Fire-resistant and anti-bacterial cotton fabric and preparation method thereof

A fabric and cotton technology, applied in the field of fire-resistant and antibacterial cotton fabric and its preparation, can solve problems affecting health, breeding bacteria, human loss, etc., and achieve the effect of improving antibacterial performance, firm combination, and good wash fastness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0053] The preparation method of described refractory and antibacterial cotton cloth, comprises the steps:

[0054] Step S1, ramie fiber, cotton, and Coolplus staple fiber are blended into spinning according to the blending ratio of 32 / 48 / 20; the spinning is woven into an inner layer fabric according to a horizontal density of 59 rows / 5cm and a vertical density of 98 rows / 5cm; weaving The completed inner layer cloth is dipped in the treatment solution for antibacterial treatment to obtain the inner lining layer of the cloth;

[0055] Step S2, flame-retardant viscose fiber, flame-retardant acrylic fiber, ramie fiber, and cotton are blended into spinning according to the blending ratio of 36 / 36 / 40 / 20; the spinning is according to the horizontal density of 62 longitudinal rows / 5cm, and the vertical density of 96 rows / 5cm is woven into a surface layer of cloth; a layer of flame-retardant film layer is sprayed on the surface of the surface layer of cloth to obtain a cloth surface;...

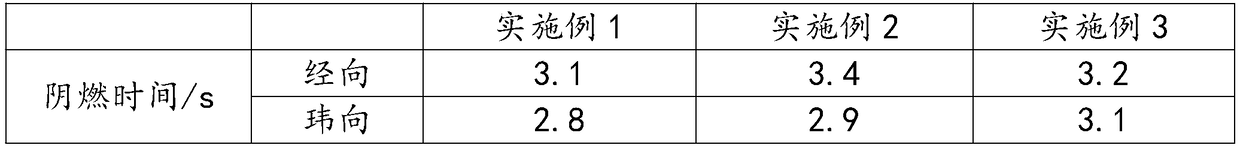

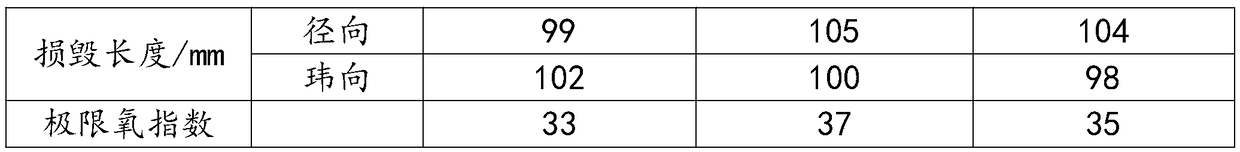

Embodiment 1

[0059] The flame retardant film layer is made of the following raw materials in parts by weight: 10 parts of polyethylene glycol methyl phosphate, 5 parts of aluminum tripolyphosphate, 18 parts of glycerin, and 35 parts of distilled water;

Embodiment 2

[0061] The flame retardant film layer is made of the following raw materials in parts by weight: 11 parts of polyethylene glycol methyl phosphate, 7.5 parts of aluminum tripolyphosphate, 21 parts of glycerin, and 10 parts of distilled water;

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| limiting oxygen index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com