Manufacturing method for glass steel pipeline in zero-degree winding manner

A production method and fiberglass technology, applied to tubular objects, other household appliances, household appliances, etc., can solve problems such as increased production costs, influence of pipe diameter, fiber difficulties, etc., achieve uniform and stable performance, reduce production costs, and uniform fiber tension Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention will be described in detail below with reference to the drawings and embodiments.

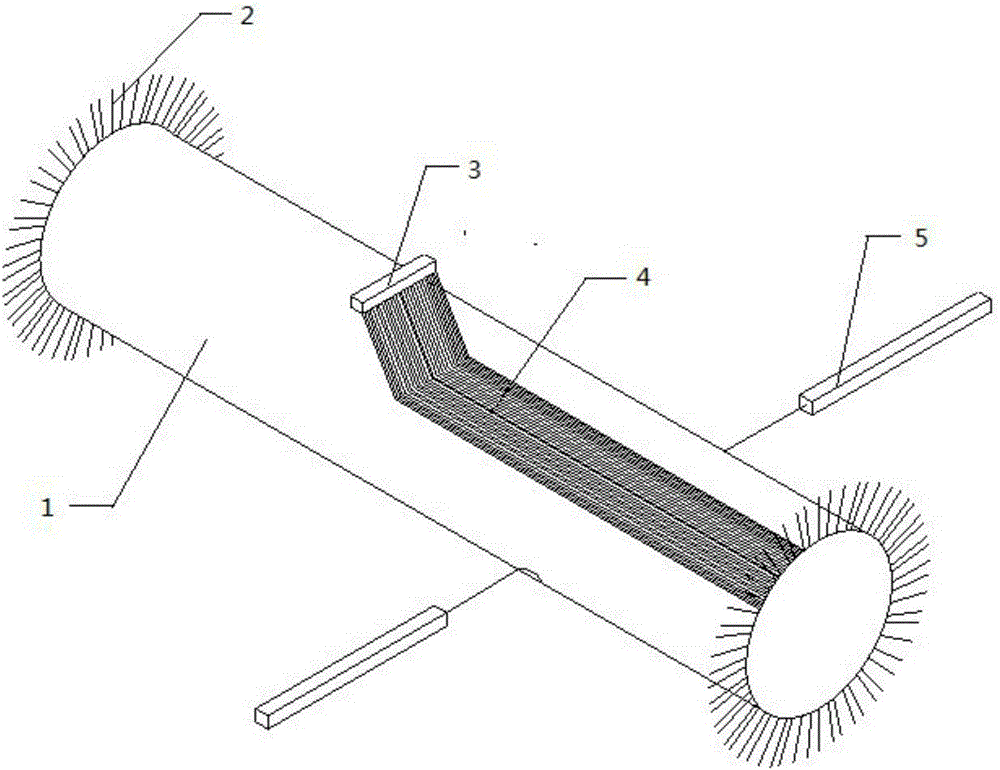

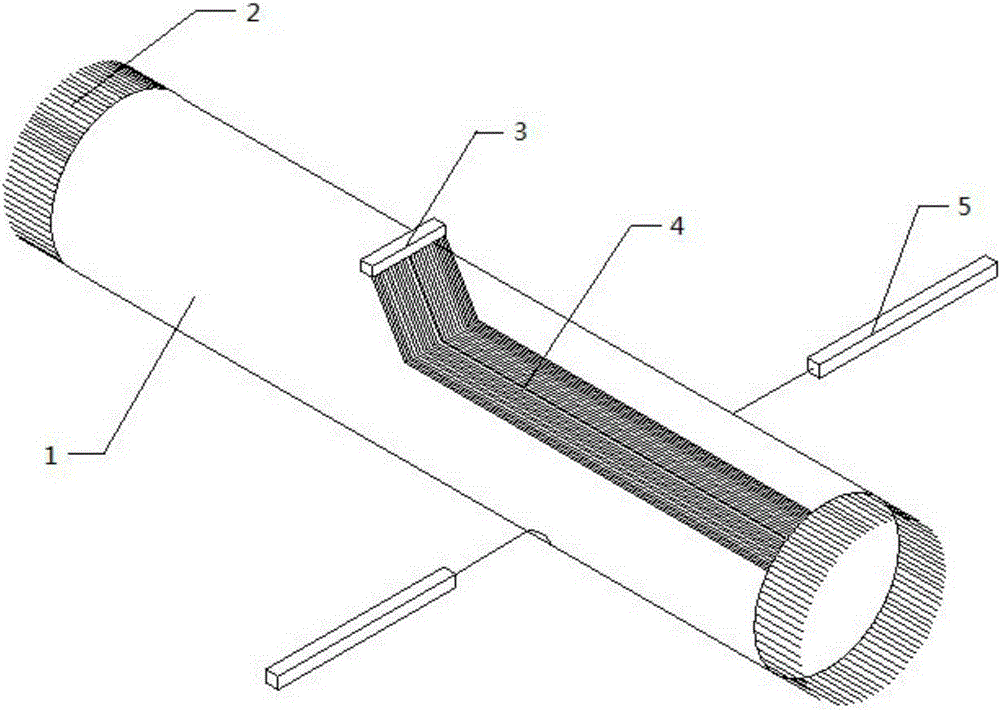

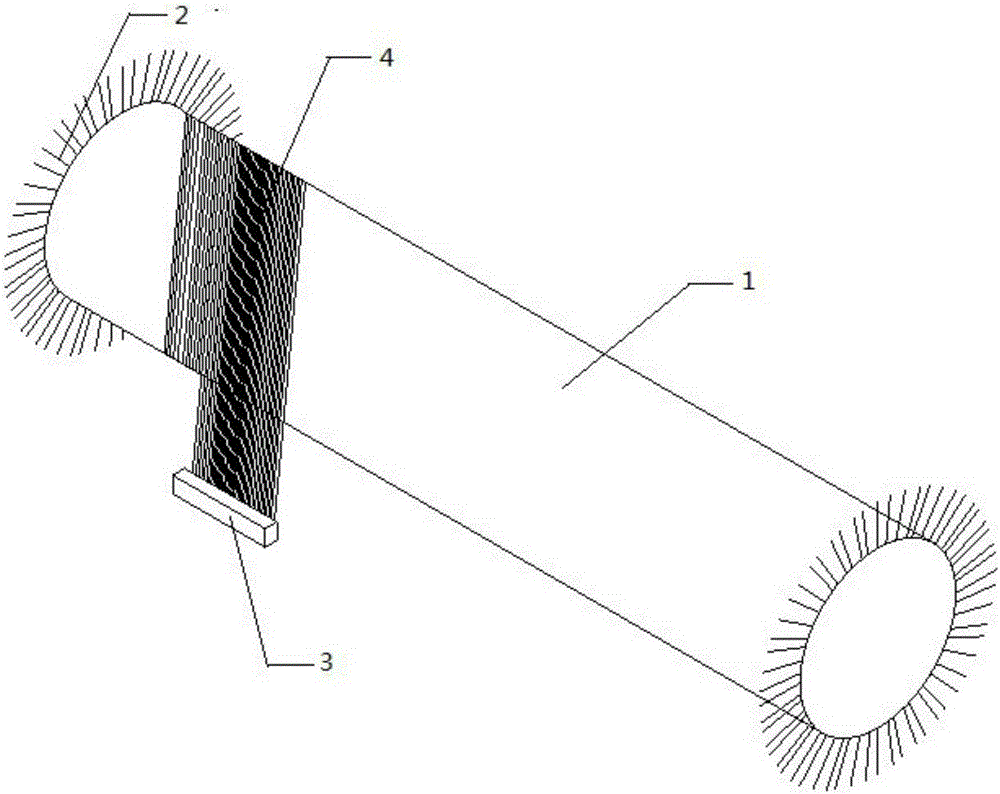

[0021] Such as figure 1 , 3 As shown, the method for manufacturing a zero-degree winding FRP pipe of the present invention includes the following steps in sequence:

[0022] 1. Lay a polyester film on the core mold 1, and wind the resin-impregnated winding yarn 4 on the core mold 1 through the guide wire head 3. The core mold rotates at a uniform speed, and the guide wire head 3 reciprocates along the axial direction to complete Circumferential winding. The width of the guide wire head 3 can be adjusted to suit different hoop windings;

[0023] 2. Set the wire guide head 3 perpendicular to the core mold 1 and set it above the core mold 1, and then hang the winding yarn 4 on the multi-tooth grate ring 2 at one end of the core mold 1. The multi-tooth grate ring 2 of this embodiment is vertical In the ring direction of the core mold 1, it can also be as figure 2 Extending ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com