Formula and production process of CPP membrane

A technology of production process and formula, applied in the direction of cleaning methods using tools, cleaning methods and utensils, chemical instruments and methods, etc., can solve the problems of decreased cleaning effect of cleaning columns, poor fixability of cleaning mechanisms, easy adhesion of dust to container tanks, etc. Achieve the effect of improving the quality of processing, increasing the cleaning function, and not easy to break

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0036] First, as Figure 1-7 As shown, the present invention provides a formula of a CPP film, including a CPP film, the CPP film is composed of a CPP base film and a coating layer, and the CPP film also includes the following components:

[0037]

[0038] A composite slurry is prepared by mixing nano-silica and sodium caseinate, which is mixed with CPP resin and cast to form a film to obtain a CPP base film. The polymer microemulsion is composed of 15-25% emulsifier and 60% water. -70% mixed with water-based initiator 10-15%.

[0039] In this embodiment, dicyandiamide, chitosan, glycerin, nano-silica and sodium caseinate are mixed and stirred according to the proportion, and then mixed with CPP resin to form a film block, and then proportioned and applied. The formula of the layer is a polymer microemulsion made by mixing 15-25% of emulsifier, 60-70% of water and 10-15% of water-based initiator, and then mixed with antistatic masterbatch and toughening agent to make spra...

Embodiment 2

[0041] Second, as Figure 1-7 As shown, the present invention also provides a production process of a CPP film formulation, the production process of the formulation of the CPP film, comprising the following steps:

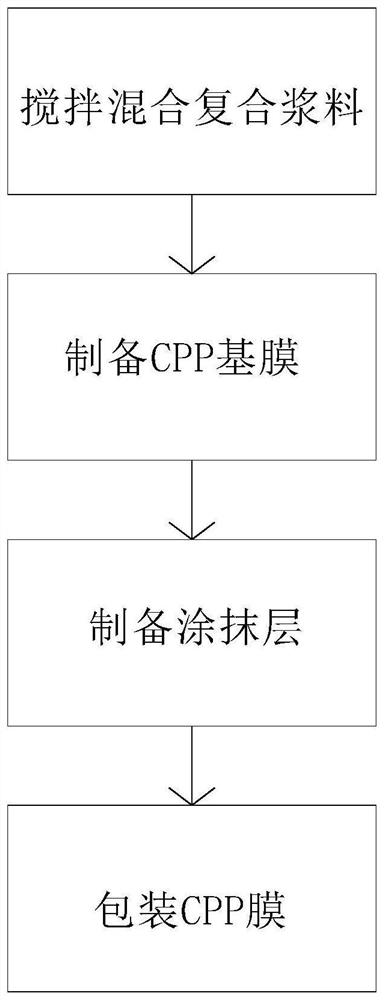

[0042] Step 1, stirring and mixing the composite slurry;

[0043] Step 2, preparing the CPP base film;

[0044] Step 3, prepare the coating layer;

[0045] Step 4, packing CPP film;

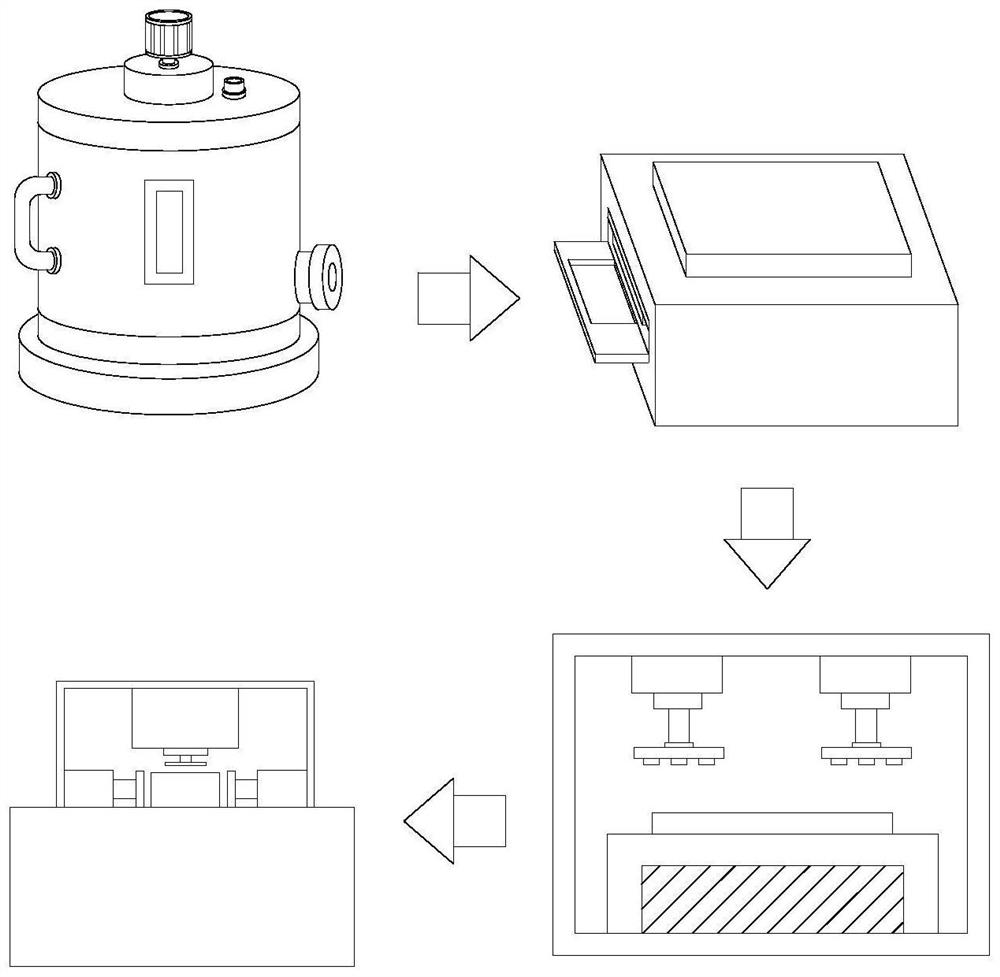

[0046]Step 1 also includes: injecting chitosan, dicyandiamide and glycerin into the stirring device according to the proportioning ratio, and placing nano-silicon dioxide and sodium caseinate inside the stirring device for mixing and stirring, and the second step further includes: The mixed materials are placed inside the preparation container, mixed with CPP resin and solidified to form a film to obtain a CPP base film, and then the polymer microemulsion, antistatic masterbatch and toughening agent are sprayed on the surface of the CPP base film by a spraying mechanism. Thereby,...

Embodiment 3

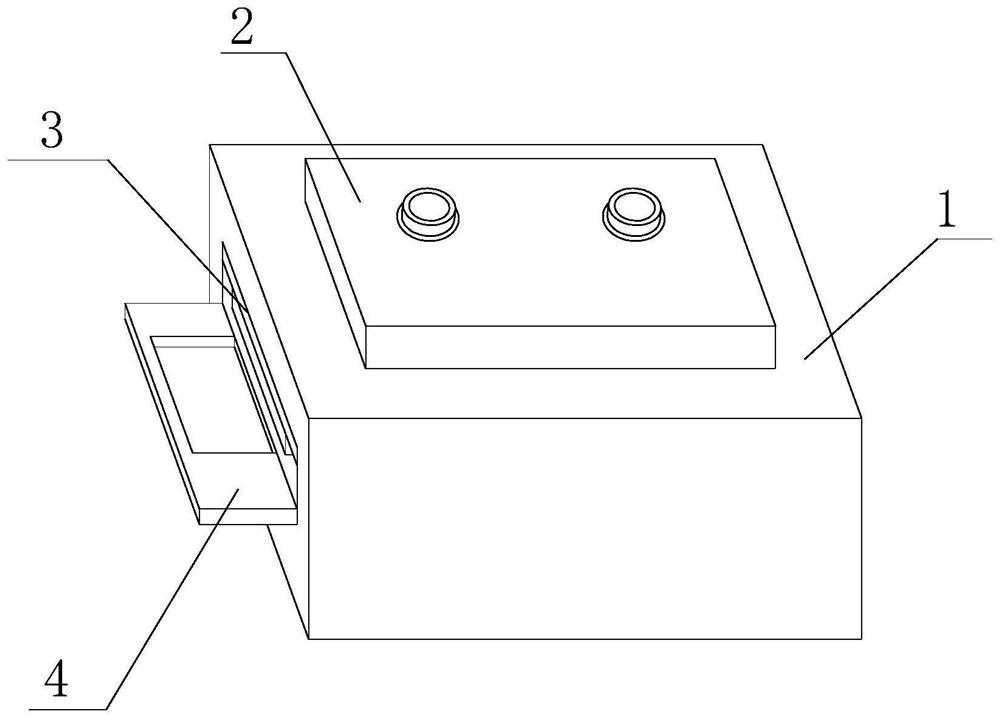

[0049] like Figure 1-7 As shown, on the basis of Example 2, the present invention provides a technical solution: preferably, the preparation container includes a shell body 1, a spraying device 2, a moving groove 3 and a container plate 4, and the top of the shell body 1 is fixedly installed with a spray coating Equipment 2, a moving groove 3 is opened on one side of the main body 1 of the casing, a container plate 4 is movably installed inside the moving groove 3, a cleaning channel is opened on one side of the container plate 4, and a preparation groove 41 is opened inside the container plate 4. Sliding slots 45 are arranged on both sides of the inside of the slot 41, and a sliding column 44 is arranged inside the sliding slot 45. A sliding block 43 is movably installed on the outer side of the sliding column 44, and a telescopic rod 46 is arranged on one side of the sliding block 43. The other end of the sliding block 43 is fixedly connected to the inside of the sliding gr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com