An additive for improving the printing performance of composite white cardboard and its preparation method

A technology of composite white cardboard and additives, which is applied in the field of papermaking, can solve the problems of composite white cardboard such as difficult adhesion, printing, and high static electricity, and achieve the effects of increasing antistatic function, improving ink absorption, and increasing ink wettability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

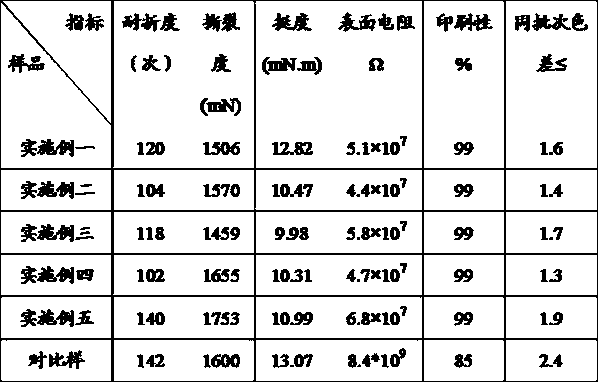

Examples

Embodiment 1

[0030] This embodiment includes the following steps:

[0031] 1) Preparation of ZnO nano thorn ball particles;

[0032] Under the condition that the temperature of the deionized water is raised to 30°C, high-purity argon gas with a purity of 99.95% is passed into the deionized water for 0.5 h, and after the oxygen in the pure water is removed, an inorganic zinc salt is added, And keep stirring, set the stirring speed to 800rpm, and the stirring time to 0.2h, then add the dispersant, stir for 0.2h to make the solution mix evenly, and obtain the mixed liquid A;

[0033] Add inorganic additives to the mixed solution A, adjust the pH value to 8, continue to stir for 0.3h, and pass argon into the mixed solution A, heat the mixed solution A, and evaporate the mixed solution A After moisture, reflux and cool down to room temperature to obtain solution B containing ZnO nano thorn ball particles, wherein the heating rate is set to 6-8°C / min, and the cooling rate is set to 5-8°C / min. ...

Embodiment 2

[0039] This embodiment includes the following steps:

[0040] 1) Preparation of ZnO nano thorn ball particles;

[0041] Under the condition that the temperature of the deionized water is raised to 50°C, high-purity argon gas with a purity of 99.95% is introduced into the deionized water for 1 hour, after the oxygen in the pure water is removed, an inorganic zinc salt is added, and Stir continuously, set the stirring speed to 1000rpm, and the stirring time to 0.2h, then add the dispersant, stir for 0.2h to make the solution mix evenly, and obtain the mixed solution A;

[0042] Add inorganic additives to the mixed solution A, adjust the pH value to 8.5, continue stirring for 0.4h, and pass argon gas into the mixed solution A, heat the mixed solution A, and evaporate the mixed solution A After moisture, reflux and cool down to room temperature to obtain solution B containing ZnO nano thorn ball particles, wherein the heating rate is set to 6-8°C / min, and the cooling rate is set ...

Embodiment 3

[0048] This embodiment includes the following steps:

[0049] 1) Preparation of ZnO nano thorn ball particles;

[0050] Under the condition that the temperature of the deionized water is raised to 70°C, high-purity argon gas with a purity of 99.95% is introduced into the deionized water for 1 hour. After the oxygen in the pure water is removed, an inorganic zinc salt is added, and Stir continuously, set the stirring speed to 1500rpm, and the stirring time to 0.2h, then add the dispersant, stir for 0.2h to make the solution mix evenly, and obtain the mixed solution A;

[0051] Add inorganic additives to the mixed solution A, adjust the pH value to 9, continue to stir for 0.5h, and pass argon into the mixed solution A, heat the mixed solution A, and evaporate the mixed solution A After moisture, reflux and cool down to room temperature to obtain solution B containing ZnO nano thorn ball particles, wherein the heating rate is set to 6-8°C / min, and the cooling rate is set to 5-8°...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com