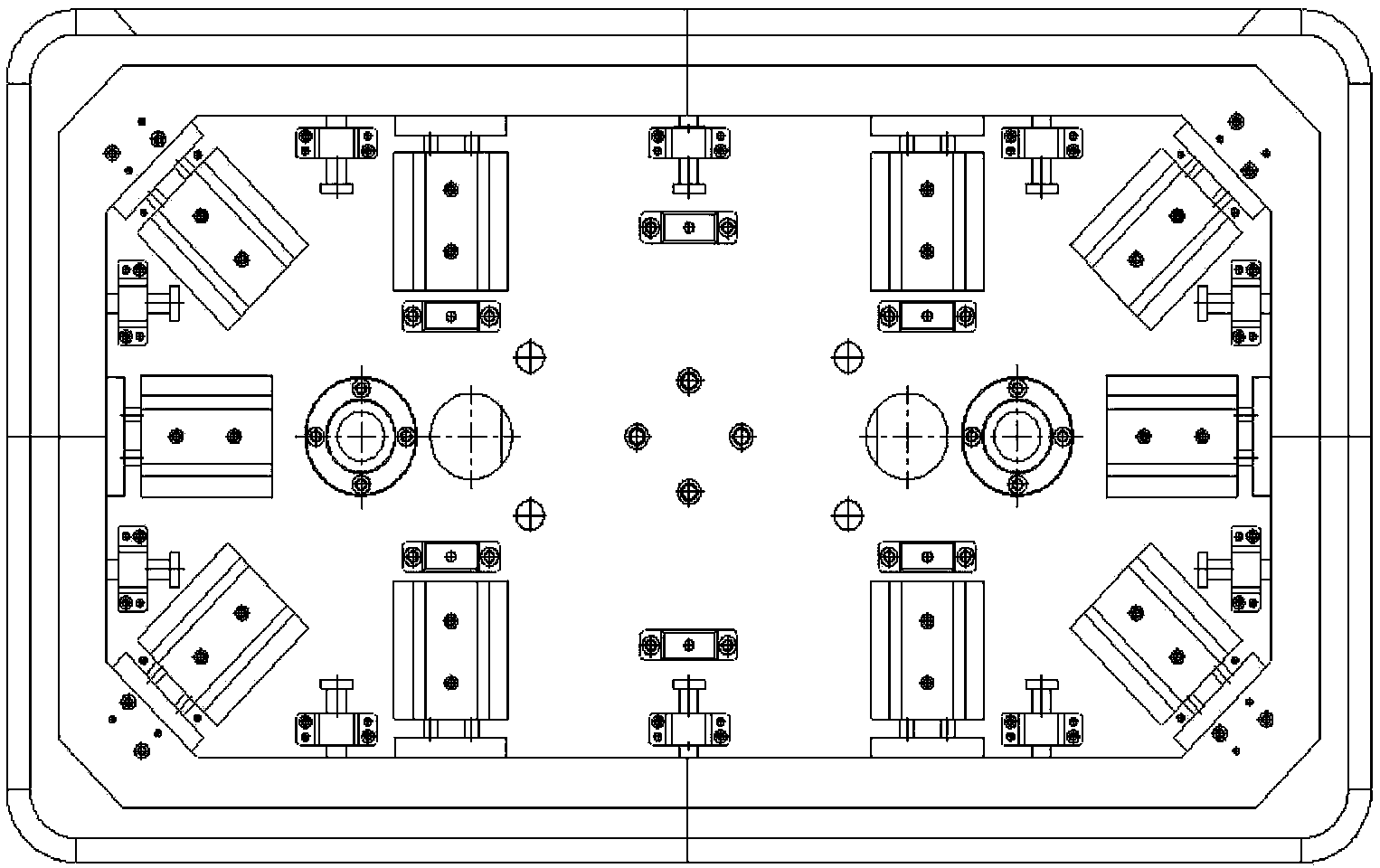

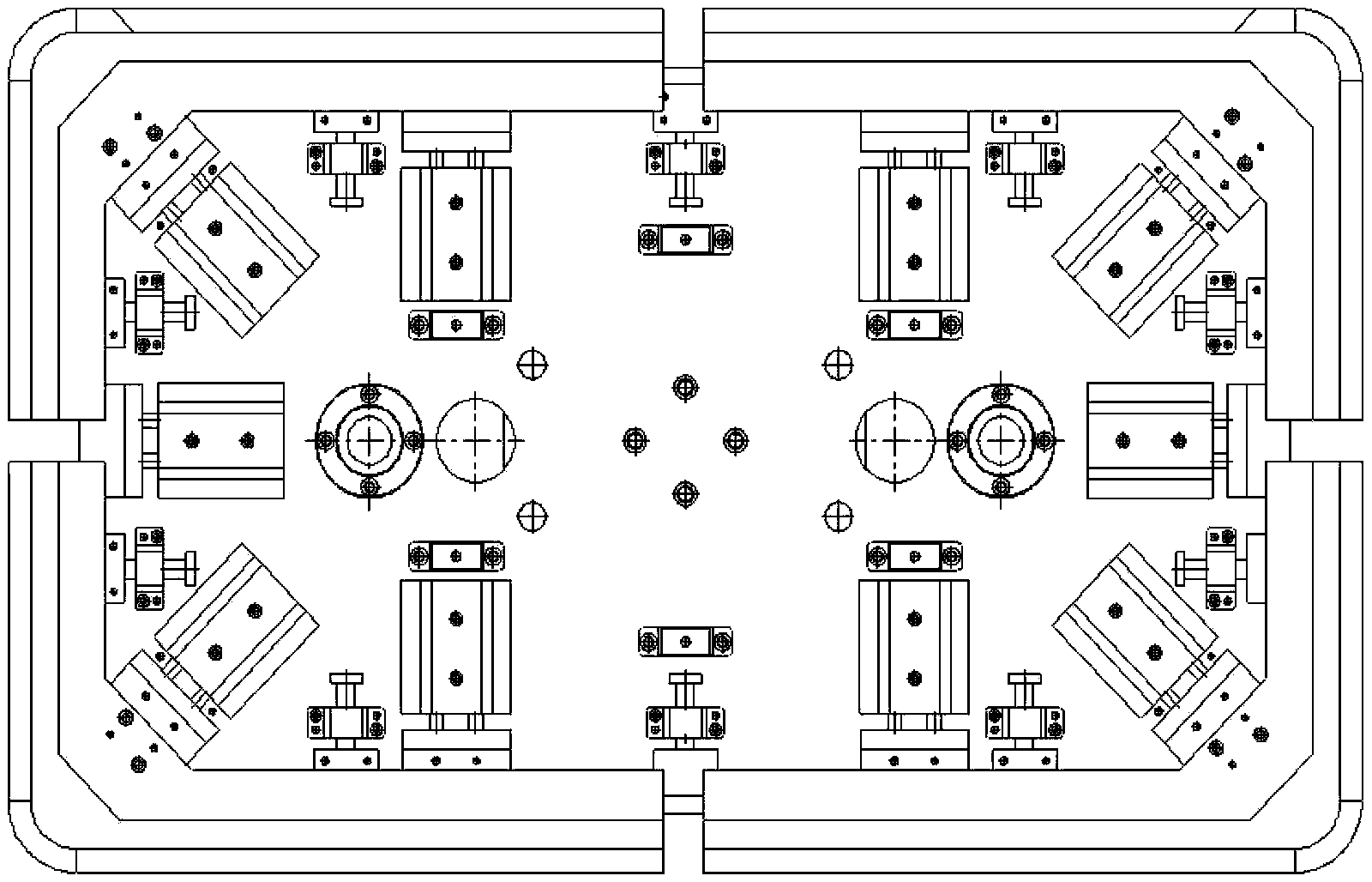

Turning device and edge covering equipment

ActiveCN104162976AGuaranteed aestheticsSolve wrinkleLaminationLamination apparatusMechanical engineeringSunroof

The invention relates to a turning device and edge covering equipment. The turning device is used for outwards turning a decorative fabric glued on the inner surface of the skylight opening part of a vehicle interior ceiling and gluing the decorative fabric to the outer surface of the skylight opening part. The turning device comprises a frame mechanism and a control mechanism, wherein the size of the frame mechanism corresponds to that of the skylight opening part; the control mechanism controls the frame mechanism to operate; the frame mechanism comprises four corner turning blocks and four edge turning blocks, the corner turning blocks are matched with shapes of corners of the skylight opening part, the edge turning blocks are matched with shapes of edges of skylight opening part, and the corner turning blocks and the edge turning blocks are contacted through inclined surfaces. During turning, the corner turning blocks and the edge turning blocks can turn the fabrics at the corners and the fabrics on the edges respectively, so that the problem of wrinkling after the fabrics at the corners are turned is solved, and the integral attractiveness of a finished product of the interior ceiling can be kept.

Owner:CENMOY AUTOMATION TECH SHANGHAI CO LTD

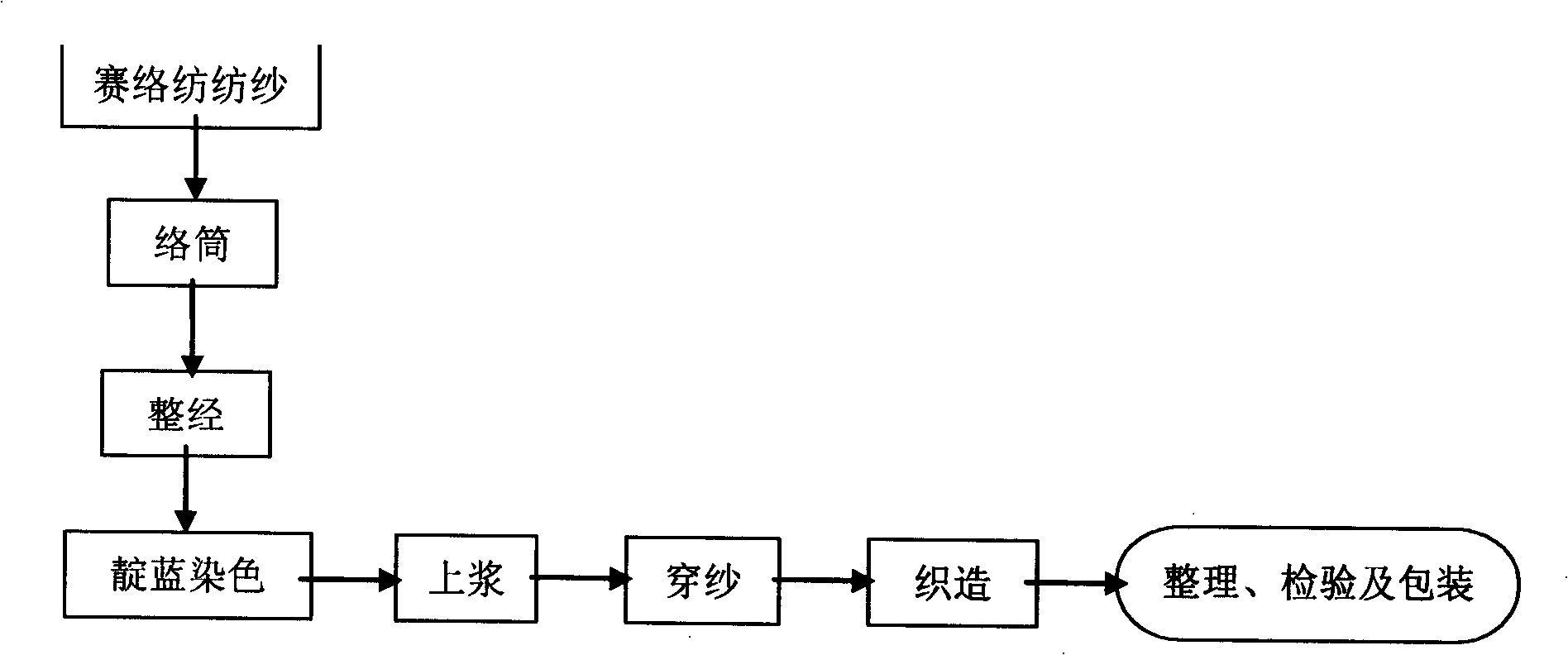

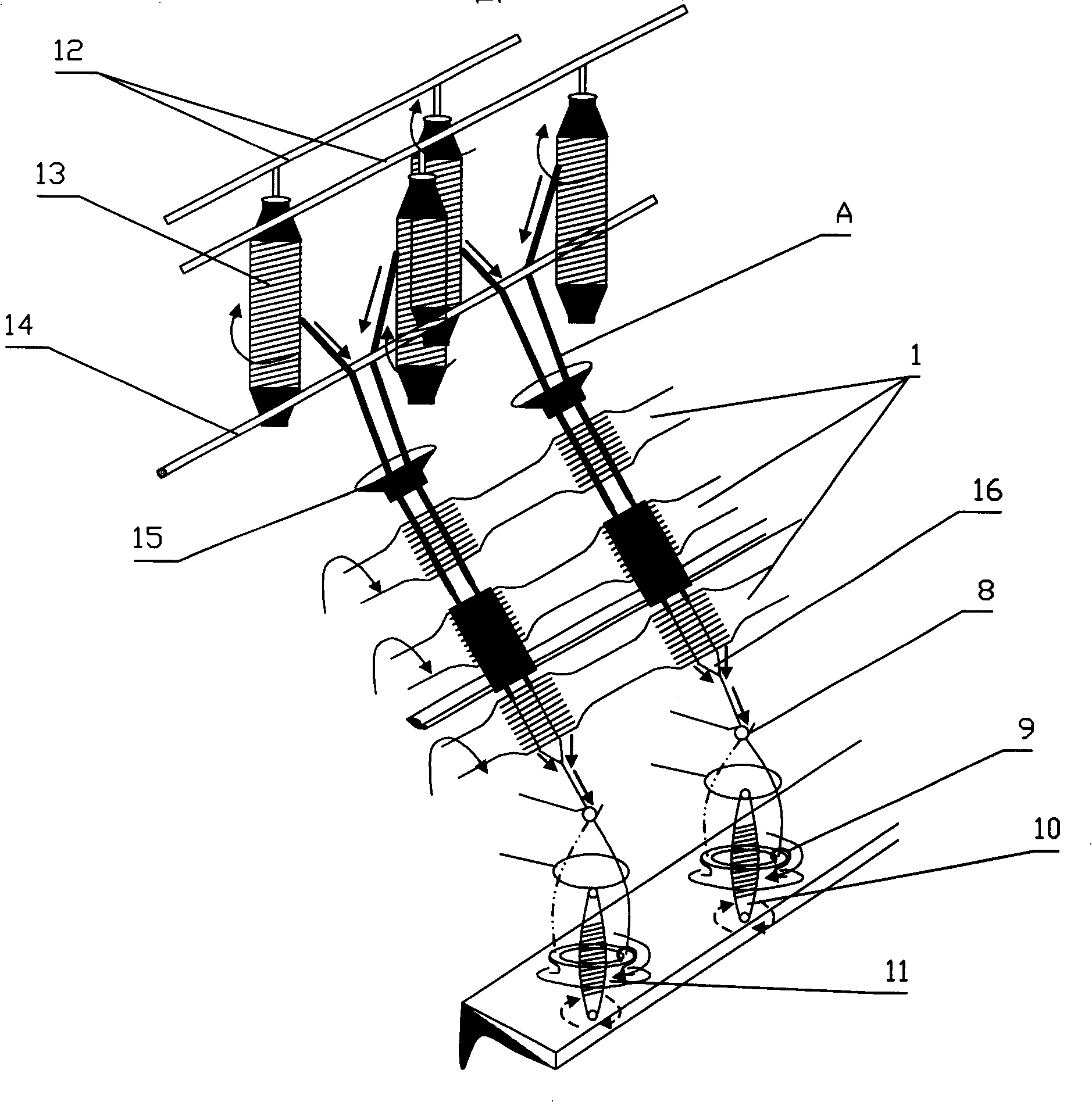

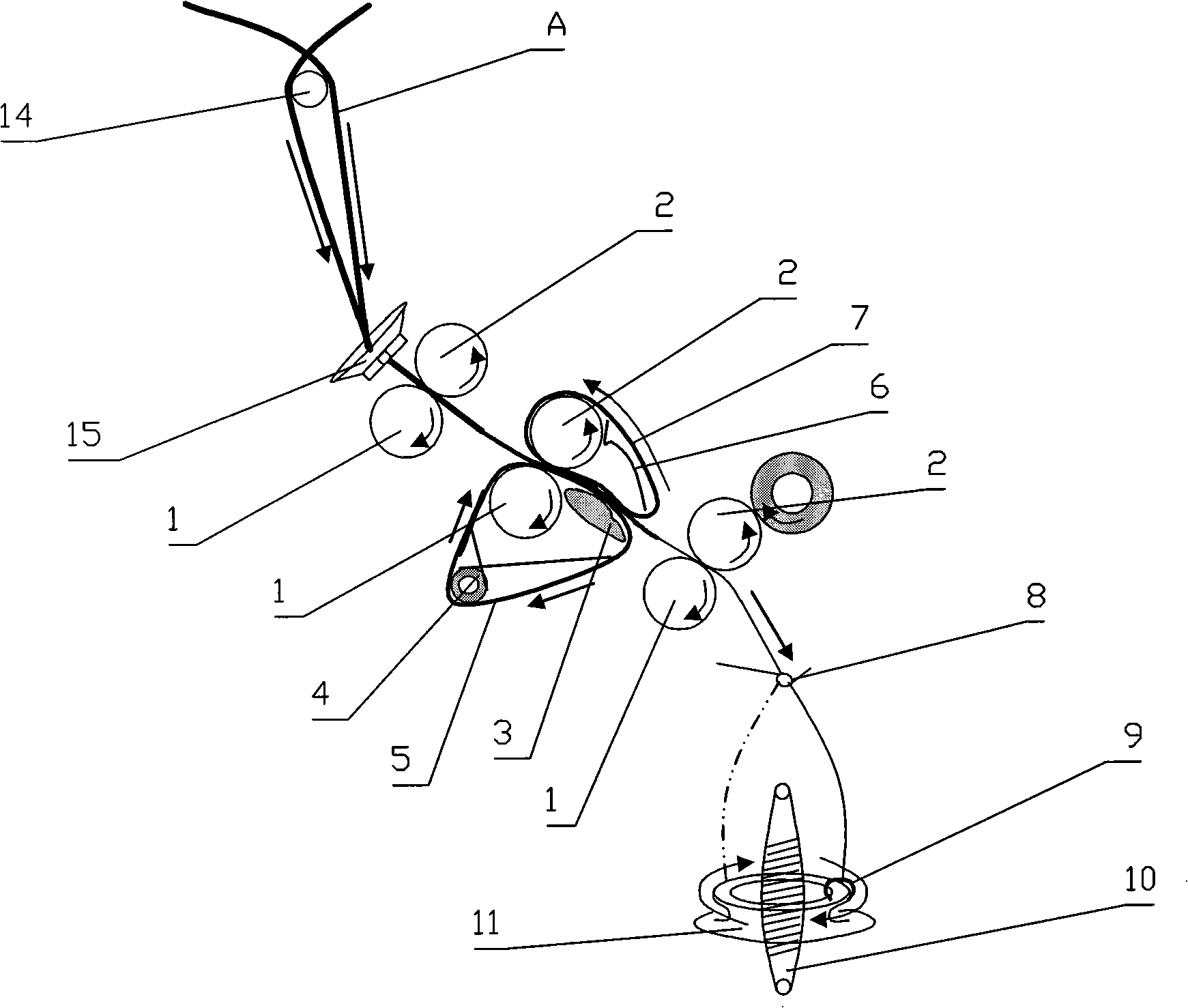

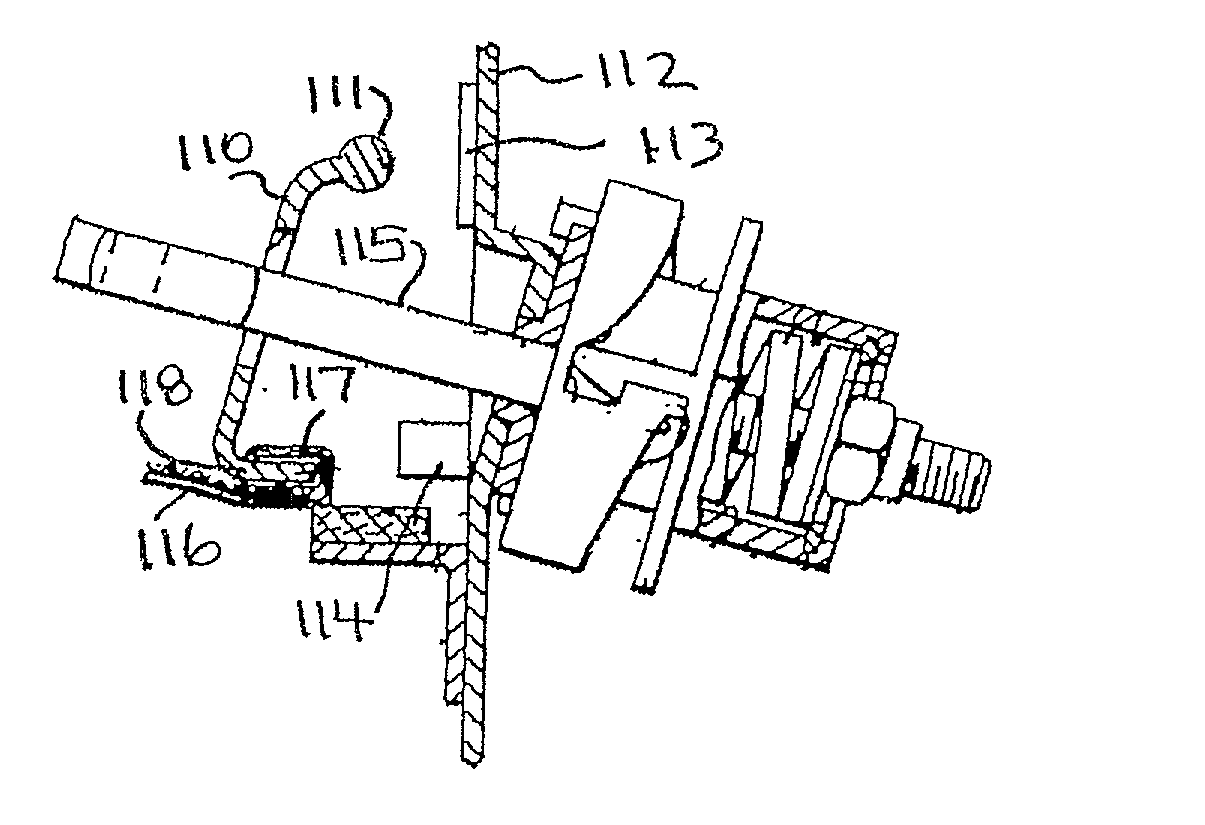

Process for manufacturing sirospun yarn jean facing material

The invention discloses a manufacture technique of a siro yarn jean fabric, in which, firstly an advanced siro yarn spinning technology is adopted to manufacture the siro yarn; the spun siro yarn is wound; then the wound siro yarn which is used as a warp is warped, dyed and starched be manufactured into a beam; then the siro yarn is used as the warp and the siro yarn, a rotor spun yarn or a ring yarn are used as an abb to be woven on a loom according to the fabric weave and the weaving technique of the jean to manufacture a grey fabric and finally the grey fabric is made into a finished product through subsequent finishing. As the siro yarn with better quality is adopted as the warp, the method has the advantages of easy yarn splitting, few broken ends, uniform colorizing, reducible sizing quality requirement as well as high heddle draft and reeding efficiency during the dyeing process, clear cut, uniform tension, few broken ends and stopping, few fly wastes in a workshop and on a machine station as well as being beneficial to the cleanness of the workshop and the maintenance of the machine station when weaving.

Owner:佛山市致兴纺织服装有限公司

Drawbar and screen system

A clamp system for releasably securing a screen to a vibratory separator apparatus, and methods of its use, and a plate for such a system, the clamp system having, in certain aspects, a plate for contacting a screen end of a screen to be mounted to a vibratory separator apparatus, the plate having a plate linear dimension and the screen end having a screen linear dimension, the plate having a plate body, a bolt with a first end extendable through the plate and a second end extendable through part of the vibratory separator apparatus, the bolt tightenable in place to hold the plate in position with respect to the screen and the vibratory separator apparatus, and the plate linear dimension substantially equal to the screen end linear dimension.

Owner:VARCO I P INC

Elevator weighing device

The invention relates to an elevator weighing device which comprises a rope hitch plate and a middle supporting plate. A plurality of rubber drums which are distributed side by side are arranged between the rope hitch plate and the middle supporting plate, a plurality of rope hitch springs corresponding to the rubber drums are arranged at the upper end of the middle supporting plate, an eddy current sensor, an overload detector switch, a rope loosening detector switch support and a rope loosening detector switch are arranged on the rope hitch plate, and an eddy current sensor magnetism blocking plate, an overload detector switch touch plate and a rope loosening detector switch touch plate are installed on the middle supporting plate. The elevator weighing device further comprises a plurality of rope hitch pull rods corresponding to the rubber drums and the rope hitch springs, the rope hitch pull rods sequentially penetrate through through holes of the rope hitch plate, the rubber drums, the middle supporting plate and the rope pitch springs, one end of each rope hitch pull rod is provided with a loosening-fastening nut for fixing the corresponding rope hitch spring, and the other end of each rope hitch pull rod is connected with the corresponding elevator lifting car lateral hauling rope through a connecting assembly. The elevator weighing device is simple in structure, high in lifting car weighing detection accuracy, low in cost, capable of saving shaft space, convenient to install, debug and operate and high in safety performance.

Owner:HITACHI ELEVATOR CHINA

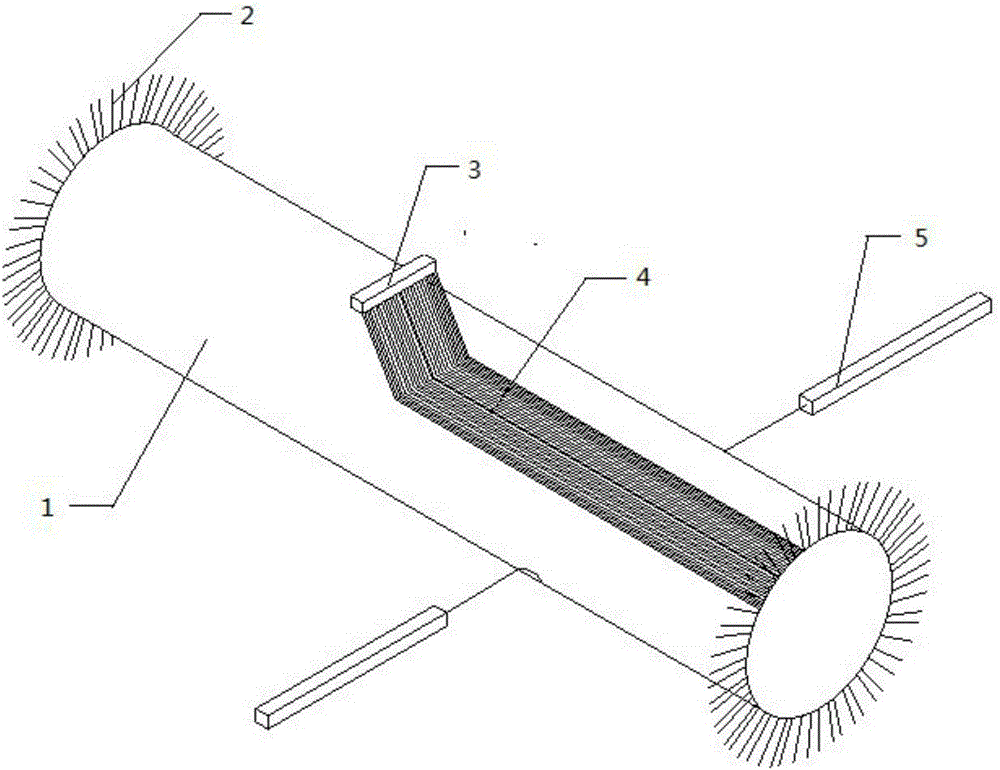

Manufacturing method for glass steel pipeline in zero-degree winding manner

The invention discloses a manufacturing method for a glass steel pipeline in a zero-degree winding manner. The method sequentially comprises the steps that winding yarn immersed in resin is used for hoop winding, then, a wire guiding head drives the winding yarn to pass multi-tooth comb rings buckled at the two ends of a core die to be axially wound, finally, winding yarn immersed in resin is in hoop winding again to stabilize an axial winding layer, hoop and axial winding is repeated, and pipeline winding with different strength requirements is achieved. Continuous winding of the axial zero degree of the winding yarn and pipelines is achieved, the axial mechanical performance of the pipelines is optimal, and then the high requirement of industrial fields for the axial performance can be met. The required axial strength is achieved, the production cost is reduced to the maximum degree, meanwhile, the pipeline thickness is reduced, and the pipelines are convenient to transport and use.

Owner:HEBEI HAOZHENG NON METALLIC MATERIALS TESTING SERVICES CO LTD

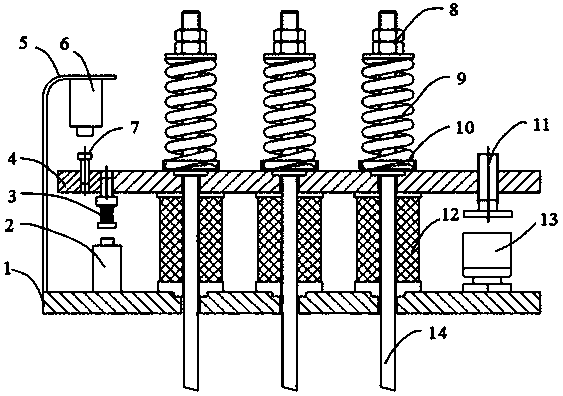

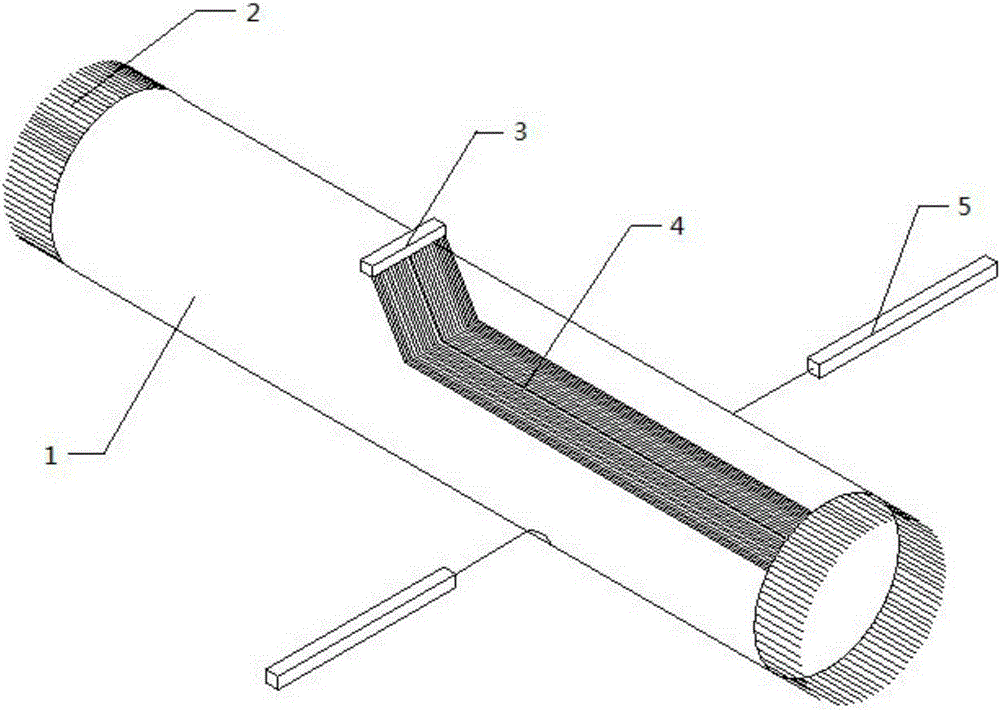

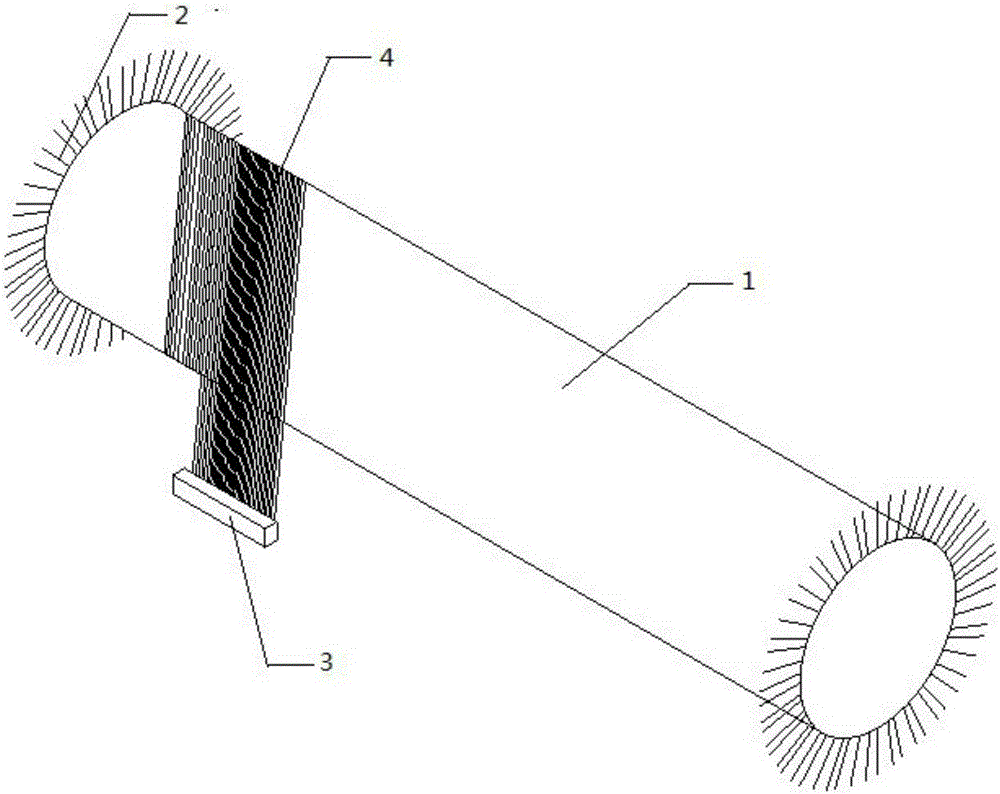

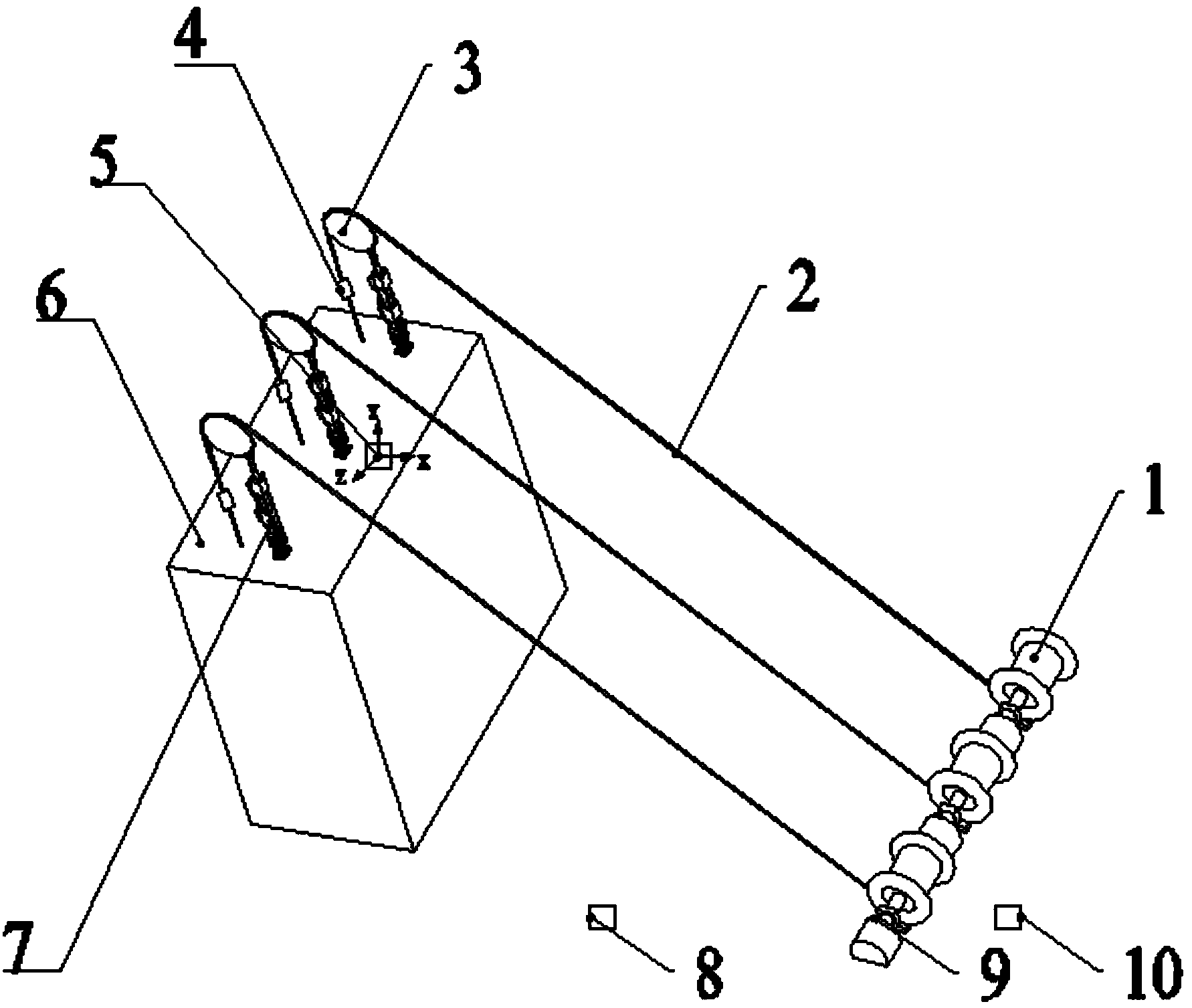

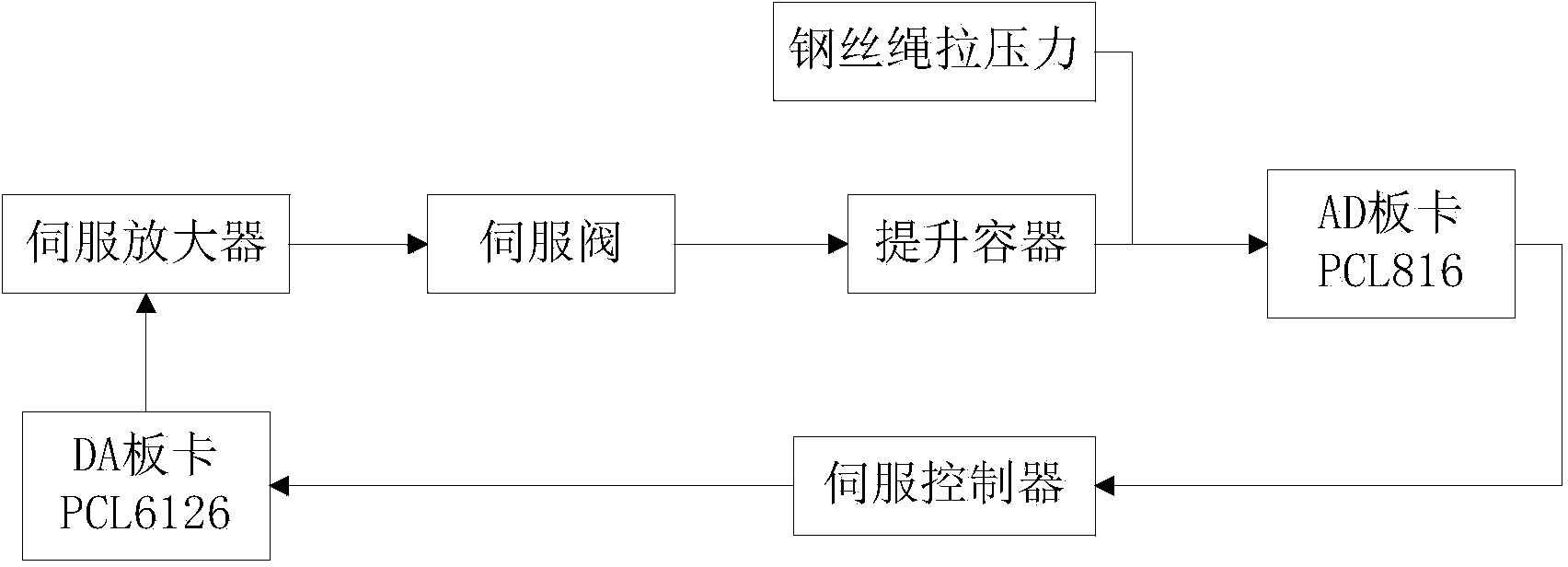

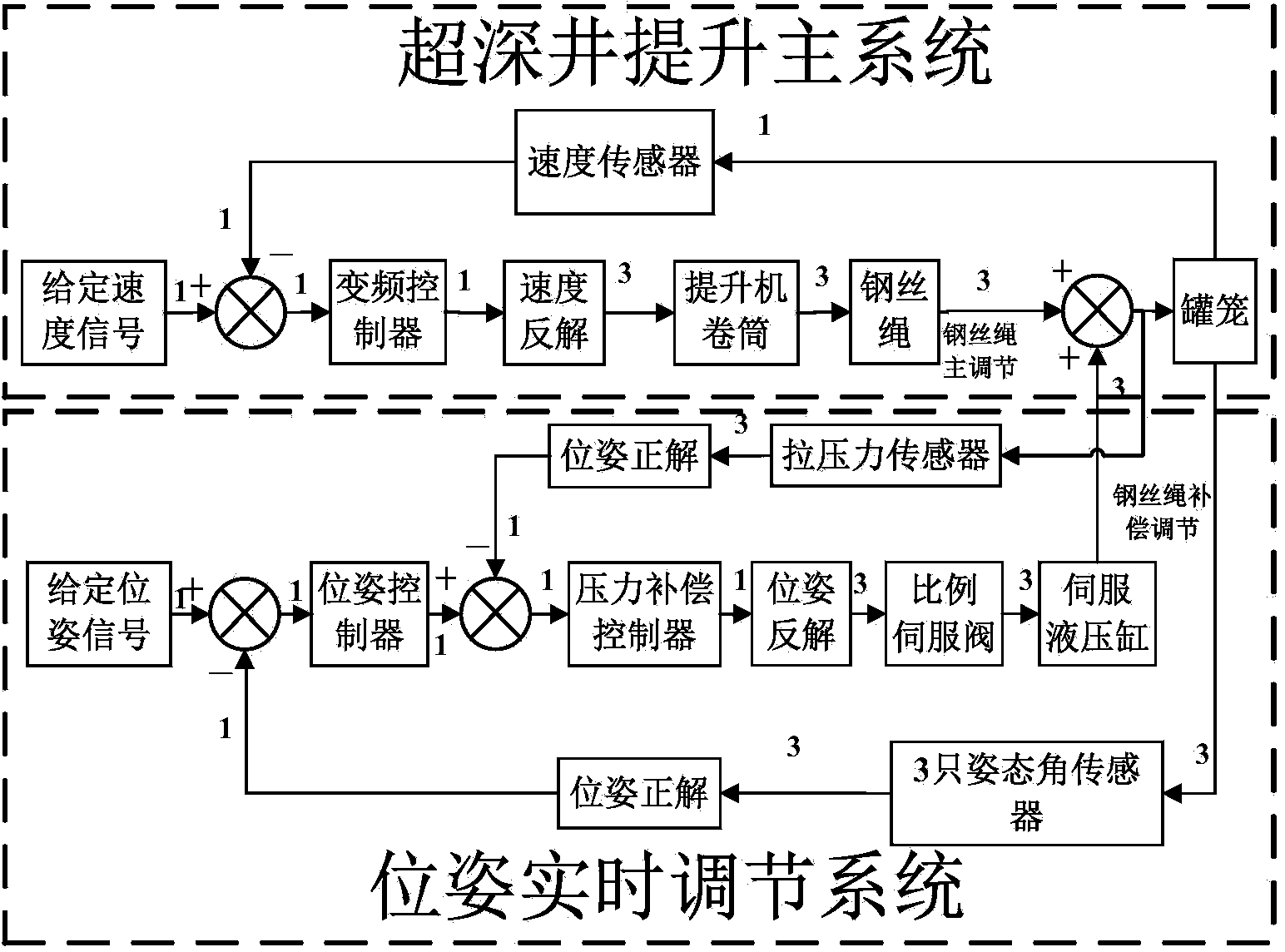

Ultra-deep mine hoist multi-rope cooperative control system and method

ActiveCN103935848AAvoid Loose Rope ProblemsUniform tensionElevatorsMine liftsWire ropeConductor Coil

The invention provides an ultra-deep mine hoist multi-rope cooperative control system and method, and belongs to a hoist multi-rope control system and method. An output shaft of each variable frequency motor is connected with a hoist winding drum, a variable frequency motor controller is connected with the variable frequency motors, each steel wire rope is connected between the corresponding hoist winding drum and a container, a servo hydraulic cylinder is arranged on the path, between the corresponding hoist winding drum and the container, of each steel wire rope, a servo hydraulic cylinder control system is connected with the servo hydraulic cylinders, the top of each servo hydraulic cylinder is connected with a hoisting sheave through a hinge support, each steel wire rope is connected with a tension and pressure sensor, and the container is connected with a position-posture-angle sensor; the servo hydraulic cylinders are connected with proportional servo valves, and the input port of each proportional servo valve is connected with an energy accumulator, an overflow valve, a one-way valve and a stop valve at the same time; the servo hydraulic cylinder control system is provided with a wireless receiver, the position-posture-angle sensor and the tension and pressure sensor are provided with wireless emitters, the position-posture-angle sensor feeds back position and posture conditions of the container and adjusts stretching out and drawing back of the hydraulic cylinders, and the situation that the container is inclined due to the fact the steel wire ropes move in a non-synchronous mode is avoided.

Owner:CHINA UNIV OF MINING & TECH

Apparatus for dyeing textile substrates with foamed dye

ActiveUS7913524B2Increases the amount of inert nitrogen in the chamber environmentReduce tensionTextile treatment containersOther washing machinesEngineeringIndigo dye

An apparatus for dyeing a textile substrate using a plurality of applicators that each apply an increment of a total dye application. In one form a reduced indigo dye in a leuco-state is applied in an inert atmosphere substantially isolated from oxidizing substances. In another form the foamed dye is applied while open to the atmosphere. In both forms holddown rollers or inverted applicators are located between applicators at decreasing depths to minimize increases in tension as the substrate travels over successive applicator faces.

Owner:GASTON SYST INC

Method and apparatus for tuning a musical drum

ActiveUS20090064844A1Simple methodSimple apparatusPercussion musical instrumentsDrumheadScrew thread

A drumhead with an outer ring member anchored to the outer periphery of a drum and having a threaded interior surface. An inner ring member having a threaded exterior surface matingly threaded to the interior surface of the outer ring.Rotating the inner ring in a first direction relative to the outer ring, increases the tension exerted on the drum skin. Similarly, rotating the inner ring in a second direction relative to the outer ring, decreases the tension exerted on the drum skin.Vertical pressure is exerted on the drum skin and drum ring when the inner ring is rotated in a first direction relative to the outer ring. Conversely, the pressure is released on the drum skin and the drum ring when the inner ring is rotated in a second direction relative to the outer ring.

Owner:OCONNOR THOMAS

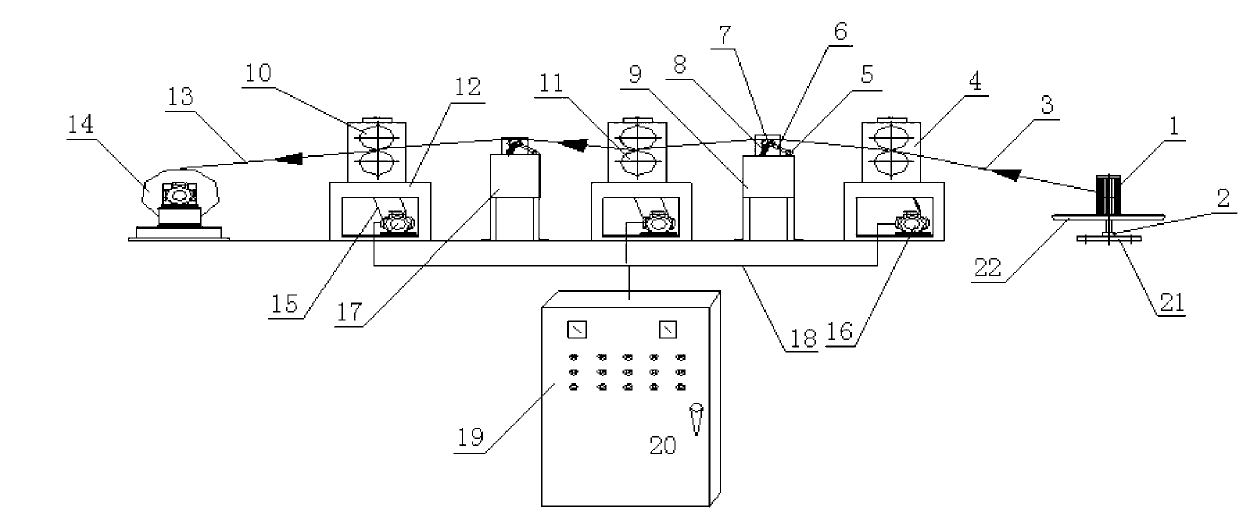

Rolling device for forming of copper alloy flat wires

InactiveCN103272840AImprove rolling precisionDimensionally stableMetal rolling arrangementsControl systemElectrical control

The invention discloses a rolling device for forming of copper alloy flat wires. The rolling device comprises a wire-unwinding mechanism, a plurality of sets of rolling mills, a synchronous tension mechanism, an electrical control system and a wire-rewinding machine. The wire-unwinding mechanism comprises a wire-unwinding plate and a halt air brake device. The rolling mills are composed of more than two stand-alone mills, and each rolling mill is composed of a rolling roller, a support, an electromotor and a belt. The synchronous tension mechanism is composed of a potentiometer, a connection rod, a guide wheel and a spring support. The electrical control system is composed of an electric cabinet, an electrical element, electric wires and cables and provides power for each rolling mill. According to the rolling device, a multi-channel continuous rolling method is utilized, the rolling device is high in accuracy, processing procedures of the copper alloy flat wires are shortened, operation speed is 1.5-2.0 times that of a conventional stand-alone mill, and production efficiency is improved. Meanwhile, as gradual rolling during a rolling process is utilized, the rolling size is very stable, the surfaces of the flat wires are smooth and bright, the fact that grooves and roughness of the surfaces of the flat wires occur in a drawing process of a traditional mould is avoided, and product quality is improved.

Owner:WUHU CHUJIANG ALLOY COPPER

Steam drying device of continuous pigment dyeing padding mangle

InactiveCN101598489ASpeed adjustmentReduce speedDrying solid materials with heatDrying gas arrangementsPulp and paper industryDrying time

The invention relates to a steam drying device of a continuous pigment dyeing padding mangle, which comprises steam drying cylinders, drying transmission mechanisms, a second humidity-discharging device, a water ratio detecting device and an electric cabinet which are arranged on a second mangle frame, wherein the steam drying cylinders are divided into two groups; and the drying transmission mechanisms are divided into two groups correspondingly. During operation, the drying transmission mechanisms drive a fabric to advances sequentially to be dried on the steam drying cylinders. If the water ratio detecting device detects that a water ratio is overhigh, the electric cabinet can be operated in an automatic or a manual mode to reduce the rotating speed of a transmission motor to increase drying time; and otherwise, the rotating speed of the transmission motor is increased to reduce the drying time. Because two groups of steam drying cylinders are adopted to achieve a high advancing speed of the fabric, the steam drying device of the continuous pigment dyeing padding mangle improves the drying efficiency and has a high processing capacity of the drying fabric.

Owner:常州慧杰电气技术有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com