Patents

Literature

219results about "Two or more solvent application treatment" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

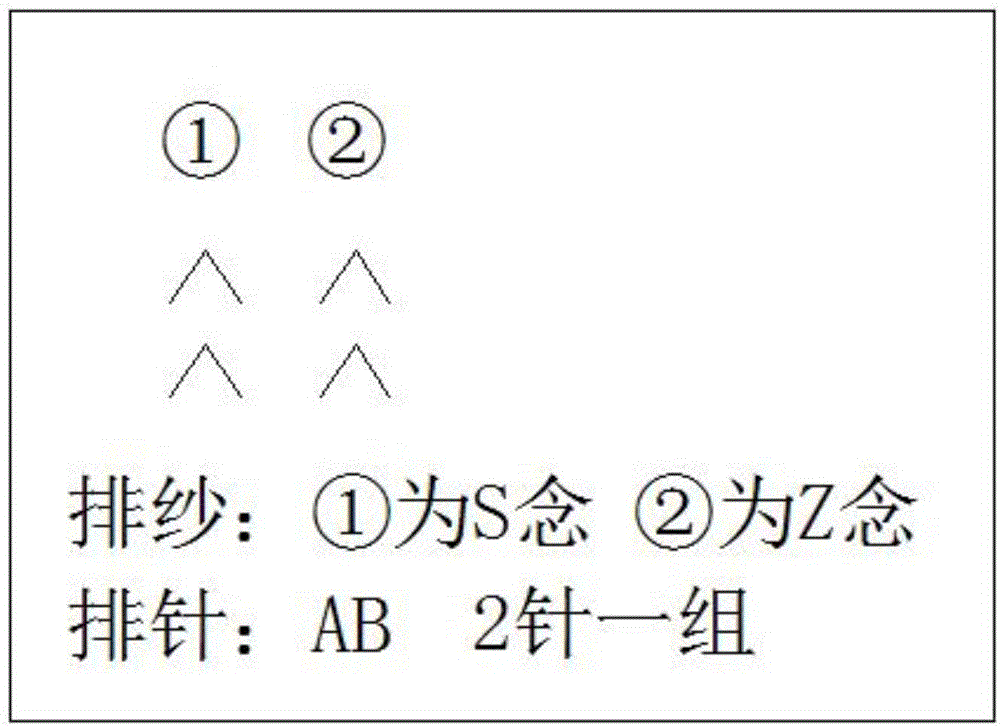

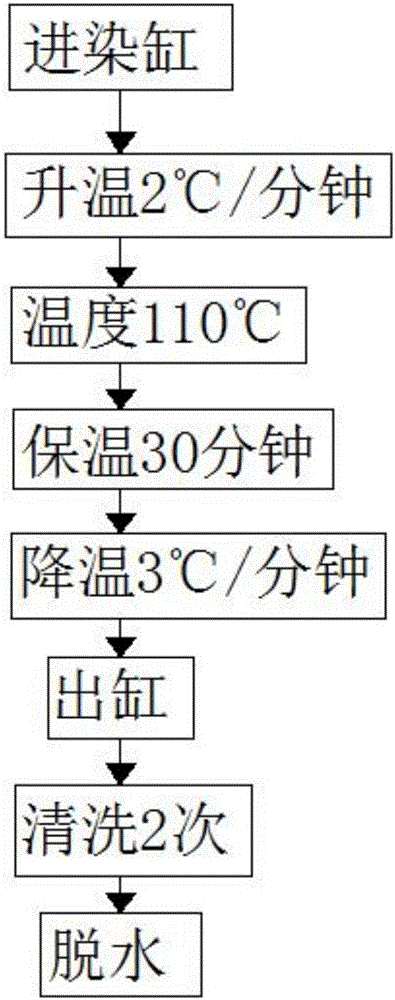

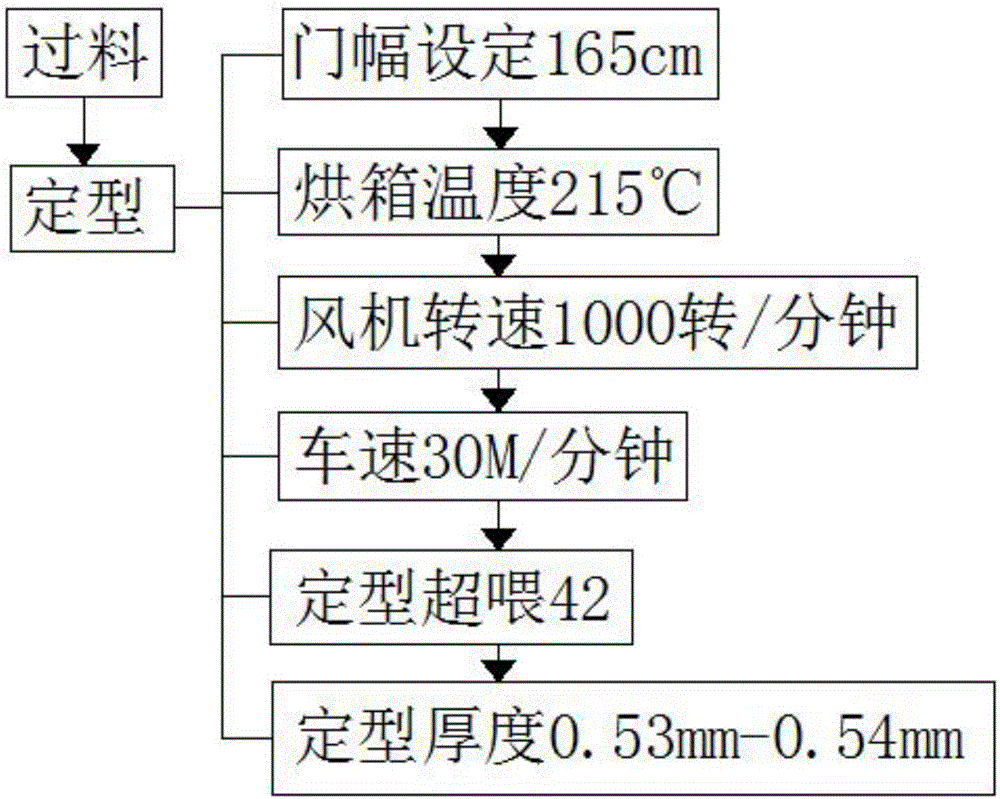

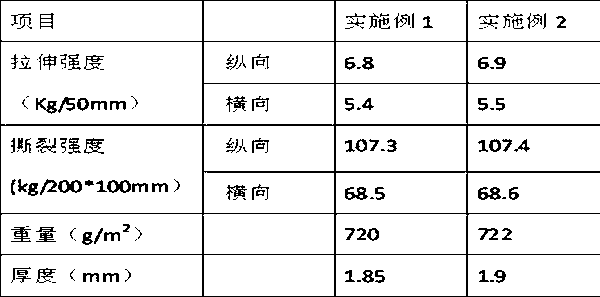

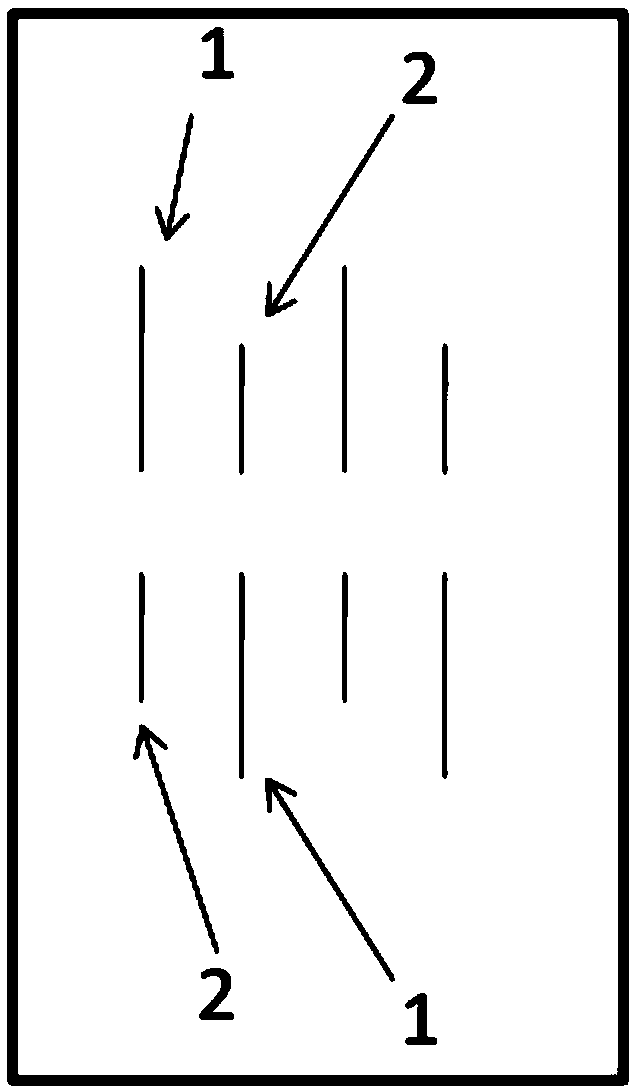

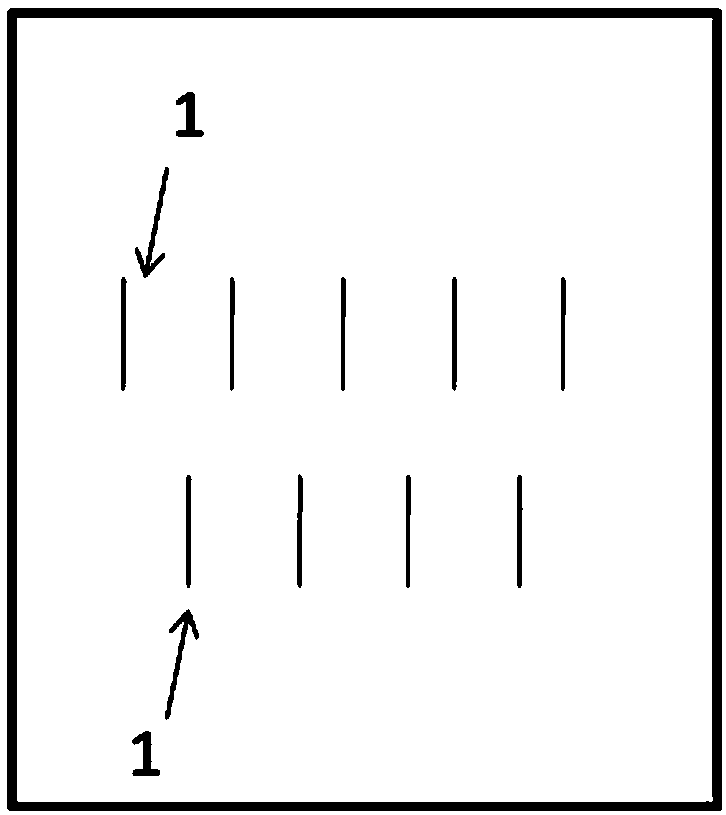

Automotive interior trim skin single face cloth

InactiveCN106048870AMeet the pullMeet tearSucessive textile treatmentsWeft knittingAfter treatmentGram

The invention relates to the technical field of automotive lining technologies, and particularly relates to an automotive interior trim skin single face cloth. The technique includes: a first step, gray fabric weaving; a second step, pretreatment (performing washing in a dyeing vat); and a third step, after-treatment (shaping). The beneficial effects of the invention are that needle arrangement and after-treatment shaping of the conventional knitting technology is changed, the skin base cloth can meet the demands of tension, tearing, and dead load tensile strength, and is decreased in gram weight and thickness; and the use cost is reduced.

Owner:信德汽车内饰材料江苏有限公司

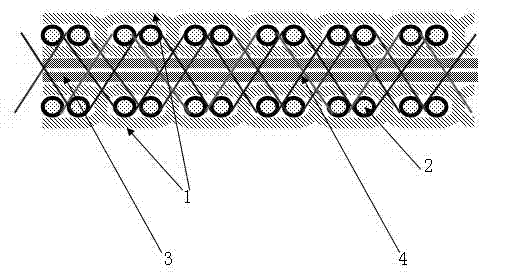

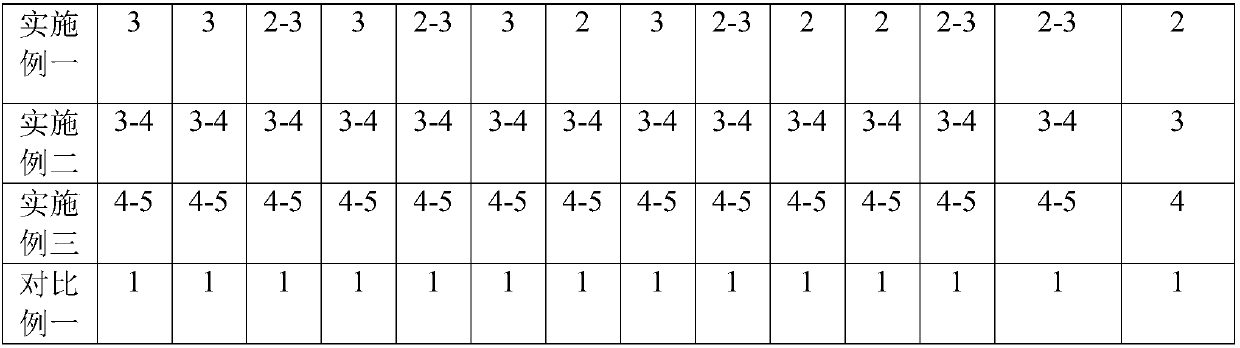

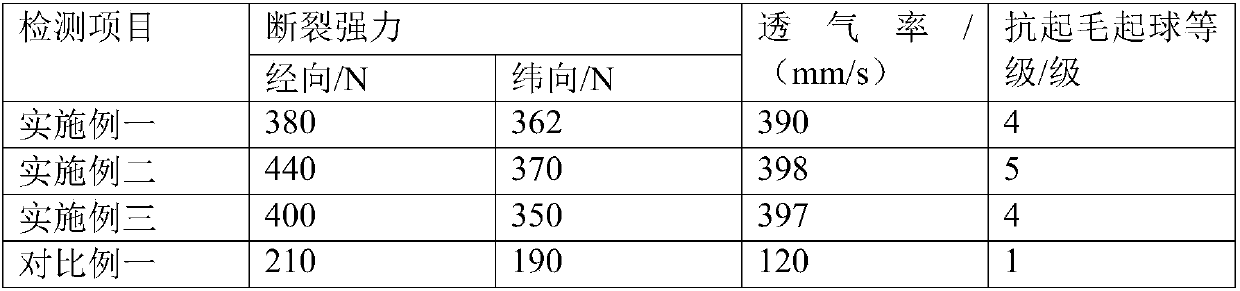

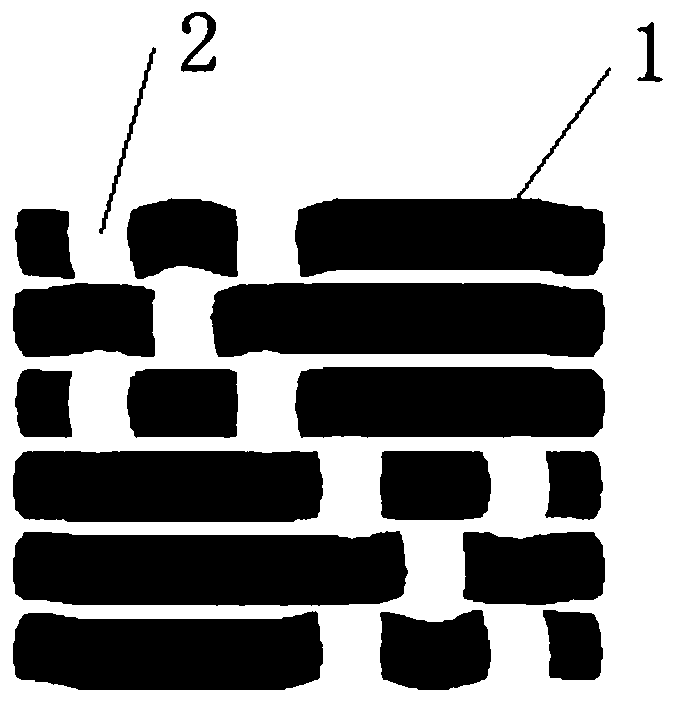

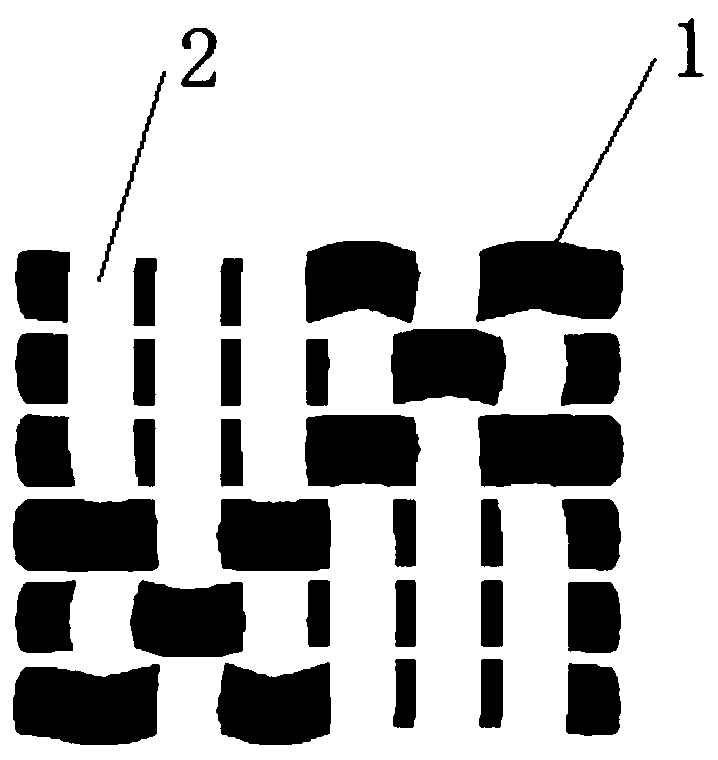

Dipped canvas fabric structure in three-dimensional structure for heavy-duty conveyor belt and production process thereof

ActiveCN102212917ASolve production technical problemsGood physical and mechanical propertiesFibre treatmentTwo or more solvent application treatmentPolyesterEngineering

The invention discloses a dipped canvas fabric structure in a three-dimensional structure for a heavy-duty conveyor belt and a production process thereof. The dipped fabric structure is characterized in that an upper layer and a bottom layer adopt ground-facing warps (1) in the plain weave structure and weft (2) interwoven with the ground-facing warp, a straight warp (3) in the straight warp structure is utilized as an intermediate layer, a bundling warp (4) is connected with the weft (2), and the upper layer, the intermediate layer, the bottom layer and the bundling warp form the three-dimensional structure. The production process comprises the following processes: the process of weaving a fabric on a machine: adopting double warp shafts to send a warp woven cloth; and the process of stipulating a dipping formula and preparing, wherein a dipping solution is a mixture of an RF (resorcinol-formaldehyde) resin water solution generated by virtue of condensation polymerization of hydroxyphenol and formaldehyde and VP (vinyl pyridine) latex (L), the total content of solids is 18-22%, the pH value is 9-11, and the ratio of the RF to the L is (1:5)-(1:7). Polyester dipped canvas in the three-dimensional structure is especially applicable to production of the heavy-duty rubber conveyor belts and has the characteristics of tear resistance, puncture resistance and impact resistance.

Owner:浙江尤夫科技工业有限公司

High-strength terylene microfiber needling fabric

ActiveCN103057219ALow costReduce water consumptionFibre typesTwo or more solvent application treatmentColour fastnessPolymer science

The invention relates to high-strength terylene microfiber needling fabric and belongs to the technical field of needling non-woven cloth. The high-strength terylene microfiber needling fabric is prepared by the following steps: performing non-woven double carding and double lapping on island type island short fiber to obtain double-layer cotton web; clamping base cloth which is obtained by using polyester filament yarn through a hydraulic loom in the middle of the double-layer cotton web; performing non-woven needling to obtain composite base cloth; starching; performing polyurethane (PU) resin impregnation; performing alkali reducing splitting; dyeing; drying; and performing double-sided sanding, wherein the polyester filament yarn is 68 to 75 D, the fineness of the island type island short fiber is 1 to 3 D, the island type island short fiber contains 37 islands and has the length of 38 to 51 mm, and the sea / island ratio is 30 / 70. The high-strength terylene microfiber needling fabric is low in dye cost and water consumption, uniform in dyeing, bright in color and luster, and high in color fastness and air permeability, enhances the stretching resistance, and takes both leather feeling and fluff feeling into consideration.

Owner:ZHEJIANG MEISHENG NEW MATERIALS CO LTD

Silver thiosulfate complex or silver-ammonia complex-containing hygroscopic silver-containing product and preparation method thereof

ActiveCN104083800ABroad spectrum antibacterialHigh antibacterial activityFibre treatmentTwo or more solvent application treatmentAdditive ingredientMoisture absorption

The invention relates to a silver thiosulfate complex or silver-ammonia complex-containing hygroscopic silver-containing product and a preparation method thereof. The invention discloses a hygroscopic silver-containing antibacterial product which comprises a silver thiosulfate complex or a silver-ammonia complex as an antibacterial ingredient, the silver thiosulfate complex or the silver-ammonia complex is evenly distributed and combined on the inner side and / or surface, the hygroscopic silver-containing antibacterial product comprises 0.01-10 wt% of silver, and the moisture absorption ability of the hygroscopic silver-containing antibacterial product is 6g / g and above. The invention also provides a preparation method of the hygroscopic silver-containing antibacterial product as well as a silver-containing antibacterial product dressing prepared from the hygroscopic silver-containing antibacterial product. The hygroscopic silver-containing antibacterial product has a very wide antibacterial spectrum, shows strong antibacterial activity to gram-negative bacteria and gram-positive bacteria, is rapid in effect, has light stability, and can be widely applied to chronic infections exudative wounds.

Owner:FOSHAN UNITED MEDICAL TECH

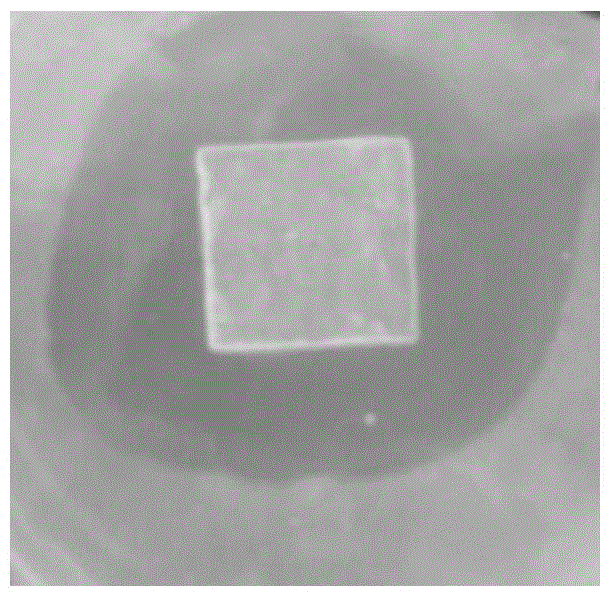

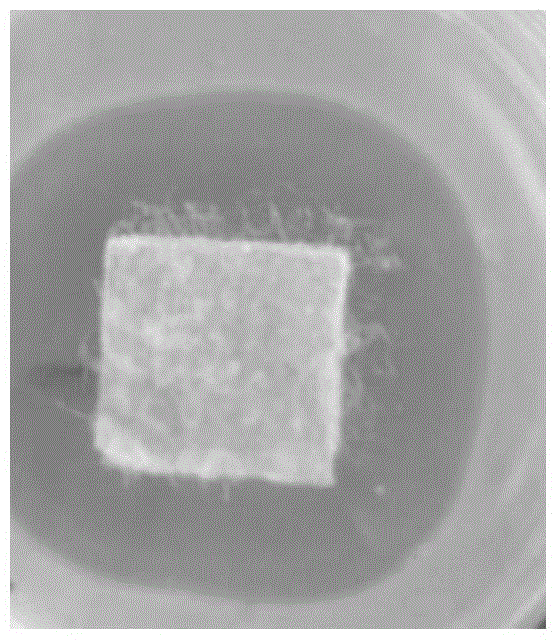

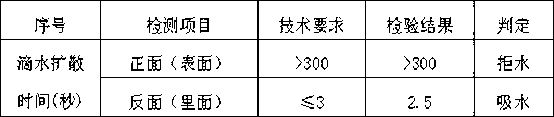

Sweat stain resisting tidying method of hygroscopic and sweat releasing knit goods

ActiveCN103161045AAchieve anti-sweat effectStay flexibleSucessive textile treatmentsTwo or more solvent application treatmentEngineeringMoisture

The invention provides a sweat stain resisting tidying method of hygroscopic and sweat releasing knit goods. The sweat stain resisting tidying method is characterized by comprising the following process procedures of mild finishing of the knit goods, size mixing, sweat stain resisting processing on front faces of the knit goods, sweat stain resisting detection and stoving. Sweat can be instantly absorbed or volatilized through the hygroscopic and sweat releasing mild finishing of the knit goods; a pigment printing mode is then used for forming a film coating with a plurality of ventilation minuteness air holes on the surfaces of the knit goods, each minuteness hole is smaller than sweat liquid and bigger than sweat molecules of a human body, and the sweat is spread out in a mode of the sweat liquid to enable sweat stains to leave no trace on the surface of clothes. Therefore, the sweat stain resisting tidying method has the effects of sweat stain resistance, the reverse sides of the knit goods after the sweat stain resisting processing can absorb moisture and rapidly dry, the surfaces of the knit goods have the effects of sweat stain resistance, and the knit goods are good in air permeability, can be comfortably wore and are favorable for popularization and use.

Owner:QINGDAO XUEDA GRP

Imitation cotton-knitted fabric and production method thereof

InactiveCN103898670ASoft touchStrong cotton feelSucessive textile treatmentsWeft knittingPolyesterFiber

The invention discloses an imitation cotton-knitted fabric and a production method thereof. The imitation cotton-knitted fabric is formed by polyester staple fibers, cotton short fibers and spandex, wherein the polyester staple fibers account for 75%-85%, and bending rigidity of the fabric is 0.02-0.06 Cn.cm<2> / cm. The imitation cotton-knitted fabric not only has soft hand feeling and is high in cotton feeling, but also has the advantages of being light and fluffy, absorbing moisture and being high in drying speed. High comfort is achieved when the imitation cotton-knitted fabric is worn, and decorous feeling and stuffiness do not exist.

Owner:TORAY FIBER RES INST(CHINA) CO LTD

Dyeing processing method of knitted denim fabric

ActiveCN106245354AHigh color fastnessGood dimensional stabilityFibre treatmentTwo or more solvent application treatmentEngineeringSulfur dye

The invention discloses a dyeing processing method of a knitted denim fabric. The method is characterized in that the whole dyeing process specifically includes the steps of: knitting, pretreatment, pre-fixation, dyeing, dehydration, scotching, drying, color fixing and shaping. Through treatment of the knitted denim fabric with pre-fixation, dyeing, and color fixing and shaping three processes, the reduction process necessary to the traditional of sulfur dye is abandoned, the whole dyeing processing does not involve sulphide, simplifies and omits some necessary processes and a lot of environmentally-unfriendly chemical products required by the traditional process, the whole dyeing processing process is short and efficient, energy saving and environment-friendly, and the processed knitted denim fabric has rich and soft colors, stable cloth cover quality, novel and unique appearance, and has good visual and tactile affinity.

Owner:SHENGZHOU SHENGTAI KNITTING

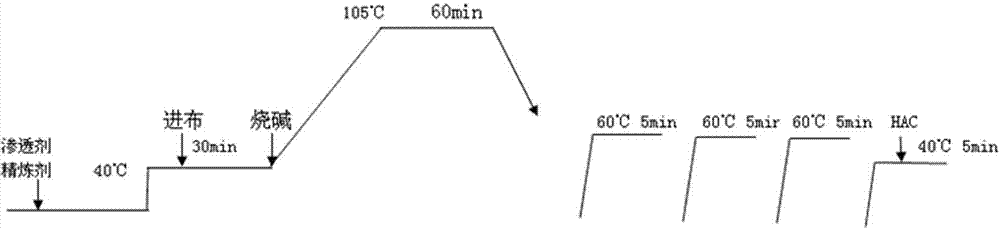

Production method of cotton acrylic shell fabric

InactiveCN106544887AShort processImprove efficiencySucessive textile treatmentsTwo or more solvent application treatmentYarnRoom temperature

The invention relates to a production method of a cotton acrylic shell fabric. The method comprises yarn loosing, pretreatment, blend dyeing and aftertreatment, wherein the yarn loosing is carrying out tube loosing on blend fiber yarn by adopting a digital winding manner; the pretreatment is adding a refining agent and sodium carbonate, heating to high temperature, performing heat preservation for a period of time and discharging, and directly adding cold water and acid for treatment; the blend dyeing is adding a retarding agent, a dispersing agent, an antireducer, cationic dyes and HAC, heating and performing heat preservation for twice and discharging materials, adding into water, heating to high temperature and discharging, adding into water at normal temperature, adding a dispersing agent and a soaping agent for water washing at high temperature for twice, discharging after each time of heat preservation, after washing with water once at the normal temperature, adding an activated dye for cotton dyeing, softening, dewatering, oven drying, and performing tube splitting and beaming or spooling, thus obtaining the needed yarns. The production method improves the color precision of the cotton acrylic shell fabric greatly.

Owner:ZHEJIANG SAINTYEAR TEXTILE

Imitation fur setting process

InactiveCN108385313AImprove uniformityQuality improvementSucessive textile treatmentsTwo or more solvent application treatmentFiberWater resources

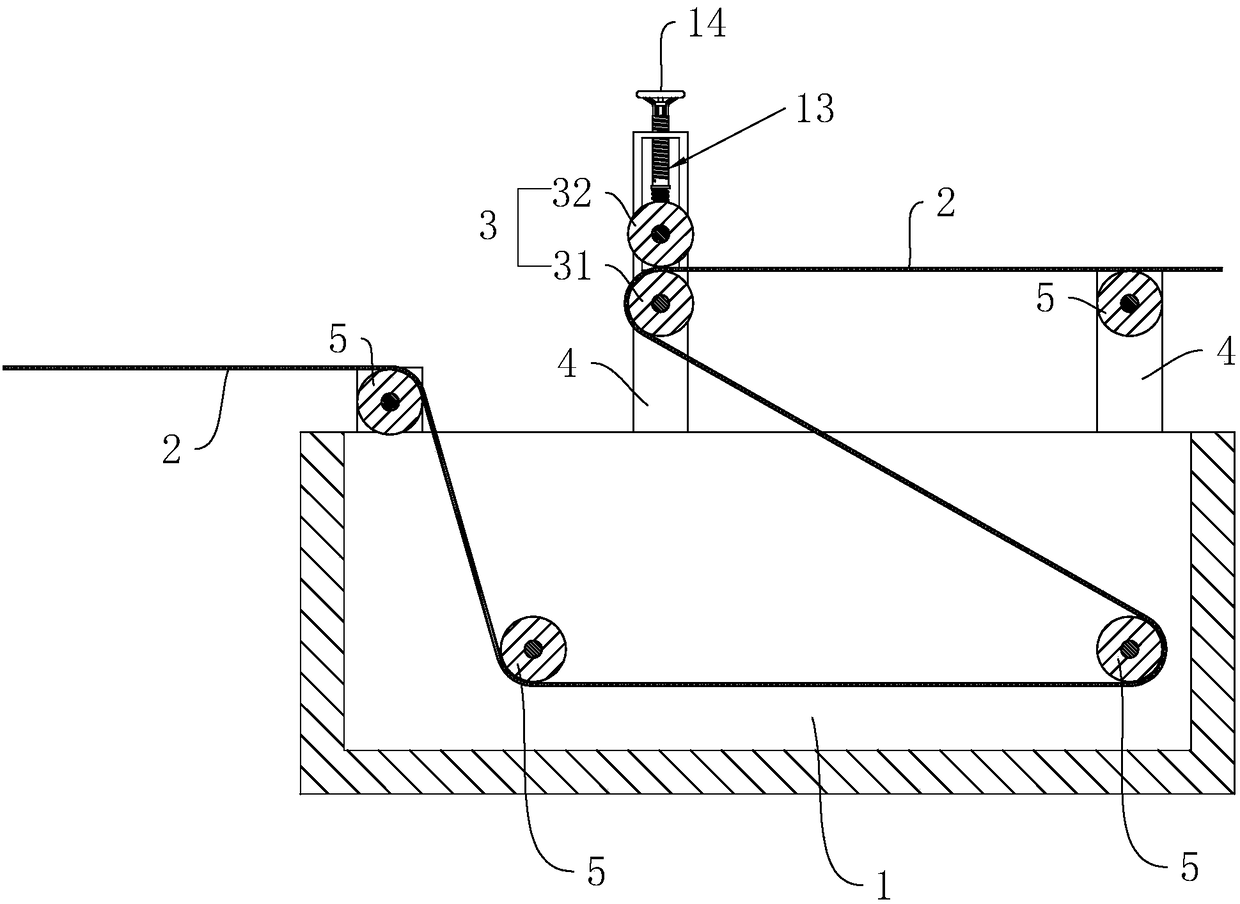

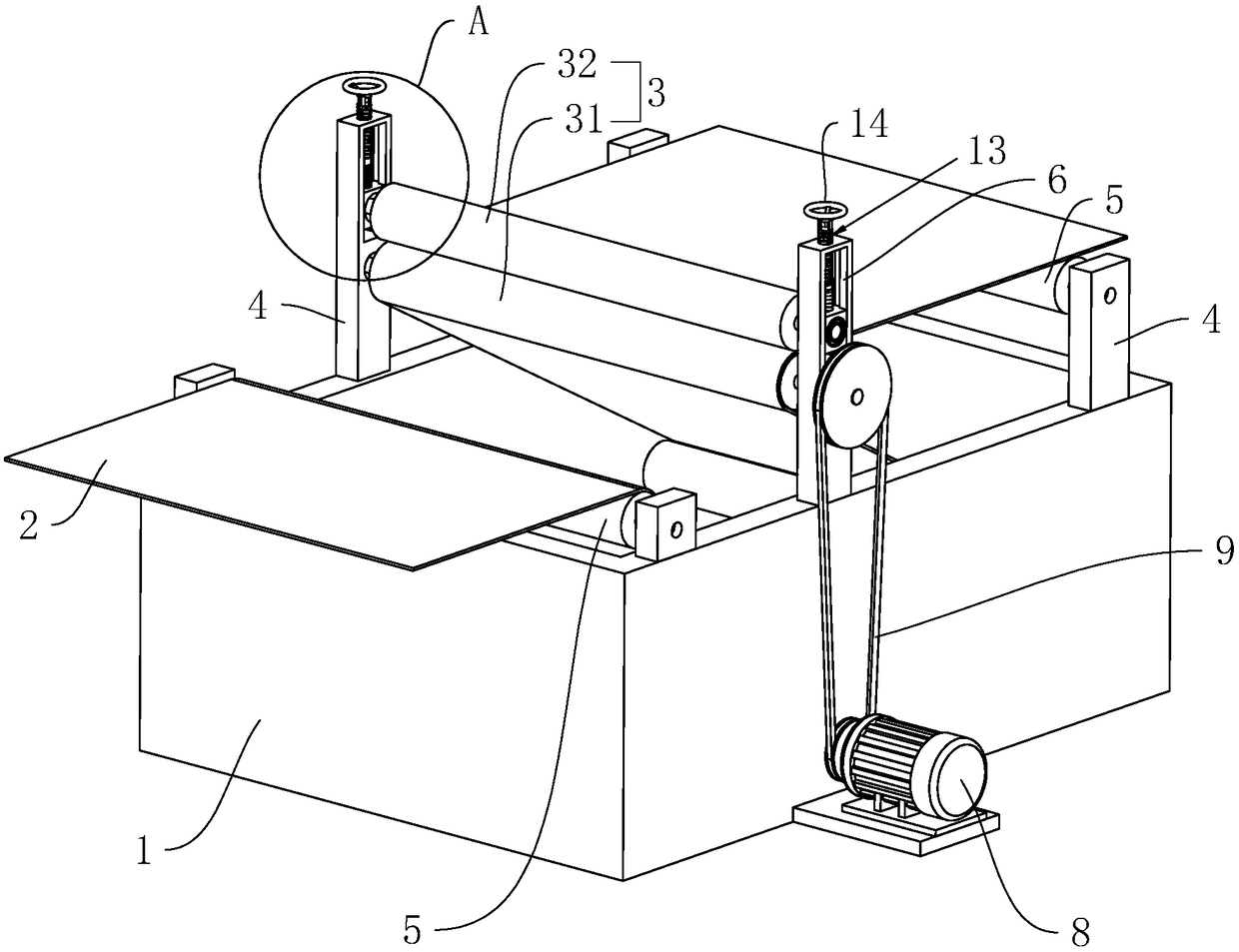

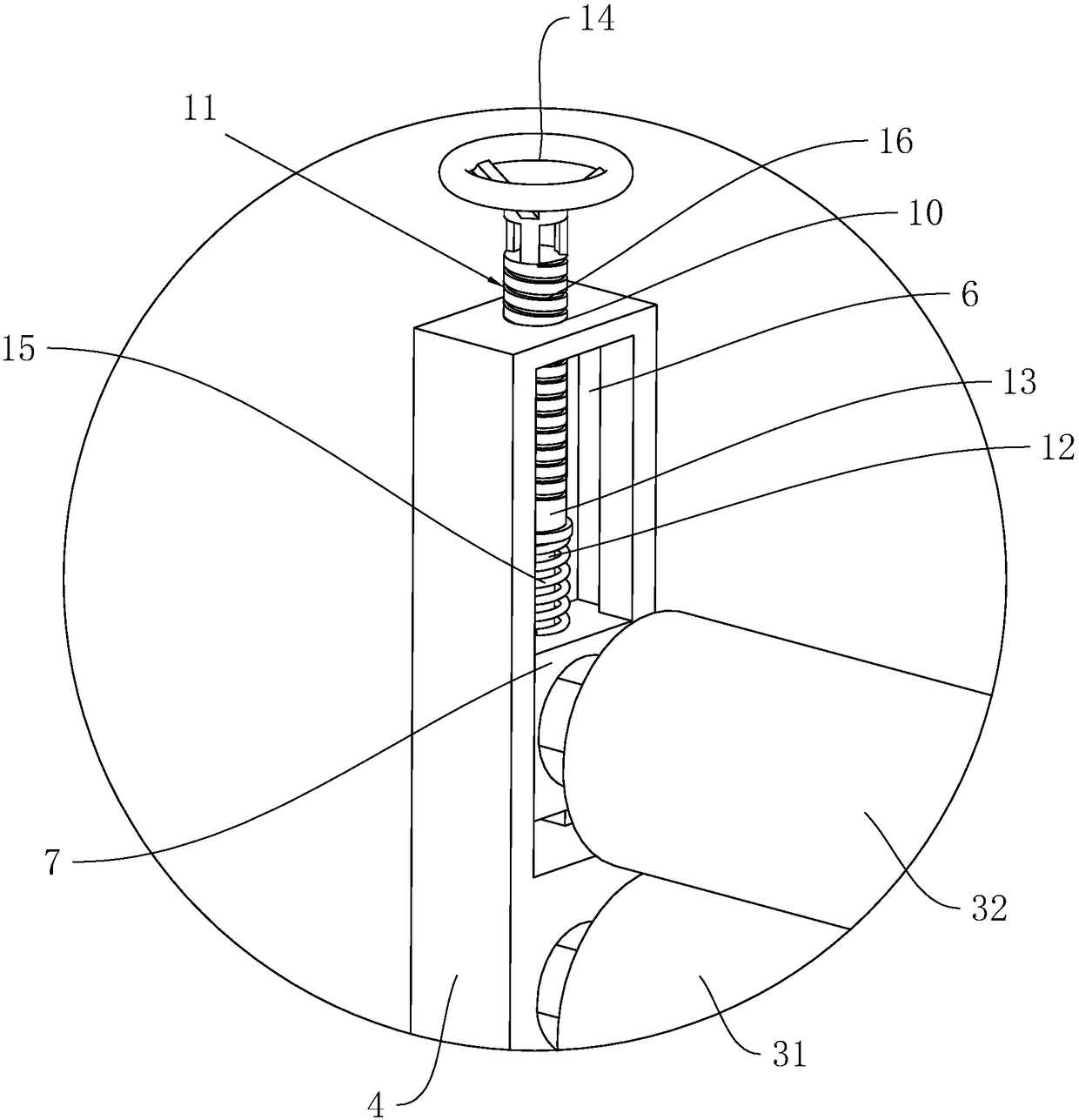

The invention discloses an imitation fur setting process, and belongs to the technical field of imitation fur processing. The imitation fur setting process is technically characterized in that an imitation fur finished product can be obtained by gray cloth unwinding, cleaning, decontaminating-flushing, dehydrating-scutching, first setting, napping, second setting-drying, third setting-drying, cooling-setting and coiling-warehousing. Through a three-setting process, the fiber uniformity among imitation fur surfaces is improved, and the imitation fur finished product is more attractive and better in quality; a water squeezing roller is provided, so that the moisture in imitation fur between a first roller and a second roller can be squeezed out and reflow into a water groove, the water resource is saved, and the comprehensive utilization rate of the water resource in the water groove is increased. Moreover, a driving assembly is provided, and the second roller is further compressed on the first roller, so that the water squeezing efficiency is increased; meanwhile, the imitation fur setting process can be suitable for water squeezing operation of imitation furs of different thicknesses, and has higher efficiency.

Owner:嘉兴市远大纺织印染有限公司

Production and pretreatment process for yarn-dyed fabrics

InactiveCN106521767AGood hygroscopicityImprove breathabilitySucessive textile treatmentsTwo or more solvent application treatmentYarnProcess engineering

The invention discloses a production and pretreatment process for yarn-dyed fabrics. The production process includes the steps: taking 36-branch cotton-wool blended yarns as raw materials; dyeing; warping; starching filaments; combining warps of warp beams to prepare beams for weaving; leasing; drafting; weaving; coldly stacking; steaming and cleaning; singeing and half mercerizing. The cotton-wool yarn-dyed fabrics woven by the process have functions of cotton fabrics and wool fabrics, better moisture absorption and air permeability and wide selling market, are not easy to crinkle, deform and pill, smooth, exquisite and comfortable in hand feeling and soft in texture, a user feels comfortable when wearing clothes prepared by the fabrics, and wearability of the fabrics is greatly improved. According to the process, the pretreatment process is added before the fabrics are printed and dyed, coldly stacking liquid and steam cleaning liquid are reasonably matched, so that the treated fabrics are better in functionality, and requirements of following processes can be effectively met.

Owner:江苏银桥纺织科技有限公司

Flax-wool blended yarn bleaching process

InactiveCN102808300AAvoid damageAvoid it happening againTwo or more solvent application treatmentBleaching apparatusYarnHydrogen

The invention relates to a flax-wool blended yarn bleaching process. The weight percentage of flax in blended yarns is 50-90 percent and the weight percentage of wool in the blended yarns is 10-50 percent. The flax-wool blended yarn bleaching process is characterized in that the process sequentially comprises the steps of acid washing, water washing, two times of oxygen bleaching and final water washing, mixed solution which contains 2g / L hydrogen peroxide, 0.7g / L non-ionic penetrating agent, 4g / L sodium silicate, 1g / L oxygen bleaching stabilizer and 0.6g / L chelating dispersant is used in the oxygen bleaching process, the pH (potential of hydrogen) value of the mixed solution is adjusted to 8-9 by using 2g / L sodium carbonate solution, treatment is conducted for 1-2 hours at 70-75DEG C, and then bleaching is conducted for another time according to the same formula. The flax-wool blended yarn bleaching process has the advantages that not only can the flax fibers be well bleached, but also the wool fibers are not damaged, the processing flow is shortened and the energy is saved.

Owner:ZHEJIANG JINLAINUO FIBER

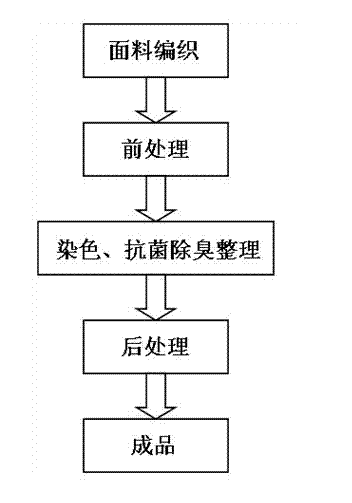

Bacterium-resisting/deodorizing/finishing technology for towel shell fabric

InactiveCN102851898AProcess arrangement is reasonableImplement process scienceFibre typesTwo or more solvent application treatmentEngineeringEnergy source

The invention provides a bacterium-resisting / deodorizing / finishing technology for towel shell fabric, which comprises the following steps: a) knitting shell fabric; b) pre-treating the shell fabric; c) dyeing, bacterium-resisting / deodorizing / finishing the shell fabric; and d) after-treating the shell fabric. A bacterium-resisting / deodorizing / finishing technology for towel shell fabric is disclosed by the invention and is characterized by reasonable work procedure arrangement, scientific, simple and convenient implementation; a bath-drying / bacterium-resisting / deodorizing / finishing technology is used, thus, the inhibition efficiency of the towel shell fabric reaches to more than 99.9%; in addition, a technology process is shortened, energy source is saved, and cost is reduced.

Owner:KUSN CHENGYU ELECTROMECHANICAL TECH

Elastic yoga body-shaping fabric and preparation technology thereof

InactiveCN106350928AAvoid bareHigh spandex contentSucessive textile treatmentsWeft knittingMasterbatchYarn

The invention discloses an elastic yoga body-shaping fabric. The elastic yoga body-shaping fabric is of a knitting structure, and is formed by weaving polyester yarns, such as 30D-105D elastic yarns and 50D-300D color yarns, wherein each elastic yarn is a dyeable spandex yarn or a color masterbatch spinning yarn; each polyester yarn is made of polytrimethylene terephthalate. The elastic yoga body-shaping fabric has the characteristics that the content of spandex is high, the weaving technology is simple and matured, the secondary damage is avoided, the white exposing of the spandex is avoided, the dyeing cost is lower, the color fastness is higher, the dirt removal and preventing property is excellent, the dyeing is easy, the hand feel is soft, the elasticity is realized, the elongation is good, and the processing is easy; the dryness and stiffness are realized, the size after shaping is stable, and the application range is wide.

Owner:JIANGSU XINKAISHENG ENTERPRISE DEV

Linen-like cool wool knitted underwear fabric and preparation method for same

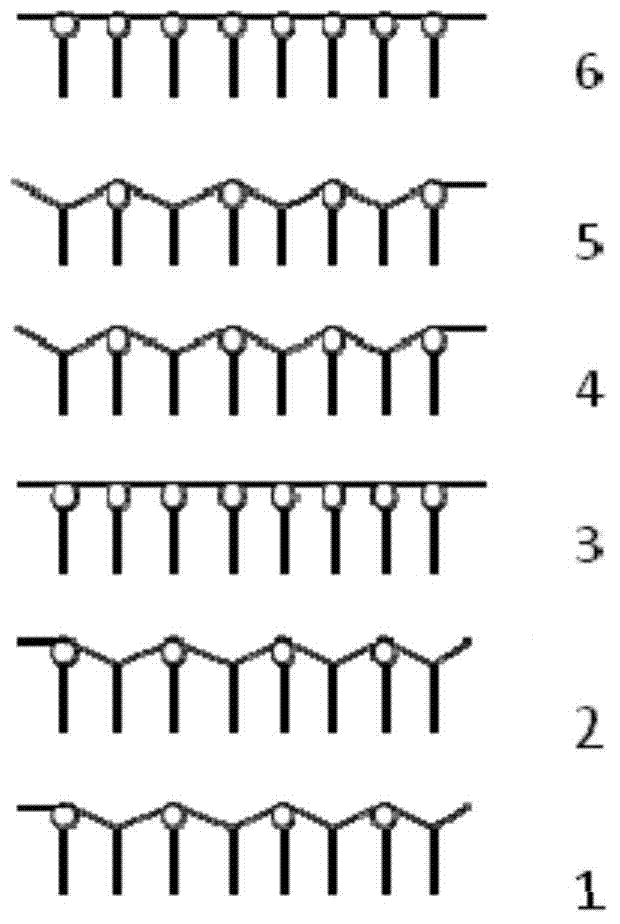

ActiveCN104323439AImprove comfortAvoid thick and shortWeft knittingTwo or more solvent application treatmentFiberEngineering

The invention relates to a linen-like cool wool knitted underwear fabric and a preparation method for the same. A woven structure of the wool knitted underwear fabric is a combined structure of close-mesh stitches and plain stitches. The preparation method comprises the following steps of performing weaving on a one-sided circular knitting machine according to the woven structure of the underwear fabric, wherein the coil length of the fabric is 13 to 14cm per 50 stitches, and the gram weight of the fabric is 110 to 150g / m<2>; performing dyeing and finishing to obtain the linen-like cool wool knitted underwear fabric by virtue of a one-bath method, wherein the dyeing bath ratio is 1:18. According to the knitted underwear fabric, regular single-stitch multi-column tucking is adopted, so that smaller concave and convex holes are formed, and twill effects are achieved, so that the knitted underwear fabric has certain linen-like effects on appearance, and has the advantages of moisture absorption, sweat releasing, coolness, permeability, bacterium inhibition, mold prevention, smooth hand-feel and the like of a linen fabric, and the shortcomings of thickness, shortness, hardness, difficulty in weaving and the like of bastose are overcome.

Owner:上海嘉麟杰纺织科技有限公司

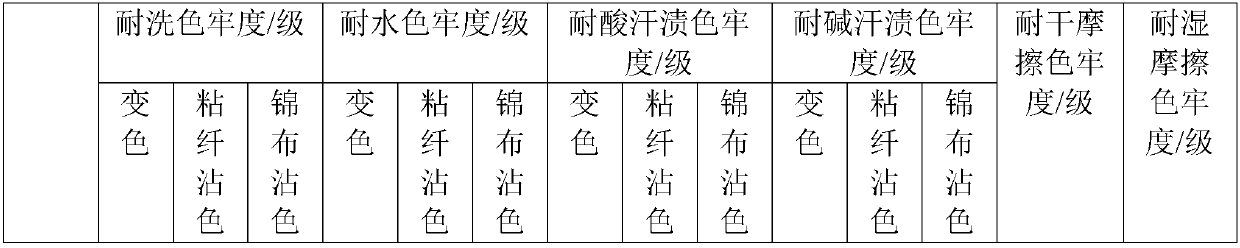

Making process of high-fastness polyamide-polyester interwoven fabric

PendingCN106757673AFashionable appearanceSoft and comfortableSucessive textile treatmentsTwo or more solvent application treatmentPolyesterColour fastness

A making process of high-fastness polyamide-polyester interwoven fabric includes the first step of yarn material selection, the second step of batched beaming, the third step of yarn sizing, the fourth step of re-beaming, the fifth step of weaving, the sixth step of desizing and washing, the seventh step of dyeing, the eighth step of water spraying finishing, the ninth step of calendaring finishing and the like. By means of the making process of the high-fastness polyamide-polyester interwoven fabric, the obtained fabric has a fashionable appearance, a soft and comfortable handfeel and a high color fastness, and the fading risk generated in the later-period use process of a consumer is lowered; the fabric is suitable for the field of fashionable down jackets. According to the polyamide-polyester interwoven fabric made through the process, the color fastness to sunlight can reach ISO 105-B02:2014 (Exposure cycle A1) level 4 or above, the color fastness to washing at 60 DEG C can reach ISO 105-C06:2010-C2S level 4 or above, and the color fastness to rubbing can reach ISO 105-X12:2001 level 4 or above.

Owner:HUAMAO (XIAMEN) WEAVING DYEING & FINISHING CO LTD

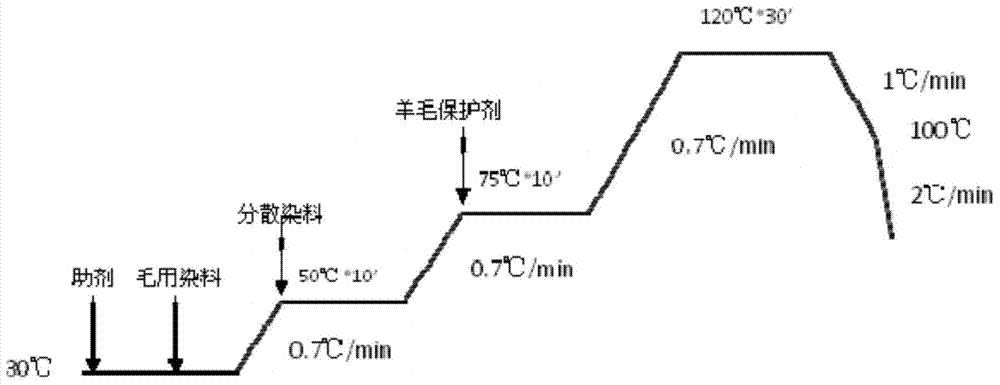

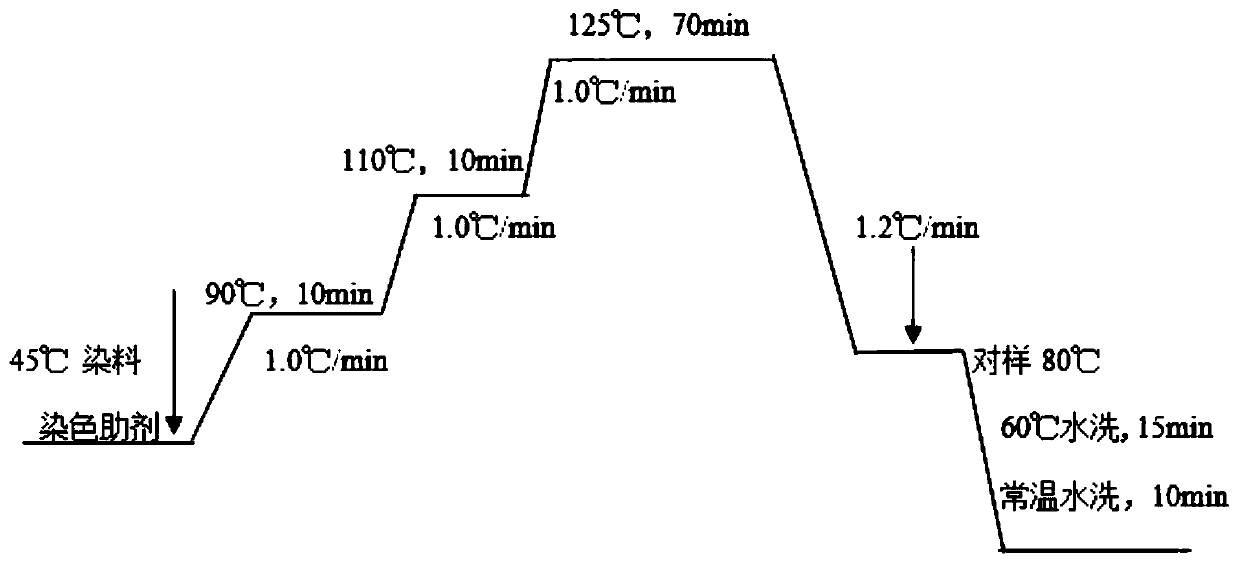

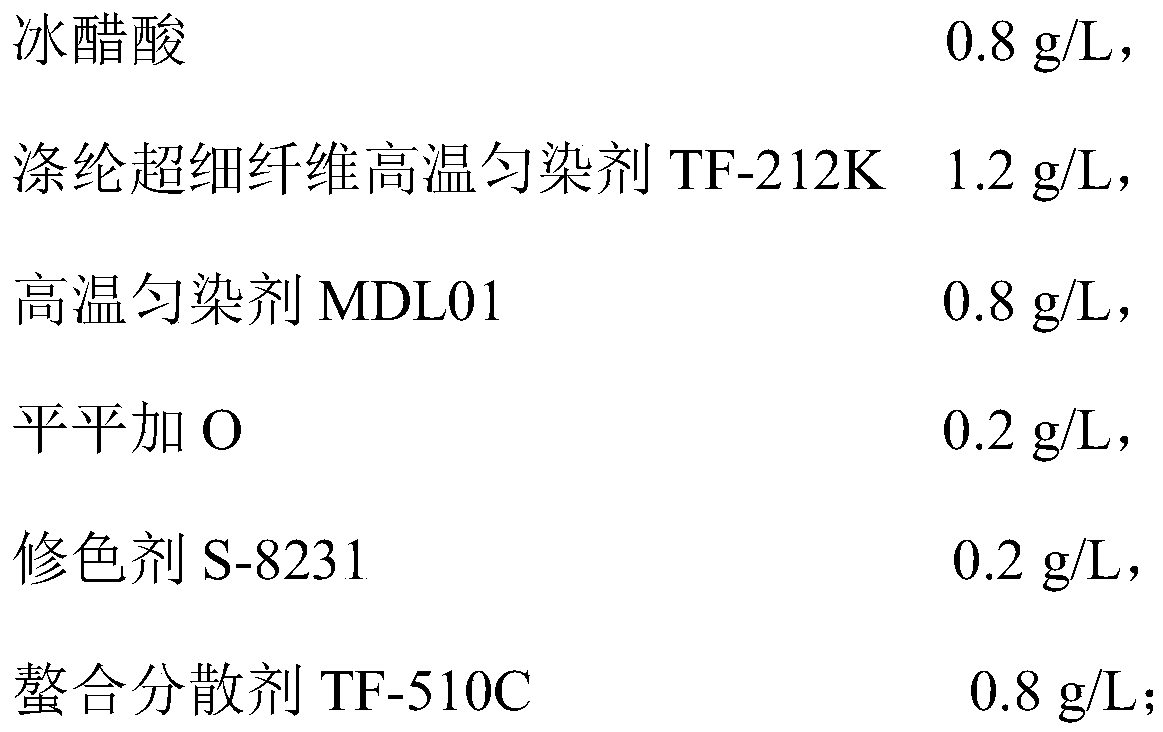

Dyeing and finishing technology for PFY (polyester filament yarn) Huayao fabric

InactiveCN110331599AGood initial dyeing effectSmall color differenceSucessive textile treatmentsTwo or more solvent application treatmentDisperse dyeColour fastness

The invention discloses a dyeing and finishing technology for PFY (polyester filament yarn) Huayao fabric. The technology comprises an open-width desizing process, a dyeing process and a setting process; a dyeing agent adopted in the dyeing process comprises a dyeing auxiliary and a dye, the dye is a disperse dye, and the dyeing process adopts a high-temperature and high-pressure overflow dyeing machine for dyeing; the initial dyeing temperature of the dyeing process is 90 DEG C, and the heat insulation time is 10 min; the formula of the dyeing auxiliary comprises components as follows: glacial acetic acid with concentration of 0.8 g / L, a superfine polyester fiber high-temperature levelling agent TF-212K with concentration of 1.2 g / L, a high-temperature levelling agent MDL01 with concentration of 0.8 g / L, peregal O with concentration of 0.2 g / L, a color-remanding agent S-8231 with concentration of 0.2 g / L and a chelating disperse agent TF-510C with concentration of 0.8 g / L. With formulation of the appropriate open-width desizing process, dyeing process and setting process, the dyeing effect of the fabric is improved, dyeing uniformity is good, so that the fabric has high color fastness, good color repeatability and good dimensional stability, touches good and meets the related wearing requirement.

Owner:吴江市平望漂染厂有限公司

Light and thin heat preservation core-spun hollow knitted fabric

ActiveCN104738821AMoisture absorption and quick dryingIt has the effect of hollow heat preservation and moisture conductionSucessive textile treatmentsWeft knittingPolyesterFiber

The invention discloses a light and thin heat preservation core-spun hollow knitted fabric. The light and thin heat preservation core-spun hollow knitted fabric comprises, by weight percentage, the raw materials of 24s cotton polyester sheath-core blending hollow yarn and 30D Dupont spandex, and the production process of the light and thin heat preservation core-spun hollow knitted fabric comprises the specific steps that material taking, yarn covering, gray fabric weaving, high-temperature preshaping, pretreatment agent preparation, pretreatment, neutralization and dyeing and shaping. Water-soluble vinylon fibers are dissolved away in the dyeing and finishing process, a hollow effect is formed, more air is reserved than that in conventional yarn, the better heat preservation effect is achieved, and meanwhile due to the fact that heart yarn is provided with a cross-shaped section, the good moisture guide function can be achieved, and the final fabric has the hollow heat preservation and moisture guide effect. Therefore, the produced fabric is thin and warm and has the moisture absorption and fast drying effects, and clothes are comfortable to wear due to the weaving structure with proper elasticity.

Owner:SHANGHAI JIALE

Modal interwoven fabric dyeing and finishing method

ActiveCN107558162AImproved anti-pilling propertiesBiochemical fibre treatmentTwo or more solvent application treatmentFiberColour fastness

The present invention discloses a Modal interwoven fabric dyeing and finishing method, which comprises: (1) fore-treatment: carrying out mercerizing water washing; (2) pretreatment: carrying out fibersplitting treatment; (3) ultra-fiber cutting: adding a biological enzyme to a sand washing machine, and carrying out ultra-fiber treatment on the pre-treated Modal interwoven fabric in the sand washing machine; (4) dying: adding an active dye to a dyeing device, and dyeing the cut pre-treated Modal interwoven fabric in the dyeing device; and (5) function finishing. According to the present invention, with the Modal interwoven fabric dyeing and finishing method, the obtained fabric has characteristics of soft surface touch feeling, fluff touch feeling, high strength and high color fastness, and the problems of fuzzing and pilling can be avoided.

Owner:HAIYAN JIAYUAN PRINTING & DYEING

Multi-component low-cost permanent inflaming retarding fabric and preparation method for same

InactiveCN106400266ALow costExcellent permanent flame retardant performanceSucessive textile treatmentsTwo or more solvent application treatmentPolyesterViscose

The invention discloses a multi-component low-cost permanent inflaming retarding fabric and a preparation method for the same. The multi-component low-cost permanent inflaming retarding fabric is made of the raw materials including aramid fibers 1313 with the mass percent of 10%-30%, inflaming retarding viscose with the mass percent of 30%-50%, inflaming retarding polyester with the mass percent of 10%-30% and modified acrylic fibers with the mass percent of 20%-40%. In comparison with the prior art, the fabric disclosed by the invention has outstanding permanent inflaming retarding performance, has a soft hand feeding, has moisture absorptivity and air permeability, and is comfortable in wearing; the fabric cost is reduced; and enterprise product core competitiveness is enhanced.

Owner:CONCORDIA ADVANCED FABRICS SUZHOU

Dyeing and finishing process for all-cotton knitted product suitable for special purposes

ActiveCN104805625AImprove product styleEasy to ventilate and dissipate heatSucessive textile treatmentsSingeingBursting strengthScreen printing

The invention discloses a dyeing and finishing process for an all-cotton knitted product suitable for special purposes. The process comprises the following steps: 1) grey cloth selection; 50S Xinjiang combed long staple cotton yarns are selected to be woven all-cotton double-side cloth by a selected Taiwan double-side circular knitting machine; 2) singeing: an Osthoff knitting and singeing machine is adopted to realize double-side singeing; 3) pretreatment: boiling-off of the cloth is carried out with a 745 chelating dispersant, a multifunctional refining agent, a 705 oil removal agent, a hydrogen peroxide stabilizer, caustic soda flack and hydrogen peroxide; 4) mercerizing: steps of using an unstressing scutching knitting mercerizing machine of a domestic self-developed Jiangsu Hongqi screen printing machine to realize mercerization and the like are carried out. According to the process, not only are all indexes required by military products met, but also the ventilation and heat dissipation, and moisture absorption and sweat releasing are improved, the wet rubbing fastness and burst strength are increased, product styles of conventional all-cotton knitted cloth are improved, and the market of the all-cotton knitted products is extended and expanded, so that the process has very strong market competitiveness.

Owner:ZHEJIANG FURUN DYEING & PRINTING

All cotton cheese slashing processing method

InactiveCN107700121AOmit sizingShort processTwo or more solvent application treatmentVegetal fibresWaxCarboxymethyl starch

The invention discloses an all cotton cheese slashing processing method. The all cotton cheese slashing processing method at least includes the following steps: spool loosening, pre-processing, and slashing. In the slashing step, the used slashing solution includes a primary slashing agent and a secondary slashing agent; the primary slashing agent includes 3-8% of modified starch having the degreeof polymerization of 200-6000, wherein the modified starch is at least one of oxidized starch, acidified starch, starch acetate, phosphate ester starch, and carboxymethyl starch; and the secondary slashing agent includes 2-8% of a decomposer, 1-3% of a smoothing agent, 0.1-0.5% of a preservative, 0.2-0.6% of caustic soda, 0.2-0.6% of wax, 0.3-1.2% of a penetrant, and the balancing being water. Compared with the prior art, the all cotton cheese slashing processing method is short in process, is simple, and can avoid a slasher.

Owner:XINJIANG RUYI TEXTILE GARMENT CO LTD +2

Antistatic finishing method for polyester fiber shell fabric

The invention discloses an antistatic finishing method for polyester fiber shell fabric. The antistatic finishing method comprises the following steps that (1) antistatic finishing liquor is prepared, and the finishing liquor is diluted into 28 percent of solid dispersion liquor; (2) the polyester fabric is soaked with the finishing liquor, the finishing liquor is put in an oven at the temperature of 58 DEG C to be melted, the melted finishing liquor is poured into clean water at the temperature of 75 DEG C to be evenly stirred, the finishing liquor is kept at the temperature of 75 DEG C, the polyester fiber shell fabric is immersed into the finishing liquor, and the fabric is kept in the finishing liquor for 10 minutes to 12 minutes; (13) liquor rolling is carried out, liquor rolling is carried out on the infected polyester shell fabric, and 70 percent of the liquor of the polyester fiber shell fabric is kept; (4) drying and hot setting are carried out, the polyester fiber shell fabric containing the liquor is dried in a drying oven at the temperature of 170 DEG C, and drying of the polyester fiber shell fabric in the drying oven is kept for one minute. By the adoption of the mode, according to the antistatic finishing method for the polyester fiber shell fabric, the finished polyester shell fabric has the long antistatic function, and can be widely used for garment fabric on the electrostatic occasion.

Owner:吴怡

Method for producing multicolor imitated woolen knitted fabrics

The invention relates to a method for producing multicolor imitated woolen knitted fabrics. The method is characterized by comprising steps of (1), weaving three types of polyester fiber filaments on a knitting machine to obtain grey cloth, to be more specific, using the first polyester fiber filaments as base filaments and using the second polyester fiber filaments and the third polyester fiber filaments as surface filaments; (2), carrying out pre-processing, to be more specific, setting the grey cloth by the aid of a drying oven, snapping extension threads of the first polyester fiber filaments which are the base filaments in the grey cloth by the aid of a pile making machine without destroying tissue structures of the second polyester fiber filaments and the third polyester fiber filaments which are the surface filaments, forming uniform lower piles on cloth surfaces by the aid of the pile making machine and then pre-setting the grey cloth; (3), dyeing the grey cloth; (4), carrying out post-finishing, to be more specific, carrying out padding on the dyed grey cloth by the aid of finishing agents, then dehydrating and drying the grey cloth and setting the grey cloth on a setting machine. The method has the advantages that special weaving, dyeing and finishing processes are selected, the method starts off from two aspects of visual effects and touch effects, and accordingly products with imitated woolen appearance and hand feel can be obtained by the aid of the method.

Owner:CHANGSHU AIS TEXTILE TECH

Production process of puncture-proof fabrics

InactiveCN109208164AImprove the protective effectImprove breathabilityWeft knittingTwo or more solvent application treatmentPolymer scienceAfter treatment

The present invention discloses a production process of puncture-proof fabrics. The ultrahigh molecular weight polyethylene filament and high-tenacity polyester filament yarns are taken as raw materials, the performance difference of the ultrahigh molecular weight polyethylene filaments and the high-tenacity polyester filament yarns is analyzed to determine the specifications of the ultrahigh molecular weight polyethylene filaments and the high-tenacity polyester filament yarns and determine the yarn usage amount of the two, through the organization structure design of the fabrics, numbers ofpaths of the ultrahigh molecular weight polyethylene filaments are reasonably distributed, a weaving process employs a weft knitting mode for weaving, a coil structure is employed to perform advantagecomplementation of the two raw materials so as to solve the problem that the ultrahigh molecular weight polyethylene filaments are difficult to weave, the weaved fabrics are processed through adoption a after treatment process to produce a finished product. The novel puncture-proof fabrics by taking the ultrahigh molecular weight polyethylene filaments and the high-tenacity polyester filament yarns as the raw materials are good in breathability, wearing comfort, flexibility and economy.

Owner:CHINA TEXTILE ACAD JIANGNAN BRANCH

Method for solving cold-batch pretreatment uneven dying

ActiveCN106012380ARemove completelyPromote moisture penetrationTwo or more solvent application treatmentDry-cleaning apparatus for textilesAcetic acidWater temperature

The invention discloses a method for solving cold-batch pretreatment uneven dying. Before the dyeing process, dyeing pretreatment is carried out on cloth and includes the steps of padding, batching and neutral washing. In the step of neutral washing, the batched cloth is put into a dye vat, water is fed, the batched cloth is operated for 10+ / -2 min in water at the temperature of 40-60 DEG C, and the water is drained; water is fed, the water temperature in the dye vat is made to be 88-98 DEG C, the cloth is operated for 10+ / -2 min and then cooled to 40-60 DEG C, and the water is drained; water is fed, the water temperature in the dye vat is made to be 40-60 DEG C, acetic acid is added, the cloth is operated for 5-10 min, then ferment is added, the cloth is operated for 5-10 min, and the water is drained. By adopting the method, the rate of additive color uneven dyeing can be reduced by 70%, and the ratio of uneven dying chromatic aberration is greatly reduced.

Owner:GUANGDONG ESQUEL TEXTILES CO LTD

Preparation process of full-polyester wool-like double-faced woolen goods

InactiveCN110284291AGood warmth retentionTufting apparatusTwo or more solvent application treatmentPolyesterLoop shaping

The invention discloses a preparation process of a full-polyester wool-like double-faced woolen goods. The process comprises the following steps of a, weaving; b, polar fleece treatment; c, dyeing; d, softening; e, shaping; f, velvet treatment; g, loop shaping. According to the provided preparation process of the full-polyester wool-like double-faced woolen goods, through the manner above, the wool-like double-faced woolen goods prepared by means of the process has wool-like appearance and is high in warm keeping performance and suitable for manufacturing of various autumn and winter garments such as coats and jackets.

Owner:常熟市易美纺织品有限公司

Modification method of linen fiber

InactiveCN105401418AImprove dye uptakeHigh color fixing rateSucessive textile treatmentsTwo or more solvent application treatmentYarnMicrowave oven

The invention relates to a modification method of linen fiber. The modification method comprises following steps: (1) linen fiber is subjected to opening, and impurities are removed; (2) linen fiber is immersed in a urea solution for 30 to 50min; (3) after immersion, linen fiber is delivered into a microwave oven for 3 to 5min of heating so as to remove alkali solutions; (6) linen fiber obtained via step (5) is immersed in a mixed solution of sulfuric acid, sodium sulfate, and zinc sulfate for acid bath; (7) linen fiber is washed with clear water until pH value of the obtained linen fiber is adjusted to be 7; (8) the linen fiber is delivered into a centrifugal dehydrator for 3 to 5min of dehydration; and (9) the obtained linen yarn is dried for 60 to 90min. Dyeing of the treated linen fiber is convenient to realize.

Owner:ZHANGJIAGANG ZHENXIN PRINTING & DYEING

Moisture-absorbing and quick-drying double-layer knitted fabric and preparation method thereof

ActiveCN111172651AStrong moisture absorption and quick drying performanceIncrease evaporation areaWeft knittingTwo or more solvent application treatmentPolymer sciencePolymer chemistry

The invention relates to a moisture-absorbing and quick-drying double-layer knitted fabric and a preparation method thereof. The preparation method comprises the following steps of weaving a double-layer knitted fabric with the inner layer having a moisture conducting function and the outer layer having a moisture absorbing function; and performing mild discontinuous hydrophilic finishing on the inner layer surface and performing mild discontinuous hydrophobic finishing on the outer layer surface to prepare the moisture-absorbing and quick-drying double-layer knitted fabric. The prepared moisture-absorbing and quick-drying double-layer knitted fabric is of a double-layer composite structure consisting of a moisture-conducting diffusion layer and a moisture-absorbing diffusion layer; the moisture-conducting diffusion layer is partially hydrophilic and partially hydrophobic; the moisture-absorbing diffusion layer is partially hydrophilic and partially hydrophobic; and the overall hydrophilic property of the moisture-absorbing diffusion layer is higher than that of the moisture-conducting diffusion layer. The preparation method of the moisture-absorbing and quick-drying double-layer knitted fabric is simple and convenient and is easy to operate, and the prepared moisture-absorbing and quick-drying double-layer knitted fabric has excellent moisture-absorbing and quick-drying effects.

Owner:DONGHUA UNIV

Polyester-cotton interwoven one-way moisture-wicking yarn-dyed fabric and dyeing and finishing processing method thereof

InactiveCN110747566AStay dry and comfortableLoose organizationShrinkingSucessive textile treatmentsPolyesterPolymer science

The invention discloses a polyester-cotton interwoven one-way moisture-wicking yarn-dyed fabric and a dyeing and finishing processing method thereof, which are characterized in that the fabric is woven with warps and wefts, the warps are polyester filaments, the wefts are pure cotton yarns, and the dyeing and finishing processing method of the fabric comprises the steps of S1, carrying out warp finishing, to be specific, unwinding, dyeing, carrying out reduction washing, and post-treating; S2, carrying out weft finishing, to be specific, dyeing, removing a surfactant, pickling, carrying out waterproof treatment, dewatering, and drying; S3, for the warps and wefts from the steps S1 and S2, carrying warping, rewinding, sizing, weaving, and maintaining gray fabric and post-treating; a honeycomb structure is adopted during weaving, the wefts are visible on the skin-fitting surface, the warps are visible on the outer surface, and the structure is loose; the post-treating procedure includesbaking, washing, shaping, setting and stentering, and preshrinking. The polyester-cotton interwoven one-way moisture-wicking yarn-dyed fabric and the dyeing and finishing processing method thereof have advantages that a certain waterproof effect is given to the skin-fitting surface of the fabric, the external surface of the fabric has excellent moisture-wicking effect, and the adopted polyester filaments with cotton yarns also improve quick-drying effect, so that the moisture loss speed is higher.

Owner:张家港市金陵纺织有限公司

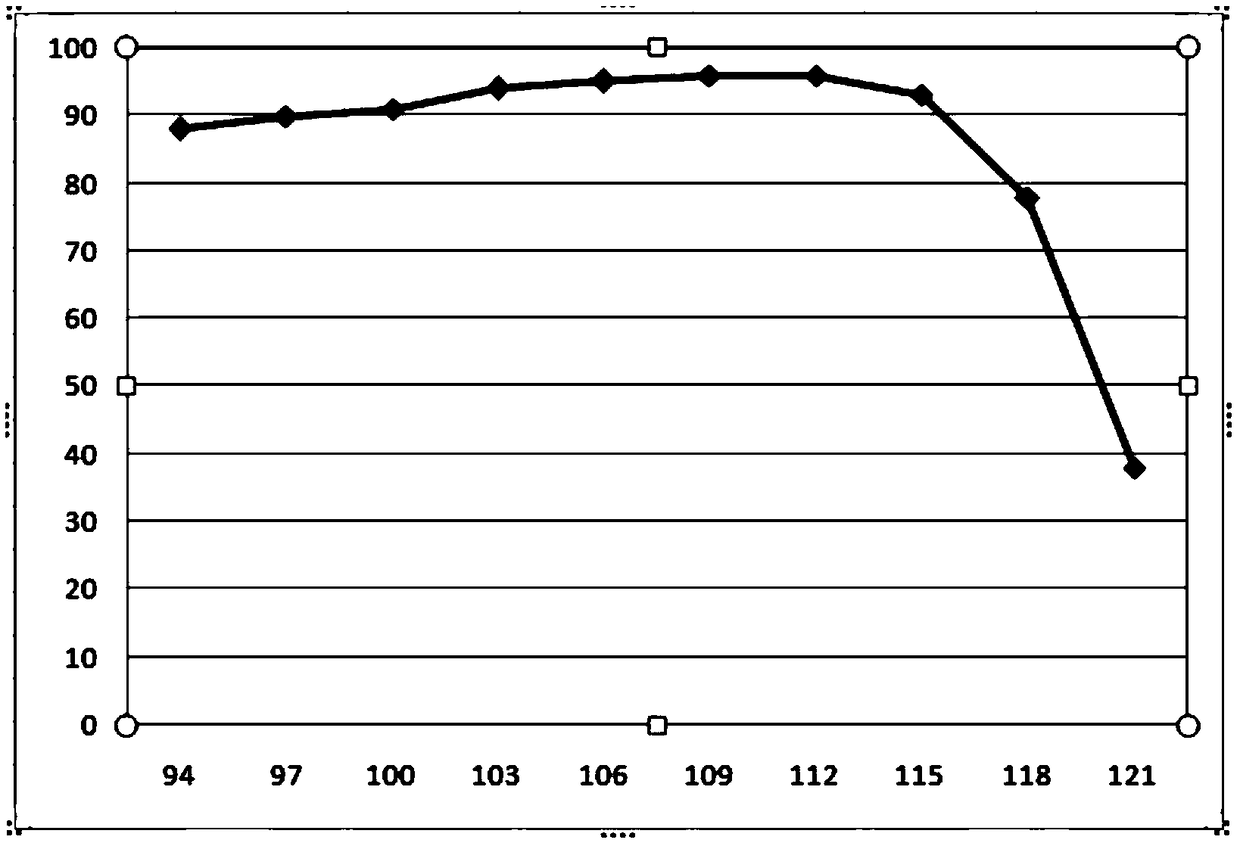

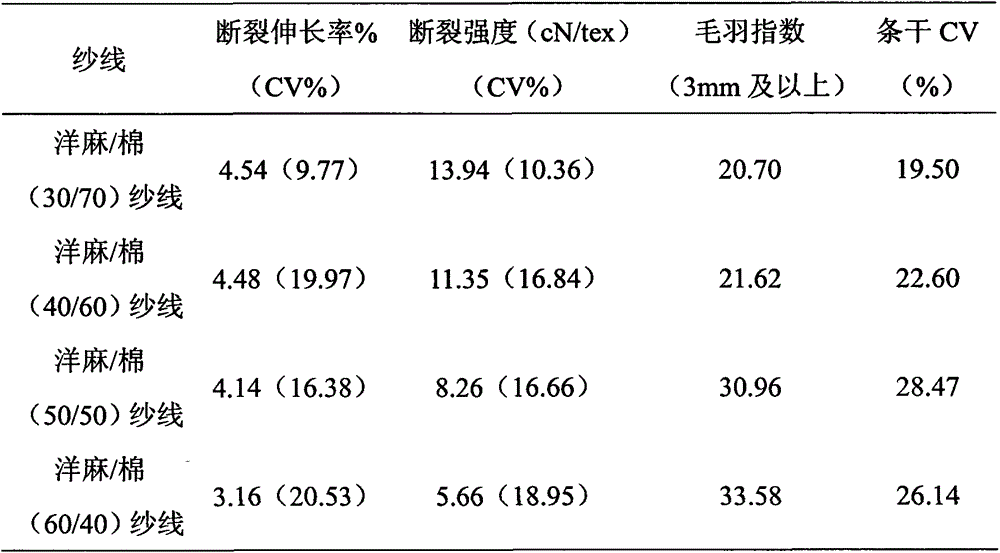

Development of kenaf and cotton blended yarns

InactiveCN106283306AGood flexibilityIncrease elasticityTwo or more solvent application treatmentYarnYarnCarding

The invention discloses a manufacturing method of kenaf and cotton blended yarns. According to the manufacturing method, the blended yarns is prepared from the following raw materials in percentage by weight: 30 to 60 percent of kenaf with the fiber length of 30 to 50 mm and 70 to 40 percent of cotton fibers with the fiber length of 30 to 38 mm. The technical process comprises the following steps: performing hermitical treatment on the kenaf through water retting, alkali-oxygen bath treatment, softening and a carding agent, then mixing the kenaf with the cotton fibers, and performing opening, carding, drawing, roving and spinning to obtain the kenaf and cotton blended yarns. The carding is carried out by using a roller type carding machine, and other operations are carried out by using cotton spinning equipment.

Owner:TIANJIN POLYTECHNIC UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com