Soil in-situ leaching remediation method

A soil and leaching technology, applied in the field of soil in-situ leaching and remediation, can solve the problems of insufficient contact between the eluent and pollutants, poor leaching and remediation effect, and limited radiation range of shafts, etc. Effects and Rates, Enhanced Repair Effects, Simple Structured Effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

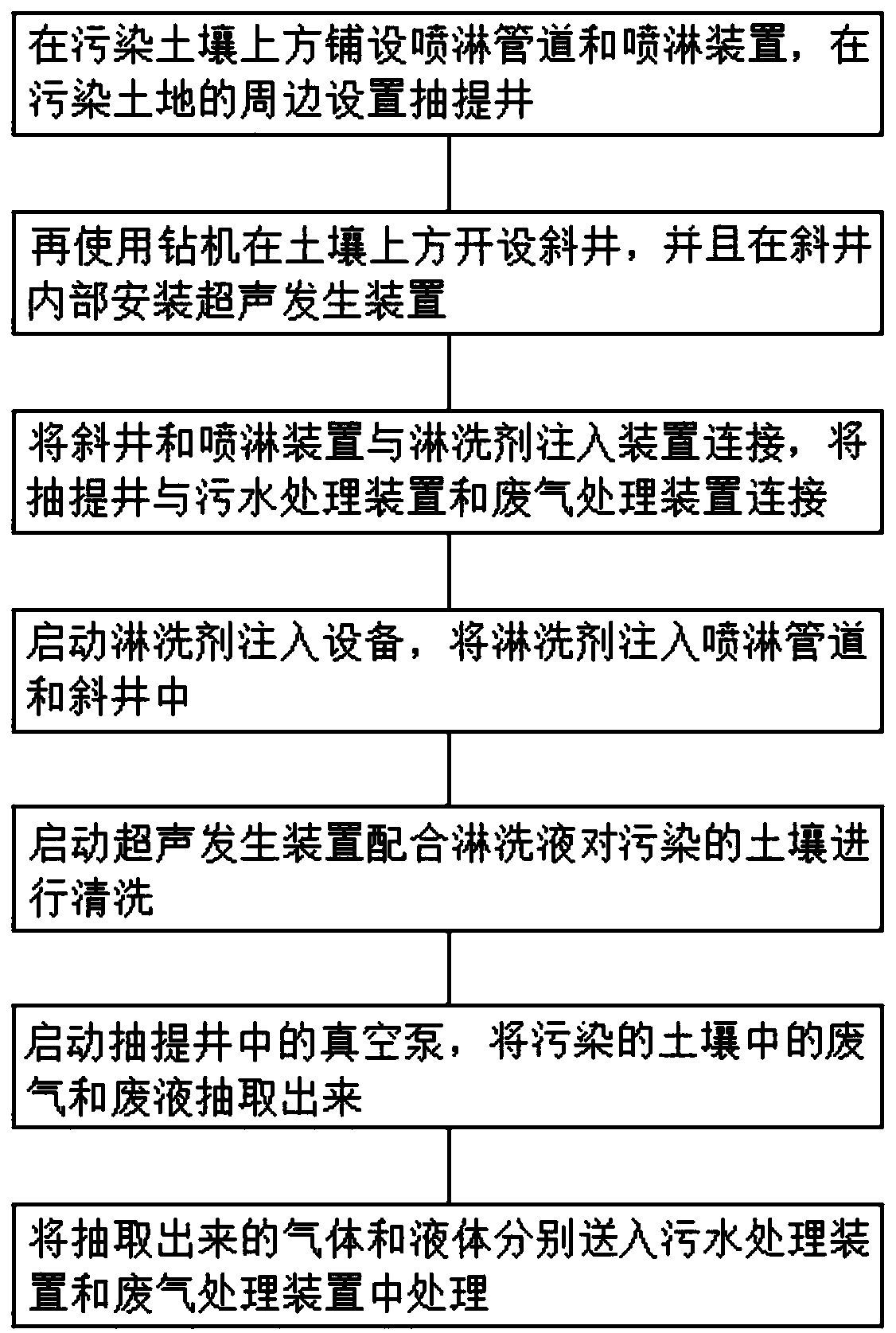

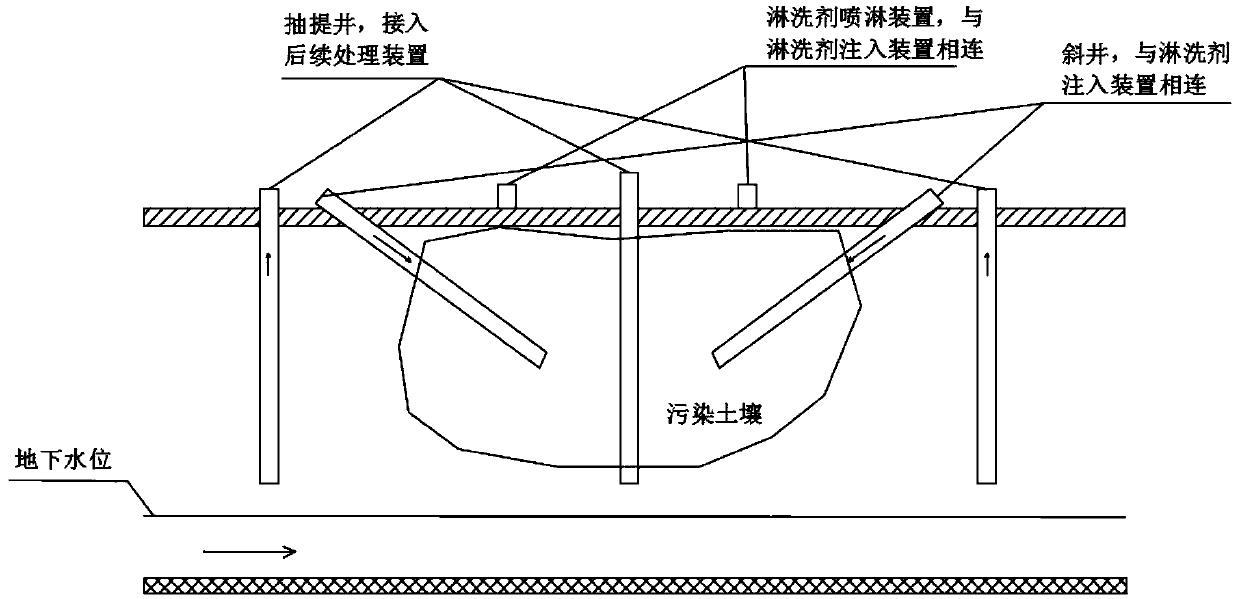

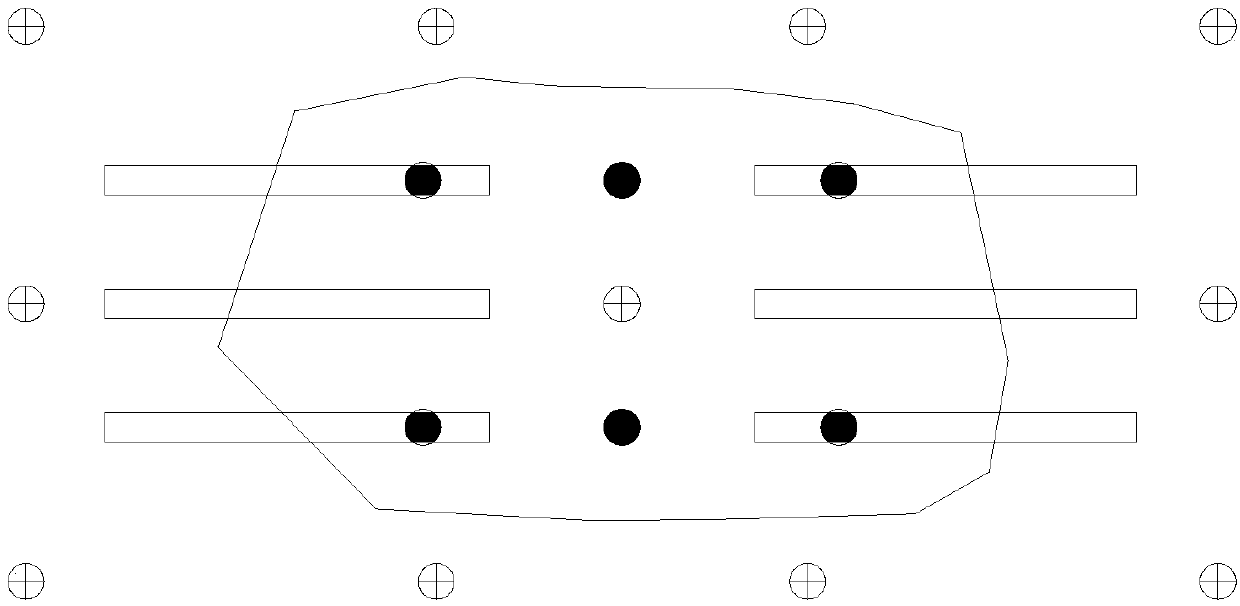

[0029] (1), lay sprinkler pipeline and shower device above the polluted soil, then set extraction well around and in the middle of the polluted soil, sprinkler pipeline and shower device are erected at 40cm above the ground, spray The device adopts high-pressure rotary nozzles, and a high-pressure rotary nozzle is installed every 10 square meters. The diameter of the extraction well is 20mm, and the depth of the well is 3.5 meters. The bottom of the extraction well is set in the soil 1.5 meters away from the groundwater. Set one every 12 square meters;

[0030] (2), use drilling rig again to offer inclined well above polluted soil, and install ultrasonic generating device inside inclined well, set an inclined well every 5 square meters, the inclination angle of inclined well is 45 °, ultrasonic generating device is set The inside of the inclined shaft is 1.0 meters away from the bottom, and the inclined shaft is symmetrically arranged in the polluted soil. The processing diffi...

Embodiment 2

[0037] (1), lay sprinkler pipeline and shower device above the polluted soil, then set extraction well around and in the middle of the polluted soil, sprinkler pipeline and shower device are erected at 40cm above the ground, spray The device adopts high-pressure rotary nozzles, and a high-pressure rotary nozzle is installed every 10 square meters. The diameter of the extraction well is 20mm, and the depth of the well is 3.5 meters. The bottom of the extraction well is set in the soil 1.5 meters away from the groundwater. Set one every 12 square meters;

[0038] (2), use drilling rig again to offer inclined well above polluted soil, and install ultrasonic generating device inside inclined well, set an inclined well every 5 square meters, the inclination angle of inclined well is 45 °, ultrasonic generating device is set The inside of the inclined shaft is 1.0 meters away from the bottom, and the inclined shaft is symmetrically arranged in the polluted soil. The processing diffi...

Embodiment 3

[0045](1), lay sprinkler pipeline and shower device above the polluted soil, then set extraction well around and in the middle of the polluted soil, sprinkler pipeline and shower device are erected at 40cm above the ground, spray The device adopts high-pressure rotary nozzles, and a high-pressure rotary nozzle is installed every 10 square meters. The diameter of the extraction well is 20mm, and the depth of the well is 3.5 meters. The bottom of the extraction well is set in the soil 1.5 meters away from the groundwater. Set one every 12 square meters;

[0046] (2), use drilling rig again to offer inclined well above polluted soil, and install ultrasonic generating device inside inclined well, set an inclined well every 5 square meters, the inclination angle of inclined well is 45 °, ultrasonic generating device is set The inside of the inclined shaft is 1.0 meters away from the bottom, and the inclined shaft is symmetrically arranged in the polluted soil. The processing diffic...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com