Patents

Literature

235results about How to "Increased diffusion area" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

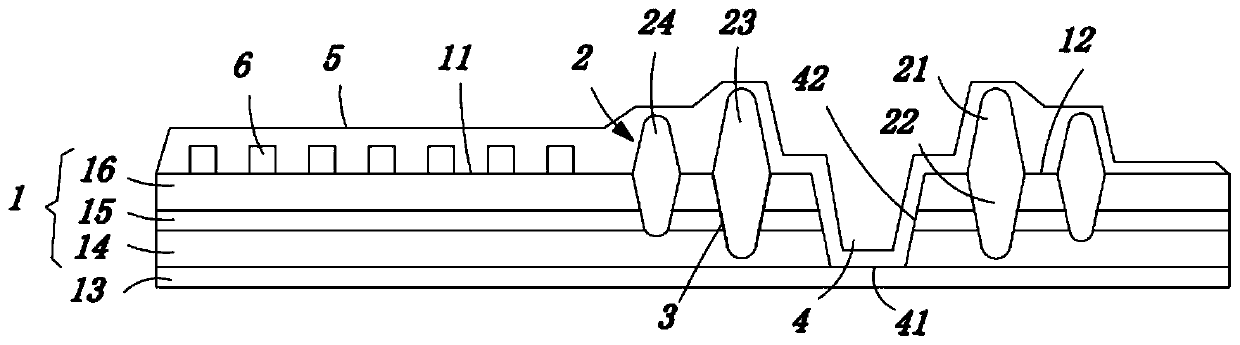

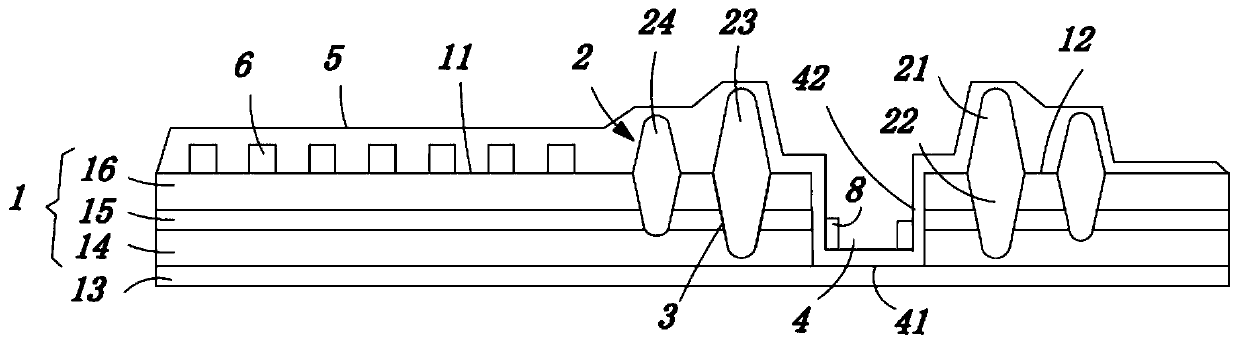

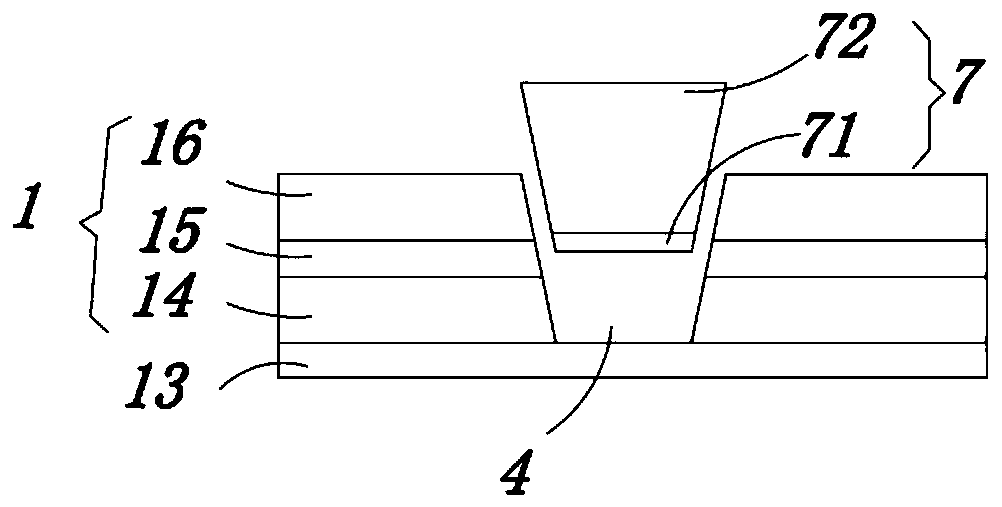

Gas dispensing device and semiconductor process plant employing the same

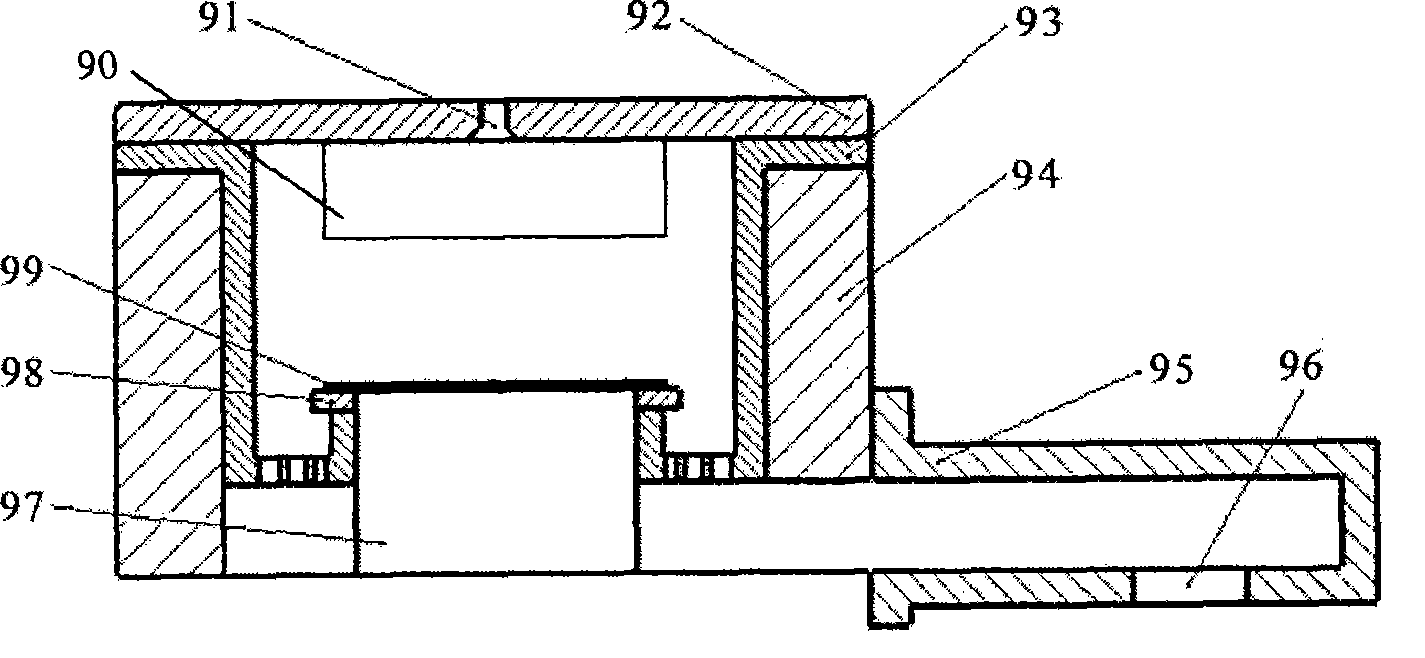

ActiveCN101499407AEvenly distributedInto the uniformElectric discharge tubesSemiconductor/solid-state device manufacturingProduct gasEngineering

The invention discloses a gas distribution device, comprising a supporting board, a spoiler and a spray header electrode, which are arranged in sequence in an overlapping way from top to bottom. An intake channel is arranged on the supporting board and an exhaust channel is arranged on the spray header electrode, wherein, at least one surface of the spoiler is provided with a spoiler concave part which is also provided with a through-hole for vertically running through the spoiler so as to lead the gas of the intake channel on the supporting board to be dispersed at the spoiler concave part, then transmitted to the spray header electrode by the through-hole, and later transmitted to a reaction cavity by the exhaust channel on the spray header electrode. In addition, the invention also discloses semiconductor processing equipment which uses the gas distribution device. The gas distribution device and the semiconductor processing equipment can distribute the gas such as process gas and the like to the inside of the reaction cavity uniformly, thus obtaining uniform distribution of the plasma and further even processing / dealing results.

Owner:BEIJING NAURA MICROELECTRONICS EQUIP CO LTD

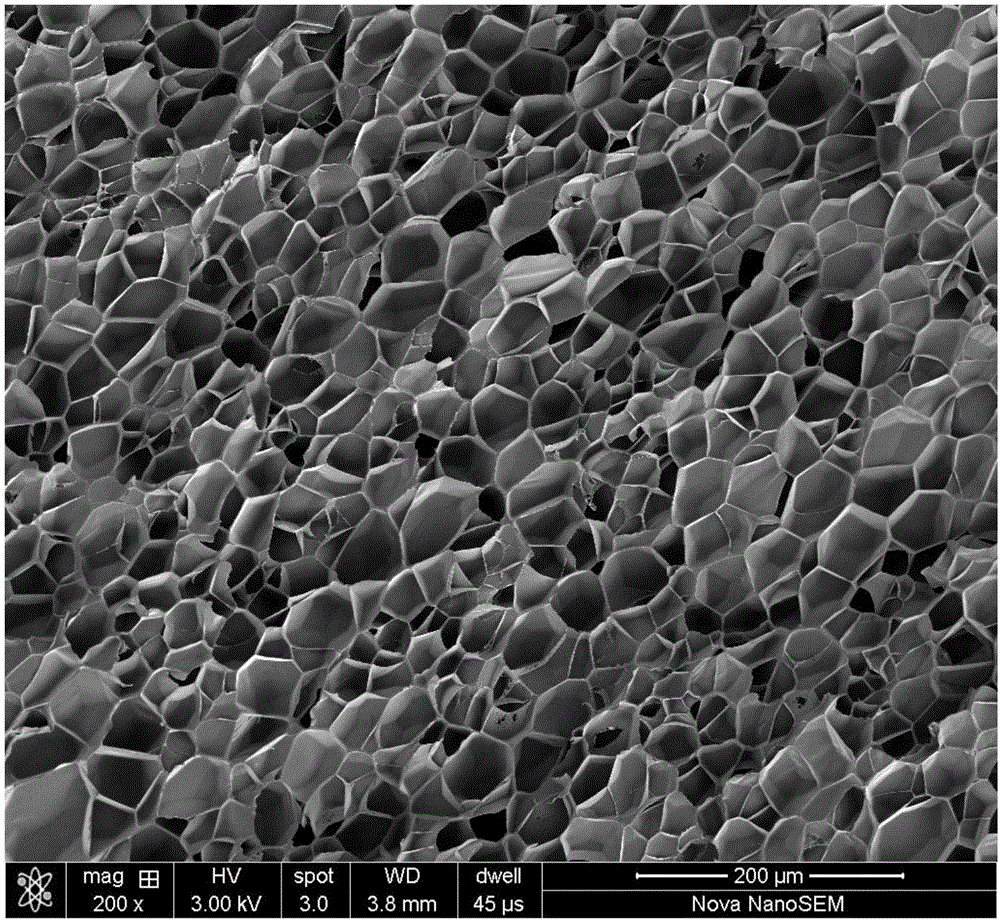

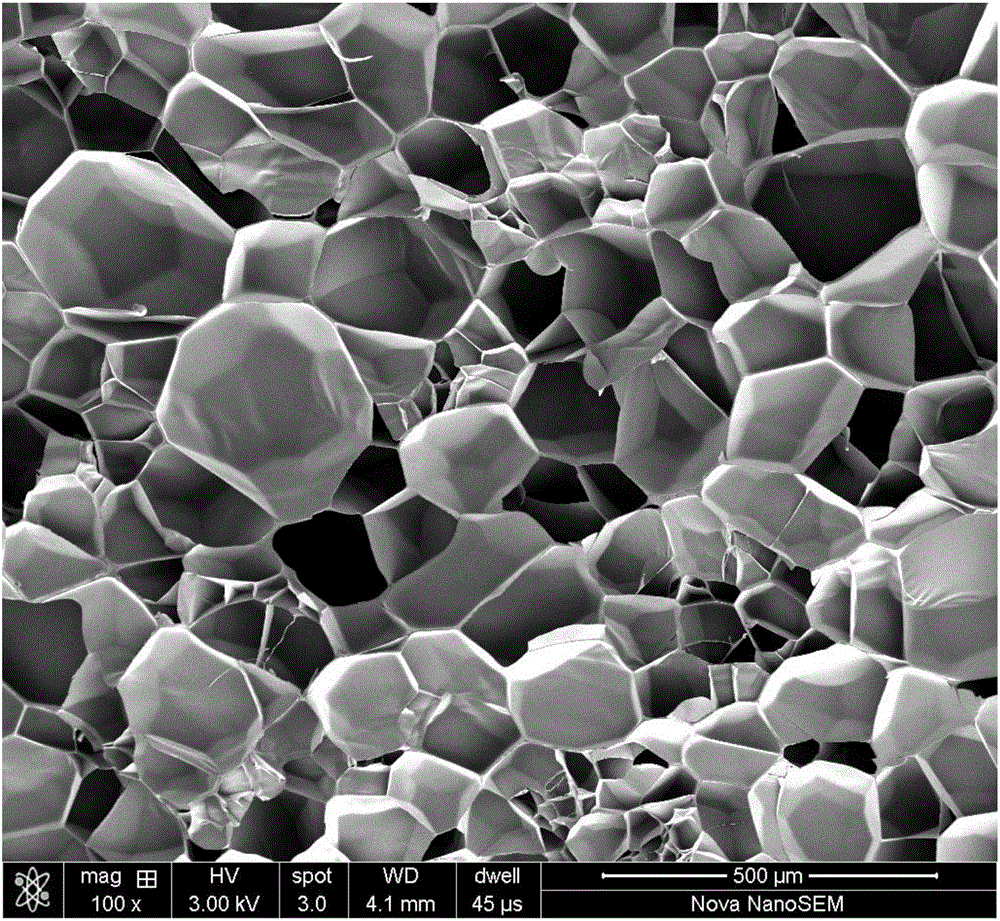

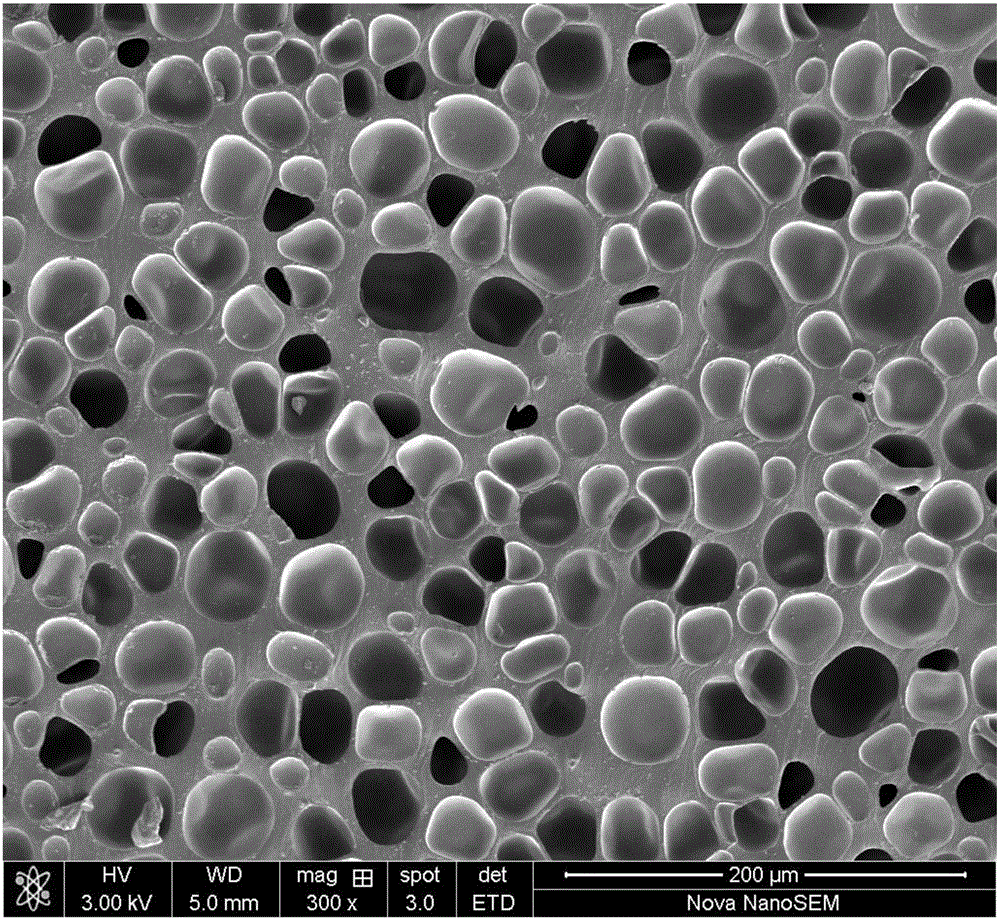

Method for preparing thermoplastic polymer foamed beads

The invention discloses a method for preparing thermoplastic polymer foamed beads. The method comprises the following steps: 1) putting polymer particles into a sealed container heated to a foaming temperature, and putting the sealed container in a vacuum environment; 2) introducing supercritical fluid into the sealed container, and performing swelling diffusion; 3) after swelling diffusion of the supercritical fluid lasts for 5-60 minutes, releasing the pressure of the sealed container to discharge out the supercritical fluid, and controlling the pressure release velocity to induce nucleation and growth of foam pores so as to enable the polymer particles to swell and grow; 4) leading the polymer particles inside the sealed container into the vacuum environment to further swell and grow, thereby obtaining the polymer foamed beads with a high foaming ratio, wherein the foaming temperature in the step 1) is a temperature that the polymer particles can generate plastic deformation but cannot flow yet, the forming temperature is within Tg-Tg+40 DEG C for an amorphous polymer, and Tg is a glass-transition temperature of the amorphous polymer; for a crystallized polymer, the foaming temperature is within Tm-20 DEG C and Tm, and Tm is a melting point of the crystallized polymer.

Owner:HANGZHOU BOSTE NEW MATERIALS TECH CO LTD

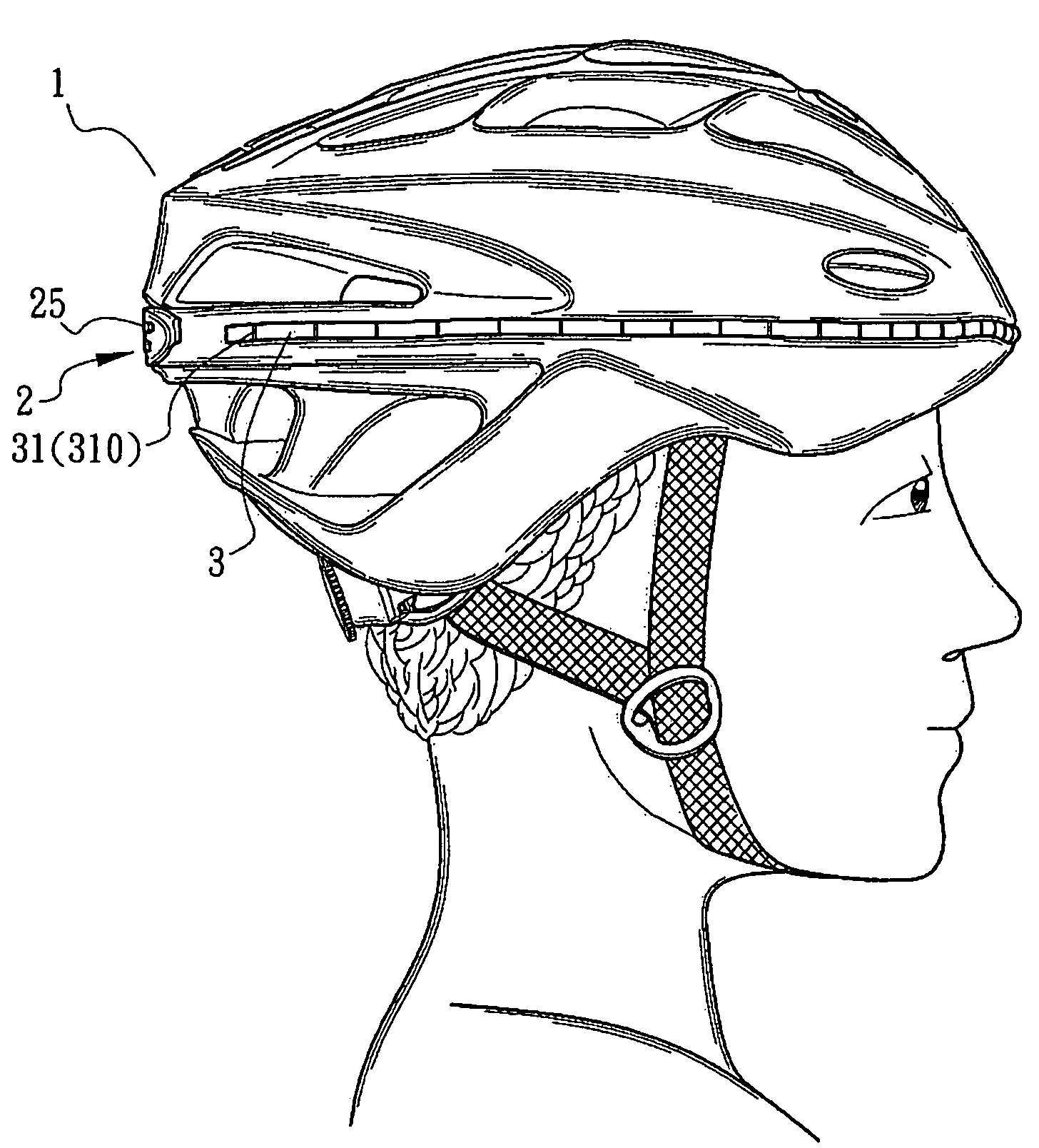

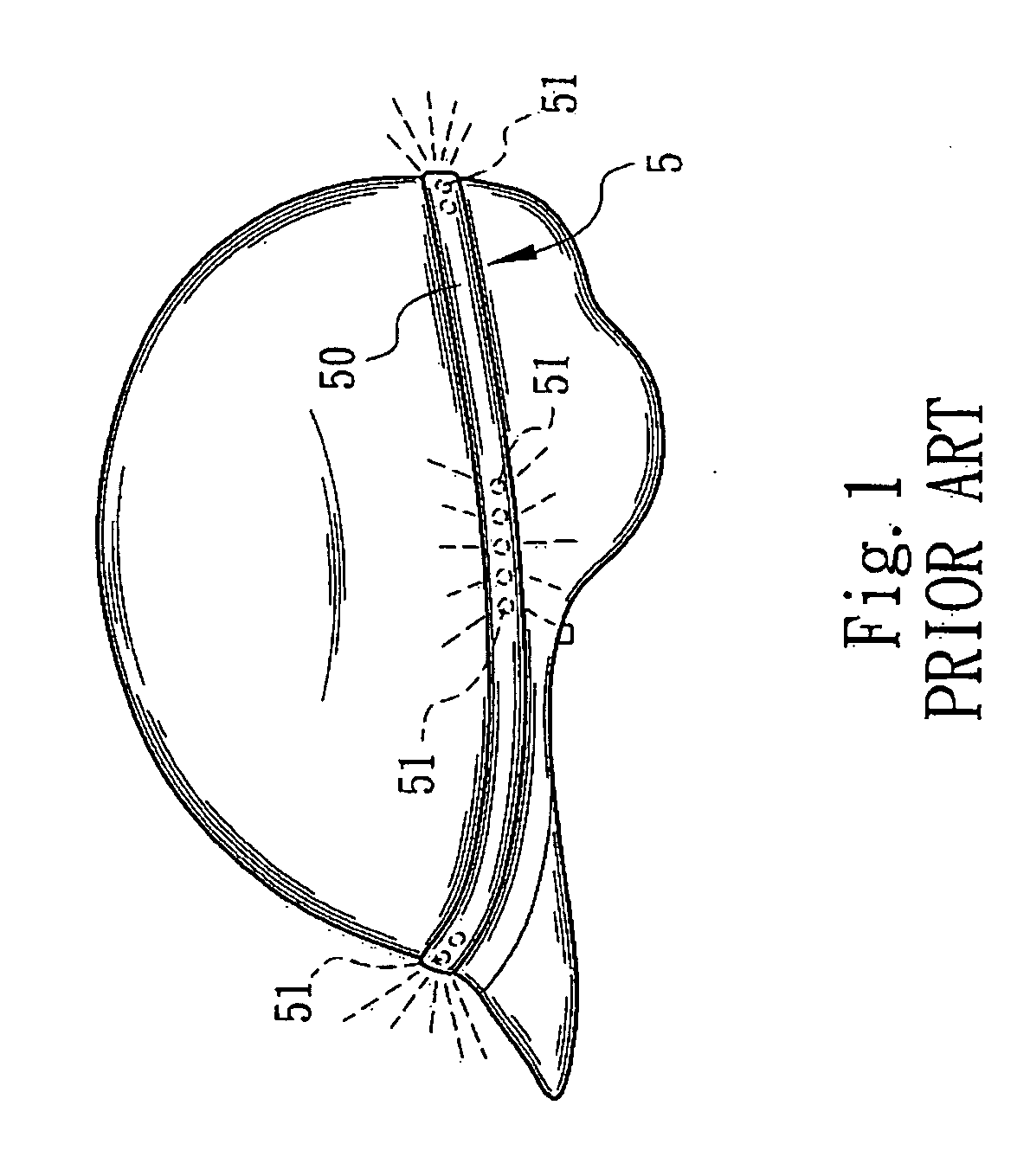

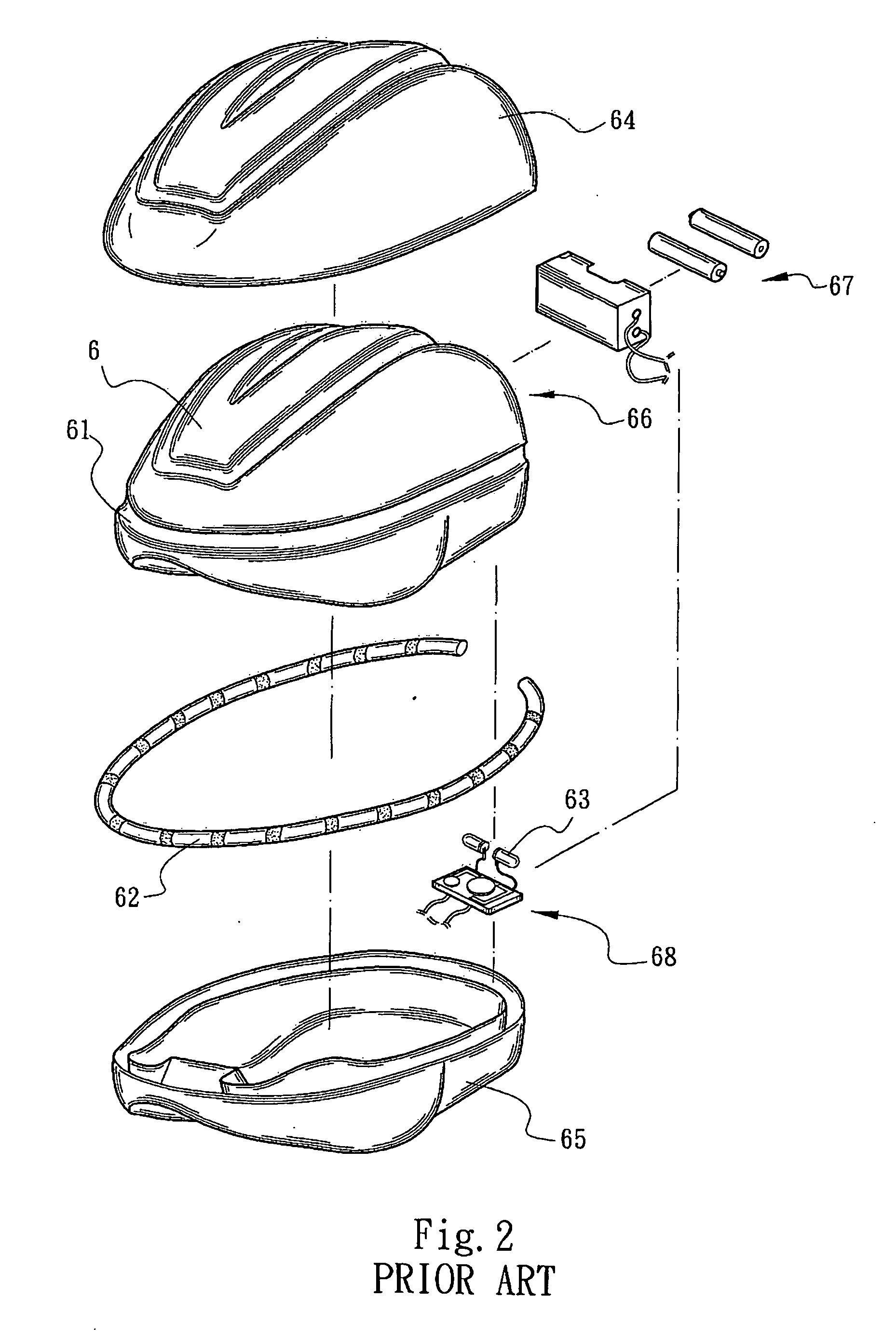

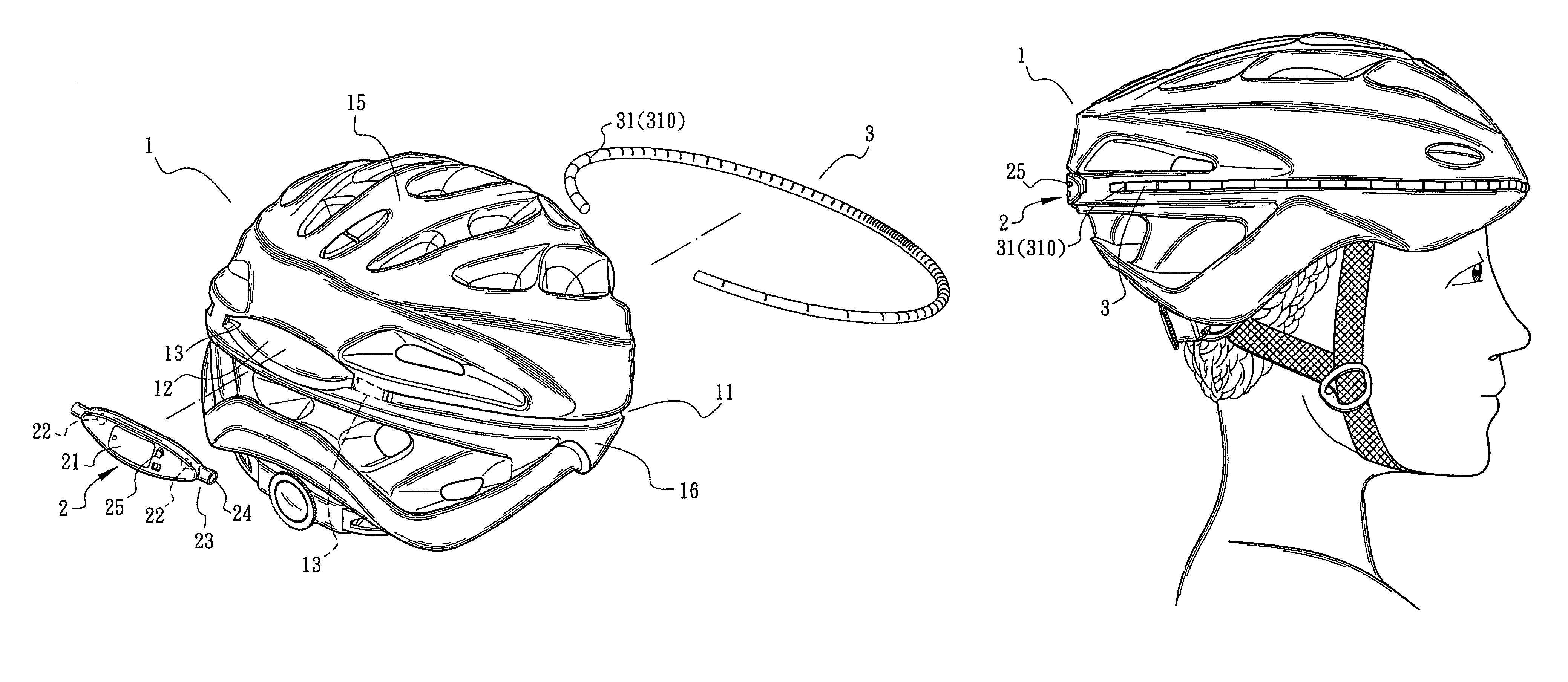

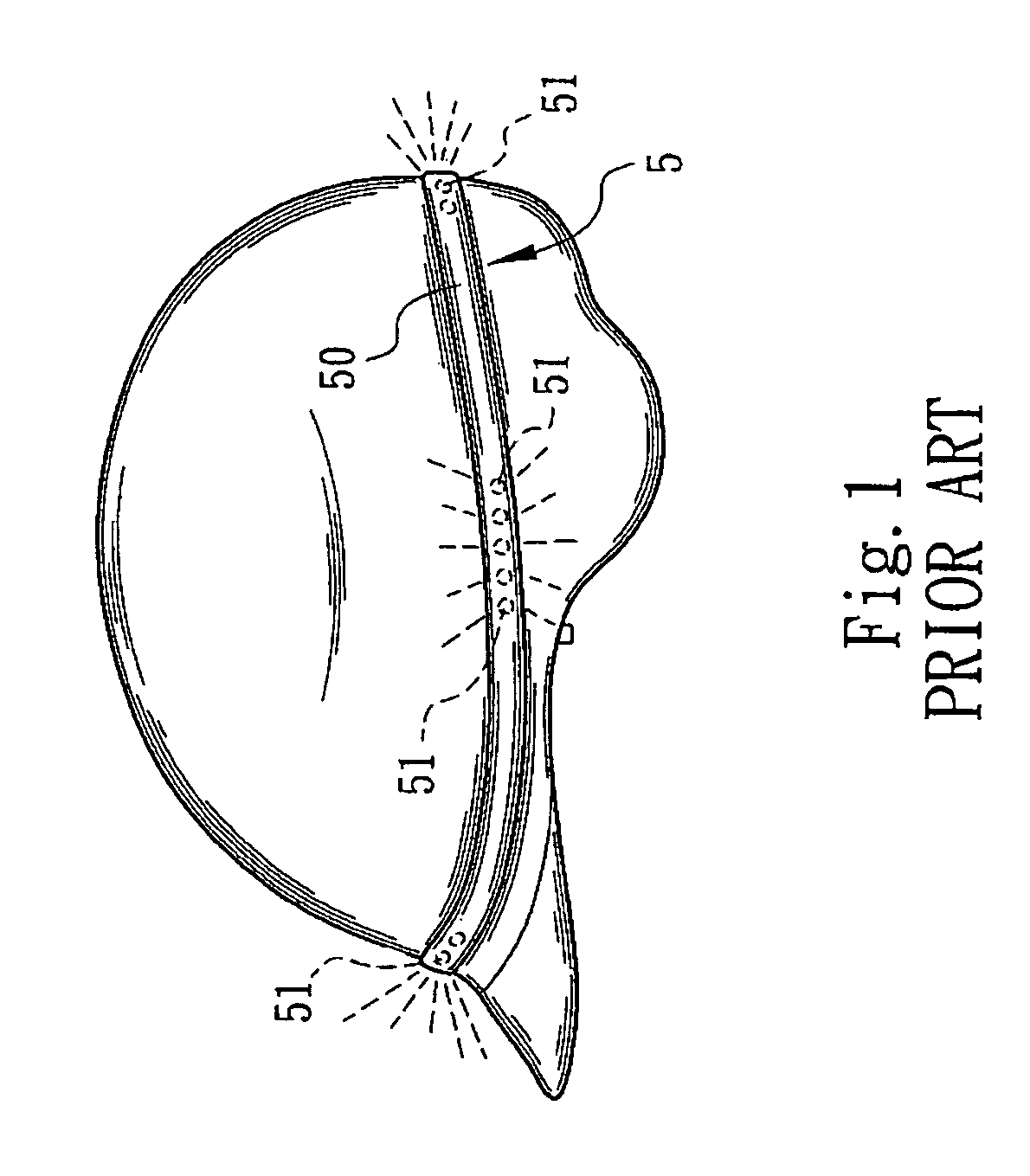

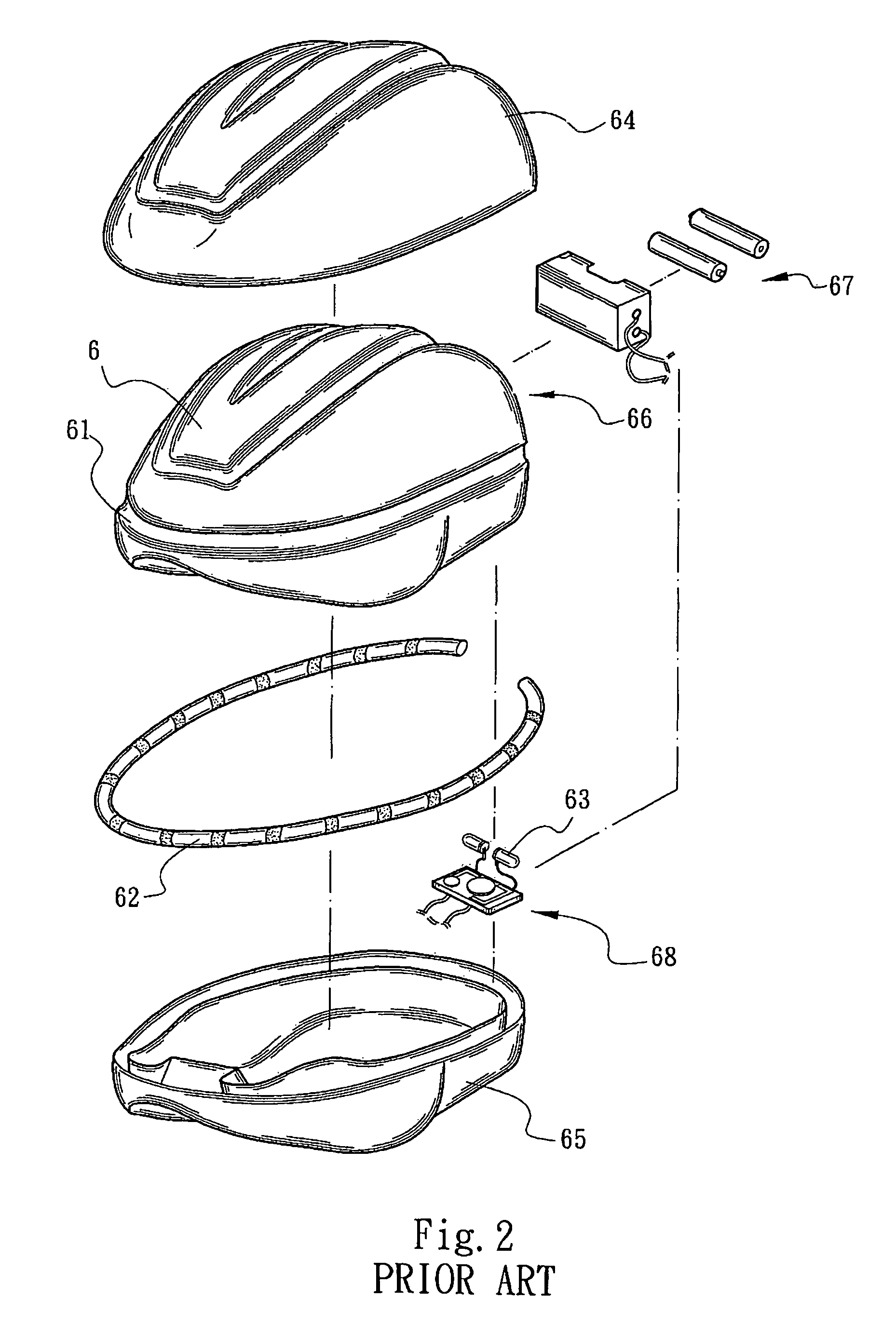

Light-emitting warning device of a safety helmet

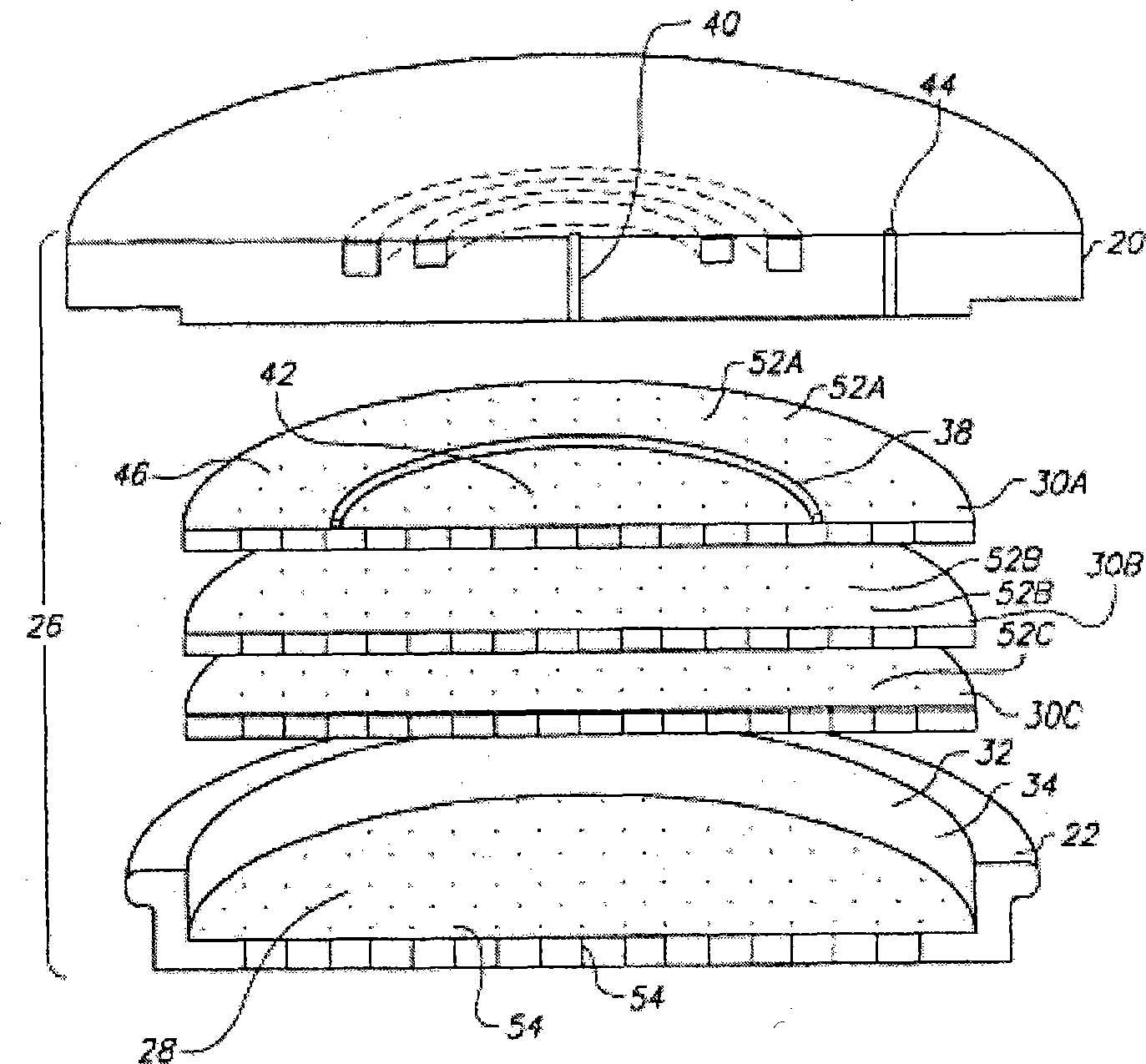

ActiveUS20100177505A1More warning effectImprove efficiencyLighting support devicesWith electric batteriesLight guideElectrical and Electronics engineering

A light-emitting warning device of a safety helmet, including a helmet main body, a light guide element and a light source control mechanism. An annular locating groove and a receiving cavity are formed on an outer face of the helmet main body. Two end sections of the locating groove communicate with the receiving cavity via two through holes formed in the helmet main body. An elongated flexible strip body is received in the locating groove. Two end sections of the light guide element extend through the through holes into the receiving cavity to connect with the light source control mechanism. The light source control mechanism project light into the light guide element, and emit as a lighting ring along the periphery of the helmet main body. The characteristic is at least partial of the said light guide element communicating with an interior of the helmet main body to avoid dropping.

Owner:HO CHANG HSIEN

Light-emitting warning device of a safety helmet

ActiveUS8070307B2More warning effectImprove efficiencyLighting support devicesWith electric batteriesLight guideElectrical and Electronics engineering

A light-emitting warning device of a safety helmet, including a helmet main body, a light guide element and a light source control mechanism. An annular locating groove and a receiving cavity are formed on an outer face of the helmet main body. Two end sections of the locating groove communicate with the receiving cavity via two through holes formed in the helmet main body. An elongated flexible strip body is received in the locating groove. Two end sections of the light guide element extend through the through holes into the receiving cavity to connect with the light source control mechanism. The light source control mechanism projects light into the light guide element, and emits as a lighting ring along the periphery of the helmet main body. The light guide element communicates with an interior of the helmet main body to avoid dropping.

Owner:HO CHANG HSIEN

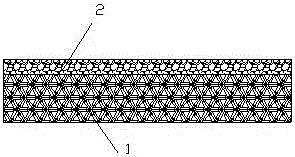

High moisture permeability coating film

ActiveCN104029449BGood moisture absorption and moisture conductivityImprove performanceSynthetic resin layered productsGas-tight/water-tight arrangementsCelluloseWater vapor

A coating film having a high water vapor transmission rate comprises: a basic film layer and a coating. The basic film layer is a bulk polytetrafluoroethylene film layer. The coating applied on the film layer is a polyurethane emulsion copolymer coating that contains hemp stem ultra-fine powder. A coating agent of the coating comprises raw materials of the following percentages by weight being evenly mixed: 20% to 25% of polyurethane, 55% to 60% of a dimethyl formamide solvent, 2% to 5% of a hydrophilic group solvent, and 18% to 25% of hemp stem ultra-fine powder. The resultant coating film has desirable moisture absorption performance and moisture guidance performance, has a high content of water vapor transmission factor cellulose of hemp stem ultra-fine powder and has micro trenches and micro pores, increases the moisture absorption area and the diffusion area, and has excellent performance of being anti-ultraviolet, water-proof, dust-proof, oil-proof, water vapor permeable, and corrosion resistant to oxidation solutions.

Owner:PAN ASIAN MICROVENT TECH JIANGSU CORP

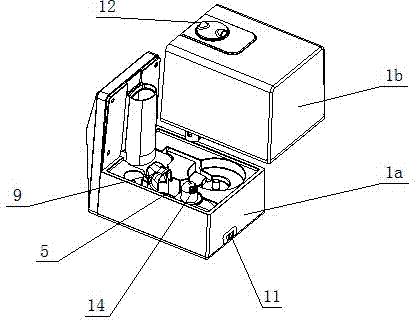

Humidifier

ActiveCN102418976AReduce liquid surface tensionWork quietlyDucting arrangementsLighting and heating apparatusElectric heatingEngineering

The invention aims to provide a humidifier with low working noise and a large vapor diffusion area. The humidifier comprises a case on which a water storing cavity, an air inlet and an air outlet are formed, wherein the air inlet and the air outlet are communicated through an air channel which is provided with a fan; an ultrasonic atomization device and a heating and vaporizing device are arranged in the case; the heating and vaporizing device consists of a heating water tank, a vaporizing cavity which is formed above the liquid level of the heating water tank, and an electric heating element; the ultrasonic atomization device consists of an ultrasonic water tank, an ultrasonic generating device and an atomization cavity which is formed above the liquid level of the ultrasonic water tank; the heating water tank and the ultrasonic water tank are communicated with the water storing cavity through the water channel; and the atomization cavity and the vaporizing cavity which serve as a part of the air channel are connected in series with the air channel. Provided with the ultrasonic atomization device and the heating and vaporizing device simultaneously, the humidifier works more quietly due to the unique air channel, the vapor diffusion area is enlarged under the condition of the same energy consumption, the practicability of the humidifier is improved, and requirements of customers are met.

Owner:FOSHAN JINXINGHUI ELECTRICAL APPLIANCE

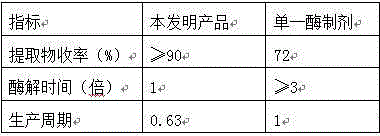

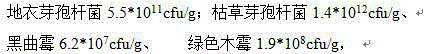

Complex enzyme preparation for extracting effective plant components and method for preparing complex enzyme preparation

InactiveCN105062990AHigh recovery rateRelease fullyMicroorganism based processesGlycosylasesBacillus licheniformisPectinase

The invention discloses a complex enzyme preparation for extracting effective plant components and a method for preparing the complex enzyme preparation. The complex enzyme preparation comprises components of glycanase, cellulase, pectinase, beta-glucanase and alpha-amylase. The activity of the glycanase is 3000IU / g, the activity of the cellulase is 2000IU / g, the activity of the pectinase is 20000IU / g, the activity of the beta-glucanase is 5000IU / g, and the activity of the alpha-amylase is 3000IU / g. The method for preparing the complex enzyme preparation includes symbiotically cultivating, extracting and concentrating bacillus licheniformis, bacillus subtilis, aspergillus niger and trichoderma viride according to certain proportions, then adding expanded plant protein carriers into the bacillus licheniformis, the bacillus subtilis, the aspergillus niger and the trichoderma viride; spraying mist at low temperatures to obtain the complex enzyme preparation. The complex enzyme preparation and the method have the advantages that the effective component recovery rate of complex enzymes can be increased as compared with a method for individually fermenting and producing various enzymes and then combining the various enzymes with one another, production technologies can be simplified, the production cycle can be shortened, the production cost can be lowered, the production efficiency can be greatly improved, the stability of the activity quality of final products can be guaranteed, and plant extraction complex enzyme production can be industrialized.

Owner:天津科建科技发展有限公司

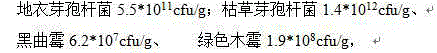

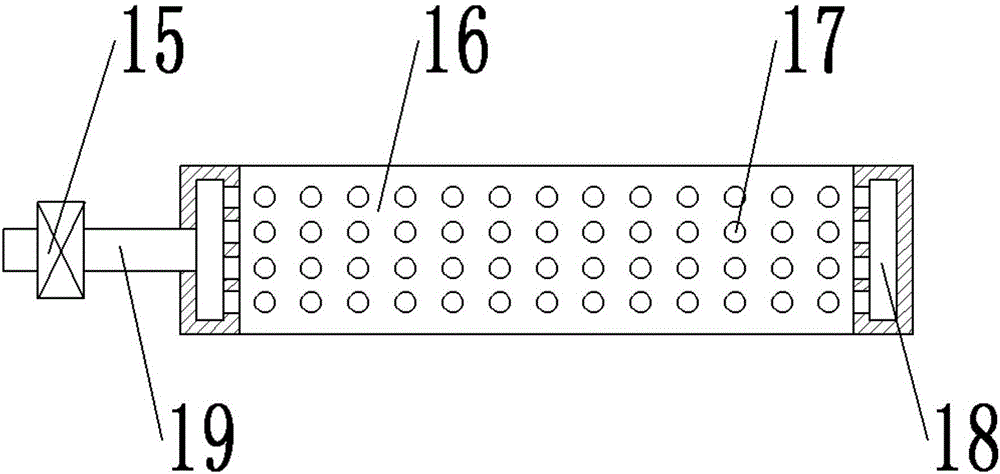

Gas-liquid distributor used for wood tar fluidized bed reactor

ActiveCN104923131AJumping up and down violentlyAvoid seal failureChemical/physical processesFluidized bedTar

The invention discloses a gas-liquid distributor used for a wood tar fluidized bed reactor, the gas-liquid distributor is mainly composed of a center pipe, a bubble cap, a non-return ball, a taper ball seat and a limit seat; the bubble cap is a cylindrical matter with a bottom opening, covers the upper end of the center pipe, and is fixedly connected with the center pipe, a material outlet is arranged on the pipe wall of the upper end part of the center pipe, the limit seat is arranged in the center pipe below the material outlet, the taper ball seat is arranged on the pipe wall of the center pipe located below the limit seat, the non-return ball is arranged on the taper ball seat; the bubble cap, the center pipe, the limit seat, the non-return ball and the taper ball seat are coaxially arranged, an annular channel is formed between the bubble cap and the center pipe, and the lower end of the center pipe is provided with a material inlet. The gas-liquid distributor can not only guarantee a gas is broken into continuous micro bubbles in a liquid, and can effectively solve or ease countercurrent congestion problem of a catalyst-carrying material when gas and liquid pressure is instable or gas and liquid material feed is suddenly interrupted, at the same time, an internal flow dead zone in the distributor is reduced, and the pressure drop is smaller.

Owner:LUOYANG PETROCHEMICAL ENG CORP SINOPEC +1

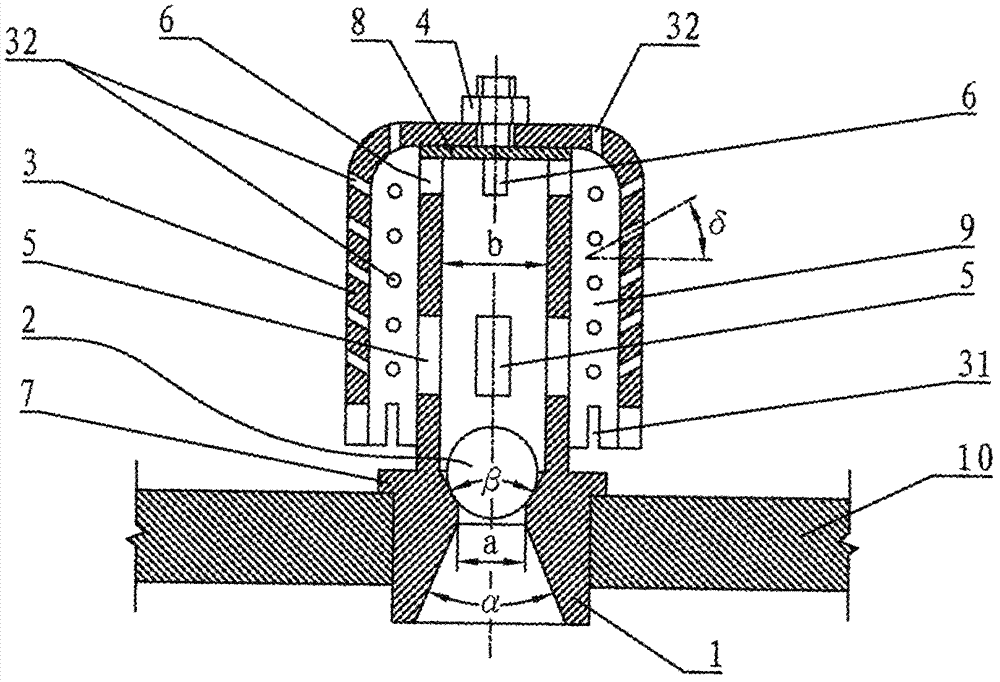

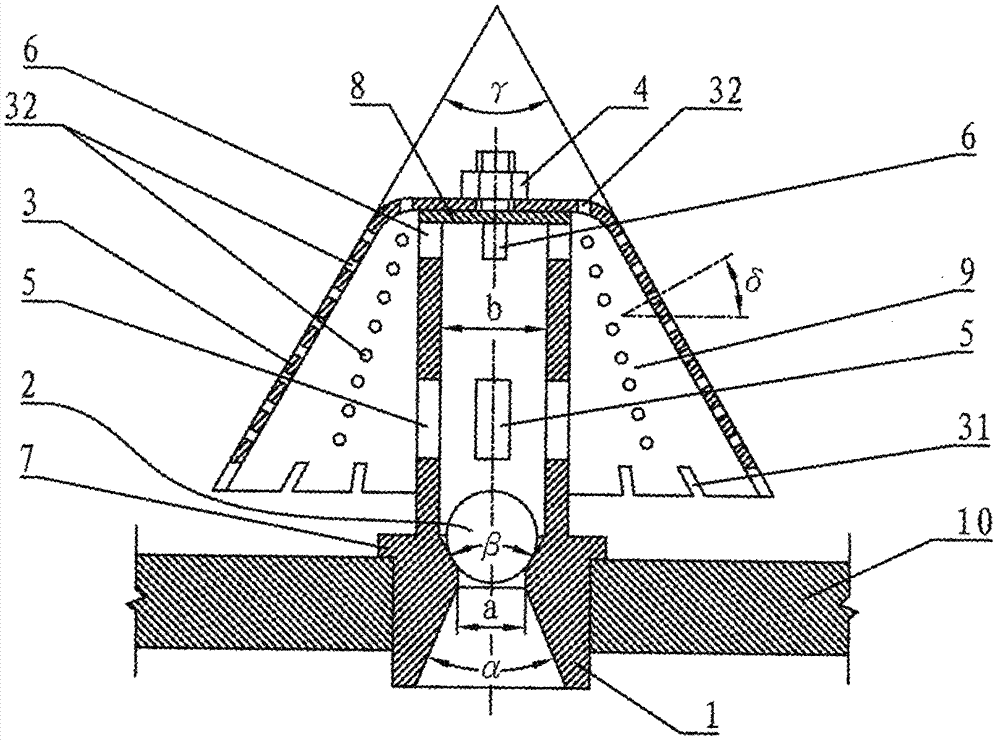

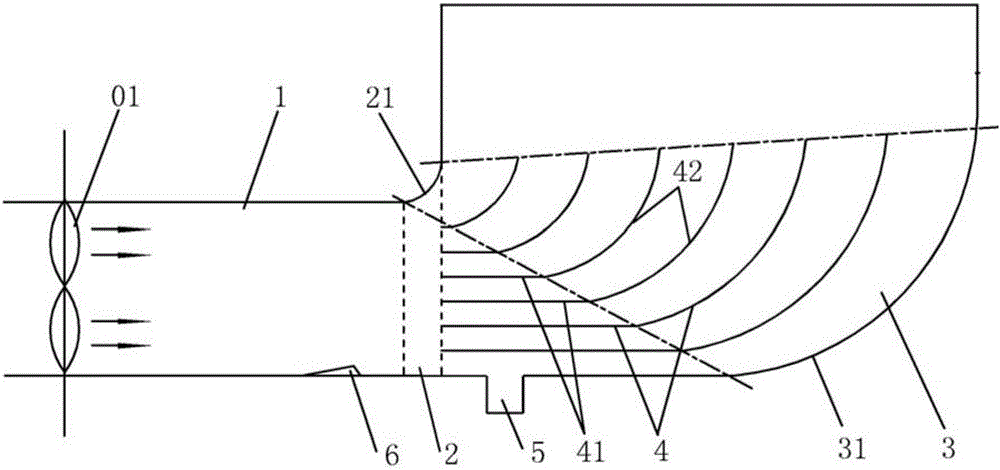

Gas distributor for slurry bed reactor

The invention discloses a gas distributor for a slurry bed reactor so as to solve the problem that bubbles cannot be broken well under the condition of large air input, gases cannot be uniformly distributed and a check ball will frequently bounce in an air-flow when a present bellcap distributor is used for gas distribution and feeding of a slurry bed reactor. The gas distributor provided by the invention is provided with a bellcap (3), an air inlet pipe (1) and a check ball (2). Gas distribution holes (32) are arranged slanting upwards on a cylindrical shell of the bellcap. The air inlet pipe is composed of an air inlet pipe upper-portion and an air inlet pipe lower-portion. The air inlet pipe upper-portion is provided with an air inlet pipe upper-portion middle-lower opening (5) and an air inlet pipe upper-portion top opening (6). An inner cavity of the air inlet pipe is composed of an inverted frutum conical air inlet pipe lower-portion upper core space, an air inlet pipe lower-portion bottleneck and a frutum conical air inlet pipe lower-portion lower core space which are arranged from top to bottom. The check ball is supported on the surface of the air inlet pipe lower-portion upper core space when placed at a sealing position. The gas distributor provided by the invention can be used in a slurry bed reactor for gas distribution and feeding.

Owner:CHINA PETROLEUM & CHEM CORP +1

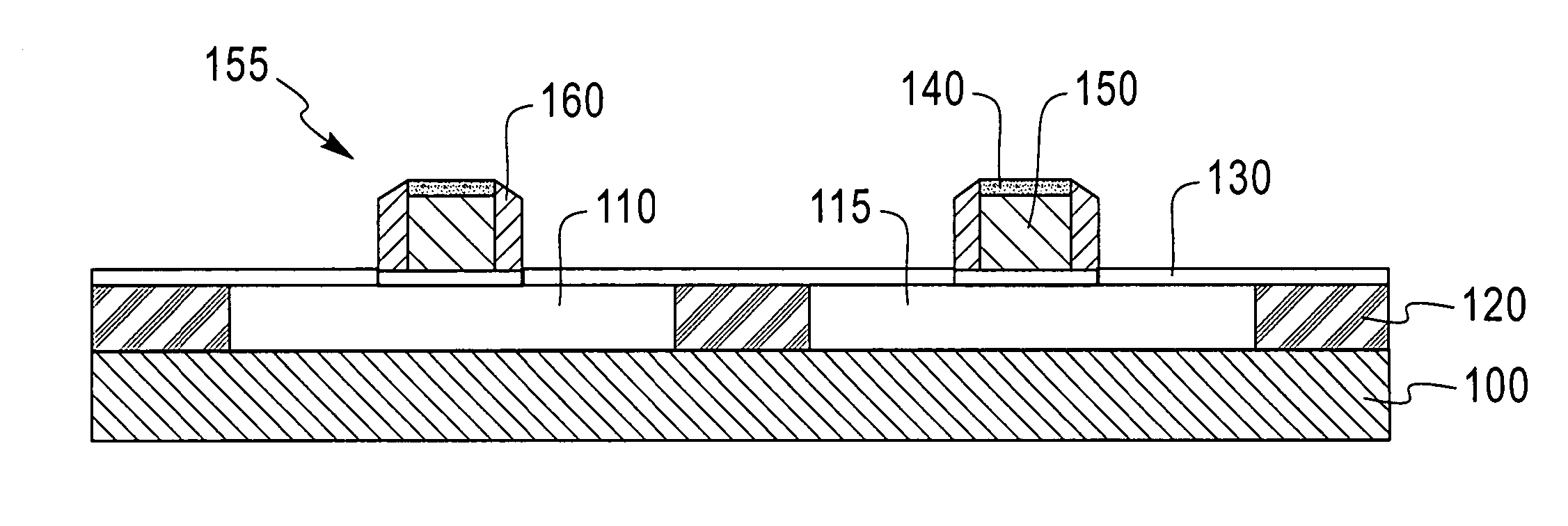

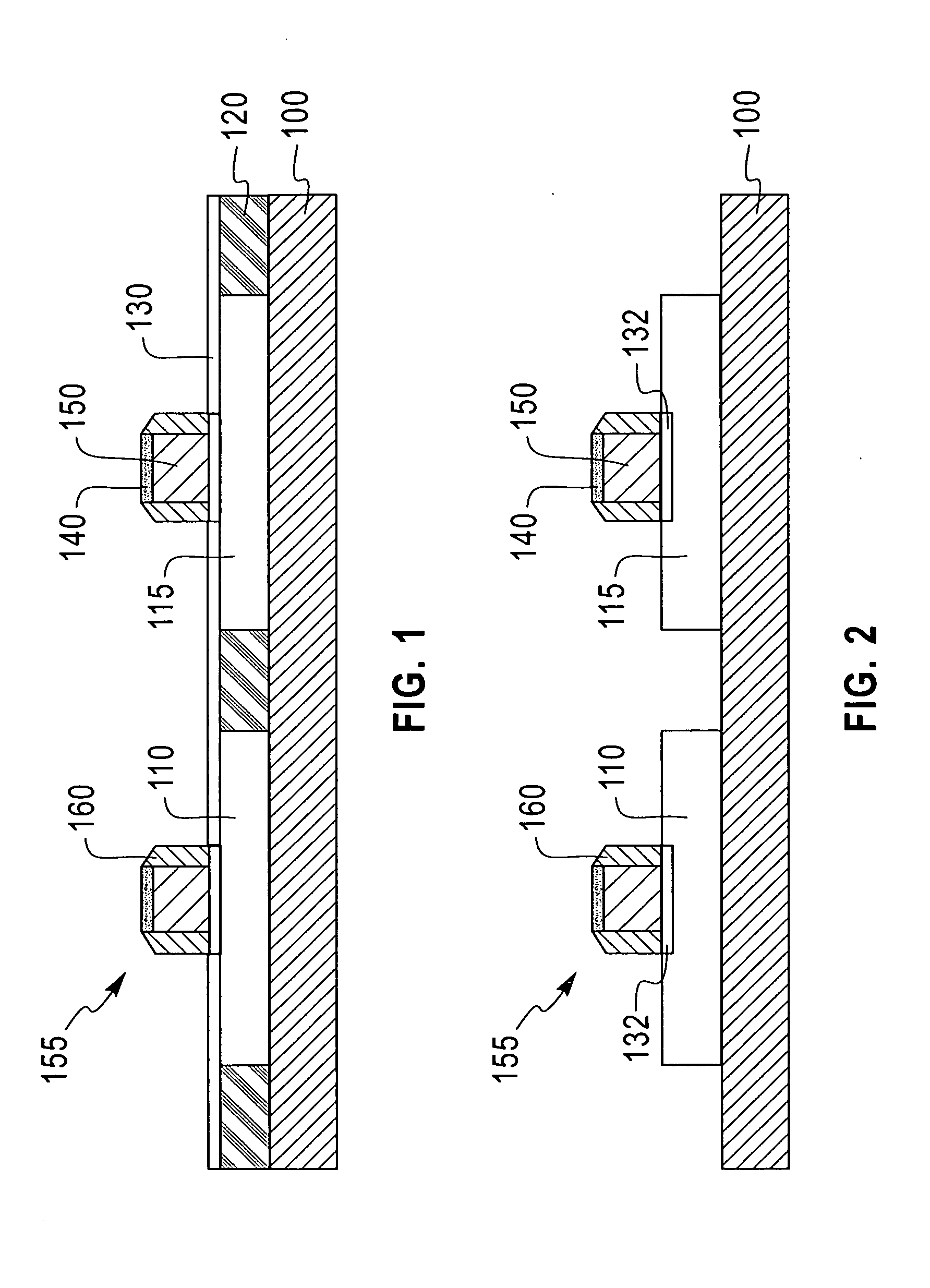

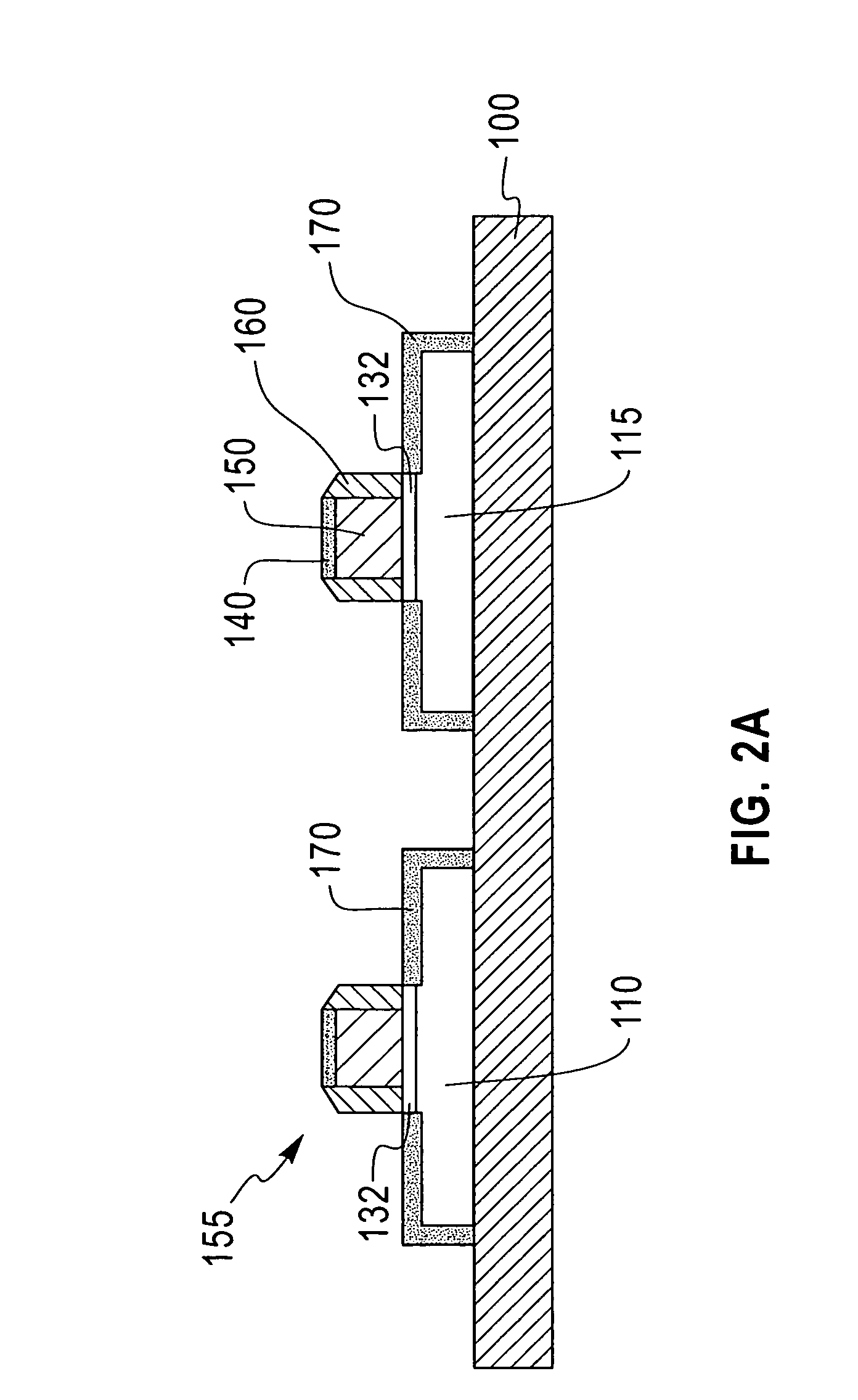

Method and structure to reduce contact resistance on thin silicon-on-insulator device

InactiveUS20070254464A1Avoiding silcidationReduced series resistanceSemiconductor/solid-state device manufacturingSemiconductor devicesEngineeringContact resistance

A method (and system) of reducing contact resistance on a silicon-on-insulator device, including controlling a silicide depth in a source-drain region of the device.

Owner:GLOBALFOUNDRIES INC

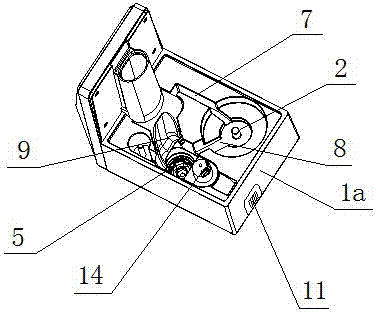

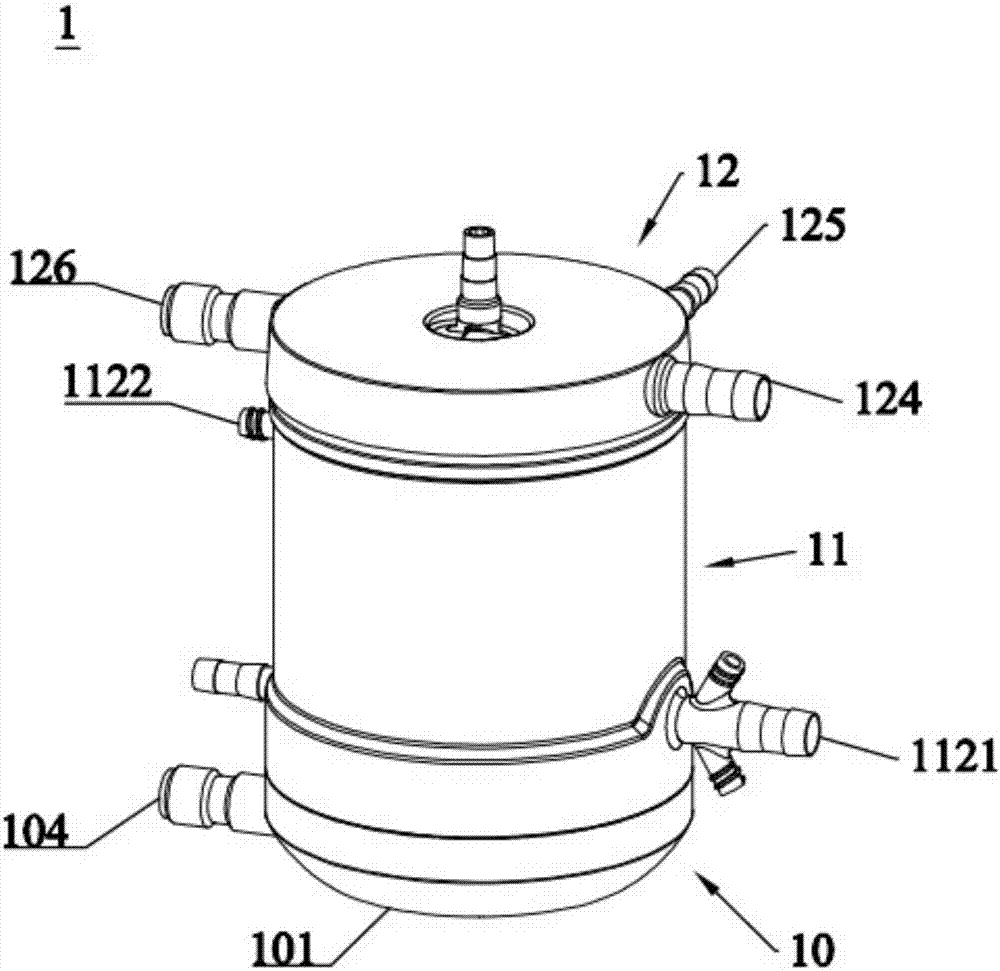

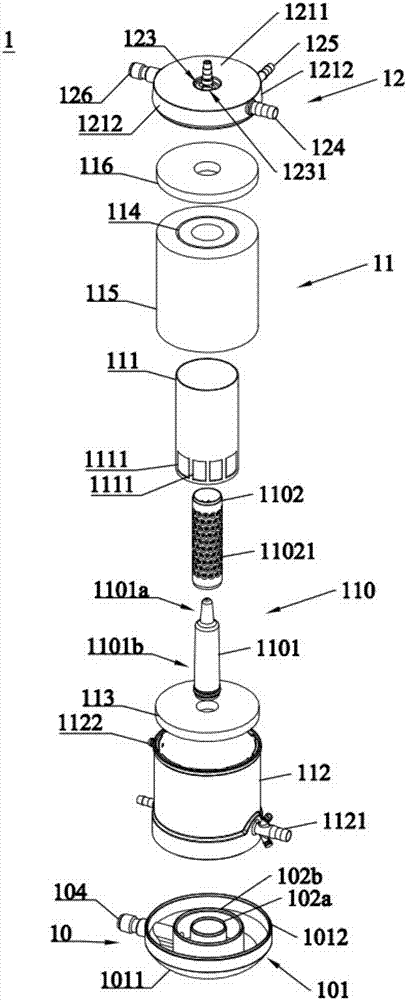

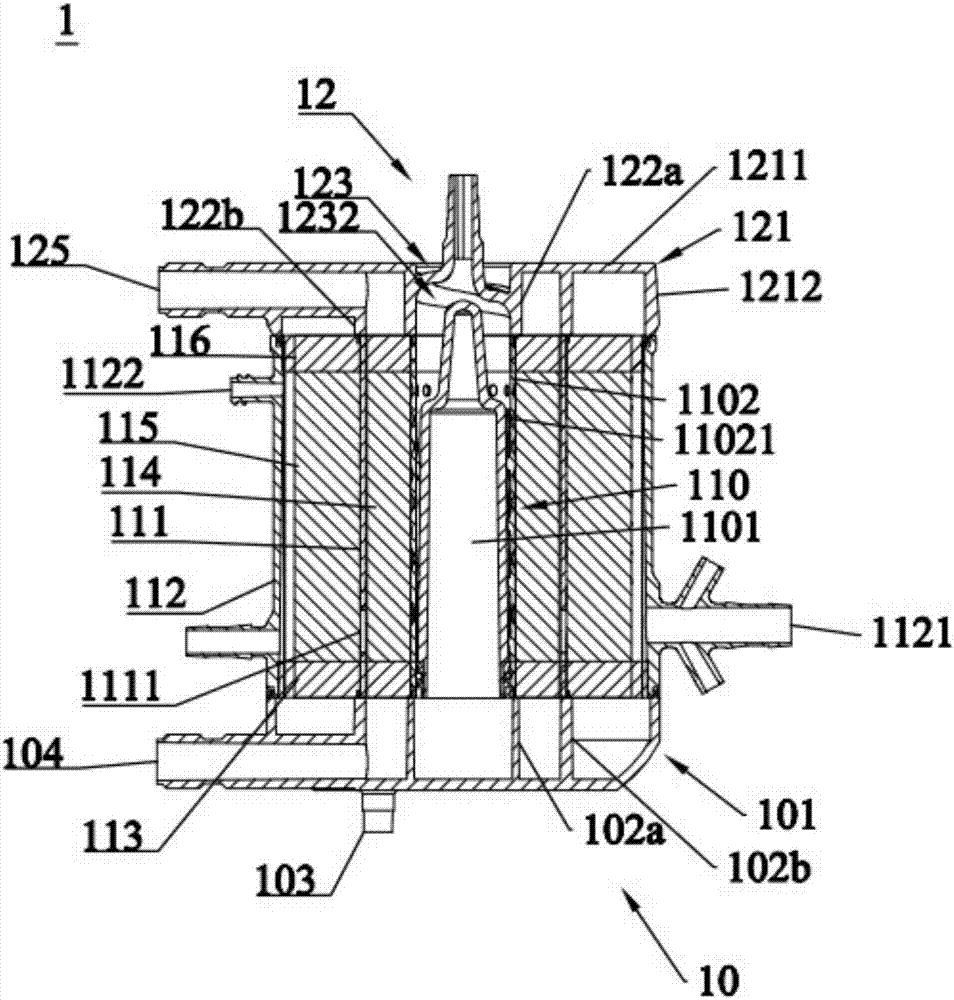

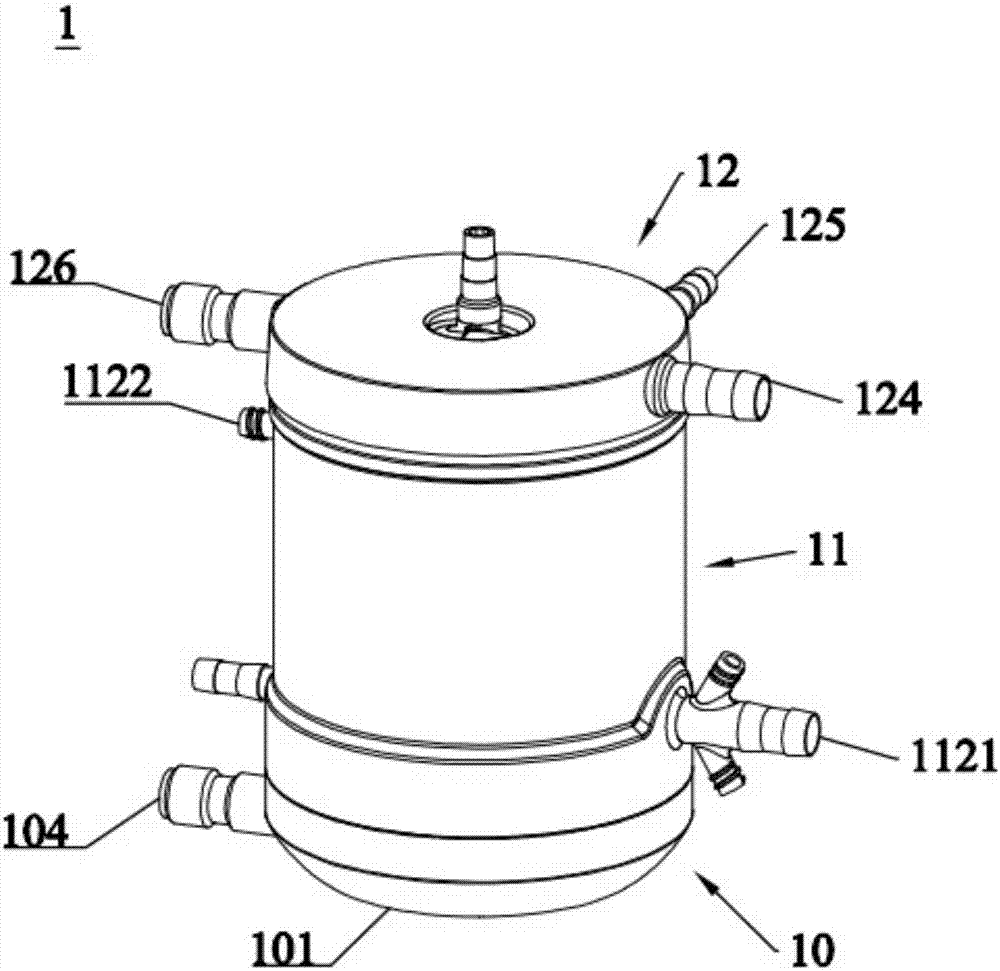

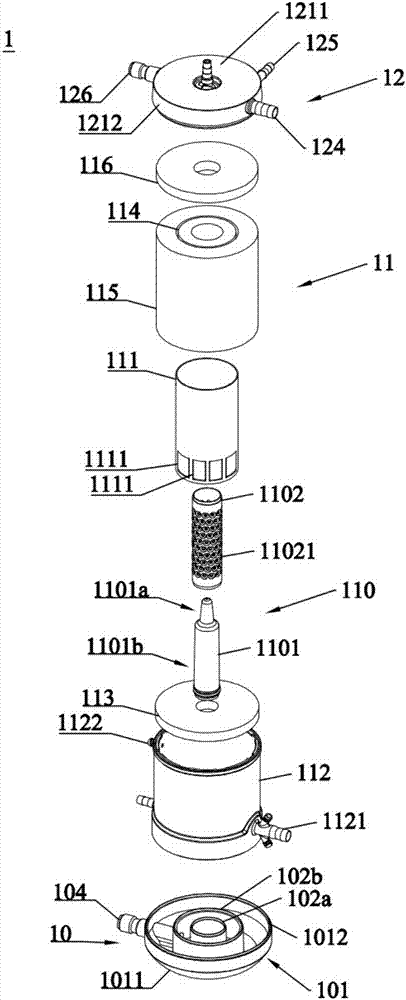

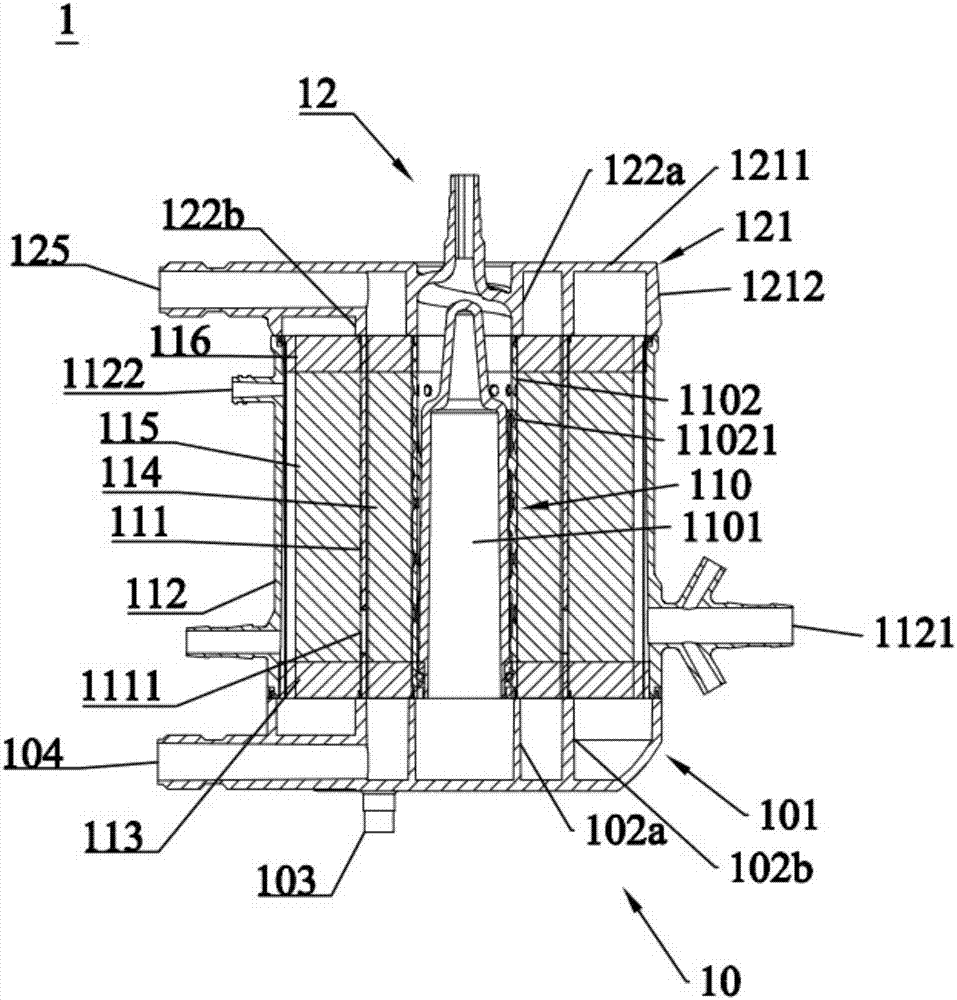

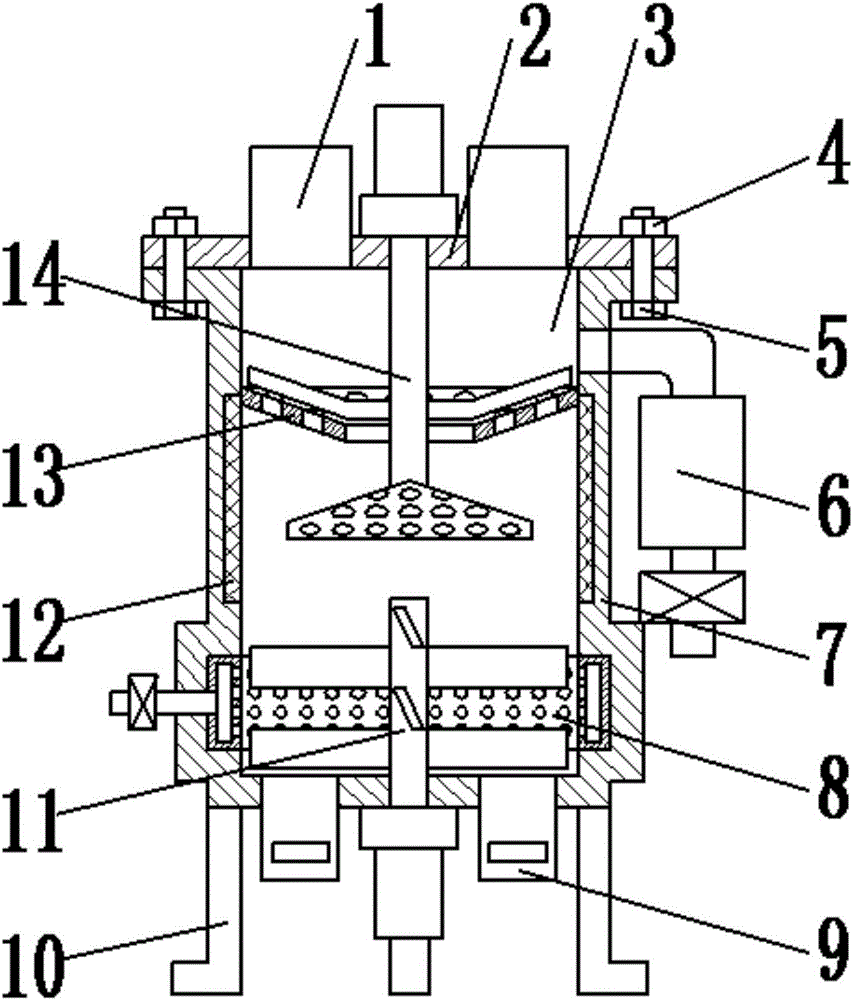

Membrane type oxygenator

ActiveCN107485744AIncreased diffusion areaIncrease contact areaOther blood circulation devicesMedical devicesMembrane oxygenatorsOxygen

The invention relates to a membrane type oxygenator which comprises a lower cover, an oxygenation portion and an upper cover. The lower cover is provided with an air outlet tube, the oxygenation portion is arranged in the lower cover and comprises a mandrel structure, an oxygenation housing and an oxygenating silk film structure, the oxygenation housing is provided with a blood outlet tube, and the blood outlet tube is close to the lower cover. The upper cover is arranged on the oxygenation portion and is provided with an eddy structure, a blood inlet structure and an oxygen inlet tube, and the eddy structure corresponds to the mandrel structure. The mandrel structure comprises a mandrel body and an annular guide plate, the mandrel body is provided with a first end and a second end, a blood channel is formed between the first end and the eddy structure, and the mandrel body is sleeved with the annular guide plate. The mandrel structure of the membrane type oxygenator is provided with the annular guide plate, the annular guide plate guides blood diffusion, the contact area and the diffusion area of blood and the silk film structure are increased, and the utilization rate of the silk film structure is improved.

Owner:DONGGUAN KEWEI MEDICAL INSTR

Method for extracting andrographolide from andrographis paniculata

InactiveCN103435578AHigh yieldIncreased diffusion areaOrganic chemistryPlant tissueBiochemical engineering

The invention relates to a method for extracting andrographolide from andrographis paniculata and in particular relates to a method for extracting andrographolide by employing the combination of a plant tissue crushing method and enzymolysis. The processing steps comprises: crushing the whole andrographis paniculata by the plant tissue crushing extraction method, carrying out enzymolysis on the crushed andrographis paniculata, extracting by the assistance of ultrasonic wave and microwave, filtering, extracting by petroleum ether, purifying by macroporous resin, concentrating under reduced pressure and re-crystallizing, thus obtaining the andrographolide with high purity. The method for extracting andrographolide from andrographis paniculata carries out crushing at room temperature, and is free from damage to ingredient, saves time, has high efficiency and saves energy, is simple and convenient to operate, beneficial to environment protection, high in extraction efficiency and purity, and applicable to production in large scale.

Owner:NANJING TONGZE AGRI SCI & TECH

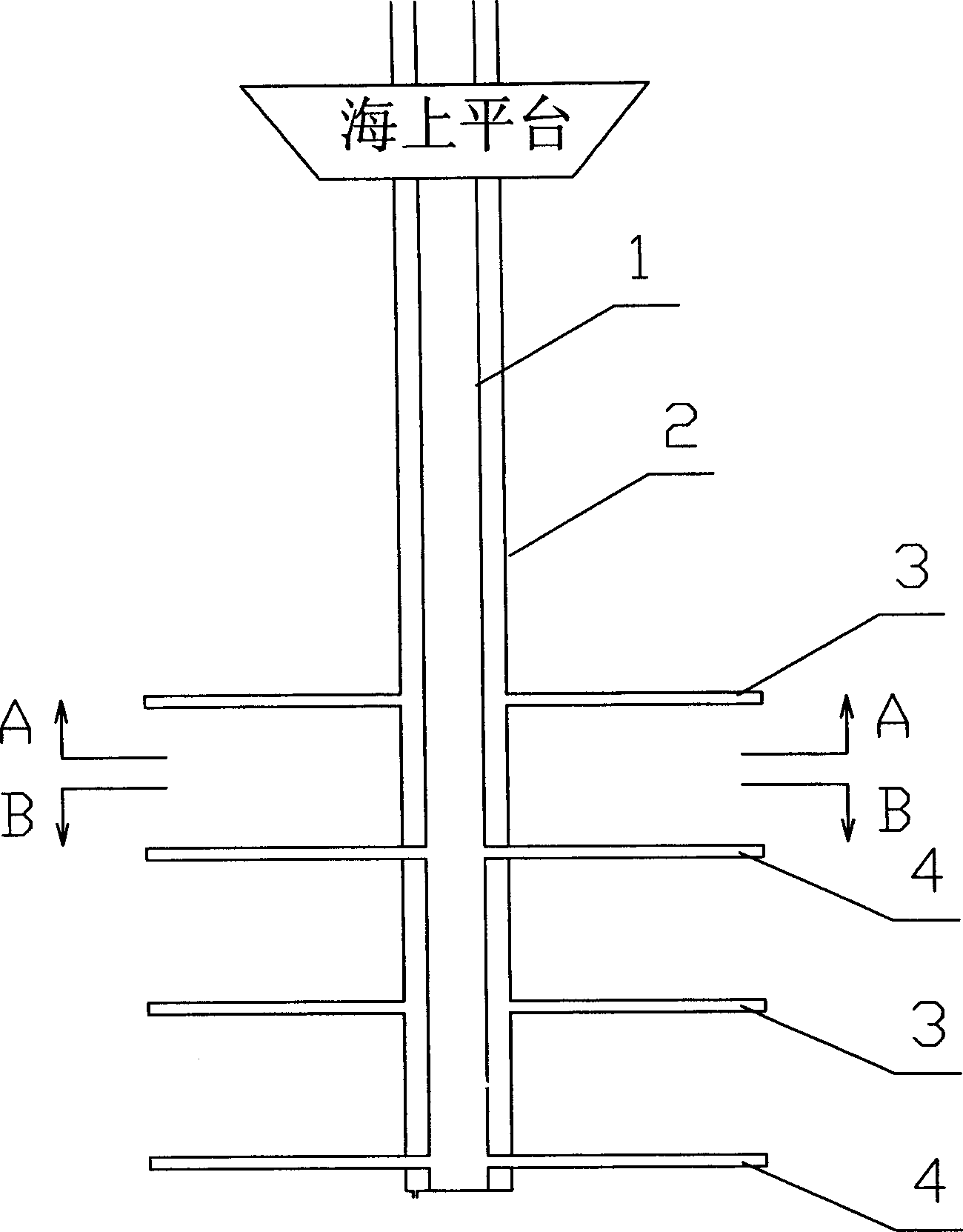

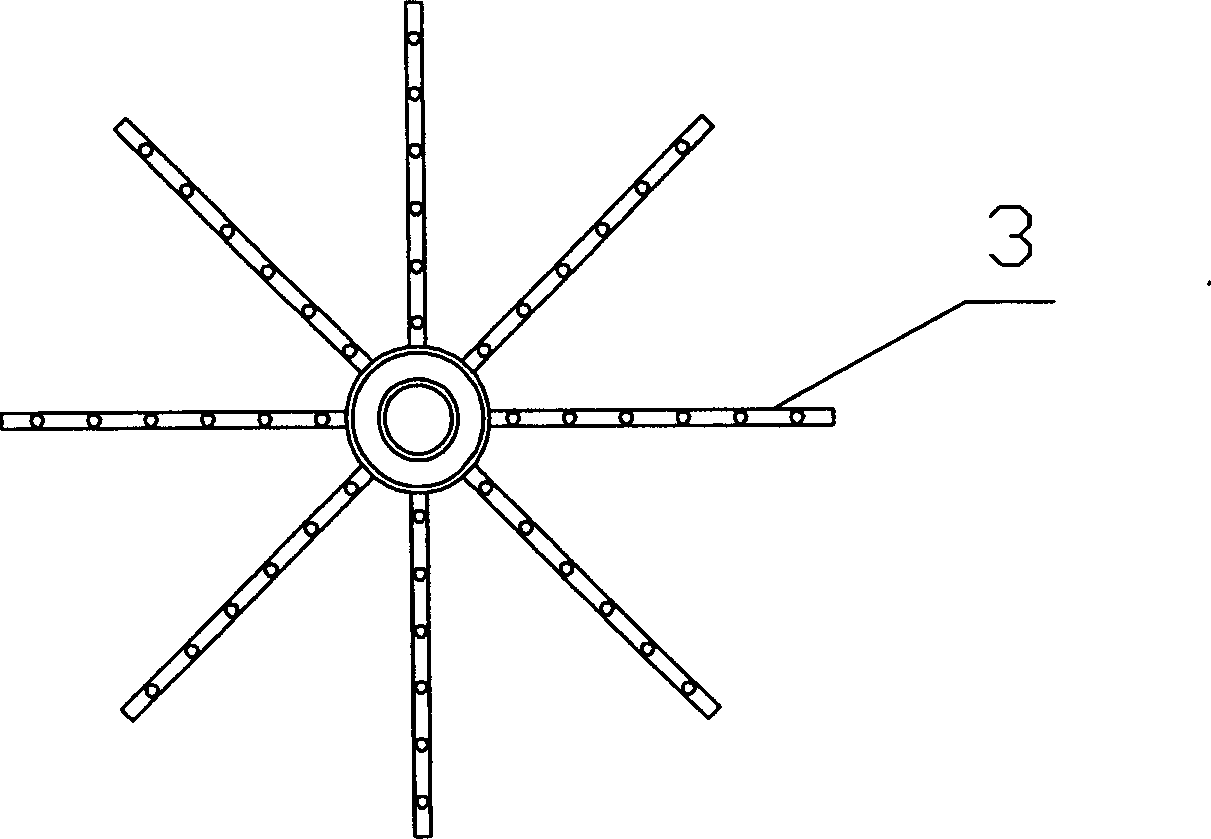

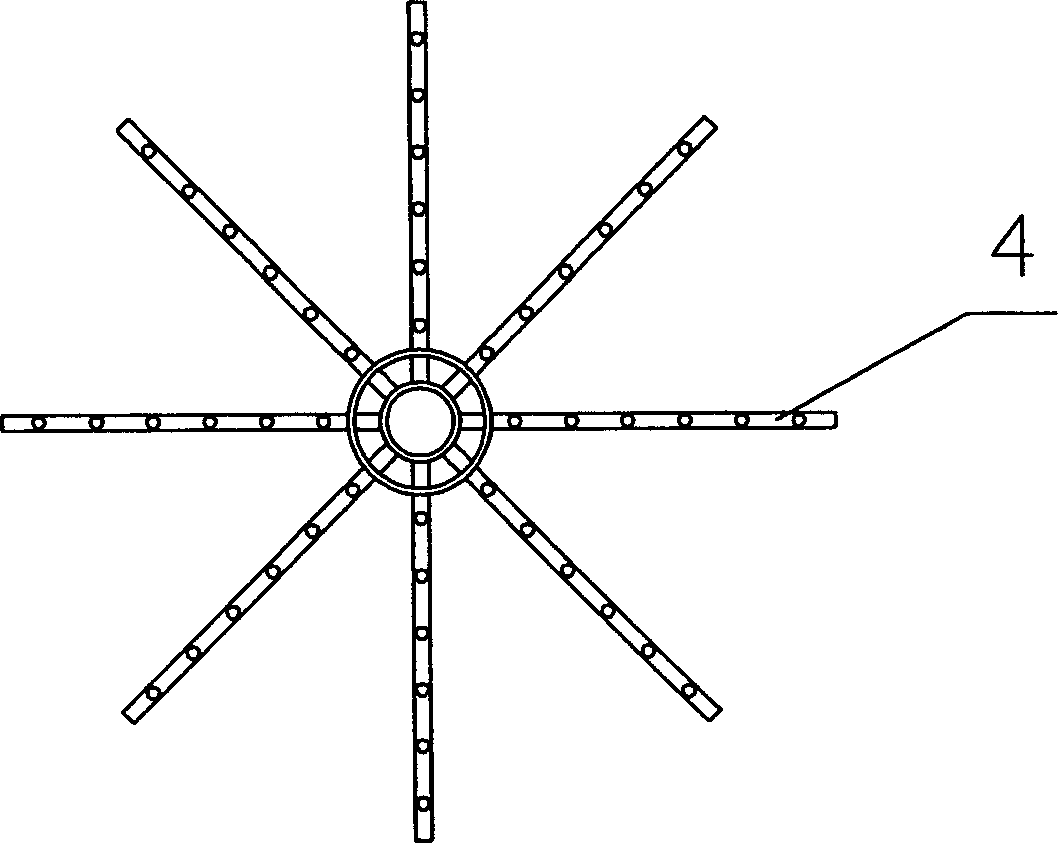

Well pattern arrangement method for underground decomposing and extracting natural gas hydrate

InactiveCN1776192AIncrease the areaImprove efficiencyConstructionsFluid removalThermal insulationEngineering

This invention provides a pattern arrangement method for underground decomposing and exploiting natural gas hydrate. It contains main pipe, injection pipe and gas producing pipe net, wherein the main pipe adopting axial sleeve structure and thermal insulation treated in inner and outer pipe, injecting fluid material and up conveying natural gas from outer pipe. In natural gas hydrate layer, the gas producing pipe and injection pipe adopting plurality of pipes in radiation distribution and having a number of in pairing distributed holes. Said invention raises injected heat and diffused area of chemical agent, enlarges gas producing area and efficiency.

Owner:GUANGZHOU INST OF ENERGY CONVERSION - CHINESE ACAD OF SCI

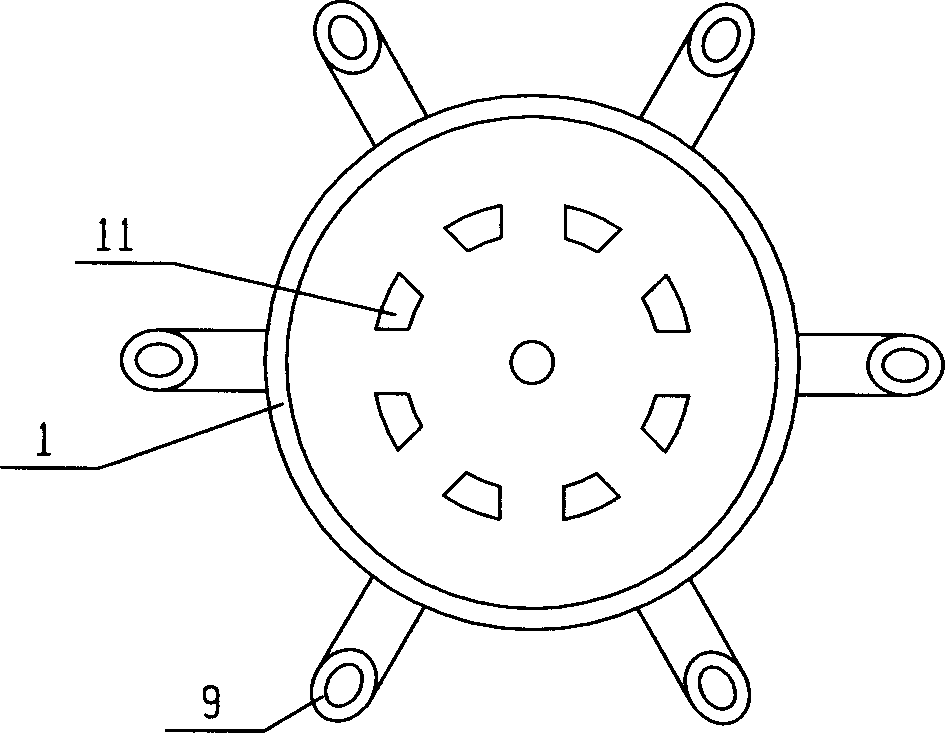

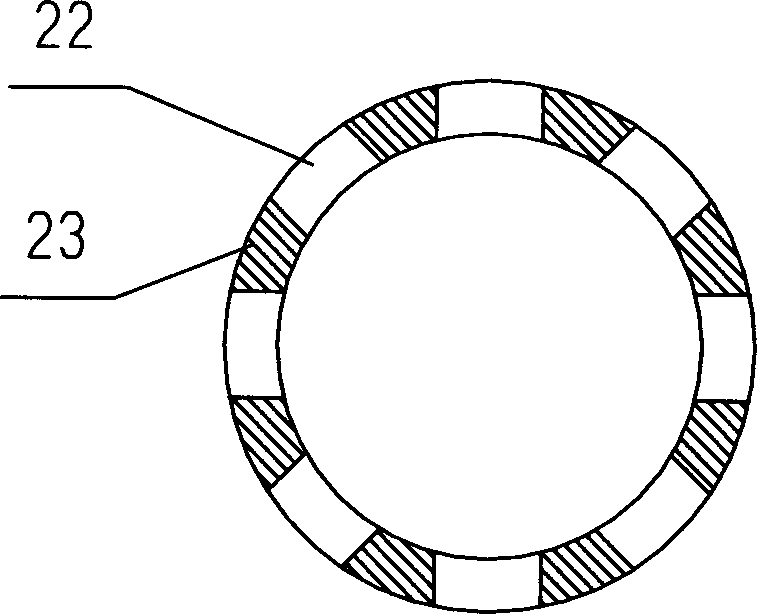

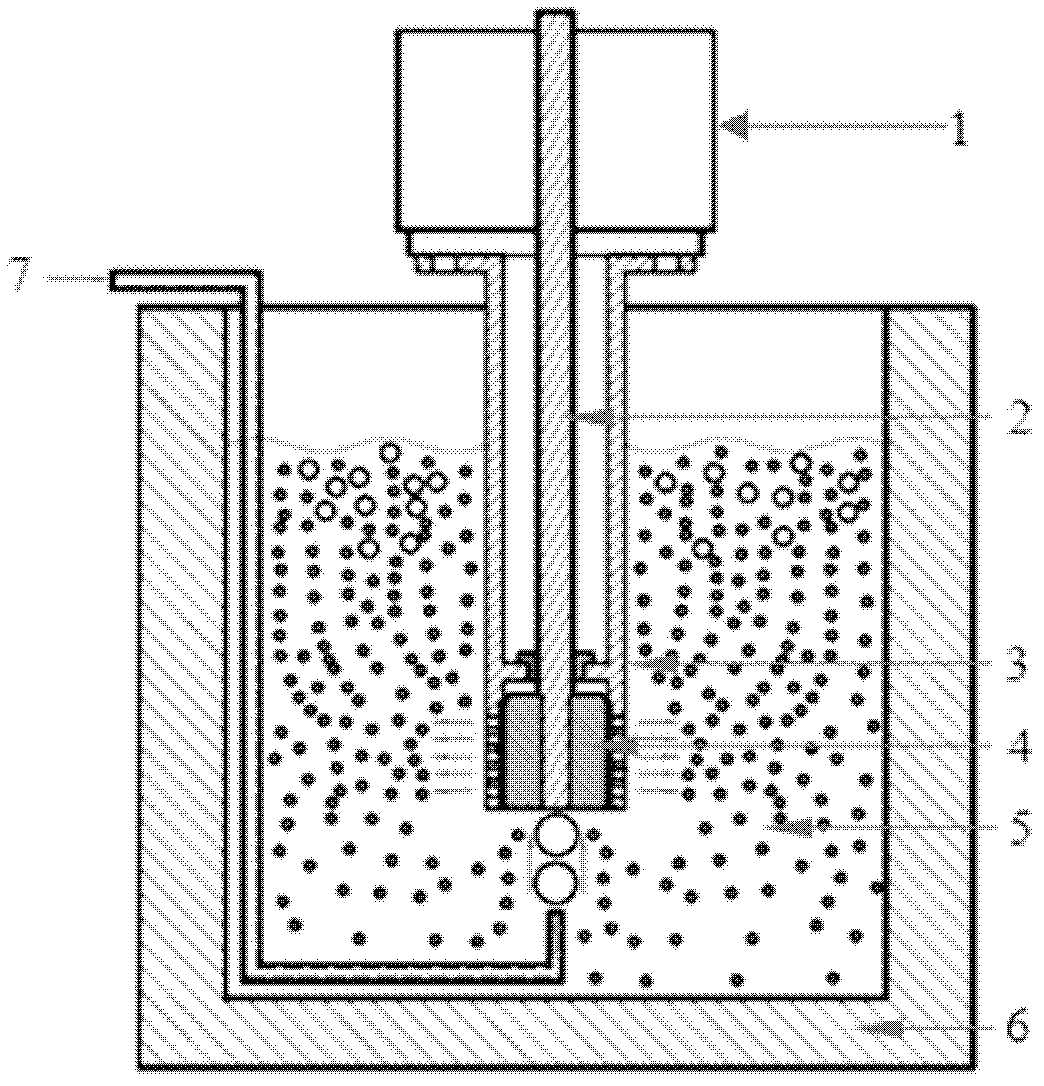

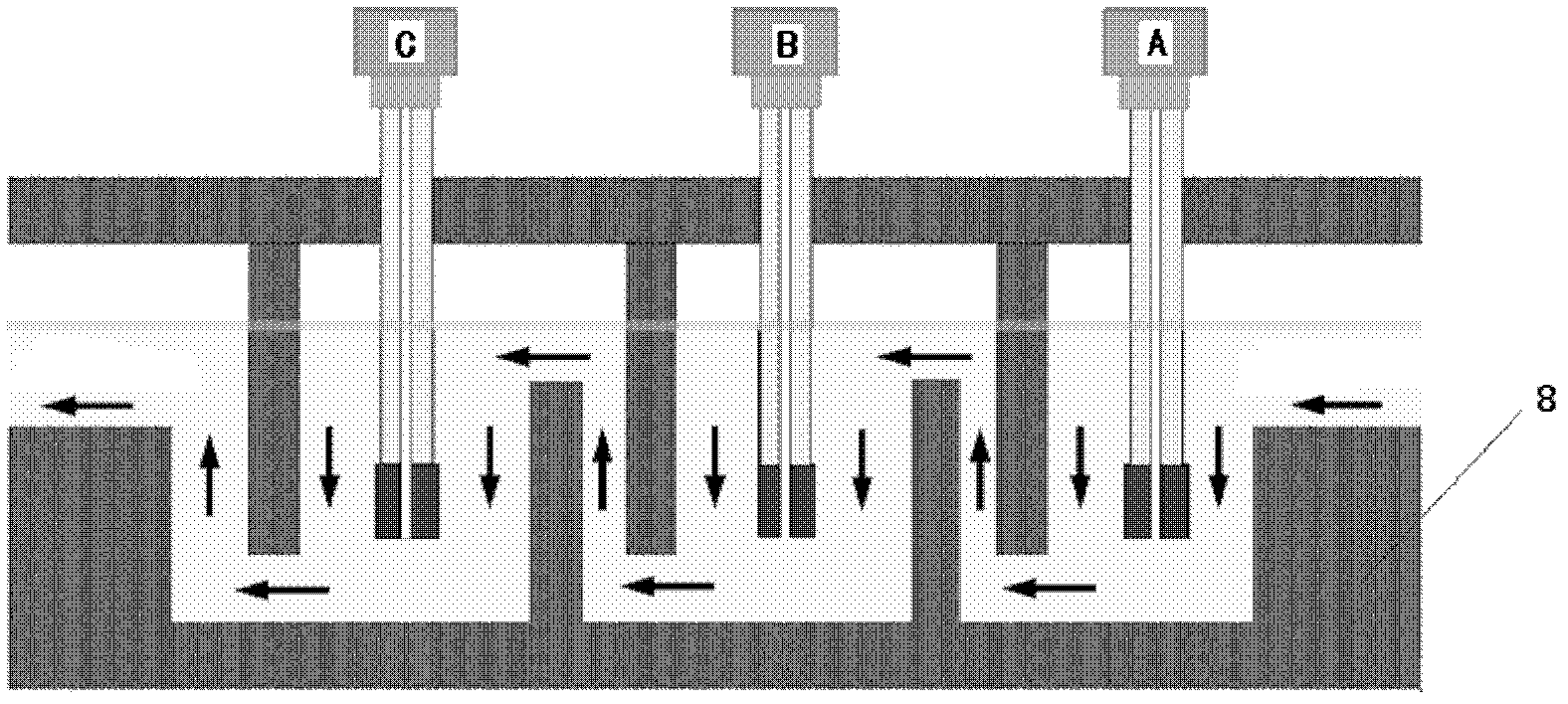

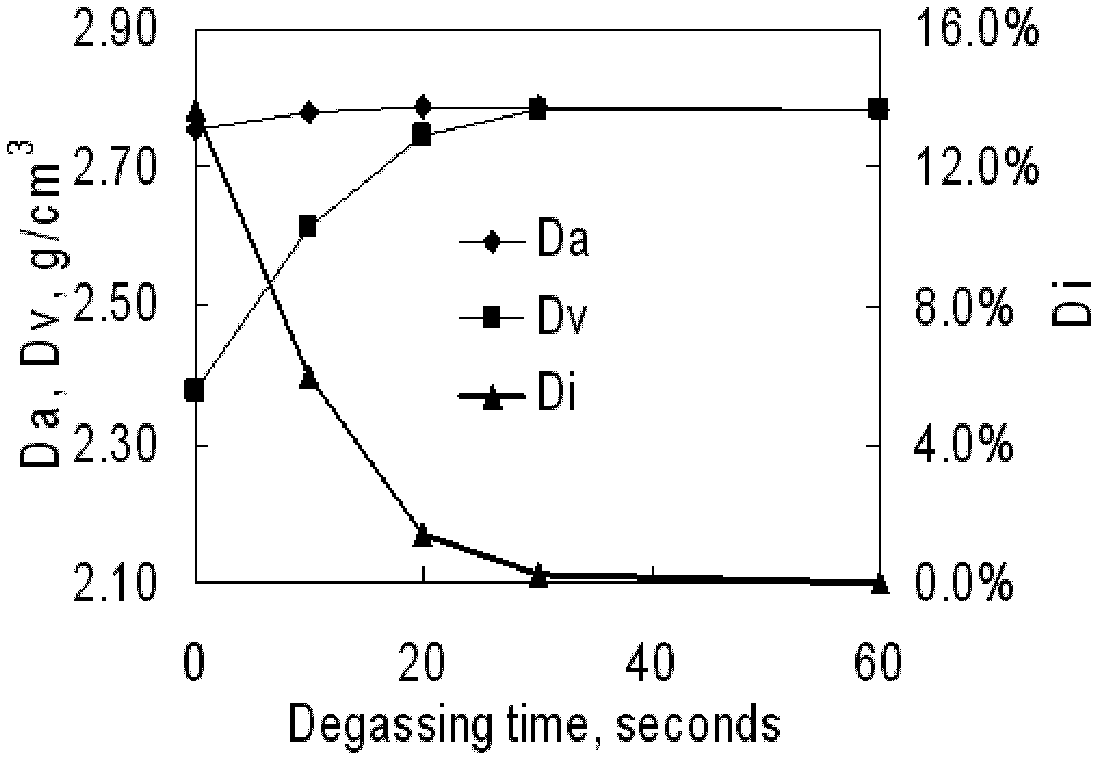

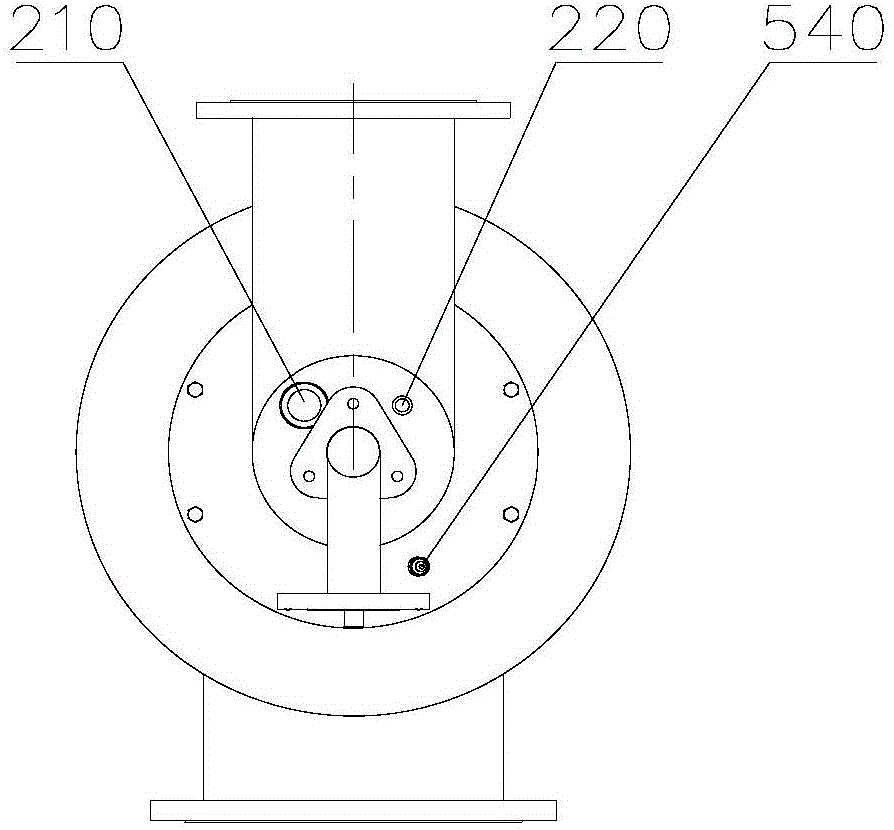

Alloy melt purifier and its method

The invention relates to an alloy melt purifier and its method, the purifier comprises a driving motor, a connection shaft, a stator and a rotor. The driving motor is directly connected with the connection shaft, the end portion of the connection shaft enables fixed connection with the rotor, the connection shaft and the rotor are arranged in the columnar stator, the stator is embedded and fixed in an insulation container, the alloy melt is filled in the insulation container, the stator is immersed in the alloy melt, an aperture is opened on the wall at the lower part of the stator, a vapor pipe is provided at one side of the insulation container, a gas outlet of the vapor pipe is in alignment with the lower part of the lower part of the rotor; The method for purifying the alloy melt by using the purifier comprises the following steps: the alloy melt and inert gas are sucked in the purifier through the high speed rotation of the rotor, high strength shearing effect formed by the stator and the rotor can be used, and the controllable forced convection can be generated under the liquid surface of the alloy melt, thereby the introduced inert gas bubbles can be smashed to fine bubbleswhich are uniformly distributed in the melt, the fine inert gas bubbles absorb impure gas in the melt and overflow the liquid surface, so that the purification of the melt with high efficiency can berealized.

Owner:NORTHEASTERN UNIV LIAONING

Method for conducting grouting construction at back of pile bottom of cast-in-place pile

A method for conducting grouting construction at the back of the pile bottom of a cast-in-place pile sequentially includes the following steps: (1) manufacturing and arranging a grouting pipe which comprises a plurality of grouting steel pipe sections sequentially connected from top to bottom with the lower end of the lowest grouting steel pipe section connected with a grouting spraying nozzle; (2) assembling a grouting station and a slurry transportation pipeline; (3) grouting. The method is characterized in that the grouting spraying nozzle used in the step (1) comprises a slurry spraying pipe body, a slurry inlet is formed in the upper end of the slurry spraying pipe body, a plurality of slurry discharging holes are formed in the lateral wall of the slurry spraying pipe body, a grouting one-way valve is installed on the slurry discharging holes, a sand wrapping device is arranged on the outside of the slurry spraying pipe body, a sand isolation layer is arranged between the sand wrapping device and the outer side of the slurry spraying pipe body, and the sand isolation layer covers the grouting one-way valve. When the grouting spraying nozzle reaches the bottom of a pile hole, and the portion of the upper end of the grouting pipe higher than the ground reaches preset height, the upper end of the grouting pipe is fixedly connected with a protection barrel at the top of the pile hole. By means of the method, smooth grouting can be achieved, grouting quality is ensured, and success ratio is ensured.

Owner:广东省第二建筑工程有限公司

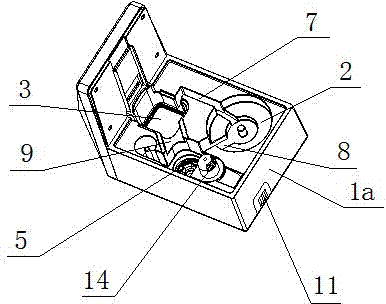

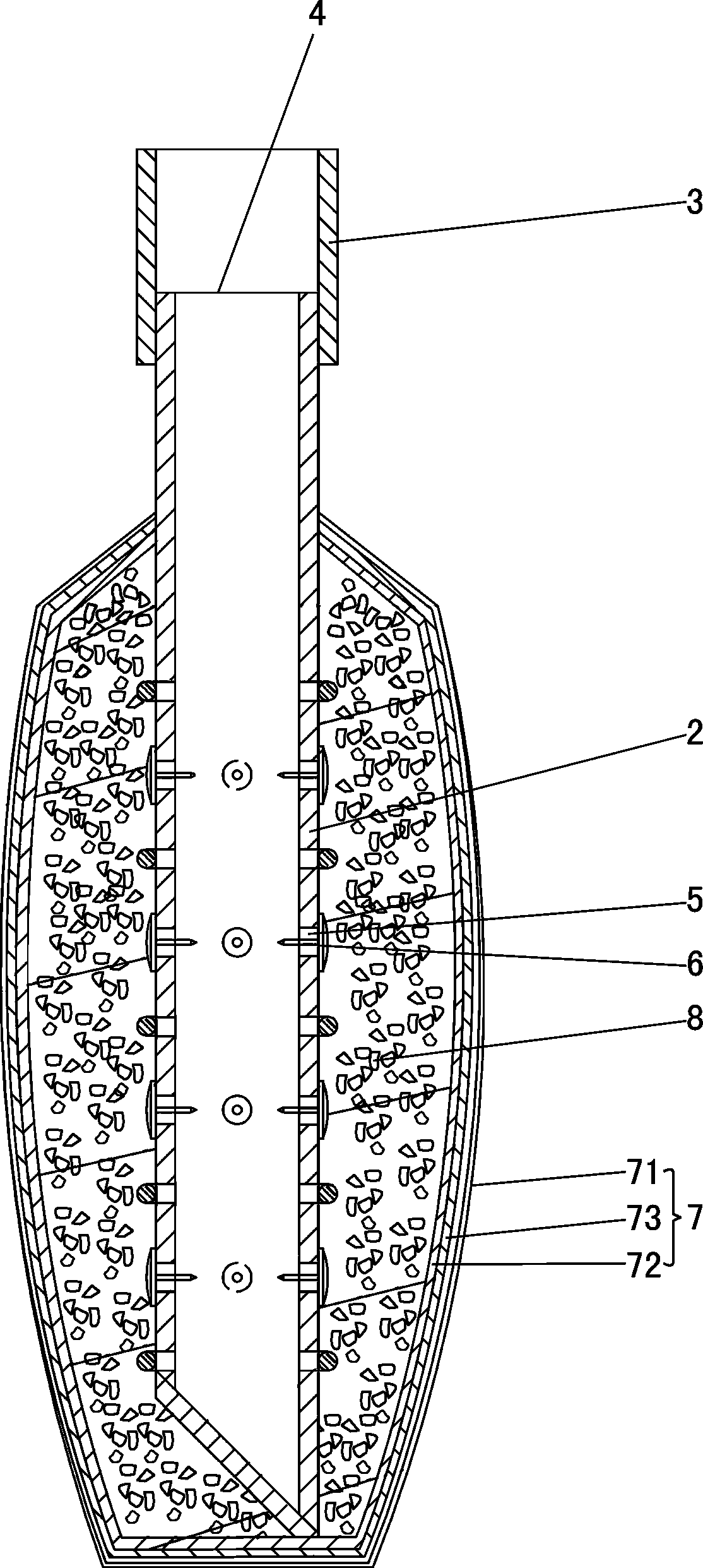

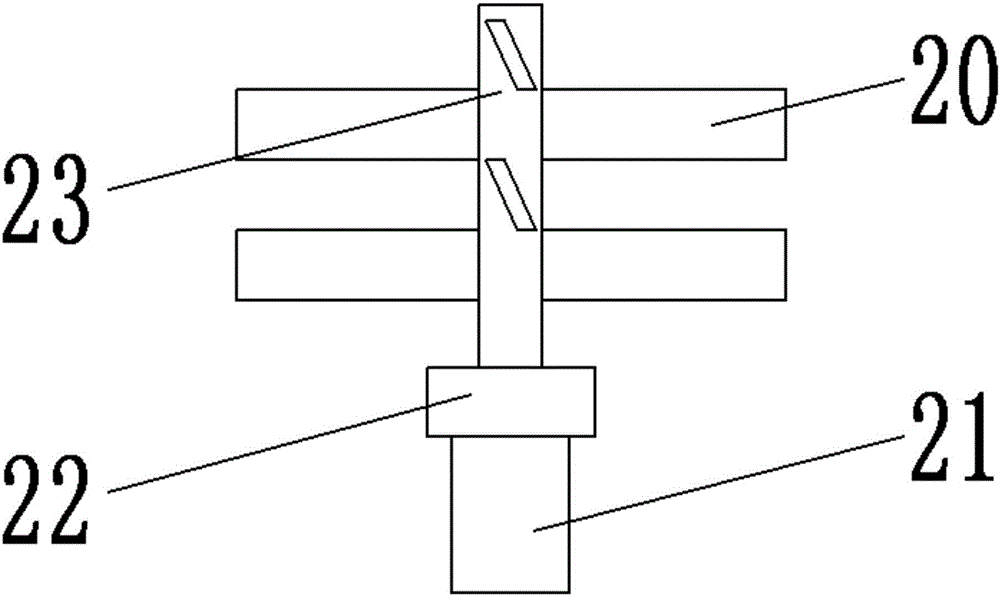

Spiral flow-guide integrated membrane oxygenator

ActiveCN107362399AIncreased diffusion areaIncrease contact areaDialysis systemsMedical devicesMembrane oxygenatorsMembrane oxygenator

The invention relates to a spiral flow-guide integrated membrane oxygenator comprising a lower cover, an oxygenation portion and an upper cover. The lower cover is provided with an air outlet pipe. The oxygenation portion is arranged to the lower cover and comprises a spindle structure, an oxygenation shell and an oxygenation cortina structure, and the oxygenation shell is provided with a blood outlet pipe close to the lower cover. The upper cover is arranged to the oxygenation portion and is provided with a blood inlet pipe and an oxygen inlet pipe. The spindle structure comprises a spindle body and an annular flow guide plate, the spindle body is provided with a first end and a second end, a blood channel is formed between the first end and the upper cover, the annular flow guide plate sleeves the spindle body and is provided with at least one flow guide through hole, and the flow guide through holes of the annular flow guide plate are distributed in the annular flow guide plate. The spindle structure of the spiral flow-guide integrated membrane oxygenator is provided with the annular flow guide plate, the annular flow guide plate guides blood to diffuse through the flow guide structure with the flow guide through holes, contact area and diffusion area of blood and the cortina structure are increased, and utilization rate of the cortina structure is increased.

Owner:DONGGUAN KEWEI MEDICAL INSTR

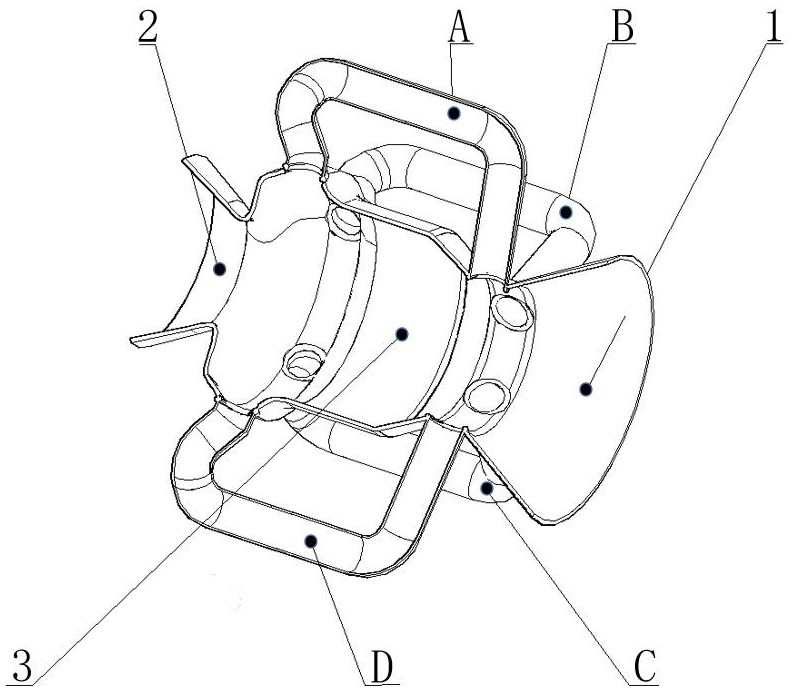

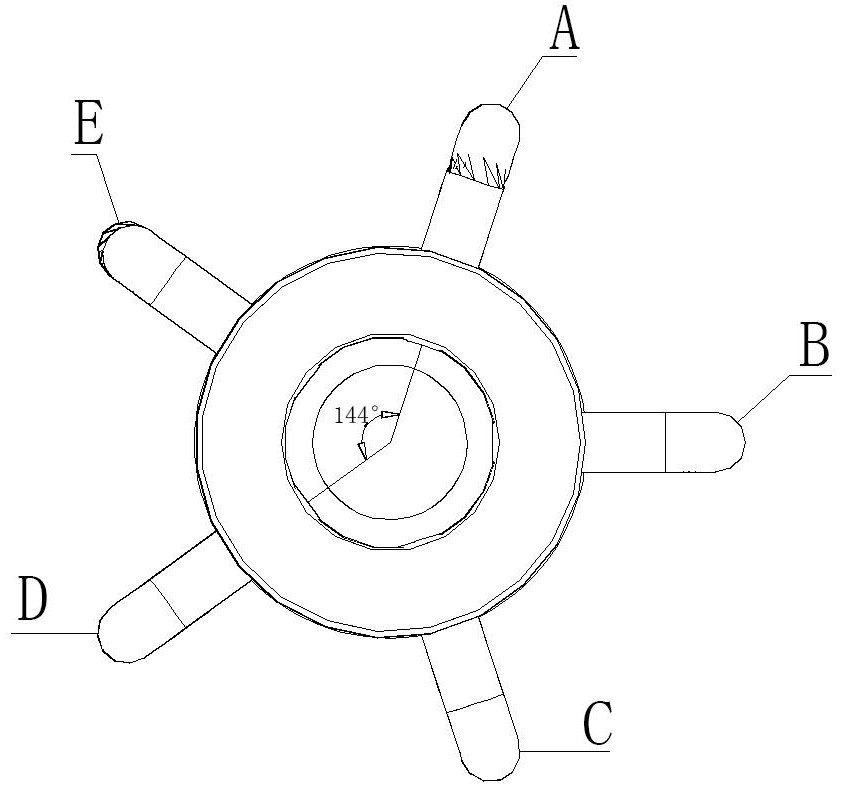

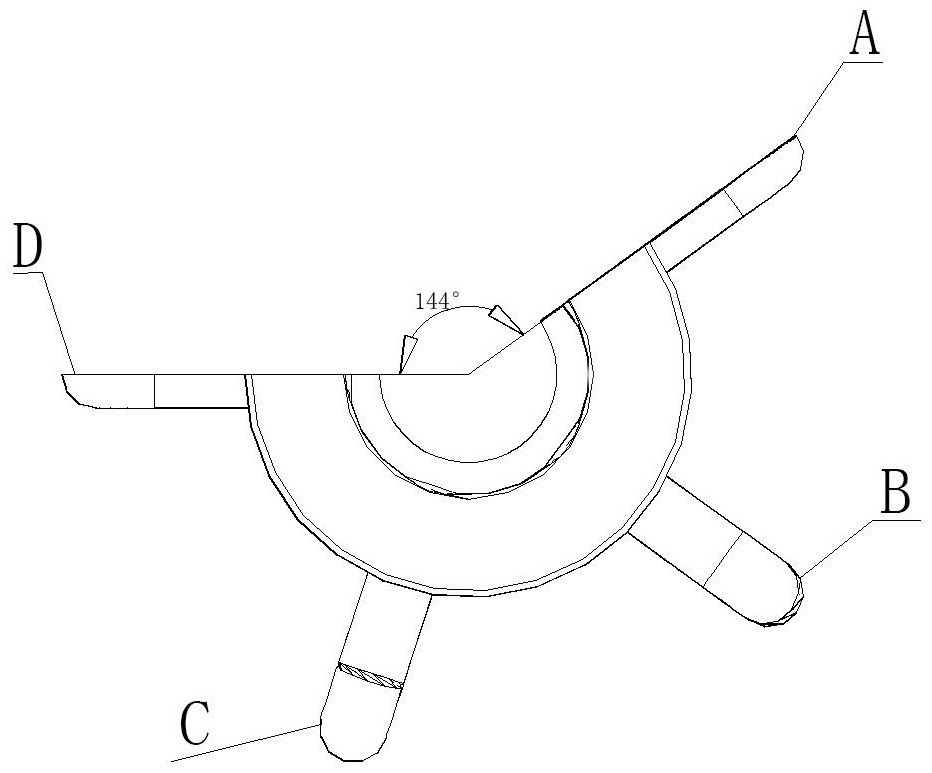

Self-oscillation jet-type mixing-increasing heat exchange air outlet device

ActiveCN111623505AIncreased diffusion areaGuaranteed heat exchange effectDucting arrangementsJet flowEngineering

The invention belongs to the technical field of air conditioning equipment mixing-increasing heat exchange, in particular to a self-oscillation jet-type mixing-increasing heat exchange air outlet device, and aims to solve the problems of fixed air outlet, poor heat exchange capability, non-uniform space temperature distribution, poor personnel comfort and the like in air outlet devices of most existing large-sized central air conditioners. The self-oscillation jet-type mixing-increasing heat exchange air outlet device comprises a main cavity and an odd number of feedback channels which are distributed on the main cavity at equal intervals, wherein the main cavity comprises a main chamber; and an air inlet and an air outlet are formed in two opposite ends of the main chamber respectively, and are in communication with each other through the main chamber. Through adoption of the mixing-increasing heat exchange air outlet device disclosed by the invention, the indoor temperature distribution uniformity is improved, and the comfort of the household living environment is improved greatly. The indoor temperature distribution is more uniform; frequent switching-on / off actions and refrigerating / heating processes of central air conditioning equipment are avoided; and the service life of the air conditioning equipment is prolonged while the running cost of the air conditioner is loweredand the electric energy is saved.

Owner:TAIYUAN UNIV OF TECH

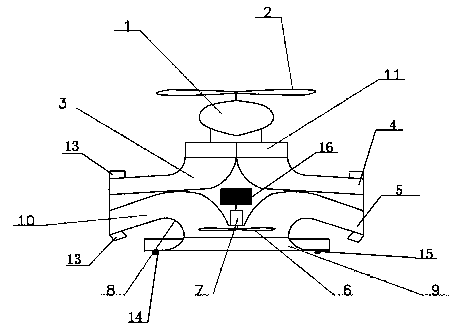

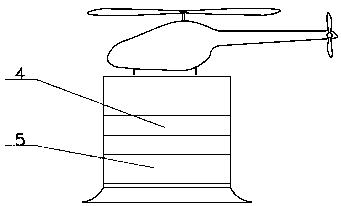

Unmanned aerial vehicle pollination device and method thereof

ActiveCN108353784AGuarantee the effectiveness of collectionIncrease profitAircraft componentsAgriculturePollinationPollen

The invention belongs to an unmanned aerial vehicle pollination device and a method thereof. The unmanned aerial vehicle pollination device comprises an unmanned aerial vehicle, wherein a rotor wing is arranged above the unmanned aerial vehicle; an air outlet flow passage is hung under the unmanned aerial vehicle; a pollen outlet passage is arranged under the air outlet passage; an air outlet of the air outlet flow passage is arranged above a pollen outlet of the pollen outlet flow passage; the air outlet and the pollen outlet are in horizontal arrangement; an air suction fan is arranged at apollen inlet of the pollen outlet flow passage; an air inlet of the air outlet flow passage is arranged under the rotor wing. The unmanned aerial vehicle pollination device can suck the pollen and horizontally spray out the pollen to the two sides of the unmanned aerial vehicle; the pollen can be diffused to a wider space through an airflow sprayed out from the air outlet. The unmanned aerial vehicle pollination method can improve the pollen utilization rate and can improve the artificial pollination efficiency.

Owner:NANJING AGRI MECHANIZATION INST MIN OF AGRI

Preparation method of high-purity lycopene

InactiveCN103449952AIncreased diffusion areaReduce resistanceHydrocarbon purification/separationHydrocarbonsEnzymeUltrasonic assisted

The invention relates to a preparation method of high-purity lycopene, which comprises the following steps: (a) removing the peel and seeds of tomatoes, and pulping; (b) performing enzymolysis by use of a bio-enzyme; (c) performing ultrasonic-assisted extraction; (d) performing saponification and impurity removal; (e) performing extraction and crystallization. According to the method provided by the invention, the tomatoes are used as raw materials, the overlay effect of the enzymolysis and ultrasonic is fully used, the lycopene in the tomatoes is dissolved out to the greatest degree, and the high-purity lycopene is obtained through a series of purification treatment. The method provided by the invention has the advantages of simple process, short extraction time, high extraction rate and high purity, and is environment-friendly and easy for realizing industrial production.

Owner:NANJING TONGZE AGRI SCI & TECH

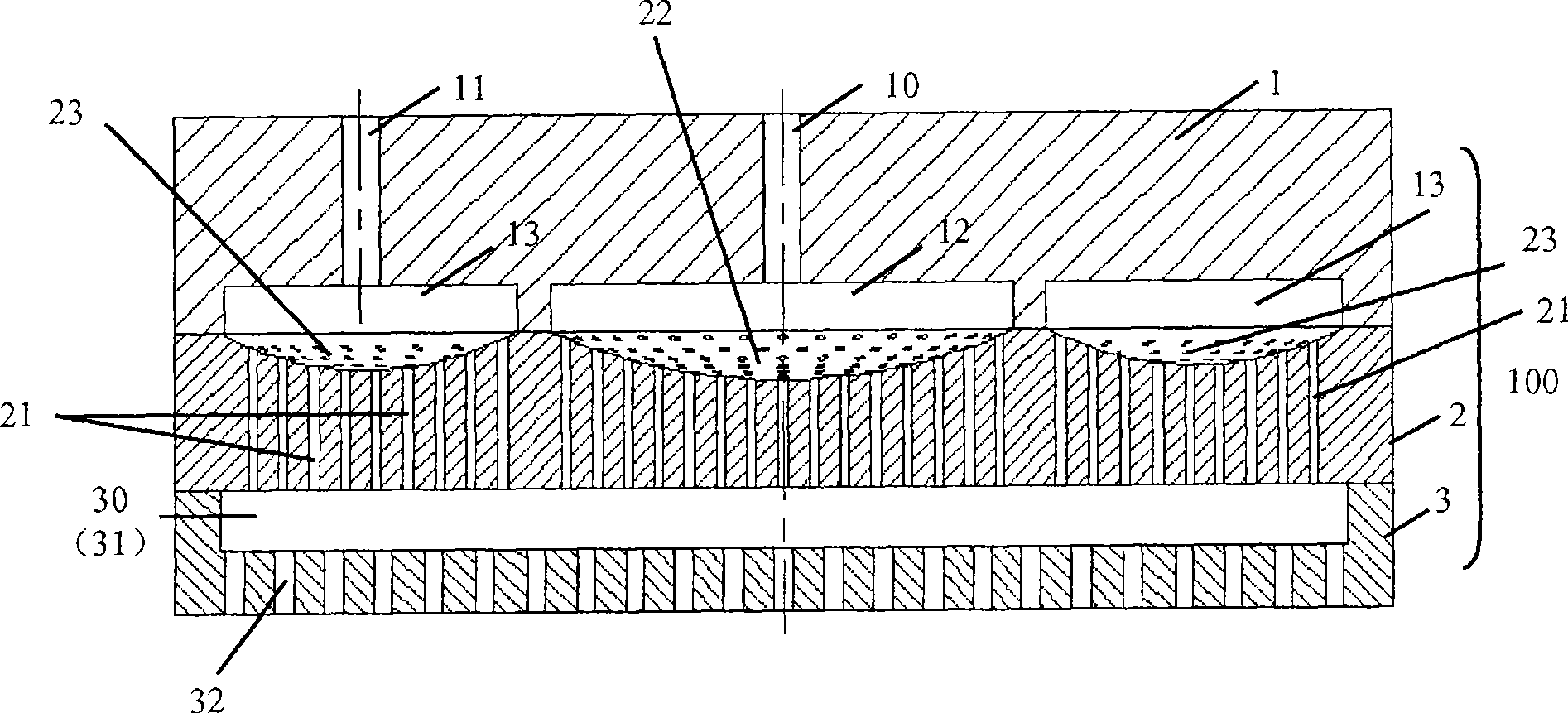

Display panel and preparation method thereof, and display device with same

ActiveCN109888126ASpeed up poolingIncreased diffusion areaSolid-state devicesSemiconductor/solid-state device manufacturingDisplay deviceEngineering

The invention relates to a display panel and a preparation method thereof, and a display device. A barrier in the related display panel comprises an upper section and a lower section extending reversely with respect to the upper section; a cambered surface is formed at the end part, extending to the bottom of the groove, of the lower section; the display panel also comprises an opening area; the barrier dam is arranged around the opening area, and an included angle of more than 90 DEG is formed between the side wall and the bottom of the opening area. According to the display panel provided bythe embodiment of the invention, the moisture collection and diffusion area is significantly enlarged via the structure that the end part of the lower section is the cambered surface; meanwhile the barrier dam deeply stretches into a barrier layer, so that the invalid packaging caused by laser drilling is avoided through improving the forming mode of the opening area, and the water oxygen entrance path is further prolonged; the technology is simple, the cost is low, the water oxygen is effectively isolated, and the packaging effect is improved.

Owner:YUNGU GUAN TECH CO LTD

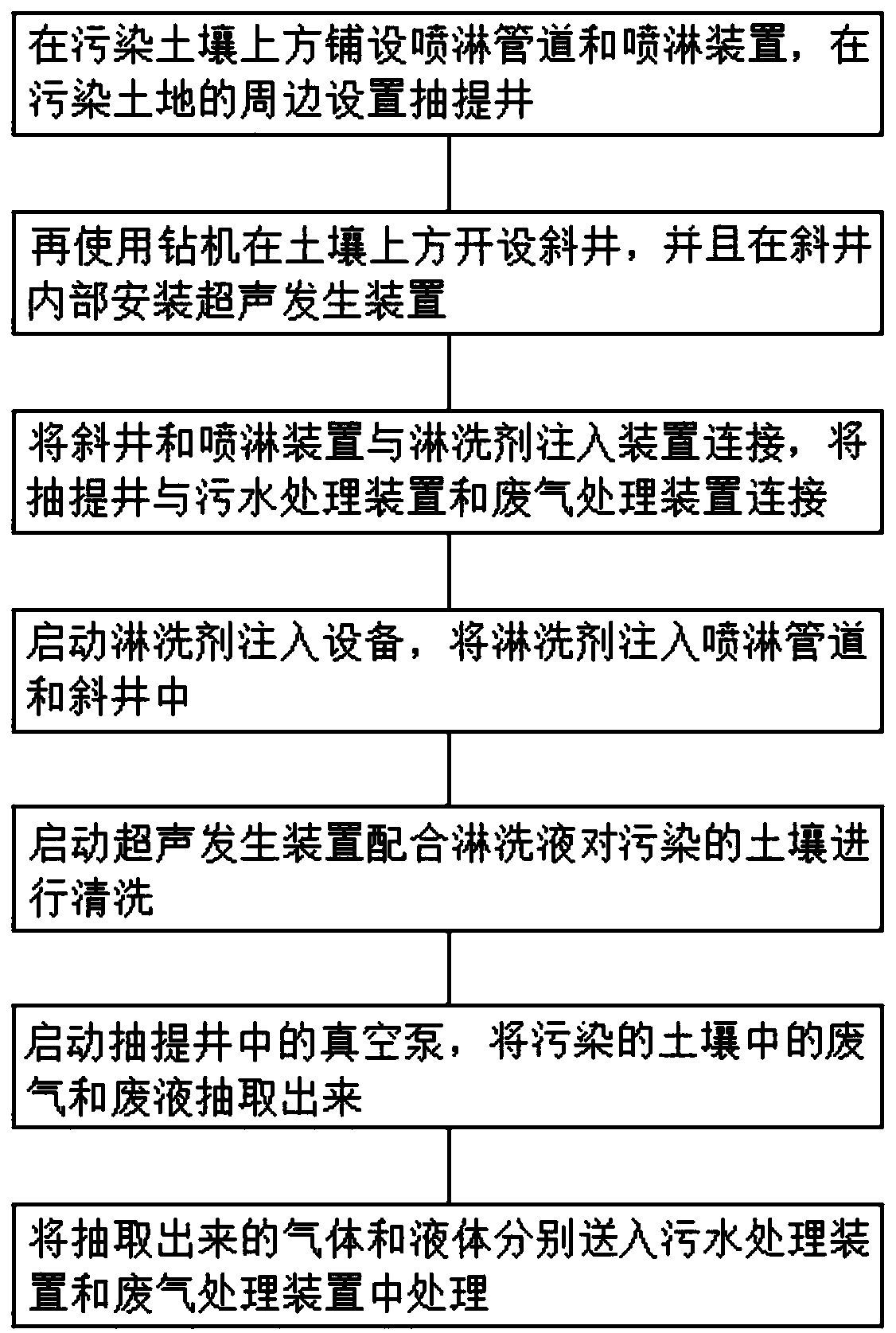

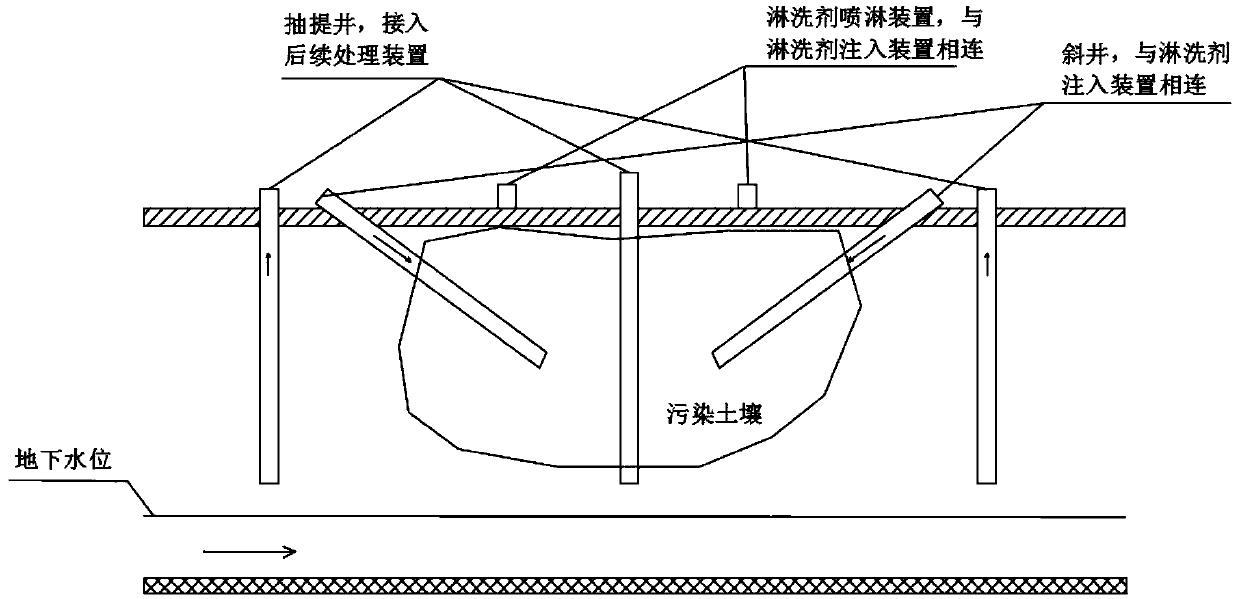

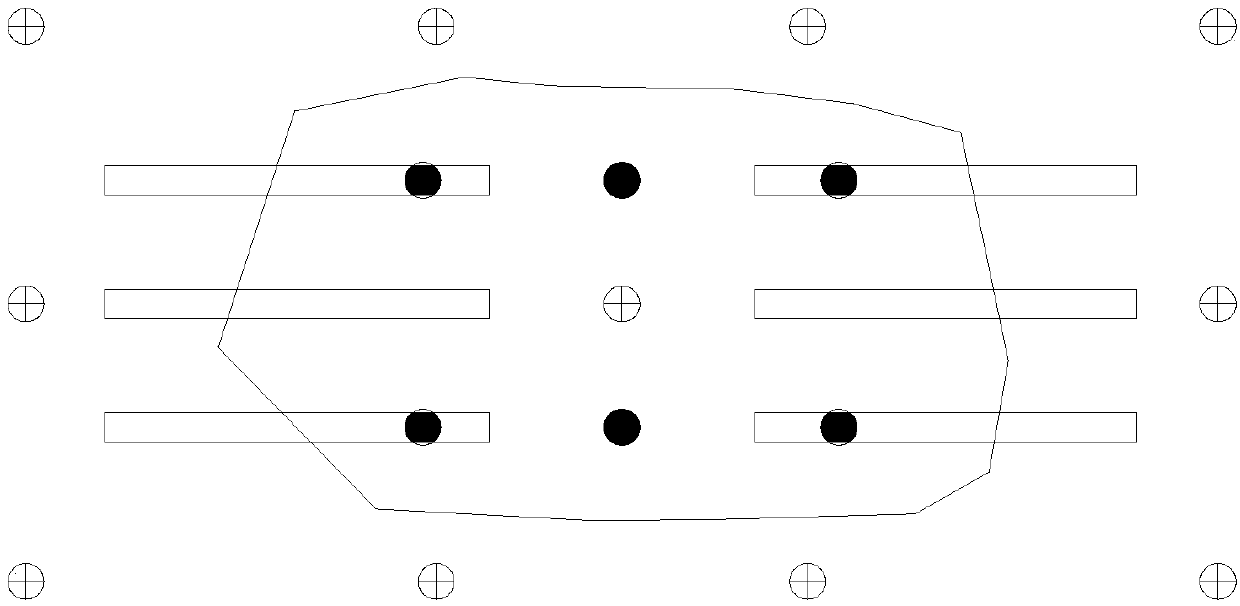

Soil in-situ leaching remediation method

InactiveCN109570212AEasy constructionIncreased diffusion areaContaminated soil reclamationEngineeringLeaching rate

The invention discloses a soil in-situ leaching remediation method. The soil in-situ leaching remediation method includes steps of laying spray pipelines and spray devices above contaminated soil, then arranging extraction wells at the peripheral edge and in the middle of the contaminated soil and mounting gas exhaust devices at the extraction wells; arranging oblique wells above the contaminatedsoil by drilling machines and mounting ultrasonic generating devices inside the oblique wells. The soil in-situ leaching remediation method has the advantages that the soil in-situ leaching remediation cost can be reduced, diffusion regions of leaching agents can be expanded, and contaminants in the soil and leacheate are wide in contact area; the leaching agents can be driven to be fed into soilparticles, and accordingly great effects can be realized; friction and stirring between the soil particles further can be promoted, the leaching agents can be diffused into soil pores, effects of desorbing the contaminants can be sufficiently realized, accordingly, leaching effects can be accelerated, the leaching rates can be increased, and the soil in-situ leaching remediation method has an excellent use prospect.

Owner:安徽国祯环境修复股份有限公司

Diffusion tower for mine air return and heat exchange

InactiveCN105003289AReduce return air speedImprove uniformityTunnel/mines ventillationEngineeringTower

The invention relates to a diffusion tower for mine air return and heat exchange. The diffusion tower is characterized by comprising a circular pipe section, a connecting section, a bent pipe section and a plurality of guide plates which are sequentially connected, wherein the circular pipe section can be liner type or divergent type; the bent pipe section is a perpendicular type bent pipe which adopts a straight line inside and an arc line outside; the top air outlet part of the bent pipe section can be externally connected with a mine air return and heat exchange device; a plurality of the guide plates are uniformly arranged inside the bent pipe section; the guide plates are connected with the two side walls inside the bent pipe section; the guide plates comprise horizontal guide sections and arc-shaped guide sections; the horizontal guide sections with equal intervals and sequentially enlarged length are arranged from the vertical position of the air inlet part of the bent pipe section; the arc-shaped guide sections correspondingly connected with the horizontal guide sections are arranged in the arc-shaped section range between the inner arc line of the connecting section and the outer arc line of the bent pipe section. According to the diffusion tower, the outlet part airflow is good in uniformity and stable in flow velocity, and a full and good heat exchange condition is provided for mine air return and heat exchange.

Owner:TECH DEV OF SHANXI COAL IMPORT & EXPORT GROUP +2

Moisture-absorbing cool double-layer fabric and preparation method

ActiveCN111172652AExcellent cooling performanceIncrease evaporation areaWeft knittingTwo or more solvent application treatmentPolyesterPolyamide

The present invention relates to a preparation method of a moisture-absorbing cool double-layer fabric. The method comprises the following steps of firstly weaving a double-layer knitted fabric with an inner layer with the contact cool feel and the moisture-guiding effect and an outer layer with the moisture-absorbing effect, then performing light non-continuous hydrophilic finishing on the surface of the inner layer and performing light non-continuous hydrophobic finishing on the surface of the outer layer to obtain the moisture-absorbing cool double-layer fabric; the inner layer is mainly formed by weaving cool polyamide, polyester fibers containing natural minerals or composite cool yarns prepared by adopting a novel spinning technology; the finally prepared moisture-absorbing cool double-layer fabric is of a double-layer composite structure composed of a contact cool moisture-guiding diffusion layer and a moisture-absorbing diffusion layer; one partial region of the contact cool moisture-guiding diffusion layer is hydrophilic, and the other partial region of the contact cool moisture-guiding diffusion layer is hydrophobic; one partial region of the moisture-absorbing diffusionlayer is hydrophilic, and the other partial region of the moisture-absorbing diffusion layer is hydrophobic; the hydrophilicity of the moisture-absorbing diffusion layer is higher than that of the contact cool moisture-guiding diffusion layer; and the fabric is good in integrated effect of contact cool feel and moisture diffusion cool feel, thereby being suitable for use as summer fabrics.

Owner:DONGHUA UNIV

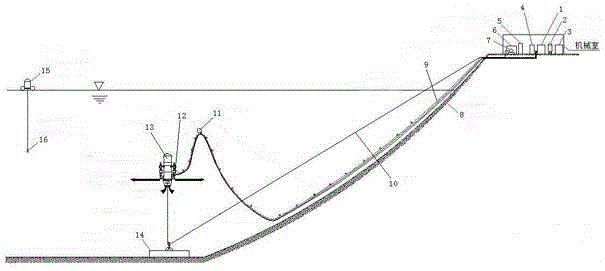

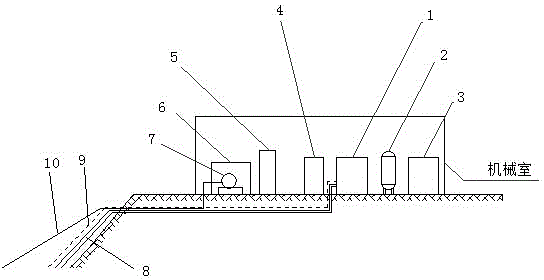

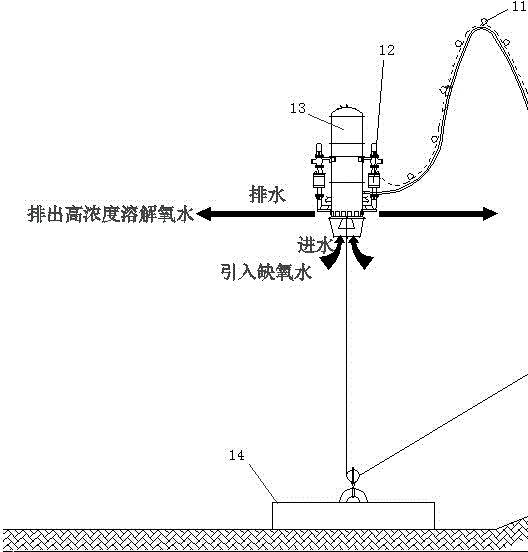

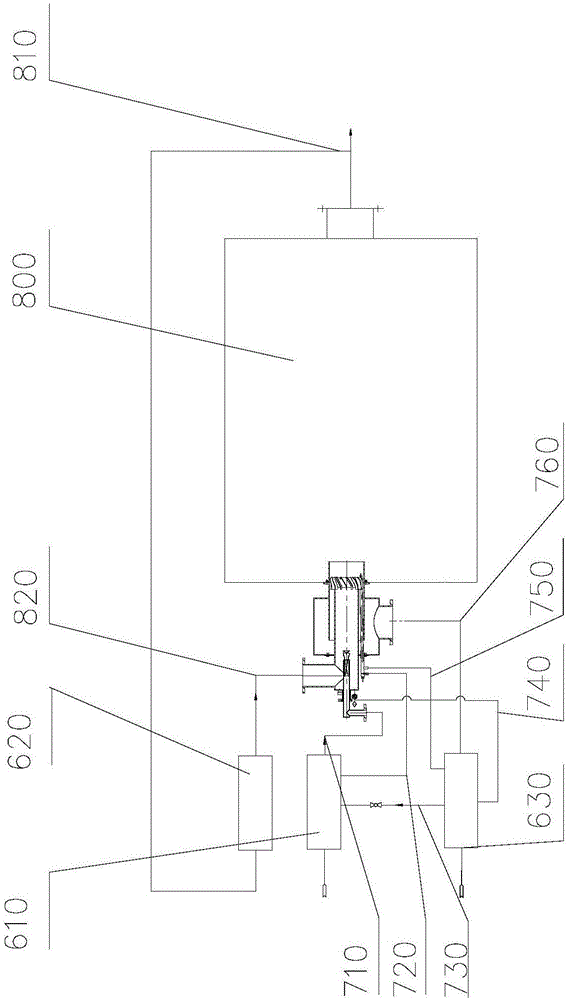

Oxygen supply system for water body

InactiveCN104671460ASmooth diffusionImprove water quality conditionsWater aerationSustainable biological treatmentSludgeWater quality

The invention belongs to the technical field of water body oxygen supply equipment and particularly discloses an oxygen supply system for a water body. The oxygen supply system for the water body is composed of a shore oxygen supply component, a gas-liquid dissolving component in the water and a water monitoring component. The oxygen supply system has the following beneficial effects: 1, the deep oxygen supply of the anoxic water zones in a reservoir can be realized, wherein the oxygenating depth is up to 60 m, and the oxygenating efficiency and the oxygenating effect can be obviously increased; 2, while oxygenating, the water body is smoothly diffused, the water bottom sludge cannot be rolled up, the underwater structure cannot be damaged, and the influence on the cultured product in the water bottom can be prevented; 3, the diffusion area is wide, the diffusion radius in the water can be greater than or equal to 1000 m, the oxygenating cover area is large and the production cost is low; 4, the air and the water are highly mixed by a gas-liquid two-phase combining device, so that the oxygen content in the water is high and the oxygen is sufficient; 5, the heights of the water pump and the gas-liquid two-phase combining device are adjusted through a wire rope, so that the oxygenating height is adjusted, the oxygen supplied in layers can be realized and the water quality of the anoxic water zones can be stereoscopically improved; 6, the system is suitable for the anoxic zones of the reservoir, the lake and the sea area and the large-area aquaculture.

Owner:JIANGSU PHILIP ENVIRONMENT ENG

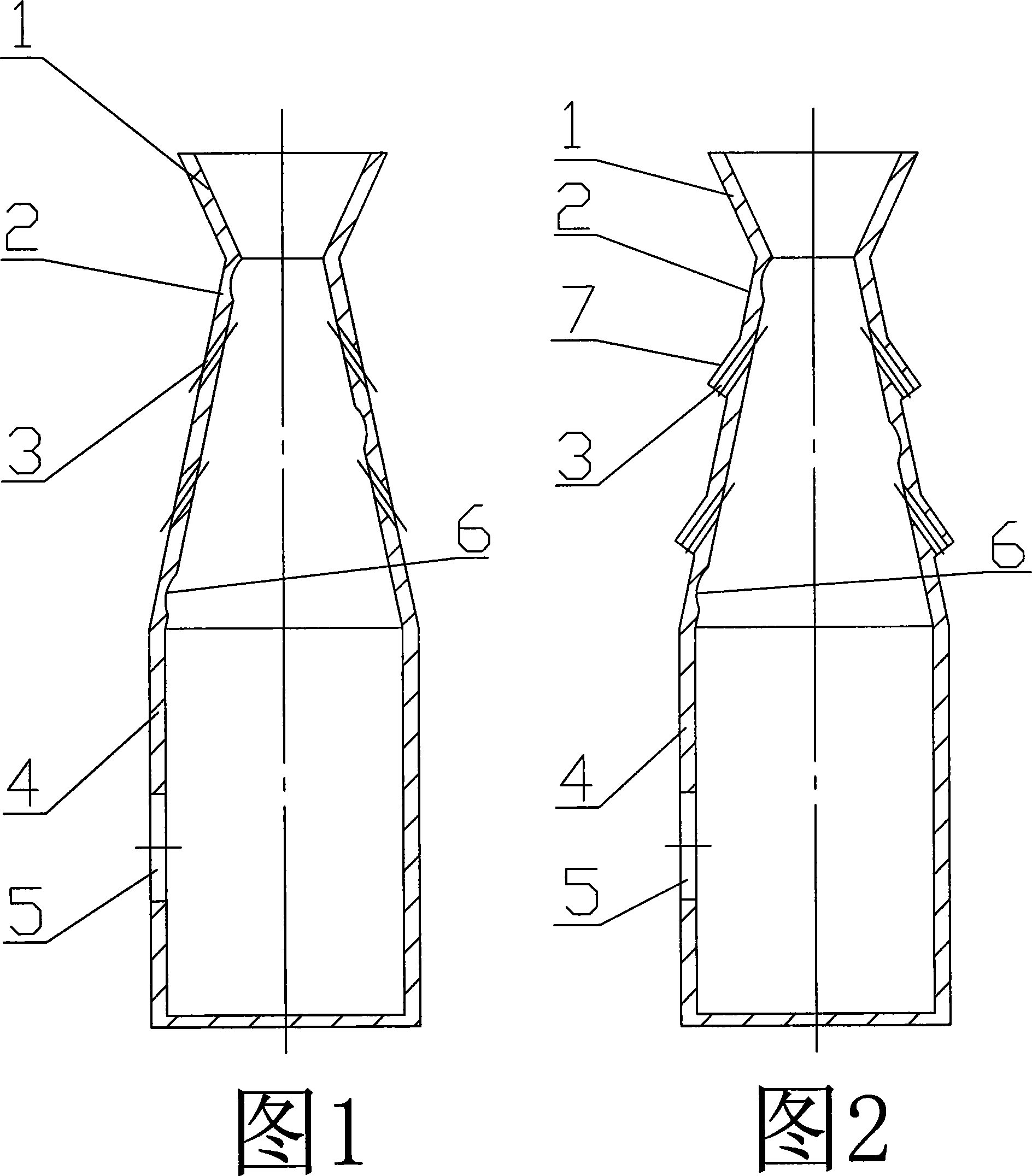

Atomizing water nozzle

InactiveCN101099953AIncreased diffusion areaReduce volumeSpray nozzlesLiquid spraying apparatusCooling towerWater flow

The present invention discloses one kind of atomizing nozzle for the atomizer in industrial no-stuffing water cooling tower. The integrated atomizing nozzle includes one nozzle body with inlet, one conic nozzle neck with through holes and helical groove in the wall and connected to the nozzle body, and one conic spout connected to the nozzle neck. Owing to the nozzle neck with through hole and helical groove, the air through the through holes may be well mixed with water flow and the water flow produces rotating centrifugal force, reaching excellent atomizing effect.

Owner:CHENGDU SHENGDONG TECH

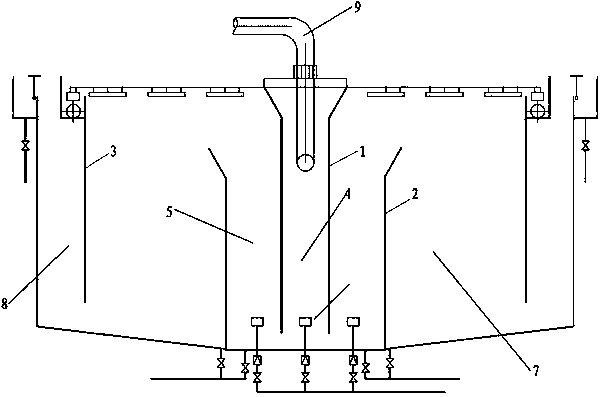

High-efficiency vertical flowing type water treatment flotation tank

The invention provides a high-efficiency vertical flowing type water treatment flotation tank which comprises a tank body, a first circular partition, a second circular partition, a third circular partition, a collision contact chamber, an adhesion contact chamber, a flotation separation chamber and a diversion effluent water chamber, wherein the collision contact chamber and the adhesion contact chamber are communicated through a clearance between the bottom of the first circular partition and a tank bottom, a diversion plate is arranged on the upper part of the second circular partition, the flotation separation chamber and the diversion effluent water chamber are communicated through a clearance formed by the bottom of the third circular partition and the tank bottom, dissolved gas releasers are evenly distributed at the bottoms of the collision contact chamber and the adhesion contact chamber, a raw water inlet pipe orifice is formed in the upper part of the collision contact chamber, a diversion plate is arranged on the upper part of the first circular partition, the edge of the diversion plate on the upper part of the first circular partition is higher than that of the diversion plate on the upper part of the second circular partition, and a mechanical deslagging system is arranged above the floatation separation chamber. According to the high-efficiency vertical flowing type water treatment flotation tank, the water quality change risk resistance capability can be improved and large-scale production can be facilitated.

Owner:SHANDONG JIANZHU UNIV

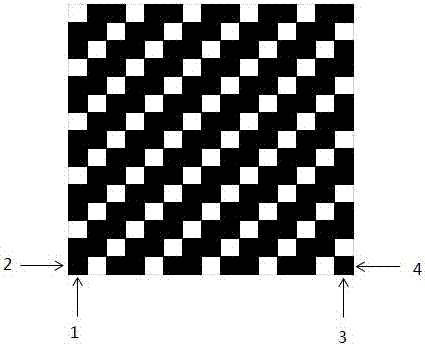

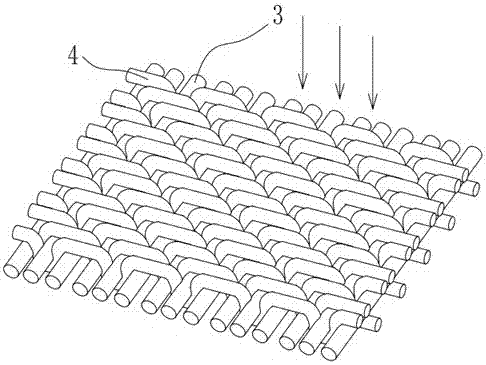

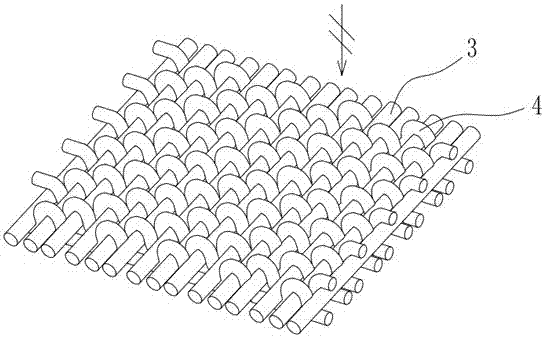

Woven fabric with one-way guiding and absorbing function and production technology thereof

The invention discloses a woven fabric with the one-way guiding and absorbing function and a production technology thereof. Warp of the woven fabric is yarn of the chemical fiber filament type, and weft is polypropylene staple fiber spun yarn or the combination of polypropylene staple fiber spun yarn and yarn of the chemical fiber filament type; or, warp is the combination of polypropylene staple fiber spun yarn and yarn of the chemical fiber filament type, and the weft is yarn of the chemical fiber filament type or the combination of polypropylene staple fiber spun yarn and yarn of the chemical fiber filament type; on the basis of the weaving technology, the polypropylene staple fiber spun yarn is displayed on the back face of the fabric in a concentrated mode, and the fabric is of a front-back dual-face three-dimensional organization structure. The production technology comprises the steps of selecting yarn, performing beam-warping, performing slashing, performing re-beaming, performing drafting and denting, weaving cotton cloth, performing desizing, performing dyeing, performing sizing and performing wet absorbent finishing. By adopting the technical scheme, the produced woven fabric has the good one-way guiding and absorbing function, and is fashionable in appearance, and the whole using function of the fabric is greatly improved.

Owner:HUAMAO (XIAMEN) WEAVING DYEING & FINISHING CO LTD

Extracting and degumming process for capsicum extract

ActiveCN105153737AImprove liquidityUnit color price increaseCarboxylic acid amide separation/purificationNatural dyesCapsicum extractCapsicum annuum

The invention discloses an extracting and degumming process for a capsicum extract. The process sequentially comprises the processing steps of carrying out solvent extraction, carrying out filtering, carrying out precipitating, carrying out mixed degumming, carrying out centrifugal separation and carrying out multistage concentrating, thereby finally obtaining a capsanthin finished product. The capsanthin prepared by the process is good in fluidity, is not solidified during low-temperature cold storage, is not layered and does not precipitate, the unit color number of the capsanthin finished product is increased by over 8%, the content of centrifugal precipitates is lower than 3.0%, and the content of acetone insolubles is lower than 1.0%. The quality of the product is greatly improved, the yield of the product is high, and the abuse that wasting of pigments is caused during the removal of colloids is avoided.

Owner:河北东之星生物科技股份有限公司

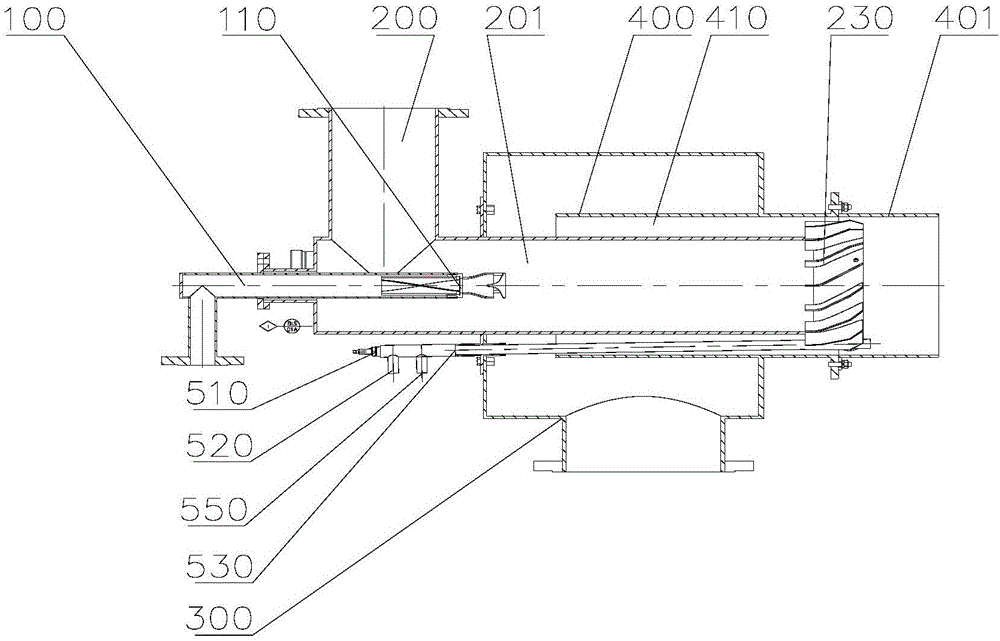

Equipment for low-nitrogen combustion and method for low-nitrogen combustion

ActiveCN106287696ASimple structureCompact and reasonable structureGaseous fuel burnerCombustion apparatusLow nitrogenFlue gas

The invention relates to equipment for low-nitrogen combustion and a method for low-nitrogen combustion. The equipment for low-nitrogen combustion comprises a device for ignition, a device for flame detection, a natural gas pipeline, a flue gas pipe, a dilution pipe for natural gas, a combustion air room, and a guiding pipe for combustion air which is inserted into and connected with the combustion air room and a fire spraying pipe. The exit end of the natural gas pipeline is inserted inside the dilution pipe for natural gas from the entry end of the dilution pipe for natural gas. The flue gas pipe connects with the dilution pipe for natural gas through inner walls of the dilution pipe for natural gas, and the exit end of the dilution pipe for natural gas is inserted into the combustion air room and further inserted inside the guiding pipe for combustion air from the entry end of the guiding pipe for combustion air inside the combustion air room. The equipment for low-nitrogen combustion adopts a way of mixing natural gas with flue gas and blending the two gases inside the dilution pipe for natural gas in order to dilute the natural gas, thereby lowering calorific value of the natural gas, reducing the flame temperature, lowering the synthesis of nitric oxide fundamentally and realizing the effect of low-nitrogen combustion.

Owner:王研

Chemical material drying equipment with stirring device

InactiveCN106482447AKeep dryReduce drying efficiencyGranular material dryingDrying gas arrangementsEngineeringInjection air

The invention provides chemical material drying equipment with a stirring device. The chemical material drying equipment comprises a tank. A drying cavity is arranged inside the tank, and an upper cover is arranged at a top opening; two material crushing devices are arranged on the top cover; an upper guide disc, a guide device, the stirring device and an air injection device are arranged in the drying cavity; the guide device comprises a first motor, a rotary shaft and a lower guide disc; the stirring device comprises a second motor, a stirring shaft and stirring blades; the air injection device comprises an air injection disc and an air inlet pipe; a dehumidification device is arranged on a side wall of the top of the tank. The chemical material drying equipment has the advantages that materials can be crushed and treated by the two crushing devices, and accordingly deterioration of the drying efficiency and the drying quality due to caked materials which are added into the tank can be prevented; the material spreading areas can be enlarged by the guide device, accordingly, the materials can be conveniently uniformly heated, and the material drying speeds can be increased; the stirring device is favorable for transferring heat and can bring convenience for drying the materials, and the chemical material drying equipment has a material mixing function.

Owner:郑州吉音动漫科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com