Anti-ultraviolet light soft warm fabric and preparation method thereof

An anti-ultraviolet and fabric technology, applied in the field of fabrics, can solve the problems of poor anti-ultraviolet performance, increase the thickness of the fabric, and low thermal performance, and achieve the effect of improving wearing comfort.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0050] A method for preparing an anti-ultraviolet light and warm fabric, comprising the following steps:

[0051] 1) the inner layer yarn and the outer layer yarn are double-sided knitted by a double-sided knitting machine to obtain a double-sided fabric gray cloth;

[0052] 2) Degreasing, dyeing, and padding the gray cloth with an anti-ultraviolet treatment solution to obtain the anti-ultraviolet soft and warm fabric.

Embodiment 1

[0055] A kind of anti-ultraviolet light and warm fabric, the fabric is a double-sided weave structure, including the inner layer yarn and the outer layer yarn; Anti-ultraviolet treatment liquid for gray cloth padding; the inner layer yarn is made of high-twist yarn, and the outer layer is made of soft-feeling siro-spun yarn;

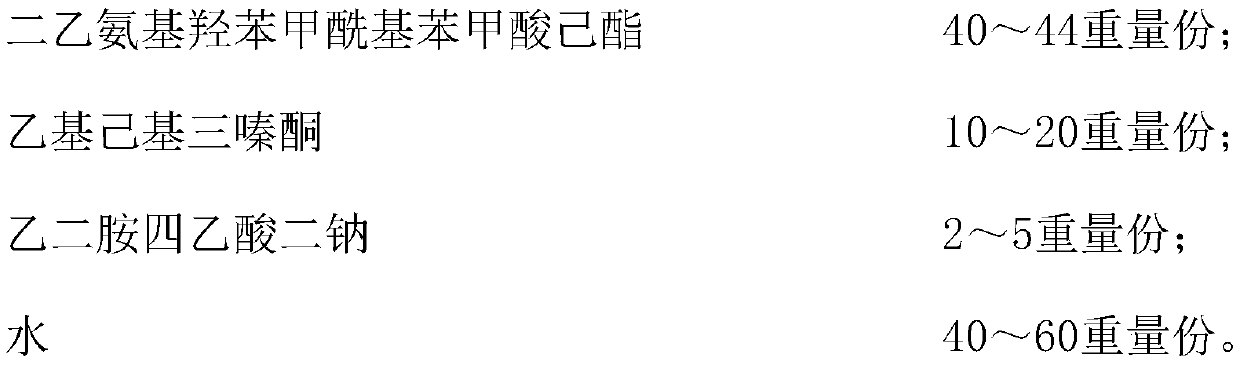

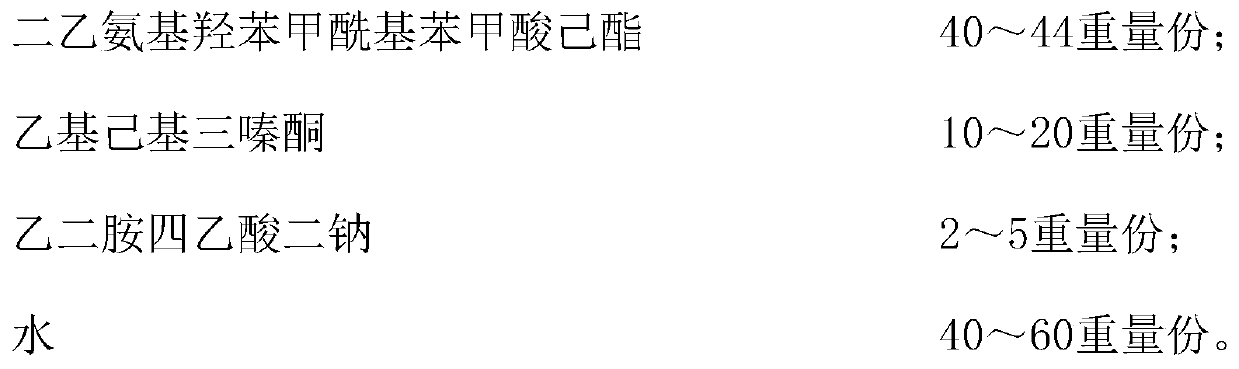

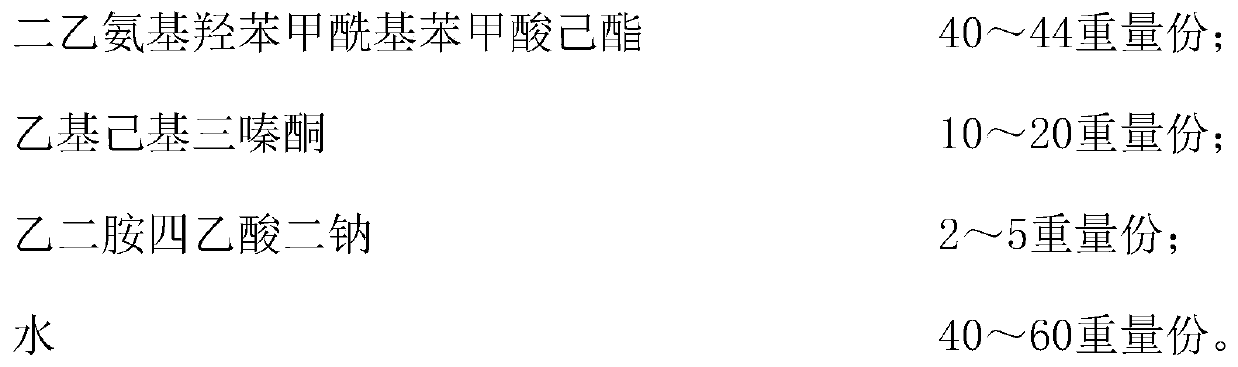

[0056] In parts by weight, siro-spun yarns include the following parts by weight:

[0057]

[0058] Regenerated fibers include 75wt% acetate fiber and 25wt% soybean protein fiber; the thickness of the inner yarn is 22SS, and the thickness of the outer yarn is 4S; the twist of the inner yarn is 68 twists / 10cm, and the outer The twist of the layer yarn is 48 twists / 10 cm.

[0059] By parts by weight, high-twisted yarns include yarns of the following parts by weight:

[0060] 60 parts by weight of cotton fiber;

[0061] 13 parts by weight of Thermogear fiber;

[0062] 2 parts by weight of polyacrylonitrile fiber.

[0063] UV treatment fluid includes t...

Embodiment 2

[0069] A kind of anti-ultraviolet light and warm fabric, the fabric is a double-sided weave structure, including the inner layer yarn and the outer layer yarn; Anti-ultraviolet treatment liquid for gray cloth padding; the inner layer yarn is made of high-twist yarn, and the outer layer is made of soft-feeling siro-spun yarn;

[0070] In parts by weight, siro-spun yarns include the following parts by weight:

[0071]

[0072] Regenerated fibers include 78wt% acetate fiber and 22wt% soybean protein fiber; the thickness of the inner yarn is 25S, and the thickness of the outer yarn is 7S; the twist of the inner yarn is 72 twists / 10cm, the outer The twist of the layer yarn is 50 twists / 10 cm.

[0073] By parts by weight, high-twisted yarns include yarns of the following parts by weight:

[0074] Cotton fiber 64 parts by weight;

[0075] 14 parts by weight of Thermogear fiber;

[0076] 3 parts by weight of polyacrylonitrile fiber.

[0077] UV treatment fluid includes the fol...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com