High moisture permeability coating film

A technology of moisture permeability and coating film, applied in the direction of coating, layered products, synthetic resin layered products, etc., can solve the problems of large number of vent plugs and unable to solve condensation, so as to increase the moisture absorption area and The effect of diffusion area, good moisture absorption and moisture conductivity, and excellent UV resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

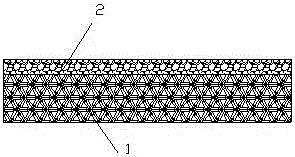

Image

Examples

Embodiment 1

[0033] The coating agent of the polyurethane emulsion copolymer coating 2 containing hemp stalk core superfine powder comprises the raw materials of following percentage by weight and evenly stirs to make:

[0034] Polyurethane 20%;

[0035] Dimethylformamide solvent 55%;

[0036] Hydrophilic group solvent 2%;

[0037] Hemp Stalk Core Superfine Powder 18%.

[0038] Wherein, the thickness of the polyurethane emulsion copolymer coating 2 containing the superfine powder of hemp stalk core is 0.012mm.

[0039] The viscosity index of the coating agent is 33 Pa.s. The coating agent contained 35% non-volatile matter.

Embodiment 2

[0041] The coating agent of the polyurethane emulsion copolymer coating 2 containing hemp stalk core superfine powder comprises the raw materials of following percentage by weight and evenly stirs to make:

[0042] Polyurethane 23%;

[0043] Dimethylformamide solvent 57%;

[0044] Hydrophilic group solvent 4%;

[0045] Hemp Stalk Core Superfine Powder 21%.

[0046] Wherein, the thickness of the polyurethane emulsion copolymer coating 2 containing the hemp stalk core superfine powder is 0.0185mm.

[0047] The viscosity index of the coating agent is 33 Pa.s. The coating agent contains 40% non-volatile matter.

Embodiment 3

[0049] The coating agent of the polyurethane emulsion copolymer coating 2 containing hemp stalk core superfine powder comprises the raw materials of following percentage by weight and evenly stirs to make:

[0050] Polyurethane 25%;

[0051] Dimethylformamide solvent 60%;

[0052] Hydrophilic group solvent 5%;

[0053] Hemp Stalk Core Superfine Micron Powder 25%.

[0054] Wherein, the thickness of the polyurethane emulsion copolymer coating 2 containing the superfine powder of hemp stalk core is 0.025mm.

[0055] The viscosity index of the coating agent is 33 Pa.s. The coating agent contains 45% non-volatile matter.

[0056] In Examples 1-3, the manufacturing process of the hemp stalk core superfine powder includes: first processing the hemp stalk core into a coarse powder, and performing pretreatment, followed by refinement treatment and activation treatment, and drying after the treatment is completed. dry, then carry out modification treatment, then carry out microniza...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| viscosity index | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com