Synergistic composite fertilizer and method for preparing same

A technology of compound fertilizer and polyaspartic acid, applied in fertilization equipment, fertilizer mixture, application, etc., can solve problems such as troubles, achieve the effect of improving quality, improving absorption and utilization rate, and improving soil structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

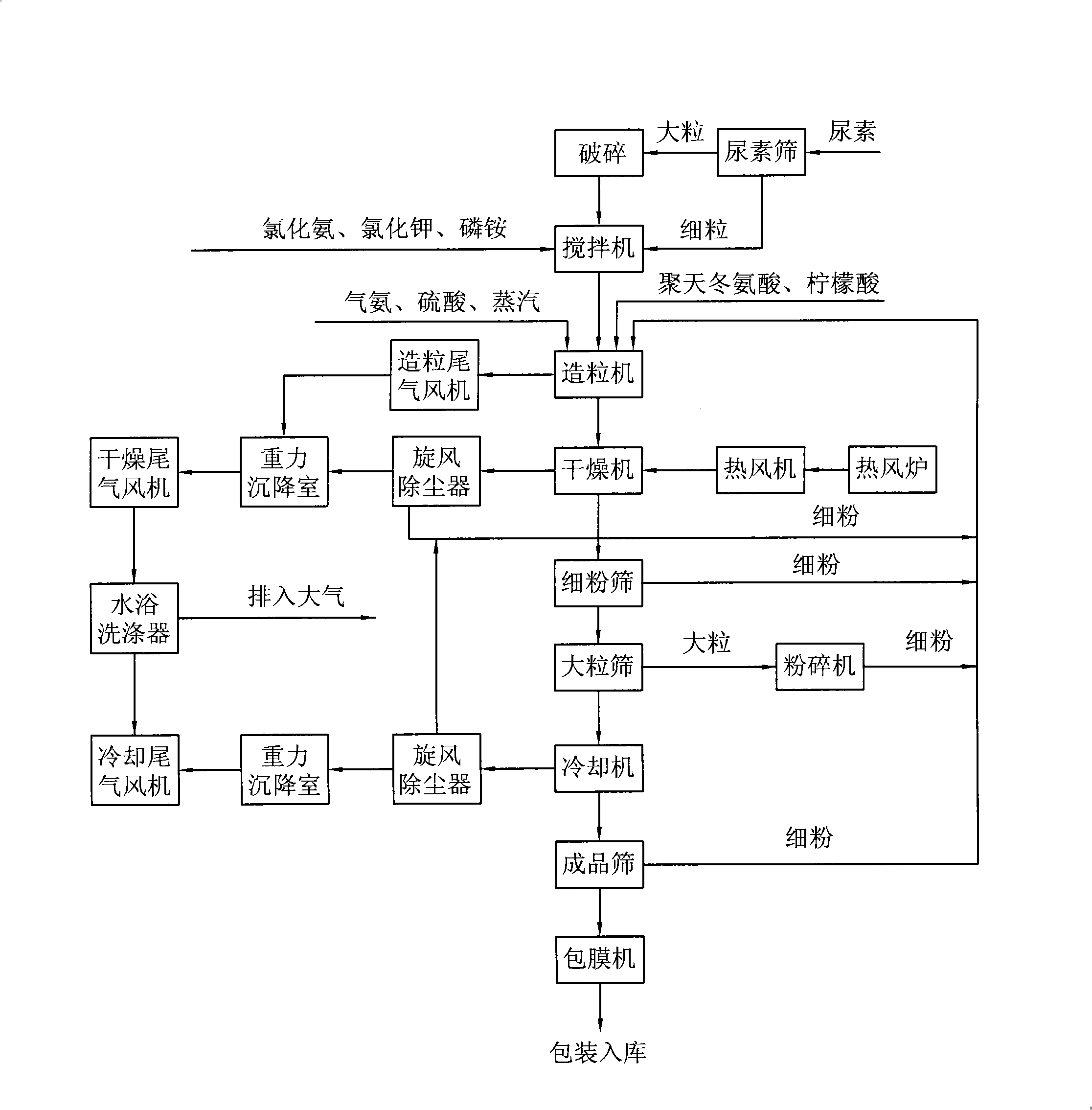

[0028] The technological process of this embodiment is as figure 1 Shown is the production process of urea-based compound fertilizer, and its equipment and process method are to utilize the existing equipment and process technology for producing urea-based compound fertilizer. The difference between this embodiment and the existing equipment is that a metering pump connected to the granulator is added before the granulator, and the aqueous solution of polyaspartic acid and citric acid is added into the granulator through the metering pump. The weight percent of polyaspartic acid in the aqueous solution of polyaspartic acid and citric acid is 30%, and the weight percent of citric acid is 15%. The flow rate of the metering pump is 100 kg / h. Polyaspartic acid and citric acid are mixed evenly with other materials in the granulator, and the materials are partially melted and cohesively granulated by using the reaction heat of sulfuric acid and ammonia and the heat and moisture pro...

Embodiment 2

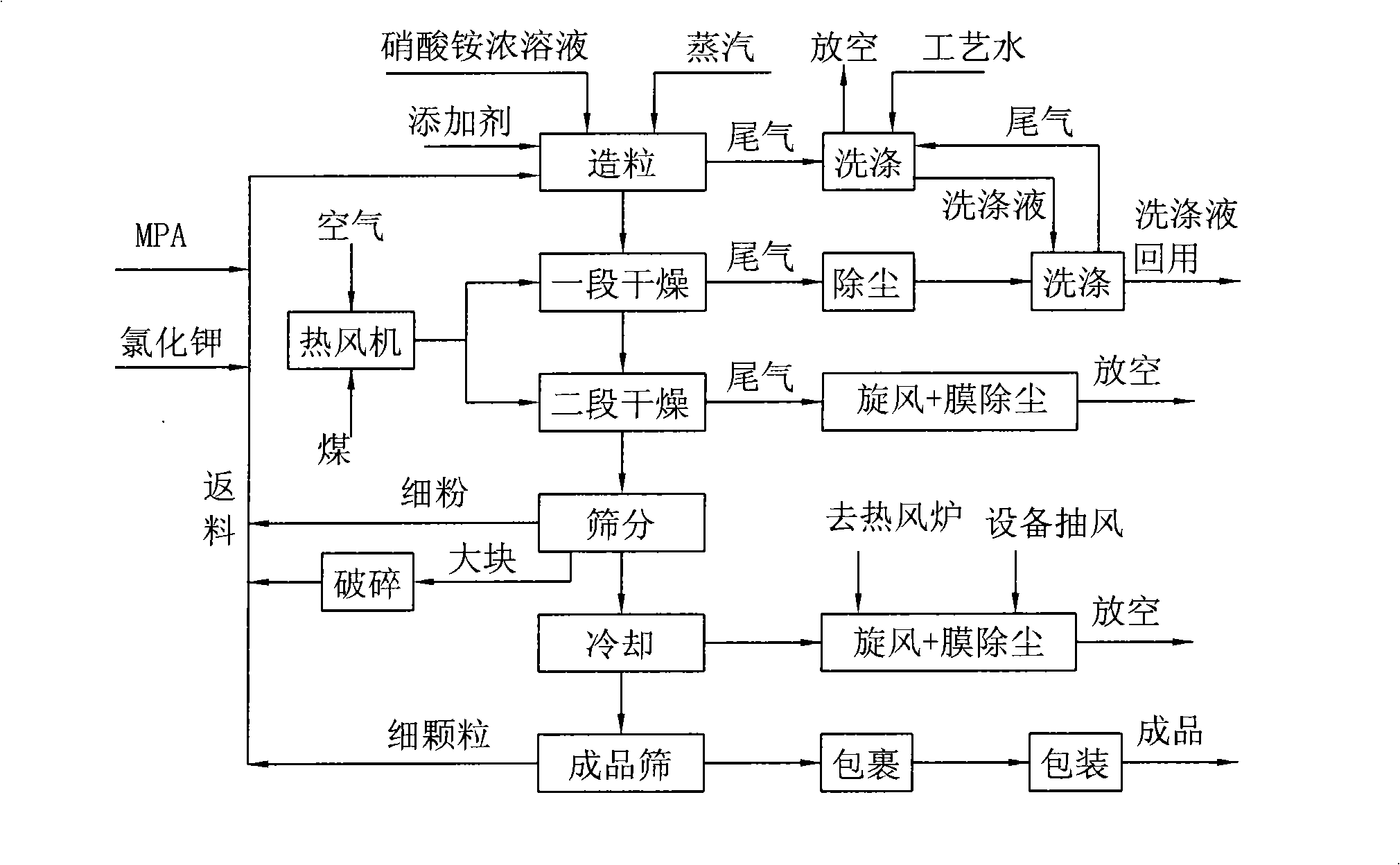

[0030] The technological process of this embodiment is as figure 2Shown is the production process of nitro compound fertilizer, and its equipment and process method are to utilize the existing equipment and process of producing nitro compound fertilizer. The difference between this embodiment and the existing equipment is that a metering pump connected with the granulator is added before the granulator. Add the aqueous solution containing 80% polyaspartic acid into the granulator through the metering pump, and the flow rate is 750Kg / h; at the same time, add the zeolite powder at the flow rate of 2T / h and the humic acid at the flow rate of 1T / h to the granulator. in the granulator. The above additives and other materials are mixed evenly in the granulator, and the solid materials are bonded and granulated by using the heat and moisture provided by the concentrated ammonium nitrate solution and steam, and finally obtain a synergistic nitro compound fertilizer with a production...

Embodiment 3

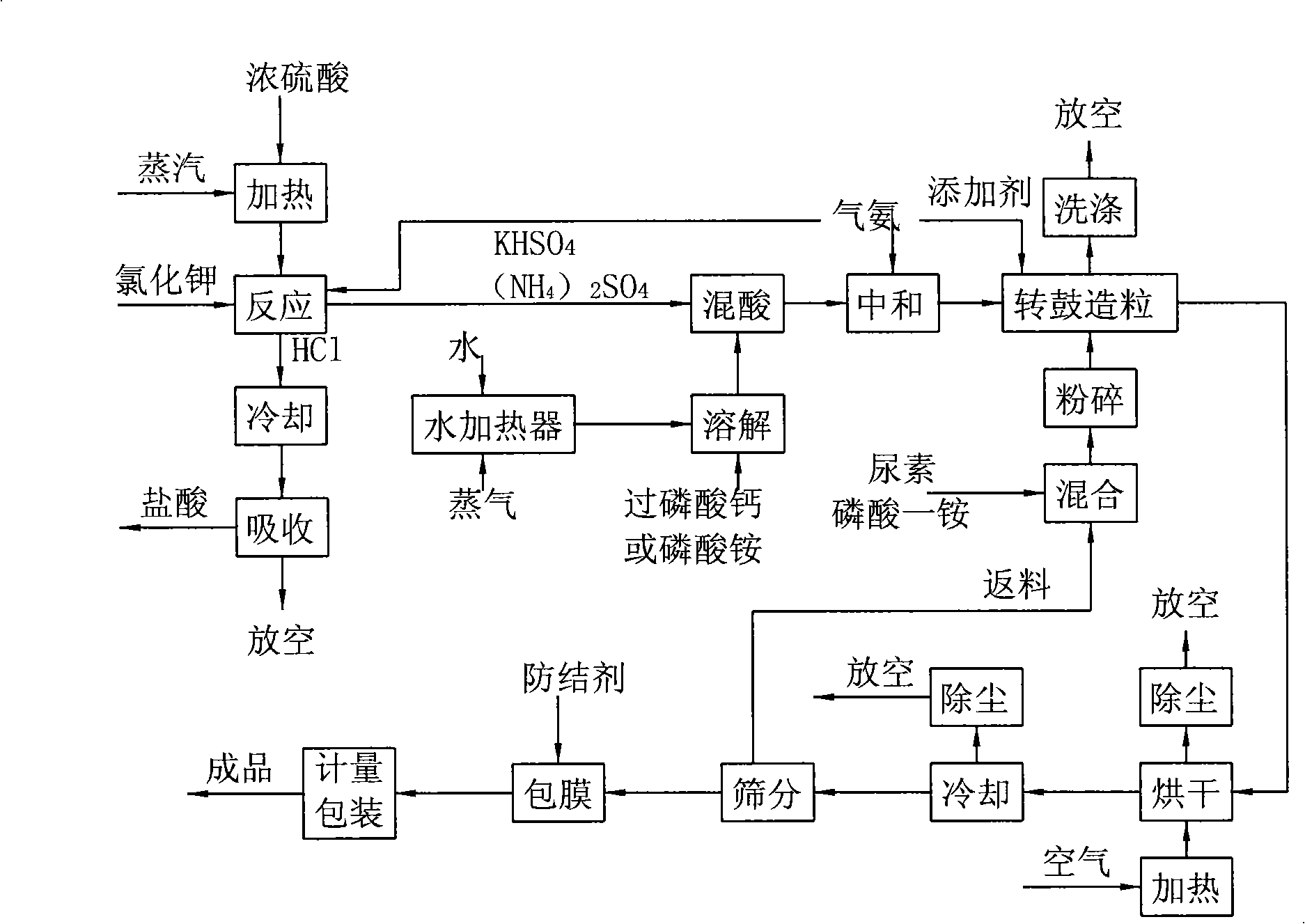

[0032] The technological process of this embodiment is as image 3 Shown is the production process of sulfur-based compound fertilizer. Its equipment and process are the same as the existing equipment and process technology for producing sulfur-based compound fertilizer. Metering pump connected to pellet machine. The 20% aqueous solution containing polyaspartic acid sodium salt is added to the granulator through a metering pump, and the flow rate is 100 kg / hour; at the same time, the zeolite powder is added in proportion to the granulator, and the addition amount is 20 kg / hour. Hour. Mix the above additives with potassium bisulfate, ammonium sulfate, superphosphate, urea, and monoammonium phosphate in a granulator and make granules. Finally, 20 tons / hour of synergistic sulfur-based compound fertilizer was obtained, and its product quality met the quality standard requirements after testing.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com