Patents

Literature

382results about How to "Does not increase production costs" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Copper alloy with no lead

This invention relates to a Pb-free Cu alloy, especially a Pb-free machinable Cu alloy, which is composed of: Cu 55.0-89%, Zn 3.0-45%, Sn 0.1-10%, Ni 0.1-2.0%, Si 0-5.0%, Bi 0.1-5.0%, Se 0-3.0%, Al 0.01-1.0%, P 0.05-0.15%, and RE 0.01-0.5%. RE, Bi, Se and P are added respectively in the forms of RE-Cu intermediate alloy, Cu-Bi intermediate alloy, Cu-Se intermediate alloy and P-Cu intermediate alloy, or RE, Bi, Se and P are added respectively in the forms of Bi-Se alloy and P-Cu alloy. This invention can eliminate harmful effects on environment and human bodies caused by Pb during production and recovery process. The Cu alloy has good machinability, mechanical properties, processability and fluidity, and has no thermal splitting. The production method is simple, and can produce the Cu alloy by using the present apparatus for producing lead-brass alloy. Besides, the contents of Se, Bi and RE are low,.

Owner:JIANGXI UNIV OF SCI & TECH

Industrialized preparation method of WC-Co hard alloy with low cost and high performance

ActiveCN101624673ASolve the problem that it is difficult to mix evenlyReduce energy consumptionPolyethylene glycolPrice ratio

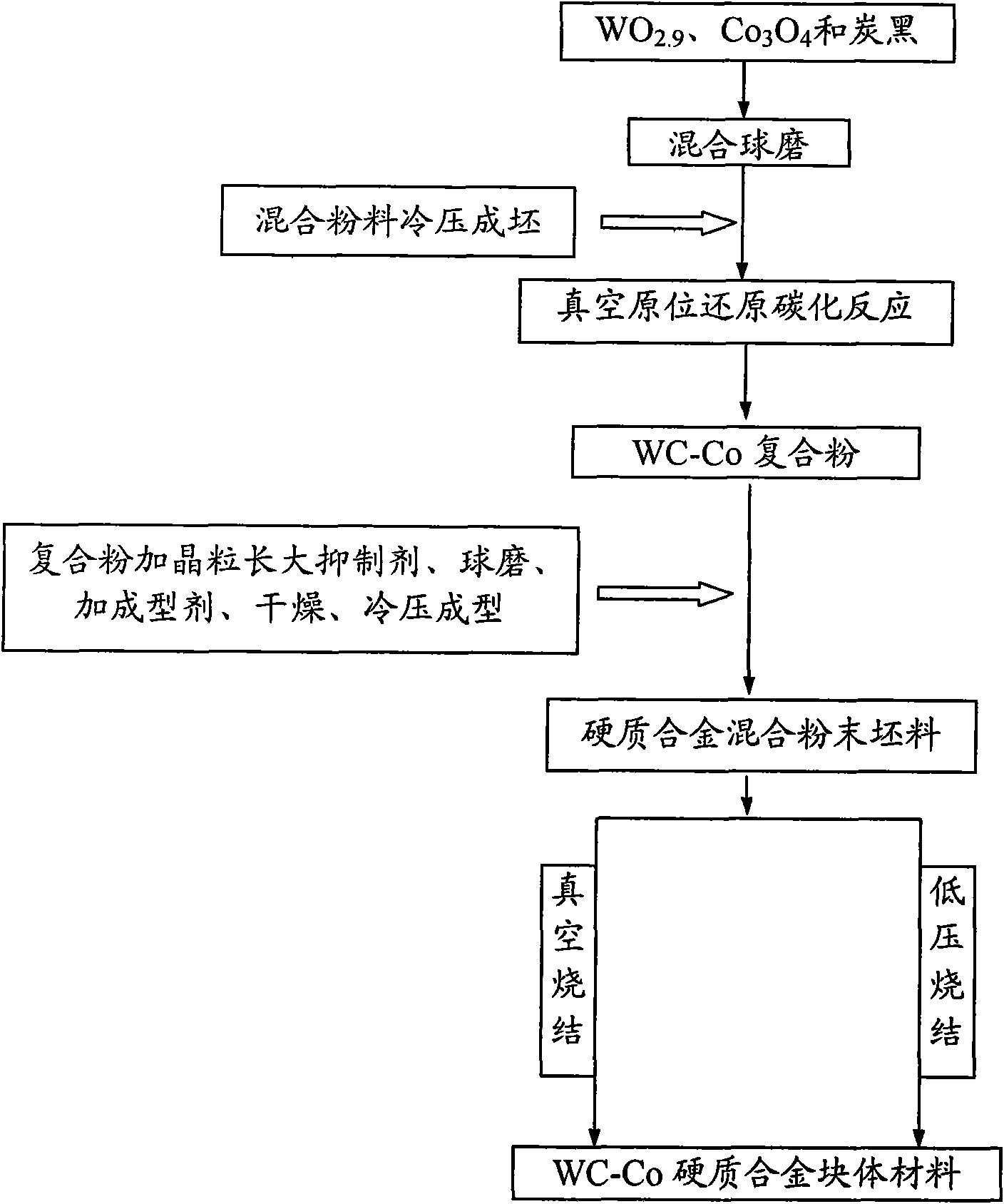

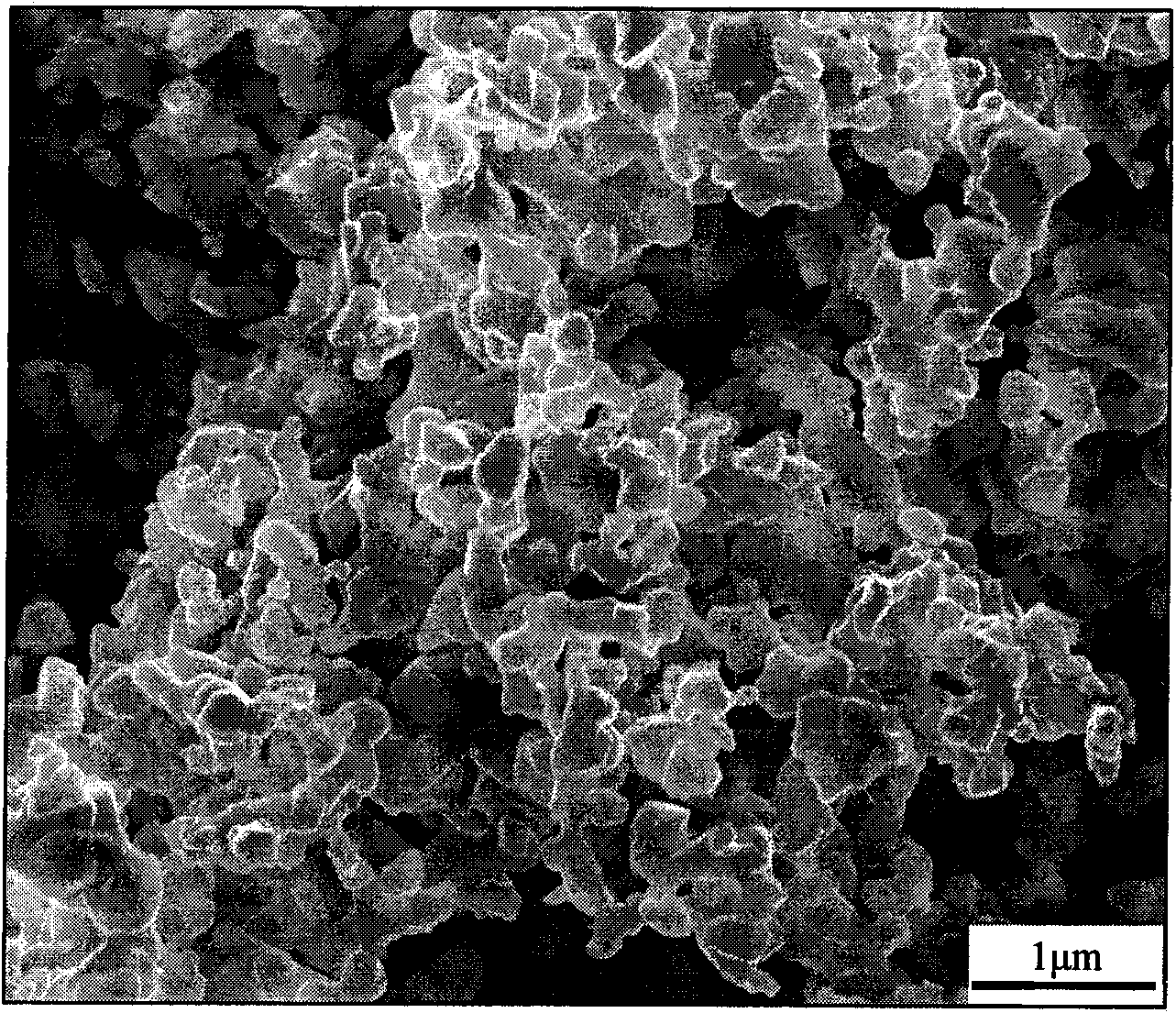

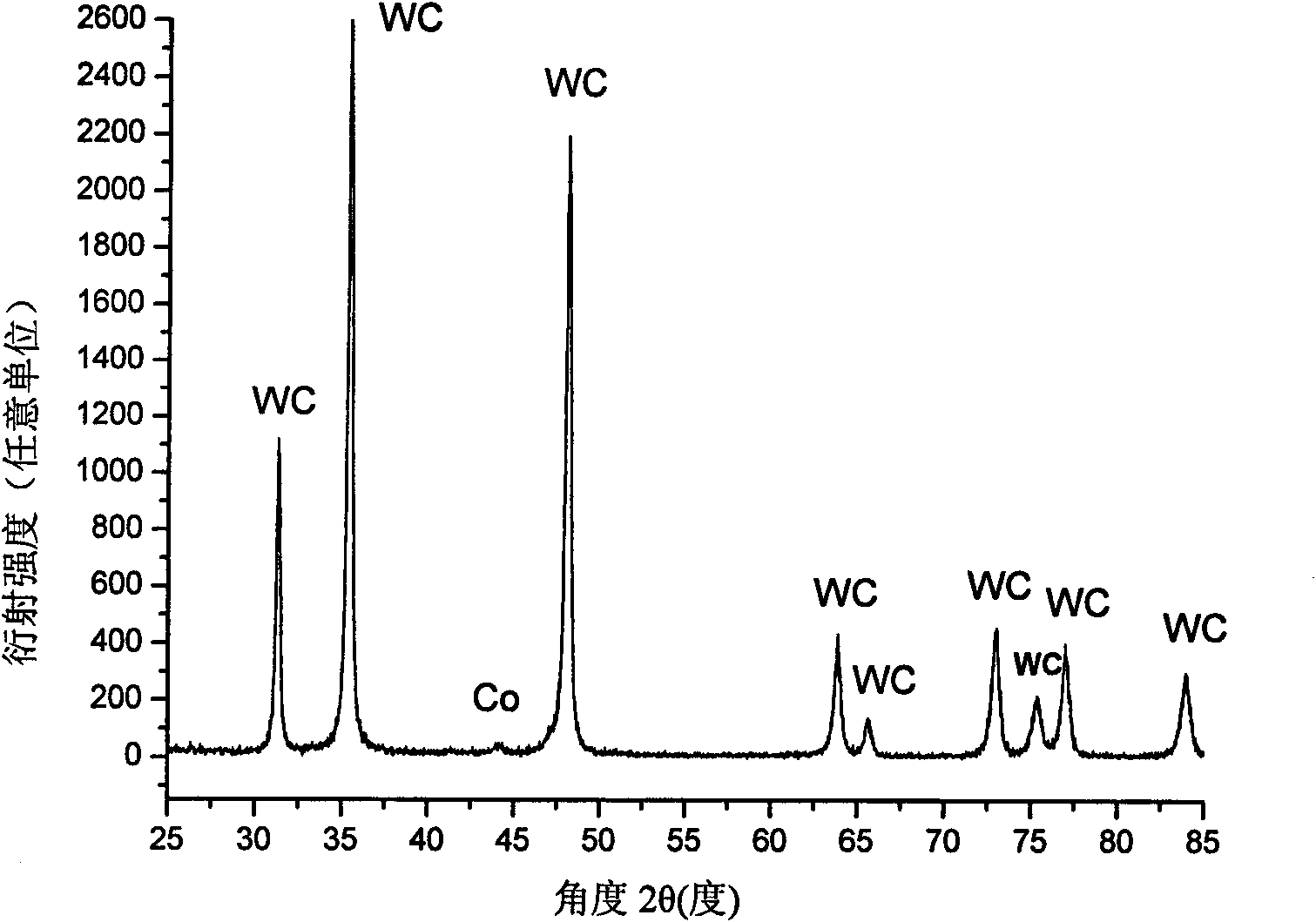

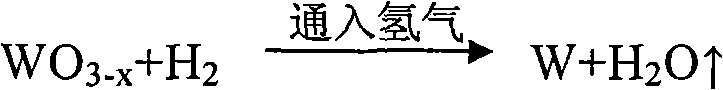

The invention relates to an industrialized preparation method of a WC-Co hard alloy with low cost and high performance, which belongs to the technical field of hard alloys and powder metallurgy. The method comprises the following steps: taking WO2.9, Co3O4 and carbon soot as raw materials, and computing the usage ratio of the three materials according to the requirement of the Co content in a final hard alloy block material; adding 0-1.0 percent by weight of grain growth inhibitor into the prepared WC-Co composite powder, and adding polyethylene glycol as a forming agent into a ball milling tank 4-8 hours before ball milling is finished, wherein 30-80ml of polyethylene glycol is added into the powder material per kilogram; acquiring WC-Co mixed powder with a nanocrystal structure after ball milling, and putting the mixed powder into a mould for press forming after vacuum drying; and sintering the mixed powder stock after press forming in a mode of vacuum sintering or low-pressure sintering. The industrialized preparation method markedly shortens a production period, the provided integrated preparation course markedly reduces the production cost while ensuring the high performance of the hard alloy and has a high performance-price ratio, and the preparation method is suitable for industrialized scale production.

Owner:北硬科技香河有限公司

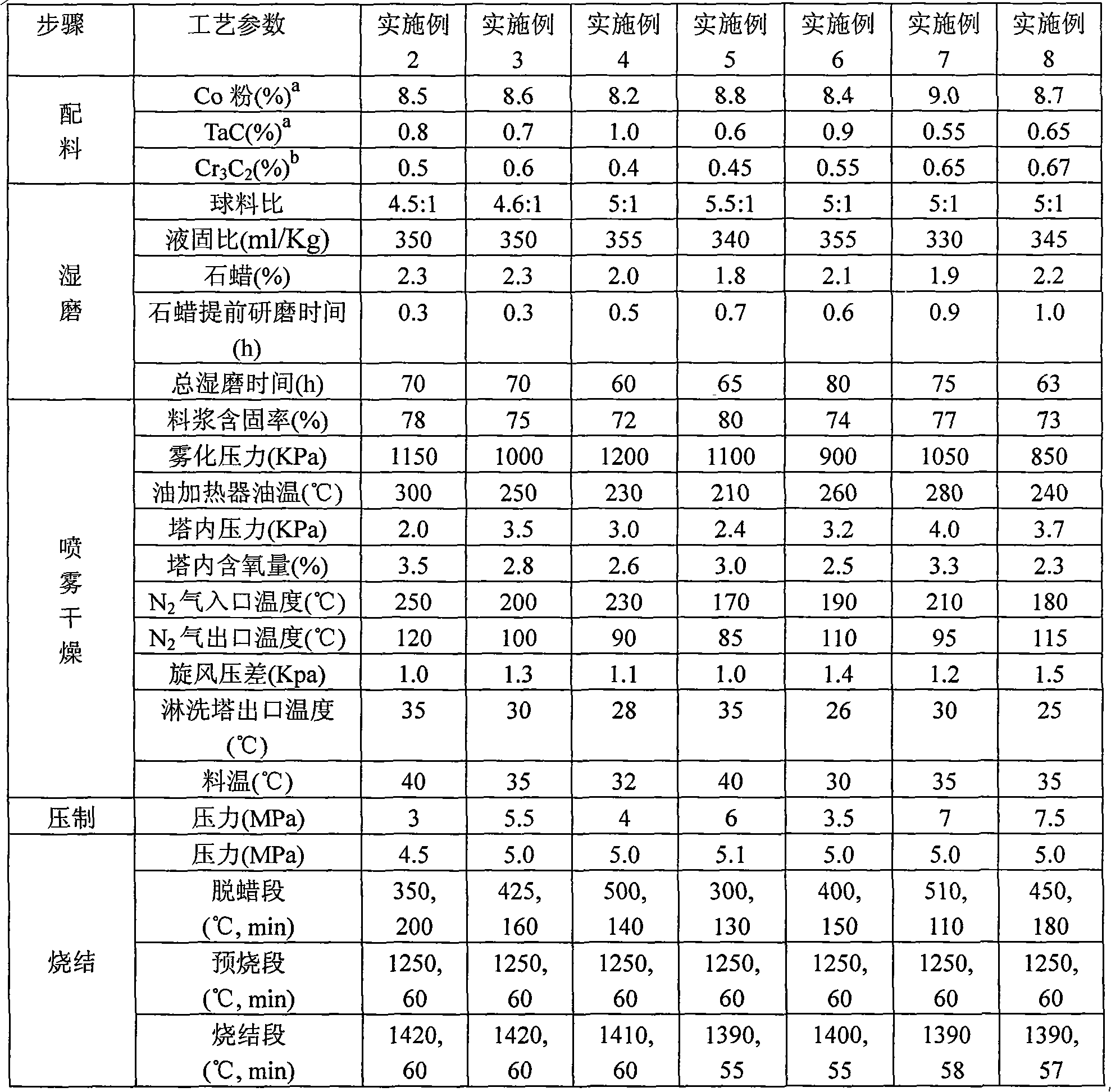

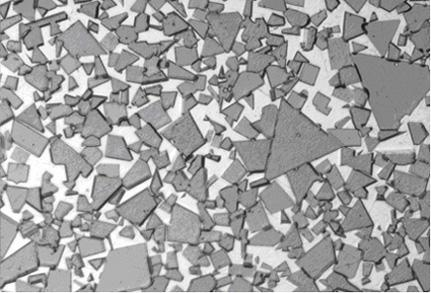

Ultrafine cemented carbide and preparation method and application thereof

The invention discloses ultrafine cemented carbide which comprises the following components in raw materials in percentage by weight: 8.0-9.0 percent of Co, 0.5-1.0 percent of TaC and the balance of WC including 0.3-2.0 percent of Cr3C2; and the preparation method comprises the steps of blending, wet milling, spray drying, pressure molding and sintering. The invention definitely limits the optimized technical conditions of all the components in the raw materials and the optimized process conditions of all the steps of preparation; the ultrafine cemented carbide has good hardness property and good strength property: the transverse rupture strength is equal to or higher than 2800 MPa, the hardness is equal to or higher than 92.5 HRA, the coercive force is 26-35 KA / m and the average grain size of the WC is 200-400 nm. And the invention also discloses application of the ultrafine cemented carbide in the preparation of cemented carbide tools.

Owner:JIANGXI RARE EARTH & RARE METALS TUNGSTEN GRP

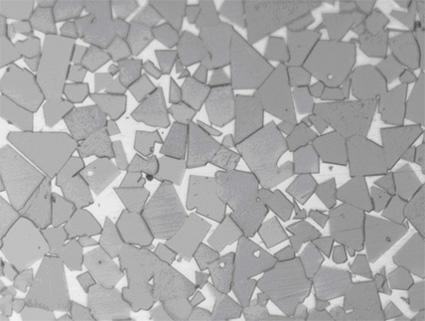

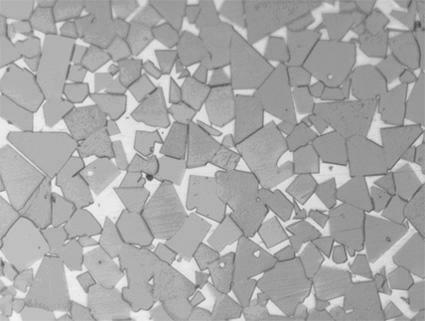

Ultra-thick hard alloy, and preparation method and application thereof

The invention discloses an ultra-thick hard alloy, a preparation method and application thereof. The raw material of the ultra-thick hard alloy comprises the following components in percentage by weight: 10.0-10.5% of Co and the balance of WC. The preparation method comprises the following steps of pretreatment, raw material preparation, wet grinding, spray drying, compression moulding and sintering. According to the invention, technical conditions of each component and technical conditions of each step are selected preferentially, and common technical problems in the preparation of ultra-thick ally in China, such as non-even grains, poor anti-impact toughness and thermal fatigue resistance and too many pores. The ultra-thick hard ally has excellent thermal conductivity, impact toughness and thermal fatigue resistance, cross breaking strength is larger than or equal to 3,100Mpa, the hardness is 86-87HRA, the coercive force is 3.0-4.0KA / m, and WC average grain size is 5-6 microns.

Owner:赣州海盛钨业股份有限公司

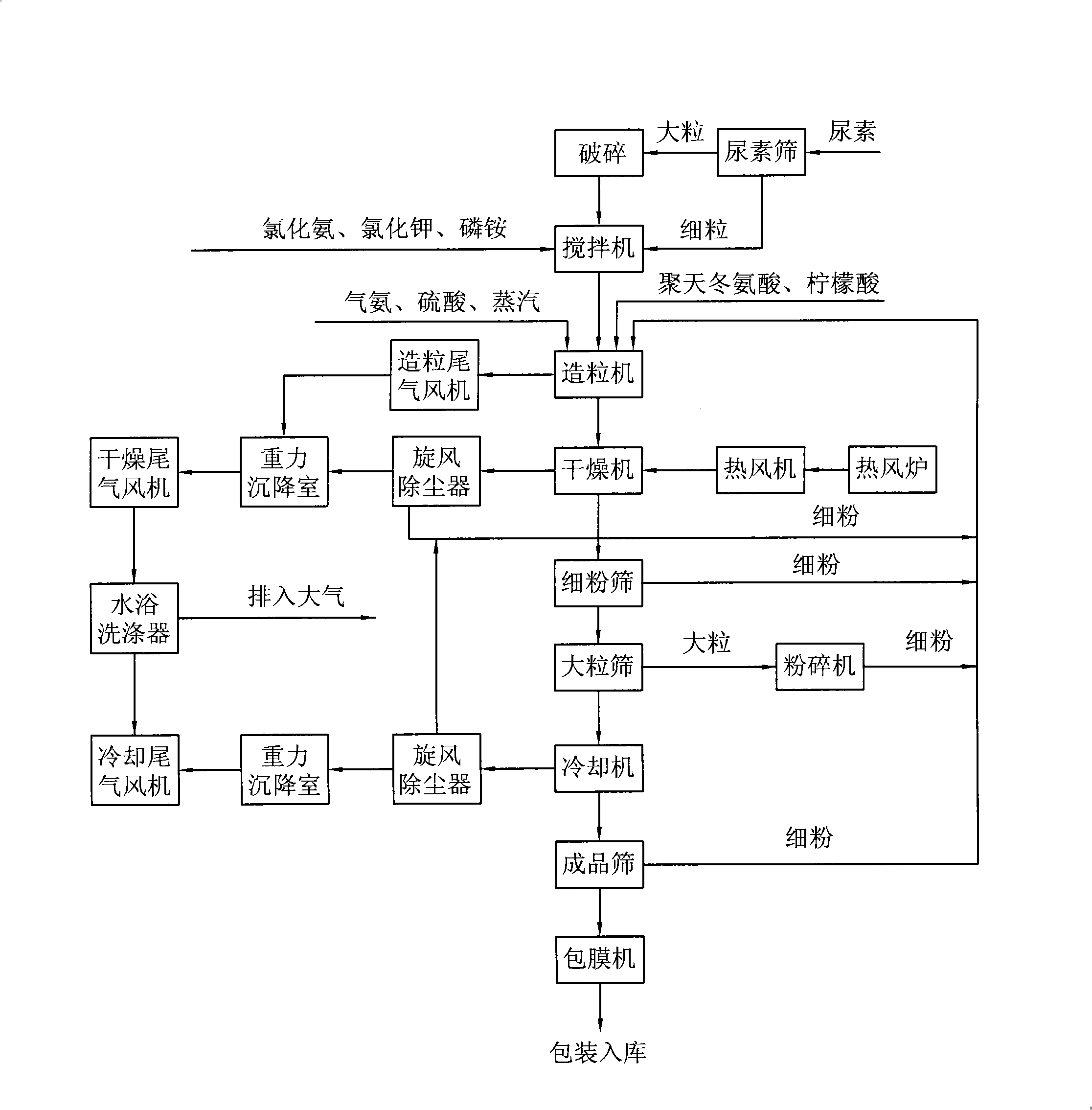

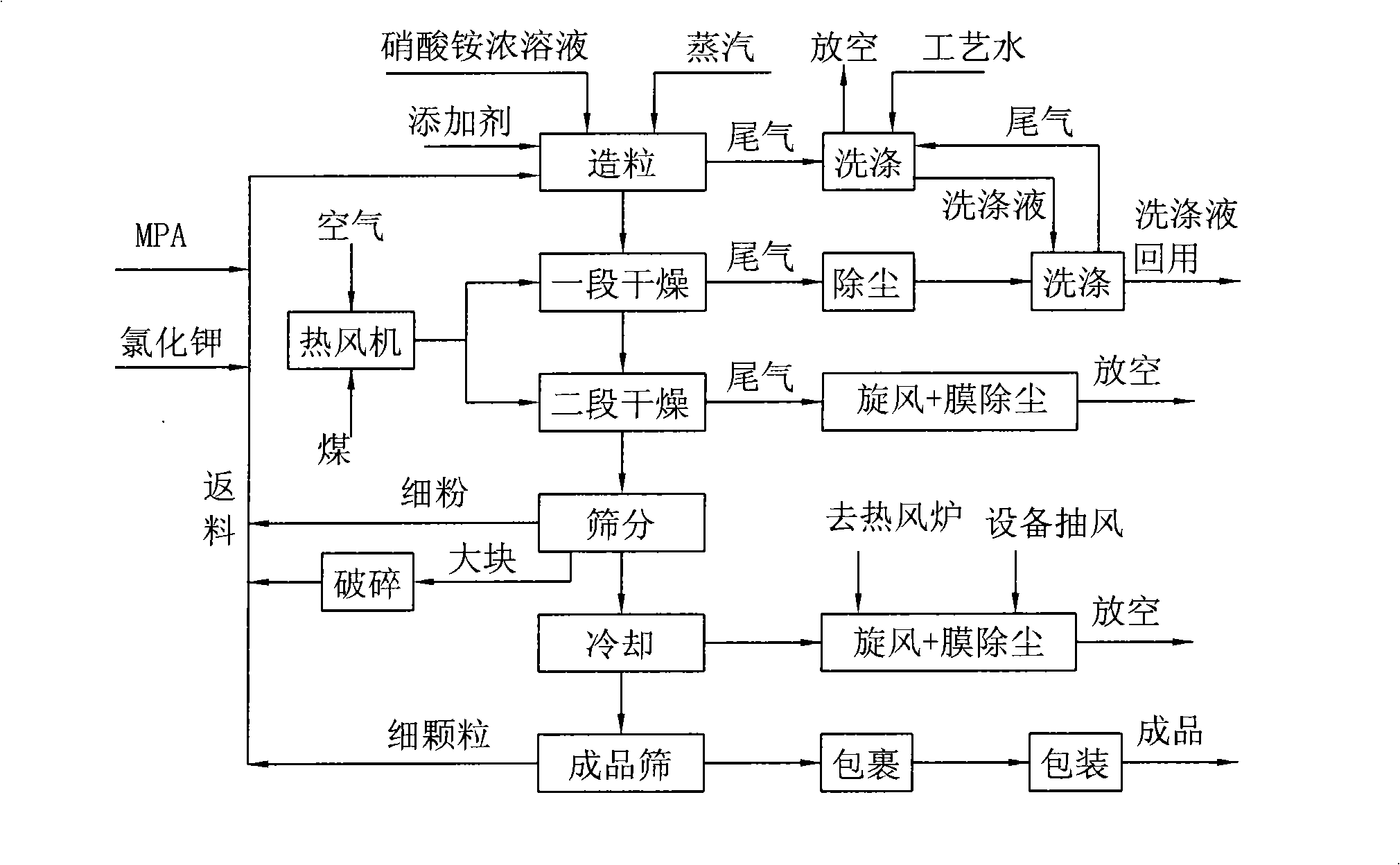

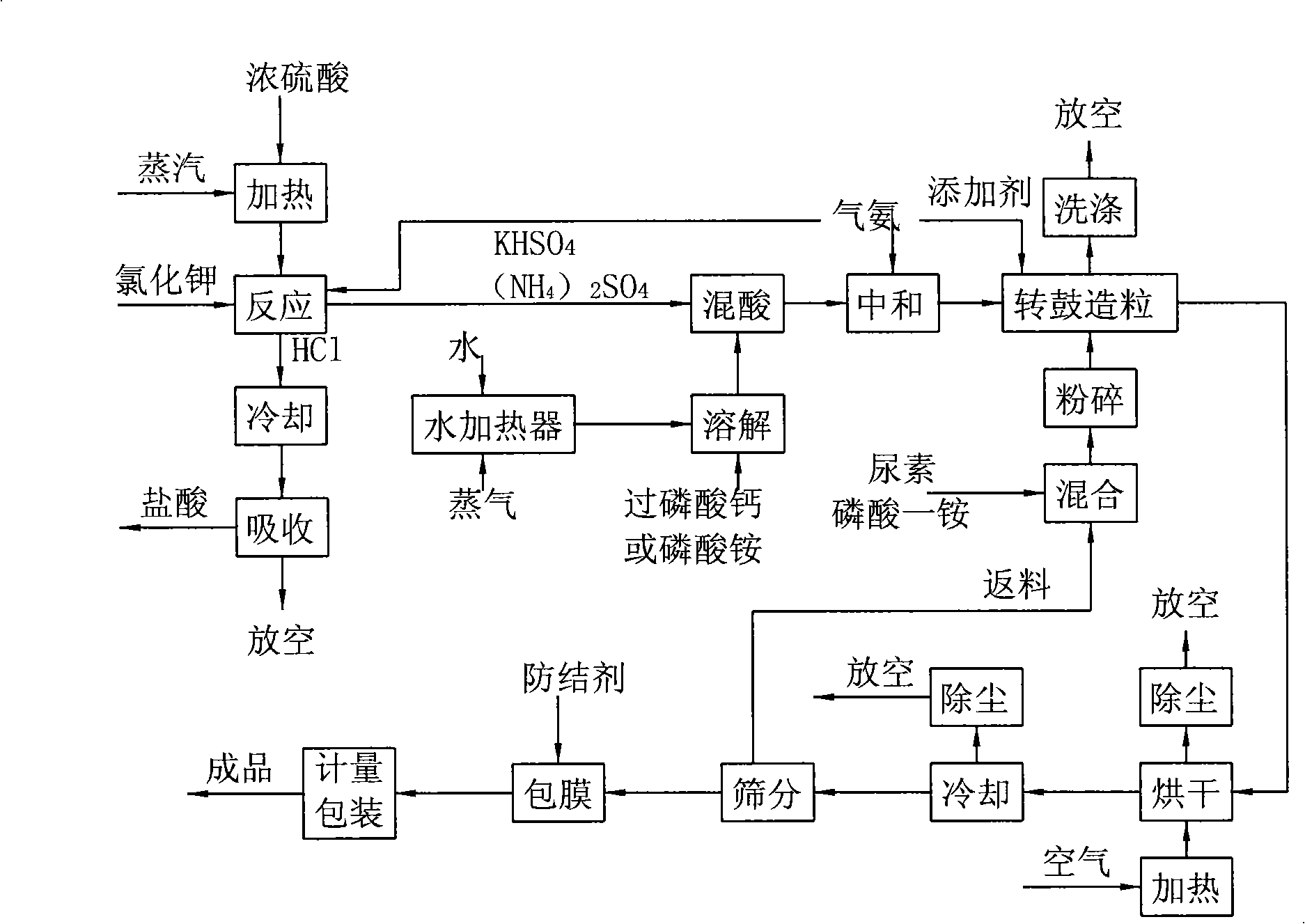

Synergistic composite fertilizer and method for preparing same

InactiveCN101289345AEnhance resilienceImprove qualityFertilizer mixturesHydroxycitric acidHumic acid

The invention discloses a synergistic compound fertilizer and a preparation method thereof. The synergistic compound fertilizer of the invention is characterized in that: poly-aspartic acid or aspartate and phosphate-dissolving agents are added into common compound fertilizer, wherein, the weight percentage of the compound fertilizer, the poly-aspartic acid or the aspartate and the phosphate agents is respectively as follows: 75.0 to 99.98 percent of the compound fertilizer, 5.0 to 0.01 percent of the poly-aspartic acid or the aspartate and 20.0 to 0.01 percent of the phosphate-dissolving agent. The phosphate-dissolving agents are the combination of one or a plurality of oxalic acid, citric acid, tartaric acid, acrylic acid, zeolite powder and humic acid. The preparation method of the synergistic compound fertilizer of the invention is that the current device and technology of producing fertilizers using the granulating method are adopted to add the poly-aspartic acid or the aspartateand the phosphate-dissolving agents into a granulator after the poly-aspartic acid or the aspartate and the phosphate-dissolving agents are measured by the measuring device arranged at the front of the granulator. The synergistic compound fertilizer can greatly facilitate the full absorption of trace elements such as nitrogen, phosphorus, potassium by crops, which can comprehensively improve fertilizer utilization ratio and the quality of crops.

Owner:HEBEI XIETONG ENVIRONMENTAL PROTECTION TECH CO LTD

Aqueous PU fog face rubbing surface treatment agent for synthetic leather and preparation method thereof

The invention discloses an aqueous PU fog face rubbing surface treatment agent for synthetic leather, comprising the following components by weight percentage: 40-50% of aqueous polyurethane resin, 30-40% of water, 3-6% of matting agent, 1-5% of organic silicon antifoaming agent, 0.5-5% of organic silicon flatting agent and 0.5-5% of aqueous polyurethane thickener. The surface treatment agent provided by the invention takes water as solvent which replaces poisonous solvents such as dimethylformamide and butanone and has the performances of non-combustion, safety, environmental protection and less cost; after being treated by the surface treatment agent provided by the invention in a wiping manner, the prepared leather has good fog face rubbing effect, sharp contrast between colours of a surface layer and a rubbing layer, good visual effect and excellent general effect.

Owner:JIANGSU BAOZE POLYMER MATERIAL

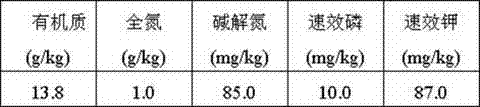

Selenium-rich organic/inorganic fertilizer for producing selenium-rick rice as well as application method thereof

InactiveCN102503632AIncrease productionImprove qualityFertilising methodsFertilizer mixturesOrganic manurePhosphate fertilizer

The invention relates to a fertilizer formula and further relates to an application method of the fertilizer. A selenium-rich organic / inorganic fertilizer for producing selenium-rick rice is prepared by mixing selenites, nitrogenous fertilizers, phosphate fertilizers, potash fertilizers, rotten organic fertilizers and silicon fertilizers according to a certain ratio and pelletizing the mixture. The selenium-rich organic / inorganic fertilizer for producing the selenium-rick rice comprises the following components in parts by weight: 0.004-0.010 parts of the selenites, 15-33 parts of the nitrogenous fertilizers, 12-24 parts of the phosphate fertilizers, 10-17 parts of the potash fertilizers, 30-50 parts of the rotten organic fertilizers and 5-8 parts of the silicon fertilizers. The fertilizer not only includes selenium element but also includes other nutrition enhancing matters requested by crop growth. As the fertilizer can be used for supplying the selenium element and the other nutrition enhancing matters requested in growth for crops simultaneously, the application of the fertilizer is good for the crop growth, so that the absorption rate and the conversion rate of selenium are improved, and the selenium-rick rice reaching a selenium-rick rice standard can be produced by applying less selenium.

Owner:广东海纳农业有限公司 +1

Aqueous PU velvet resin used for synthetic leather

InactiveCN101634109ALow costThe ratio is scientific and reasonableFibre treatmentDimethyl formamideChemistry

The invention discloses an aqueous PU velvet resin used for synthetic leather, which comprises the following raw materials by weight percent: 40-50% of aqueous polyurethane resin, 40-50% of water, 2-5% of low-temperature sheep bar powder, 2-4% of silicon dioxide velvet powder, 1-3% of organic silicone oil smoothing agent, 1-4% of extinction powder, 0.5-1% of organic silicon flatting agent, 2-5% of organic silicon antifoaming agent and 0.5-2% of aqueous polyurethane thickening agent. The aqueous PU velvet resin used for synthetic leather of the invention takes water as solvent to replace toxic solvent, such as dimethyl fomamide, butanone and the like and has the advantages of being non-combustible, safe and environment-friendly, saving cost and the like. The aqueous PU velvet resin also has the advantages of good film-forming resistance, firm bonding, coating solvent resistance, cold resistance, hydrolysis resistance and heat-proof aging. Products fabricated by using the resin have the characteristics of plump feel, unique velvet effect, strong real leather quality, fine and smooth texture, good air permeability and the like.

Owner:JIANGSU BAOZE POLYMER MATERIAL

Vacuum negative pressure real type phenolic sand molding lost foam casting method

InactiveCN101342573AImprove casting precisionGuaranteed to be smooth and tidyFoundry mouldsFoundry coresVacuum pumpingProduct gas

The present invention relates to a method for casting a vacuum sub-pressure solid resin sand molding lost mould, and belongs to the casting technical field, in particular relates to a method for casting a vacuum sub-pressure lost mould, which mainly comprises the steps such as molding, coating, sand-box patternmaking, tapping, pouring, vacuum pumping, heat preservation and cooling, and adopts the casting steps: a. foam plastic mould is made according to the shape of the casting piece; b. the outer surface of the foam plastic mould is coated with coating; c. the foam plastic mould that is coated with coating is arranged inside a sand box, and the patternmaking is performed with resin sand; d. the sand box after the patternmaking is arranged inside a tapping device so as to tap the patternmaking sand inside the box and to be dried; e. while pouring the iron liquid, the sand box is vacuum pumped synchronically by a vacuum pumping machine, and the gas that is obtained from the vacuum pumping is discharged after being purified; f. after the pouring is completed, the vacuum pumping is stopped, and the casting piece is taken out to be arranged inside a heat-preservation oven, so that the temperature is increased to 1100 DEG C, and the casting piece can be produced after the heat preservation and cooling. The method of the present invention has simple process, precise processing, easy operation and low production cost.

Owner:QUEJING CHENGJIE SHIXIN FOUND

Easy cutting brass alloy containing silicon without lead

The present invention belongs to the field of metal material producing technology, and the easy-to-cut brass alloy contains Cu 80-84 wt%, Si 2.5-5.0 wt%, As 0.02-0.10 wt%, except Zn and 0.05 wt% below impurity. It may be used in replacing widely applied corresponding lead brass alloy to avoid lead pollution while ensuring excellent cutting performance, mechanism performance and conducting performance.

Owner:ZHEJIANG HAILIANG

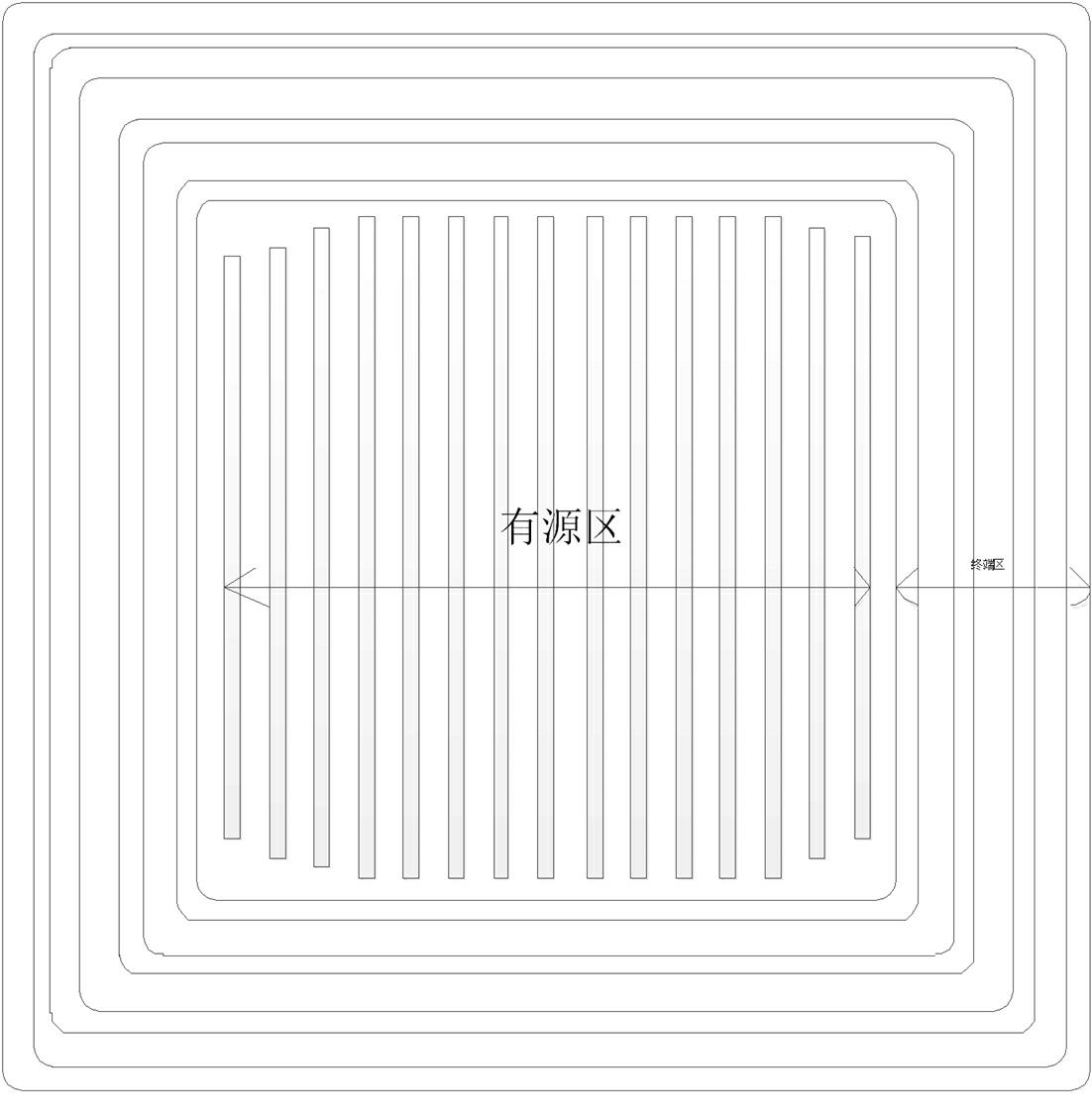

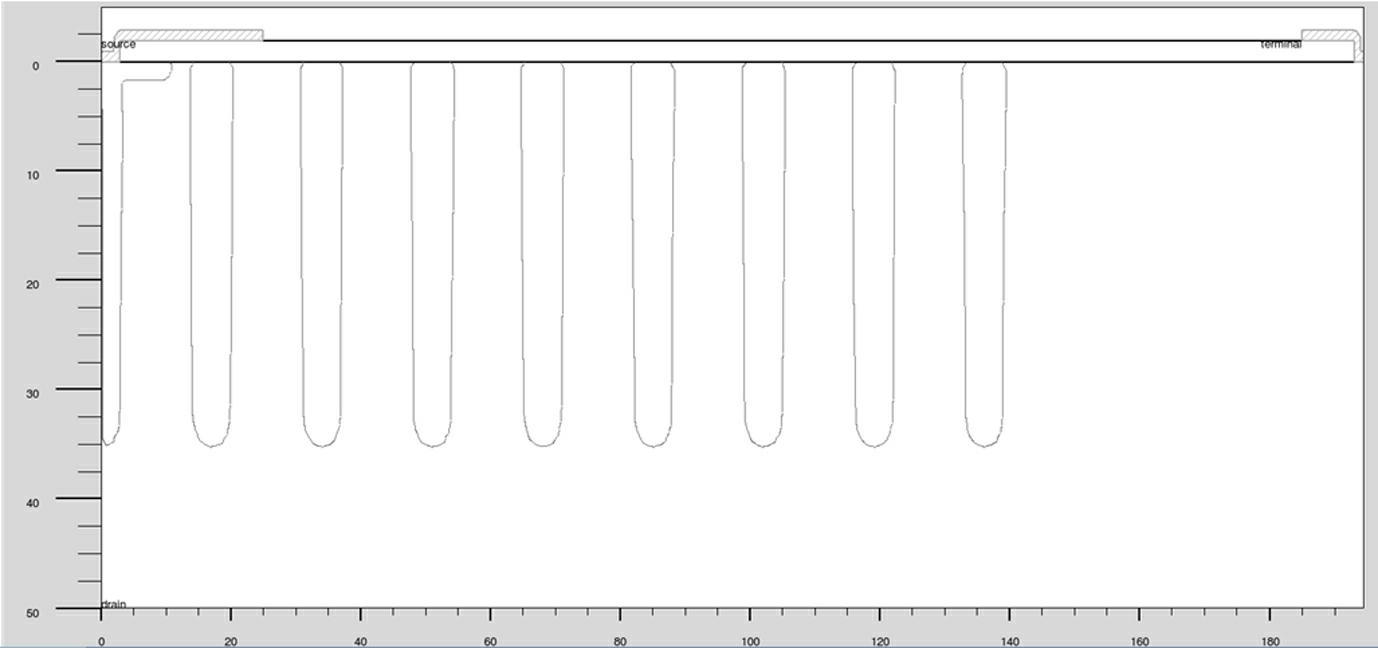

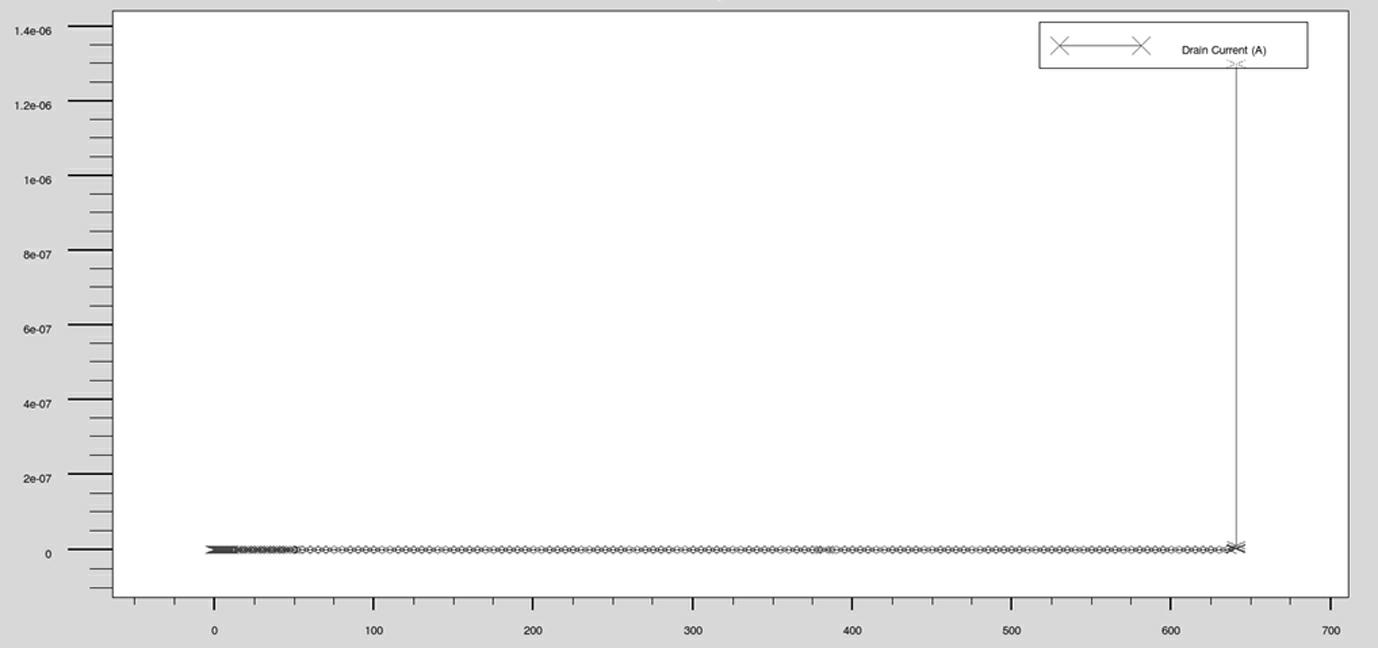

Super junction high-voltage power device structure

ActiveCN102683408AImprove pressure resistanceImprove reliabilitySemiconductor devicesPower semiconductor deviceCell region

The invention relates to a super junction high-voltage power device structure. A power semiconductor device many be influenced by a junction curvature effect to cause aggregation of an electric field close to a junction, so that a device is extremely easy to break down; and thus, the voltage withstanding degree of the device is required to be improved. The super junction high-voltage power device structure comprises an active region and a terminal region, wherein an epitaxial layer of a first conduction type material is arranged on a substrate layer; a composite buffer layer is formed on the epitaxial layer and comprises first semiconductor regions constituted by the first conduction type material and second semiconductor regions constituted by a second conduction type material, and the second semiconductor regions and the first semiconductor regions are arranged alternately; a well region of a second conduction type is positioned on the surface of the second semiconductor region, and is between two first semiconductor regions or between the final first semiconductor region and a cut-off ring. According to the super junction high-voltage power device structure, the withstanding voltage and the reliability of the terminal of the super junction device can be improved, so that withstanding voltage close to that of a cell region can be born by the terminal; and the structure can be realized by using the conventional super junction semiconductor manufacturing process without increasing the difficulty and the production cost of the process.

Owner:XIAN LONTEN RENEWABLE ENERGY TECH

High frequency efficient breeding control technique of meat sheep

InactiveCN101361471AIncrease profitShort turnaround timeAnimal reproductionAnimal feeding stuffSheep breedVaginal Suppository

The invention discloses a mutton sheep breeding and regulating technology with high frequency and high efficiency. In China, the mutton sheep breeding and regulating technology with high frequency and high efficiency is applied relatively widely, but the situation of organically combining a plurality of technologies and the popularization thereof does not appear. The technology comprises an oestrus hormone-regulation proposal, a production system and a high-efficiency breeding technology; wherein, the oestrus hormone-regulation proposal relates to a progestogen vaginal suppository-PMSG method, the production system of twice producing one year or three producing two year is adopted, the high-efficiency and high frequency breeding technology adopts gonadotropin, grouping hybridization and nutritional regulation. The technology is applied to high-efficiency industry which leads the sheep industry to develop into industrialization.

Owner:黑龙江省农业科学院畜牧研究中心 +2

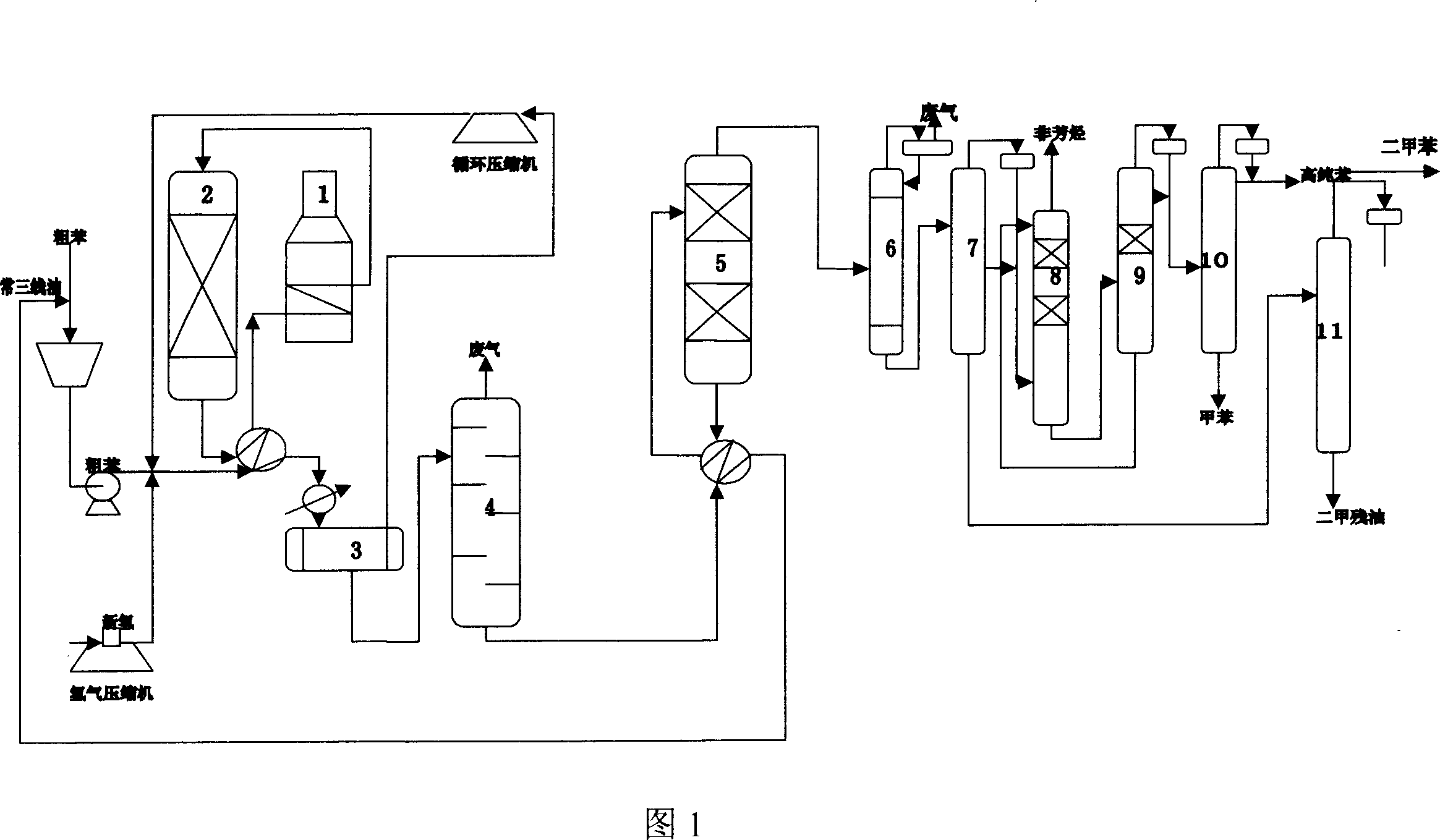

Method for producing benzene arenes from coarse benzene

ActiveCN101028985ALess investmentEasy to operateDistillation purification/separationRefining to eliminate hetero atomsSolventImpurity

Owner:HUNAN CHANGLING PETROCHEM SCI & TECH DEV CO LTD

Waterborne PU high smooth wax resin for synthetic leather

The invention discloses a waterborne PU high smooth wax resin for synthetic leather and the resin comprises the following raw materials by weight percent: 30-40% of waterborne silicon-fluorine resin,20-30% of waterborne polyurethane, 10-30% of water, 0.2-0.8% of waterborne wax emulsion, 1-3% of organic silicone oil smoothing agent, 0.5-1% of organic silicone flatting agent, 2-5% of organic silicone defoamer and 0.5-2% of waterborne polyurethane thickener. The waterborne PU high smooth wax resin for synthetic leather provided by the invention uses water as solvent instead of toxic solvents such as dimethyl formamide, butanone and the like and has the advantage of noninflammability, safety, environmental protection, cost-saving and the like. The finished product prepared from the waterbornePU high smooth wax resin for synthetic leather provided by the invention has full hand feeling, high luster and high luminance, extremely smooth waxy feeling, delicate texture and good air permeability; and the prepared synthetic leather has good comprehensive effect in hand feeling, smoothness, water resistance, waxy feeling and the like.

Owner:JIANGSU BAOZE POLYMER MATERIAL

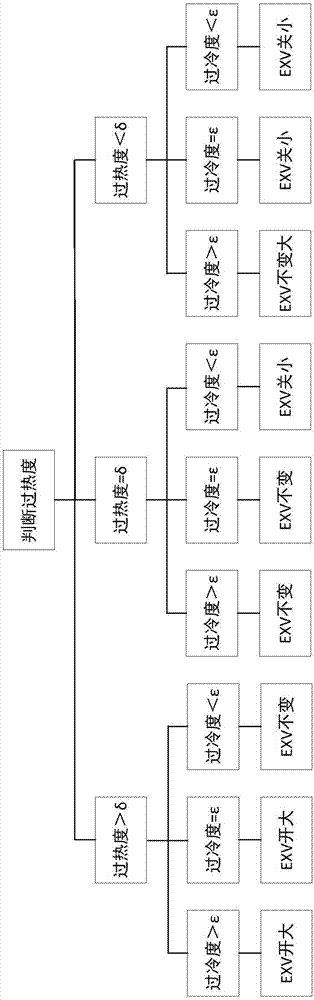

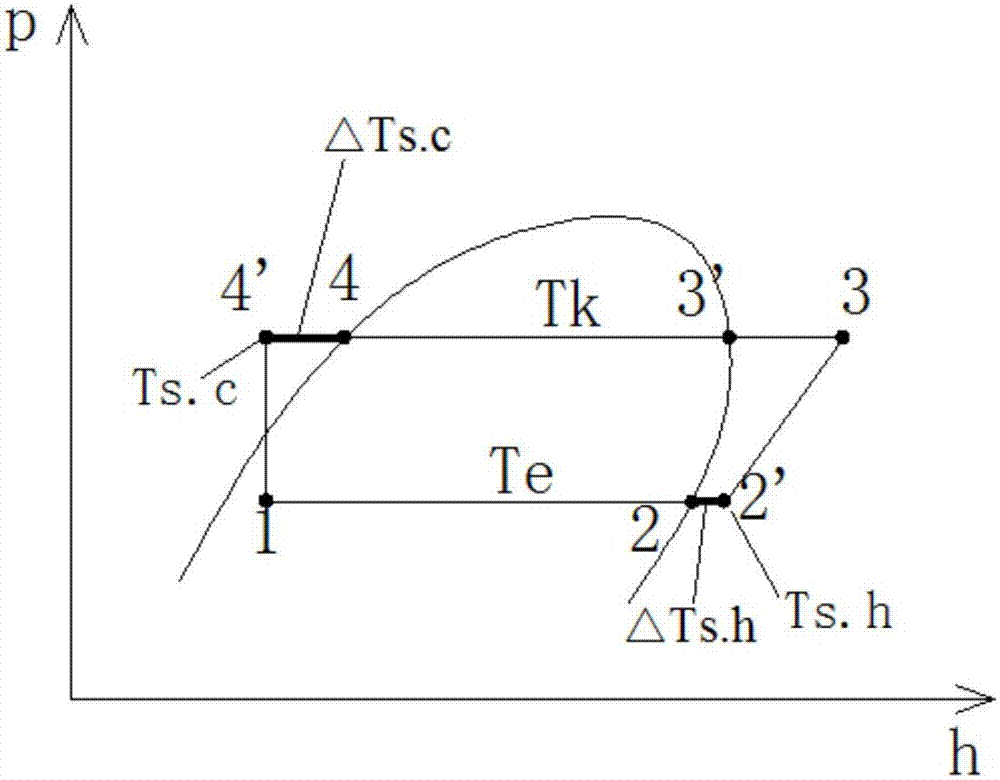

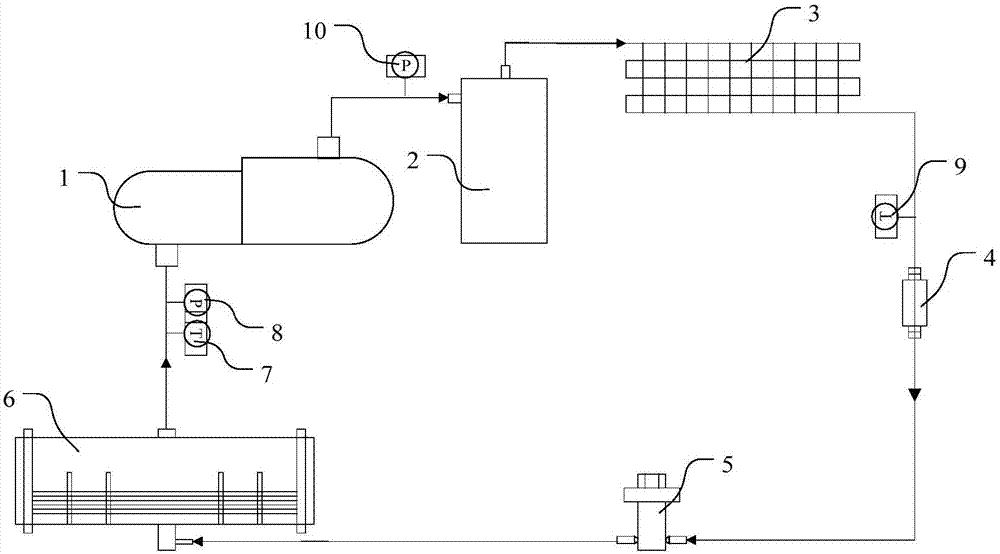

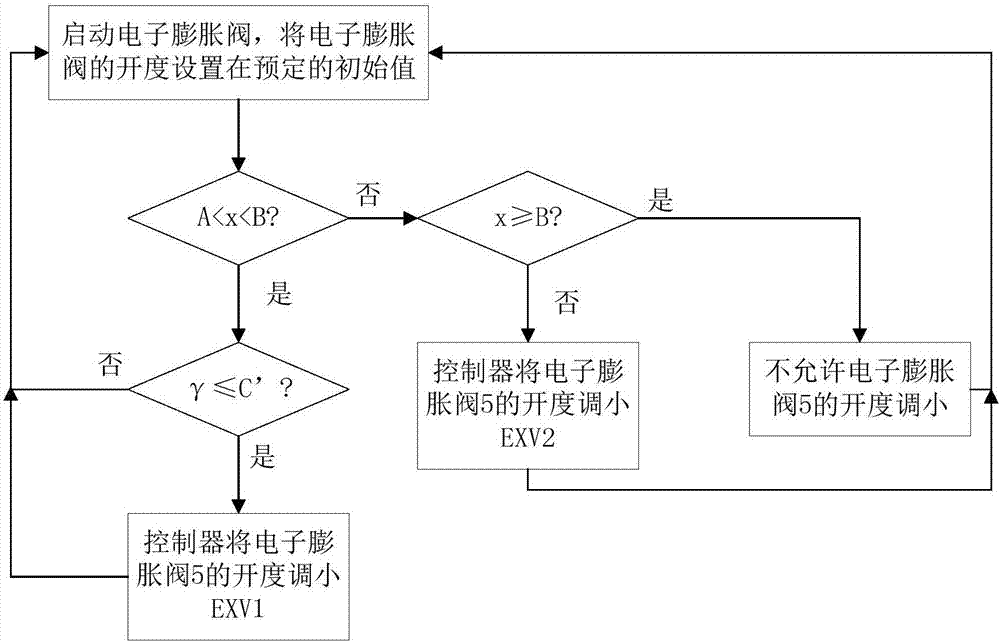

Electronic expansion valve control method and refrigerant circulation system

ActiveCN107990609AAvoid aspiration of fluidImprove heat transfer effectMechanical apparatusEfficient regulation technologiesEngineeringElectronic expansion valve

The invention provides an electronic expansion valve control method and a refrigerant circulation system. The control method comprises the steps of acquiring a current actual degree of superheat delta' and a current actual degree of supercooling epsilon' of the refrigerant circulation system; obtaining a first comparing result by comparing the actual degree of superheat delta' with a preset degree of superheat threshold value delta or a preset degree of superheat range [delta 1, delta 2], wherein the delta 1 is a first degree of superheat threshold value, and the delta 2 is a second degree ofsuperheat threshold value; obtaining a second comparing result by comparing the actual degree of supercooling epsilon' and a preset degree of supercooling threshold value epsilon or a preset degree of supercooling range [epsilon 1, epsilon 2], wherein the epsilon 1 is a first degree of supercooling threshold value, and the epsilon 2 is a second degree of supercooling threshold value; and adjusting the opening degree of an electronic expansion valve by comprehensively comparing the first comparing result and the second comparing result. According to the control method of the electronic expansion valve, heat exchange capacity and energy efficiency of the system can be improved while gas suction with liquid is avoided, the structure of system is not changed, and the production cost of the system is not increased.

Owner:GREE ELECTRIC APPLIANCES INC

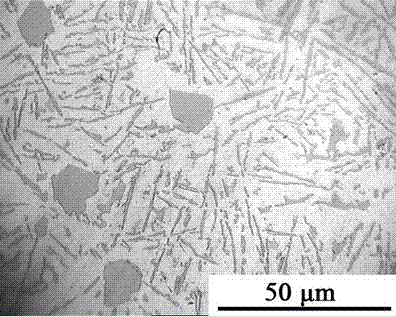

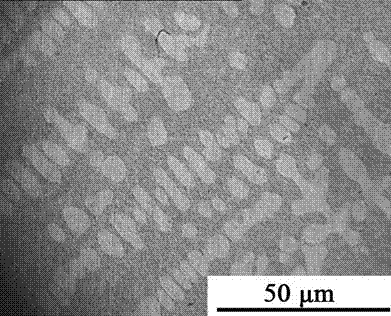

Al-Si-Nd rare-earth cast aluminum alloy and preparation method thereof

The invention discloses Al-Si-Nd rare-earth cast aluminum alloy and a preparation method thereof. The method comprises the following steps of: keeping the temperature of an alloy melt for 10 to 15 minutes, stirring for 3 to 5 minutes at the speed of 40 to 50 revolutions / minute, and keeping the temperature for 10 to 15 minutes; and degassing and refining the alloy melt, cooling the melt until the temperature is reduced to be 700 to 710 DEG C, and casting for sampling. The Al-Si-Nd rare-earth cast aluminum alloy has the advantages that due to the addition of rare earth Nd, the form of a silicon phase in the alloy can be improved obviously, and alpha-phase tissue can also be refined, so that massive primary silicon is eliminated, and the shape of eutectic silicon is changed into dotted shape or short rod shape from the thick needle shape. The method is simple in process, safe, reliable and convenient to operate, and the pollution of waste water, waste gas and industrial residues is avoided.

Owner:NANCHANG UNIV

Water-soluble PU nubuck low-temperature foamex for synthetic leather

InactiveCN101666039ALow costThe ratio is scientific and reasonableFibre treatmentSolventWater soluble

The invention discloses water-soluble PU nubuck low-temperature foamex for synthetic leather, prepared by the following raw materials in percentage by weight: 30-40 percent of water-soluble polyurethane, 40-50 percent of water, 2-10 percent of low-temperature nubuck foam powder, 2-5 percent of organosilicon levelling agent, 2-5 percent of organosilicon antifoaming agent and 0.5-2 percent of water-soluble polyurethane thickener. The mixture ratio of each component of the water-soluble PU nubuck low-temperature foamex for synthetic leather is scientific and reasonable, and the components mutually coordinate and jointly act. The nubuck low-temperature foamex has the advantages of good film reforming property and firm adhesion, and coating is resistant to solvent, cold, hydrolysis and thermalageing. The original effect of the leather surface of a finished product prepared from the water-soluble PU nubuck low-temperature foamex can not be influenced; after the leather surface is treated bythe foamex, low-temperature foaming is carried out to produce nubuck leather, and therefore, the effect of the leather surface is unique; moreover, the synthetic leather has exquisite texture, good air permeability and excellent resultant effect of hand feeling, water proofing, adhesion and the like.

Owner:JIANGSU BAOZE POLYMER MATERIAL

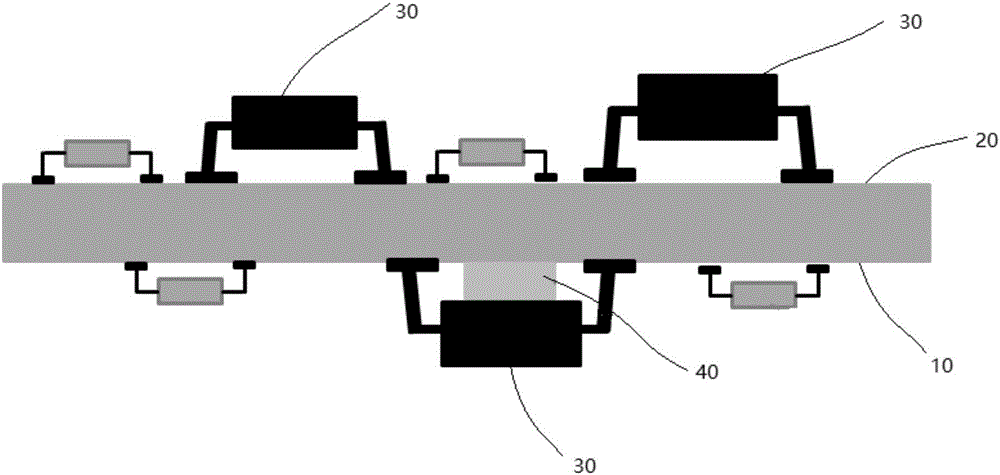

Surface mounting method for printed circuit board

InactiveCN106604564ASolve the problem of falling partsDoes not increase production costsPrinted circuit assemblingMetallurgical bondingSurface mountingAdhesive

The invention relates to a surface mounting method for a printed circuit board, wherein the printed circuit board is provided with a large device including a large device body and a soldering pin. The method comprises the following steps: (1) obtaining an empty board including a first face and a second face, the first face being provided with a large device mounting area including a bonding pad area and a blank area; (2) a first side printing: printing solder paste in the bonding pad area; (3) gluing and the first face mounting: putting an adhesive in the blank area to form an adhesive layer and then mounting the large device on the large device mounting area; (4) reflow soldering: subjecting the mounted large device to reflow soldering; (5) second face treatment: subjecting the second face to conventional printing, patch mounting and reflow soldering. The method solves the dropping of the large device in the first face, does not need to increase the size of the PCB, reduces the production cost, improves the PCB layout efficiency, and is simple and convenient for industrial application.

Owner:GUANGDONG VTRON TECH CO LTD

Water-based PU high solid resin combination for synthetic leather

The invention discloses a water-based PU high solid resin combination for synthetic leather, which comprises the following materials by weight percent: 25 to 35 percent of water-based polyurethane resin, 45 to 55 percent of water, 10 to 20 percent of modified organic silicon polymer, 0.5 to 1.5 percent of organic silicon flatting agent, 1 to 3 percent of organic silicon foam killer and 1.5 to 4.5 percent of water-based polyurethane thickening agent. The water-based PU ironing finishing agent has the advantages that the mixture ratio of the component is scientific and reasonable, and the components are coordinated with each other and act together; the high solid resin combination has the advantages of good film reforming property, firm bonding, solvent resistance, cold resistance, hydrolysis resistance and thermosenescence resistance of coating; the finished product made of the synthetic leather, the surface of which is treated by the high solid resin combination, has the advantages that the original effect of the leather surface is not affected, raised patterns on the leather surface are sufficient in contrast to the leather sole after the leather surface is treated and modified, and the leather surface has unique high solid effect.

Owner:JIANGSU BAOZE POLYMER MATERIAL

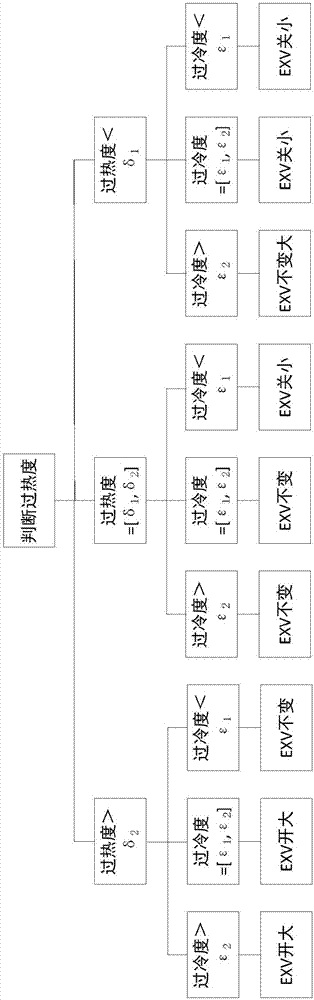

Control method of electronic expansion valve and heat pump system

ActiveCN107421176AIncrease production costImprove heat transfer effectMechanical apparatusEfficient regulation technologiesEngineeringElectronic expansion valve

The invention provides a control method of an electronic expansion valve and a heat pump system. The control method comprises the following step: when the current actual air suction superheat degree x of the heat pump system is within a preset range, adjusting the opening degree of the electronic expansion valve according to the current actual supercooling degree gamma of the heat pump system and the current load of a compressor. In the control method provided by the invention, the opening degree of the electronic expansion valve is adjusted according to the actual supercooling degree and the current load when the actual air suction overheat degree is within the preset range, so that the supercooling degree of the heat pump system can be matched with the actual load of the compressor. Accordingly, the heat exchange capacity and the energy efficiency of the heat pump system can be improved when the entrainment of a liquid in air suction is avoided, the own structure of the heat pump system cannot be changed, and the production cost of the heat pump system cannot be increased.

Owner:GREE ELECTRIC APPLIANCES INC

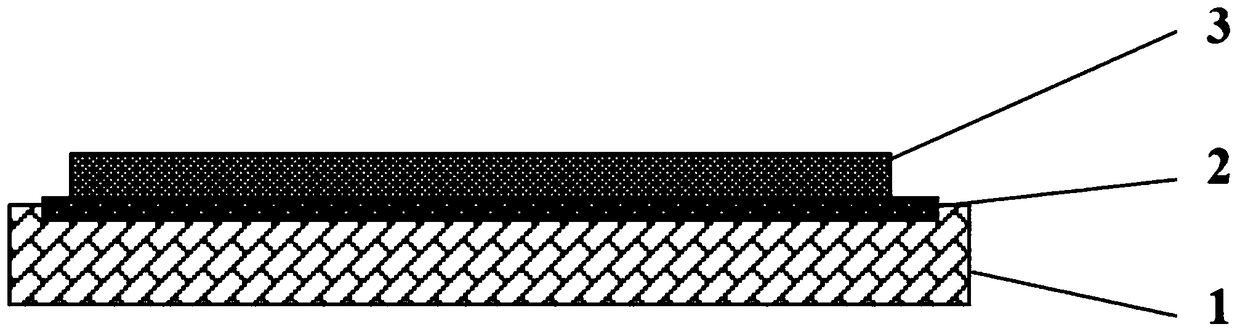

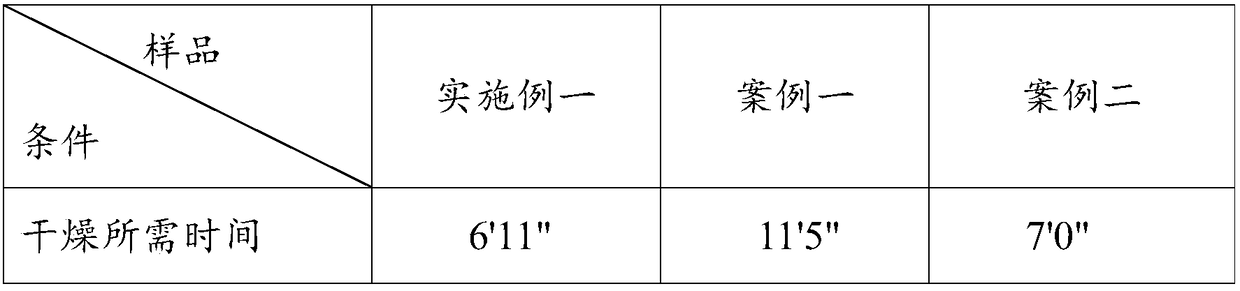

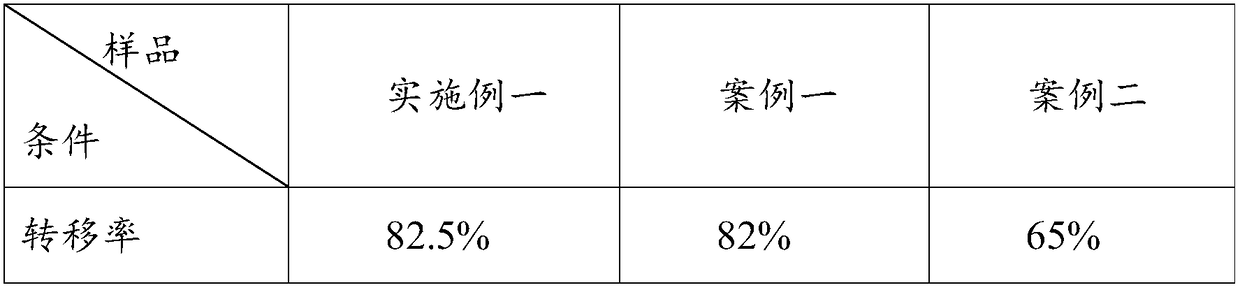

Thermal dye sublimation transfer paper suitable for on-line high-speed production

PendingCN108894053AFast dryingImprove transfer rateCoatings with pigmentsWater-repelling agents additionCarboxymethyl celluloseEngineering

The invention provides thermal dye sublimation transfer paper suitable for on-line high-speed production. The thermal dye sublimation transfer paper comprises body paper, a gluing layer and a coatinglayer, and the gluing layer and the coating layer coat the body paper in sequence according to an on-line processing technology; coating in the coating layer is at least prepared from a water absorbing material, an ink absorbing material and resin. The thermal dye sublimation transfer paper is characterized in that the water absorbing material is a composition containing one or more of sodium polyacrylate resin, aluminium silicate, calcined kaolin and silicon dioxide according to any proportion, and the ink absorbing material is a composition containing one or more of sodium carboxymethyl cellulose, polyacrylamide, sodium alginate, oxidized starch and natural polymer glue. The thermal dye sublimation transfer paper produced by means of the technology solves the problems in the prior art that thermal dye sublimation transfer paper prepared by means of an on-line coating method is low in ink absorbing amount, low in transfer rate, high in ink permeability and low in printing precision.

Owner:赵慧哲

Water-based PU brush surface conditioning agent for synthetic leather

InactiveCN101705623AExcellent crosslink hardnessGood recoatabilityFibre treatmentWater basedSilicon dioxide

The invention discloses a water-based PU brush surface conditioning agent for synthetic leather, which comprises the following materials by weight percent: 10 to 20 percent of water-based stoving varnish resin, 1 to 6 percent of water-based polyurethane, 60 to 70 percent of water, 5 to 13 percent of silicon dioxide matting agent, 0.5 to 2 percent of organic silicon flatting agent, 1 to 5 percent of organic silicon foam killer and 2 to 6 percent of water-based modified polyethylene wax emulsion. In the water-based PU brush surface conditioning agent for synthetic leather, water is taken as solvent to replace noxious solvents, such as dimethyl formamide and butanone, so that the water-based PU brush surface conditioning agent has the performances of non-inflammation, safety, environmental protection and cost saving, and resin has the advantages of good film reforming property, firm bonding, solvent resistance, cold resistance, hydrolysis resistance and thermosenescence resistance of coating, and the finished product made of the surface conditioning agent has unique brush effect, strong dermis effect, water resistance and good air permeability.

Owner:JIANGSU BAOZE POLYMER MATERIAL

Method and system for calibrating optical sensor of mobile terminal

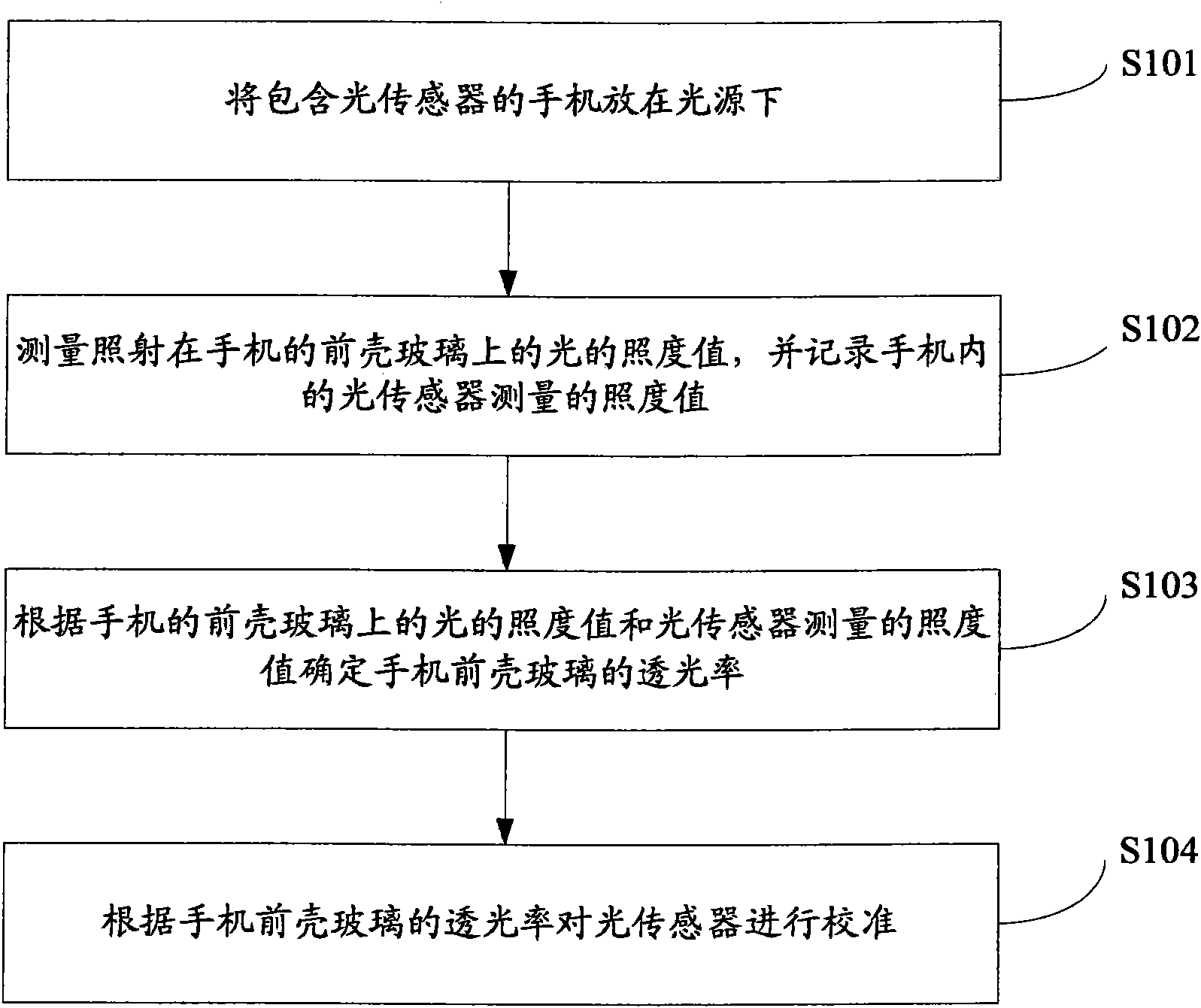

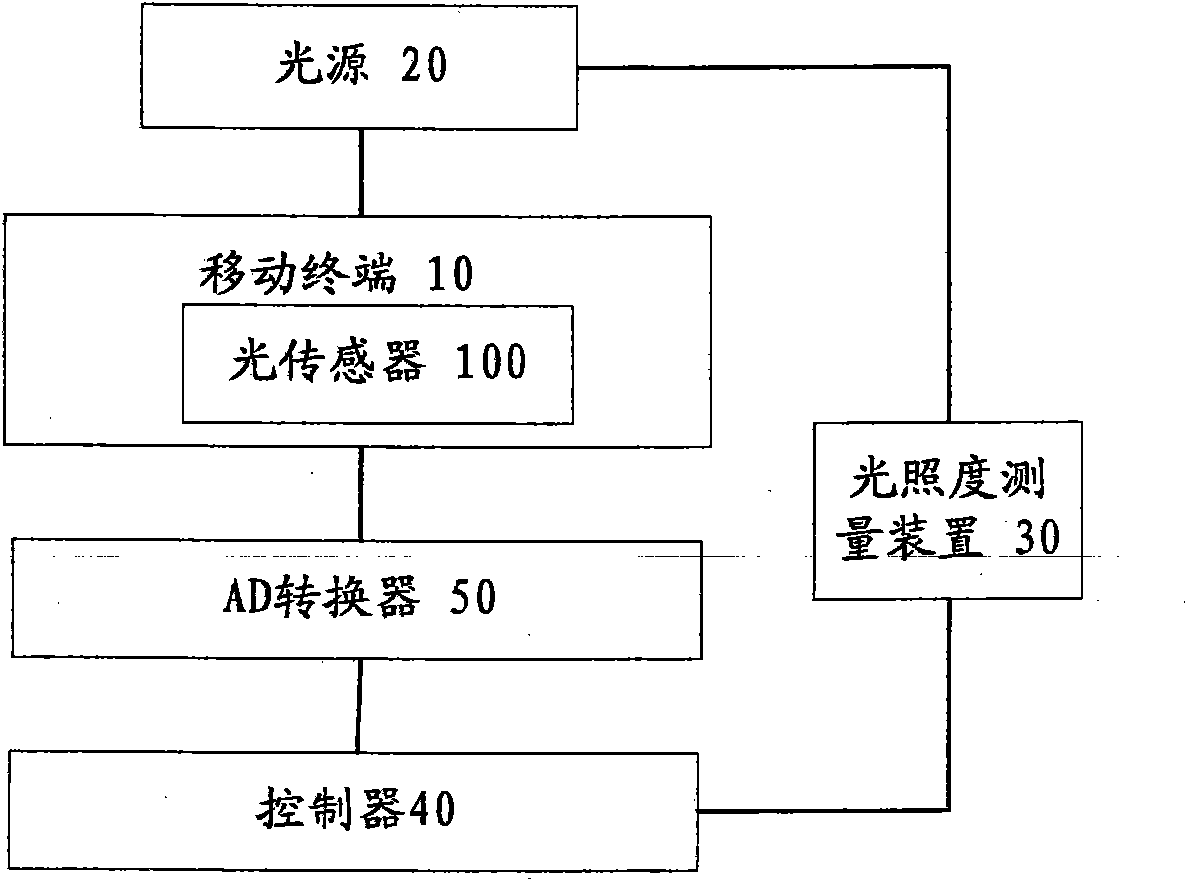

InactiveCN102466515AHigh precisionEasy to usePhotometry using electric radiation detectorsTelephone set constructionsComputer terminalLight transmission

The invention provides a method and a system for calibrating an optical sensor of a mobile terminal, wherein the method comprises the following steps: placing the mobile terminal containing the optical sensor under a light source; measuring the illuminating value of light irradiated on the front shell glass of the mobile terminal, and recording an illuminating value measured by the optical sensor in the mobile terminal; determining the light transmission ratio of the front shell glass of the mobile terminal according to the illuminating value of the front shell glass of the mobile terminal and the illuminating value measured by the optical sensor; and calibrating the optical sensor according to the light transmission ratio of the front shell glass of the mobile terminal. According to the invention, the optical sensor is calibrated through referring to the influence of the light transmission ratio of the front shell glass, thus not only can the calibration precision be improved, but also the calibration method is simple and practicable.

Owner:BYD CO LTD

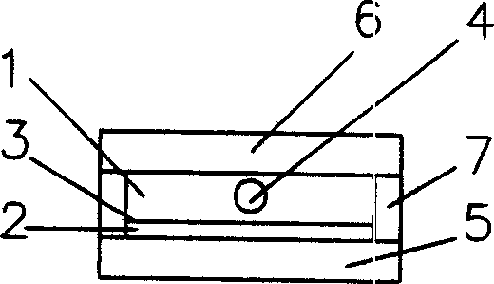

Glasses leg and its procesing method

InactiveCN1588172AImprove product gradeDoes not increase production costsSpecial ornamental structuresLight effect designsTransmittanceBiomedical engineering

The invention relates to a glasses feet and its processing method, it provides glasses feet which can display stereo pattern in semitransparent or transparent material. The processing method includes following steps: selects at least glue board combined with materials with different transmittance or refractive index, and carries on mold cutting according to the shape of glasses feet. 2. Heats the glasses feet and softens them. 3. Uses clamping device to clamp the softened glasses feet and injects copper pin from on end, one surface of the clamping device is metal template etched with patterns, the surface contacting to the template have correspondent patterns, the layer structure is changed too, thus the correspondent pattern on the external surface is polished off. 4. Grinding and bending.

Owner:林永汉

Pretreatment process for automobile deformed aluminum alloy plate

The invention relates to a technique of processing low-copper vehicle wrought aluminium alloy boards such as 6022, 6016 and the like, especially relates to a preprocessing technique for assuring baking hardenability and formability of vehicle wrought aluminium alloy boards.The preprocessing technique of vehicle wrought aluminium alloy boards is characterized by placing aluminum alloy boards into a furnace for solid solution treatment, 30 minutes after the solid solution heating and heat preserving under a temperature of 520 DEG C-550 DEG C, placing them into a polyether water-soluble medium of 5-10% for quenching, putting them in a room temperature for 2-3 days after being cooled, putting them into an aging treatment furnace for being treated for 10-15 minutes under a temperature of 140-170 DEG C. The invention which is a simple technique improves the yield strength, tensile strength and specific elongation of aluminum alloy boards, therefore, improving the formability, aging -resisting stability and baking hardenability of aluminum alloy boards, can achieve an satisfactory baking and overhardening effect on the existing oil paint line, improves rate of final products formed by pressing, reduces the pressing cost and promotes the application of aluminum boards in the lighteningof vehicles.

Owner:HENAN SUDA ELECTRIC AUTOMOBILE TECH

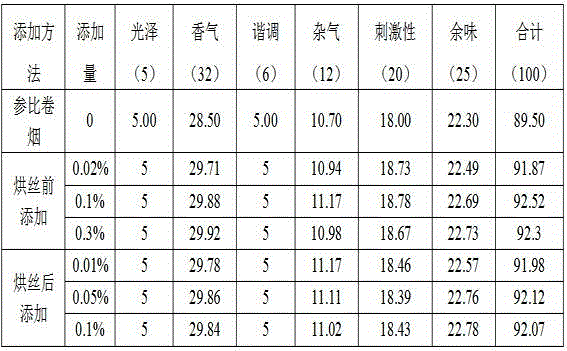

Sugar cane juice Maillard reaction product, preparation method thereof and application thereof to cigarettes

ActiveCN104152265AHighlight the "roasted sweet" aroma of cigarettesImprove smoking qualityTobacco treatmentEssential-oils/perfumesBiotechnologyMaillard reaction

The invention discloses a preparation method of a sugar cane juice Maillard reaction product. The method comprises the steps of cleaning, squeezing, filtering, enzymatic hydrolysis, concentrating, reacting and the like. Sugar cane is subjected to cleaning, squeezing, filtering, enzymatic hydrolysis and concentrating, and undergoes a Maillard reaction with proline at the temperature of 110-130 DEG C. The prepared sugar cane juice Maillard reaction product is uniformly sprayed onto tobacco shreds in a cigarette feeding procedure, so that the sweet flavor of cigarettes is highlighted, the smoking quality and feel comfort of the cigarettes are improved, the fragrance of the cigarettes is improved remarkably, the aftertaste is improved, and the irritation and offensive odor are reduced greatly. The product is low in cost, is simple in process, is high in safety, and is worthy of industry-wide popularization and application.

Owner:CHINA TOBACCO HENAN IND

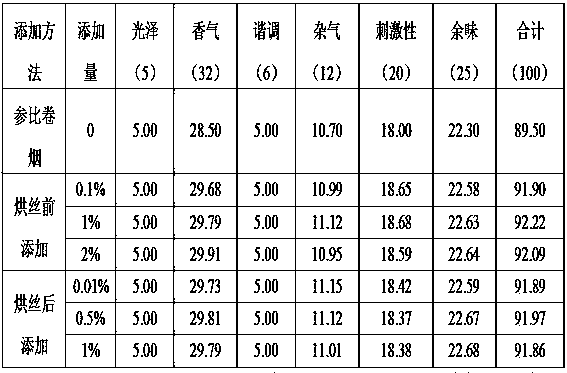

Roasted potato spice, preparation method thereof and application of roasted potato spice in cigarettes

ActiveCN104178340AHighlight the "toasted fragrance" aroma of cigarettesImprove smoking qualityTobacco treatmentEssential-oils/perfumesBiotechnologyRoast potato

The invention discloses a preparation method of a roasted potato spice. The preparation method comprises the following steps: cleaning and peeling, crushing and pulping, pressure-reduced filtration, yeast fermentation, high-temperature baking, homogeneous emulsification and the like, i.e., the method comprises the following steps: performing cleaning and peeling, crushing and pulping, pressure-reduced filtration and yeast fermentation treatment on potatoes, performing high-temperature baking at 60-350 DEG C, and then performing homogeneous emulsification by virtue of a colloid grinder. The prepared roasted potato spice disclosed by the invention is uniformly sprayed on cut tobaccos in a cigarette feeding process, and the 'baking fragrance' notes of the cigarettes can be showed, so that the smoking quality and sensory comfort level of the cigarettes can be improved, the aroma of the cigarettes can be significantly increased, the aftertaste can be improved, and the irritation and miscellaneous odors also can be relatively greatly reduced. The product disclosed by the invention is low in cost, simple in process and high in safety, and is worthy of popularization and application in the whole industry.

Owner:CHINA TOBACCO HENAN IND

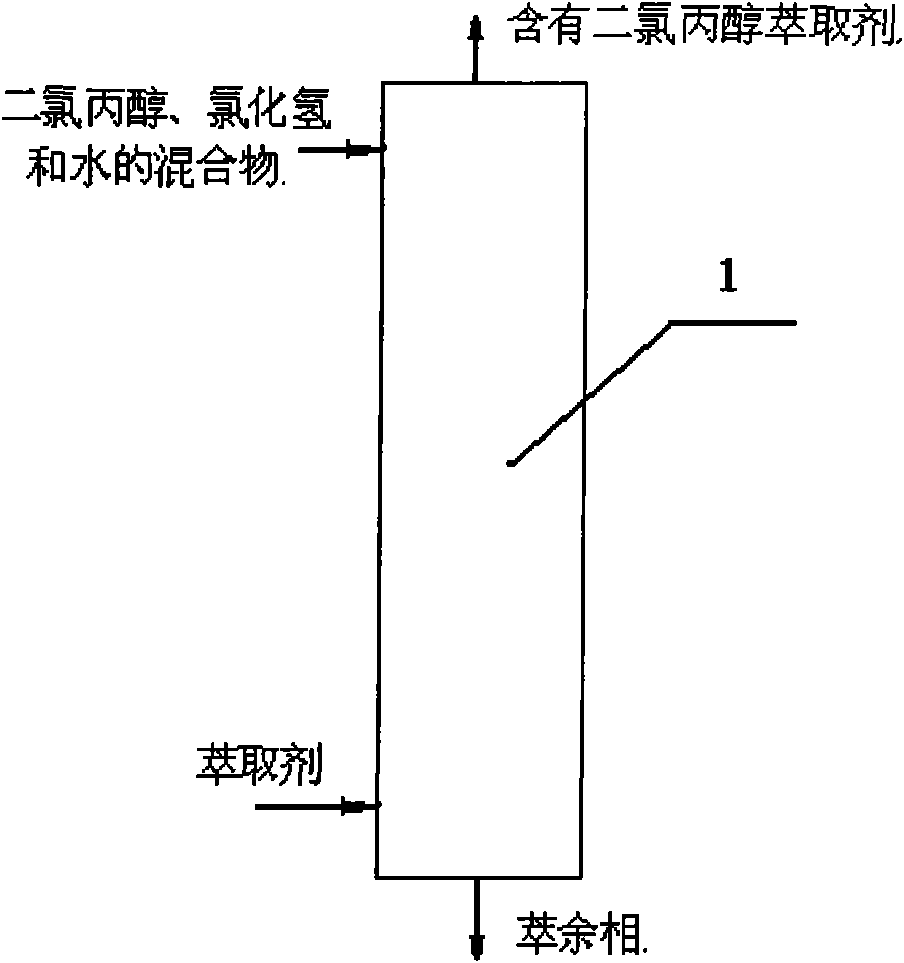

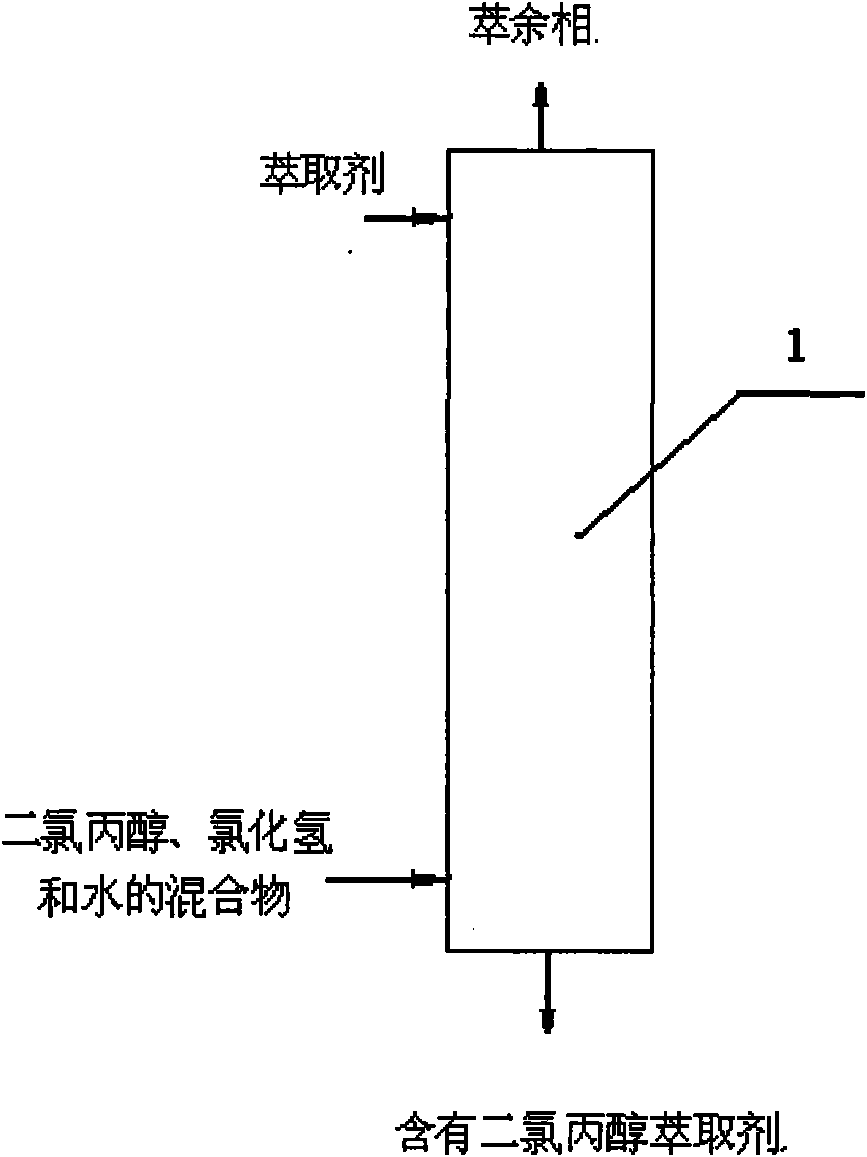

Method for separating dichlorohydrin from compound

InactiveCN101538189AReduce pollutionDoes not increase production costsOrganic compound preparationHydroxy compound preparationGas phaseEther

The invention provides a method for separating dichlorohydrin from compound, comprising the following steps: mixing the compound of dichloropropanol, chlorine hydride and water with extraction agent; then collecting the extraction agent containing dichloropropanol and adopting the method of rectification to obtain dichloropropanol by separation. The method of the invention uses the method of extraction to recover the dichloropropanol in the gas phase, thus not increasing production cost while reducing environmental pollution and achieving good separation effect and high recovery rate; in particular, the resolved solvent can still be recovered and reused, therefore, in many cases, the advantages in terms of technology, economy and environmental protection are demonstrated. Cross current solvent extraction is carried out on N-butyl ether on a four-stage basis, extraction yield of dichloropropanol reaches 91%; cross current solvent extraction is also carried out on n-octyl alcohol on a four-stage basis, the extraction yield of the dichloropropanol reaches 99%; cross current solvent extraction is also carried out on dutch liquid on a five-stage basis, the extraction yield of the dichloropropanol reaches 91%.

Owner:SHANGHAI CHLOR ALKALI CHEM +1

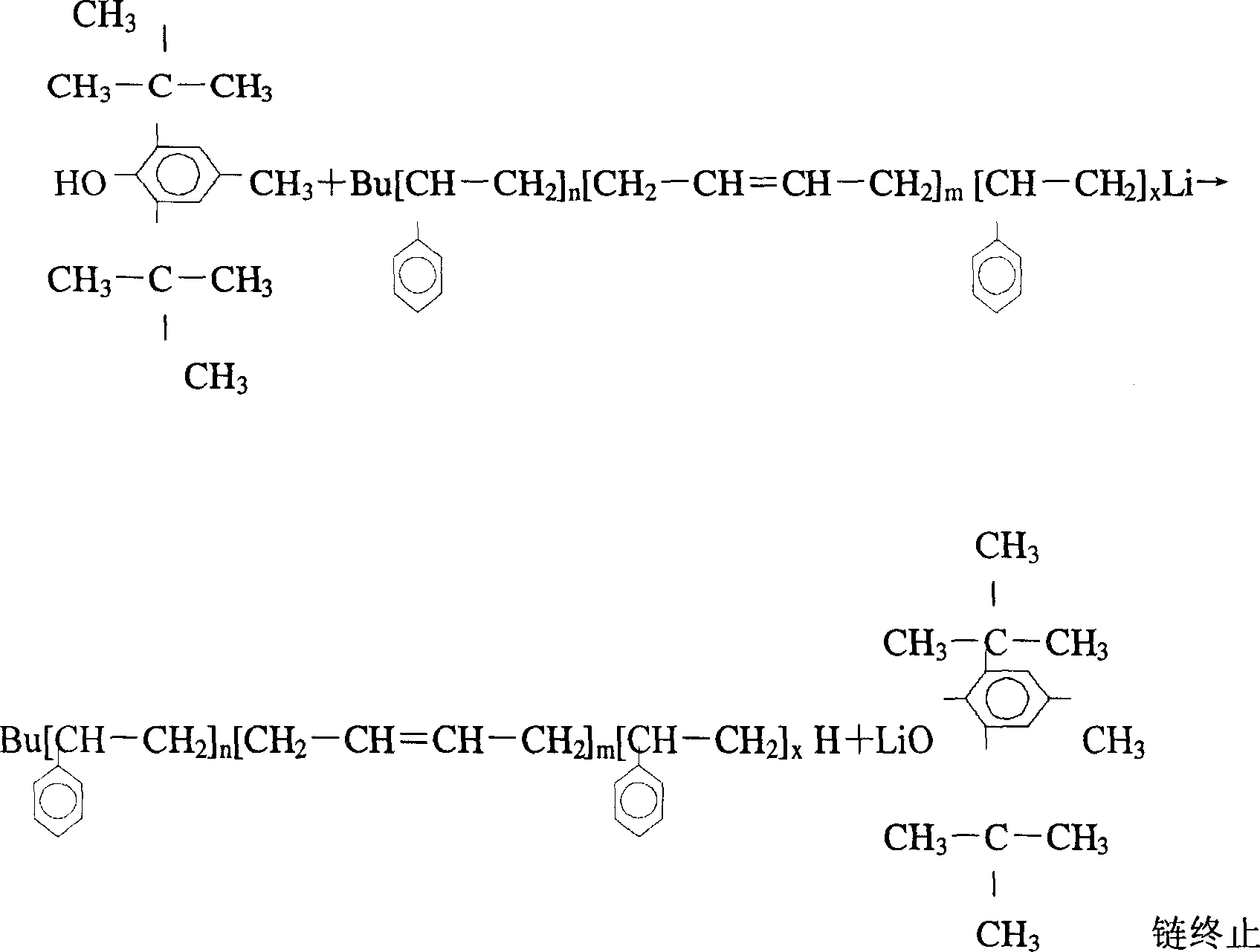

Method of terminating polymerization reaction containing conjugated diolefin polymer

InactiveCN1919881AGuarantee product qualityDoes not increase macromolecular contentPolymer scienceEmulsion

The invention discloses a method to terminate polymerization reaction of polymer with conjugated olefin, which is characterized by the following: the polymer with conjugated olefin is polybutadiene rubber, poly-emulsion butadiene styrene rubber, poly-solution butadiene styrene rubber,styrene thermo plasticity elastic body SBS, SIS, SEBS, SEPS, isoprene rubber, low cis-form polybutadiene rubber, K-pitch; adding phenols material being measured into autoclave as terminal catalyst; stirring fully; reacting at least 1min.

Owner:CHINA PETROCHEMICAL CORP +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com