Production process of puncture-proof fabrics

A production process and fabric technology, applied in two or more different solvent-based treatment materials, fabric surface trimming, heating/cooling fabrics, etc., can solve the difficult weaving of ultra-high molecular weight polyethylene fibers and unstable product quality. and other problems, to achieve the effect of good style and feel, good protection and good flexibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

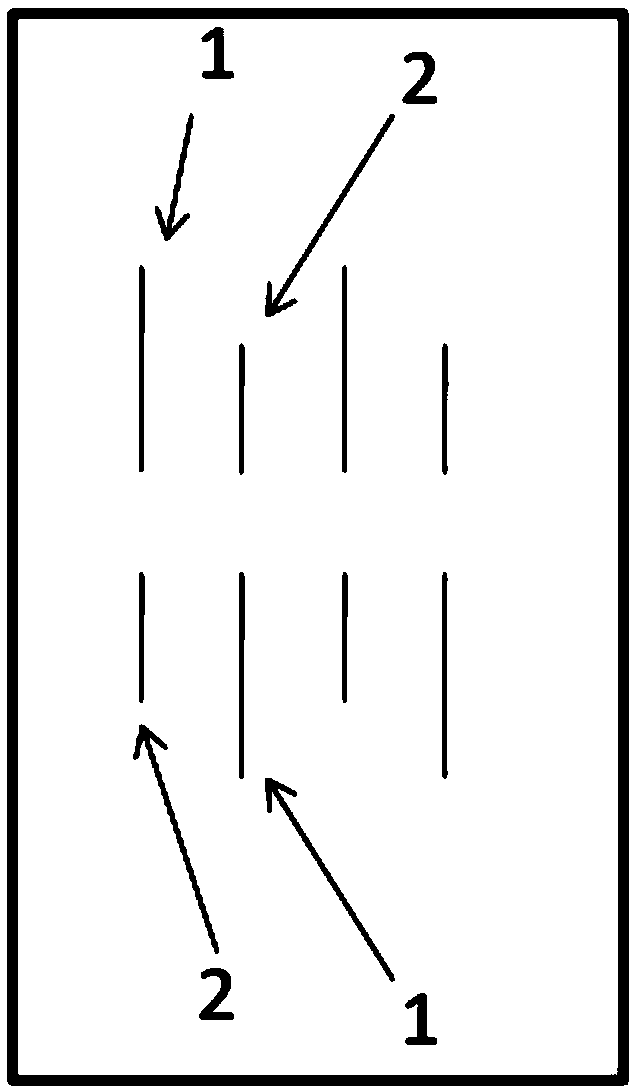

[0088] A kind of production technology of anti-stab fabric, comprises the following steps:

[0089] 1. Raw material performance test and analysis:

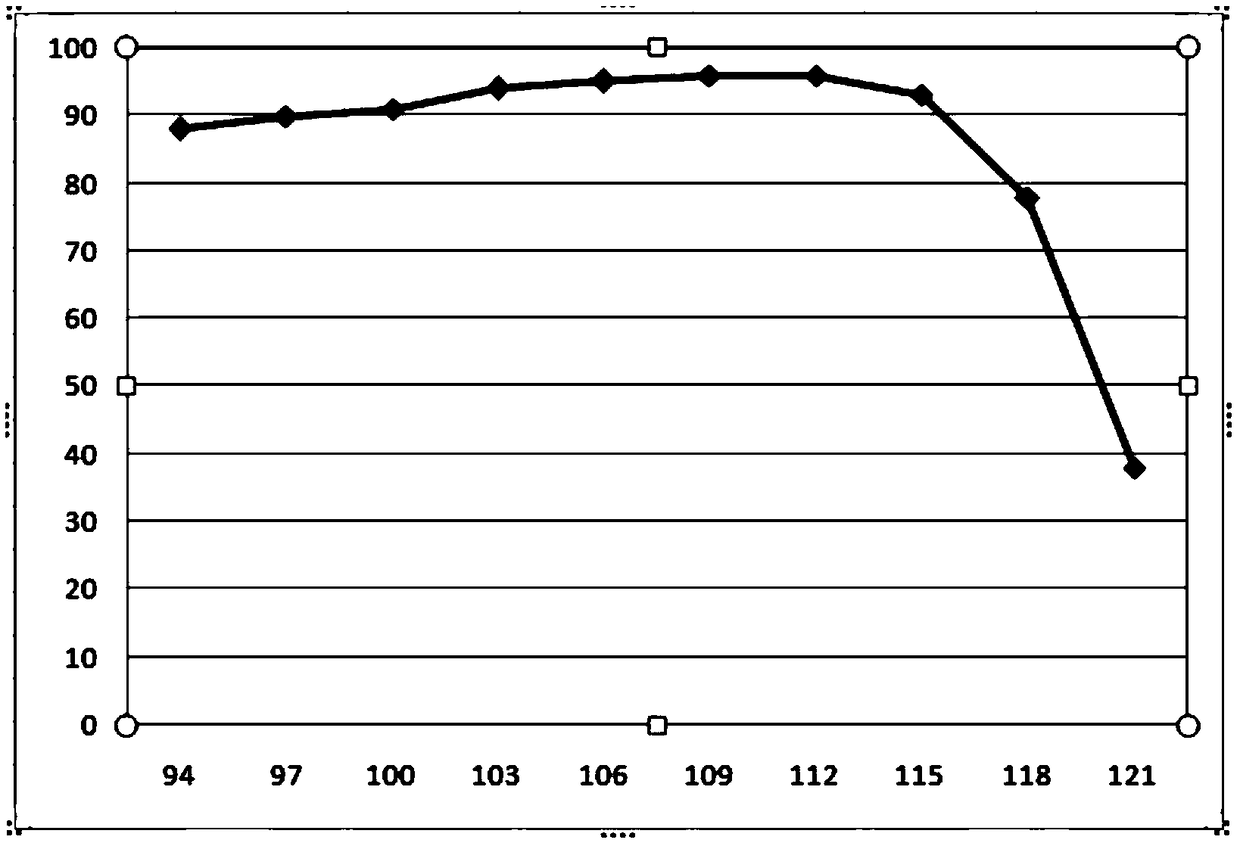

[0090]Single-yarn performance tests were performed on high-strength polyester filaments and ultra-high molecular weight polyethylene filaments, and the obtained data were compared, researched and analyzed. The breaking strength of ultra-high molecular weight polyethylene filaments of the same fineness is 3 to 5 times that of high-strength polyester filaments, but the elongation at break is less than half of that of high-strength polyester filaments. When high-strength polyester filaments are tested When the elongation at break of the ultra-high molecular weight polyethylene filament is reached, the force it bears is only about 40% of its own breaking strength. The difference in breaking strength and elongation at break of the two raw materials provides a new idea for the design of the fabric structure and the design of the yarn r...

Embodiment 2

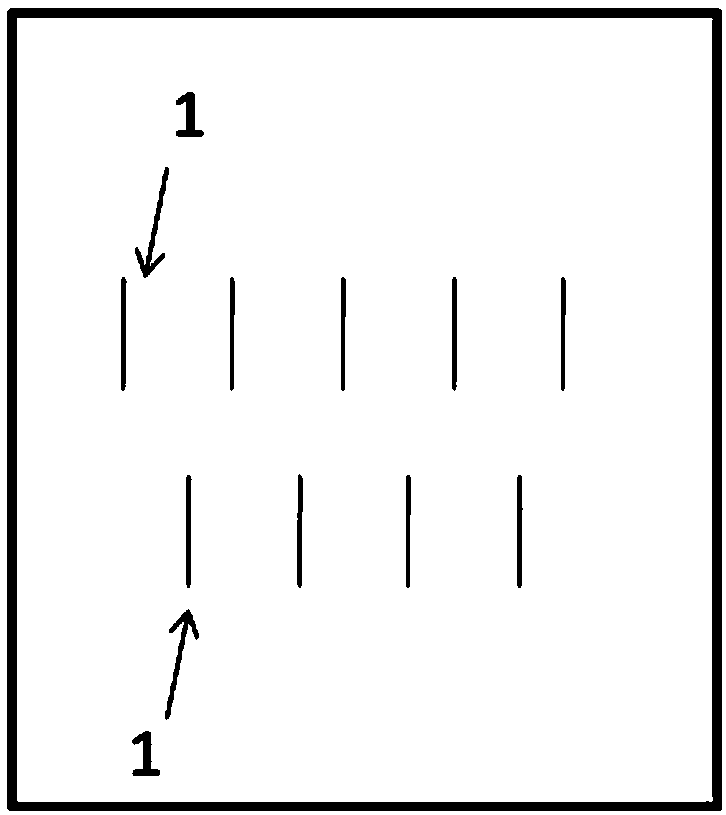

[0146] A kind of production technology of anti-stab fabric, comprises the following steps:

[0147] 1. Raw material performance test and analysis:

[0148] Single-yarn performance tests were performed on high-strength polyester filaments and ultra-high molecular weight polyethylene filaments, and the obtained data were compared, researched and analyzed. The breaking strength of ultra-high molecular weight polyethylene filaments of the same fineness is 3 to 5 times that of high-strength polyester filaments, but the elongation at break is less than half of that of high-strength polyester filaments. When the elongation at break of ultra-high molecular weight polyethylene filament, the force it bears is only about 40% of its own breaking strength. The difference in breaking strength and elongation at break of the two raw materials provides a new idea for the design of the fabric structure and the design of the yarn ratio.

[0149] The specification of the high-strength polyester...

PUM

| Property | Measurement | Unit |

|---|---|---|

| elongation at break | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com