Color management method and device of maximized uncoated paper printing color gamut

A color management and printing color technology, applied in printing devices, printing, padding devices, etc., can solve the problems of unfavorable artwork reproduction design intentions, small color gamut of uncoated paper, etc., to improve printing quality and reduce manufacturing processes , the effect of a friendly environment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

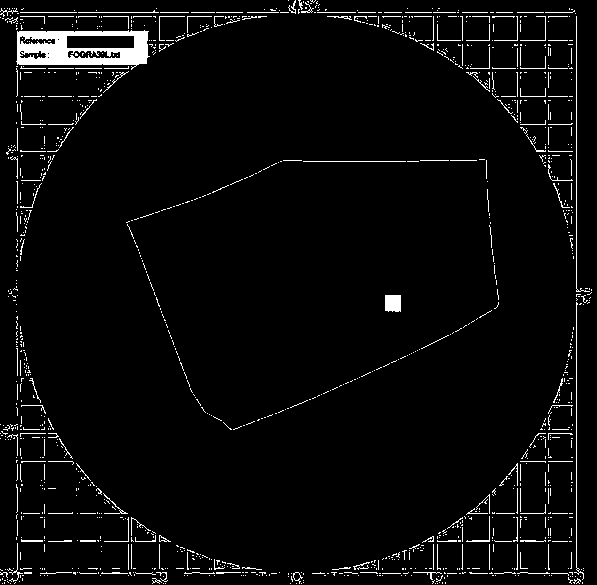

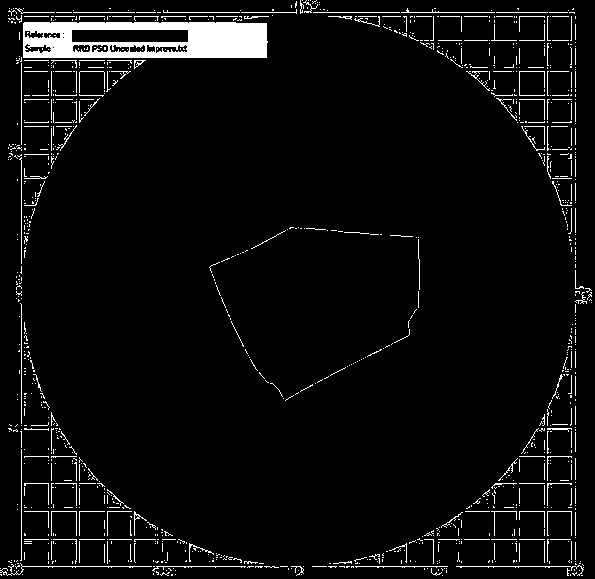

Image

Examples

Embodiment Construction

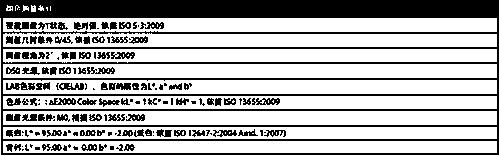

[0031] The invention discloses a color management method for maximizing the printing color gamut of uncoated paper, which includes the following steps:

[0032] (1) Through the pre-press setting, set the dot shape to compound screening: less than 30% and more than 70% are 20u FM nets, and 30%-70% are square-circle nets, so as to increase the spread of dots in different secondments and expand Ink reflection area improves visual perception of color. Using FM mesh at a tone below 30% can increase the spread of ink on the paper surface and expand the ink reflection surface; using FM mesh at a tone above 70% can reduce the accumulation of ink on the paper surface while increasing the ink density .

[0033] (2) Through the pre-press publishing compensation curve setting: reduce the dot expansion of CMYK to 13-16%, to increase the image tone level.

[0034] (3) Increase the four-color density value of the printing ink to C 1.20-1.25 M 1.20-1.25 Y 0.95 K 1.25-1.30, and the saturated...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com