Patents

Literature

48results about How to "Add anti-static function" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

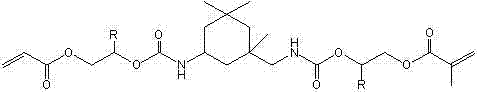

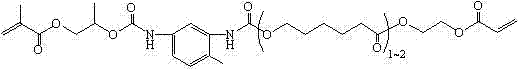

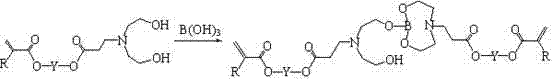

(Methyl) acrylate oxazole heterocycle borate, and preparation and application thereof

InactiveCN102225945ALower surface resistivityAdd anti-static functionInksGroup 3/13 element organic compoundsAdhesivePrinting ink

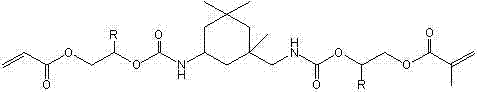

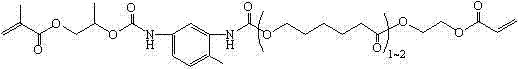

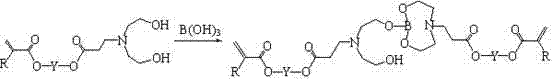

The invention discloses a (methyl) acrylate oxazole heterocycle borate compound, which is annular borate containing (methyl) acrylate group and tertiary amine composition. The invention also discloses a preparation method of the compound. The method comprises the steps that: bi-functional (methyl) acrylate compound or tri-functional (methyl) acrylate compound is subject to a reaction with N,N-bi(hydroxyalkyl)secondary amine; through a Michael addition reaction upon acrylate group, (methyl) acrylate with N,N-bi(hydroxyalkyl)amid is obtained; Under the coexistence of a desiccant and a polymerization inhibitor, (methyl) acrylate with N,N-bi(hydroxyalkyl)amid is subject to a condensation reaction with boric acid, such that (methyl) acrylate azacyclo-borate is obtained. The (methyl) acrylate oxazole heterocycle borate prepared by the present invention can be applied to the fields of light-cured paint, printing ink or adhesive, and has good anti-hydrolytic stability, adhesive performance, wear resistance and antistatic performance.

Owner:SUN YAT SEN UNIV

Dry powder type ecological interior wall paint based on shell powder

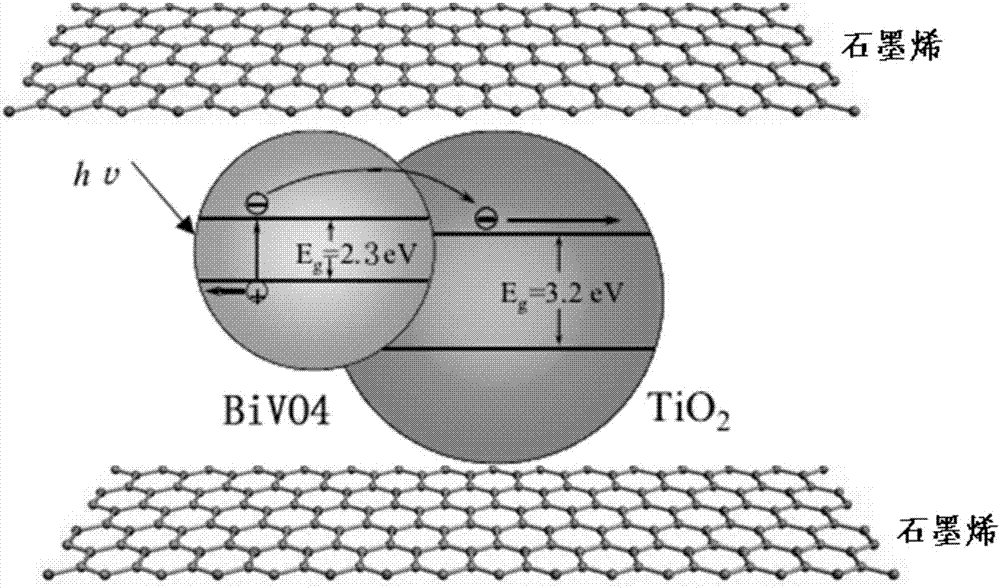

ActiveCN106554645AHigh UV-visible photocatalytic functionBacteriostaticAntifouling/underwater paintsPaints with biocidesBismuth vanadatePrecipitated calcium carbonate

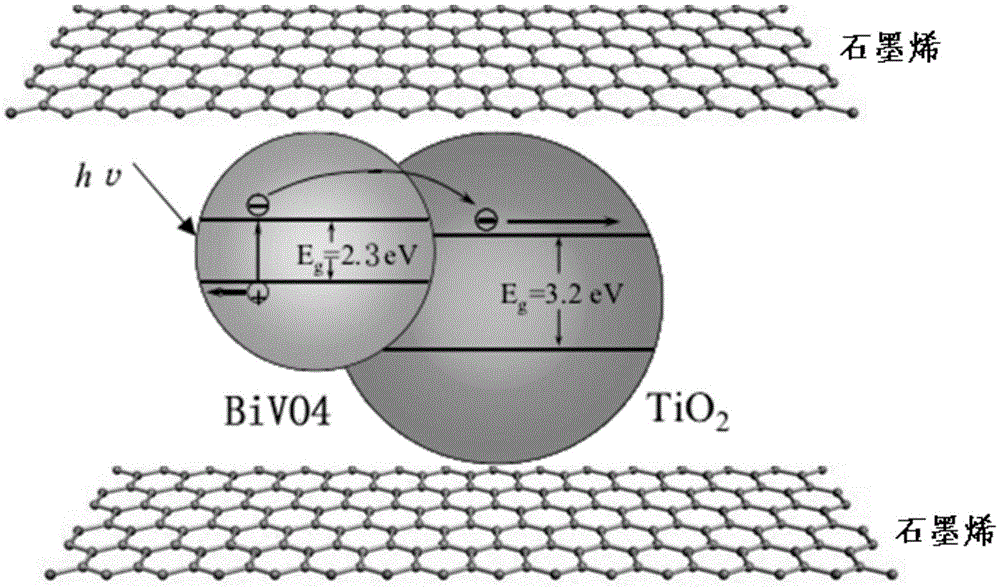

Dry powder type ecological interior wall paint based on shell powder is disclosed. Raw materials of the paint include, by mass, 30-50% of the shell powder the particle size of which is 500-1300 meshes, 10-20% of kaolin, 10-20% of precipitated calcium carbonate, 10-20% of nanometer silica, 1-10% of a TiO2-bismuth vanadate-graphene ternary nanometer composite material and 10-20% of adhesive powder. The paint has high ultraviolet-visible light photocatalysis functions, functions of adsorbing and decomposing harmless gas and odor, and antibacterial, sterilizing and antistatic functions, has characteristics of excellent physical performance, elegant appearance, and the like, can be widely applied in indoor decoration and overcomes disadvantages that indoor air purification materials at present are high in cost, high in energy consumption, low in visible light utilization rate, and the like.

Owner:广东优冠生物科技有限公司

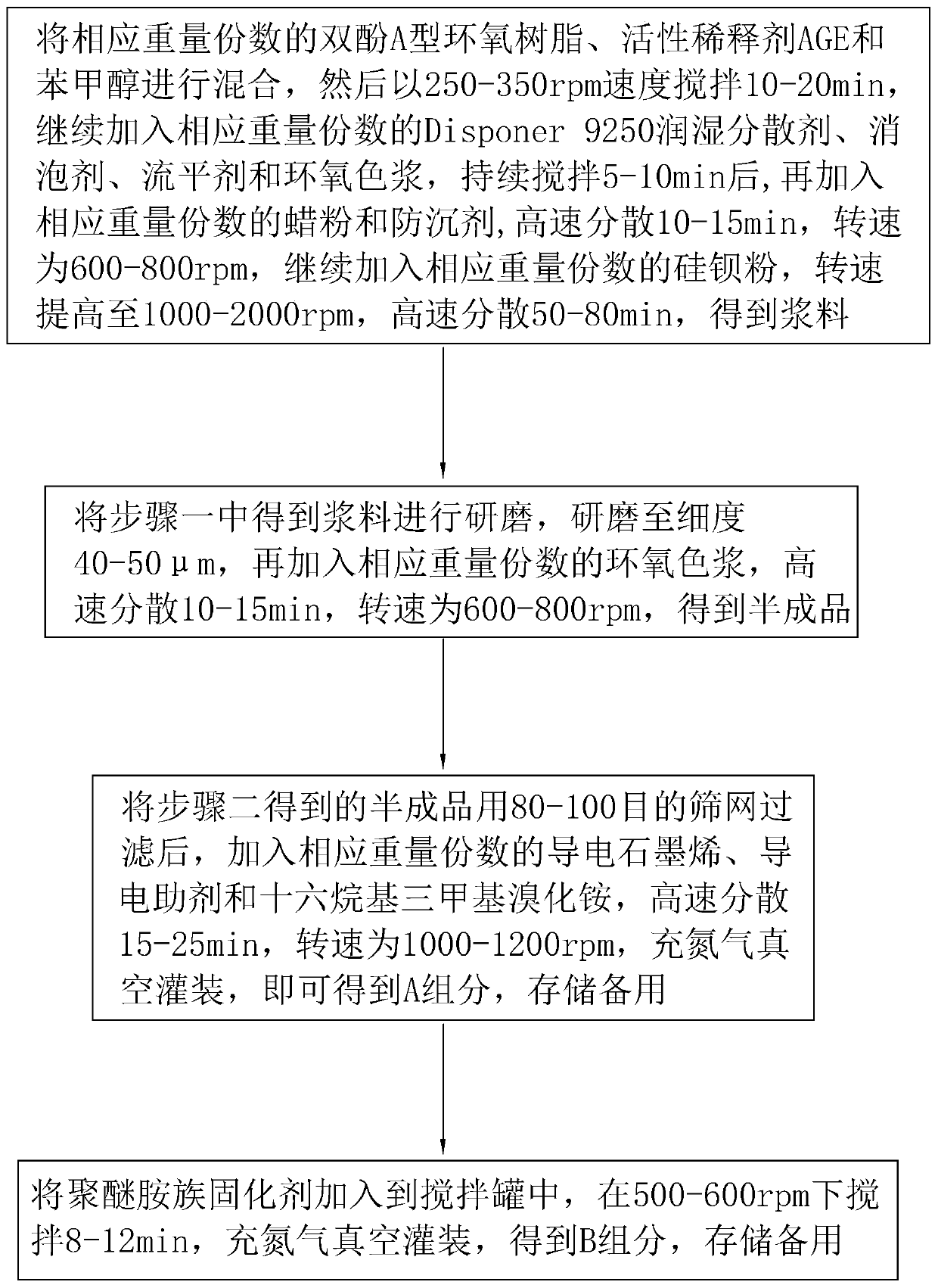

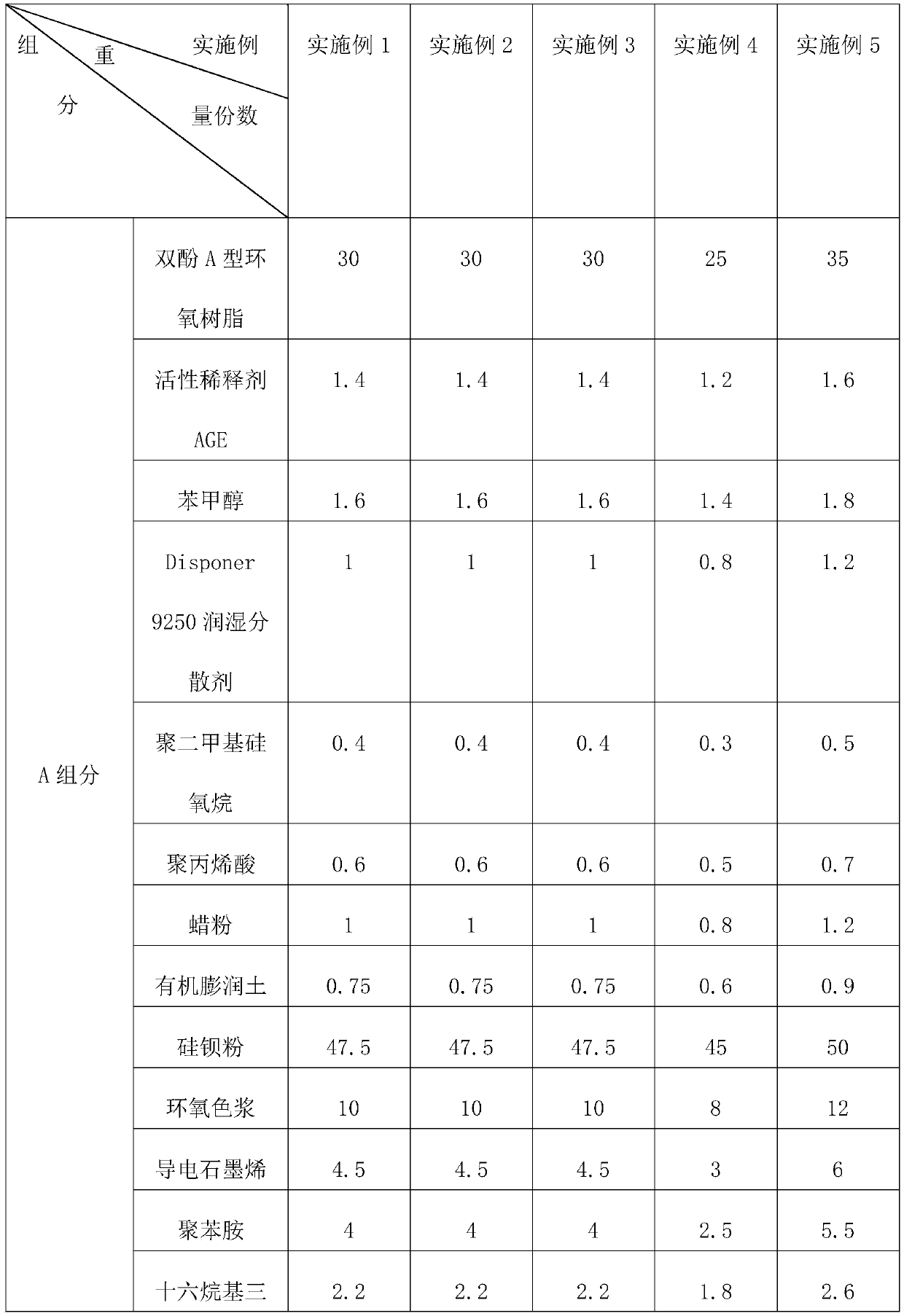

Solvent-free epoxy self-leveling antistatic finish paint and preparation method thereof

ActiveCN111334163AQuick evacuationAvoid gatheringPhysical treatmentFibre typesPolymer scienceSolvent free

The invention discloses solvent-free epoxy self-leveling antistatic finish paint and a preparation method thereof and relates to the technical field of epoxy self-leveling paint. The problems that theantistatic endurance performance of the floor coating is poor; the solvent-free epoxy self-leveling antistatic finish paint comprises a component A and a component B, the component A and the component B are independently stored and mixed according to the weight part ratio of (4-6): 1 in use, and the component A comprises the following raw materials in parts by weight: 25-35 parts of bisphenol A type epoxy resin; 1.2 to 1.6 parts of a reactive diluent AGE; 1.4 to 1.8 parts of benzyl alcohol; 0.8 to 1.2 parts of a Disponer 9250 wetting and dispersing agent; 0.3 to 0.5 part of a defoaming agent;0.5 to 0.7 part of leveling agent; 0.8 to 1.2 parts of wax powder; 0.6 to 0.9 part of an anti-settling agent; 45 to 50 parts of silicon barium powder; 8 to 12 parts of epoxy color paste; 3-6 parts ofconductive graphene; 2.5 to 5.5 parts of a conductive auxiliary agent; 1.8 to 2.6 parts of hexadecyl trimethyl ammonium bromide; and the component B is a polyether amine curing agent. The solvent-free epoxy self-leveling antistatic finish paint provided by the invention has stable and lasting antistatic performance.

Owner:上海博歌建材有限公司

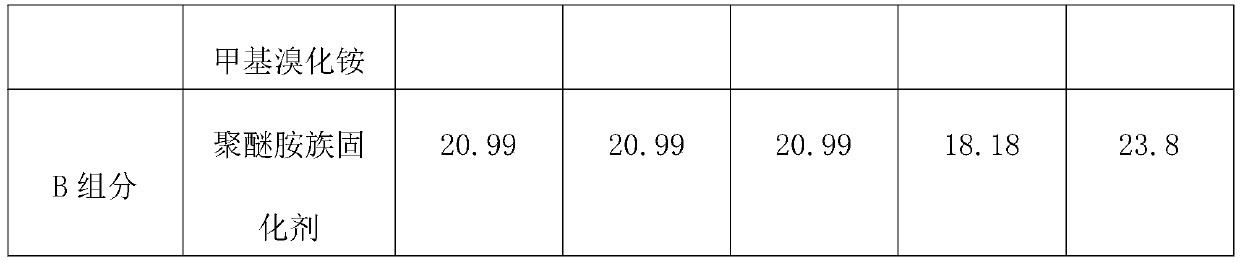

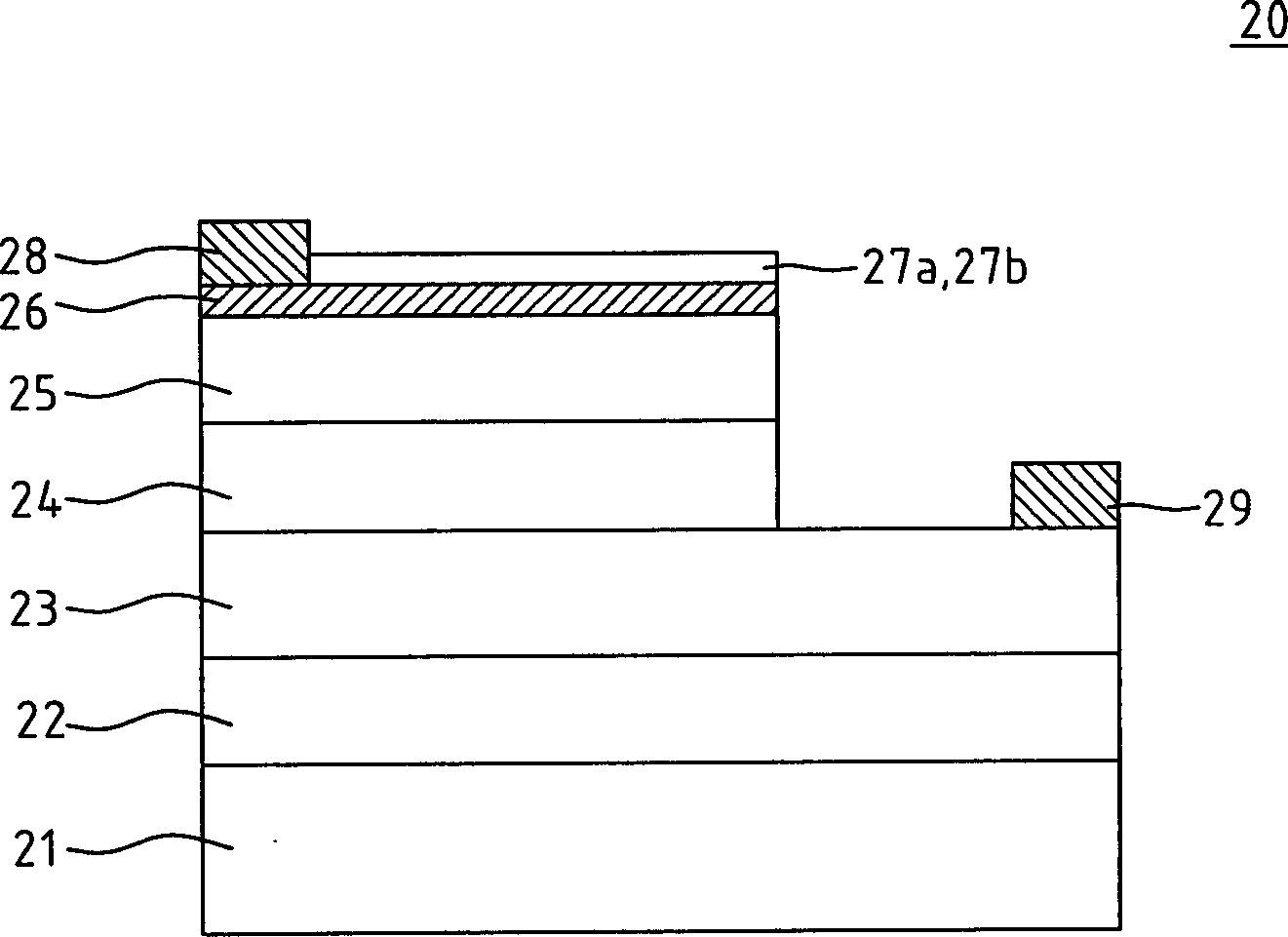

LED structure

The invention mainly provides a structure of a GaN light-emitting diode with digital penetrating layer, for overcoming the disadvantages and limits of a light-emitting diode in the existing technique and largely improving reverse voltage-proof and antistatic properties of the GaN light-emitting diode. The invention also provides a device for reducing the resistance between the transparent conductive layer and P-type GaN contact layer arranged in the GaN light-emitting diode, according to a digital penetrating layer between the two layers which can make internal carrier penetration, making an ohm contact state formed between the transparent conductive layer or oxide layer and the P-type GaN contact layer so as to be able to reduce the resistance between them. In addition, the invention provides a material able to make internal carrier penetration. The invention replaces the traditional Ni / Au with a material with excellent visible light photopermeability, such as indium tin oxide as the transparent conductive layer.

Owner:FORMOSA EPITAXY INCORPORATION +1

Compound textile printing and dyeing auxiliary and preparation technology thereof

The invention provides a compound textile printing and dyeing auxiliary and a preparation technology thereof. The compound textile printing and dyeing auxiliary is prepared from the following raw materials at weight ratio: alpha-sulpho-omega-octadecane polyoxyethylene ether, biosurfactant, rare earth oxide, coconut oil diethanolamide, polyoxyethylene water sorbitol monopalmitate, diamino silicon oil, cocamidopropyl betaine, tartaric acid, sodium polyacrylate, poloxamer 407, methyl chloride isothiazolinone, sodium tripolyphosphate, isopropyl myristate, glycol and water. The compound textile printing and dyeing auxiliary provided by the invention had the advantages of high dyeing rate, high dye use ratio, excellent overall printing and dyeing effect, color fastness, capability of enhancing antibacterial and antistatic functions of printed and dyed textile, capability of meeting the application requirement of the consumers and wide application prospect.

Owner:SUZHOU INST OF TRADE & COMMERCE

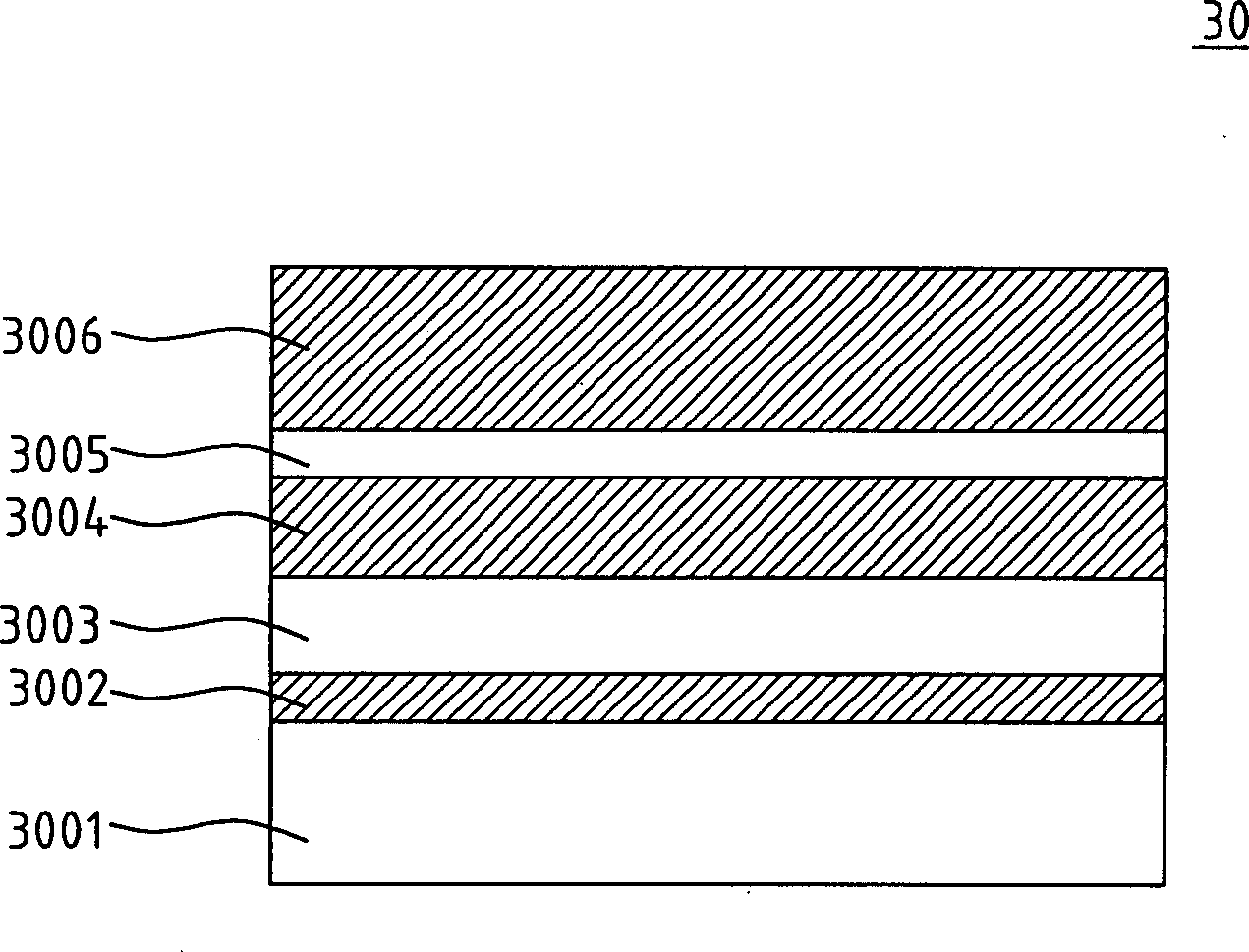

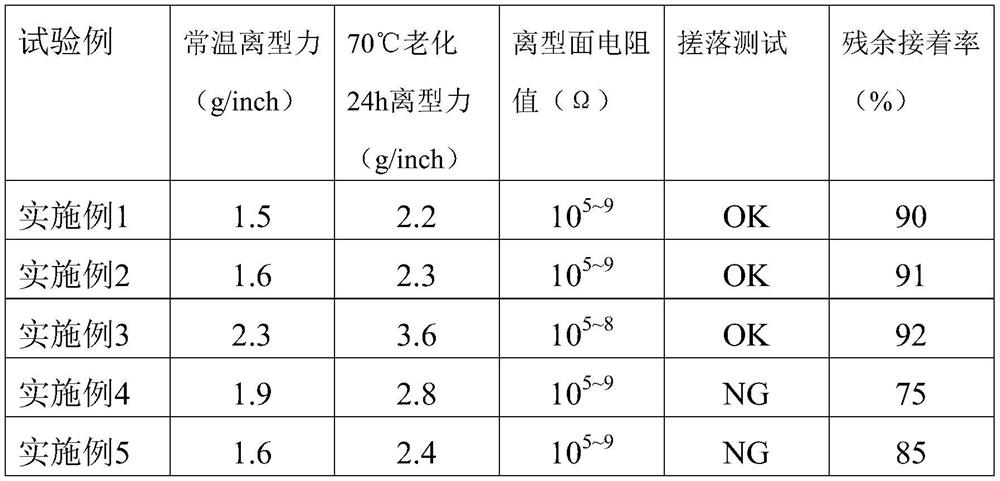

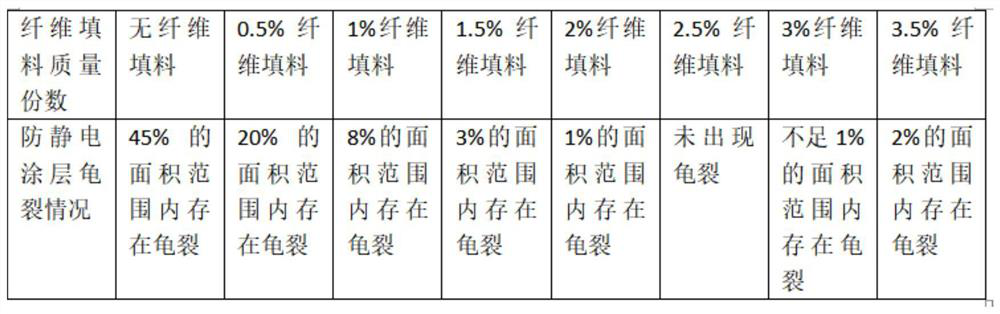

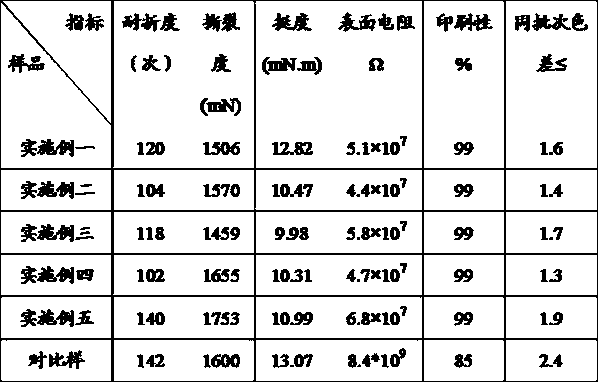

Production process of double-sided antistatic ultralight release film and release film

InactiveCN113333250AAdd anti-static functionIncreasing the thicknessPretreated surfacesSpecial surfacesPolymer sciencePtru catalyst

The invention discloses a production process of a double-sided antistatic ultralight release film. The production process comprises the following steps: S1, preparing antistatic coating liquid and release agent coating liquid; S2, coating two surfaces of a base film layer with the antistatic coating liquid, and curing for the first time to obtain a film with two antistatic layers; S3, coating the release agent coating liquid on the surface of at least one antistatic layer, and curing for the second time to obtain a release film semi-finished product; and S4, curing the release film semi-finished product to prepare the double-sided antistatic ultralight release film. The release agent coating liquid is mainly composed of main agent release silicone oil, a cross-linking agent, an anchoring agent, a platinum catalyst, an anti-sticking agent, an inhibitor, a silane coupling agent and a solvent. According to the production process, the adhesive force is further improved through the silane coupling agent and secondary curing, the thickness of the release layer is increased, and the release film with ultralight release force and good release force high-temperature stability is obtained; and the antistatic function of the antistatic layer is also improved by the first-time curing. The invention further discloses the release film.

Owner:JIANGYIN TONGLI OPTOELECTRONICS TECH

Biaxially oriented polypropylene heat-sealing film and preparation process thereof

PendingCN112500634AHigh absorption strengthIncrease disorderSynthetic resin layered productsFlat articlesAntioxidantPetroleum resin

The invention discloses a biaxially oriented polypropylene heat-sealing film and a preparation process thereof. The biaxially oriented polypropylene heat-sealing film comprises an outer surface layer,a core layer and an inner surface layer, and is prepared by co-extruding the outer surface layer, the core layer and the inner surface layer from top to bottom. The core layer is prepared from the following components in parts by weight: 87 to 92 parts of homo-polypropylene, 5 to 10 parts of hydrogenated petroleum resin, 0.8 to 1.2 parts of nano glass powder, 0.4 to 0.8 part of calcium carbonate,0.25 to 2.5 parts of nucleating agent, 0.2 to 0.5 part of stabilizer and 0.01 to 0.2 part of antioxidant. By arranging the biaxially oriented film layer structure, the components and the preparationprocess of the biaxially oriented film layer structure, the performance of a prepared tobacco film is improved, the strength, the mechanical performance, the glossiness and the humidity of the prepared tobacco film are improved, the wear resistance and the moisture barrier capacity of the prepared tobacco film are improved, moisture condensation and permeation can be effectively prevented, the existing tobacco quality and tobacco film appearance are kept, and the film is suitable for wide popularization and use.

Owner:JIANGYIN ZHONGDA FLEXIBLE PLASTIC NEW MATERIALS CO LTD

A preparing method of coconut charcoal fiber

InactiveCN105442095AAdd anti-static functionProtect the environmentElectroconductive/antistatic filament manufactureCelluloseAntistatic agent

A preparing method of coconut charcoal fiber is disclosed. The method includes (1) a step of preparing master batch, namely a step of recovering waste coconut shells, extracting coconut shell cellulose by dipping, beating, removing impurities and airing, heating the coconut shell cellulose to 1200 DEG C, performing high-temperature carbonization to prepare coconut charcoal, smashing the coconut charcoal into nanometer powder by utilization of a particle collision principle and through a dry grinding manner, adding anionic antistatic agent powder into the coconut charcoal powder, and fully mixing to obtain the coconut charcoal master batch, and (2) a step of spinning the coconut charcoal fiber, namely a step of preparing the hollow type coconut charcoal fiber with a three-dimensional crimp configuration by melt spinning, drawing, sizing, crimping, oiling, cutting and packaging. The prepared coconut charcoal fiber has good antibacterial, far infrared and anion-releasing performances, and the like, and accords with functional, healthy and environment friendly ideas pursued in product development. For better application in development of home textile products, the antistatic property of the fiber is improved by adding the antistatic agent, thus improving product quality.

Owner:SHANGHAI SHUIXING HOME TEXTILE

Release agent for aluminum alloy casting and preparation method thereof

ActiveCN109226665AImprove the lubrication effectImprove high temperature resistanceFoundry mouldsFoundry coresTemperature resistanceMaterials science

The invention discloses a release agent for aluminum alloy casting. The release agent is mainly prepared from the following raw materials in parts by weight: 8-10 parts of graphite lubricating oil, 6-8 parts of a slipping agent, 4-6 parts of a lotus leaf water repellent agent, 3-5 parts of methyl modified silicone oil, 2-3 parts of an organic silicon defoamer, 18-24 parts of butyl-3-methylimidazolium hexafluorophosphate, 50-60 parts of deionized water, 1-2 parts of a heat stabilizer and 0.6-0.8 part of a flow promotor. The invention provides a preparation method for the release agent for aluminum alloy casting. According to the release agent and the preparation method thereof, through the graphite lubricating oil and the methyl modified silicone oil, the lubricity of the release agent is improved, in addition, the high-temperature resistance is improved, moreover, through ER erucyl amide, octadecanamide and the lotus leaf water repellent agent, the anti-adhesion property, the lubricityand the anti-static property of the release agent can be improved, the release agent is smoother, the fluidity is improved through the flow promotor and vegetable fat, the uniform smoothness of the release agent is improved, and the phenomenon that the use next time is influenced due to the fact that the release agent is retained and adheres to the wall can be avoided.

Owner:佛山市南海镕信金属制品有限公司

Flame-retardant antistatic paint

The invention discloses flame-retardant antistatic paint which comprises a common paint raw material, a flame-retardant component and an antistatic component and is characterized by also comprising nanoscale aluminum powder and nanoscale copper powder. According to the flame-retardant antistatic paint disclosed by the invention, based on the original paint functions, a fireproof antistatic functional material as well as nanoscale aluminum powder and copper powder are added, so that the flame-retardant and antistatic function is further enhanced, and the adhesive capacity and gloss of the paint also can be improved.

Owner:丁小铁

Preparation method of functional cotton-imitating antistatic water-absorbing warp-knitted nap fabric and product thereof

ActiveCN109778417AImprove comfortIncrease antistatic functionSucessive textile treatmentsFibre typesPolyesterYarn

The invention discloses a preparation method of a functional cotton-imitating antistatic water-absorbing warp-knitted nap fabric and a product thereof. The method includes the steps that a fiber raw material is subjected to warping, knitting, shaping and dyeing; in the fiber raw material, face yarn or bottom yarn comprises antistatic polyester, the weight ratio of the antistatic polyester in the face yarn or the bottom yarn is 20-100%, and middle yarn is hydrophilic modified polyvinyl fiber. According to the method, the hydrophilic modified polyvinyl fiber is adopted as the middle yarn, one side of the face yarn or the bottom yarn adopts antistatic fiber, and the other side of the face yarn or the bottom yarn adopts common fiber, so that the weave structure design is beneficial to forminga siphonic effect; the middle yarn can absorb moisture, and meanwhile the bottom yarn can maintain a certain degree of dryness, so that the comfort of the fabric is improved; moisture stored in the middle yarn is beneficial to improving the antistatic function and has a synergistic effect with the antistatic fiber.

Owner:HAIAN QI HONG TEXTILE TECH CO LTD

Antibacterial and anti-pilling acrylic yarn and spinning process thereof

InactiveCN112663186AHas antibacterial propertiesImprove antibacterial propertiesLiquid/gas/vapor removalYarnYarnPolymer science

The invention discloses antibacterial and anti-pilling acrylic yarn and a spinning process thereof, belongs to the field of acrylic yarn. Now the following scheme is provided: the antibacterial and anti-pilling acrylic yarn is prepared from the following raw materials in parts by weight: 100 to 120 parts of acrylic fibers, 0.1 to 3.0 parts of silver fibers, 5.0 to 12.0 parts of aloe viscose fibers, 10.0 to 15.0 parts of cotton fibers, 3.0 to 7.0 parts of bamboo fibers and 3.0 to 5.0 parts of modal fibers. The spinning process comprises the step of material selection, wherein the acrylic fibers, silver fibers, aloe viscose fibers, cotton fibers, bamboo fibers and modal fibers are put into a fiber mixing machine according to the weight parts to obtain mixed fibers, then the mixed fibers are combed into wool tops, the cleaned yarn is put into a drying machine to be dried, the drying speed is 35-55 m / min, and the drying temperature is 80-100 DEG C. The antibacterial and anti-pilling acrylic yarn is ingenious in design, reasonable in component and simple in process, and has antibacterial and anti-pilling functions.

Owner:肇庆市高要区长河毛纺有限公司

Antistatic printing additive

InactiveCN107869072AImprove performanceAdd anti-static functionDyeing processChemistryAntistatic agent

The invention relates to an antistatic printing additive. The antistatic printing additive is prepared from the following components in parts by mass: 10 to 20 parts of antistatic agent, 25 to 35 parts of thickener, 20 to 30 parts of growing additive, and 20 to 45 parts of water. The antistatic printing additive has the advantages that by adopting N-hydroxymethyl acrylamide and sodium taurate, theantistatic function is realized for paste; the natural and synthetic thickening matters are mixed to form the high-efficiency thickener, so that the thickening effect is obviously improved; the property of the additive is improved.

Owner:SUZHOU RUNHONG TRADING

Antistatic clothes conditioning agent

InactiveCN105886135ASoft and fluffy with good effectNo damageNon-ionic surface-active compoundsOrganic detergent compounding agentsMicroorganismCoconut oil

The invention relates to an antistatic clothes conditioning agent being composed of following raw materials including, by weight, 13-25 parts of myristic acid, 15-35 parts of dodecyl carboxylic diethanolamine, 4-5 parts of carboxymethylcellulose, 30-50 parts of glycerol monolaurate, 4-25 parts of mannitol, 19-25 parts of sorbitol, 15-45 parts of extract liquids of agastache rugosus and lily, and 13-35 parts of coconut oil. The conditioning agent has an antistatic effect on clothes during laundry, is excellent in washing and cleaning capabilities, has strong killing effect on common harmful microorganisms, especially pathogenic bacteria, ensures the clothes to be sterilized after washing, has good softening and loosening effects, is free of damage on clothes, has good stability and is free of damaging skin.

Owner:王萍

Antistatic far-infrared health-care fabric

InactiveCN103600537ALong-lasting and efficient far-infrared functionEnhance the efficacy of far infraredSynthetic resin layered productsPolyesterFiber

The invention discloses an antistatic far-infrared health-care fabric. The antistatic far-infrared health-care fabric comprises a flame-retardant fabric base layer and an antistatic layer is coated on the upper surface of the flame-retardant fabric base layer. The flame-retardant fabric base layer is prepared from flame-retardant polyester fibers. The antistatic layer has the thickness of 0.1-0.2mm. Compared with the prior art, the antistatic far-infrared health-care fabric has lasting flame resistance; and surface resistivity of the antistatic far-infrared health-care fabric is reduced to 100MOhm by the antistatic layer on the surface of the antistatic far-infrared health-care fabric so that the antistatic far-infrared health-care fabric has good antistatic effects and dirt resistance.

Owner:汕头市丽婴服饰有限公司

Composite fabric with pull resistance and rapid sweat absorption function

InactiveCN108995339ATensileFunctionalSynthetic resin layered productsCellulosic plastic layered productsWear resistantEngineering

The invention discloses composite fabric with pull resistance and a rapid sweat absorption function. The composite fabric comprises a wear-resistant layer and a conductive fiber layer, wherein the lower surface of the wear-resistant layer is connected with a microfiber heat insulation cotton layer; a meryl layer is arranged on the lower surface of the microfiber heat insulation cotton layer; upperand lower sides of the conductive fiber layer are connected with the meryl layer and a quick drying layer respectively; quick drying through holes are formed in the wear-resistant layer, the microfiber heat insulation cotton layer, the meryl layer, the conductive fiber layer and the quick drying layer; an inner overlock is arranged on the inner side surface of each quick drying through hole; external overlocks are arranged on the microfiber heat insulation cotton layer and are connected through Dry-Tec waterproof cloth strips. The composite fabric with pull resistance and the rapid sweat absorption function has wear resistance, heat of a user's body can be dissipated conveniently, and then dryness heat of the user is reduced; the composite fabric has toughness, thereby having pull resistance and further having waterproofness and the rapid sweat absorption function.

Owner:嘉兴星创科技有限公司

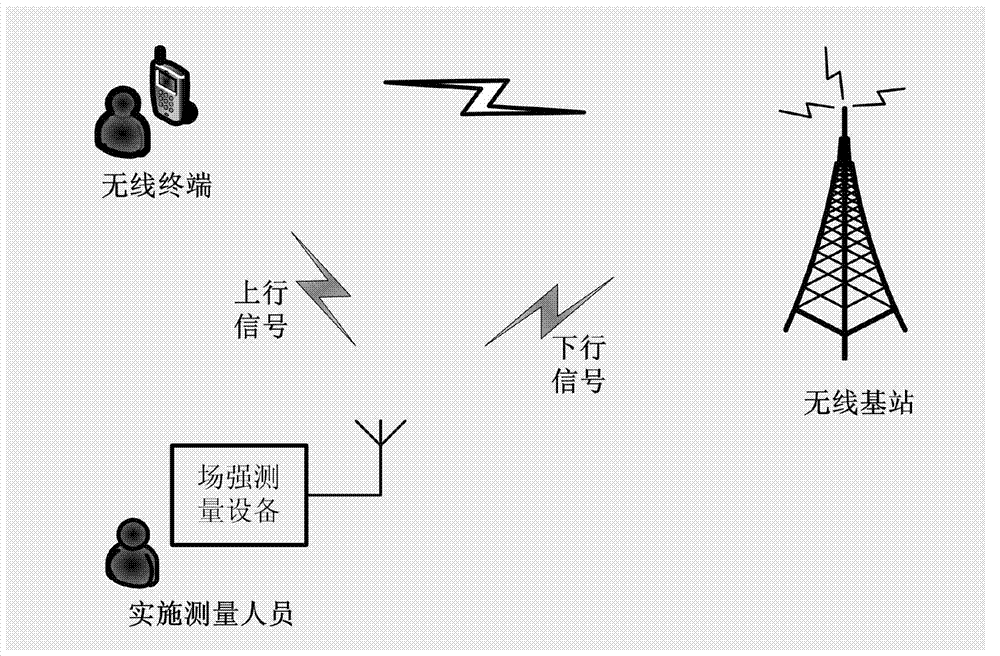

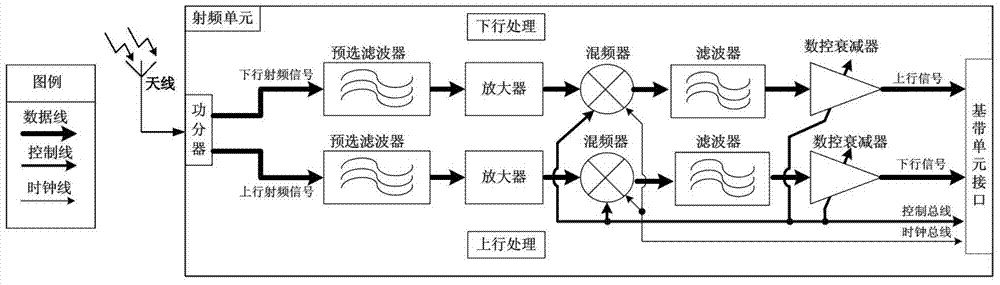

Portable WCDMA (Wideband Code Division Multiple Access) wireless signal field intensity measuring device

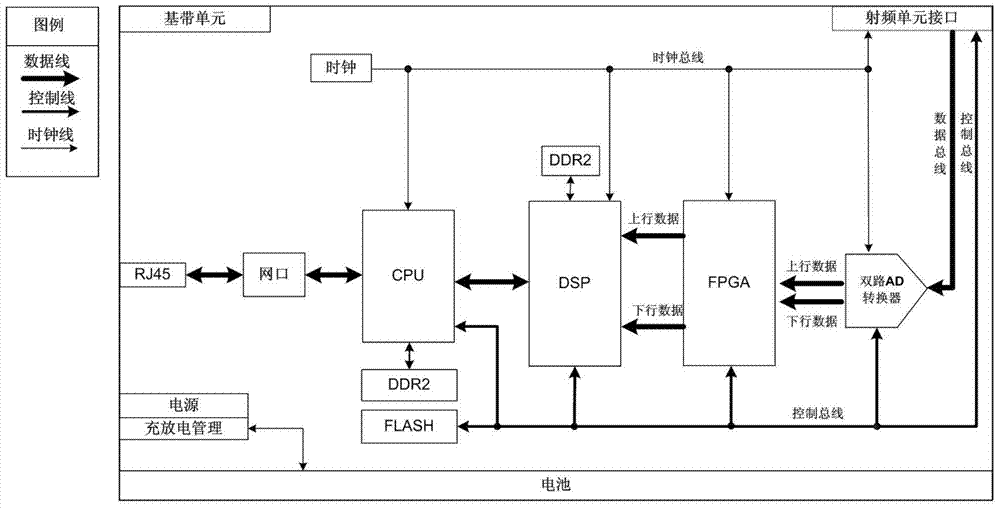

ActiveCN104519518AReplaceableImprove reliabilityWireless communicationCode division multiple accessEngineering

The invention discloses a portable WCDMA (Wideband Code Division Multiple Access) wireless signal field intensity measuring device. The portable WCDMA wireless signal field intensity measuring device comprises a baseband unit and a radio frequency unit, wherein the radio frequency unit has a tidy super heterodyne structure, so that the size can be reduced, and the same receiving sensitivity as a base station radio frequency unit can be achieved; in the baseband unit, the functions of a plurality of board cards are clipped, so that a brand new wireless portable baseband processing framework is formed on a baseband processing board card; the radio frequency unit is connected with the baseband unit through a radio frequency cable provided with a lock catch, so that field intensity measuring devices of different systems can be switched by only replacing the radio frequency unit; and meanwhile, a charging and discharging management unit of a portable unit for a lithium ion battery is added, so that a battery power supply working mode is supported, and the maneuverability of the field intensity measuring device is enhanced. The portable WCDMA wireless signal field intensity measuring device can meet flexible field intensity measuring requirements in various complex wireless environments.

Owner:RUN TECH CO LTD BEIJING

A dry powder type ecological interior wall coating based on shell powder

ActiveCN106554645BHigh UV-visible photocatalytic functionBacteriostaticAntifouling/underwater paintsPaints with biocidesBismuth vanadateVisible light photocatalytic

Dry powder type ecological interior wall paint based on shell powder is disclosed. Raw materials of the paint include, by mass, 30-50% of the shell powder the particle size of which is 500-1300 meshes, 10-20% of kaolin, 10-20% of precipitated calcium carbonate, 10-20% of nanometer silica, 1-10% of a TiO2-bismuth vanadate-graphene ternary nanometer composite material and 10-20% of adhesive powder. The paint has high ultraviolet-visible light photocatalysis functions, functions of adsorbing and decomposing harmless gas and odor, and antibacterial, sterilizing and antistatic functions, has characteristics of excellent physical performance, elegant appearance, and the like, can be widely applied in indoor decoration and overcomes disadvantages that indoor air purification materials at present are high in cost, high in energy consumption, low in visible light utilization rate, and the like.

Owner:广东优冠生物科技有限公司

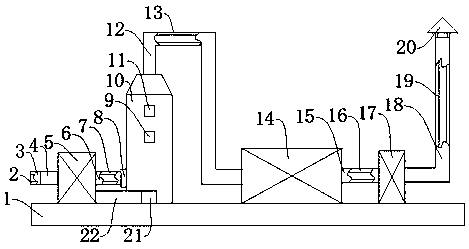

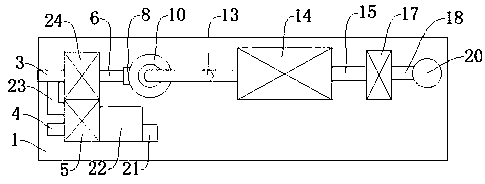

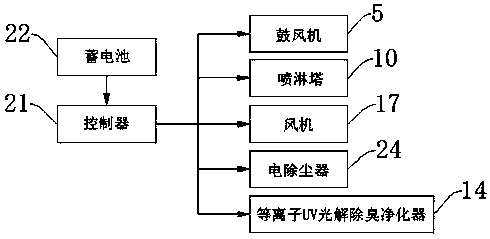

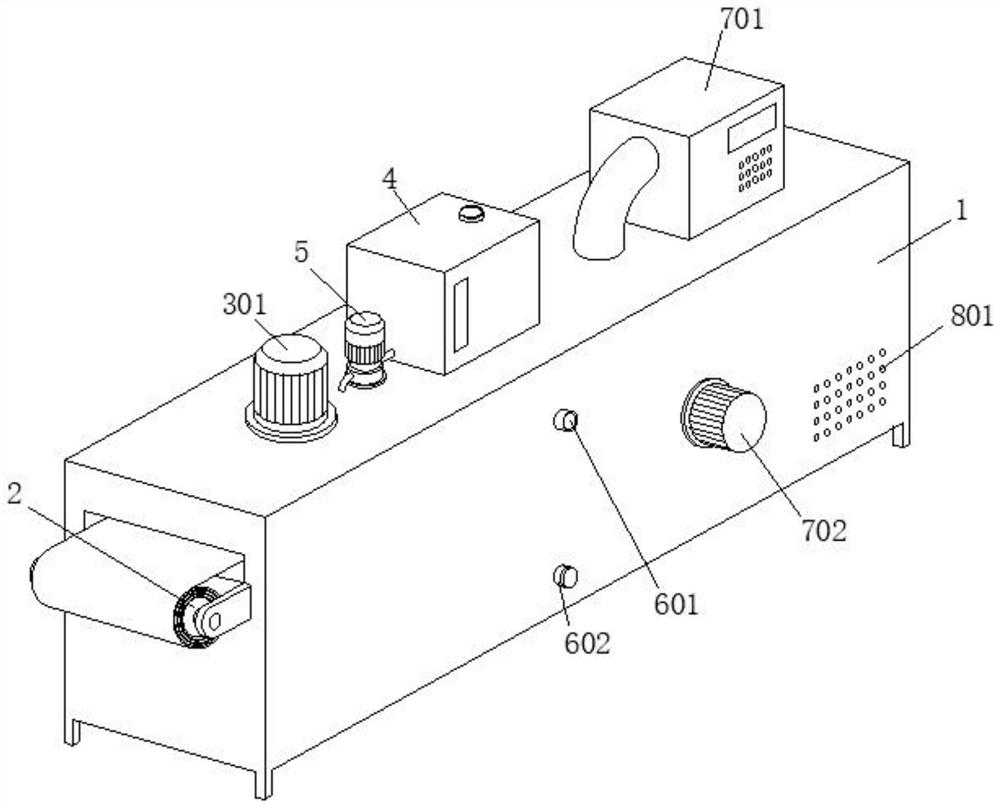

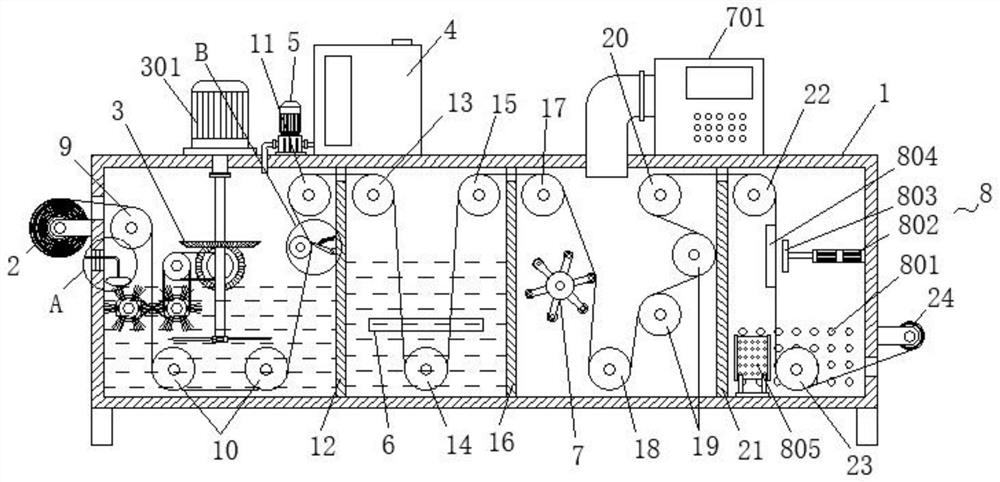

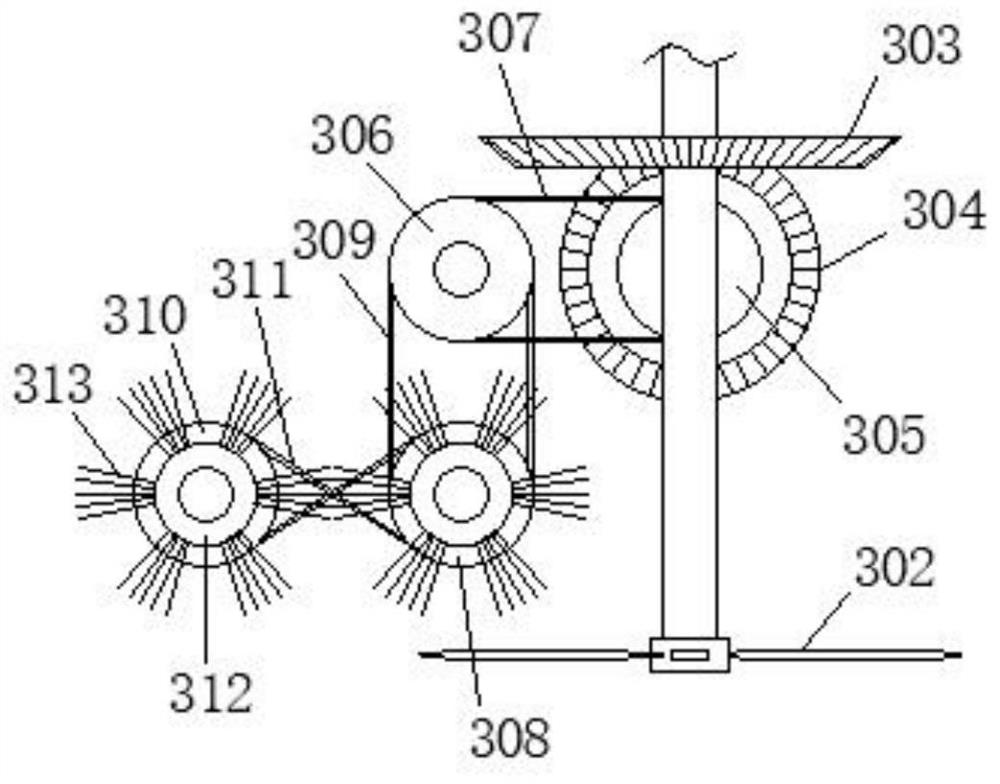

Waste gas treatment and transport device for environment protection equipment

InactiveCN108579354AAvoid damageAdd anti-static functionCombination devicesElectrostatic chargesFirestopSpray tower

The invention discloses a waste gas treatment and transport device for environment protection equipment, which comprises a bottom plate, a spray tower and a plasma photodegradation deodorizing purifier. A waste gas pipe is arranged on one side of the upper side of the bottom plate, and a first anti-static layer is arranged on the inner wall of the waste gas pipe. An electric precipitator is arranged on the side of the upper side of the bottom plate far away from the waste gas pipe. A blower is arranged in the front of the electric precipitator. A fourth connection pipe is arranged on the sideof the blower close to the waste gas pipe. An air pipe is arranged in the front of the fourth connection pipe. The waste gas treatment and transport device has the advantages that the anti-static function is added via the arrangement of the first anti-static layer, a second anti-static layer, a third anti-static layer, a fourth anti-static layer and a fifth anti-static layer, the firestop and explosion proof function is added owing to the arrangement of a deflagration fire arrestor, the function of waste gas release is added owing to the arrangement of the blower, the air pipe and the fourth connection pipe, and a rain shielding cover prevents rain from entering an exhaust pipe, causing damage to the blower.

Owner:浙江银烽环保装备有限公司

Auxiliary capable of improving printing performance of composite ivory board and preparation method thereof

The invention discloses an auxiliary capable of improving printing performance of a composite ivory board and a preparation method thereof. The auxiliary is prepared from, by weight, 10-20 parts of inorganic zinc salt, 10-20 parts of inorganic additive, 0.5-1 part of surfactant, 0.5-1 part of dispersant and 60-80 parts of deionized water. ZnO nano acanthosphere particles after surface modification are adopted as the auxiliary in the process of printing the composite ivory board; the ZnO nano acanthosphere particles have siphon microstructure, and an active agent is adopted for chemical surface modification, so that ink absorptivity of the composite ivory board can be further improved.

Owner:贵州金马包装材料有限公司

Drying and washing device for textile fabric processing

PendingCN112779704AAdd anti-static functionQuality improvementLiquid/gas/vapor removal by squeezing rollersHeating/cooling textile fabricsBevel gearChemical agent

The invention discloses a drying and washing device for textile fabric processing. The device comprises a machine case; the two ends of the machine case are rotationally connected with a first winding roller and a second winding roller through a pair of fixed frames respectively; the distance between the first winding roller and the ground is larger than the distance between the second winding roller and the ground; and a textile fabric is stored between the first winding roller and the second winding roller. A coating mechanism is arranged in the machine case, a first motor is used for driving a driving bevel gear to rotate, and then a plurality of guide wheels are arranged for conveying, so that the anti-static function of the fabric can be improved, the quality of the fabric is improved, and the fabric is more beneficial for customers to use; by arranging a cleaning mechanism in the machine case, residual chemical liquid on the fabric can be quickly removed, so that the situation that the fabric carrying the chemical agent is directly processed into clothes, so that selling of the clothes is affected and the customers are hurt is avoided; and a drying mechanism and an ironing mechanism are arranged in the machine case, so that the subsequent clothes design and processing are better facilitated, the fabric quality is greatly improved, and the use is better facilitated.

Owner:安徽君翰纺织科技有限公司

Antibacterial and acarus-killing laundry detergent and preparation method thereof

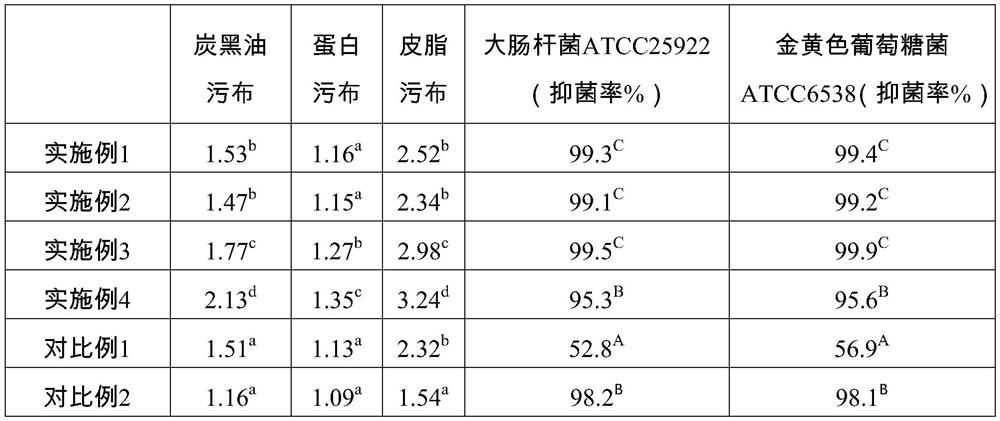

InactiveCN112625812AImprove decontamination abilityGood antibacterial effectNon-ionic surface-active compoundsOrganic detergent compounding agentsBiotechnologyStaphyloccocus aureus

The invention provides an antibacterial and acarus-killing laundry detergent and a preparation method thereof, and belongs to the technical field of detergents. The antibacterial and acarus-killing laundry detergent is prepared from sodium alcohol ether sulphate, cocamidopropyl betaine, coco fatty acid diethanolamide, plant essential oil mixed oil, papain, propylene glycol, potassium laurate, a thickening agent, a preservative and deionized water. According to the antibacterial acarus-killing laundry detergent, sodium alcohol ether sulphate, cocamidopropyl betaine and coco fatty acid diethanolamide are adopted as main components, self-made plant essential oil mixed oil is added, and the antibacterial acarus-killing laundry detergent has the advantages of being super-strong in dirt-removing power, good in antibacterial effect and rich in acarus-killing function through component cooperation and dosage optimization. The decontamination capability of the antibacterial acarus-killing laundry detergent on carbon black oil stain cloth, protein stain cloth and sebum stain cloth is higher than that of a standard laundry detergent; in addition, the sterilization rate of the antibacterial acarus-killing laundry detergent on escherichia coli and staphylococcus aureus reaches 99%, and the acarus-killing rate reaches 91.75%-95.47%.

Owner:合创博远(北京)科技有限公司

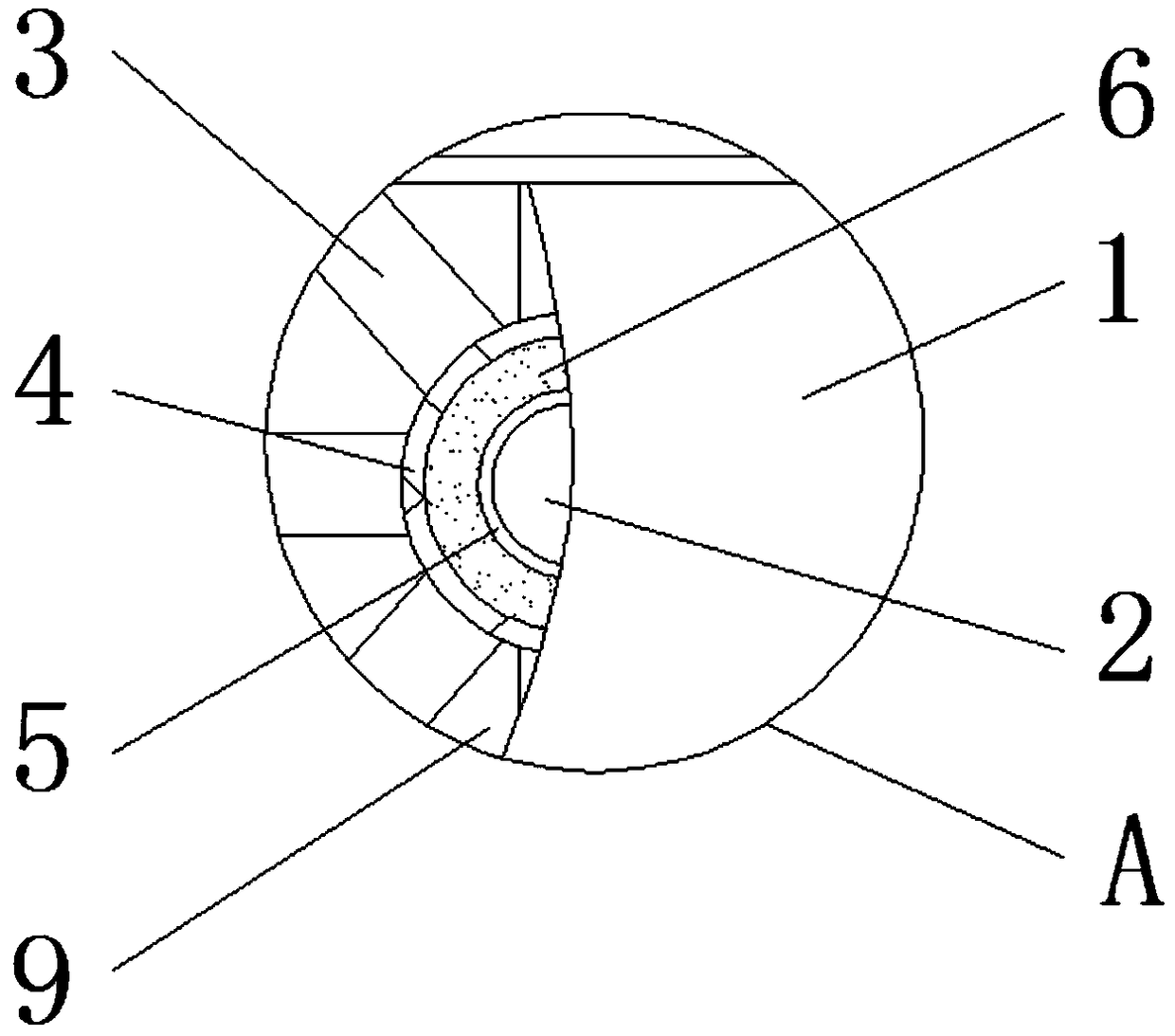

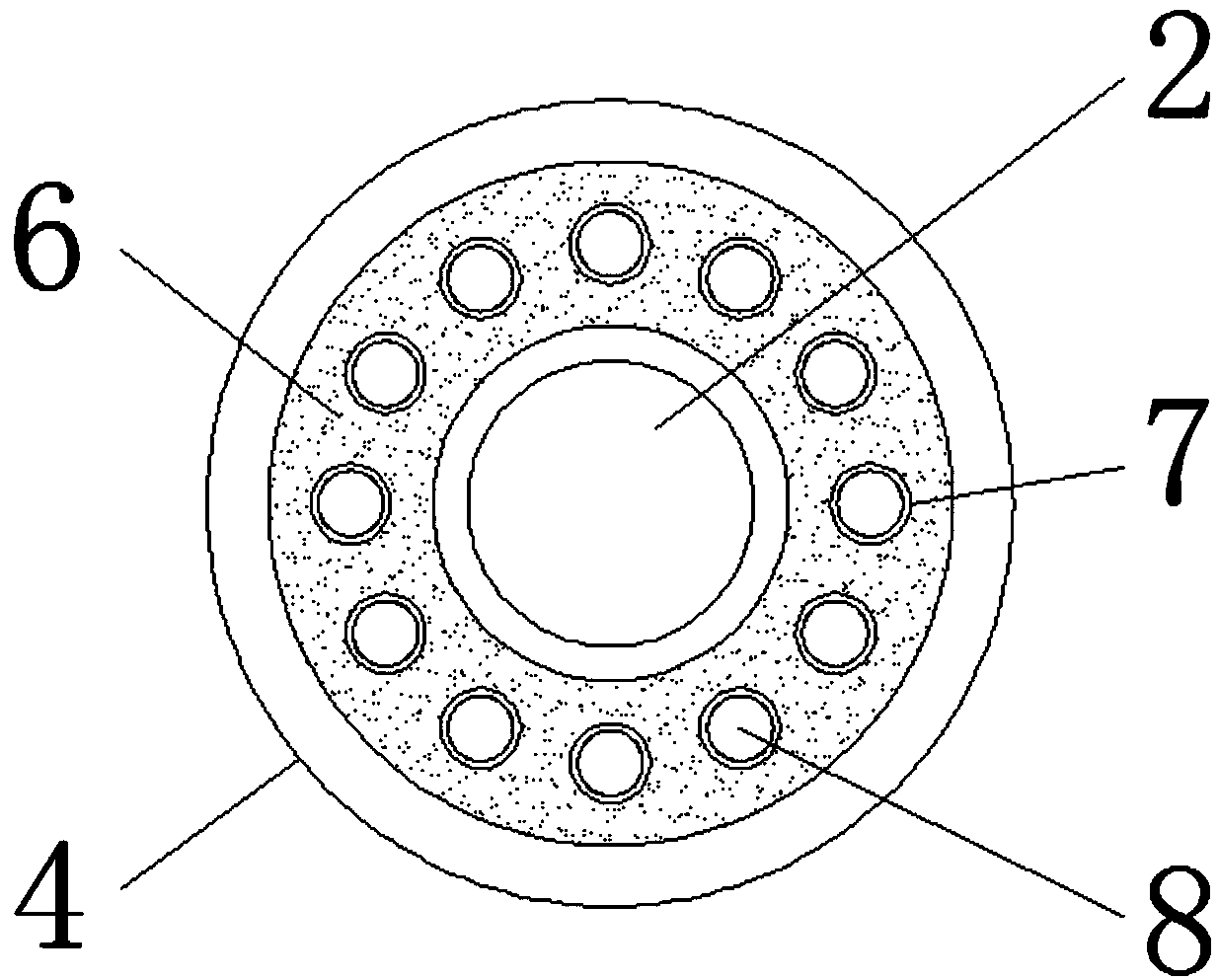

Raw material formula of PU wheel, raw material production process and processing method thereof

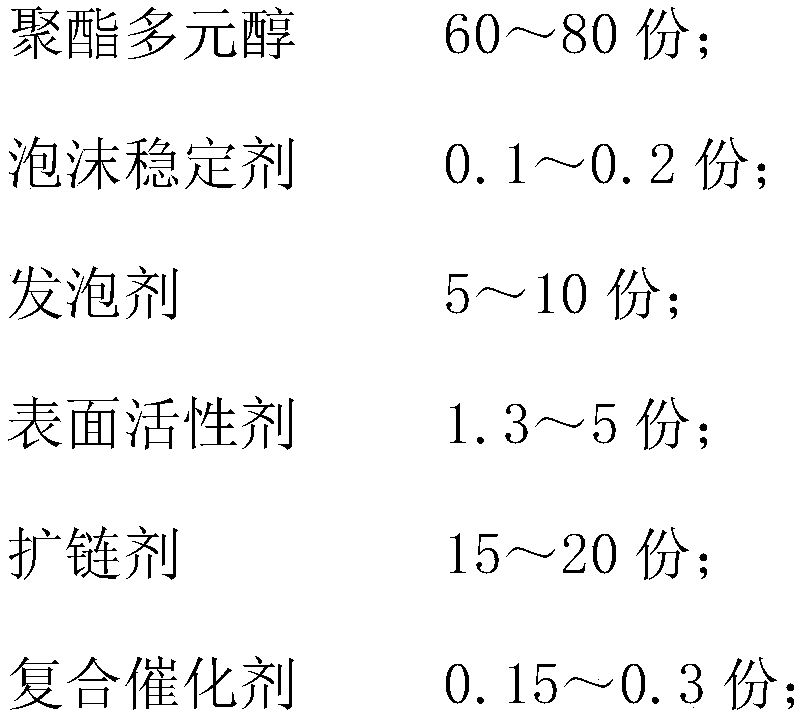

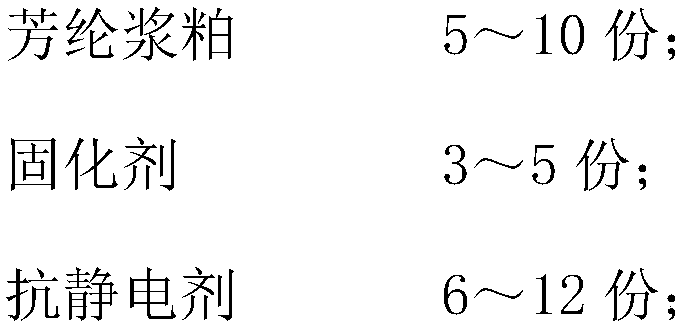

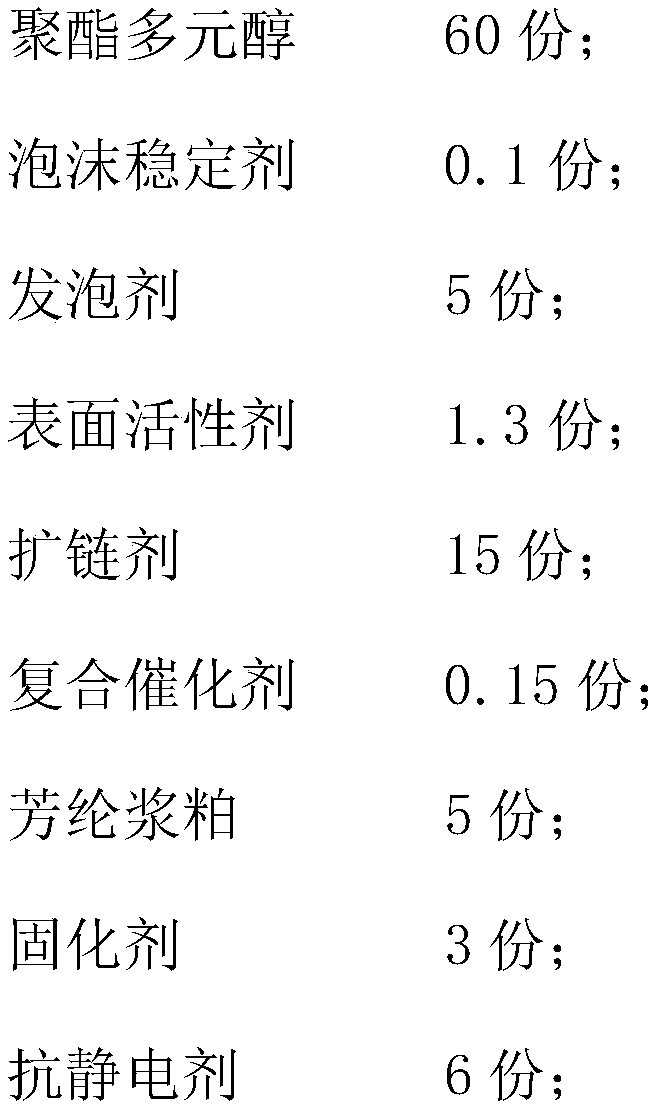

InactiveCN108752909AIncrease elasticityImprove shock absorptionDomestic articlesPolyesterAntistatic agent

The invention discloses a raw material formula of a PU wheel, a raw material production process and a processing method thereof. The raw material formula of the PU wheel comprises a component A and acomponent B, wherein the component A is prepared from the following raw materials in parts by weight: 60-80 parts of polyester polyol, 0.1-0.2 part of foam stabilizer, 5-10 parts of foaming agent, 1.3-5 parts of surfactant, 15-20 parts of chain extender, 0.15-0.3 part of composite catalyst, 5-10 parts of aramid pulp, 3-5 parts of curing agent and 6-12 parts of antistatic agent. The component B isprepared from the following raw materials in parts by weight: 20-50 parts of polyester polyol, 5-30 parts of polyether polyol and 80-90 parts of isocyanate. The PU wheel produced by the formula has elasticity, is excellent in damping effect, strong in road holding force, low in possibility of slippage, high in abrasion resistance, high in tearing strength, high in safety and long in service life.

Owner:江苏唯源橡塑制品有限公司

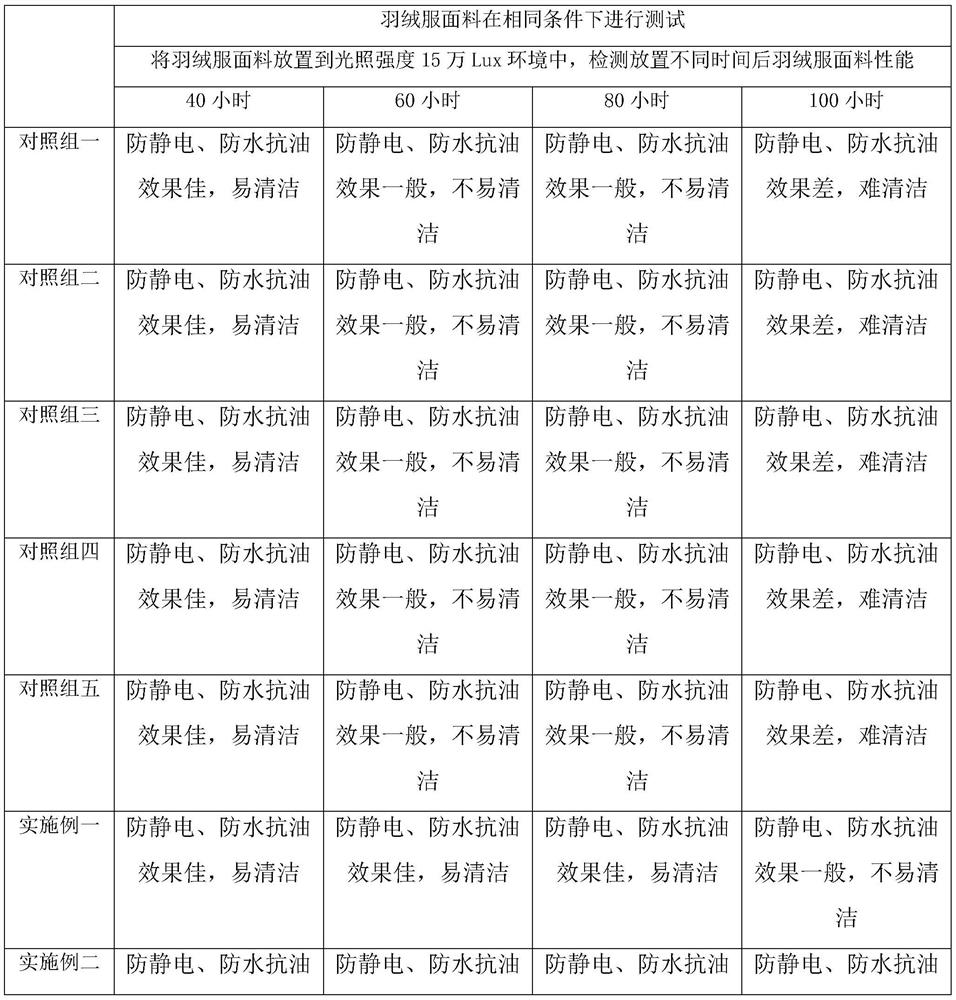

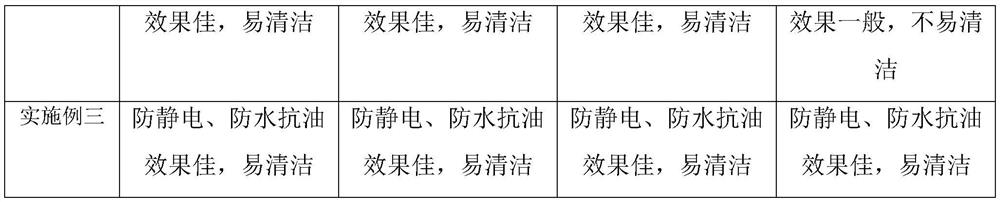

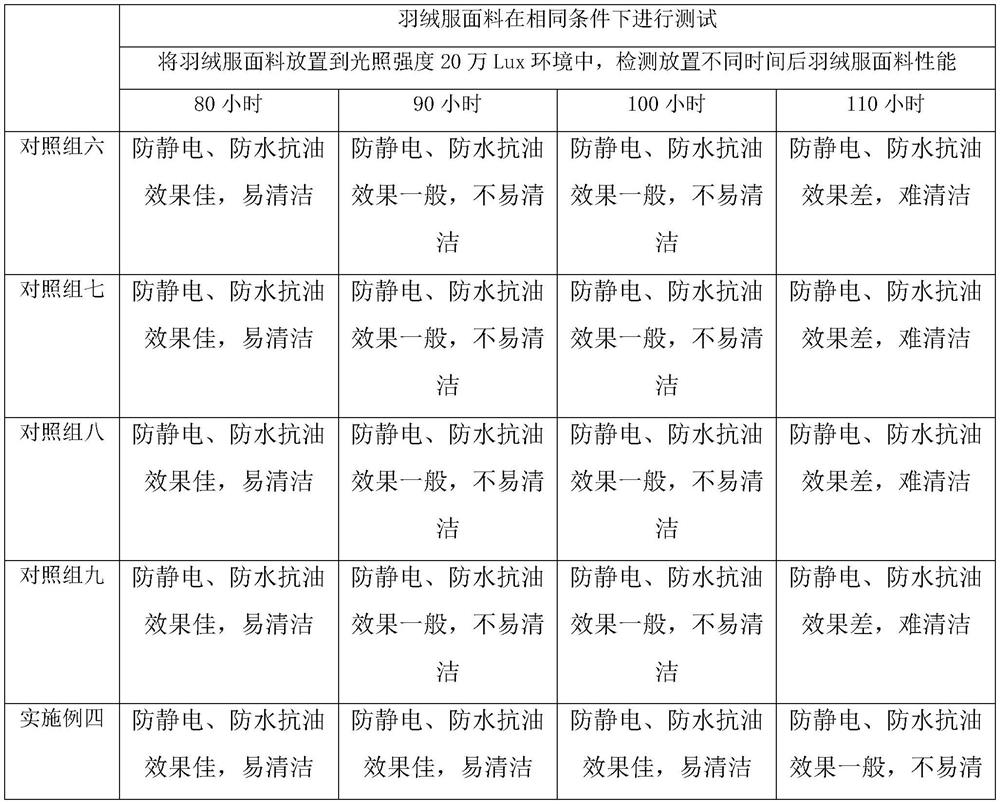

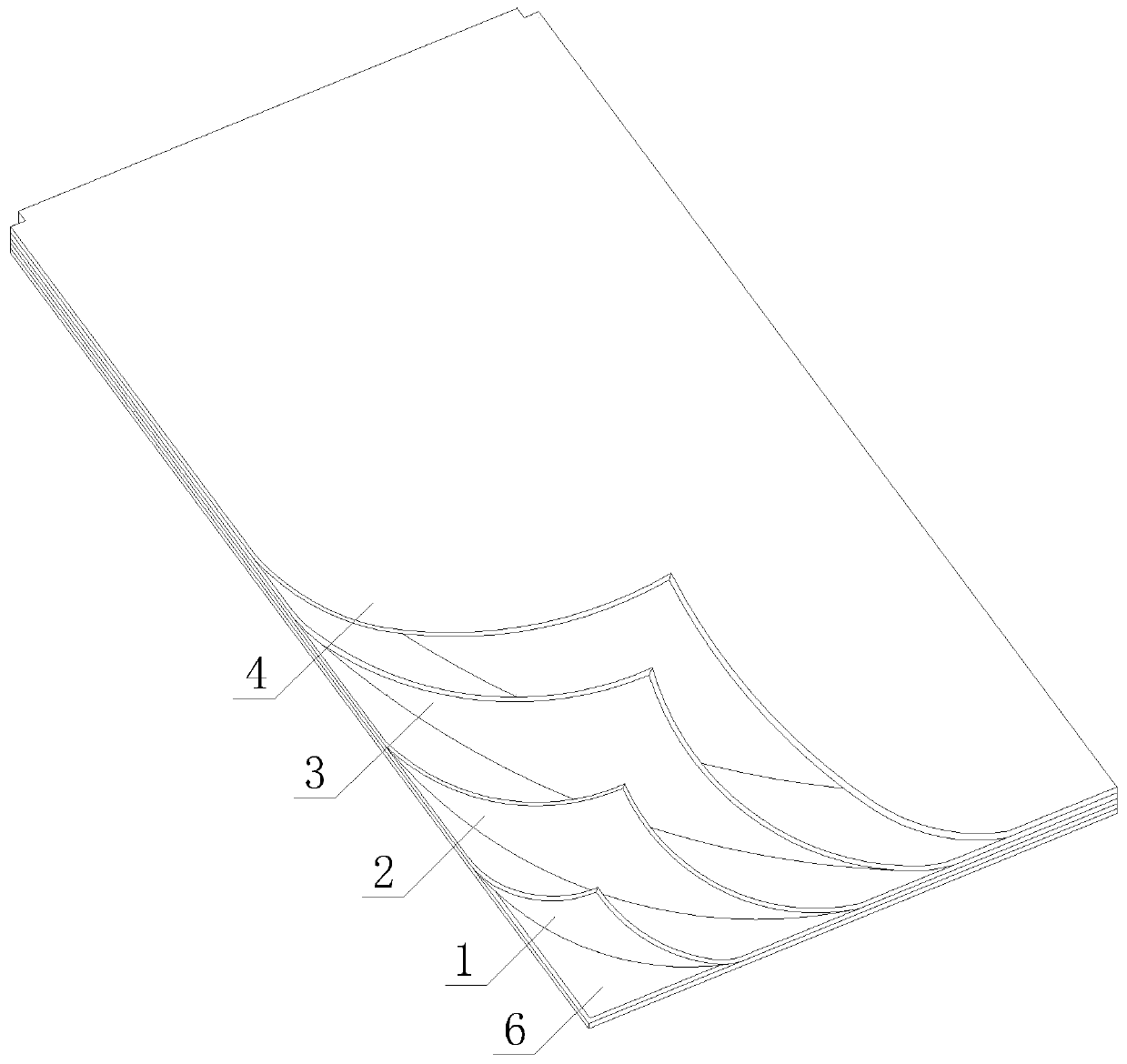

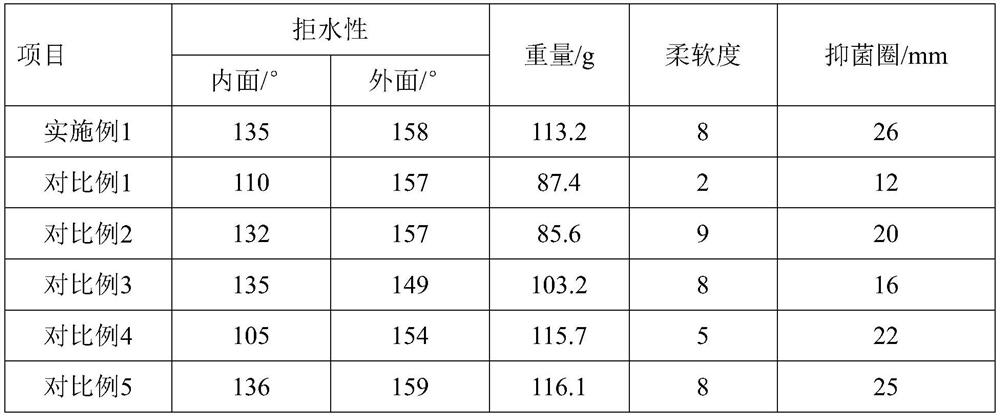

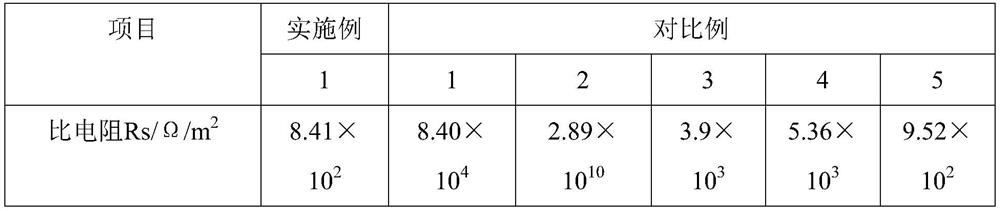

Down jacket fabric with anti-static function and manufacturing process thereof

PendingCN113818251AImprove antibacterial propertiesImprove waterproof performanceBiochemical fibre treatmentLiquid repellent fibresFiberPolymer science

The invention discloses a down jacket fabric with an anti-static function and a manufacturing process thereof, and particularly relates to the technical field of down jacket fabrics. The down jacket fabric comprises base cloth, polyurethane, polytetrafluoroethylene and a composite modifier. According to the invention, the down jacket fabric can still keep good antibacterial, antistatic, waterproof, oil-resistant and easy-to-clean properties after long-time high-intensity illumination; the polyurethane, the polytetrafluoroethylene and nano-silver are matched with one another, so that the breathable and anti-static properties of the base cloth can be effectively enhanced; a fluorine-containing acrylate polymer emulsion can be prepared by compounding, so that the waterproof and anti-static properties of the base cloth can be effectively enhanced; and polyimide fiber supports the nano-silver and nano-titanium dioxide, is compounded with part of chitosan and the fluorine-containing acrylate polymer emulsion, and then is subjected to electrostatic spinning, so that the raw materials can be effectively compounded to prepare composite nano-fiber, and the water resistance, the antibacterial property, the anti-static property and the easy-cleaning property of the base cloth are effectively enhanced.

Owner:浙江迪亚服饰有限公司

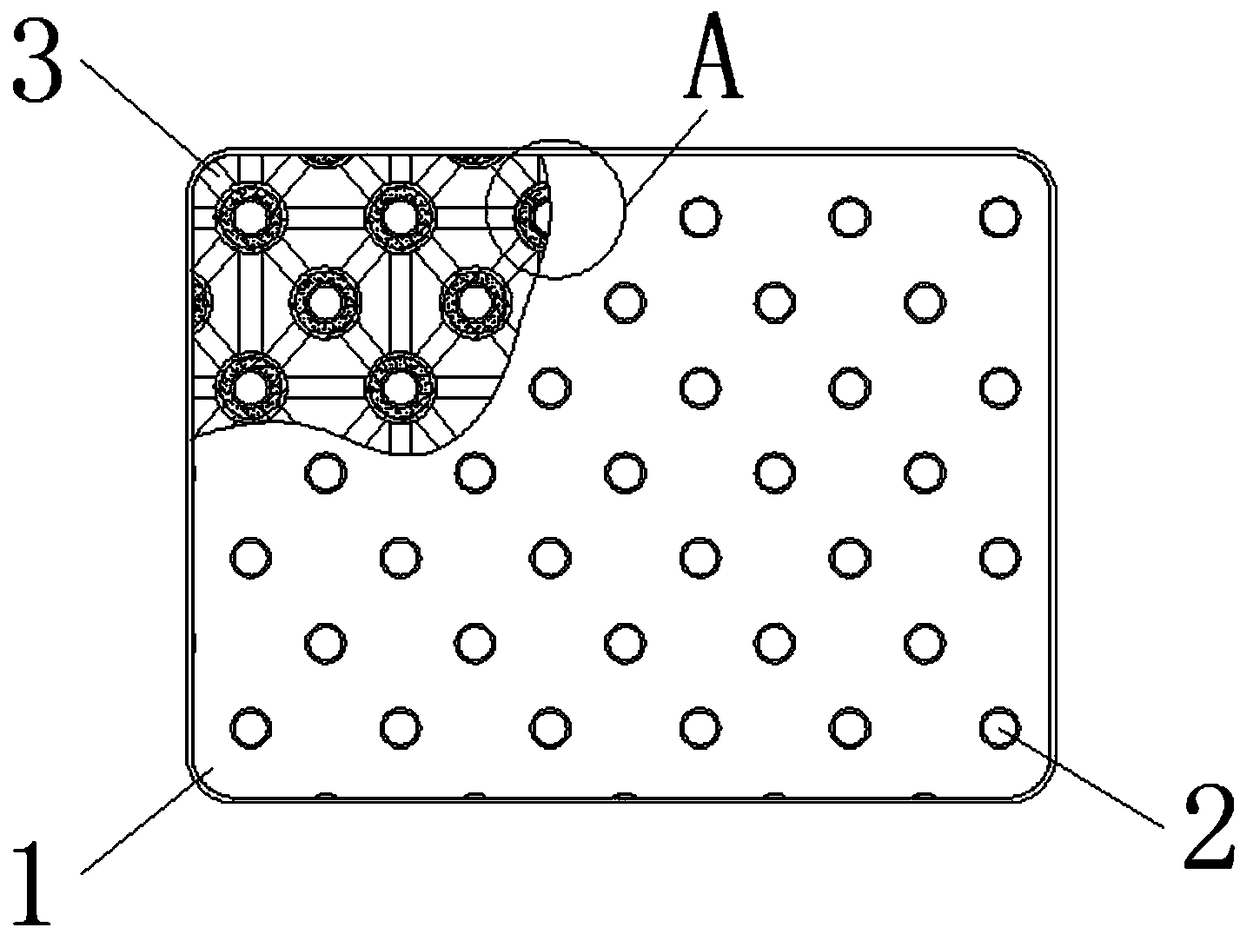

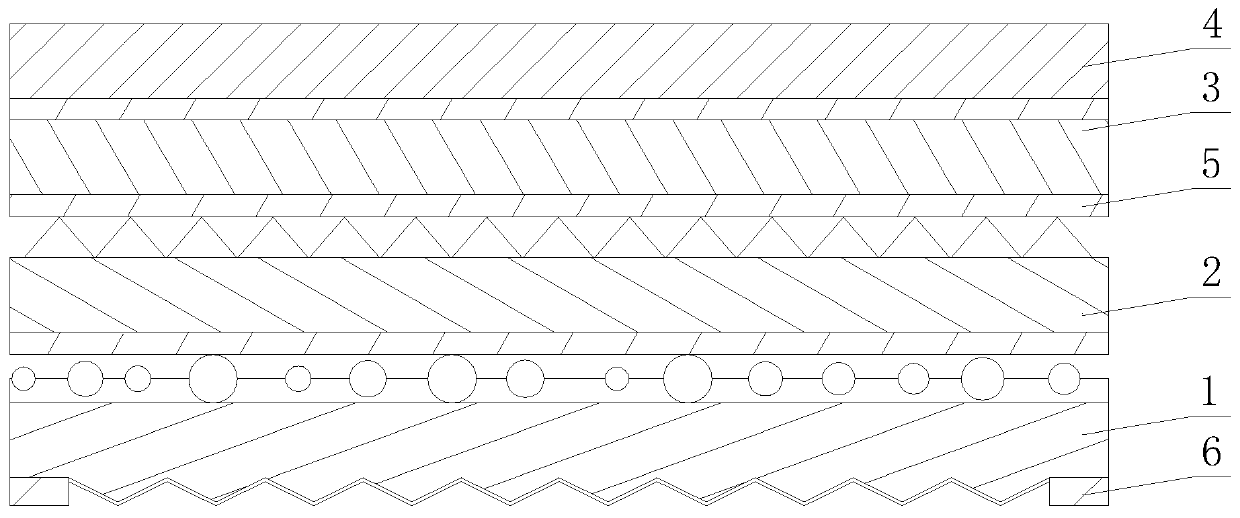

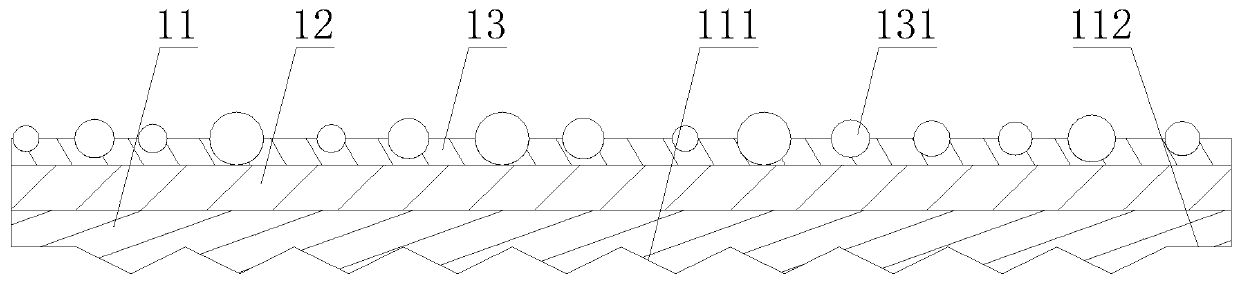

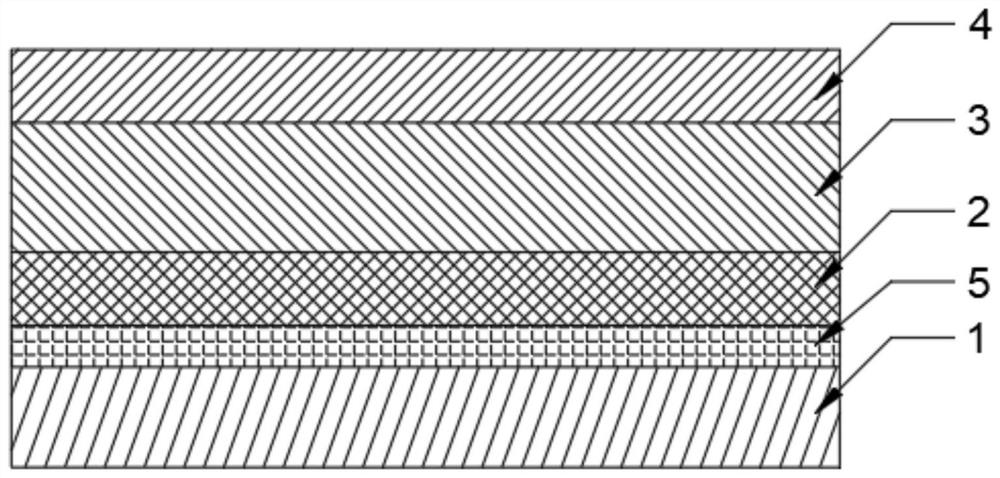

Dynamic backlight LED optical composite film and preparation method thereof

InactiveCN111487700AHigh hardnessImprove stiffnessPrismsDiffusing elementsLight guideDiffuse reflection

The invention discloses a dynamic backlight LED optical composite film and a preparation method thereof. The dynamic backlight LED optical composite film comprises a diffusion film, a brightness enhancement prism film, a polarizing film and a micro lens film, wherein the diffusion film, the brightness enhancement prism film, the polarizing film and the micro lens film are sequentially bonded through glue layers from bottom to top; the lower surface of the diffusion film is connected with an isolation film; and the diffusion film comprises an antistatic layer, a PET substrate layer and a diffuse reflection layer, wherein the lower surface of the PET substrate layer is connected with the upper surface of the antistatic layer. According to the dynamic backlight LED optical composite film andthe preparation method thereof, the antistatic layer is added to the lower surface of a traditional diffusion film, so that the antistatic function of the diffusion film is improved, and the circuit can be effectively protected; in addition, the lower surface of the antistatic layer is provided with the strip-shaped edge grooves and the fixing grooves, so that a deformation space is provided for the diffusion film; meanwhile, the tips of the strip-shaped edge grooves make contact with a light guide plate, so that the diffusion film and the light guide plate can be prevented from being bonded together; and the isolation film is added, so that elasticity is good, softness is achieved, and the optical composite film can be prevented from scratching light guide.

Owner:马鞍山东毅新材料科技有限公司

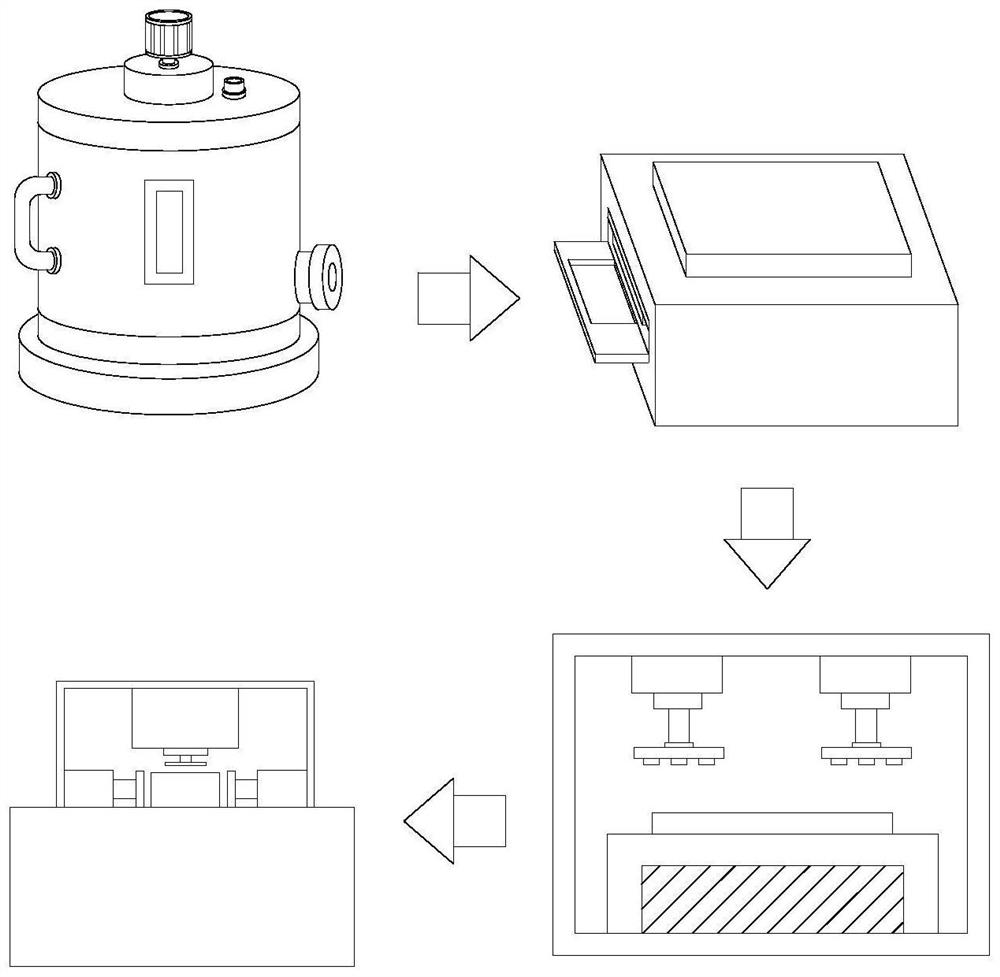

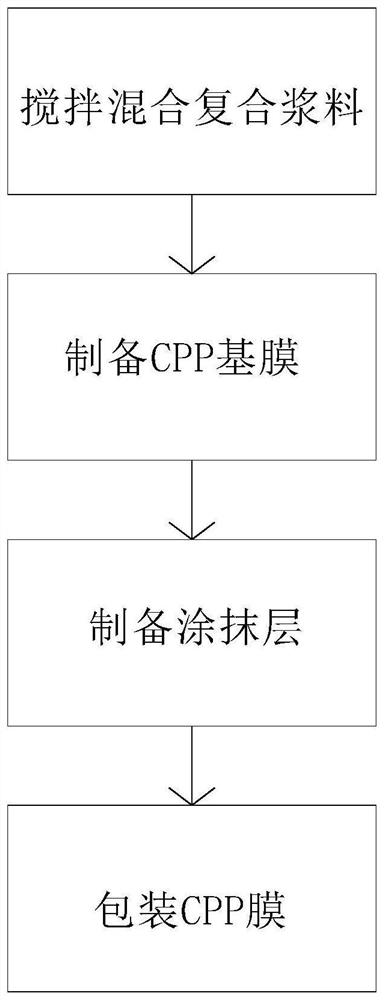

Formula and production process of CPP membrane

InactiveCN114058058AAchieve cleaning effectSolve the dust that is easy to stick, fromCleaning using toolsPolymer scienceSodium Caseinate

The invention discloses a formula and a production process of a CPP membrane, and relates to the technical field of polymeric membranes, the CPP membrane is composed of a CPP base membrane and a coating layer, and the CPP membrane further comprises the following components: 4-12% of dicyandiamide, 12-16% of nano-silica, 5-10% of sodium caseinate, 25-45% of glycerin, 12-23% of chitosan, 4-12% of an antistatic master batch, 3-6% of a polymer microemulsion, and 8-14% of a toughening agent. The two ends of the limiting shaft are limited and fixed through the damping rings, then the extrusion blocks and the buffering pressing columns are matched with each other, the extrusion blocks are driven to extrude the two ends of the limiting shaft through the telescopic elasticity of the buffering pressing columns, the compressing and fixing functions are achieved, the buffering pressing layers and the compressing pads are matched with each other, the buffering pressing layers are stressed to extrude the elastic blocks, and the elastic blocks extrude each other and cooperate with the rebound resilience of the elastic blocks, so that the function of buffering the acting force is achieved, the problem that the cleaning mechanism is poor in fixity and easily shakes is solved, the stability of the device is improved, and the cleaning efficiency of the cleaning mechanism is improved.

Owner:徐州宏恩包装新材料有限公司

Vacuum nano waterproof breathable fabric and application thereof

PendingCN113910701AAdd anti-static functionApplicable to wearChemical protectionHeat protectionChemistryCotton fibre

The invention relates to a vacuum nano waterproof breathable fabric, and belongs to the technical field of fabrics. The vacuum nano waterproof breathable fabric comprises a built-in layer, a cloth base material, a nano waterproof layer and a nano water-repellent plating. The built-in layer and the nano waterproof layer are respectively compounded on the two sides of the cloth base material through hot pressing. The nano water-repellent plating layer is formed by depositing a layer of film on the nano waterproof layer in a vacuum nano coating mode. The built-in layer is formed by weaving modified polyimide fibers and cotton fibers treated by water-repellent finishing liquid. By compounding the built-in layer, the cloth base material, the nano waterproof layer and the nano water-repellent plating layer, the fabric has excellent waterproof and breathable effects and certain softness, and meanwhile, the fabric is anti-static, bacteriostatic and flame-retardant.

Owner:GAOFAN (ZHEJIANG) INFORMATION TECH CO LTD

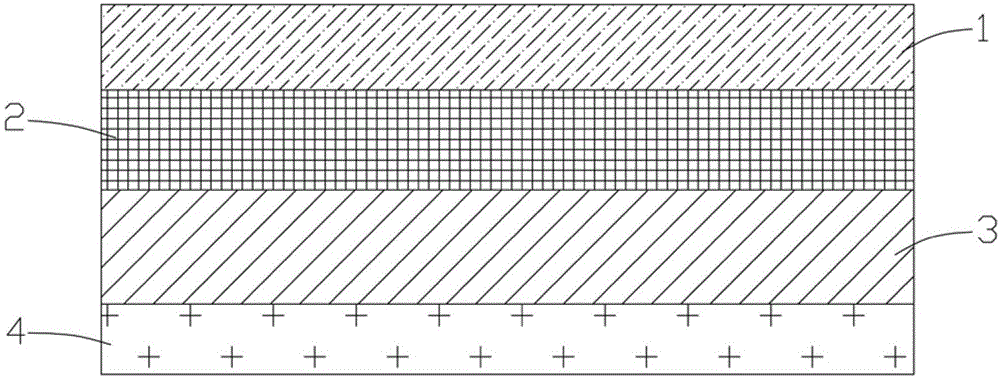

Acrylic anti-static plate

InactiveCN112430440AAdd anti-static functionImprove cleanlinessFilm/foil adhesivesPolyureas/polyurethane adhesivesPolymer scienceAcrylic adhesive

The invention discloses an acrylic anti-static plate. The acrylic anti-static plate comprises a bottom layer, an acrylic adhesive layer, a transparent acrylic thin plate layer and an anti-static coating, wherein the acrylic anti-static plate comprises the bottom layer, the acrylic adhesive layer, the transparent acrylic thin plate layer and the anti-static coating from top to bottom. The bottom layer is used for improving the bonding strength when the acrylic anti-static plate is bonded with other articles. An anti-static material is contained in the acrylic adhesive layer, so that the acrylicadhesive layer also has an anti-static function while playing a role in adhesion. In order to further improve the anti-static function of the acrylic anti-static plate, the anti-static coating is sprayed on the surface of the transparent acrylic thin plate layer, and the anti-static capacity of the acrylic anti-static plate is further improved. In conclusion, the acrylic anti-static plate disclosed by the invention has an anti-static function, so that dust is prevented from being adsorbed on the acrylic plate due to electrostatic adsorption, and the acrylic plate has the advantage of keepingself-cleanness.

Owner:瑞昌荣联环保科技有限公司

An additive for improving the printing performance of composite white cardboard and its preparation method

The invention discloses an auxiliary capable of improving printing performance of a composite ivory board and a preparation method thereof. The auxiliary is prepared from, by weight, 10-20 parts of inorganic zinc salt, 10-20 parts of inorganic additive, 0.5-1 part of surfactant, 0.5-1 part of dispersant and 60-80 parts of deionized water. ZnO nano acanthosphere particles after surface modification are adopted as the auxiliary in the process of printing the composite ivory board; the ZnO nano acanthosphere particles have siphon microstructure, and an active agent is adopted for chemical surface modification, so that ink absorptivity of the composite ivory board can be further improved.

Owner:贵州金马包装材料有限公司

A kind of (meth)acrylated oxazole heterocyclic borate and its preparation method and application

InactiveCN102225945BLower surface resistivityAdd anti-static functionInksGroup 3/13 element organic compoundsMethacrylatePolymer science

The invention discloses a (methyl) acrylate oxazole heterocycle borate compound, which is annular borate containing (methyl) acrylate group and tertiary amine composition. The invention also discloses a preparation method of the compound. The method comprises the steps that: bi-functional (methyl) acrylate compound or tri-functional (methyl) acrylate compound is subject to a reaction with N,N-bi(hydroxyalkyl)secondary amine; through a Michael addition reaction upon acrylate group, (methyl) acrylate with N,N-bi(hydroxyalkyl)amid is obtained; Under the coexistence of a desiccant and a polymerization inhibitor, (methyl) acrylate with N,N-bi(hydroxyalkyl)amid is subject to a condensation reaction with boric acid, such that (methyl) acrylate azacyclo-borate is obtained. The (methyl) acrylate oxazole heterocycle borate prepared by the present invention can be applied to the fields of light-cured paint, printing ink or adhesive, and has good anti-hydrolytic stability, adhesive performance, wear resistance and antistatic performance.

Owner:SUN YAT SEN UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com