Preparation method of skin-friendly polyester cotton blended hemp-like fabric

A technology of chaotic and polyester-cotton, which is applied in the field of preparation of skin-friendly polyester-cotton chaotic fabrics, and achieves the effects of good mechanical properties, improved wearing comfort, and good moisture absorption and moisture conductivity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

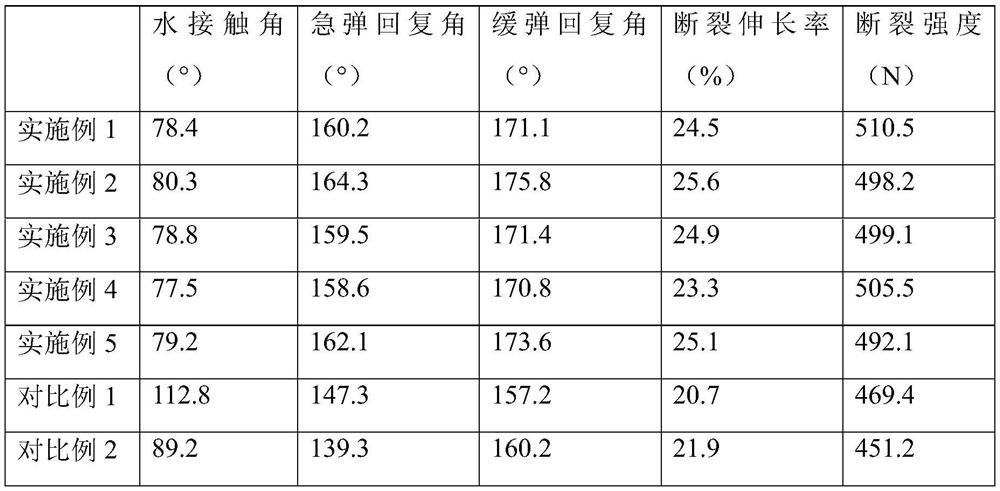

Examples

Embodiment 1

[0020] A preparation method of skin-friendly polyester-cotton hemp fabric, comprising the following steps:

[0021] S1. Dissolving the soybean protein polypeptide with a molecular weight of 5000 in water to form an aqueous solution with a concentration of 2.5wt% soybean protein polypeptide;

[0022] S2. Dissolving the aloe gel powder in water to prepare a 10wt% aloe gel aqueous solution, dialyzing the aloe gel aqueous solution, concentrating and drying the dialyzed aloe gel to obtain aloe powder;

[0023] S3. Aloe powder, 4-dimethylaminopyridine, and glycidyl methacrylate are dissolved in dimethyl sulfoxide, and the mass ratio of aloe powder, 4-dimethylaminopyridine and glycidyl methacrylate is 1: 0.2:0.02, react under anaerobic conditions, then add acid to neutralize the solution to neutrality, then add ethanol to precipitate solids, and obtain modified aloe vera powder;

[0024] S4. Add the modified aloe powder prepared in step S3 to the soybean protein polypeptide aqueous ...

Embodiment 2

[0027] A preparation method of skin-friendly polyester-cotton hemp fabric, comprising the following steps:

[0028] S1. Dissolving the soybean protein polypeptide with a molecular weight of 2000 in water to form an aqueous solution with a concentration of 6.5 wt% soybean protein polypeptide;

[0029] S2. Dissolving the aloe gel powder in water to prepare a 60wt% aloe gel aqueous solution, dialyzing the aloe gel aqueous solution, concentrating and drying the dialyzed aloe gel to obtain aloe powder;

[0030] S3. Aloe powder, 4-dimethylaminopyridine, glycidyl methacrylate are dissolved in dimethyl sulfoxide, the mass ratio of aloe powder, 4-dimethylaminopyridine and glycidyl methacrylate is 5: 1:0.1, react in anaerobic state, then add acid to neutralize the solution to neutral, then add ethanol to precipitate solids, and obtain modified aloe vera powder;

[0031] S4. Add the modified aloe powder prepared in step S3 to the soybean protein polypeptide aqueous solution, the content...

Embodiment 3

[0034] A preparation method of skin-friendly polyester-cotton hemp fabric, comprising the following steps:

[0035] S1. Dissolving the soybean protein polypeptide with a molecular weight of 3500 in water to form an aqueous solution with a concentration of 4wt% soybean protein polypeptide;

[0036] S2. Dissolving the aloe gel powder in water to prepare a 25wt% aloe gel aqueous solution, dialyzing the aloe gel aqueous solution, concentrating and drying the dialyzed aloe gel to obtain aloe powder;

[0037] S3. Aloe powder, 4-dimethylaminopyridine, glycidyl methacrylate are dissolved in dimethyl sulfoxide, the mass ratio of aloe powder, 4-dimethylaminopyridine and glycidyl methacrylate is 2: 0.8:0.08, react under anaerobic conditions, then add acid to neutralize the solution to neutrality, then add ethanol to precipitate solids, and obtain modified aloe vera powder;

[0038] S4. Add the modified aloe powder prepared in step S3 to the soybean protein polypeptide aqueous solution, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com