Thermal dye sublimation transfer paper suitable for on-line high-speed production

A high-speed production, sublimation technology, applied in printing, paper, papermaking and other directions, can solve the problems of high ink penetration, low transfer rate, low printing accuracy, etc., to achieve high transfer rate, fast drying speed, high printing accuracy Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

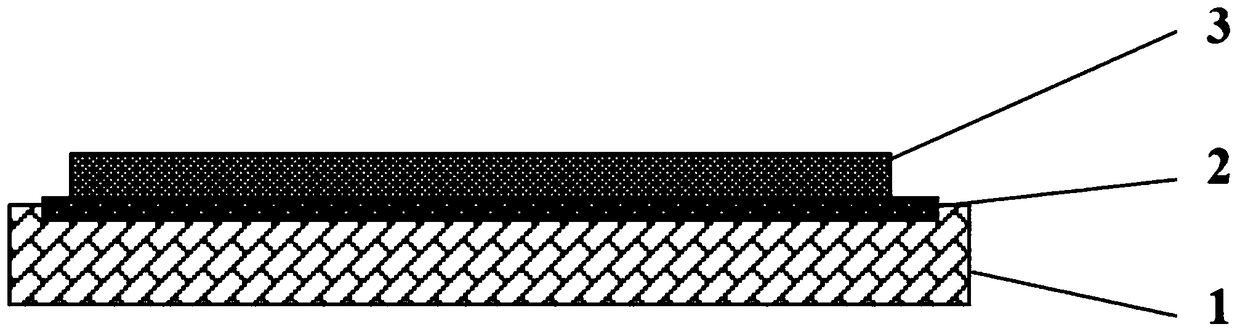

[0020] See figure 1 The thermal sublimation transfer paper of the present invention comprises a base paper 1, a sizing layer 2 and a coating layer 3 formed of soft polymer glue that are successively covered on one side of the base paper 1 along the thickness direction of the base paper 1, through which the sizing layer can Reduce the penetration of ink in the paint layer into the base paper. When sizing, the sizing material can penetrate into all base paper 1 coated with the sizing material.

[0021] The sizing material of the sizing layer 2 is prepared by sizing agent, filling material and auxiliary agent, wherein the sizing agent, filling material and auxiliary agent are respectively 30-80 parts, 10-30 parts, 1 -10 copies. The sizing agent contains any one or more of polyvinyl alcohol, alkyl ketene dimer, alkenyl succinic anhydride, carboxymethyl cellulose, styrene-maleic anhydride copolymer, and modified oxidized starch. The proportion of the composition, the sizing agen...

Embodiment 2

[0027] This embodiment is the method for producing the sublimation transfer paper in the first embodiment.

[0028] The method is an in-machine production from base paper forming to surface sizing to in-machine coating for one-time forming, specifically including the following steps:

[0029] Step 1: Copy base paper 1.

[0030] The pulp used to make base paper 1 is formed and dried on a high-speed paper machine to obtain unsized base paper 1 . Wherein, the composition and preparation of the base paper 1 slurry can be the composition and preparation of the base paper 1 slurry commonly used in the field, so it will not be repeated here.

[0031] Step 2: In the high-speed paper machine, the sizing material is embedded in the inner surface layer of the base paper 1 obtained in the step 1 to form a sizing layer 2 by means of roller sizing, wherein the sizing amount is 0.5-2g / m 2 .

[0032] Before sizing, it is necessary to configure the sizing material for configuring the sizing...

Embodiment 3

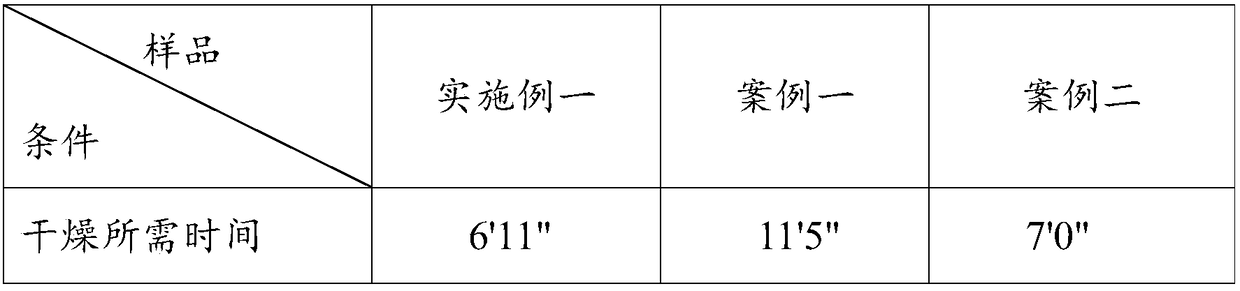

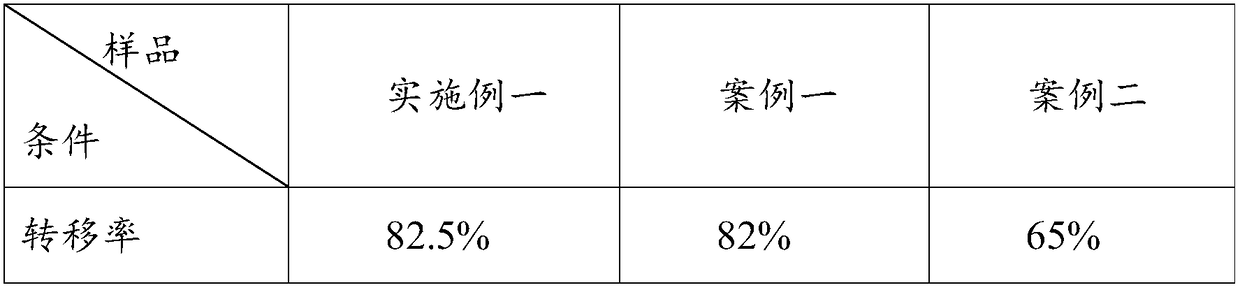

[0041] This embodiment is to compare the drying speed and transfer rate of the thermal sublimation transfer paper in Example 1 with the drying speed and transfer rate of the thermal sublimation transfer paper in the prior art. Two cases: Case 1, the sublimation transfer paper coated outside the machine on the market; Case 2, the sublimation transfer paper coated inside the machine sold on the market.

[0042] The following is a further description of the two important technical indicators of the drying speed and transfer rate of the sublimation transfer paper.

[0043] (1) Drying speed

[0044] The printing drying speed of sublimation transfer paper is usually combined with the actual application situation, and the evaluation method of printing drying speed based on the principle of bonding and sticking is developed. That is to choose a color block with a darker color (the darker color pattern has a large amount of printing ink, and the drying speed is usually slower after prin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com