Patents

Literature

42results about How to "Good moisture absorption and moisture conductivity" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

High moisture permeability coating film

ActiveCN104029449BGood moisture absorption and moisture conductivityImprove performanceSynthetic resin layered productsGas-tight/water-tight arrangementsCelluloseWater vapor

A coating film having a high water vapor transmission rate comprises: a basic film layer and a coating. The basic film layer is a bulk polytetrafluoroethylene film layer. The coating applied on the film layer is a polyurethane emulsion copolymer coating that contains hemp stem ultra-fine powder. A coating agent of the coating comprises raw materials of the following percentages by weight being evenly mixed: 20% to 25% of polyurethane, 55% to 60% of a dimethyl formamide solvent, 2% to 5% of a hydrophilic group solvent, and 18% to 25% of hemp stem ultra-fine powder. The resultant coating film has desirable moisture absorption performance and moisture guidance performance, has a high content of water vapor transmission factor cellulose of hemp stem ultra-fine powder and has micro trenches and micro pores, increases the moisture absorption area and the diffusion area, and has excellent performance of being anti-ultraviolet, water-proof, dust-proof, oil-proof, water vapor permeable, and corrosion resistant to oxidation solutions.

Owner:PAN ASIAN MICROVENT TECH JIANGSU CORP

Metal wire colored woven plus material

InactiveCN101191272ABright and full colorsGood moisture absorption and moisture conductivityLoomsWoven fabricsMetal filamentEngineering

The invention relates to a metal filament yarn dyed fabric and belongs to the textile fabric technical field. The invention is mainly characterized in that: warp threads adopt terylen after blend dyeing and regenerated cellulose modal as raw materials; weft yarns adopt metal filament with two colors; the fabric adopts weave structure of double layers of textile; the warp threads are arranged on the reverse side of the textile, and the weft yarns are arranged on the right side of the textile. After being weaved by a multi-jet weaving machine, the invention has good effects of moisture absorption and wet permeability and also has good softness and comfort level. Moreover, because the textile adopts the weave structure of the double layers and the blended yarns are arranged on the reverse side of the textile, sweat exhausted from the human body can be quickly absorbed and transferred to the surface of the textile, and dryness and comfort when the textile contacts the skin are always maintained and people feel comfortable as well even the textile is worn next to the skin, thereby the weaved fabric not only can be used in fields like military industry, protection, leisure garment and so on but also is more suitable for making leisure undergarments which are worn next to the skin.

Owner:YANGZHOU JIYUAN TEXTILE

Multifunctional health-care porous elastic big-belly yarn and preparation method thereof

The invention relates to a preparation method and application of a multifunctional health-care porous elastic big-belly yarn. The multifunctional health-care porous elastic big-belly yarn is prepared from two core yarns, two fixed yarns and a decorative yarn, wherein the fixed yarns are core-spun yarns obtained by carrying out blended processing on silver fibers, copper fibers, soft silk fibers and DOW-XLA elastic fibers; the core yarns are blended hollow yarns obtained by carrying out blended processing on Porel fibers, hollow polyester fibers and provilion; the decorative yarn is a blended rough yarn obtained by carrying out blended processing on nettle fibers, apocynum fibers and alpaca wool fibers. The multifunctional health-care porous elastic big-belly yarn not only has a special form, but also is rich in yarn colors, multiple in shapes and ever-changing; products developed by using the multifunctional health-care porous elastic big-belly yarns are natural and environment-friendly, have the health care functions of resisting bacteria and eliminating inflammation, protecting skin and keeping fitness, absorbing moisture and releasing sweat, deodorizing and resisting aging, and the like, are good in comfortableness, and do not cause adverse effects when being contacted with a human body; the multifunctional health-care porous elastic big-belly yarn is mainly used for various textiles such as yarn-dyed female lines, knitted fabrics, tweed, coarse worsted fabrics, decorative articles, hand knitted fabrics and shawls.

Owner:ZHONGYUAN ENGINEERING COLLEGE

Coolplus moisture-absorption sweat-releasing and warming Raschel woolen blanket

ActiveCN107419423ARaw material composition is simpleLow costFibre typesWarp knittingPolyesterEngineering

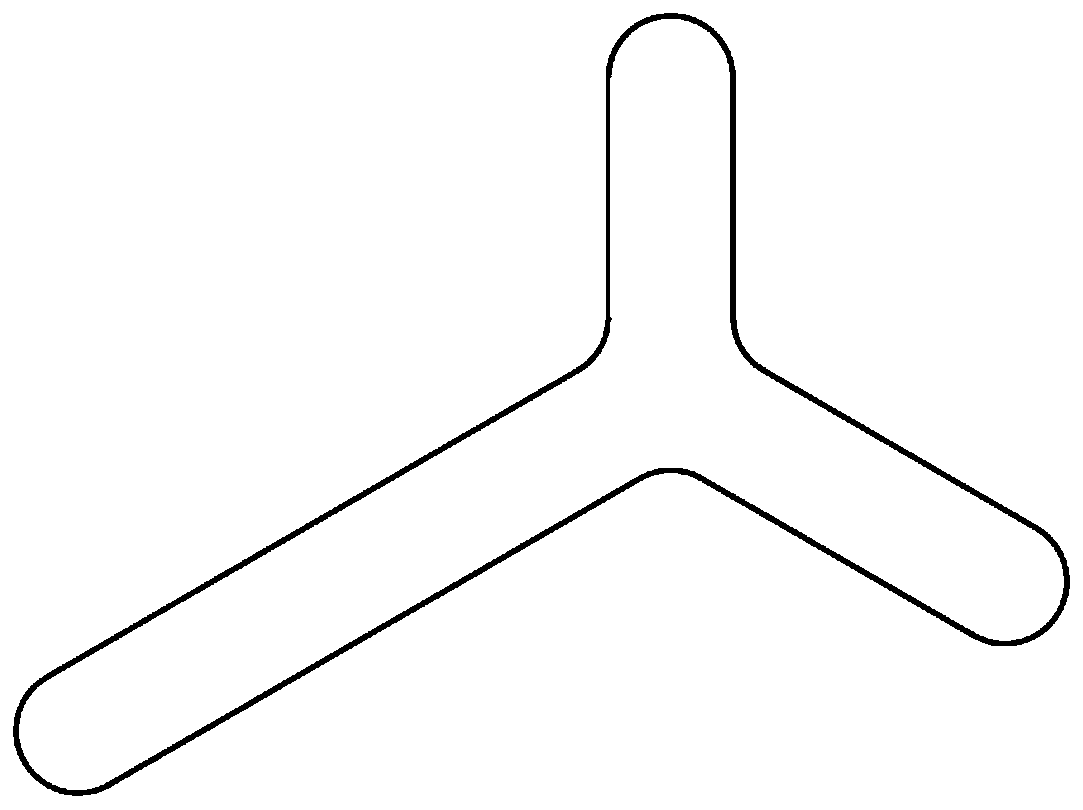

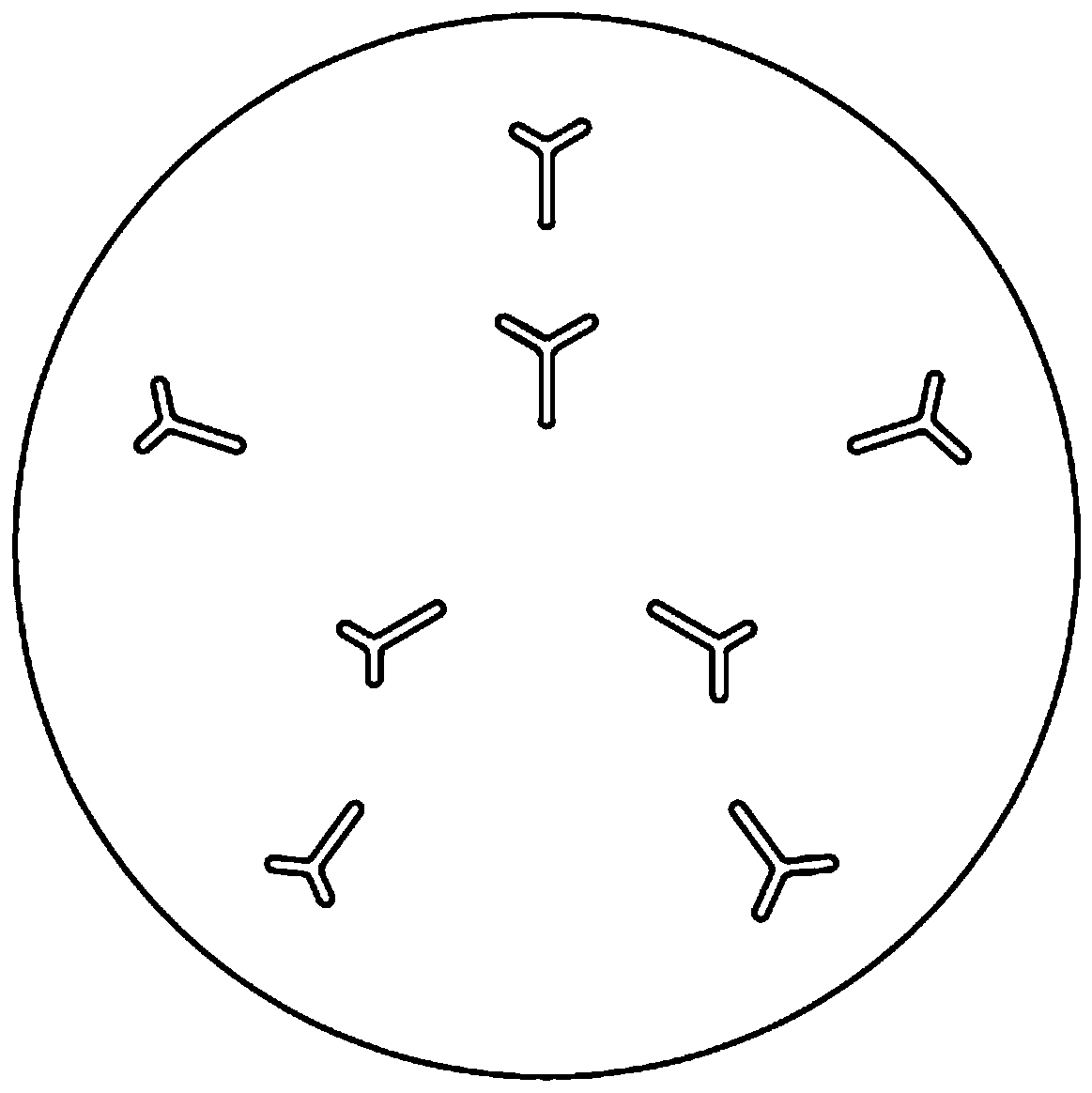

The invention discloses a Coolplus moisture-absorption sweat-releasing and warming Raschel woolen blanket. The Coolplus moisture-absorption sweat-releasing and warming Raschel woollen blanket is woven on a two-needle bar Raschel warp knitting machine by using blended yarns of Coolplus fibers and acrylic fibers as nap yarns and using polyester silk as basic silk. Special-shaped polyester fibers can be acquired by using a +-shaped herringbone or Chinese character mi-shaped spinning assembly; air plasma and alkali peeling treatment is performed on the polyester fibers; regular micro grooves and micro holes are formed in surfaces of the polyester, and the grooves and the holes can generate a significant capillary effect, moisture and sweat excreted by a human body are diffused and transmitted, and then are discharged out, and skins can keep dry; and noncurrent static air is stored in the regular micro grooves and micro holes, and the static air can significantly improve the warming performance of the Raschel woolen blanket.

Owner:ZHEJIANG TRUELOVE CARPET IND SCI & TECH

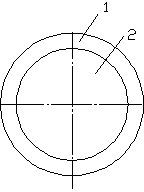

Moisture-absorbing rapid-drying composite polyester fiber filament and machining process thereof

PendingCN107400937AHigh strengthImprove breathable and moisture-wicking channelsElectroconductive/antistatic filament manufactureFilament/thread formingPolyesterFiber

The invention belongs to the technical field of chemical fibers, in particular to a moisture-absorbing rapid-drying composite polyester fiber filament. The composite polyester fiber filament comprises a core layer and an outer layer for coating the core layer, wherein the core layer is prepared from a polyester dacron slice A; the outer layer is prepared from the polyester dacron slice A and a modified polyester dacron slice B. The invention further discloses a process of machining the moisture-absorbing rapid-drying composite polyester fiber filament. The machining process comprises the following steps: (1) drying the polyester dacron slice A and the modified polyester dacron slice B; (2) physical preparation: a component I is taken as the materials of the outer layer, and is prepared by co-blending the polyester dacron slice A and the polyester dacron slice B according to the proportion; a component II is taken as the material of the core layer, and is prepared from the polyester dacron slice A; (3) feeding the component I and the component II into a screw rod for extruding to obtain the composite polyester fiber filament with the outer layer and the core layer. The prepared composite polyester fiber filament has high moisture-absorbing and rapid-drying performance.

Owner:HANGZHOU HUVIS YONGSHENG CHEM FIBERS +1

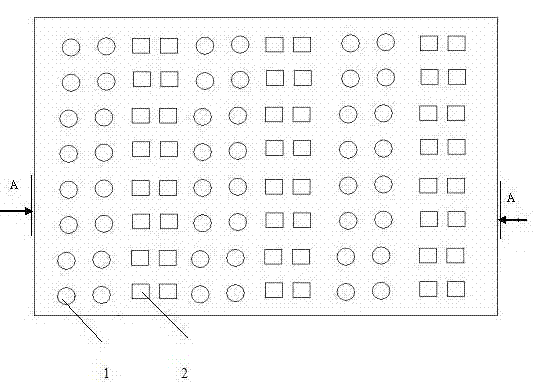

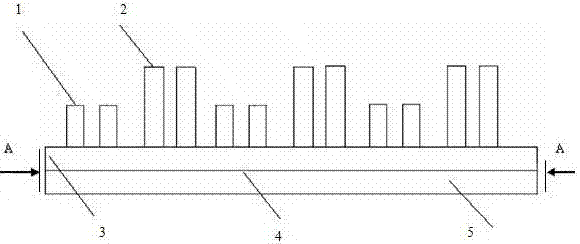

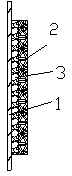

Manual tufting carpet with moisture absorption and moisture guide functions and weaving method of manual tufting carpet

ActiveCN102783892AImprove moisture absorption and moisture conduction functionIncrease contact areaEmbroidering machines apparatusFloor carpetsFiberHigh humidity

The invention discloses a piece of manual tufting carpet with moisture absorption and moisture guide functions and a weaving method of the manual tufting carpet. The carpet is woven by Coolmax fiber subjected to alkali weight reducing processing, after the Coolmax fiber is subjected to the alkali weight reducing processing, the cross section of the Coolmax fiber has special groove structures, the surface area is increased, the moisture absorption and moisture guide functions are further improved, fiber broken end and loop end alternate arrangement at intervals is adopted in the weaving method, the loop end and broken end height difference is regulated, the three-dimensional effect of veins is enhanced, the contact area between the Coolmax fiber and the air is increased, the moisture absorption and moisture guide speed is accelerated, and the function is enhanced. Bottom cloth with nonuniform warp and weft yarns, thick warp yarns, thin weft yarns and low density is used at the bottom of the carpet, so gap passages are formed on contact surfaces between the bottom and the ground, air with high humidity can be fast guided out from the bottom of the carpet, the moisture absorption and moisture guide effects of the carpet are promoted, the use comfort of the carpet is improved, the Coolmax cheese weight reducing time is controlled in the weaving process, and the twist degree of the weight reducing fiber is properly increased, so the softness of the carpet is enhanced, and the falling cannot easily occur.

Owner:NANTONG TEXTILE VOCATIONAL TECH COLLEGE

Yarn dyed fabric

InactiveCN102677259AExcellent water absorptionExcellent air permeabilityMulti-ply fabricsAdhesiveMoisture absorption

The invention discloses a yarn dyed fabric, which comprises warps and wefts, and is characterized in that: blend dyed terylene and regenerated cellulose modal are used as raw materials for the warps of the fabric; and the raw materials are formed by processing wood pulp meal prepared by using spruce and beech into fibers through a special spinning process. A gray 100 D low-elasticity round weave material is selected and used by the wefts; a breathable and moisture permeable anti-flocking transparent adhesive is coated on the surfaces of the wefts; the weight ratio of the terylene to the regenerated cellulose modal is 58-62 / 38-420; the latitude of the fabric is 62 shuttles per centimeter; the fabric has a double-layer fabric organization structure; and the warps are arranged on the back face of the fabric and the wefts are arranged on the front face of the wefts. The yarn dyed fabric has excellent moisture absorption and guide effects and excellent softness and comfort; and since the fabric has the double-layer organization structure, the blended yarn is arranged on the back face of the fabric, and sweat discharged by a human body can be quickly transferred to the surface of the fabric, and dryness and comfort for contact of the fabric and the skin are kept all the time, and the fabric is also extremely comfortable to wear even though the fabric is close-fitting to a human body; and thus, the woven fabric can be used for the fields of military industry, defense, leisure coats and the like and is more suitable for manufacturing leisure underwear for close-fitting wear.

Owner:江苏红运果服饰有限公司

Preparation method of recyclable ultra-clean wiping cloth

InactiveCN105970338AGood moisture absorption and moisture conductivityImprove wiping effectWoven fabricsMonocomponent polyesters artificial filamentPolymer sciencePolyethylene glycol

The invention relates to a preparation method of recyclable ultra-clean wiping cloth, which belongs to the technical field of textile preparation. In the present invention, after the coconut shell is pretreated, it is soaked in the supernatant liquid prepared by composting plant ash, vermicompost and deionized water, filtered, the filter cake is beaten, washed and dried to obtain dried coconut fiber, which is then carbonized and pulverized Finally, it is mixed with self-cultivated yeast mycelium suspension, heated and stirred, filtered, and the filter cake is dried, mixed with polyethylene terephthalate, and melt-spun and other steps to obtain recyclable ultra-clean wipe cloth. Add coconut charcoal powder in the wiping cloth prepared by the present invention, make it form microporous shape on fiber surface, increase the specific surface area of fiber, make wiping cloth have good moisture absorption and moisture conductivity, improve its wiping performance; And after washing, Sun exposure and other methods, its adsorption capacity can be regenerated, and it can be recycled for many times.

Owner:丁玉琴

Preparation method of multifunctional health-care fancy yarn with antibacterial and skin-care functions

InactiveCN107503012AReflect the advantages of learning from each otherRich and colorfulYarnPolyesterPolypropylene

The invention provides a preparation method of multifunctional health-care fancy yarn with antibacterial and skin-care functions. The yarn is composed of two pieces of core yarn, one piece of decorative yarn and two pieces of fixed yarn, wherein the core yarn is blended yarn formed by blending and processing calotropis gigantea fibers, mulberry bark fibers, Amicor antibacterial fibers and copper fibers, the fixed yarn is composed of far-infrared polyester filaments and tourmaline fiber filaments, and the decorative yarn is blended rough yarn formed by blending and processing tea leaf fibers, banana stem fibers, antibacterial odor-resistant acrylic fibers and rabbit hair fibers; or the core yarn is blended yarn formed by blending and processing sarcandra glabra fibers, luminous fibers, pineapple leaf fibers and silver fibers, the fixed yarn is negative ion polypropylene filaments, and the decorative yarn is blended rough yarn formed by blending and processing lotus fibers, anti-ultraviolet polyester fibers, double-resistant acrylic fibers, yak wool fibers and alpaca fibers. The yarn developed through the method does not generate adverse effects when making contact with the human body, products are not easy to damage by worms or rot, and the yarn is mainly used for various textiles such as yarn-dyed cotton suiting for women, roved and spun fabrics, decorative articles, hand knitted products and shawls.

Owner:ZHONGYUAN ENGINEERING COLLEGE

Soybean fiber quilt

InactiveCN102327003AGood moisture absorption and moisture conductivityImprove breathabilityElectrotherapyBed-coversFiberHuman body

The invention discloses a soybean fiber quilt, which comprises a quilt cover and a quilt core. A plus material of the quilt cover is a pure cotton jacquard plus material, and the quilt core comprises 40-70% of soybean fibers and 30-60% of superfine fibers. In the invention, the soybean fibers and the superfine fibers are mixed and made into the quilt core; the warmness keeping property of the quilt core is superior to that of a common cotton quilt core; further, the quilt core has a soft tactile feeling, moisture absorption and air permeability; soybean protein fibers contain a plurality of amino acids necessary for a human body; after the soybean protein fibers are in contact with the skin, the collagens of the skin can be activated; the pruritus of the skin is restrained; and the activity of the skin is encouraged.

Owner:JIANGSU BAOMAN BEDROOM ARTICLES

Cool sweat-absorbing summer clothing fabric

ActiveCN107245787AGood moisture absorption and moisture conductivityImprove breathabilityHeating/cooling textile fabricsWoven fabricsPolyesterWrinkle skin

The invention discloses a cool sweat-absorbing summer clothing fabric. The fabric is formed by interweaving warp and weft in a one-up one-down plain weave, honeycomb micro-pore modified polyester / jade fiber / viscose blended yarn is adopted as the warp, modified bamboo fiber / hemp fiber / soy protein fiber blended yarn is adopted as the weft, and the fabric is prepared after heat setting and wrinkle-resistant softening post-finishing. The cool sweat-absorbing summer clothing fabric has the advantages that the fabric has excellent sweat-absorbing property and excellent breathability, can effectively control the adhesion feel caused by sweating from exercises, and has a good cool sense, anti-bacterial property and anti-ultraviolet property; the fabric is good in anti-wrinkling effect and easy to color, has a smooth soft hand feel and wash durability, and has a good wearing comfort, so that it is healthier for people to wear; it is not necessary to consider contraction after cloth cutting, sewing and ironing, the fabric is easy to produce, simple in processing technology, easy to operate and control, stable in quality, high in production efficiency, and easy for large-scale industrialized production.

Owner:山东恒利纺织科技有限公司

High water vapor transmission rate coating film paster for automobile lamp

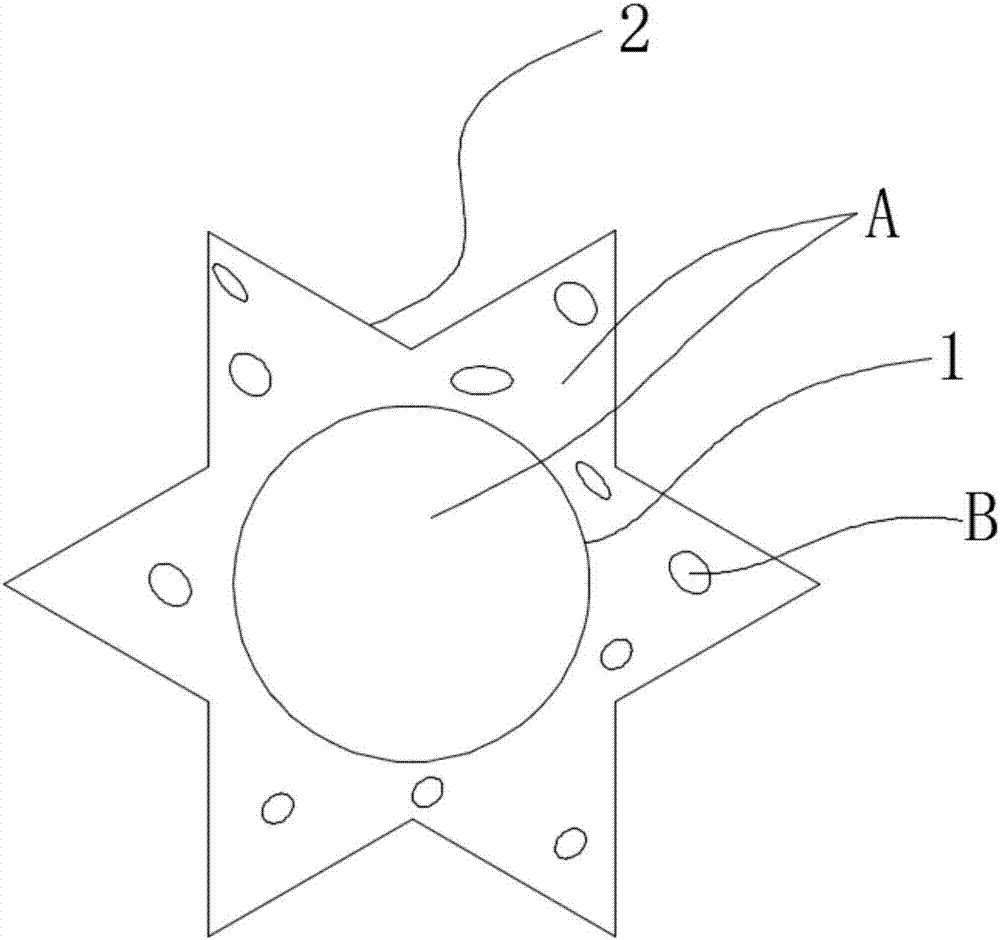

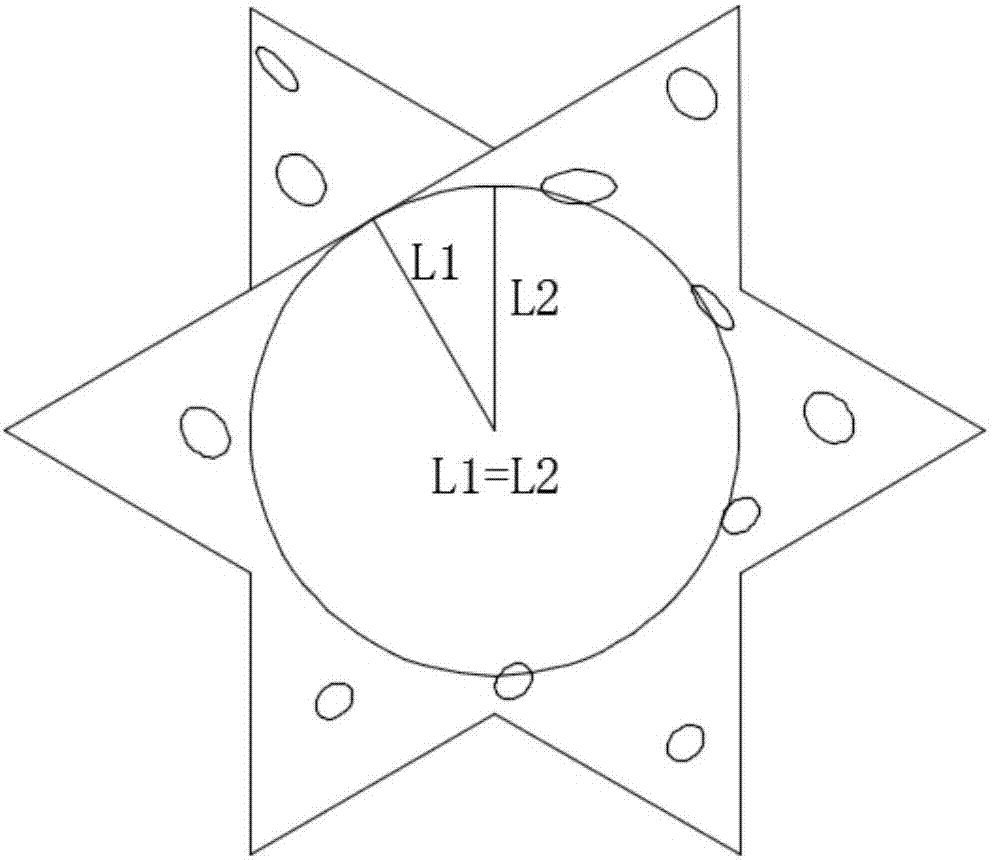

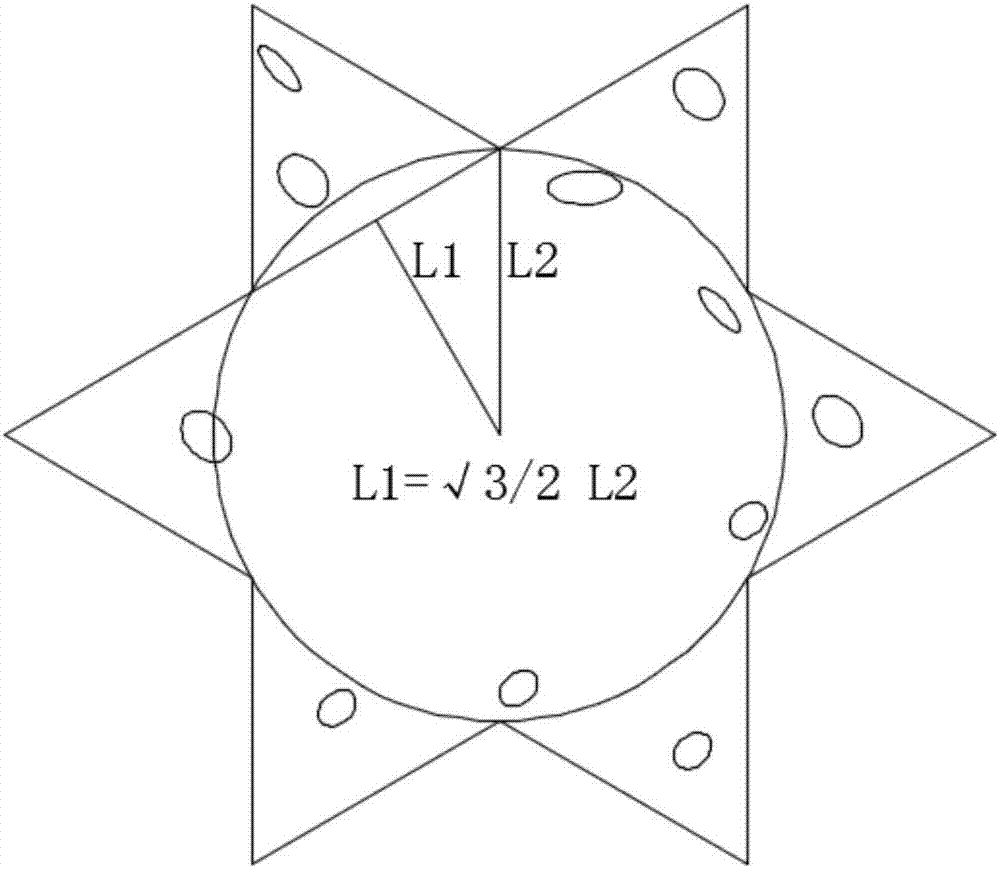

ActiveCN104029450ANo condensation and condensationPrevent infiltrationSynthetic resin layered productsGas-tight/water-tight arrangementsCannabisWater vapor

The invention discloses a high water vapor transmission rate coating film paster for an automobile lamp. The high water vapor transmission rate coating film paster comprises a film carrier strip and a high water vapor transmission rate coating film. The high water vapor transmission rate coating film comprises an expanded polytetrafluoroethylene film layer and a coating containing superfine cannabis sativa stalk core micro-powder hydrophilic groups, wherein the surface on one side of the expanded polytetrafluoroethylene film layer is covered with the coating containing the superfine cannabis sativa stalk core micro-powder hydrophilic groups; the coating containing the superfine cannabis sativa stalk core micro-powder hydrophilic groups is compositely connected with the film carrier strip. By adopting a mode, the high water vapor transmission rate coating film paster is good in moisture absorption and guide performance, so that a shell of the automobile lamp is internally free of fogging or condensation phenomenon, the lighting performance of the lamp is not affected by a wet air environment, and the circuit shortcut caused by condensation on the surface of an electric element is avoided; the permeation of rainwater and dust is prevented, and the shell of the automobile lamp can be in a non-pollution dust security classification state; meanwhile, superfine cannabis sativa stalk core micro-powder can adsorb volatile matters generated when the plastic shell of the automobile lamp is heated, so that the light ray reflecting property of a mirror surface of the automobile lamp can be kept.

Owner:PAN ASIAN MICROVENT TECH JIANGSU CORP

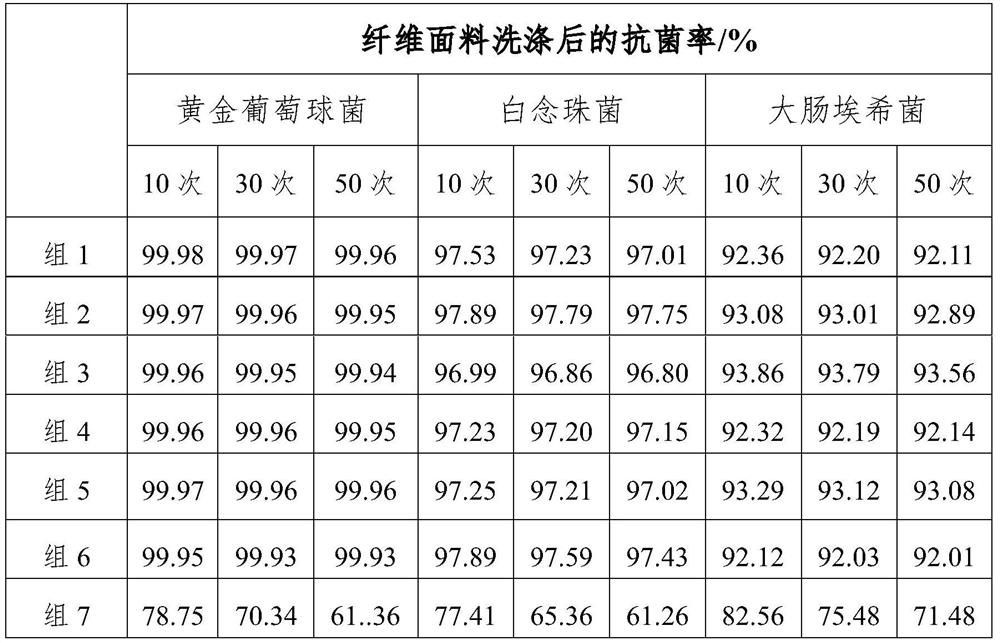

Fire-resistant and anti-bacterial cotton fabric and preparation method thereof

InactiveCN109098002AImprove antibacterial propertiesImprove comfortBiochemical fibre treatmentWoven fabricsSurface layerViscose

The invention discloses a fire-resistant and anti-bacterial cotton fabric. The fabric is set as a double-sided structure and comprises a fabric lining layer and a fabric surface layer, wherein the fabric lining layer is made by ramie, cotton and a Coolplus staple fiber via blending; the fabric is made by anti-flaming viscose, an anti-flaming acrylic fiber, ramie and cotton via blending; in the fabric lining layer, the specification of the ramie is 1.67 dtes * 38 mm, the specification of the cotton fiber is 1.85 dtex * 33 mm and the specification of the Coolplus staple fiber is 1.56 dtex * 38 mm; in the fabric surface layer, the specification of the anti-flaming viscose is 1.72 dtex * 36 mm and the specification of the anti-flaming acrylic fiber is 1.56 dtex * 28 mm. The invention furthermore discloses a preparation method of the fire-resistant and anti-bacterial cotton fabric. The cotton fabric is set as the double-sided structure and comprises the fabric lining layer and the fabric surface layer; the fabric lining layer undergoes antibacterial treatment in aloe extracting solution and organic germanium treatment solution; an anti-flaming thin film layer is sprayed on the surface of the fabric surface layer, so that the cotton fabric has more excellent anti-flaming and anti-bacterial properties.

Owner:SHENZHEN NANSHUO MINGTAI TECH CO LTD

Natural warm-keeping fiber blended fabric

InactiveCN104188212AGood moisture absorption and moisture conductivityProtective garmentSpecial outerwear garmentsKapok fiberMoisture

The invention reveals a natural warm-keeping fiber blended fabric. The natural warm-keeping fiber blended fabric is formed by soybean protein fiber, nanometer antibacterial regenerated protein fiber, cashmere fiber and kapok fiber in a blended woven mode. According to the weight percent of each kind of fiber of the natural warm-keeping fiber blended fabric, the soybean protein fiber accounts for 23% to 27%, the nanometer antibacterial regenerated protein fiber accounts for 16% to 20%, the cashmere fiber accounts for 27% to 31% and the kapok fiber accounts for 22% to 34%. The fabric is formed by the soybean protein fiber, the nanometer antibacterial regenerated protein fiber, the cashmere fiber and the kapok fiber in the blended woven mode, the woven fabric is environmentally friendly and free of pollution and can be degraded after being discarded, and the woven fabric has the advantages of being soft, comfortable, capable of keeping warm, light, and good in moisture absorbing and conducting performance.

Owner:汪荣江

Antibacterial medical yarn for vortex spinning

The invention discloses an antibacterial medical yarn for vortex spinning. The antibacterial medical yarn comprises a yarn body which adopts a composite core-spun yarn structure and comprises a plurality of first core yarns, a plurality of second core yarns, a middle coating layer and an outer coating layer, wherein the first core yarns and the second core yarns are untwisted and are arranged in parallel; the first core yarns are antibacterial moisture absorption core filaments; the antibacterial moisture absorption core filaments are of skin-core structures and comprise moisture absorption short fibers and silks spirally wound outside the moisture absorption short fibers; the second core yarns are bamboo fibril yarns; the middle coating layer is spirally wound and coated outside the firstcore yarns and the second core yarns; the middle coating layer adopts PLA fibers; the outer coating layer is spirally wound and coated outside the middle coating layer; and the outer coating layer adopts industrial hemp fibers. The antibacterial medical yarn has very good moisture absorbing and transferring performance, is soft in touch, is good in skin friendliness, is high in strength, is goodin antibacterial performance, and is an excellent medical yarn.

Owner:SUZHOU CITY XINGJINGZE FIBER TECH CO LTD

A kind of preparation method of super imitation cotton modified polyester fiber functional printing blanket

InactiveCN104313898BIncrease elasticitySoft and comfortableFibre typesDry-cleaning apparatus for textilesPolyesterFiber

The invention provides a method for preparing a super imitation cotton modified polyester fiber functional printing blanket. The method is characterized by comprising the following specific steps: weaving; polishing; sizing; printing; steaming fixation; functional finishing; washing; drying; printing blank polish-shearing; finishing and packing. The printing blanket with good moisture absorption and conductivity, flexible and comfortable touch sense, good elasticity, bright color, clear pattern and flame retardant, anti-mite and antibacterial functions can be obtained by the method provided by the invention; the successful development and application of the product can develop novel application of super imitation cotton modified polyester fibers and enhance the quality and international competitiveness of Chinese polyester fiber textiles.

Owner:DONGHUA UNIV +2

Preparation method of double-sided different-velvet fiber fabric

ActiveCN111041678AGood warmth retentionGood moisture absorption and moisture conductivitySucessive textile treatmentsWeft knittingPolyesterPolymer science

The invention relates to a preparation method of a double-sided different-velvet fiber fabric. Cationic polyester fully-drawn yarns are adopted as velvet yarn raw materials, CDP FDYs are adopted as bottom yarn raw materials, the cationic polyester fully-drawn yarns and the CDP FDYs are subjected to beaming, warp knitting and slitting to prepare a gray fabric, and the gray fabric is subjected to napping, front ironing, back carding, shearing, first-time anti-pilling treatment, presetting, ironing, second-time anti-pilling treatment and setting to obtain the double-sided different-velvet fiber fabric, wherein a preparation process of the cationic polyester fully-drawn yarns comprises the steps of performing cooling by cross air blow after a CDP melt is extruded from trilobal spinneret holesin a spinneret plate, and preparing the FDYs according to an FDY process, namely, obtaining the cationic polyester fully-drawn yarns. The prepared double-sided different-velvet fiber fabric has the gram weight being 200-250 g / m<2>, the wicking height being 11. 6-12.7 cm, the thermal resistance being 0.40-0.43 K.m<2> / W, the fullness being 4.5-5.0 and the softness being 4.5-5.0.

Owner:JIANGSU HENGLI CHEM FIBER

Milk and tencel fiber denim and production process thereof

InactiveCN104975406AMeet comfort requirementsGood moisture absorption and moisture conductivitySingeingWarping machinesFiberEnvironmentally friendly

The invention provides milk and tencel fiber denim. The milk and tencel fiber denim is characterized in that the blending proportion of milk fiber and tencel fiber is 40:60 by weight. A production process of the milk and tencel fiber denim is characterized in that the production process includes the following steps of spooling, warping, sizing dyeing, drafting, weaving, running repair, singeing and packaging and warehousing. Compared with the prior art, the grade of the denim is enhanced, high technical content is given to traditional denim, the denim is soft, comfortable and smooth in touch feeling like cashmere, the fiber looks white, has natural gloss like silk and is elegant in appearance and the like, and spinnability is excellent; products developed through the process accord with the environmentally-friendly dressing idea of people and meet the fashion demands of people for nature, comfort and beautiful appearance, and the milk and tencel fiber denim and the production process have good market prospects.

Owner:JIANGSU DELIHENG COTTON

Special-shaped-DTY-based moisture-wicking sweat-wicking knitted fabric and production method thereof

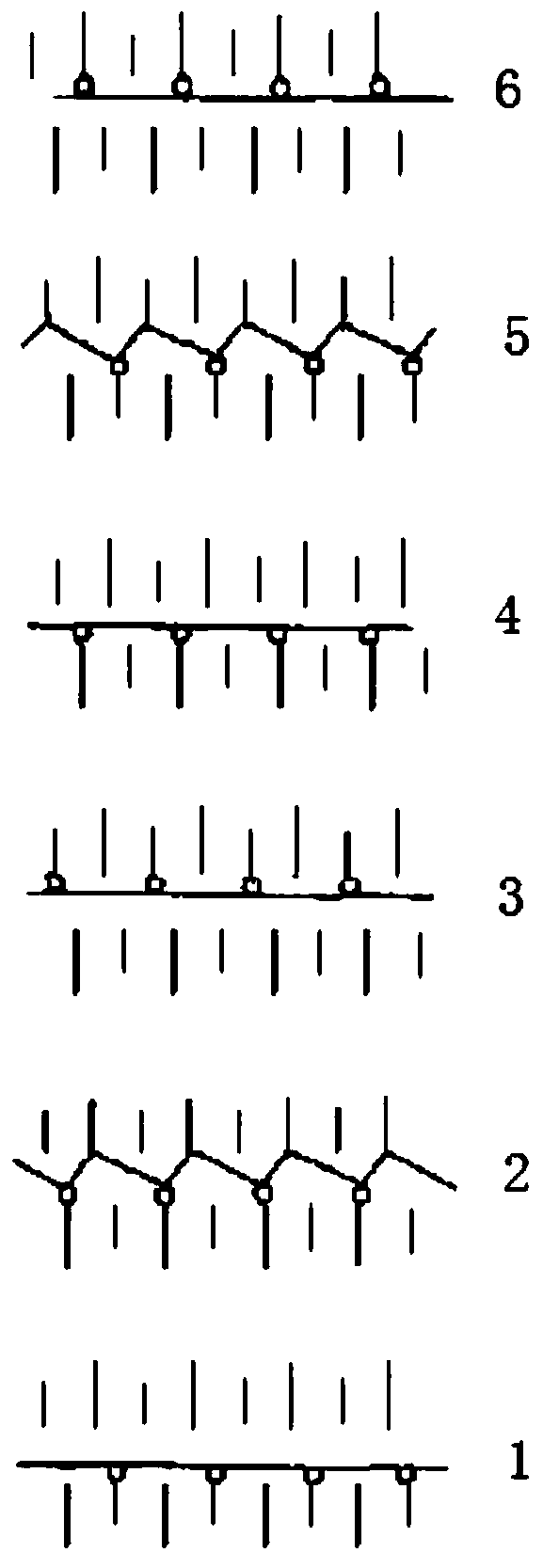

InactiveCN110983800AGood moisture absorption and moisture conductivityGood moisture absorption and releaseHollow filament manufactureFilament/thread formingYarnFiber

The invention discloses a special-shaped-DTY-based moisture-wicking sweat-wicking knitted fabric which comprises a base fabric. A polyurethane napping layer is arranged on the surface of the base fabric, and the base fabric is of a three-layer structure, the inner layer is a moisture-wicking layer, the middle layer is a connecting layer, and the outer layer is a moisture-releasing layer; and the moisture-wicking sweat-wicking fabric is made by weaving with a weft-knitted structure, the weft-knitted structure is made by weaving with 6 ways of loop forming systems, the 1<st> and 3<rd> loop forming systems use blended yarn of cotton yarn and natural bamboo fiber to weave the moisture-releasing layer, the 2<nd>, the 4, the 5 and the 6 loop forming systems use the special-shaped-DTYto weave the moisture-wicking layer, the special-shaped-DTY of the 2<nd>and the 5 loop forming systems connect the moisture-wicking layer and the moisture-releasing layer in order to form the connecting layer, and the cross-section of the special-shaped-DTY is of a hollow structure. The invention further discloses a production method of the moisture-wicking sweat-wicking knitted fabric. The moisture-wicking sweat-wicking knitted fabric has good air permeability moisture-wicking property, the dry and comfortable feeling of the inner layer of the fabric can be ensured, the elasticity and strength are good, the fabric is soft and fluffy in hand feeling, and the outer layer of the fabric has comfort velvet feeling.

Owner:苏州萧然新材料有限公司

Preparation method of novel antibacterial and deodorant fabric

InactiveCN112356529AAntibacterial and anti-inflammatoryHigh bonding strengthCarbon fibresBiochemical fibre treatmentFiberPolymer science

The invention discloses a novel antibacterial and deodorant fabric and a preparation method thereof, the novel antibacterial and deodorant fabric comprises a base cloth layer, a fabric layer and an antibacterial and deodorant layer arranged between the base cloth layer and the fabric layer, and the antibacterial and deodorant layer is formed by weaving warp yarns and weft yarns; wherein the warp yarns are antibacterial fibers containing antibacterial nano particles, and the weft yarns are antibacterial fibers containing antibacterial deodorant finishing liquid; the novel antibacterial and deodorant fabric prepared by the preparation method disclosed by the invention has good moisture absorption and moisture conduction performance and moisture absorption and sweat releasing functions, has good plant antibacterial and deodorant effects and natural antibacterial and deodorant effects, and also has the functions of cooling, smoothness, antisepsis and anti-inflammation.

Owner:无锡市晟鑫纺织有限公司

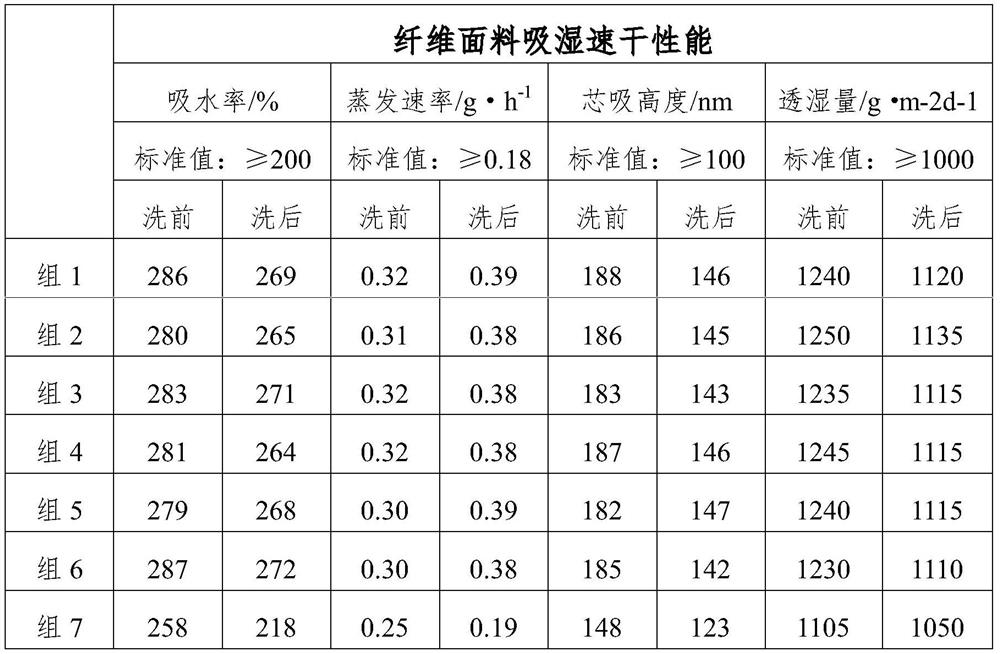

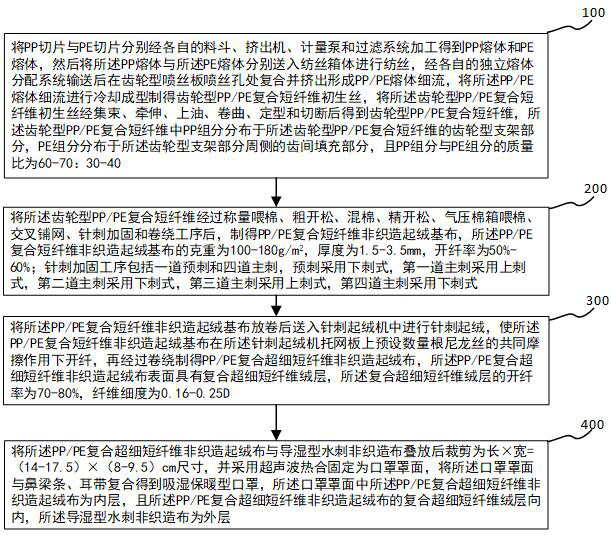

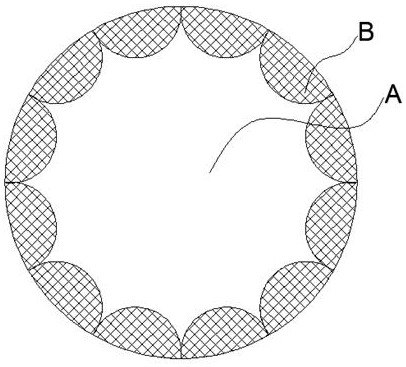

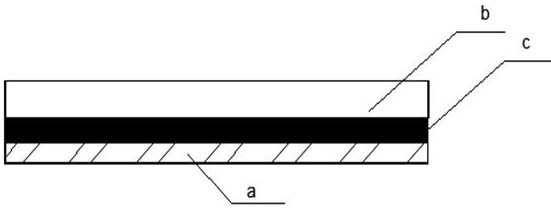

Moisture-absorbing and warm-keeping type mask and preparation method thereof

ActiveCN113103700AReduce difficultyReduce energy consumptionProtective equipmentSynthetic resin layered productsFiberMoisture absorption

The invention discloses a moisture-absorbing and warm-keeping type mask and a preparation method thereof, and relates to the technical field of articles of daily use. According to the moisture-absorbing and warm-keeping type mask, through preparation of gear type PP / PE composite short fibers, setting of pre-needling and main needling process parameters in the needling reinforcing process and setting of needling raising process parameters, prepared PP / PE composite superfine short fiber non-woven raising cloth has the high splitting rate; the further prepared moisture-absorbing and warm-keeping type mask has a gradient layer-by-layer filtering effect and is high in filtering efficiency, good in air permeability and good in moisture absorbing and guiding performance, and meanwhile the warm keeping performance is further improved through the composite superfine short fiber fleece layer of the PP / PE composite superfine short fiber non-woven fleece. The moisture-absorbing and warm-keeping type mask has the efficient filtering performance, the moisture absorption and conduction performance and the warm keeping performance, and the technical effects that the warm keeping performance of the mask is improved, and the man-machine relation of the mask to a user wearing glasses in winter is improved are achieved.

Owner:JIAXING UNIV

Method for manufacturing polyester double-point low-temperature high-strength adhesive lining cloth

InactiveCN101831809AReduce distortionGood dimensional stabilityFibre treatmentPolyesterHigh intensity

The invention relates to a method for manufacturing polyester double-point low-temperature high-strength adhesive lining cloth, comprising the following steps of: coating a punctiform high melting point polyester glue layer on treated base cloth; pouring low melting point polyester rubber powder when the high melting point polyester glue does not solidify completely; removing redundant low melting point polyester rubber powder which is not poured on the high melting point polyester glue line; and finally carrying out high-temperature molding. The method has the advantages that original color and luster of the cloth can be remained after bonding, and the cloth has better shape stability, washing size stability, moisture absorption and moisture conductivity and alkali resistance and solves the problem that fabric foaming of clothing occurs after daily washing for many times.

Owner:天津奔骜服饰有限公司

A kind of cool and sweat-absorbing summer clothing fabric

ActiveCN107245787BGood moisture absorption and moisture conductivityImprove breathabilityHeating/cooling textile fabricsWoven fabricsPolyesterWrinkle skin

Owner:山东恒利纺织科技有限公司

Moisture-proof mildew-proof fiber, preparation method thereof and fabric

InactiveCN112144274APrevent internal moldProtects against moisture and mildewWeft knittingBiochemical fibre treatmentHollow fibreChemistry

The invention relates to the technical field of textiles, and discloses a moisture-proof and mildew-proof fiber, a preparation method thereof and a fabric. The moisture-proof and mildew-proof fiber comprises a hollow fiber and a mildew-proof and moisture-proof agent arranged in a cavity of the hollow fiber; the hollow fiber is a chitosan modified hollow viscose fiber; the mildew-proof and moisture-proof agent comprises a calcined shell powder inner core and a modified hydroxyapatite shell; the modified hydroxyapatite shell coats the calcined shell powder inner core in a dotted manner; the modified hydroxyapatite is hydroxyapatite which is subjected to graft modification by gamma-aminopropyl triethoxysilane; and camphor tree essential oil is loaded in the calcined shell powder inner core. According to the moisture-proof and mildew-proof fiber, the release rate of the camphor tree essential oil can be adjusted according to the environment humidity, the mildew-proof requirements under different humidity degrees can be met, meanwhile, excessive release of the camphor tree essential oil is avoided, and long-acting mildew prevention is achieved.

Owner:长沙柔织新材料科技有限公司

A kind of microfiber summer mat and preparation method thereof

ActiveCN110667211BNo stickinessRefreshingLamination ancillary operationsArtificial thread manufacturing machinesPolymer scienceMoisture absorption

The invention discloses a superfine fiber mat and a preparation method thereof, and relates to the technical field of home textile products. A kind of superfine fiber mat provided by the present invention and its preparation method and preparation method thereof, through the preparation process design of segmental segmented PA6 / HDPE composite ultra-short fiber, and the segmental segmental type PA6 / HDPE composite ultra-short fiber is developed The superfine fiber non-woven fabric of the upper layer is prepared through the process of fiber, mixing and forming into a net, and the superfine fiber mat is prepared by compounding with the warp-knitted spacer cloth of the lower layer. The fast moisture absorption and moisture conduction performance and the bulkiness and elasticity of the warp-knitted spacer fabric in the lower layer solve the technical problems of poor sweat absorption and sweat-wicking ability of existing mats and poor user experience, and help to improve the use of mats by users It can avoid various skin problems caused by the adhesion of sweat on the surface of the mat to the skin of the human body.

Owner:JIAXING UNIV

Preparation method of multi-micropore polyester fibers

InactiveCN111349980APolyester homogeneousEasy OverrideMonocomponent polyesters artificial filamentArtifical filament manufactureOxalateTrans esterification

The present invention discloses a preparation method of multi-micropore polyester fibers. According to the polyester fibers, esterification or ester exchange is performed on terephthalic acid and / or dicarboxylic terephthalate and dibasic alcohol monomers, and further polymerization is performed in the presence of double oxalate and a conventional polycondensation catalyst to prepare polyester. Theobtained polyester is subjected to slicing, granulating and melt spinning so as to prepare the polyester fibers. The obtained polyester fibers are treated with high-temperature hot water, so that thesurfaces and the interiors of the obtained fibers contain a large amount of through micropores, the fiber density is 1.15-1.30 g / cm<3>, and cloth prepared from the fibers has good moisture absorptionand air permeability.

Owner:江苏银兆新材料科技有限公司

A coolplus moisture-wicking and warm-keeping raschel blanket

ActiveCN107419423BPromote popularizationSimple compositionFibre typesWarp knittingPolyesterChinese characters

The invention discloses a Coolplus moisture-absorption sweat-releasing and warming Raschel woolen blanket. The Coolplus moisture-absorption sweat-releasing and warming Raschel woollen blanket is woven on a two-needle bar Raschel warp knitting machine by using blended yarns of Coolplus fibers and acrylic fibers as nap yarns and using polyester silk as basic silk. Special-shaped polyester fibers can be acquired by using a +-shaped herringbone or Chinese character mi-shaped spinning assembly; air plasma and alkali peeling treatment is performed on the polyester fibers; regular micro grooves and micro holes are formed in surfaces of the polyester, and the grooves and the holes can generate a significant capillary effect, moisture and sweat excreted by a human body are diffused and transmitted, and then are discharged out, and skins can keep dry; and noncurrent static air is stored in the regular micro grooves and micro holes, and the static air can significantly improve the warming performance of the Raschel woolen blanket.

Owner:ZHEJIANG TRUELOVE CARPET IND SCI & TECH

Environment-friendly functional jacket

InactiveCN104382253AIncrease warmthGood hygroscopicityJacketsProtective garmentFiberMoisture absorption

The invention discloses an environment-friendly functional jacket. The environment-friendly functional jacket comprises a shell fabric layer, a splicing layer and a lining layer, wherein the shell fabric layer, the splicing layer and the lining layer are sequentially distributed from outside to inside and are adhered to one another. The shell fabric layer is formed by blending and weaving of 50-70wt% of Dacron and 50-30wt% of soft-filament fibers. The splicing layer is formed by blending and weaving of 20-40wt% of silk floss and 80-60wt% of cotton. The lining layer is formed by blending and weaving of 50-70wt% of cotton and 50-30wt% of soybean protein fibers. The environment-friendly functional jacket is formed by adhesion of the shell fabric layer, the splicing layer and the lining layer which are formed by blending, the shell fabric layer is high in moisture absorption capability, bright in dyed color, soft in gloss and degradable, the lining layer has excellent moisture absorption and guide effects, and heat insulation performance of the jacket is further improved by the splicing layer.

Owner:SUZHOU ROSTION CLOTHES

Preparation method of skin-friendly polyester cotton blended hemp-like fabric

PendingCN113235298AGood moisture absorption and moisture conductivityGood mechanical propertiesWrinkle resistant fibresVegetal fibresPolyesterSoybean Proteins

The invention provides a preparation method of a skin-friendly polyester cotton blended hemp-like fabric. The preparation method comprises the following steps of S1, preparing a soybean protein polypeptide aqueous solution; S2, preparing aloe powder; S3, preparing modified aloe powder; and S4, adding the modified aloe powder prepared in the step S3 into a soybean protein polypeptide aqueous solution, uniformly mixing to obtain a finishing solution, adding a fabric into the finishing solution, then adding acrylamide, fully stirring, and adding N, N, N', N'-tetramethylethylenediamine and ammonium persulfate to obtain the modified fabric with the surface grafted with aloe gel and soybean protein. The soybean protein polypeptide and the aloe vera gel are uniformly distributed on the surface of the fabric, the fabric is a functional fabric which is friendly to skin and has relatively good mechanical performance, and when the fabric is worn, protein and aloe vera gel are in contact with the skin of a human body, so that the wearing comfort is improved.

Owner:吴江市南麻恒兴丝织厂

Anti-ultraviolet light soft warm fabric and preparation method thereof

InactiveCN110344167AImprove wearing comfortUV resistantWeft knittingBiochemical fibre treatmentYarnBanana fiber

The invention discloses an anti-ultraviolet light soft warm fabric which is of double-side weave structure and which comprises inner yarns and outer yarns. The inner yarns and the outer yarns are subjected to double-side knitting to obtain a double-side fabric body; the double-side fabric body is subjected to padding with an anti-ultraviolet treating liquid; the inner yarns are high twist yarns; the outer yarns are soft siro-spun yarns. The siro-spun yarns are made with, by weight 60-70 parts of cotton fibers, 15-17 parts of regenerated fibers and 3-6 parts of banana fibers. The anti-ultraviolet light soft warm fabric has the advantages that the double-side fabric body is subjected to padding with the anti-ultraviolet treating liquid, the ingredients of the anti-ultraviolet treating liquidcoordinatively promote one another through compatibility, and therefore, the prepared fabric has good ultraviolet resistance and better wearing comfort.

Owner:南通明富纺织品有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com