Moisture-absorbing rapid-drying composite polyester fiber filament and machining process thereof

A compound polyester, moisture-absorbing and quick-drying technology, which is applied in the direction of conjugated synthetic polymer artificial filament, fiber treatment, fiber chemical characteristics, etc., can solve the problem of affecting the production efficiency of spinning and weaving production efficiency in subsequent processes, and is prone to broken ends It can improve the moisture absorption and moisture conduction ability, improve the spinnability, and ensure the smooth production and use.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

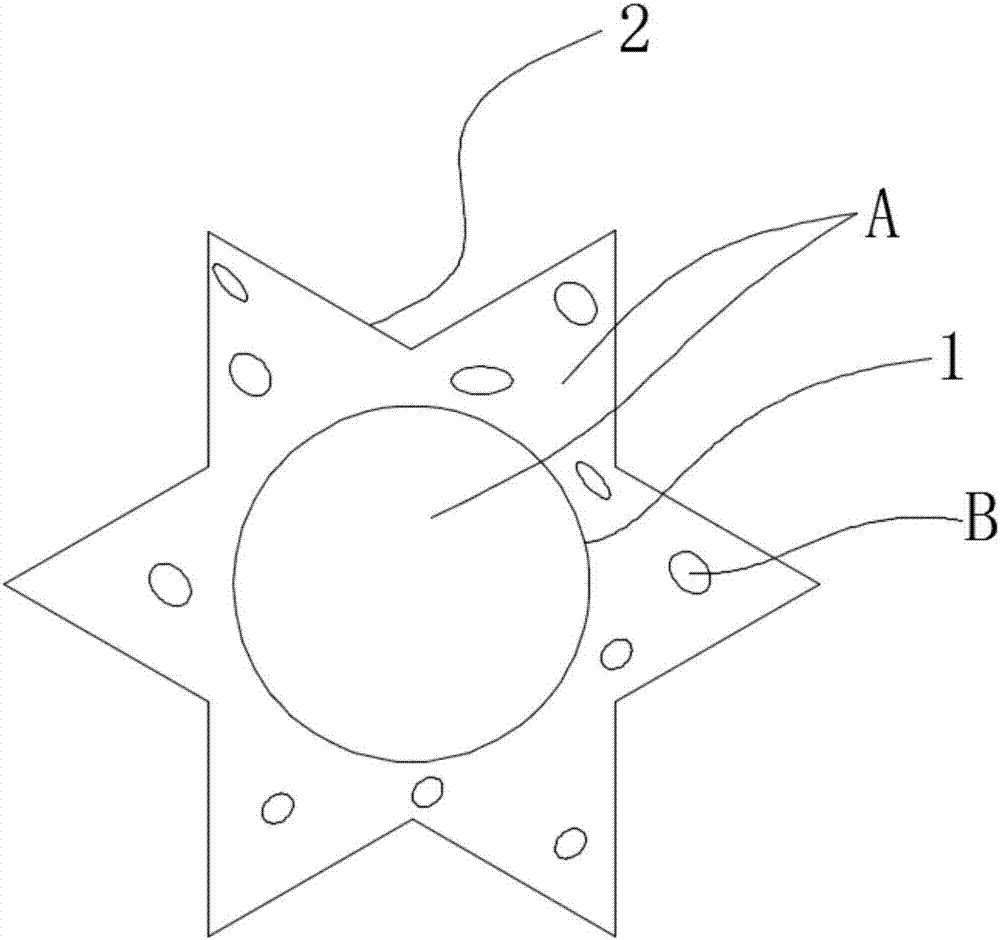

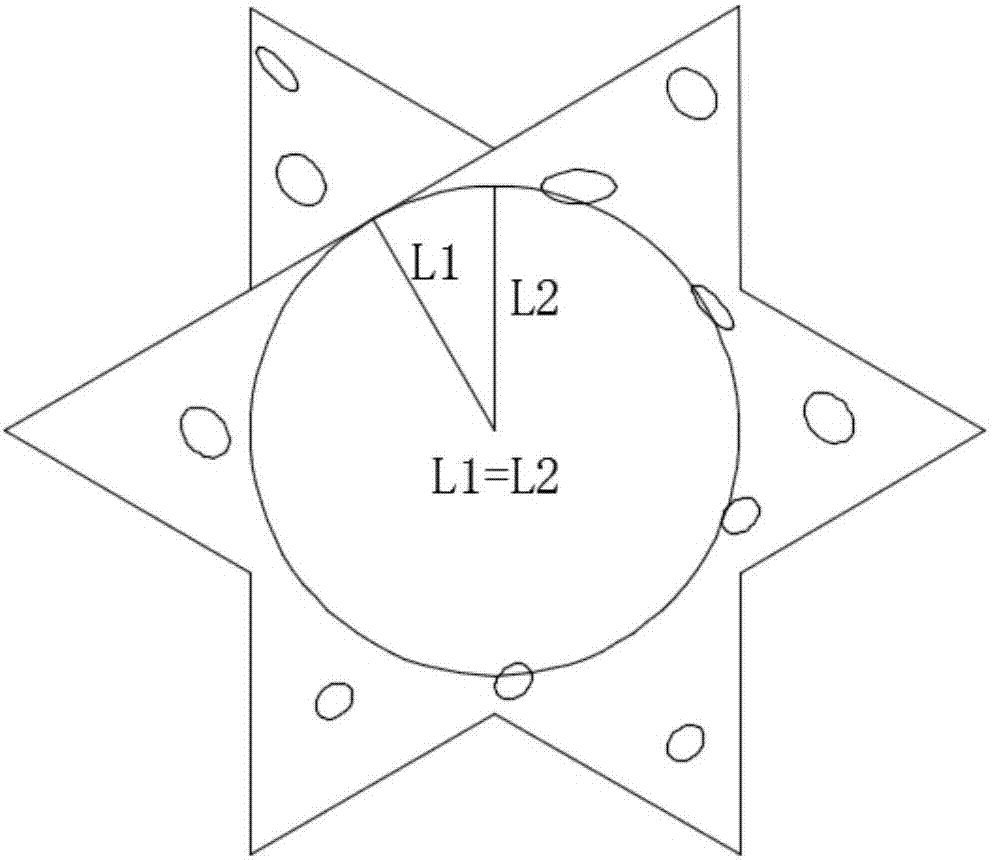

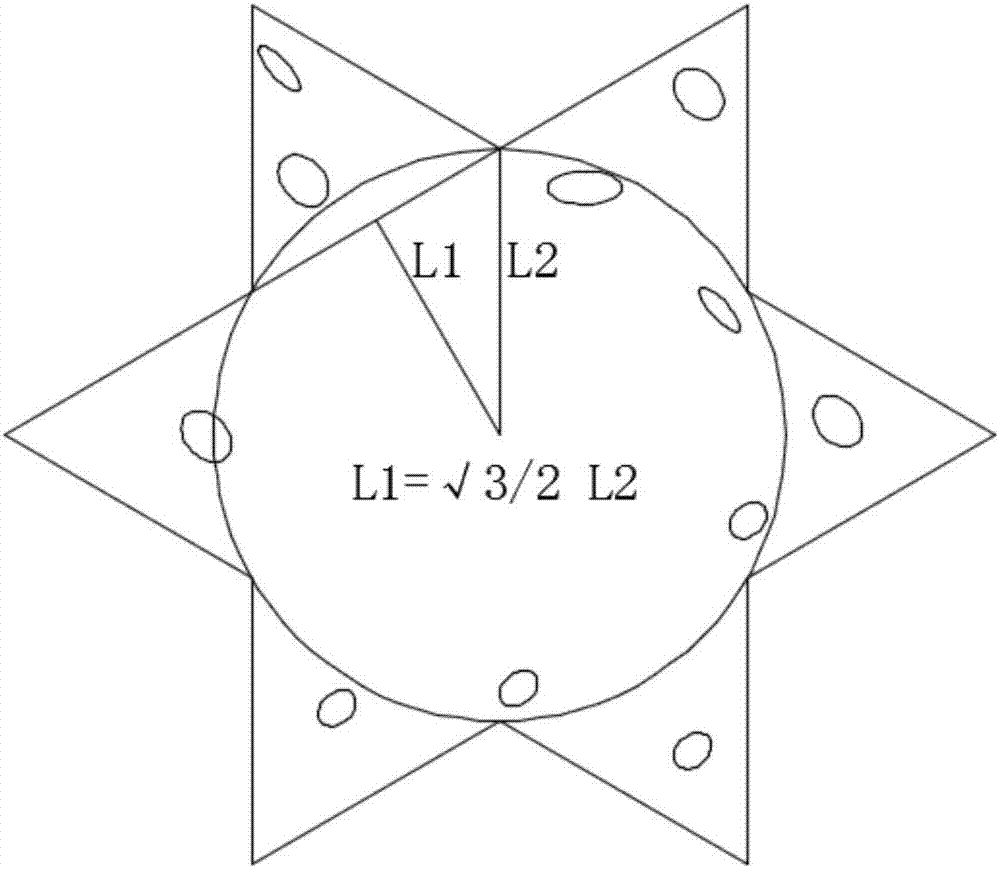

[0038] The moisture-absorbing and fast-drying composite polyester fiber filament of this embodiment is composed of polyester polyester chips modified by copolymerization of ethylene glycol isophthalate-5-sulfonic acid sodium and polyols and conventional polyester polyester chips. filaments formed. Such as figure 1 As shown, the composite polyester fiber filaments include a core layer 1 with a circular cross section and a skin layer 2 wrapping the core layer. The composite polyester fiber filaments have a regular hexagonal star shape in cross section and six grooves. Compared with other The shape structure has better breathable and quick-drying effects; and the cross-section of the composite polyester fiber filament is concentric with the cross-section of the core layer, and the cross-section of the cortex is the part of the regular hexagonal star except the circular core layer.

[0039] The cortex comprises conventional polyester polyester slice A and ethylene glycol isophtha...

Embodiment 2

[0042] This embodiment is the processing technology of the hygroscopic and quick-drying composite polyester fiber filament of embodiment 1, comprising the following steps:

[0043] 1) The processing steps of slice B: Polyterephthalic acid PTA (45 parts), ethylene glycol EG (28 parts), polyisophthalic acid PIA (10 parts), sodium benzenesulfonate (5 parts), poly Mix ethylene glycol PEG (2 parts), react at 200-250°C for 3-5 hours under normal pressure; then add quaternary ammonium salt (0.5 part), antioxidant 1010 (0.6 part), triphenyl phosphite Ester (0.5 parts), heated up to 250-280°C, pumped under low vacuum for 1 hour, and then under 0.1KPA vacuum condition for 1-2 hours, prepared ethylene glycol isophthalate-5-sodium sulfonate modified polystyrene Ester polyester chips B.

[0044] 2) Slice A and slice B are crystallized at 70-80°C, and then dried at 110-130°C. After drying, the cortex material and core layer material are mixed: the cortex material is slice A (35 parts) and ...

Embodiment 3

[0046] The difference between the hygroscopic and quick-drying composite polyester fiber filament of this embodiment and that of Embodiment 1 is that the cortex of this embodiment includes conventional polyester polyester chip A and ethylene glycol isophthalate-5-sodium sulfonate modification. Permanent polyester polyester chip B, wherein, by weight: chip A is 48 parts, and chip B is 10 parts; The core layer is conventional polyester polyester chip A, and the weight part is 50 parts.

[0047] Ethylene glycol isophthalate-5-sulfonate modified polyester polyester chips B, comprising the following components by weight: 48 parts of polyethylene terephthalic acid PTA, 30 parts of ethylene glycol EG, polyisophthalic acid 11 parts of PIA diformic acid, 5.5 parts of sodium benzenesulfonate, 2.5 parts of polyethylene glycol PEG, 0.7 parts of quaternary ammonium salt, 0.8 parts of antioxidant 1076, and 0.6 parts of triphenyl phosphite; Technical characteristics refer to embodiment 1. C...

PUM

| Property | Measurement | Unit |

|---|---|---|

| elongation at break | aaaaa | aaaaa |

| elongation at break | aaaaa | aaaaa |

| elongation at break | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com