Patents

Literature

239results about "Metallurgical bonding" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

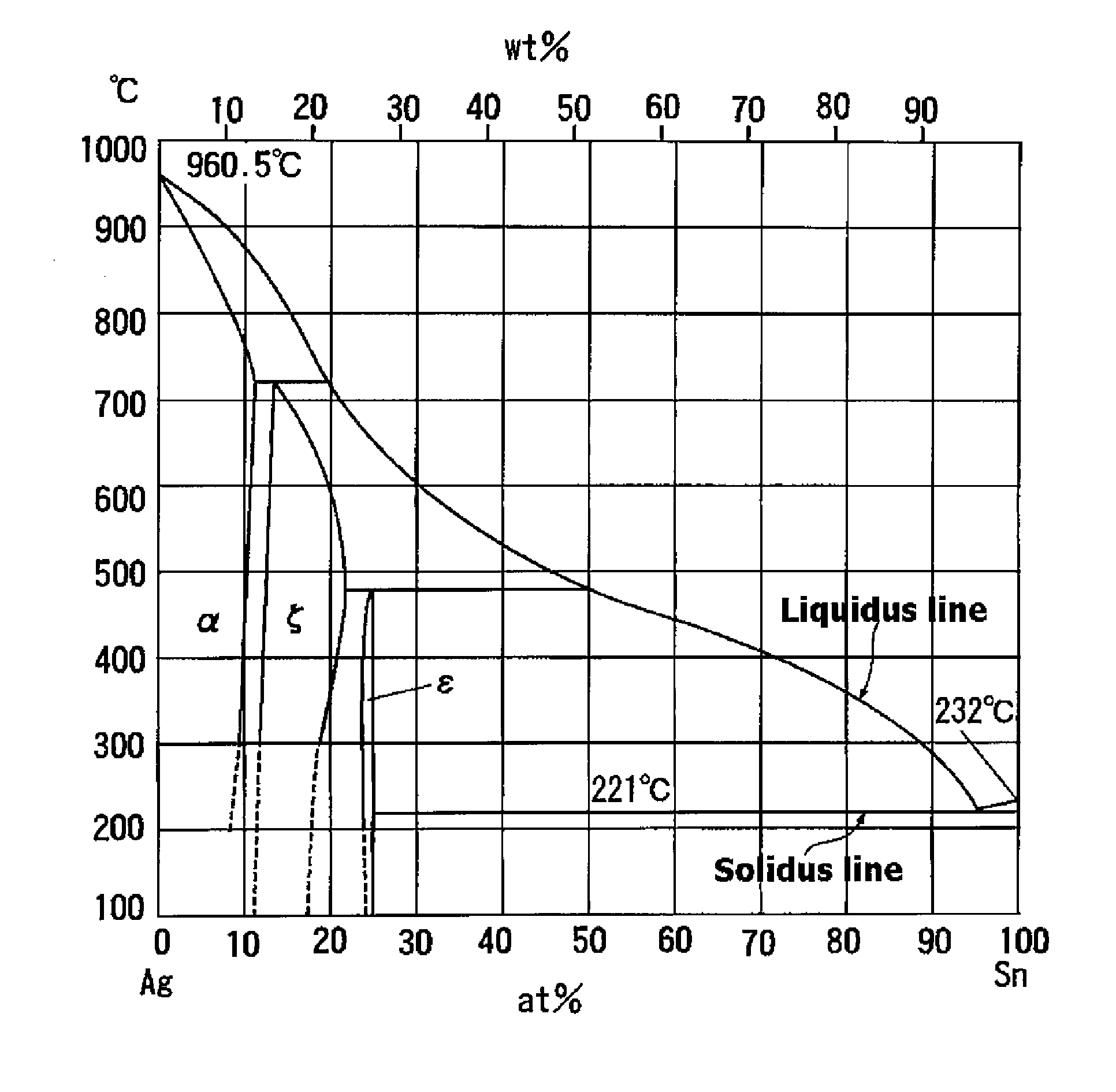

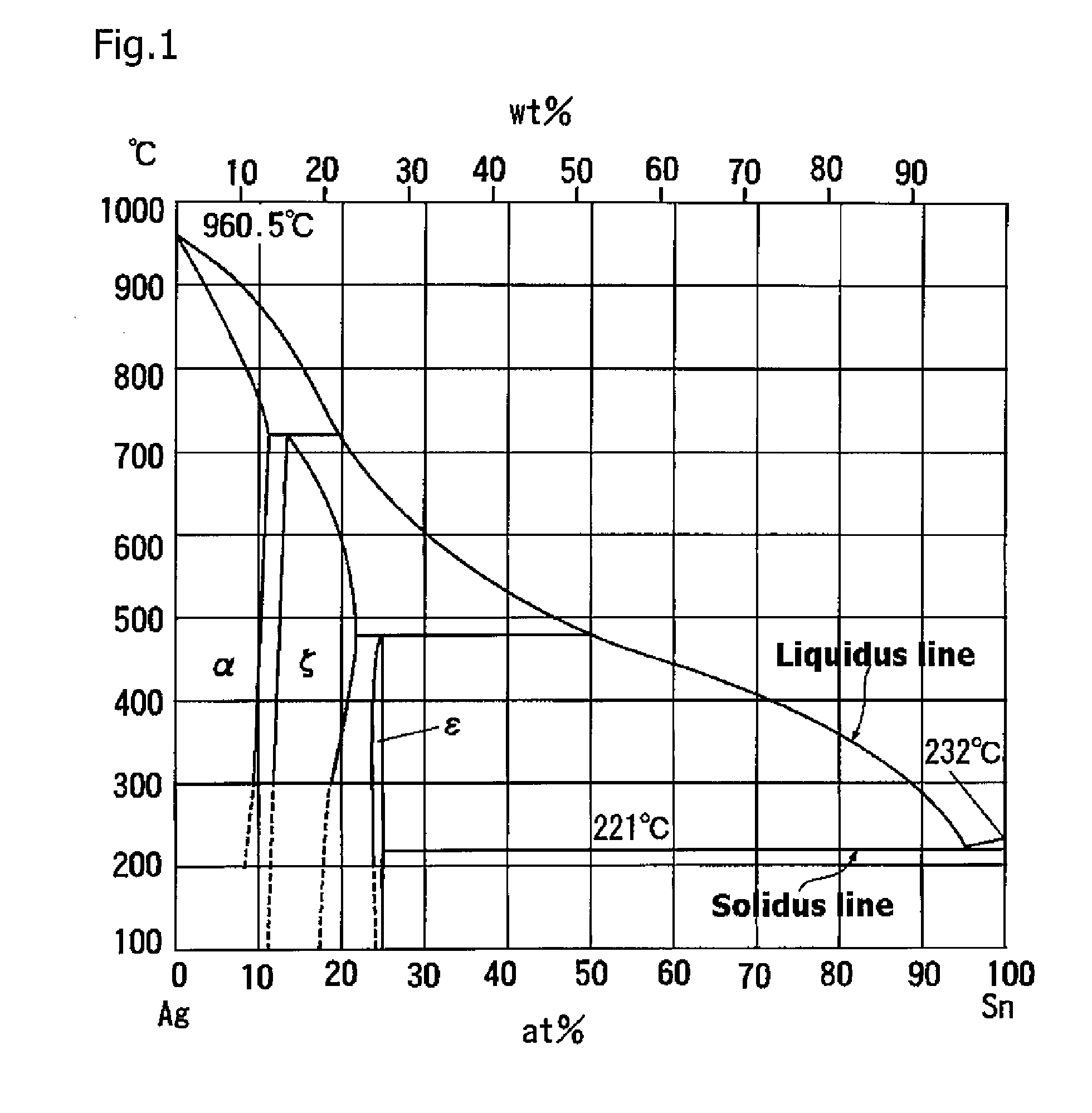

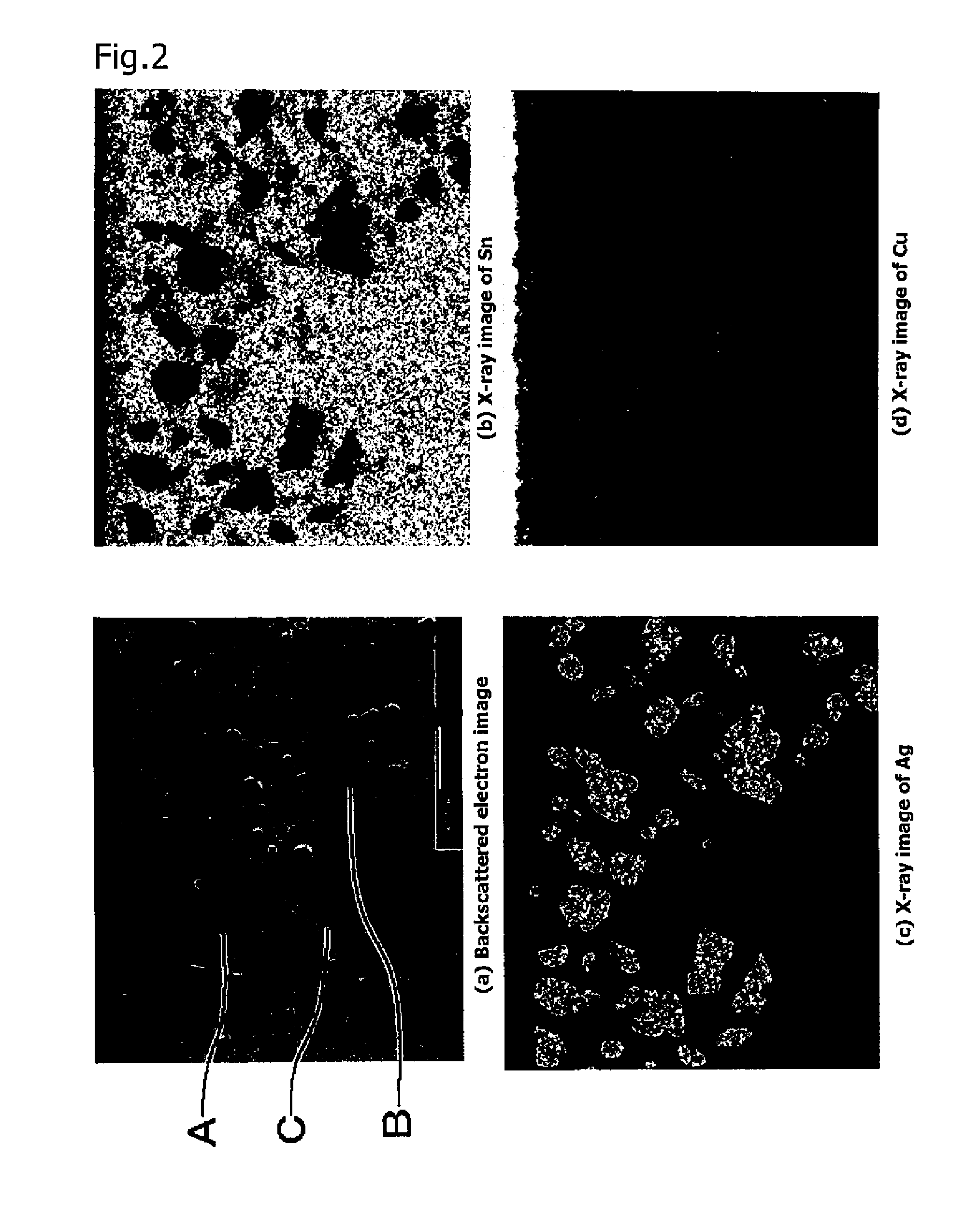

Cream solder and method of soldering electronic part

ActiveUS20120018048A1Improve adhesionHigh strength stabilityPrinted circuit assemblingPrinted circuit aspectsThermal stabilityUltimate tensile strength

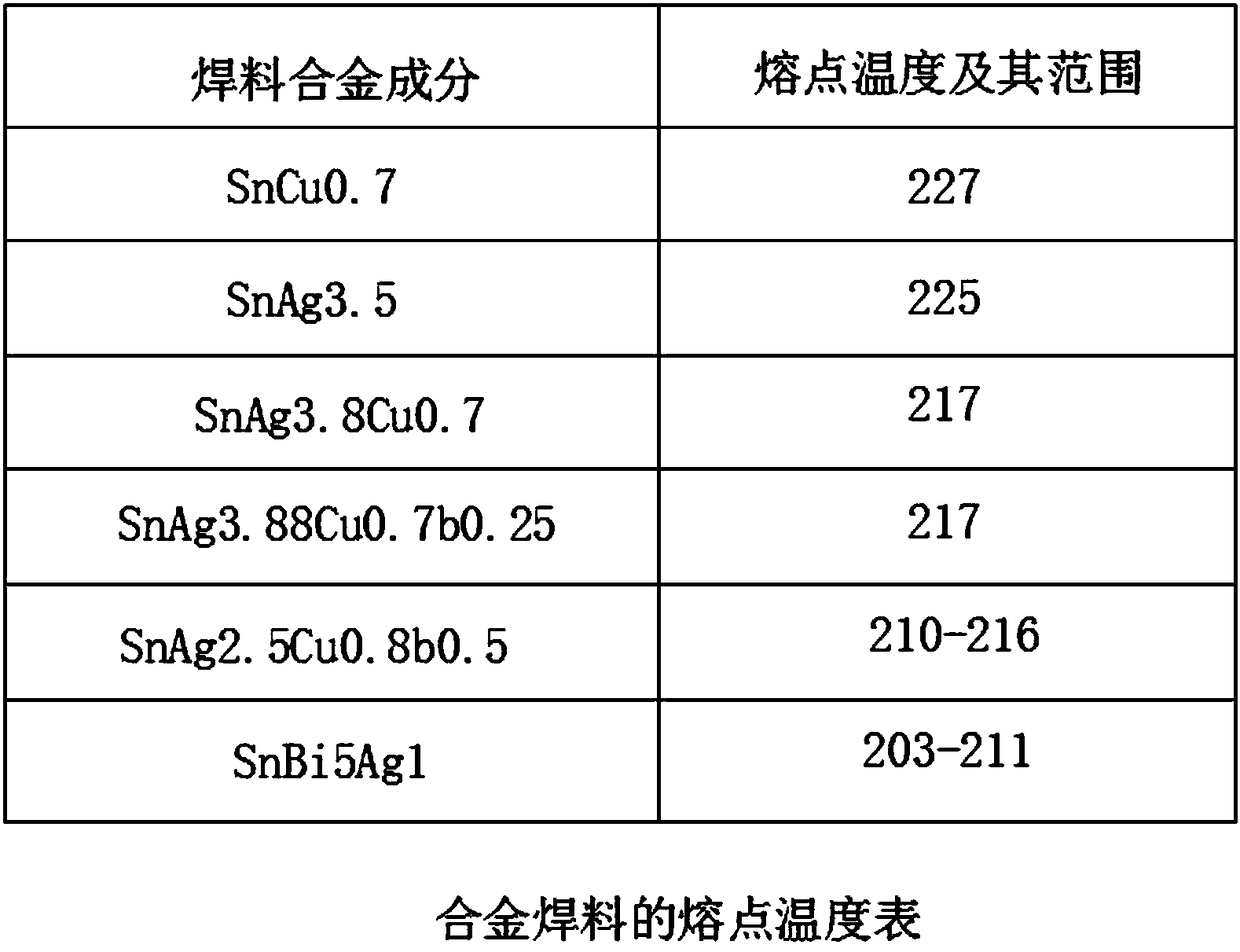

A cream solder obtained by kneading an Sn—Ag—Cu alloy together with a flux, wherein the Sn—Ag—Cu alloy includes a mixture of a first powdery alloy and a second powdery alloy, the first powdery alloy is represented by an Sn—Ag phase diagram having a solid-liquid coexistence region and has a given silver amount which is larger than that in the eutectic composition (3.5 wt. % silver), and the second powdery alloy has a silver amount which is that in the eutectic composition (3.5 wt. % silver) or which is close to that in the eutectic composition and is smaller than that in the first powdery alloy. This cream solder has excellent strength and thermal stability, and satisfactory bonding properties. It is based on an inexpensive Sn—Ag—Cu solder alloy. It is suitable for use as a high-temperature-side lead-free solder material conformable to temperature gradation bonding. Also provided is a method of soldering.

Owner:NIHON HANDA +1

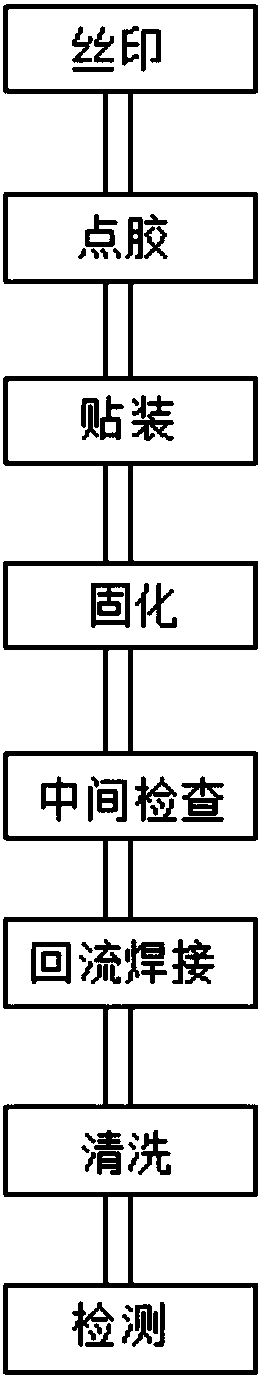

SMT patching process

InactiveCN108521722AHigh viscosityGuarantee product qualityPrinted circuit assemblingMetallurgical bondingPrinting pressSolder paste

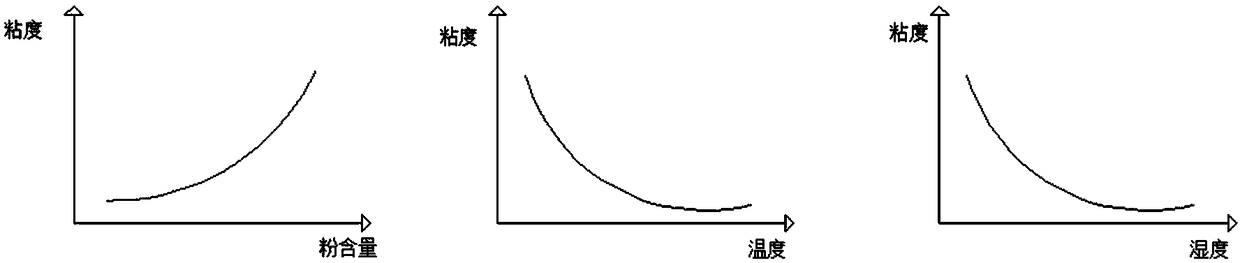

The invention discloses an SMT patching process which comprises the following steps: S1, silk screening: patching a circuit board to the lower surface of a steel screen after an optical camera detectsthat the circuit board is free of errors, then printing soldering paste or patch leaked glue to a welding plate of a PCB through a screening printer to be prepared for welding of components; S2, gluedispensing: dropping glue to a fixed position of the circuit board after the step of silk screening by means of action of a glue dispenser, wherein the electric components are fixed to the circuit board; and S3, pasting: feeding the circuit board after the step of glue dispensing to a chip mounter. The SMT patching process has the beneficial effects that influence of environmental factors is avoided by controlling the environmental factors in the whole process technology well, so that the viscosity of solder paste can be improved; meanwhile, metal powder in the solder paste is changed to overcome the condition that original cooling speed is small and the surface of the solder paste is not steady; and furthermore, the quality of the circuit board is enhanced.

Owner:贵州贵安新区众鑫捷创科技有限公司

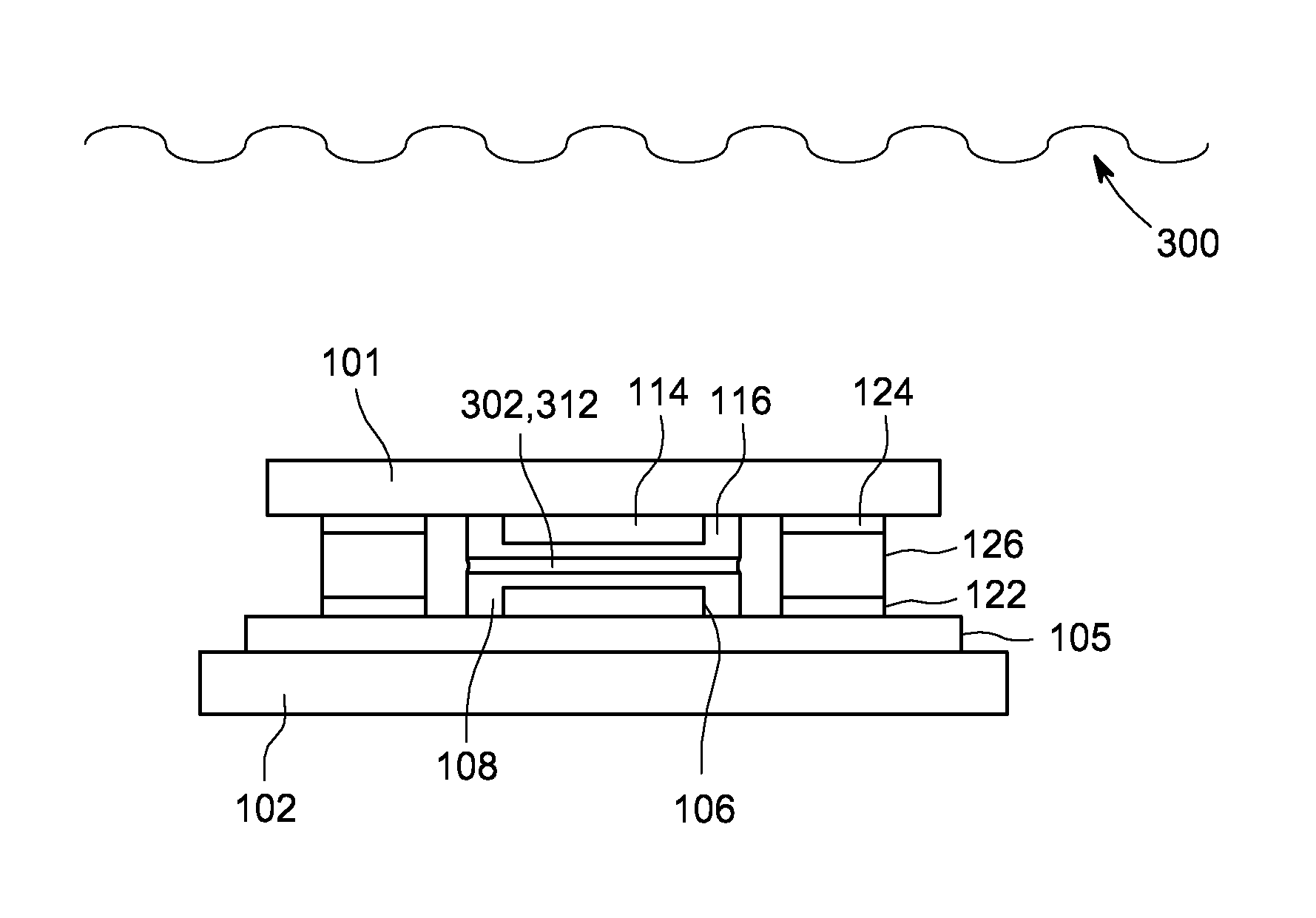

Advanced device assembly structures and methods

Owner:INVENSAS LLC

Advanced device assembly structures and methods

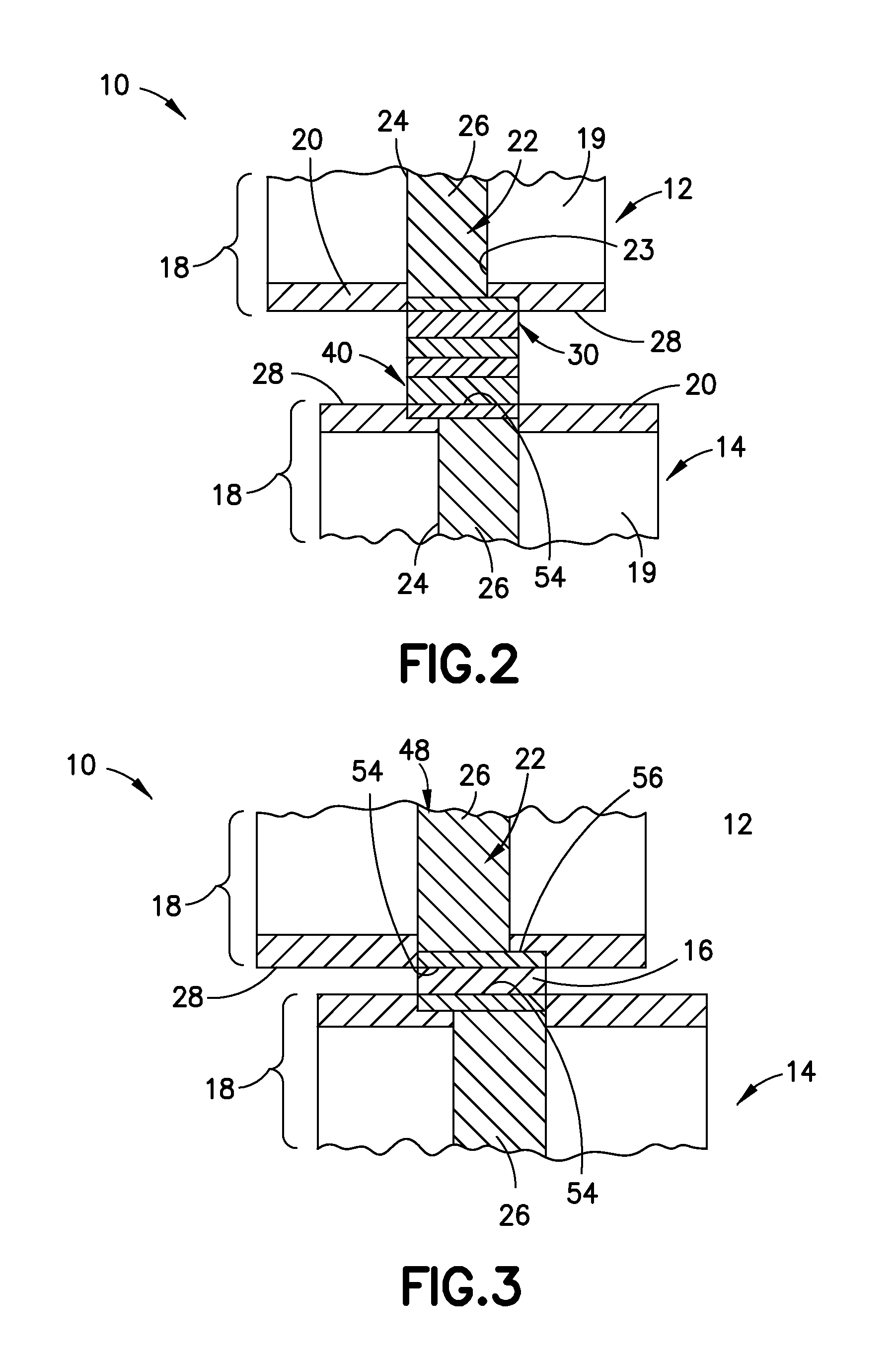

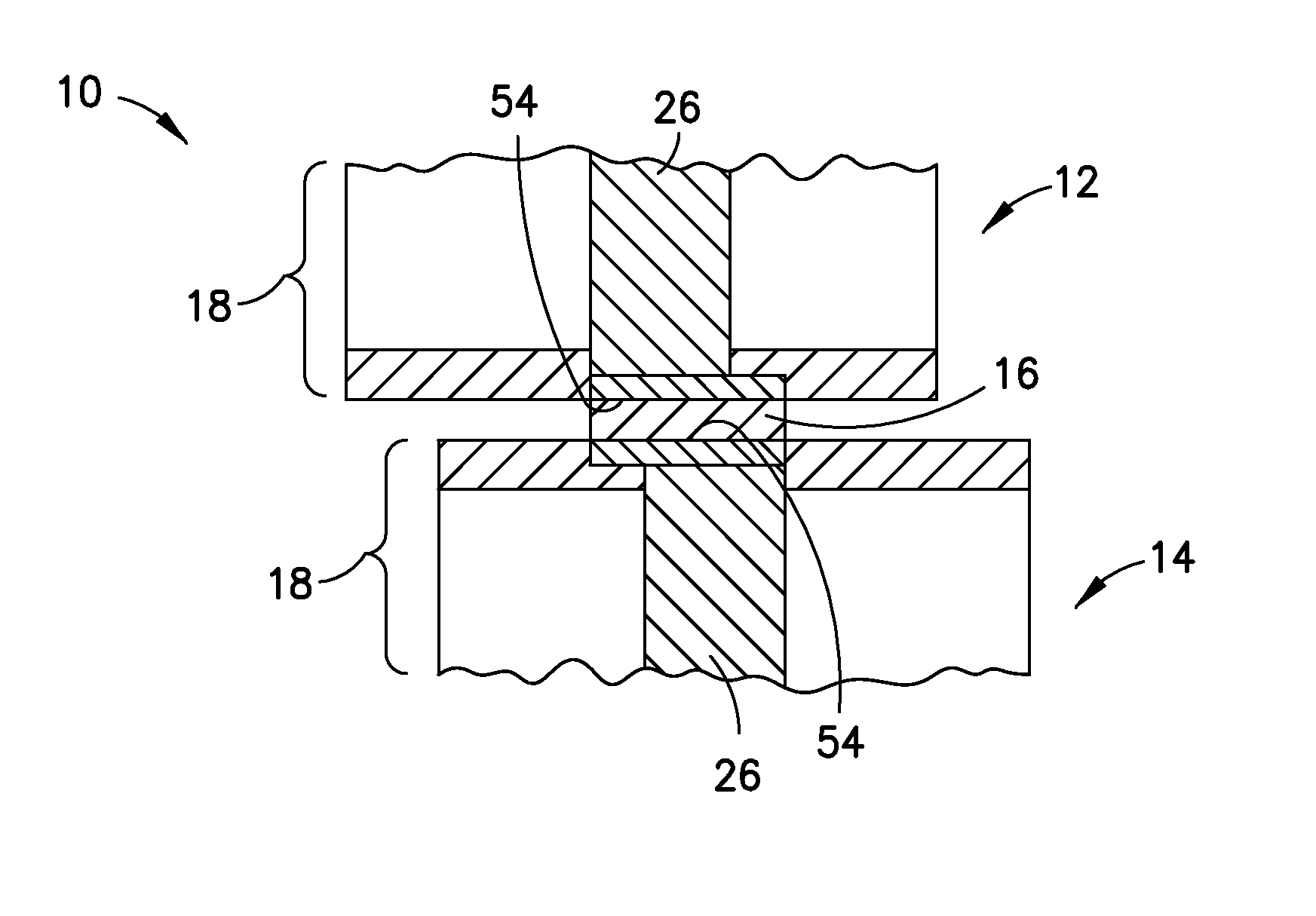

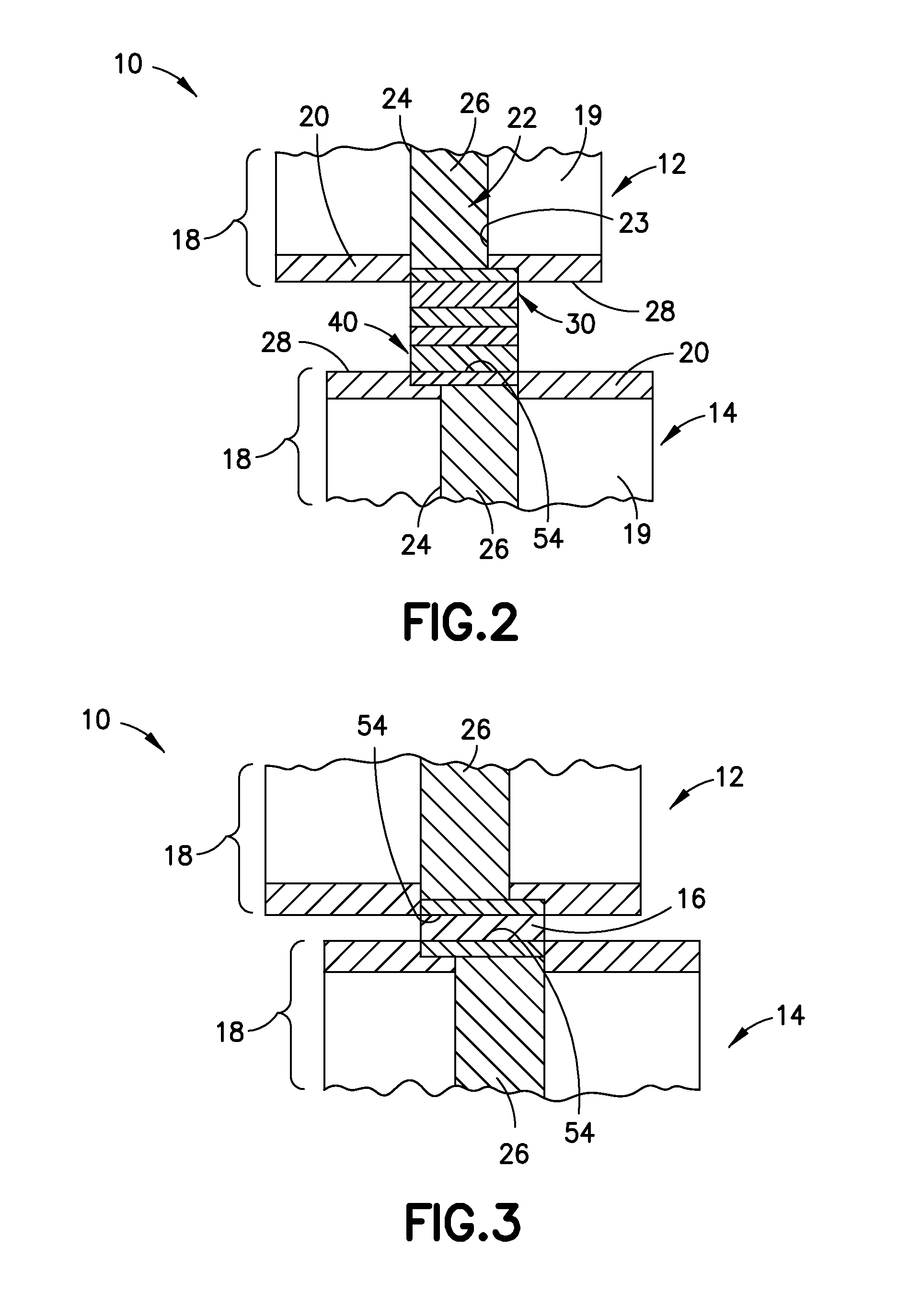

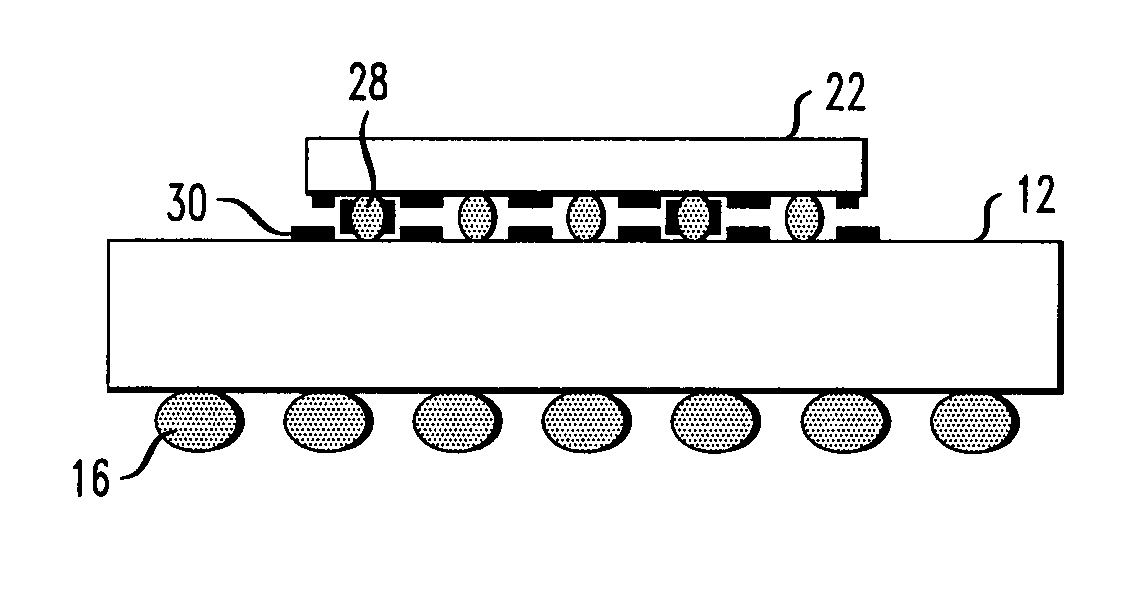

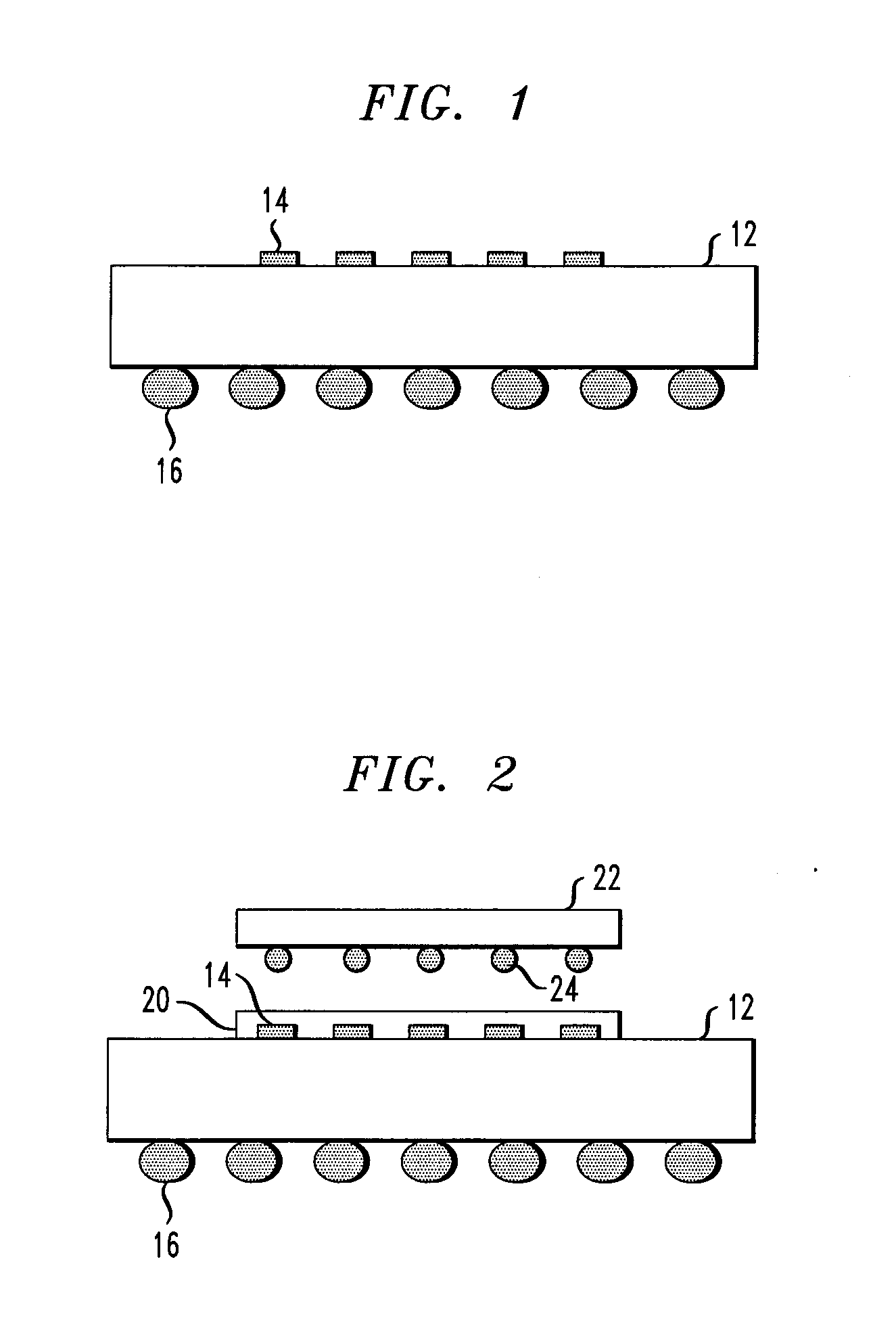

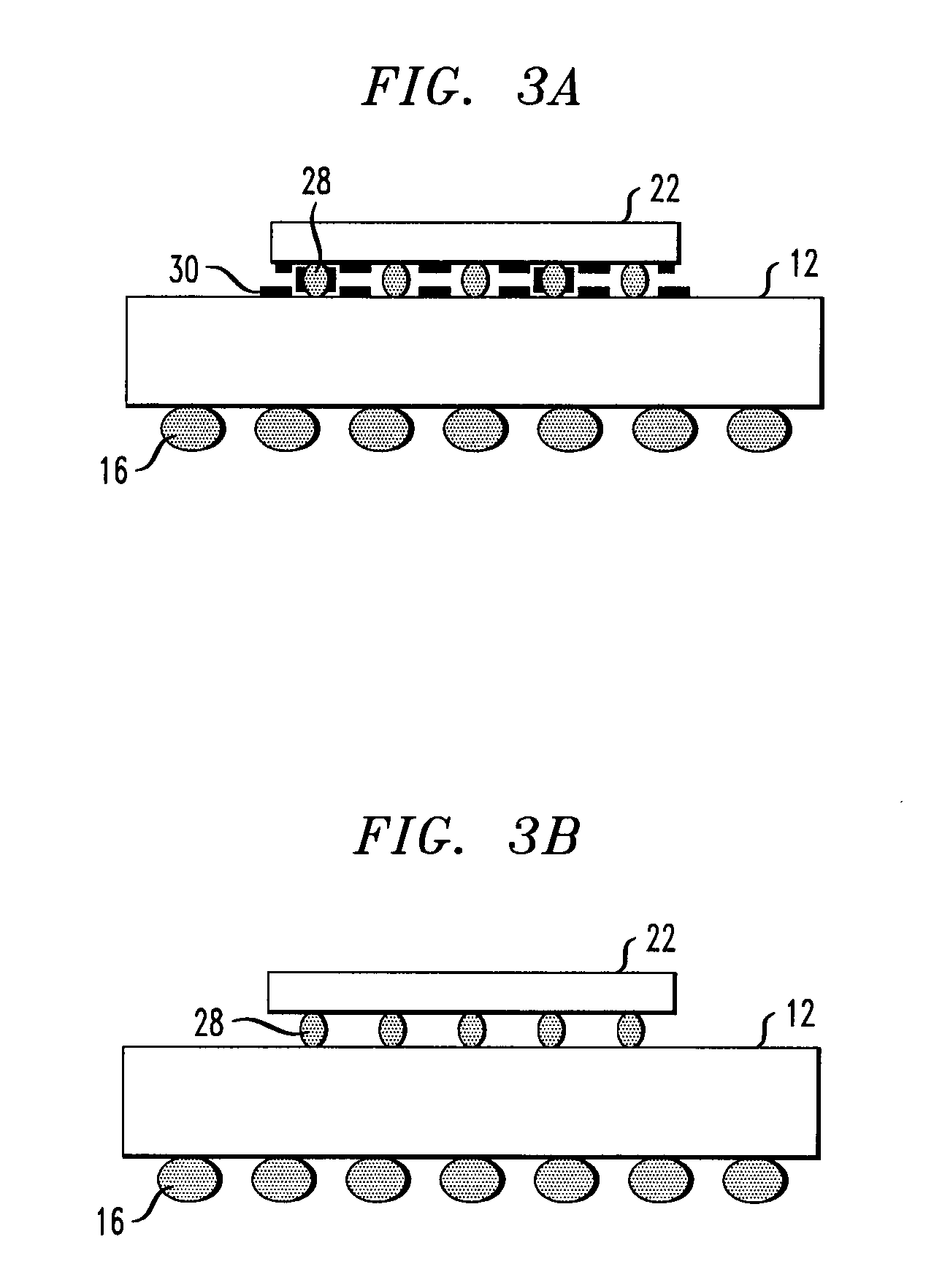

ActiveUS20140153210A1Printed circuit assemblingSemiconductor/solid-state device detailsAlloyAssembly structure

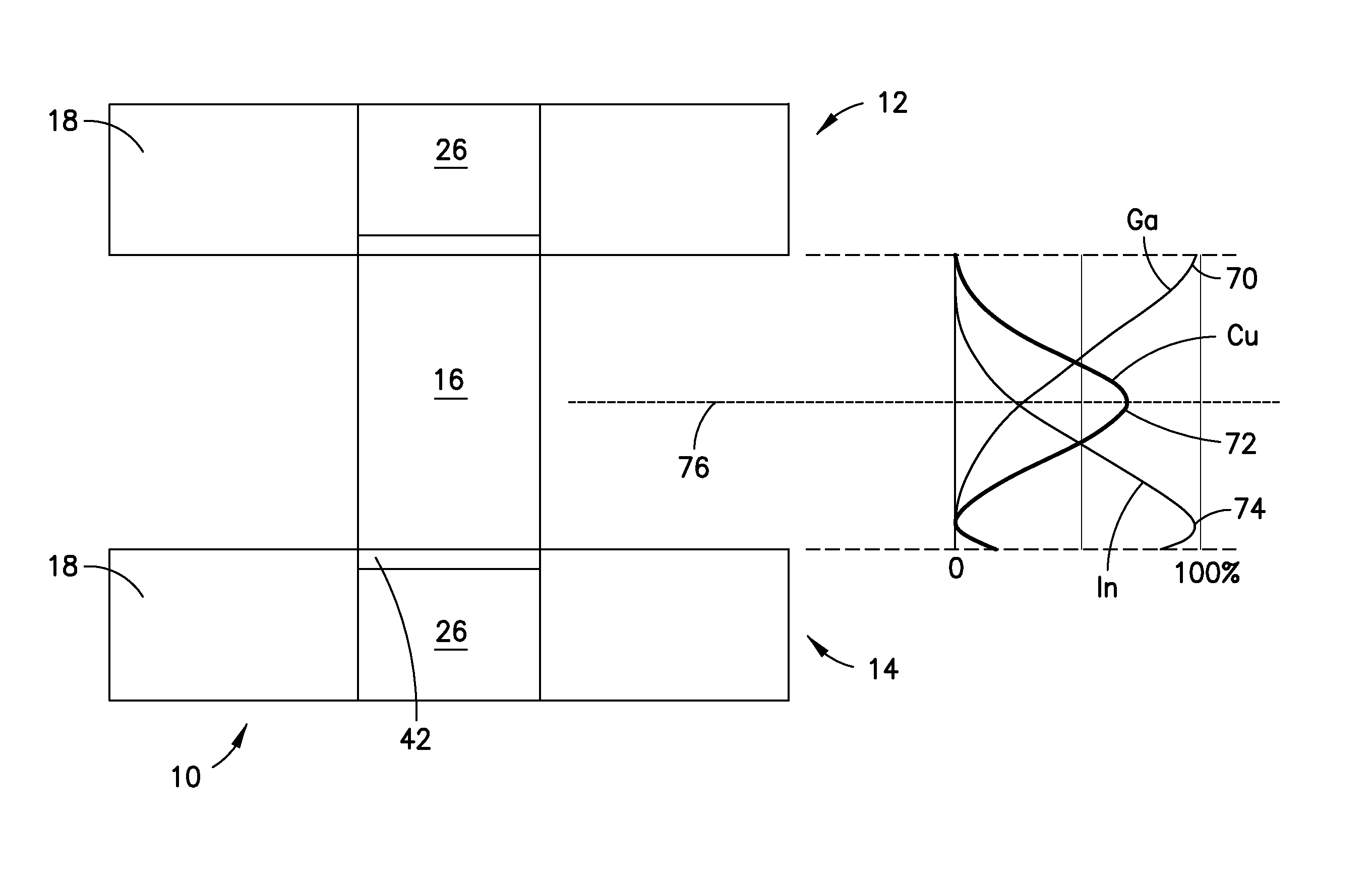

A microelectronic assembly includes a first substrate having a surface and a first conductive element and a second substrate having a surface and a second conductive element. The assembly further includes an electrically conductive alloy mass joined to the first and second conductive elements. First and second materials of the alloy mass each have a melting point lower than a melting point of the alloy. A concentration of the first material varies in concentration from a relatively higher amount at a location disposed toward the first conductive element to a relatively lower amount toward the second conductive element, and a concentration of the second material varies in concentration from a relatively higher amount at a location disposed toward the second conductive element to a relatively lower amount toward the first conductive element.

Owner:INVENSAS LLC

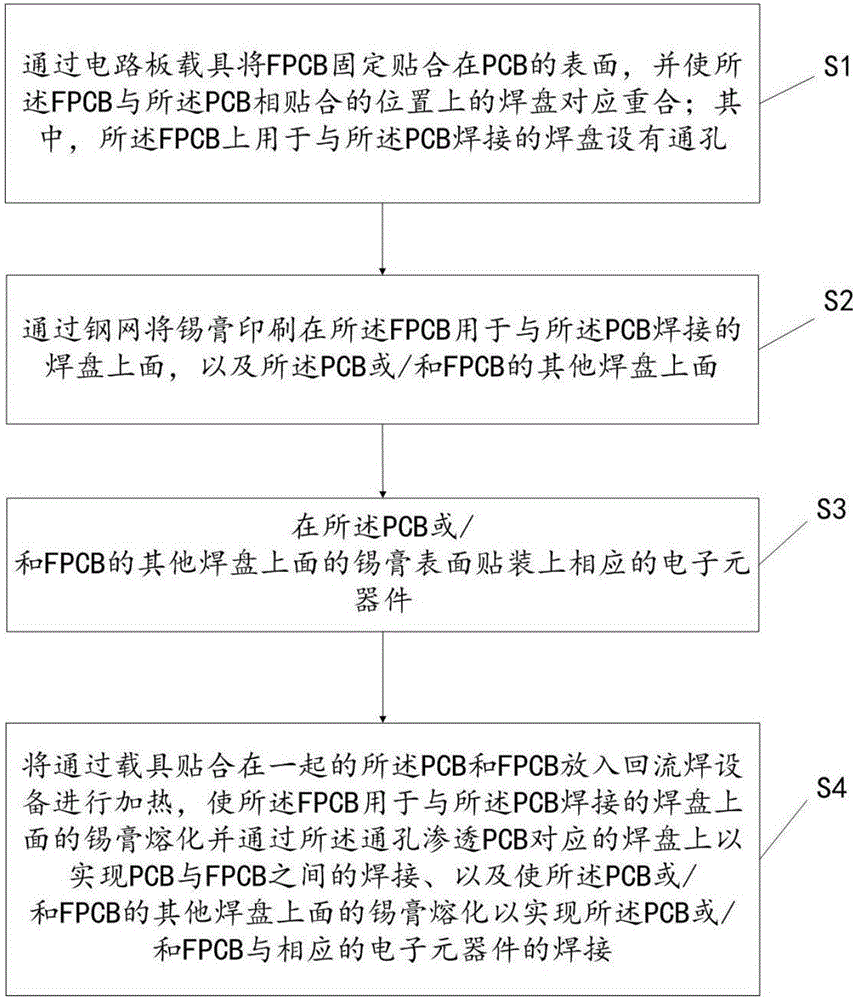

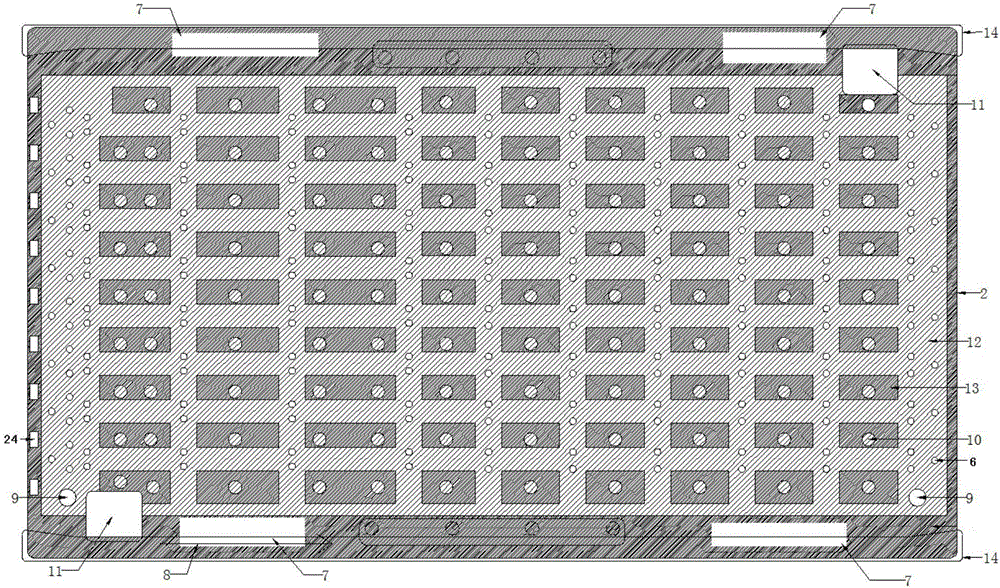

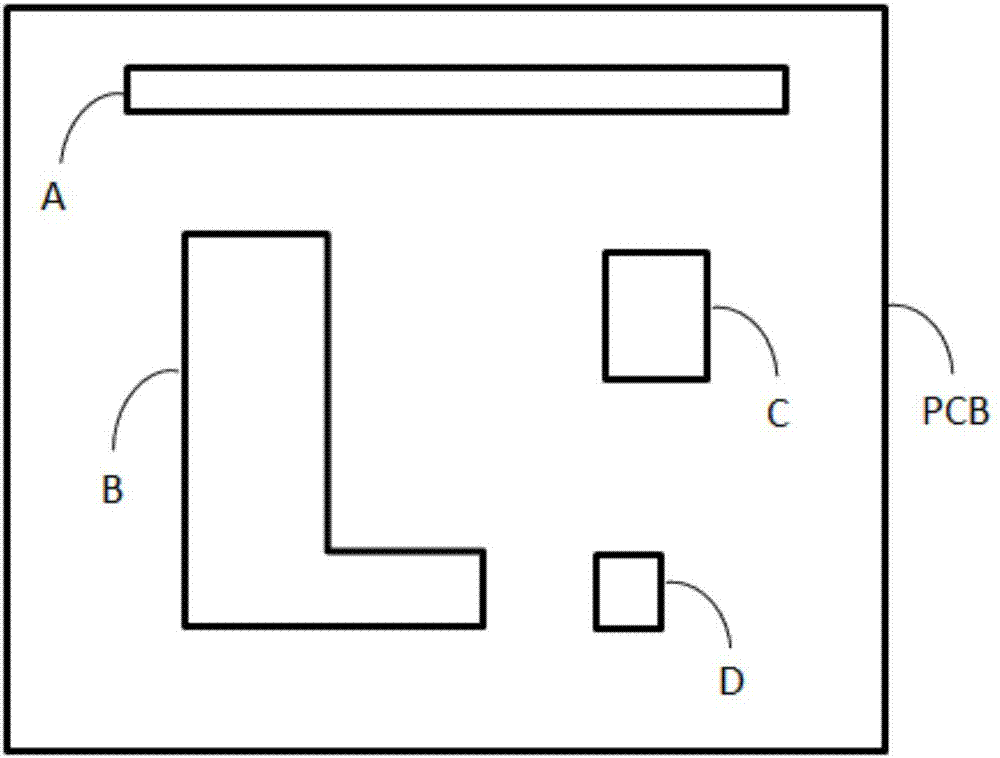

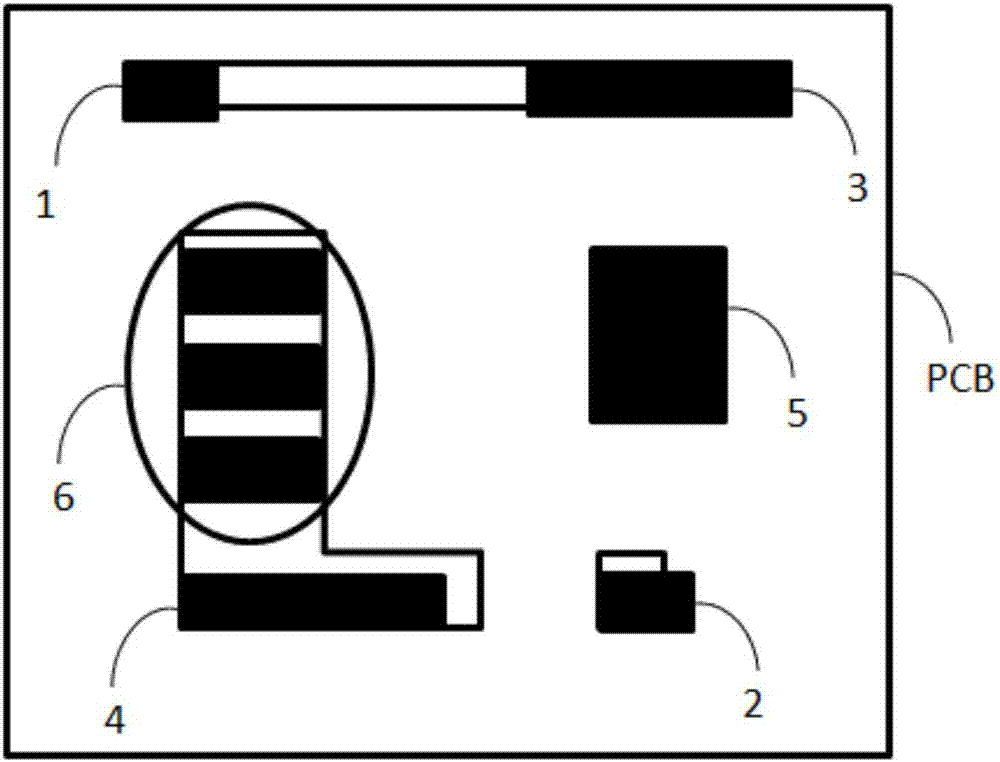

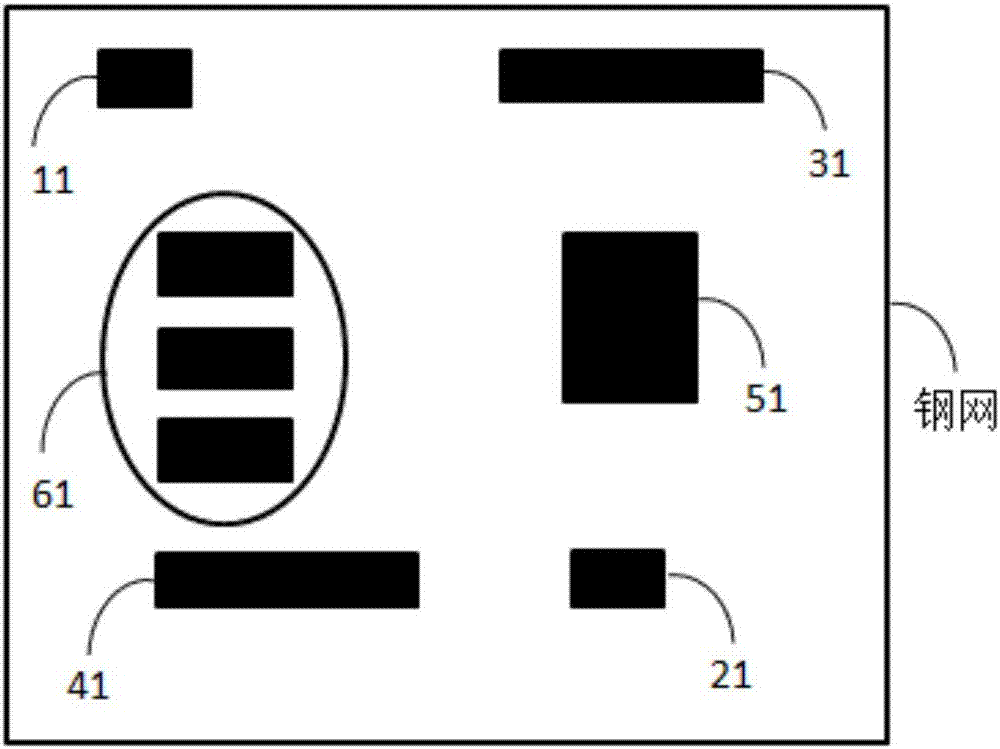

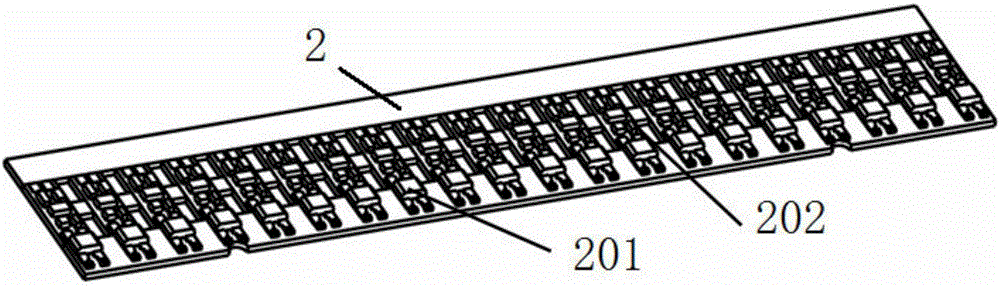

Welding structure and welding method for PCB and FPCB

ActiveCN106304688AIncrease productivityImprove qualityPrinted circuit assemblingMetallurgical bondingElectronic componentTin

The invention discloses a welding method for a PCB and an FPCB. The welding method comprises the following steps of S1, enabling the FPCB to be fixedly attached to the surface of the PCB through a circuit board carrier, and enabling bonding pads in the attached position to be aligned and attached; S2, printing tin paste on the bonding pads of the attached FPCB and PCB through a steel net; S3, mounting electronic components on the corresponding bonding pads; and S4, putting the PCB and the FPCB which are attached together through the carrier into reflow soldering equipment to be heated to realize the welding of the PCB and the FPCB and the welding of the corresponding electronic components at the same time. The invention discloses a welding structure for the FCB and the FPCB. The welding between the FCB and the FPCB realized by the welding method and the welding structure has the advantages of high production efficiency, capability of reducing cost, and stable welding quality.

Owner:广州明美新能源股份有限公司

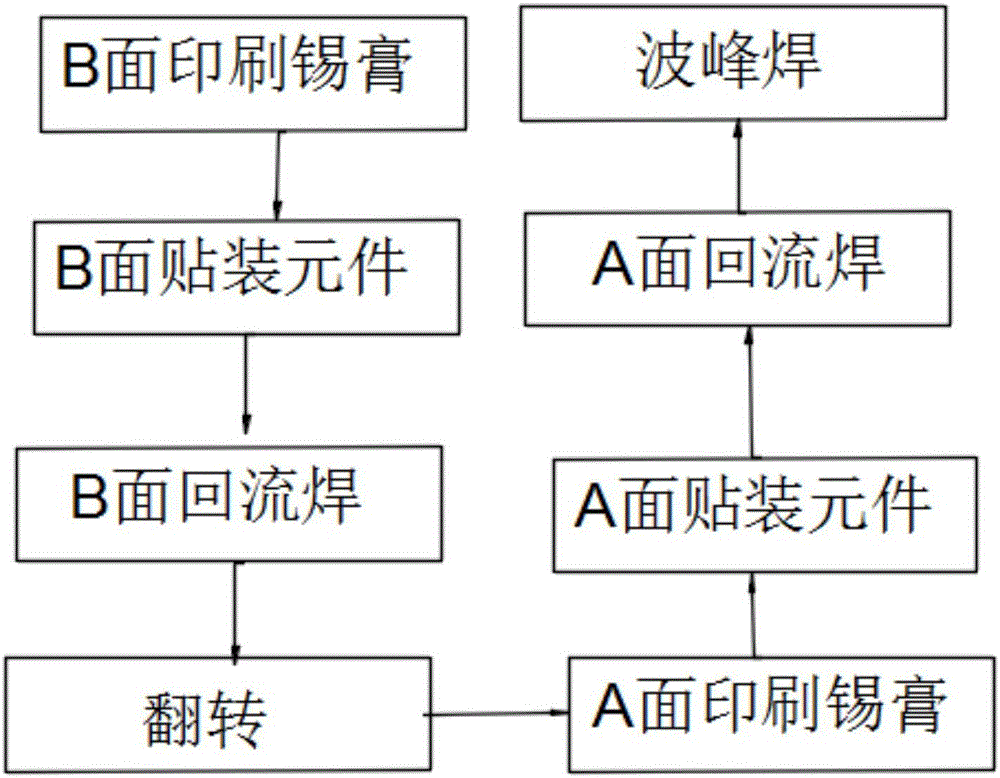

Hybrid surface-mounting process of double-side board

InactiveCN106413281ASimple processImprove pass ratePrinted circuit assemblingPrinted circuit aspectsSurface mountingEngineering

The invention discloses a hybrid surface-mounting process of a double-side board. The hybrid surface-mounting process comprises the steps of S1, printing tin paste on a B surface, in which the tin paste is printed on a bonding pad on the B surface of a PCB (Printed Circuit Board) under push of a scraper; S2, surface-mounting a component on the B surface, in which a surface-mounted component is accurately arranged on a fixed position of the B surface of the PCB; S3, performing reflow soldering on the B surface, in which quantity-controllable tin paste and a solvent are applied onto a surface to be connected, the component is placed on positions of the tin paste and the solvent, and the tin paste is molten by increasing a temperature and heating so that the surface-mounted component and the B surface of the PCB are firmly bonded; S4, performing turnover, in which the circuit board is turned over to complete printing of an A surface; S5, printing the tin paste on the A surface; S6, surface-mounting a component on the A surface; S7, performing reflow soldering on the A surface; and S8, performing wave soldering, in which molten soft welding material is sprayed by a power-driven pump or an electromagnetic pump to form a soldering material wave required by design so that a welding end or a pin of the component and the bonding pad of the printed circuit board are welded. The hybrid surface-mounting process of the double-side board is simple, the qualified rate of a product is high, and the curing speed is fast.

Owner:WUXI NASCH CONTROL & TEST TECH

Surface mounting method for printed circuit board

InactiveCN106604564ASolve the problem of falling partsDoes not increase production costsPrinted circuit assemblingMetallurgical bondingSurface mountingAdhesive

The invention relates to a surface mounting method for a printed circuit board, wherein the printed circuit board is provided with a large device including a large device body and a soldering pin. The method comprises the following steps: (1) obtaining an empty board including a first face and a second face, the first face being provided with a large device mounting area including a bonding pad area and a blank area; (2) a first side printing: printing solder paste in the bonding pad area; (3) gluing and the first face mounting: putting an adhesive in the blank area to form an adhesive layer and then mounting the large device on the large device mounting area; (4) reflow soldering: subjecting the mounted large device to reflow soldering; (5) second face treatment: subjecting the second face to conventional printing, patch mounting and reflow soldering. The method solves the dropping of the large device in the first face, does not need to increase the size of the PCB, reduces the production cost, improves the PCB layout efficiency, and is simple and convenient for industrial application.

Owner:GUANGDONG VTRON TECH CO LTD

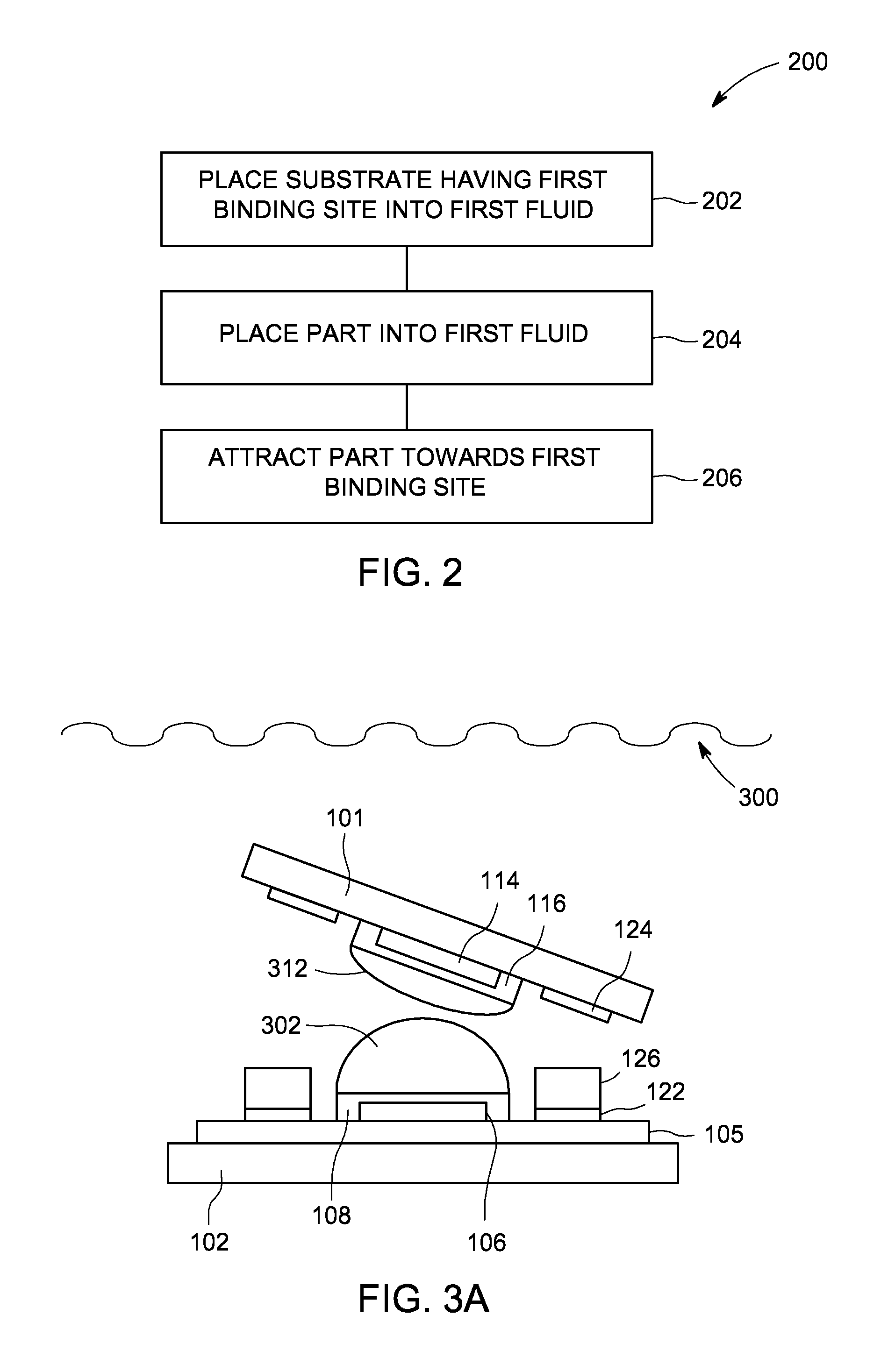

Electromagnetic field assisted self-assembly with formation of electrical contacts

InactiveUS20130199831A1Minimize repulsive forceLamination ancillary operationsFinal product manufactureElectricityFree rotation

A method and apparatus for self-assembling a part on a substrate are disclosed herein. In some embodiments, a method includes placing a substrate having a first binding site capable of generating a first magnetic field and having a first shaped surface with a first droplet conformably disposed thereon into a first fluid; placing a part having a second binding site capable of generating a second magnetic field and having a second shaped surface with a second droplet conformably disposed on the second shaped surface into the first fluid; and attracting the part towards the first binding site such that an equilibrium is formed between an attractive force and a repulsive force such that the part is free to rotate about the first binding site to minimize the repulsive force when the first and second shaped surfaces rotate into an alignment causing the part to aligned with the first binding site.

Owner:UNITED STATES OF AMERICA THE AS REPRESENTED BY THE SEC OF THE ARMY

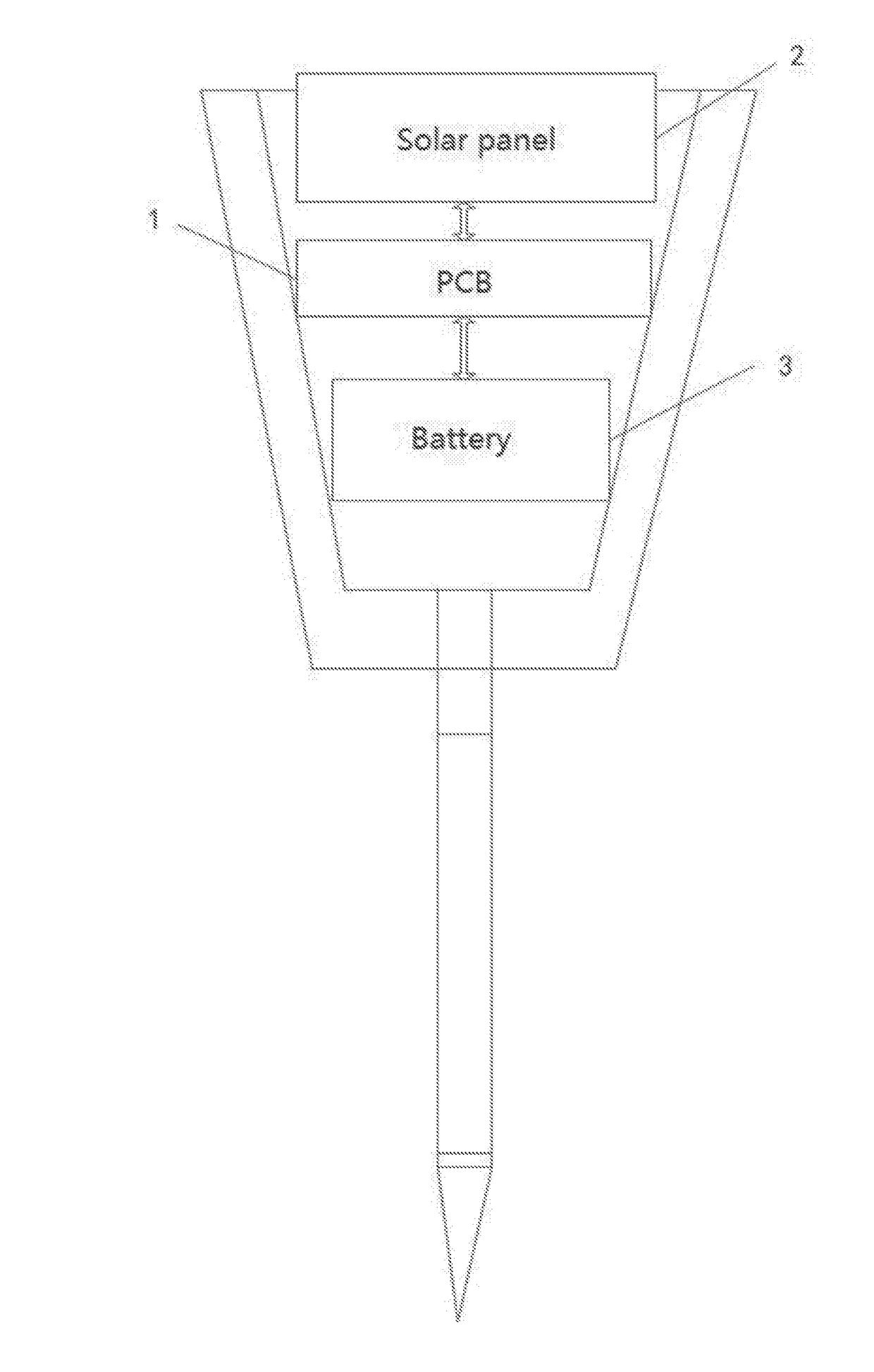

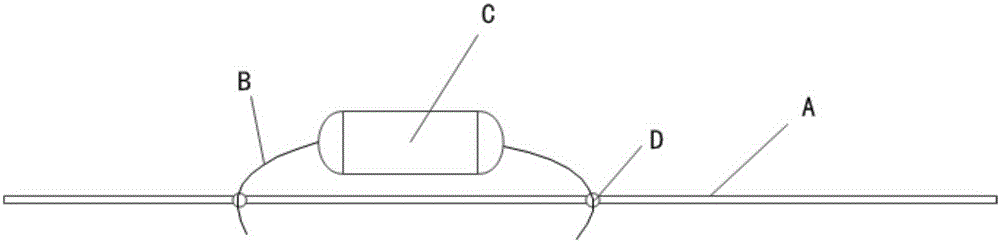

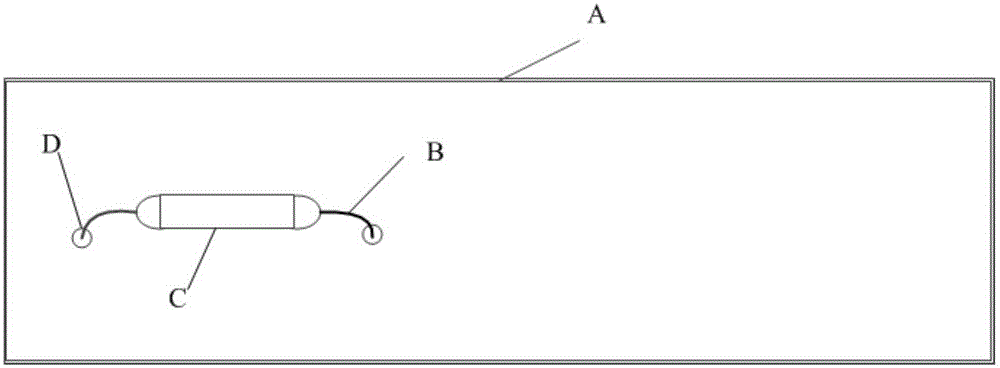

Solar Lamp, PCB Circuit for the Solar Lamp and a Preparation Method Thereof

InactiveUS20170135226A1Low costImprove product qualityPrinted circuit assemblingPoint-like light sourceProduction rateEngineering

A PCB adaptation for a solar lamp, characterized in that, at least one slot is set on the PCB, both sides of the slot comprises a pad, the pad connects to an inner circuit on the PCB, two leads of a leaded component is respectively soldered to the pad which is located on the both skies of the slot. By cutting a slot on the PCB in the present invention, auto surface-mount technology can be implemented to automatically solder the leaded component to the PCB. Low-cost leaded component and surface-mount technology are used in above technical solution, which can decrease the cost and increase the productivity and product quality.

Owner:FUJIAN JOY SOLAR TECHNOLOGY CORPORATION

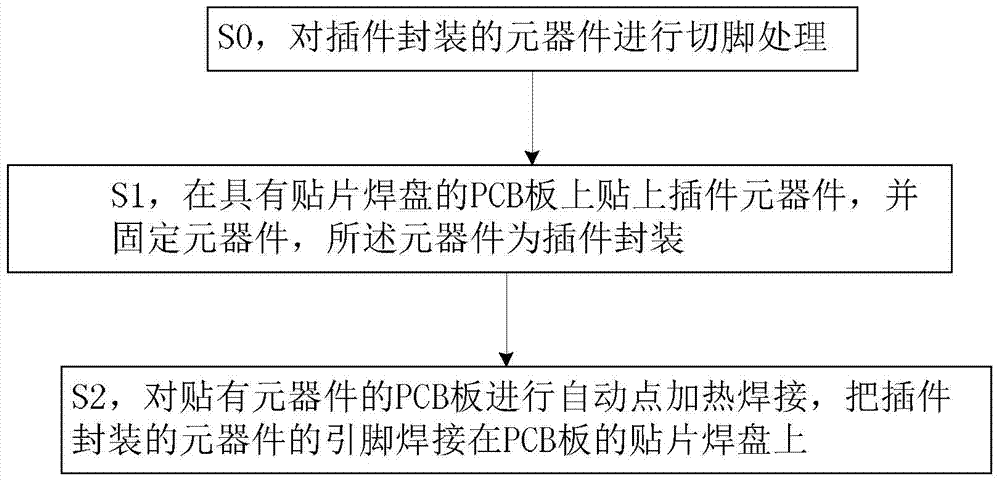

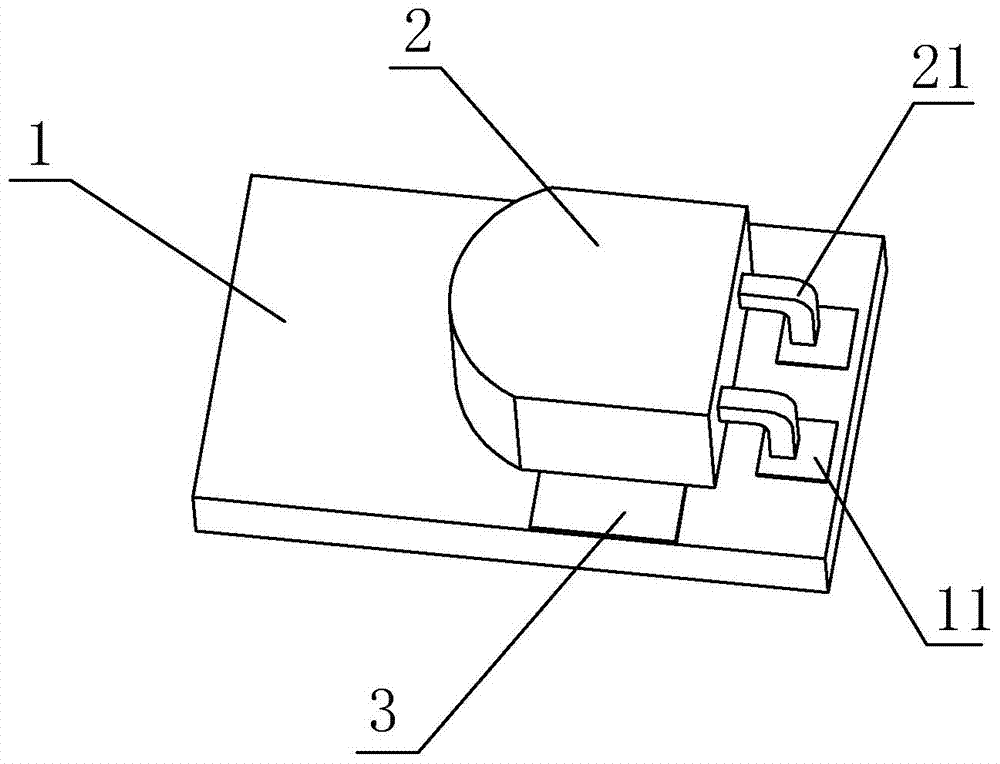

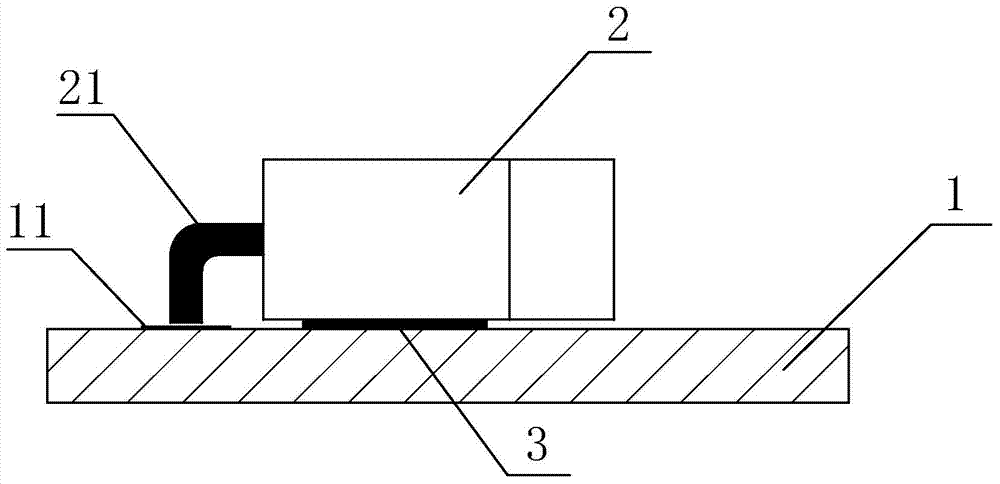

Plug-in component technology and surface mount technology combination based PCBA (printed circuit board assembly) machining method and PCBA

ActiveCN104507271AReduce temperature requirementsIncrease productivityPrinted circuit assemblingPrinted circuit aspectsSurface mountingEconomic benefits

The invention discloses a plug-in component technology and surface mount technology combination based PCBA (printed circuit board assembly) machining method and a PCBA. The method includes the steps: S1, attaching a plug-in component on a PCB with a surface mount bonding pad, and fixing the component which is packaged in a plug-in manner; S2, subjecting the PCB mounted with the component to automatic spot heating welding, and welding pins of the component in plug-in package on the surface mount bonding pad of the PCB. The PCB is provided with the plug-in packaged component and the surface mount bonding pad, and the pins of the plug-in packaged component are welded on the surface mount bonding pad. The advantages of plug-in technology and the surface mount technology are fused, the plug-in packaged component and the PCB with the surface mount ponding pad are utilized, and the automatic spot heating welding technology is combined, so that labor cost and material cost of PCBA machining are saved, the requirement on temperature resistance of the component is lowered, production efficiency and product percent of pass of the PCB are increased, and good social and economic benefits are gained. The method can be widely applied to various PCBA machining technologies.

Owner:深圳市凯健奥达科技有限公司

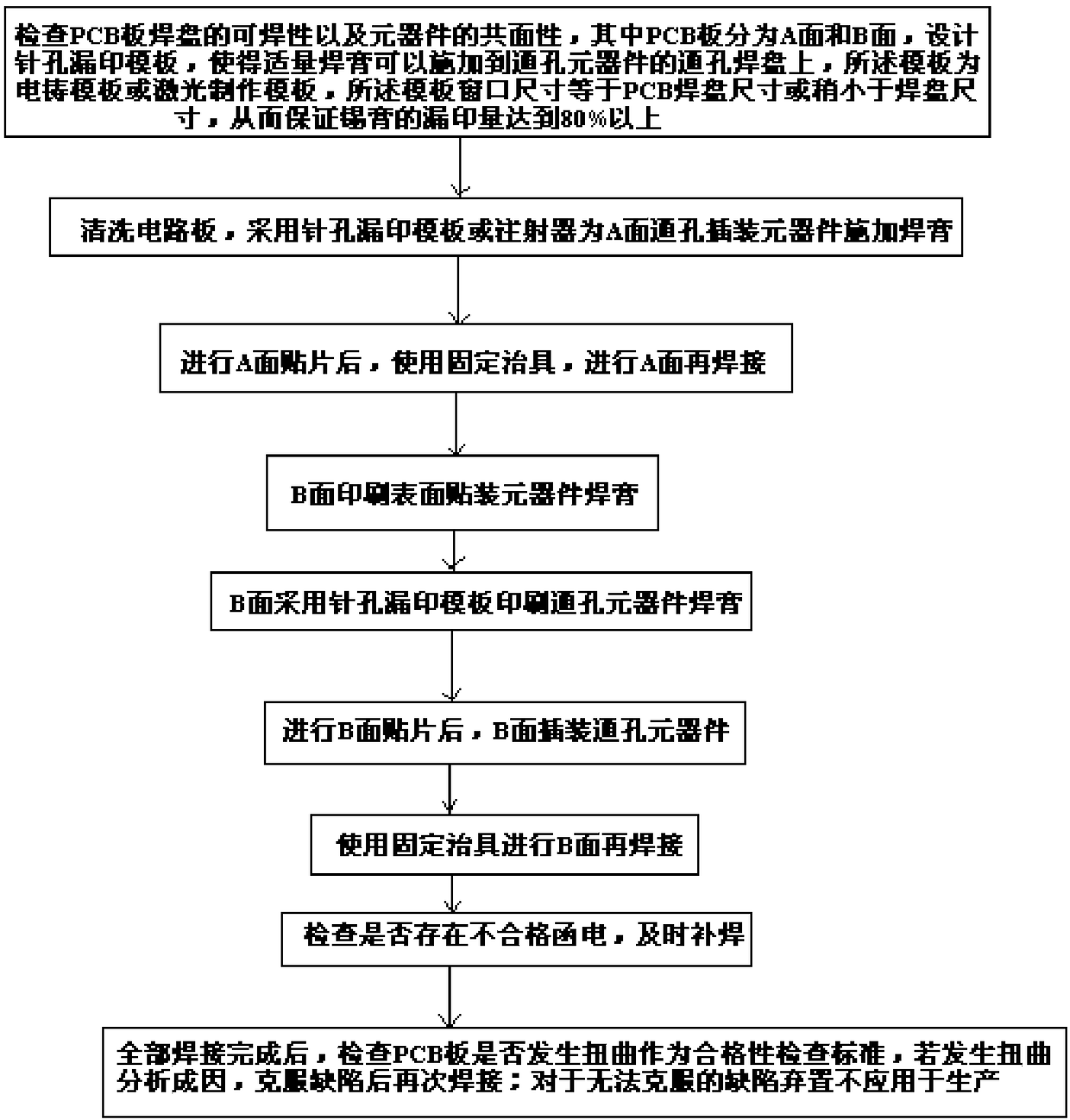

Method for welding circuit board

ActiveCN108337821ARelieve pressureIncrease stiffnessPrinted circuit assemblingMetallurgical bondingEngineeringSolder paste

The invention provides a method for welding a circuit board. The method comprises the following steps: (1) checking weldability of a PCB welding disc, and coplanarity of an element, wherein a PCB comprises a plane A and a plane B and is designed as a pinhole skip printing template; (2) cleaning the circuit board, and applying a welding paste to elements inserted into through holes in the plane A by using the pinhole skip printing template or an injector; (3) performing plane A pasting, and welding the plane A by using a fixing jig; (4) pasting an element welding paste to a printing surface ofthe plane B; (5) printing the plane B with a hole element welding paste by using the pinhole skip printing template; (6) performing plane B pasting, and inserting through hole elements into the planeB; (7) welding the plane B by using the fixing jig; (8) checking whether unqualified welding points are resulted or not, and performing welding replenishing in time; (9) after welding is completed, checking whether the PCB has distortion or not as a qualification inspection standard, analyzing reasons of distortion, overcoming defects, performing welding again, and discarding products which defects which cannot be overcome.

Owner:汉通(沧州)电子有限公司

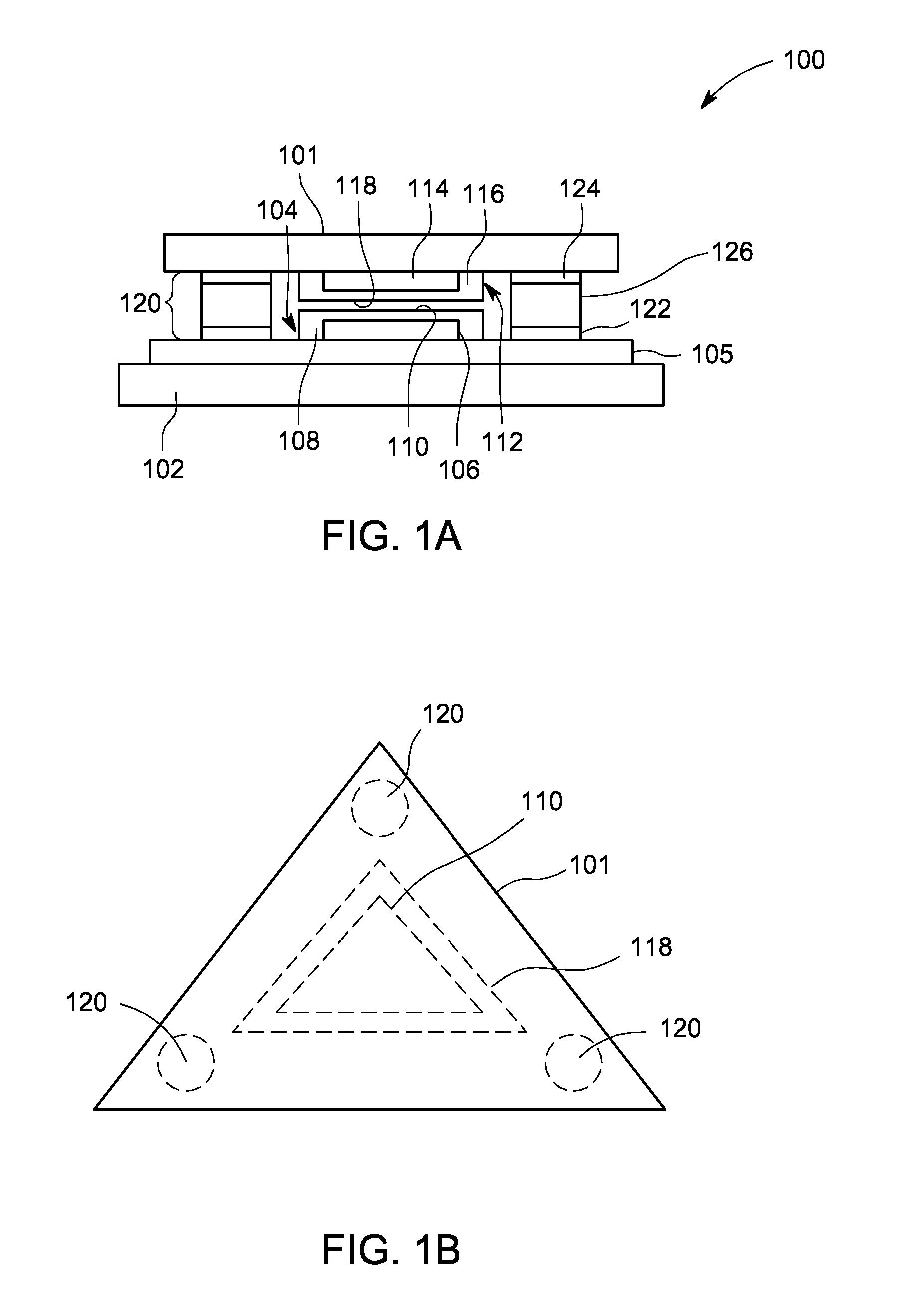

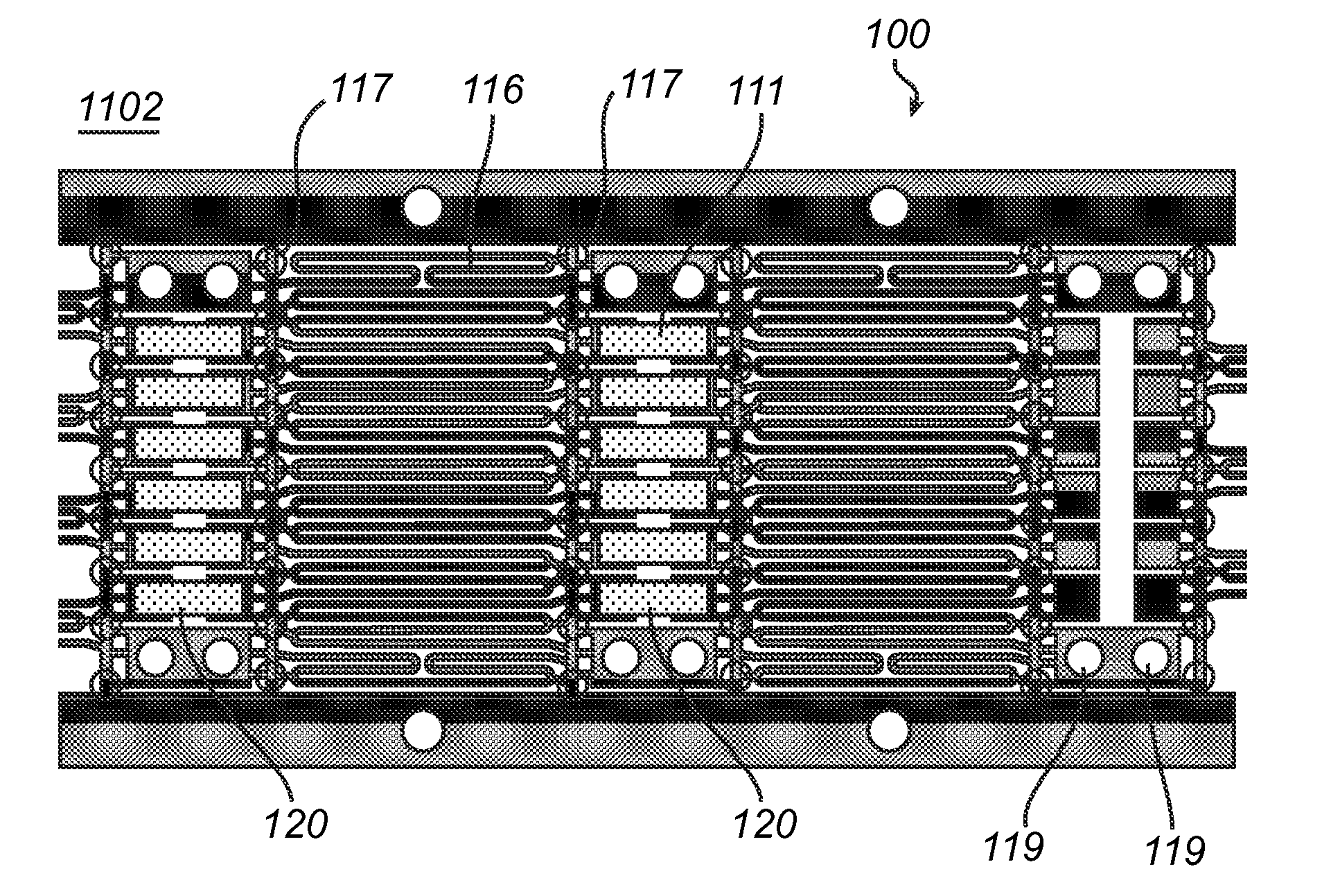

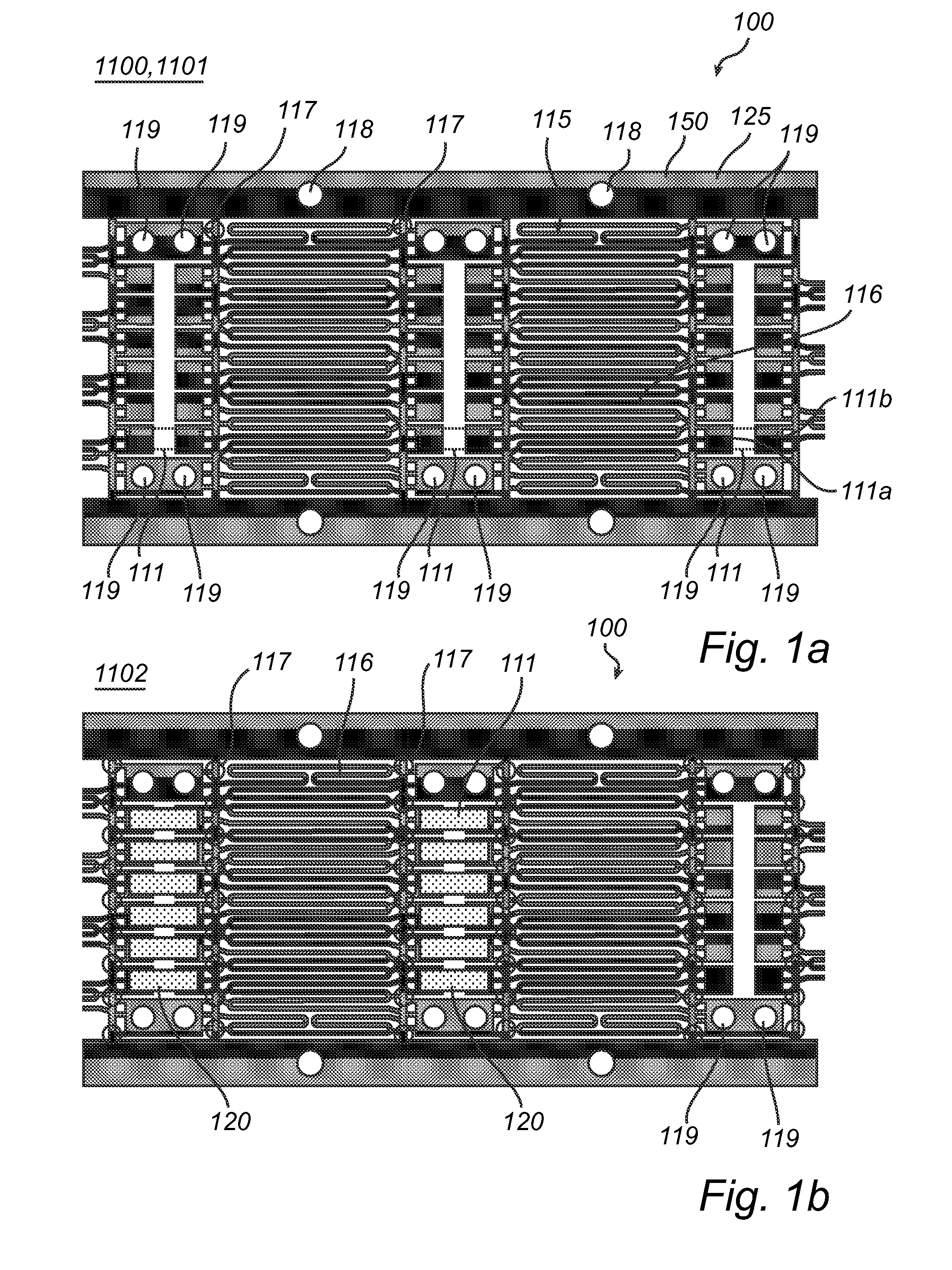

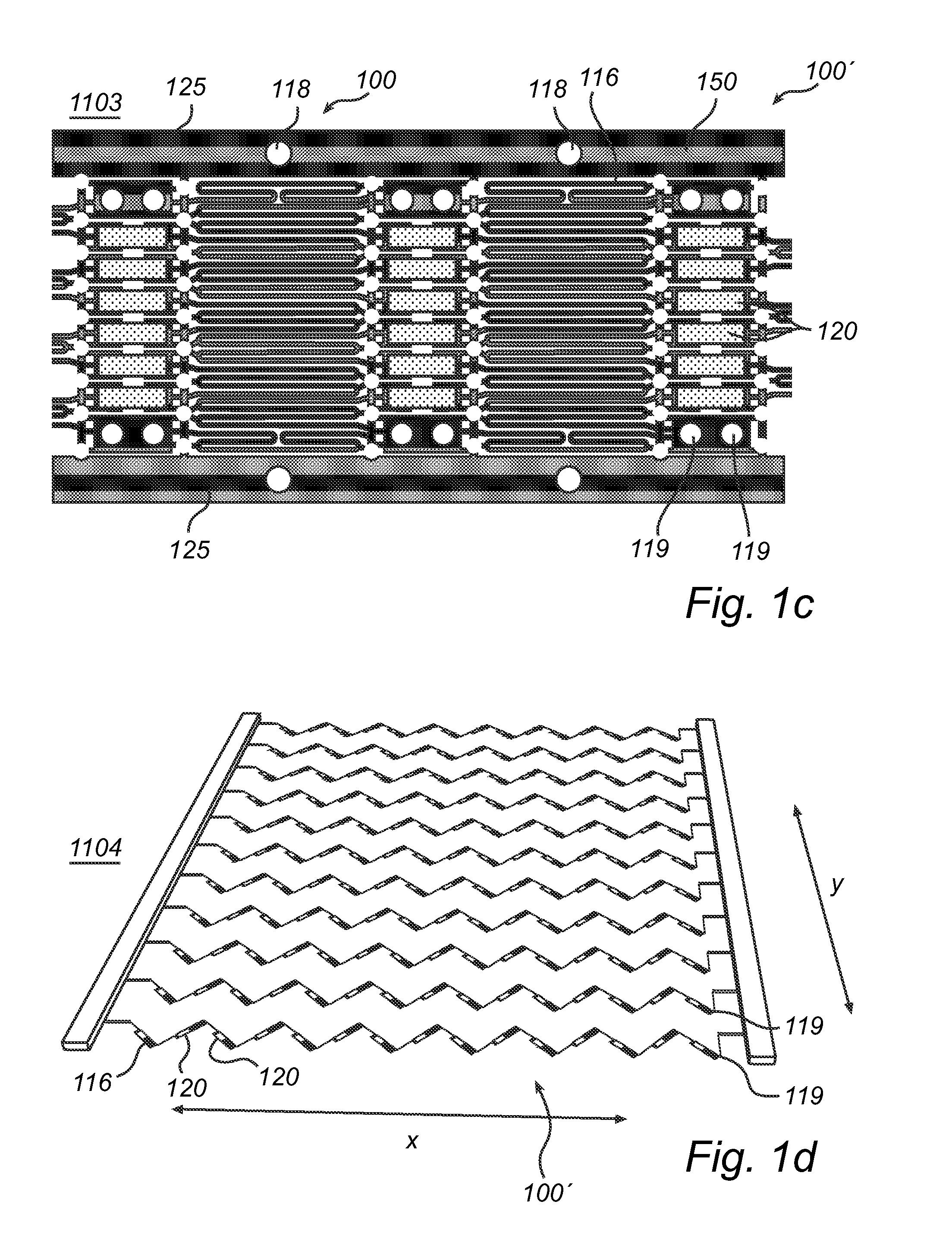

Method and device of a LED matrix

ActiveUS20140209942A1Low costEasy to weldLighting support devicesLaminating printed circuit boardsLead ConductorLight-emitting diode

There is provided a method for manufacturing a light emitting diode, LED, matrix (100) comprising the steps of providing with a maintained integrity a conductor sheet (150) with a plurality of component areas (111) interconnected with meandering connection tracks (116), mounting a plurality of LEDs (120) to a respective component area thereby forming a subassembly (100″), trimming and stretching the subassembly thereby straightening the connection tracks such that an m×n LED conductor matrix is formed during the step of stretching.

Owner:KONINKLIJKE PHILIPS ELECTRONICS NV

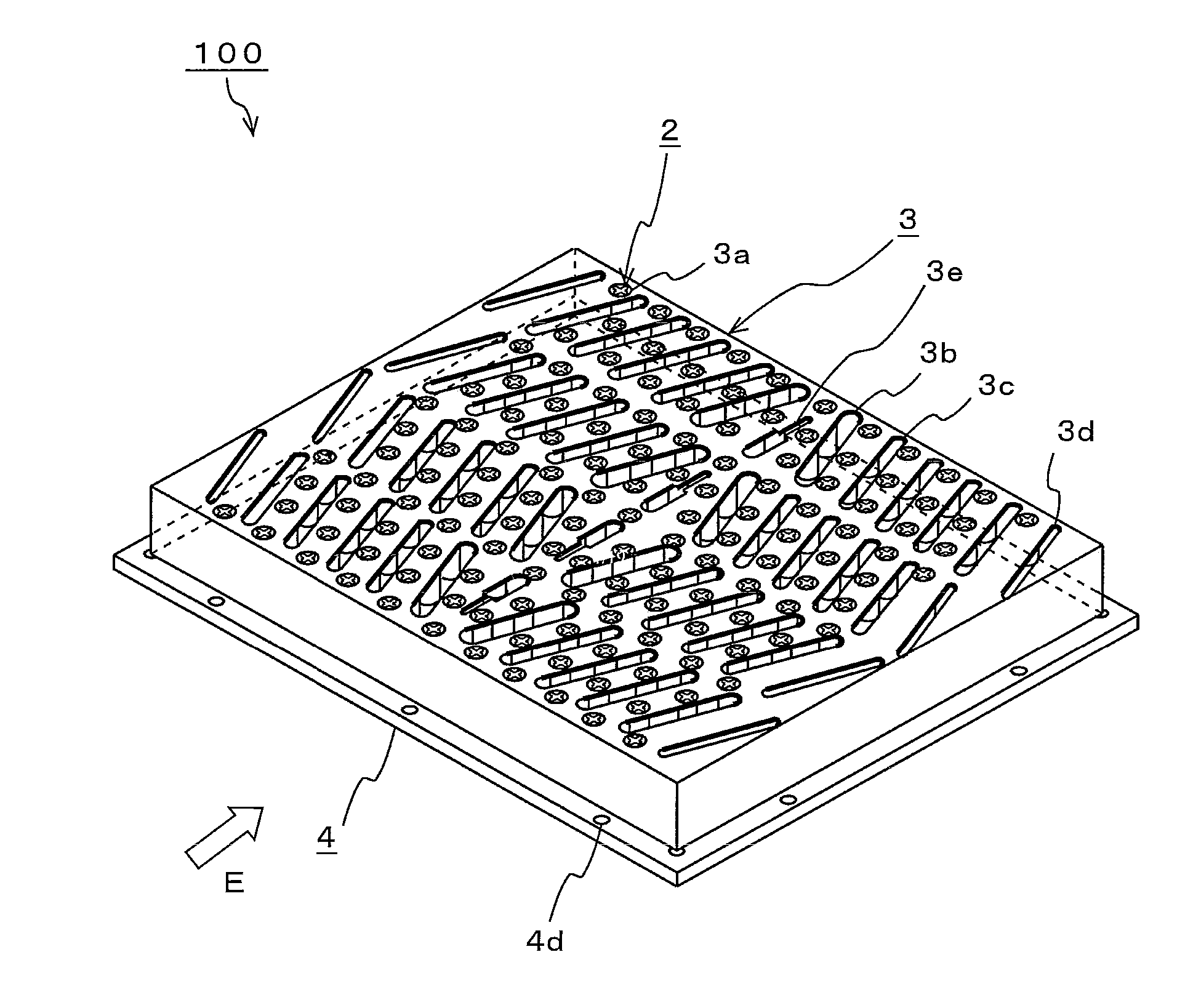

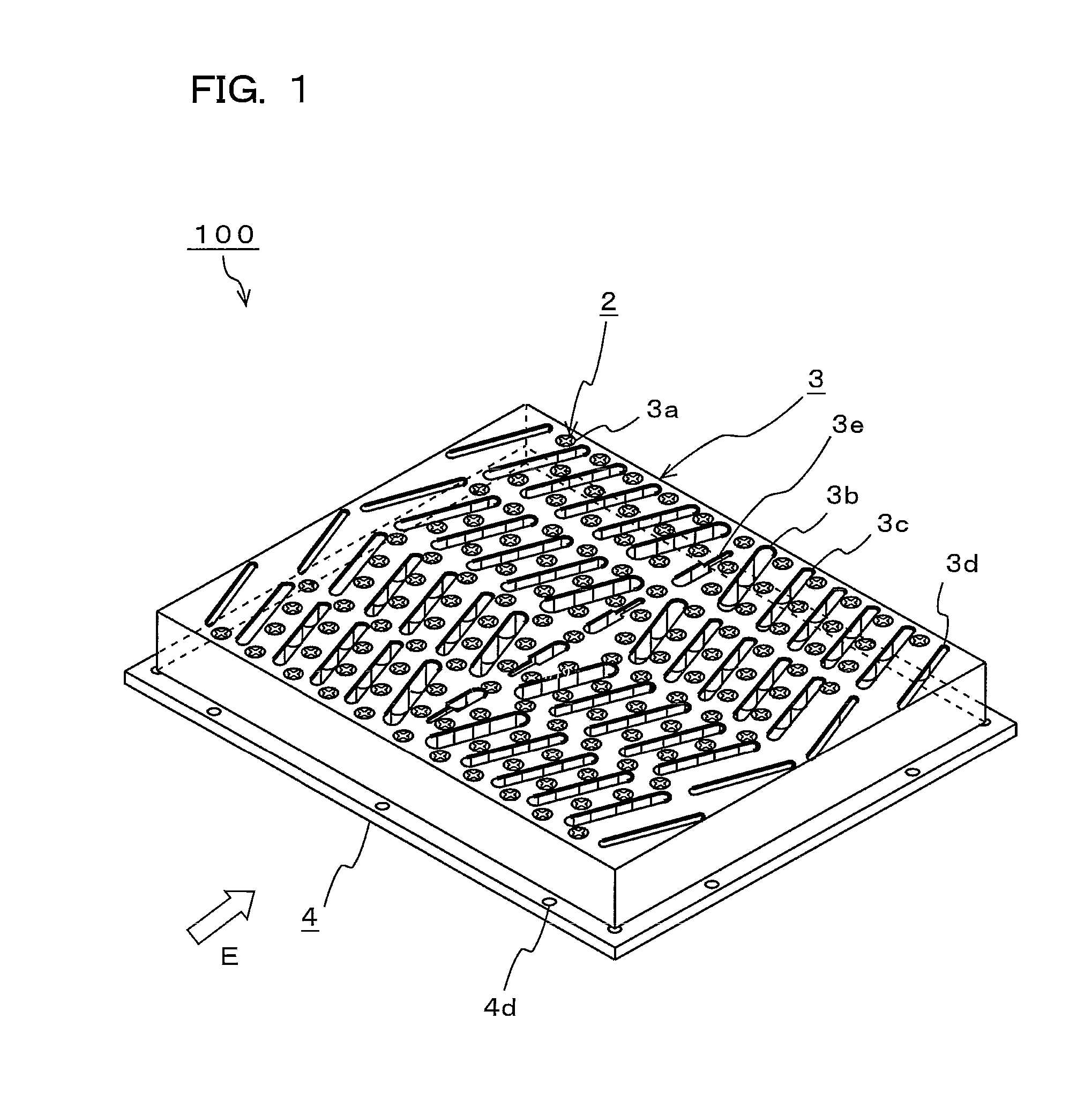

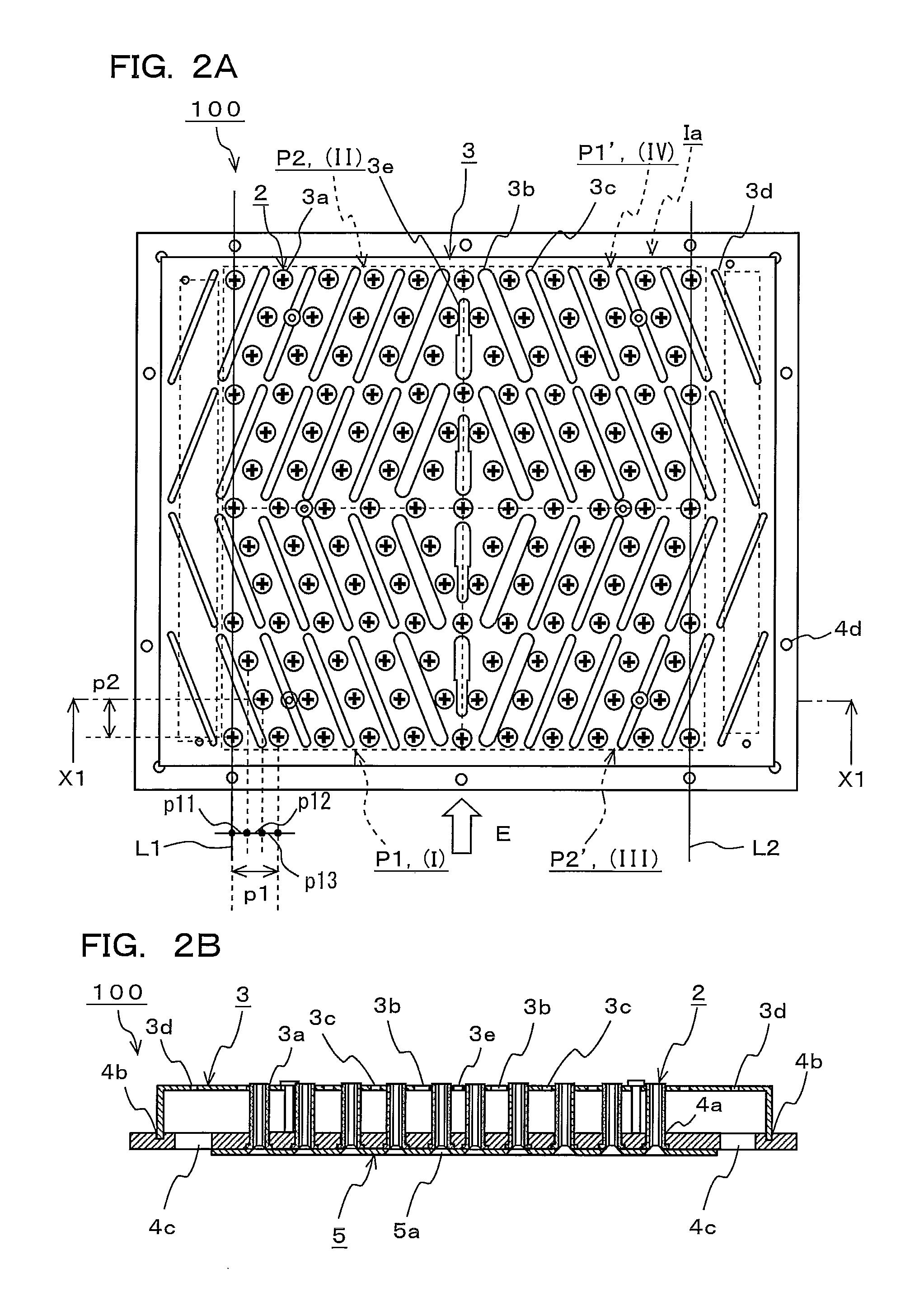

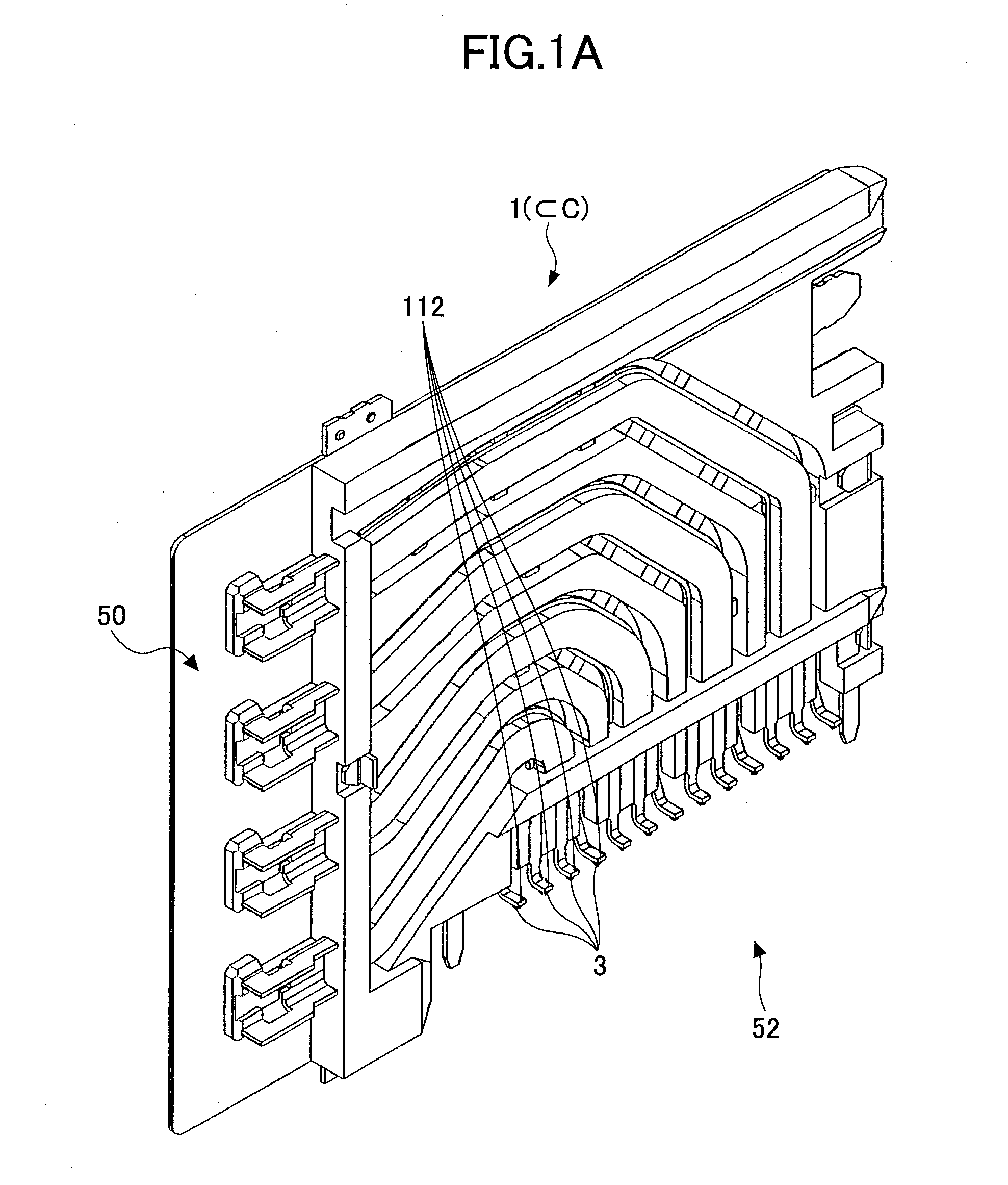

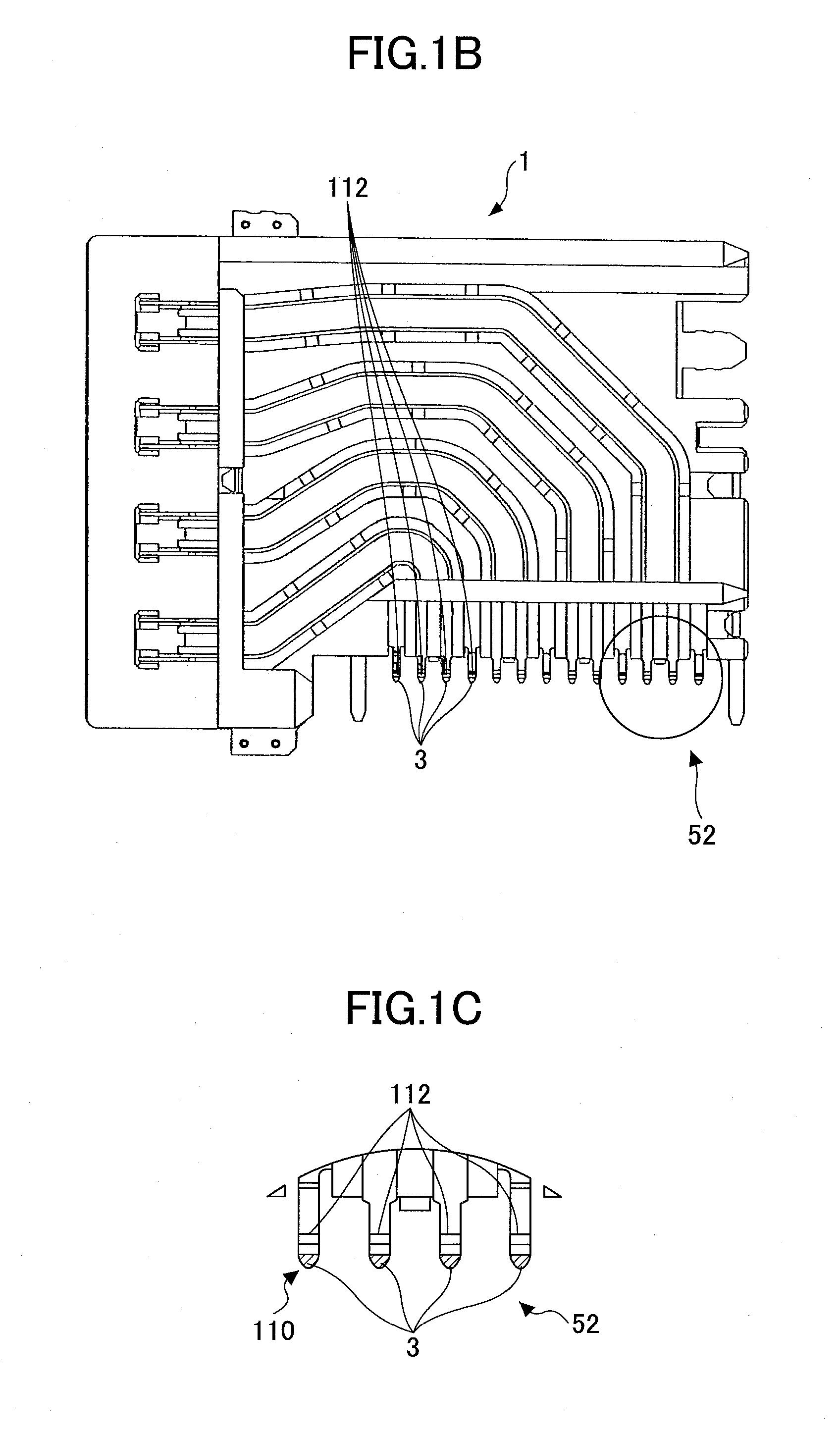

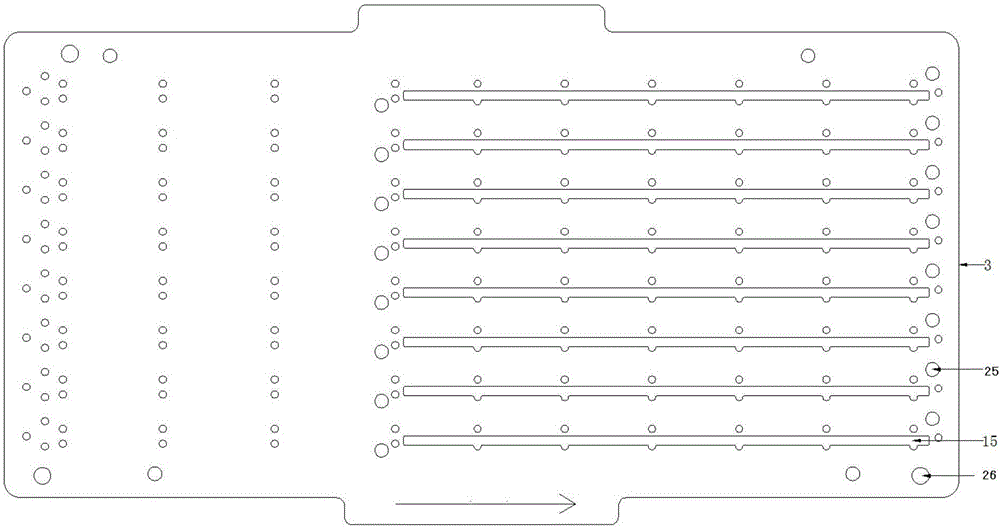

Gas-blowing-hole array structure and soldering apparatus

ActiveUS20150382482A1Heating evenlyImprove reliabilityPrinted circuit assemblingMetallurgical bondingEngineeringSoldering

In a gas-blowing-hole array structure, which enables gas to be blown to the whole surface of the conveyed member such as a printed circuit board, a semiconductor wafer or the like almost concentrically and allows the whole surface of conveyed member to be very uniformly heated or cooled, a nozzle pattern P2 of blowing nozzles 2 is arranged to be line symmetry with a nozzle pattern P1 of the blowing nozzles 2 in upper and lower divided sections of one side of the nozzle cover 3 relative to a center portion thereof that is orthogonal to a conveying direction, as shown in FIG. 1. In order for the arrangement patterns diagonally arranged in the nozzle cover 3 to become identical, the nozzle pattern P1 is arranged to be line symmetry with the nozzle pattern P2 of the blowing nozzles 2 in upper and lower divided sections of the other side of the nozzle cover 3.

Owner:SENJU METAL IND CO LTD

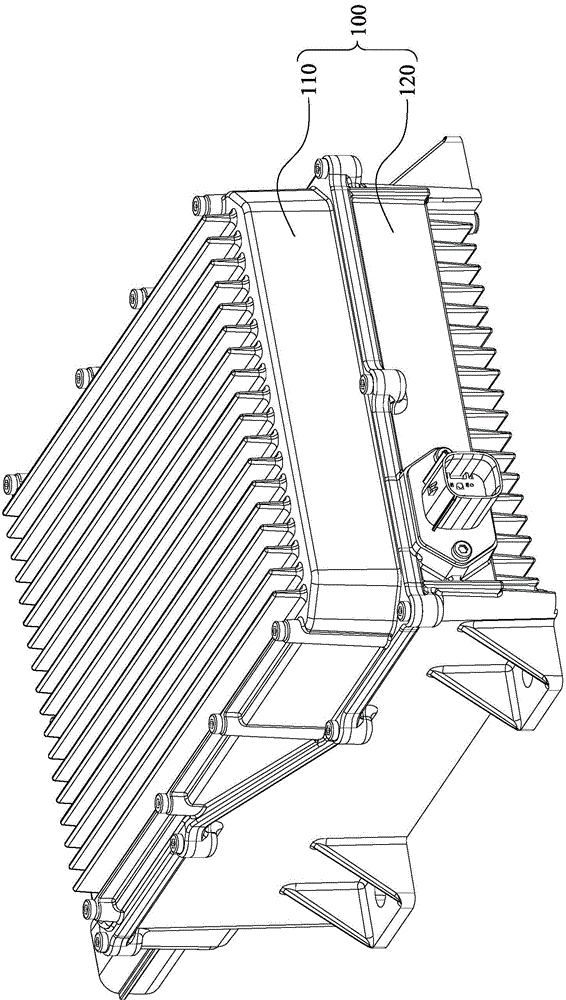

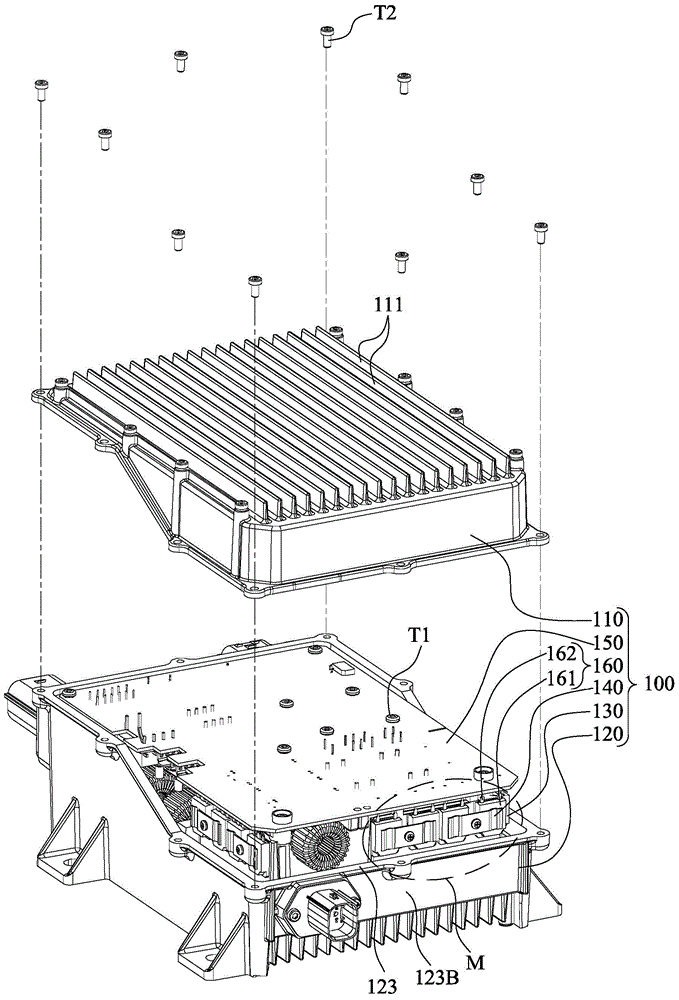

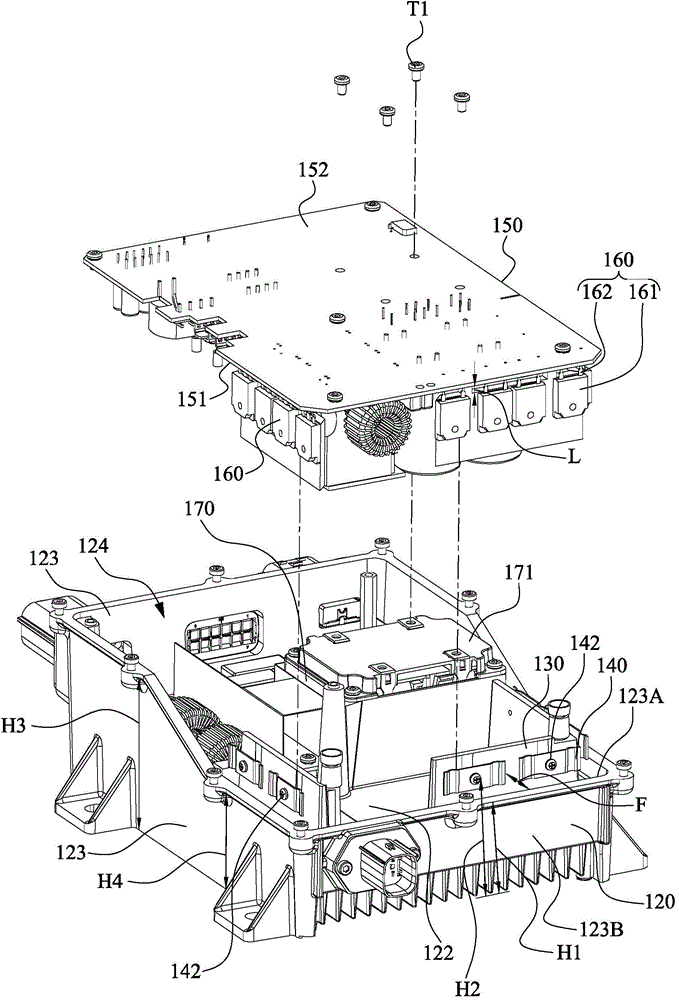

Electronic device and assembling method thereof

ActiveCN104684337AImprove cooling effectReduced risk of thermal failureElectrodynamic brake systemsSemiconductor/solid-state device detailsElectricityEngineering

An electronic device includes a bottom case, an accommodation unit, an electromagnetic induction module, a heat-dissipating component, an elastic clip, a printed wiring board, and an electronic component. The accommodation unit is disposed on the bottom case. At least one portion of the electromagnetic induction module is disposed in the accommodation unit. The heat-dissipating component is disposed on the bottom case and is positioned separately from the accommodation unit. The elastic clip is partially mounted on the heat-dissipating component. The printed wiring board has a first surface and a second surface, and the first surface faces the accommodation unit. The electronic component includes a main body and pin feet. The pin feet are electrically connected to the printed wiring board, and the main body is clamped between the heat-dissipating component and the elastic clip.

Owner:DELTA ELECTRONICS SHANGHAI CO LTD

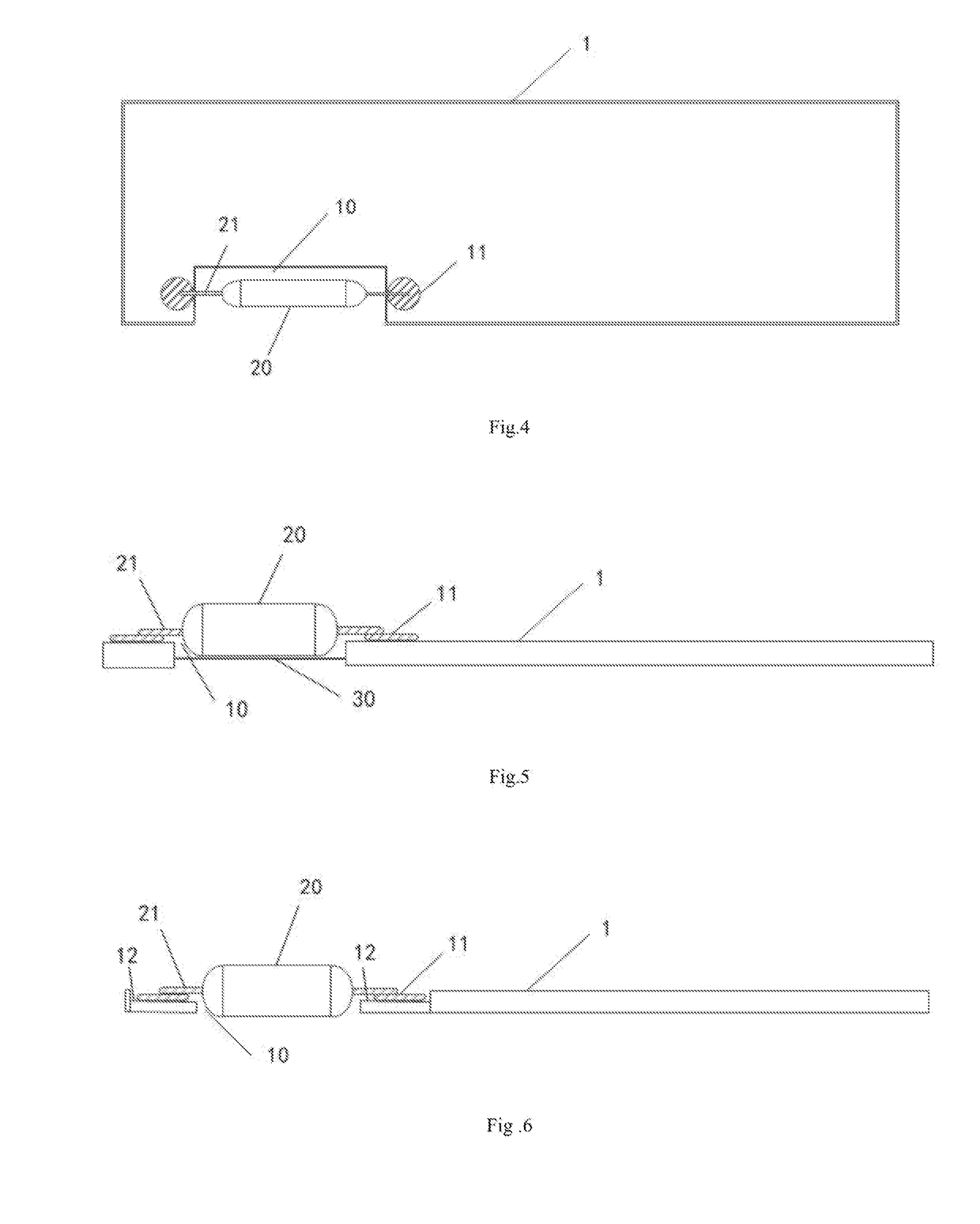

Surface mount device and method of manufacturing the same

InactiveUS20120193139A1Firmly connectedVariation in lengthFinal product manufactureSemiconductor/solid-state device detailsSurface mountingEngineering

Disclosed is a surface mount device to be mounted on a base member, including plural lead units, each of the plural lead units including, a lead including a body portion and a foot formed at an end of the lead; a solder portion formed at the foot of the lead to protrude toward the direction of the base member to have a summit portion, and a diffusion prevention portion provided on the lead for preventing a diffusion of a solder along the body portion of the lead.

Owner:FUJITSU COMPONENENT LTD

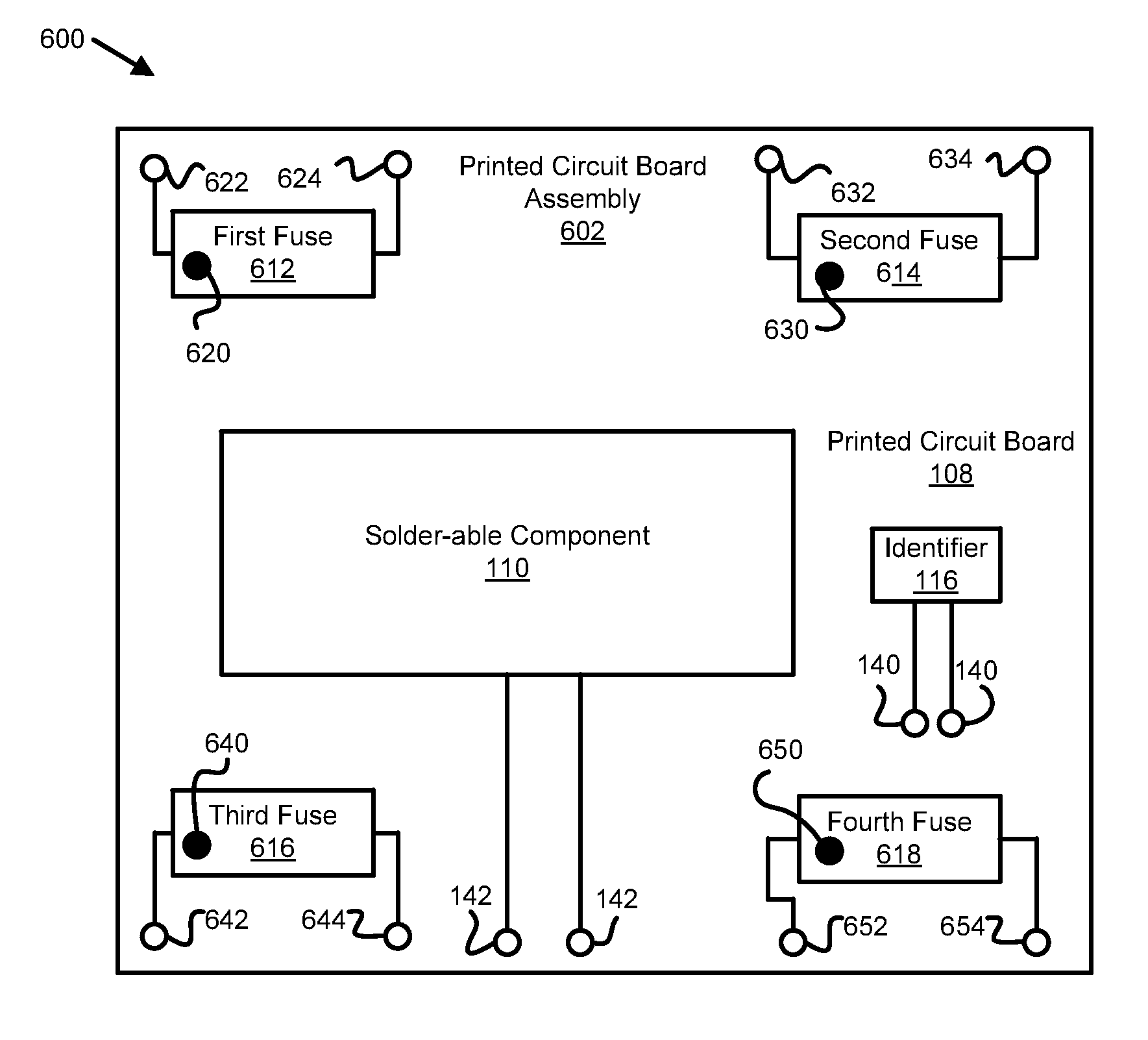

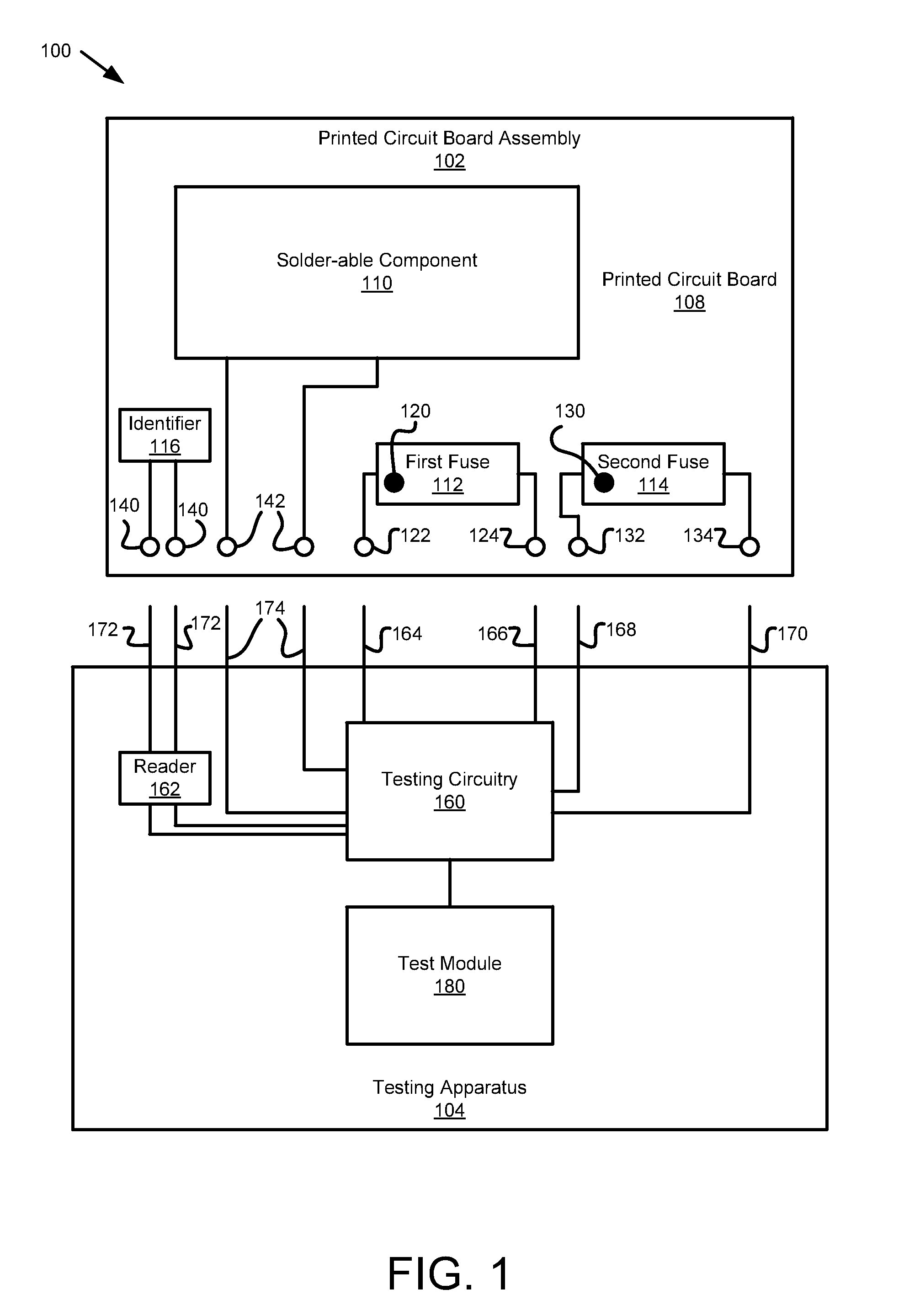

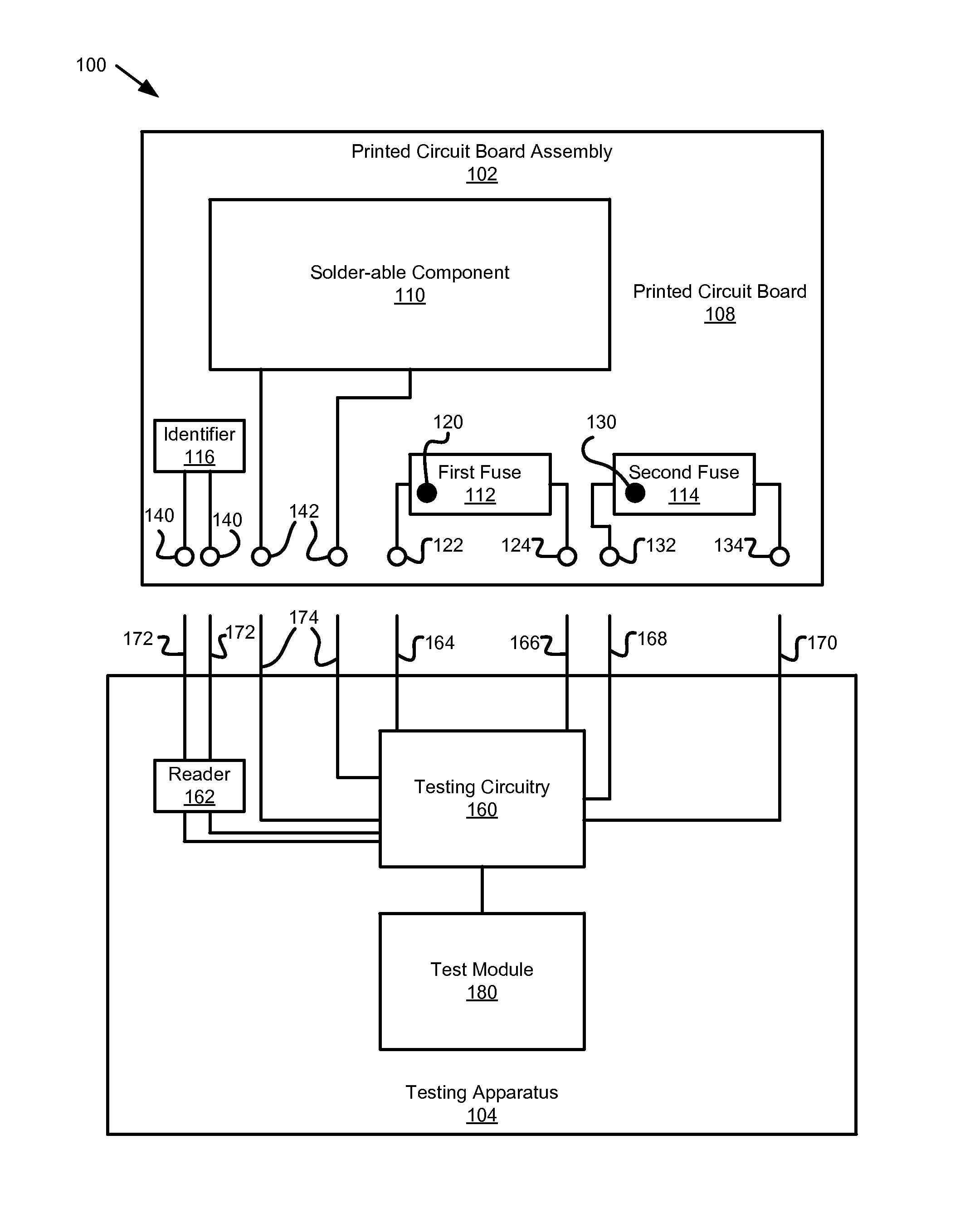

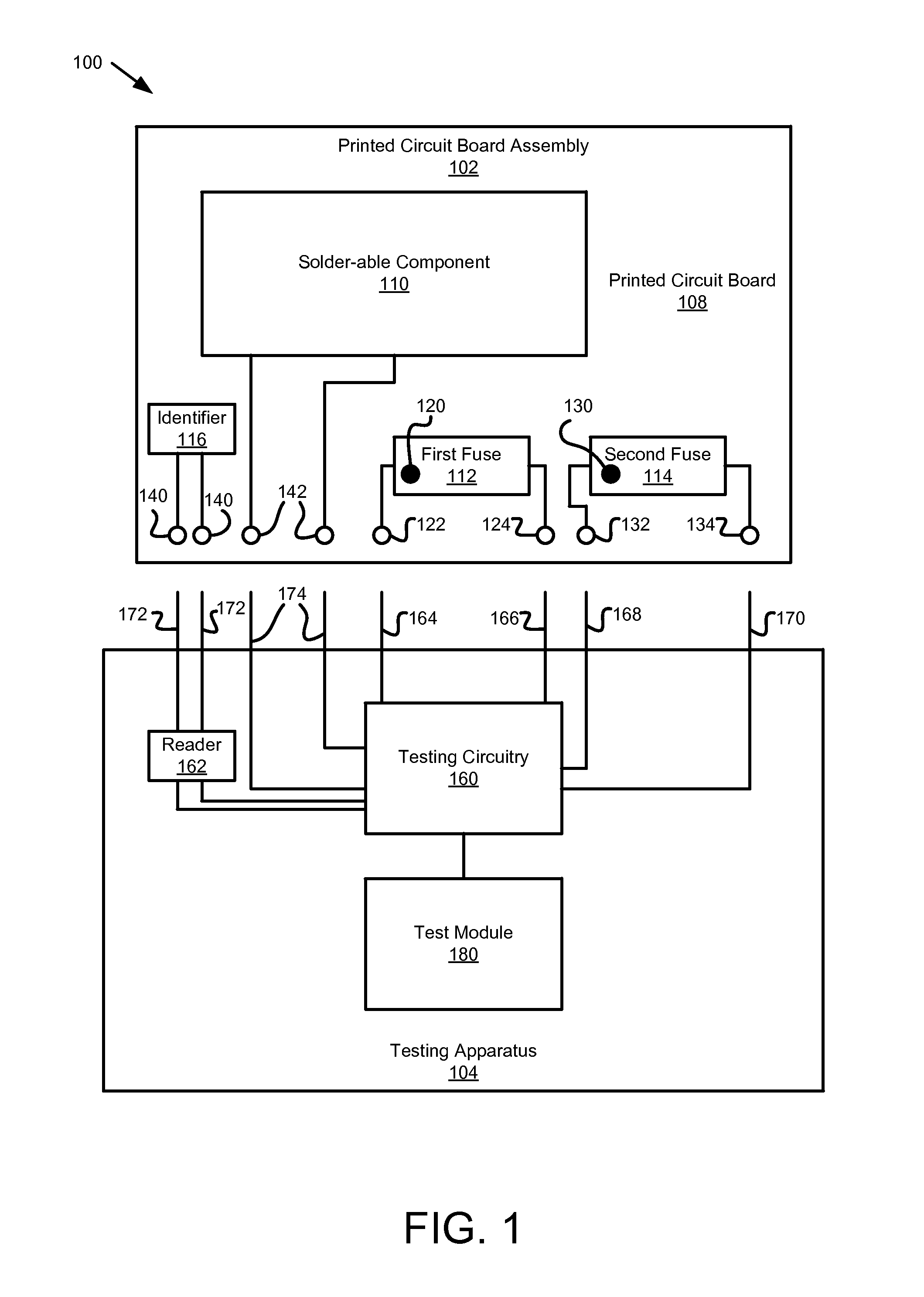

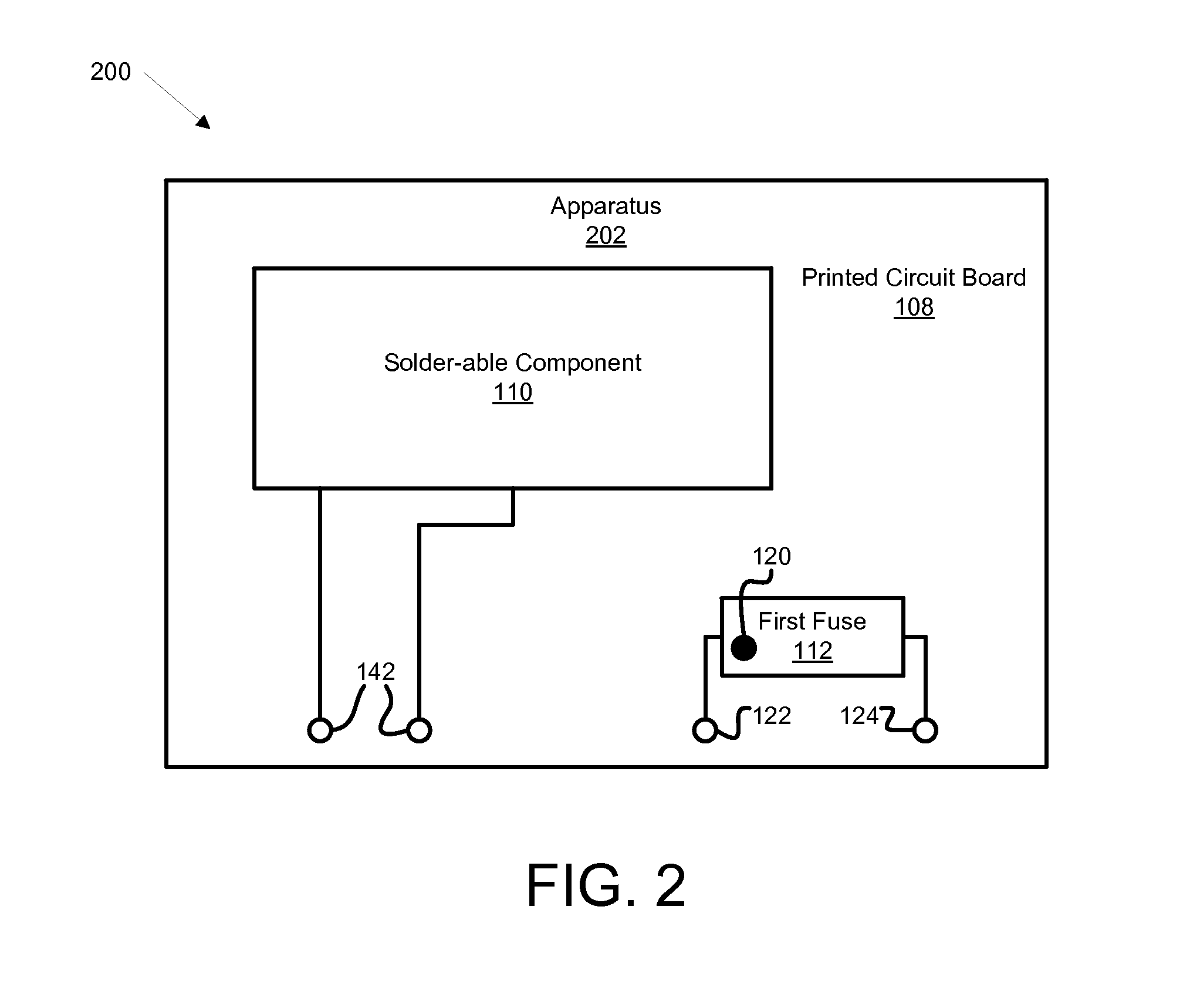

Solder assembly temperature monitoring process

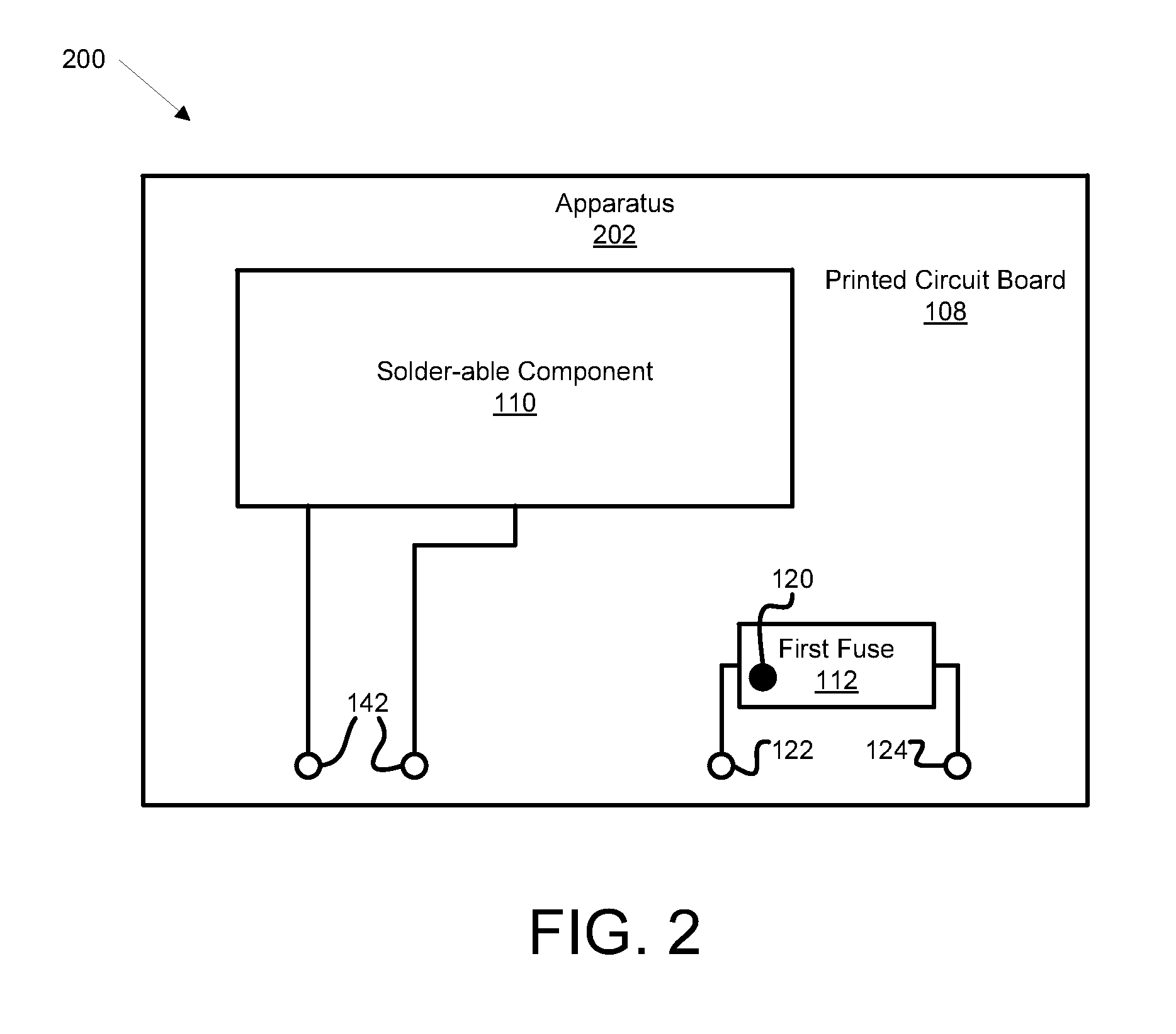

ActiveUS20140198424A1Printed circuit assemblingSoldering apparatusTemperature monitoringThreshold temperature

An apparatus according to the invention may include one or more fuses placed on a printed circuit board on which an printed circuit board assembly is formed. Each fuse changes in response to ambient thermal conditions beyond a threshold temperature. The change can be detected with a testing apparatus such as in in-circuit tester after a process such as a solder assembly process to determine whether the process was performed within the desire temperature range. Fuses may be positioned at different locations on the printed circuit board to provide localized and differentiated temperature measurements. An array of fuses may be designed to change at a progressing sequence of ambient temperatures to enable trends in the process temperature to be recorded. Temperature data may be recorded and linked to an identifier on the apparatus such as a product serial number.

Owner:IBM CORP

Flux Composition and Techniques for Use Thereof

The present invention is directed to flux compositions and uses thereof. One composition comprises an activator and a solvent being a glycerol ethoxylate with a molecular weight of 200-500. Another composition comprises an activator, a solvent being a glycerol ethoxylate with a molecular weight of 200-500 and an amine. A soldering method for joining objects is also provided, comprising the steps of applying a flux composition to at least a portion of one or more of the objects, and joining the objects.

Owner:IBM CORP

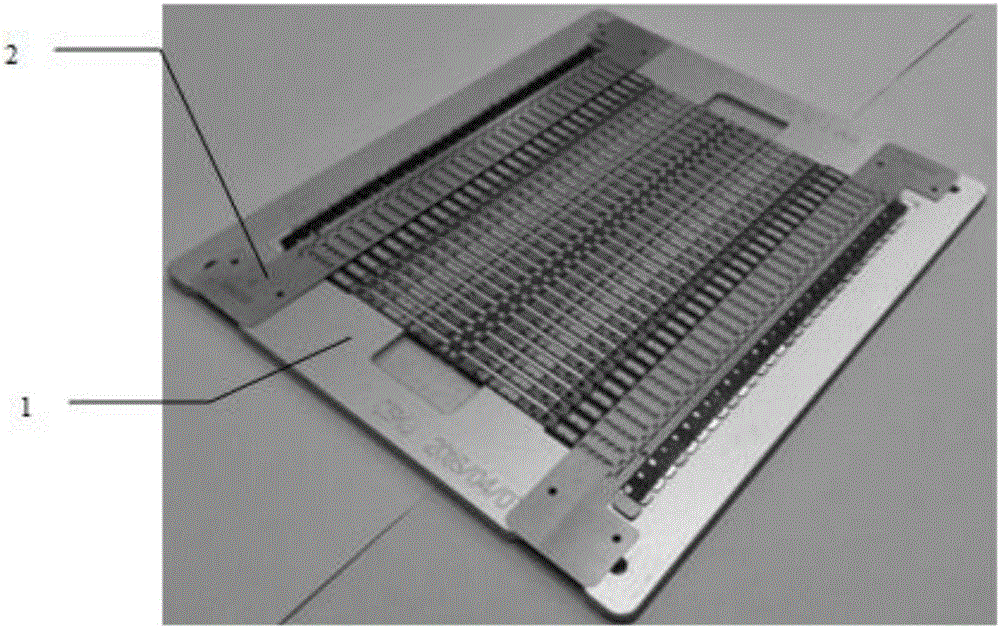

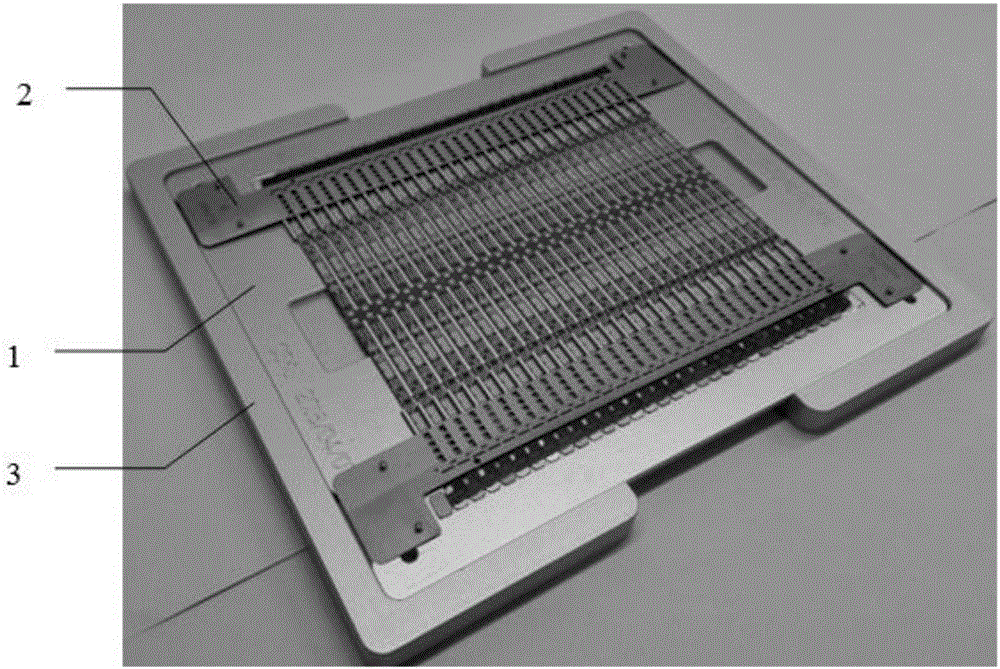

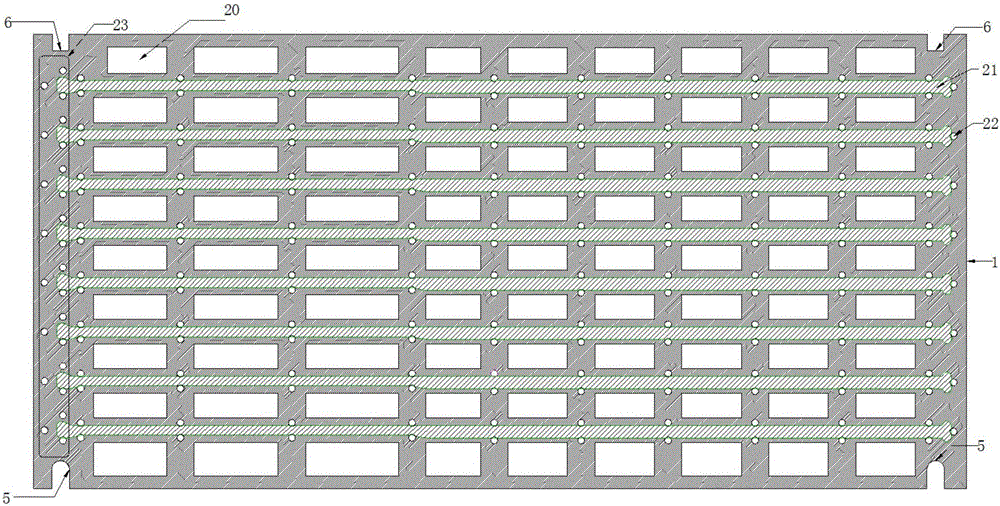

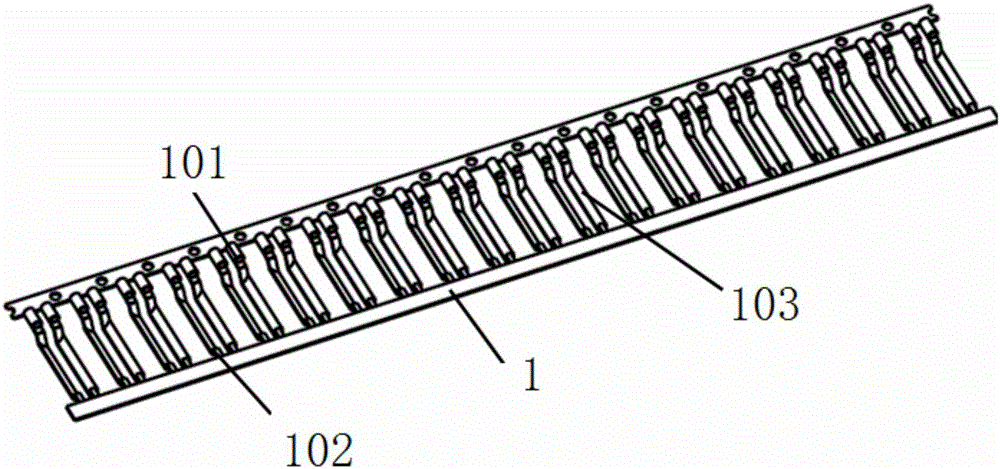

Multifunctional reflow jig for FPC lamp bar

ActiveCN106180956ANo soldering requiredEasy to usePrinted circuit assemblingWelding/cutting auxillary devicesReusabilityDie casting

The invention discloses a multifunctional reflow jig for an FPC lamp bar, and solves the technical problems that the influence of an existing jig for an FPC lamp bar on the temperature of a reflow welding furnace is excessive, and a steel cover piece and a magnetic structure of the jig both need welding, and have poor reusability. The following technical scheme is adopted: the multifunctional reflow jig for the FPC lamp bar comprises a carrying disc formed from a synthetic stone material in a die-casting manner, a location base matched and clamped with the carrying disc to form one piece and formed from an aluminium alloy material in a die-casting manner, a magnet embedded on the location base, and a steel cover piece closely attracted through the magnet, used for sealing the carrying disc on the location base and formed from a steel material in a die-casting manner. The multifunctional reflow jig has the following advantages: heat absorption influence is reduced through using the carrying disc formed from the synthetic stone material and a reflow fixing fixture, clip connection is used in the structure for many times, and a lighting fixture is designed, thus an assembly process is greatly simplified, and the production efficiency is increased.

Owner:NANJING CHINA ELECTRONICS PANDA LIGHTING

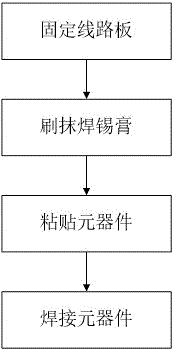

Circuit board patch welding method for LED lamp

InactiveCN106535498AImprove welding efficiencyImprove efficiencyPrinted circuit assemblingMetallurgical bondingLED lampSolder paste

The invention discloses a circuit board patch welding method for an LED lamp. The method comprise steps of a, circuit board fixing; b, soldering paste brushing; c, component pasting; and d, component welding. The method is advantaged in that labor cost is saved, the mounting process is simple and direct, quality of welding components is guaranteed, patch welding efficiency is greatly improved, and improvement of efficiency and precision of patches is facilitated.

Owner:SUZHOU HONGJIA ELECTRONICS CO LTD

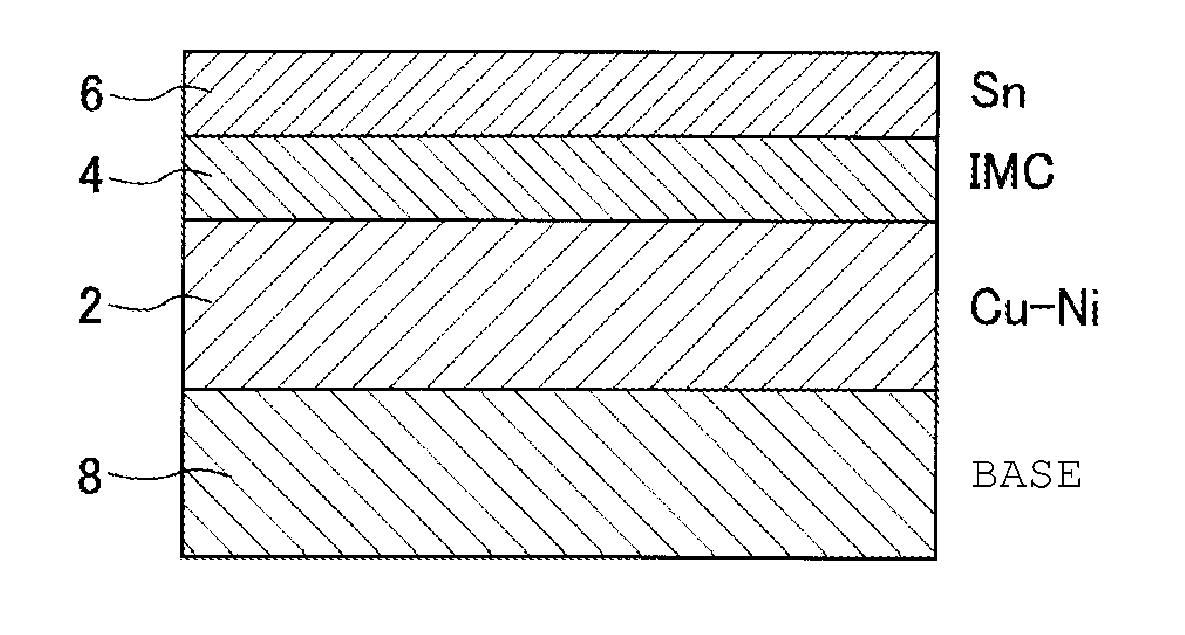

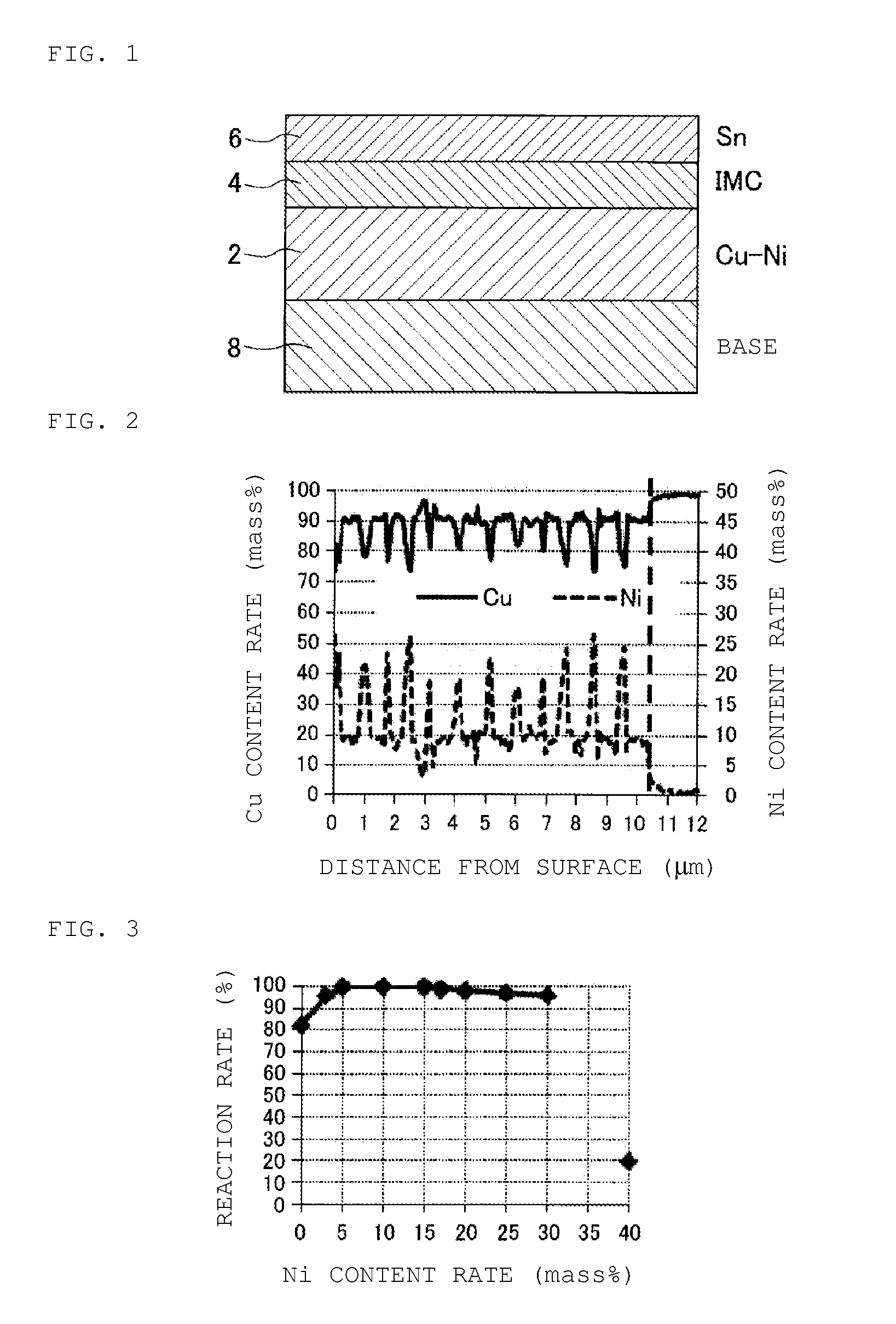

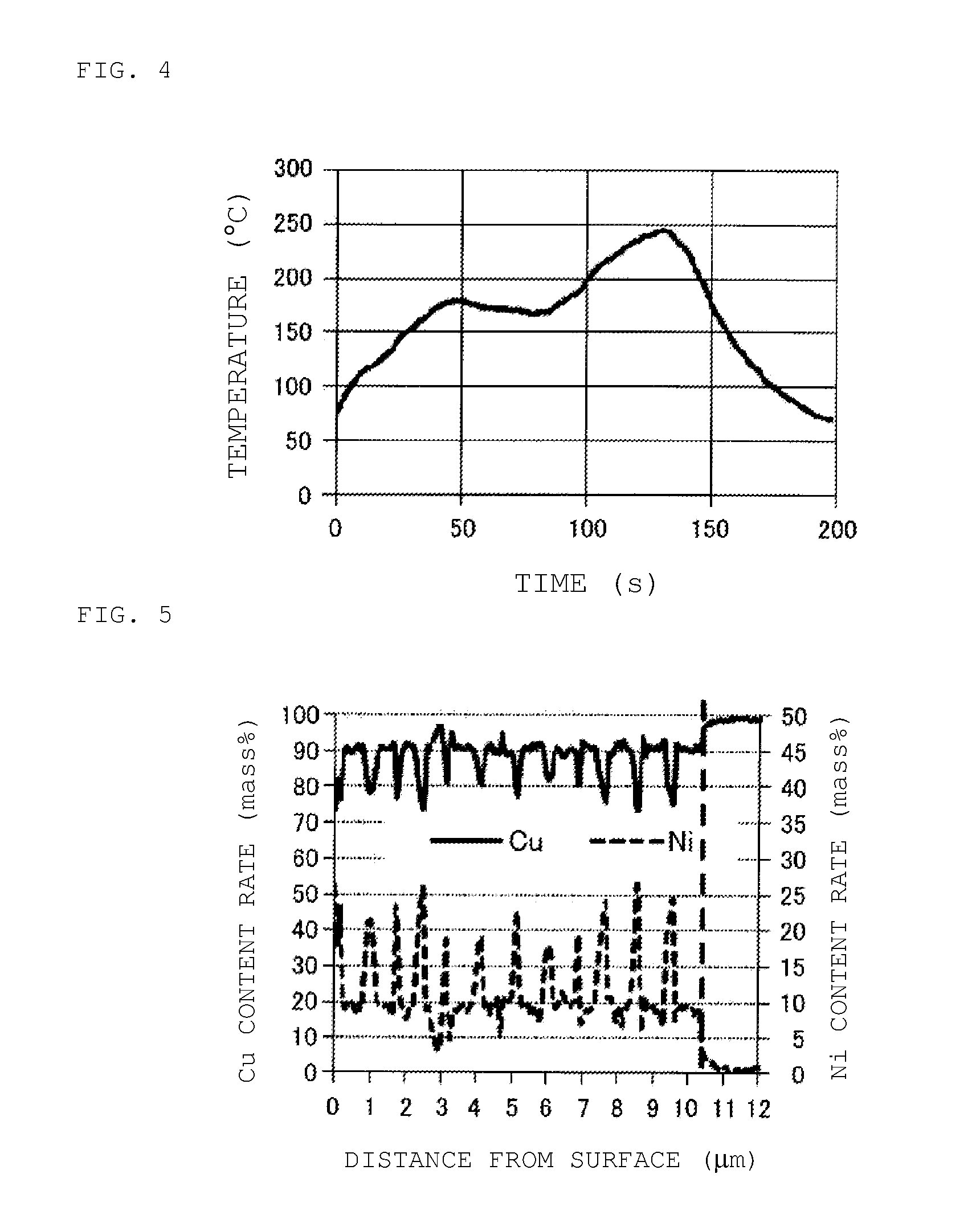

Bonding member

A bonding member that includes a plating film containing a Cu—Ni alloy as its main constituent. In this plating film, the Cu mass ratio Cu / (Cu+Ni) is increased and decreased between 0.7 and 0.97 in the film thickness direction. In addition, the amplitude between the increase and decrease in the Cu mass ratio is larger than 0.1. Therefore, when the plating film containing the Cu—Ni alloy as its main constituent and Sn-based solder material or the like are joined by soldering, an intermetallic compound layer with a high melting point is formed. In addition, the plating film has a layer with a slow reaction rate, and thus can slow the reaction rate of alloying reaction between the Cu—Ni alloy and a Sn-based metal.

Owner:MURATA MFG CO LTD

PCBA asymmetric solder pad steel mesh windowing method and system

ActiveCN107278050AImprove yieldSolve deviationPrinted circuit assemblingMetallurgical bondingPull forceDiagonal

The invention provides a PCBA asymmetric solder pad steel mesh windowing method and system. The method comprises the following steps that the actual tin soldering area of a solder pad is determined, and the area of the diagonal direction of the tin soldering area is identical and the area of the left and right sides is identical; the corresponding steel mesh thickness of the solder pad is determined; and cutting and windowing are performed according to the corresponding position of the actual tin soldering area of the solder pad in the steel mesh. The diagonal area of windowing of the steel mesh is set to be identical and the left and right area is set to be identical, and the tin paste volume of the position of the identical area is the same in performing tin paste printing so that the pull force for the electrical element pins of the identical area position is the same, the problems of poor quality of deviation, inclination and floating can be effectively solved, the yield rate of circuit board production can be greatly enhanced, the production cost can be reduced and the circuit board competitiveness can be enhanced.

Owner:ZHENGZHOU YUNHAI INFORMATION TECH CO LTD

Solar lamp, PCB used for solar lamp and manufacturing method thereof

InactiveCN105228345ALow costIncrease productivityPrinted circuit assemblingPoint-like light sourceSurface mountingEngineering

An embodiment of the invention provides a solar lamp, a PCB used for the solar lamp and a manufacturing method thereof. At least one gap groove is arranged on the PCB, two sides of the gap groove are provided with bonding pads, the bonding pads are connected with an internal circuit of the PCB, and two pins of a plug-in type electronic component are welded to the bonding pads at the two sides of the gap groove. Through the gap groove on the PCB, automatic welding of the plug-in type electronic component on the PCB can be realized by adoption of an automatic surface-mounting process. The abovementioned technical scheme adopts the plug-in type electronic component which is relatively low in cost, and also adopts the automatic surface-mounting process, thereby realizing improvement of production efficiency and product quality while saving cost.

Owner:FUJIAN JOY SOLAR TECHNOLOGY CORPORATION

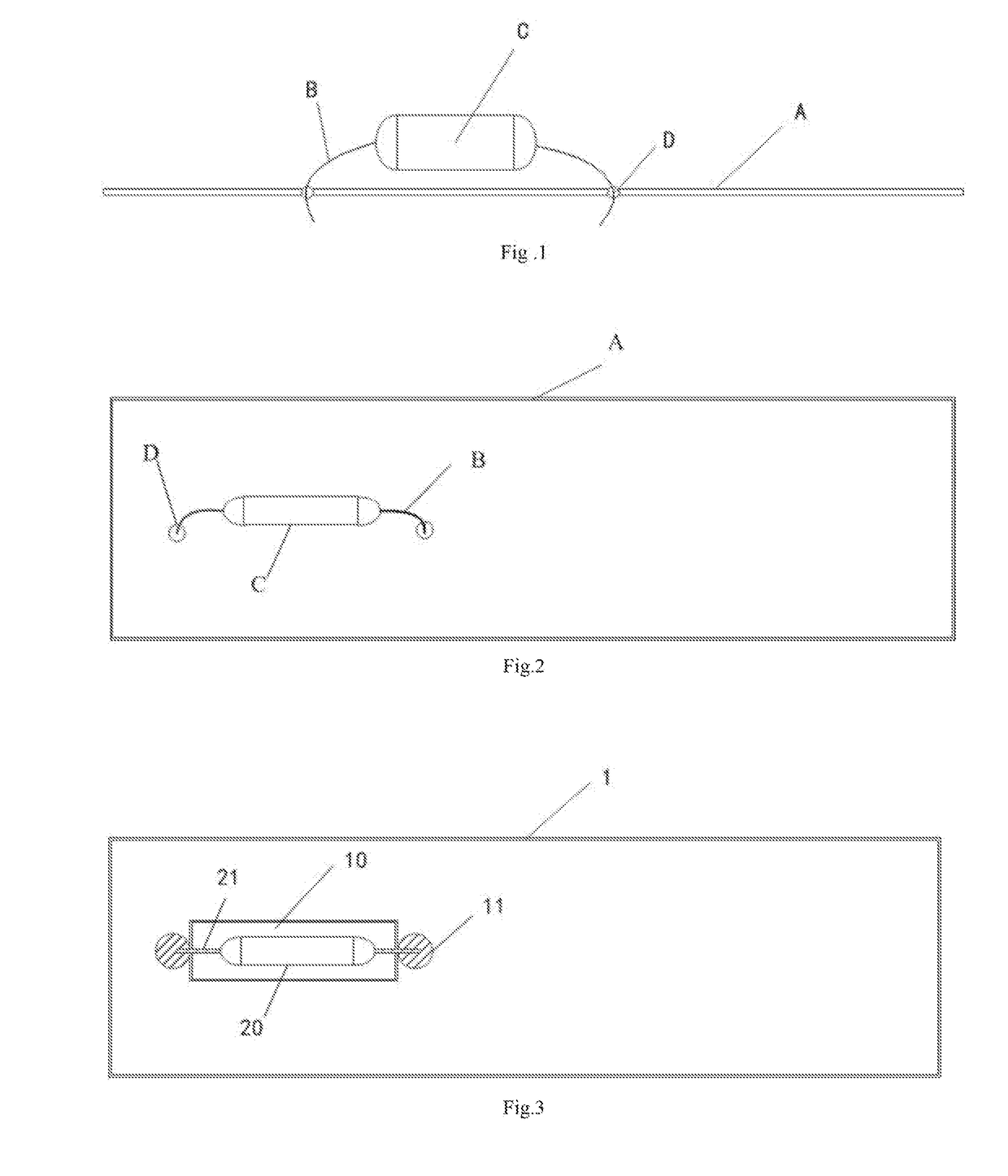

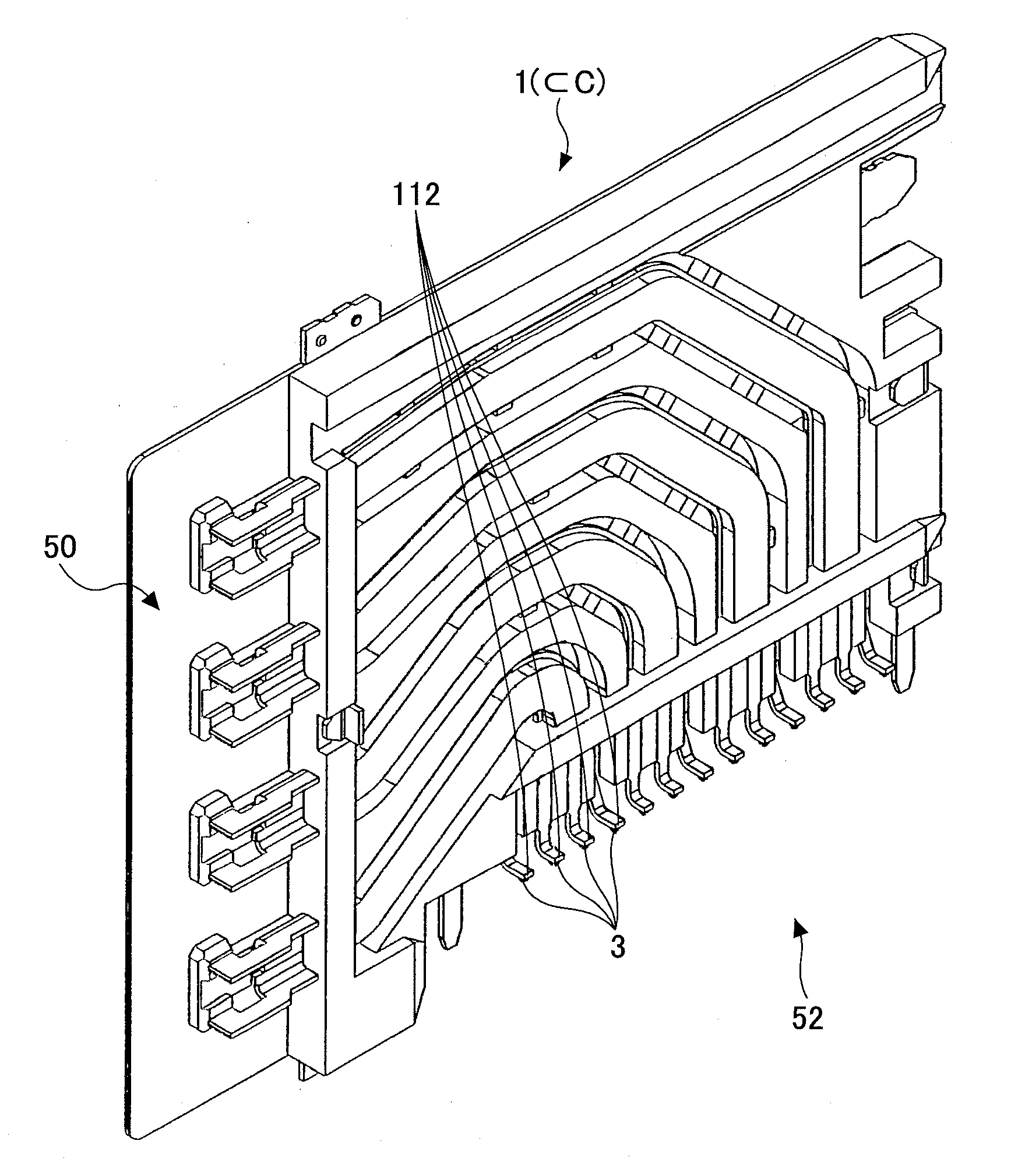

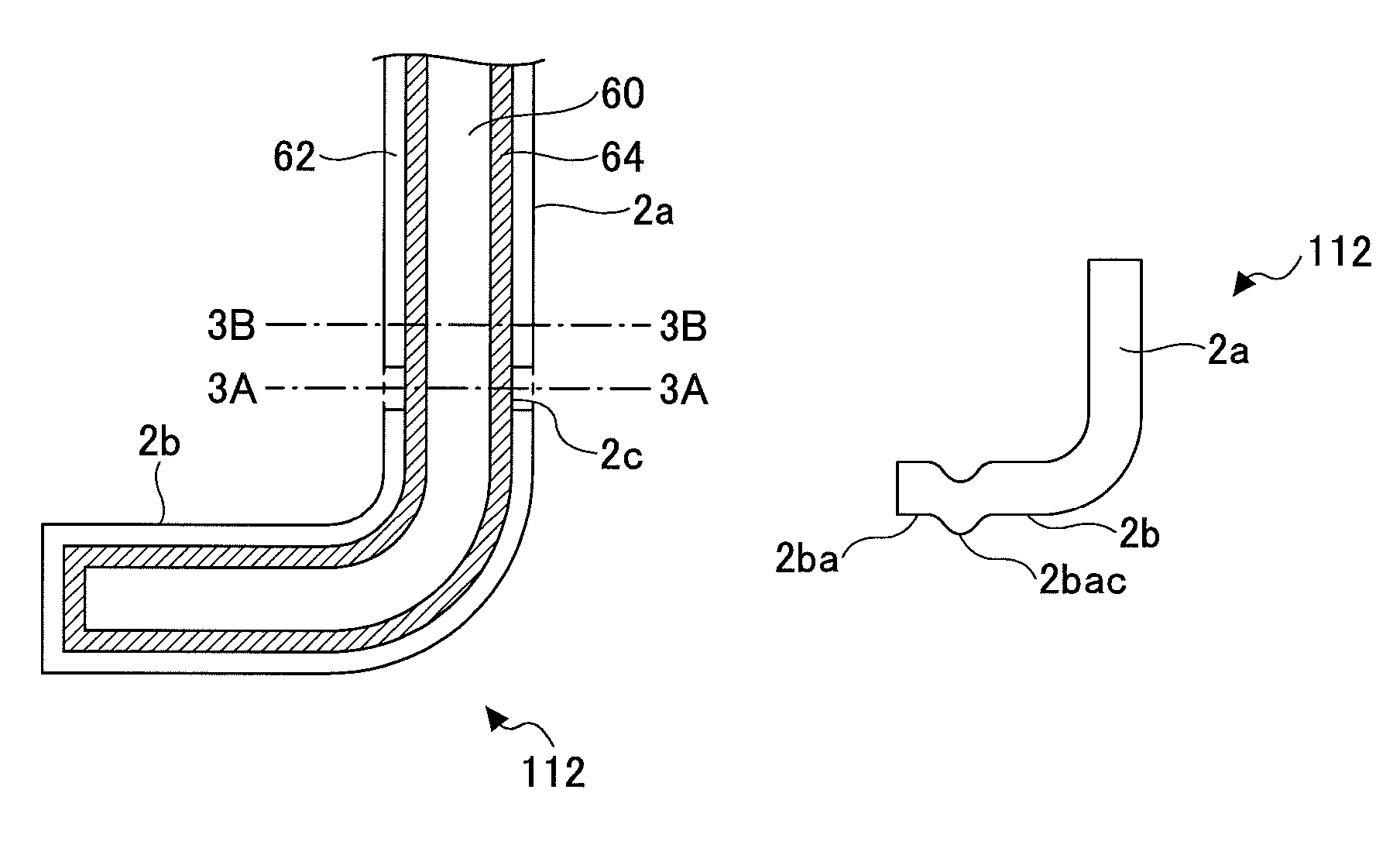

Method of soldering an electronic component with a high lateral accuracy

ActiveUS20150223347A1High positioning accuracyImprove accuracyPrinted circuit assemblingPrinted circuit aspectsMetal alloyElectronic component

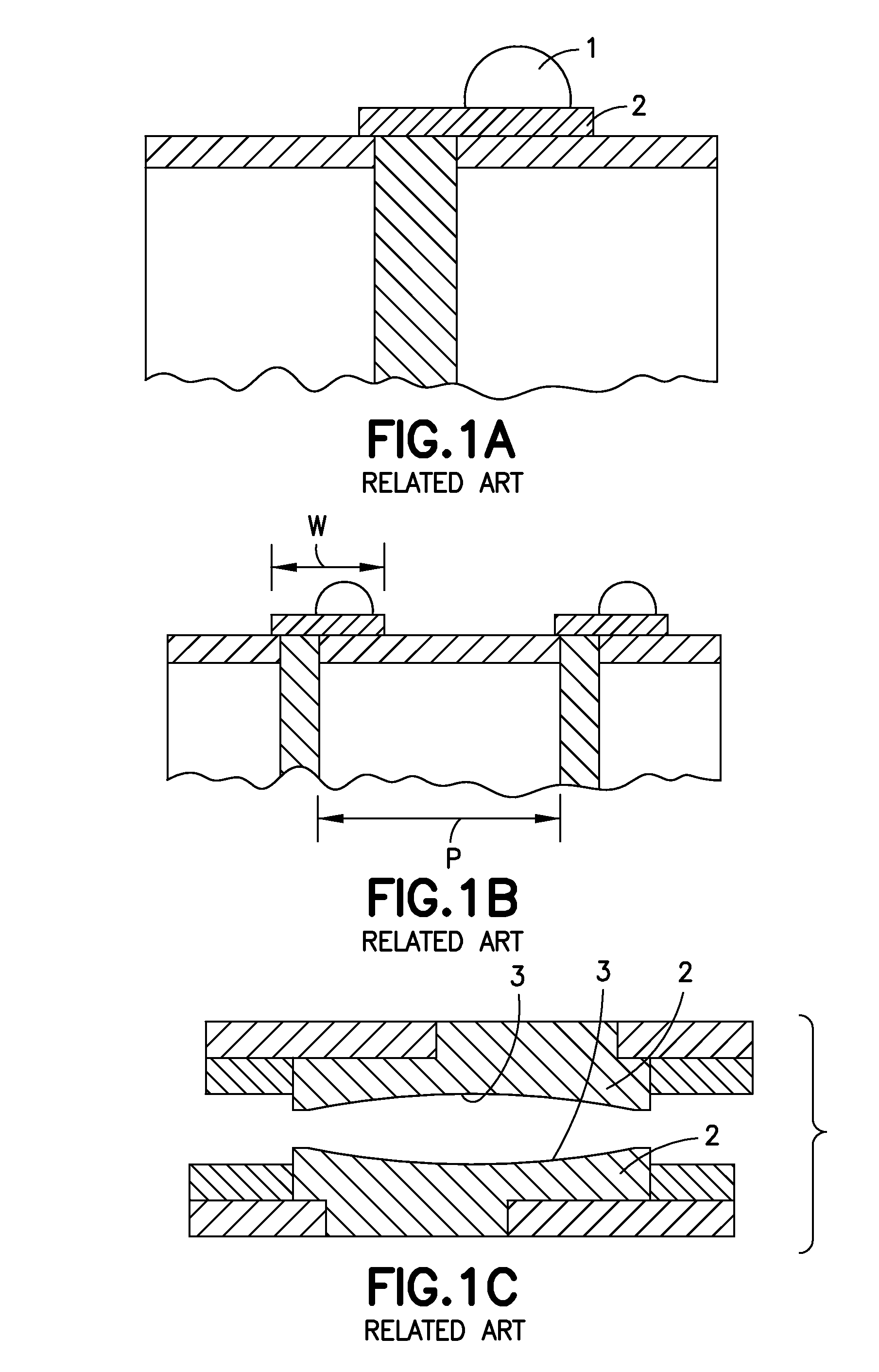

The present invention relates to a method of soldering an electronic component (3) to a substrate (1) with high accuracy using transient liquid phase soldering. The component (3) is exactly positioned above the substrate (1) with a handling tool, placed in the melted solder (2) and pressed against the substrate (1). The component (3) is then released and the solder (2) allowed solidifying. Due to the use of a solder (2) having a sufficiently high amount of a second metal or metal alloy of a higher melting point which only partly dissolves in the melted first metal or metal alloy of a lower melting point, a solid framework forms during the liquid phase soldering which inhibits a lateral movement of the placed component (3) during soldering. Since the positioning of the component (3) is made using exact reference features on the substrate (1), the whole soldering process results in a highly accurate lateral position of the soldered component.

Owner:LUMILEDS

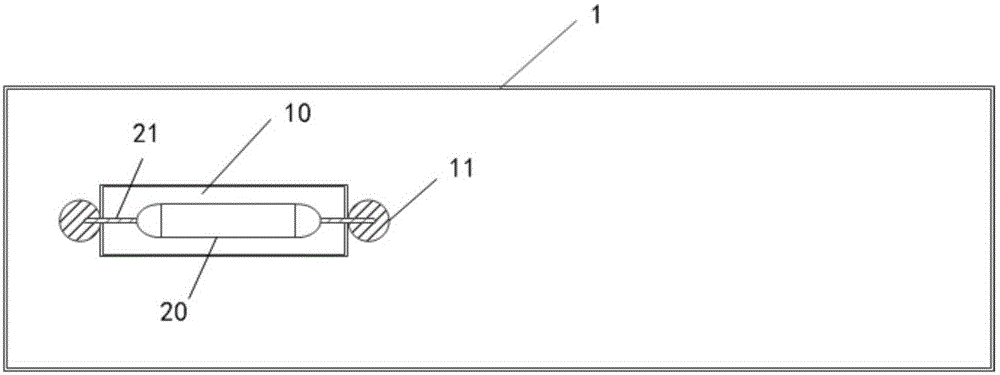

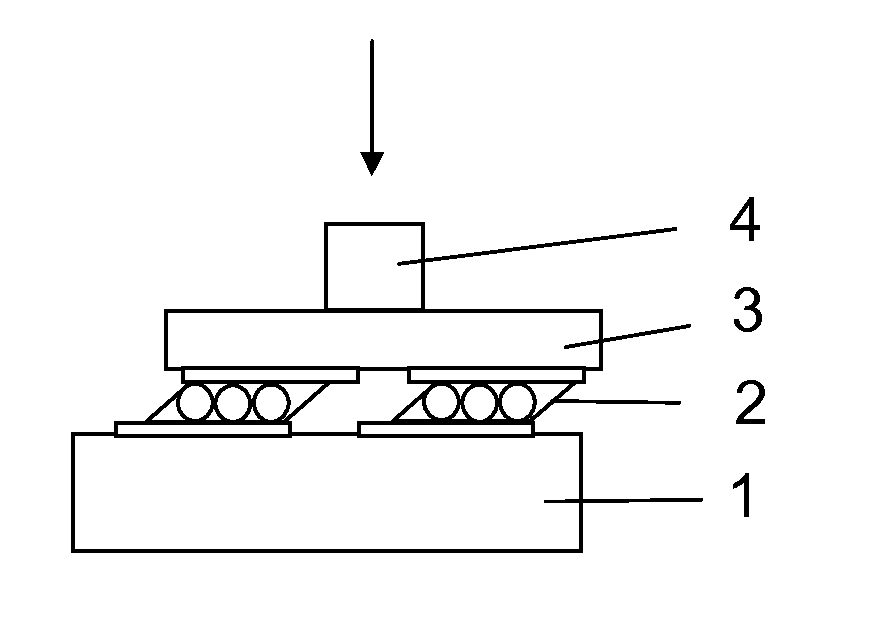

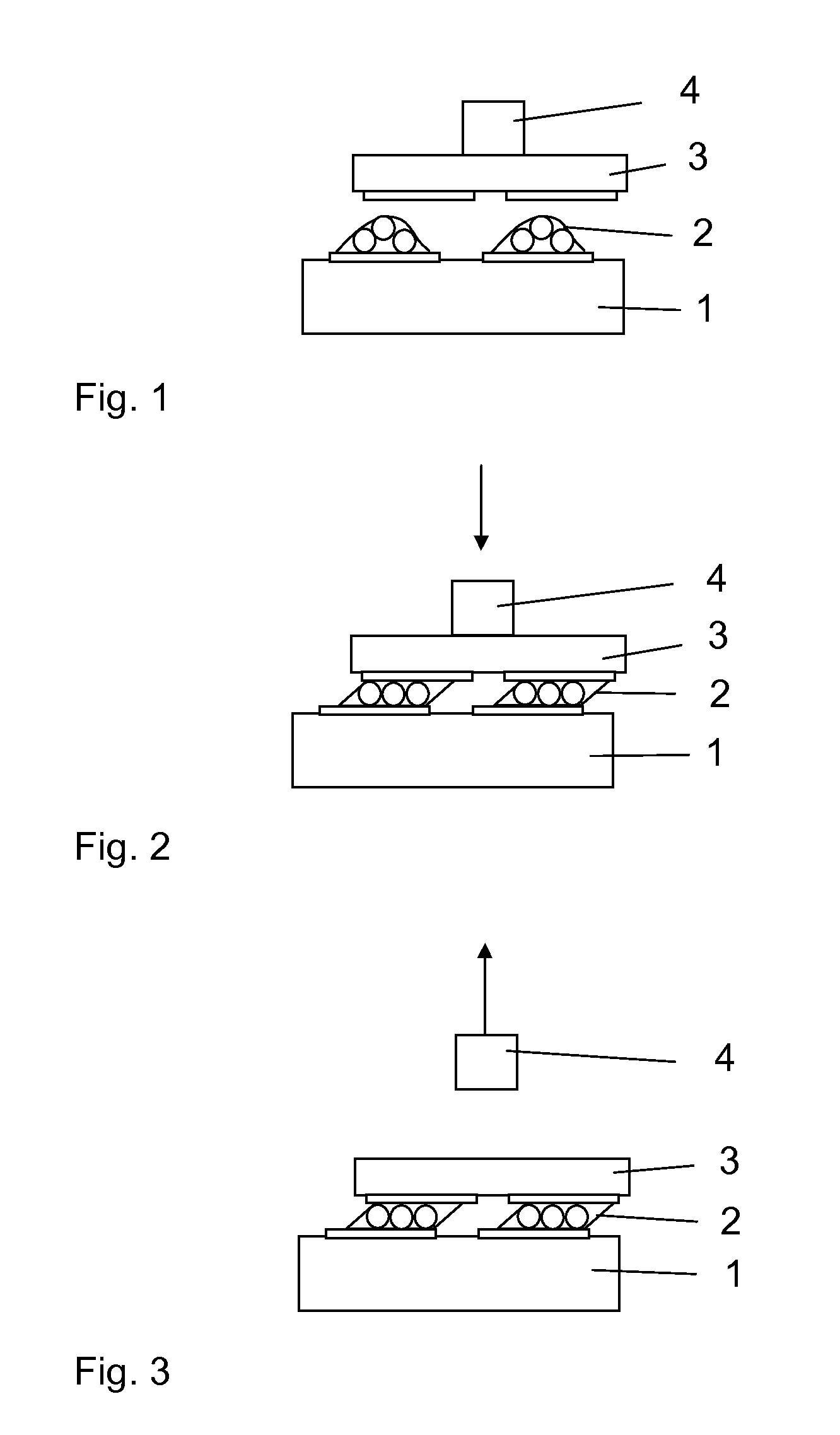

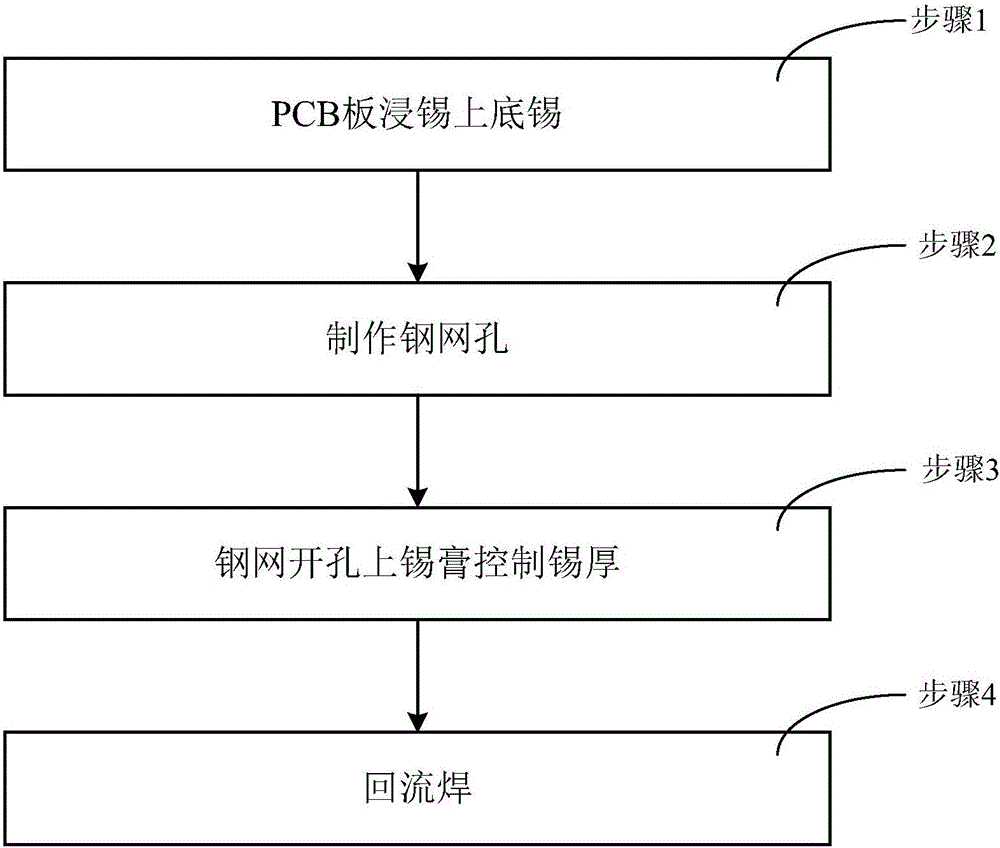

Method of coating PCB with solder paste

InactiveCN106604565AImprove yieldGet rid of dependencePrinted circuit assemblingMetallurgical bondingSolder pasteTin

The invention discloses a method of coating a PCB with solder paste. The method concretely includes the following steps: after printing of a pad or through hole of a PCB is finished, adding a layer of bottom tin on the pad or the ring of the through hole corresponding to a place that needs welding through tin immersion of a tin furnace; making a steel mesh, wherein holes in the steel mesh correspond to the pad or the through hole of the PCB; coating the steel mesh with solder paste, making a scraper move in a balanced manner to fill the holes in the steel mesh, corresponding to the pad or the through hole of the PCB, with the solder paste on the steel mesh; and separating the steel mesh with the PCB after reflow soldering is carried out by a tin press for the PCB. The beneficial effects are that the thickness of tin needs not to be controlled during tin immersion of the PCB, the holes are disposed in the steel mesh and filled with the solder paste during a SMT process when the PCB is coated with the bottom tin so that the thickness of tin is controlled, the cost is not added, the quality is reliable, management and control is convenient, the yield rate of a finished product is greatly improved, and the method can be independent of skills of employees; and after solder paste is disposed in welding positions, standards for the thickness of tin immersion can be loose, and the yield rate of a PCB semi-finished product can be increased.

Owner:SHENZHEN SUCCESS ELECTRONICS LTD +3

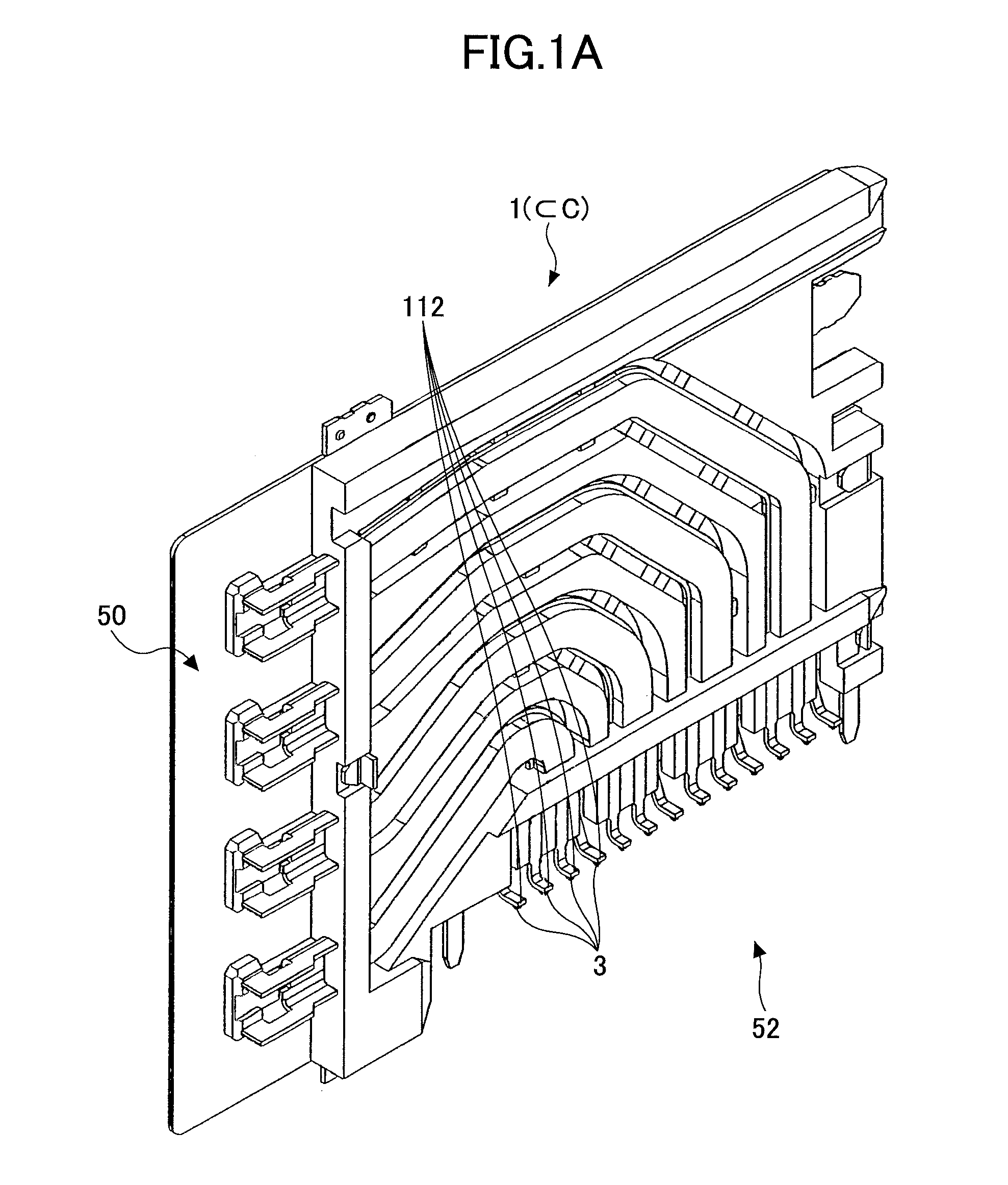

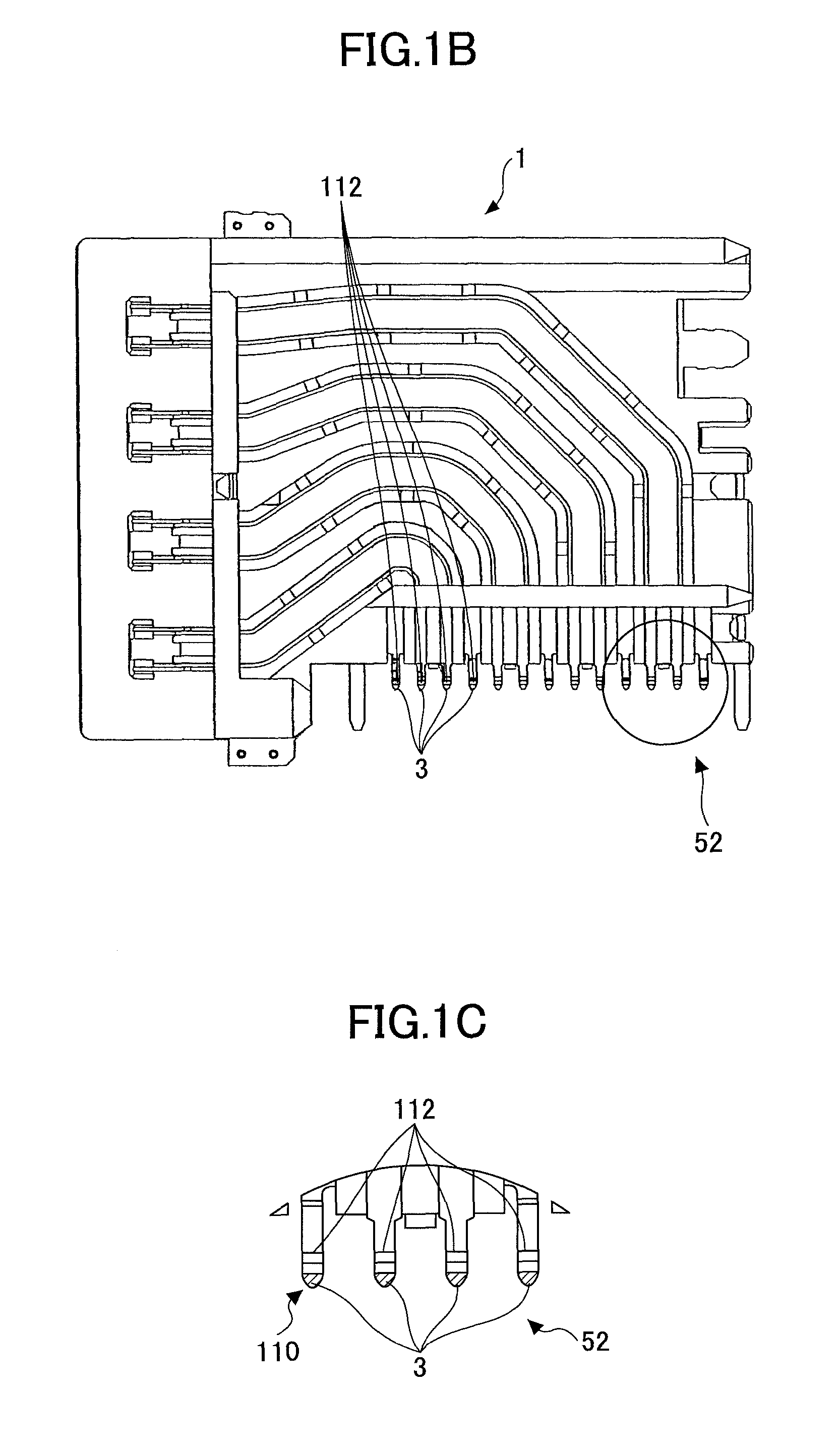

Surface mount device

InactiveUS9106005B2Firmly connectedVariation in lengthPrinted circuit assemblingPrinted circuit detailsSurface mountingSummit

Disclosed is a surface mount device to be mounted on a base member, including plural lead units, each of the plural lead units including, a lead including a body portion and a foot formed at an end of the lead; a solder portion formed at the foot of the lead to protrude toward the direction of the base member to have a summit portion, and a diffusion prevention portion provided on the lead for preventing a diffusion of a solder along the body portion of the lead.

Owner:FUJITSU COMPONENENT LTD

Novel electronic detonator control module structure and special production tool and method thereof

ActiveCN106802114AQuick connectionIncrease productivityPrinted circuit assemblingMetallurgical bondingCapacitanceDetonator

The invention discloses a novel electronic detonator control module structure and a special production tool and method thereof. A capacitor bracket is designed and used for connecting an electronic detonator control module and electronic detonator leg wires, the structures including rubber sealing bodies and fuse head protecting sleeves are arranged outside the capacitor bracket and can guarantee the effect that the electronic detonator control module is not damaged in the producing, assembling and circulating processes, and the tail of a produced electronic control module is provided with a rapid connecting leg wire terminal which can achieve rapid connection with the electronic detonator leg wires. The invention further provides the special production tool and method of the novel electronic detonator control module structure. By means of the production tool and method, production efficiency and production quality can be remarkably improved, and product safety and reliability are remarkably improved.

Owner:BEIJING QAML OF SCI & TECH CO LTD

Solder assembly temperature monitoring process

InactiveUS20160011061A1Printed circuit assemblingSoldering apparatusTemperature monitoringThreshold temperature

A method includes providing a printed circuit board (“PCB”) supporting a solderable component, and supporting a first fuse on the PCB, where the first fuse includes a first temperature-sensitive element that measurably changes in response to exposure to ambient thermal conditions exceeding a first threshold temperature. The PCB, the solderable component, and the first fuse define an apparatus. The method includes performing a PCB assembly manufacturing process, and then testing the first fuse to determine whether, during the PCB assembly manufacturing process, the first fuse was exposed to ambient thermal conditions exceeding a first threshold temperature. The first threshold temperature is a minimum temperature where the PCB assembly manufacturing process is to be carried out, a maximum temperature at which the PCB assembly manufacturing process is to occur, or a first intermediate temperature between the minimum and maximum temperatures.

Owner:IBM CORP

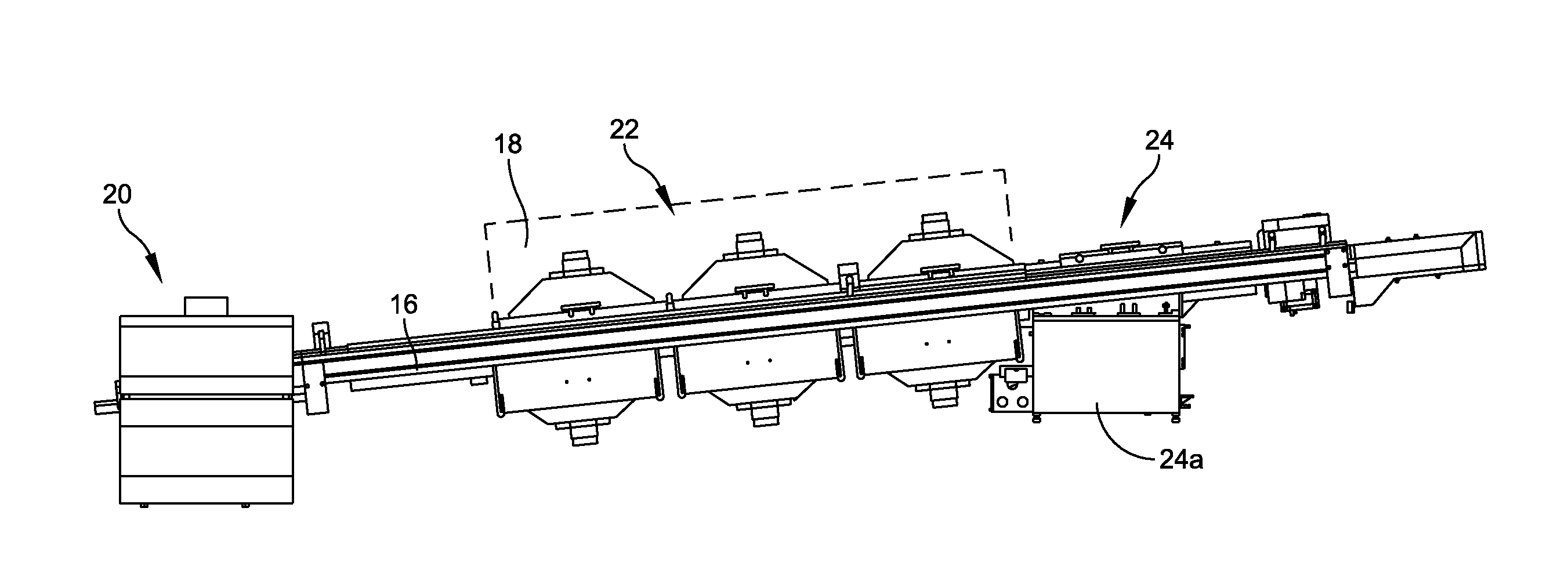

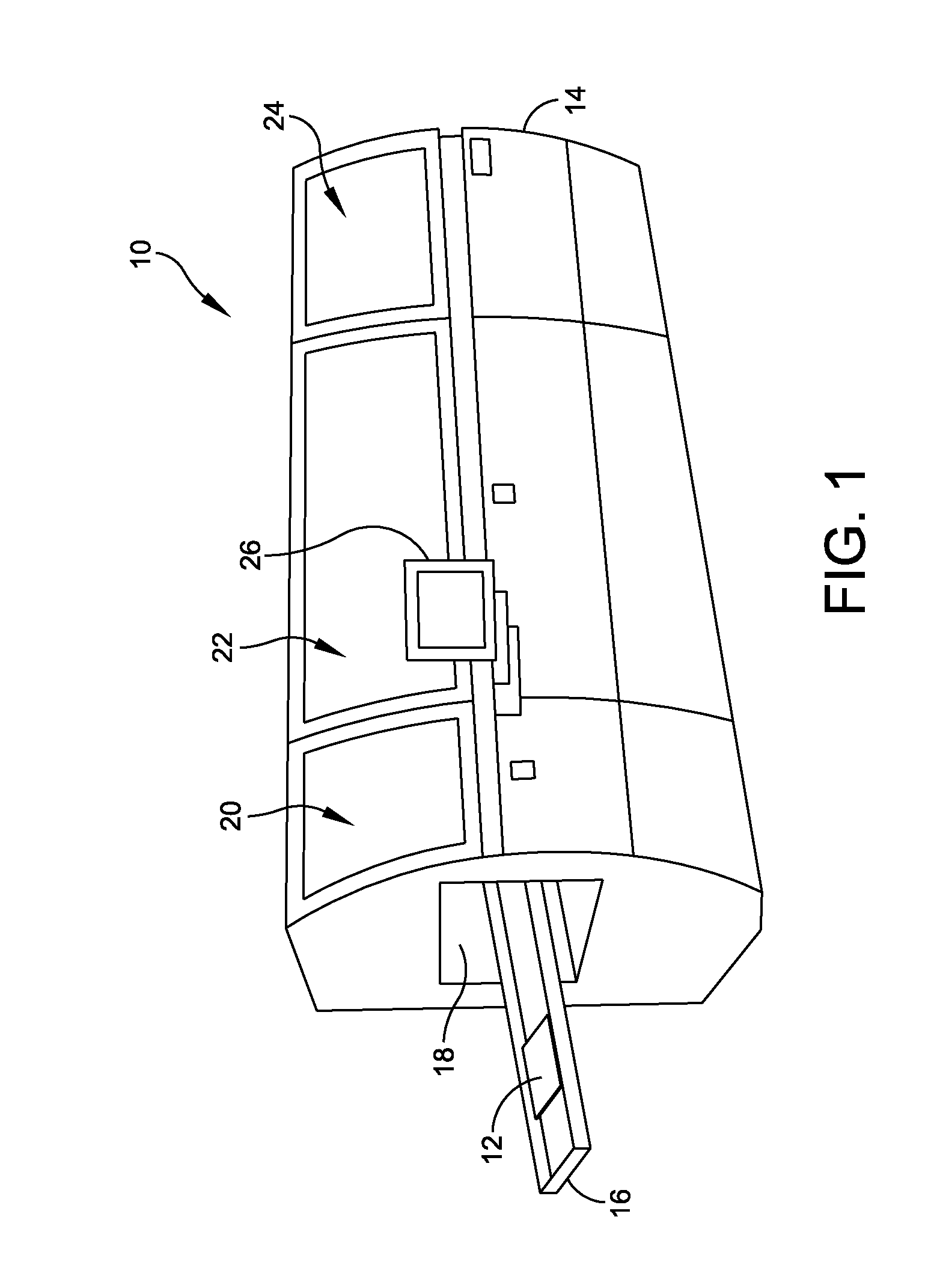

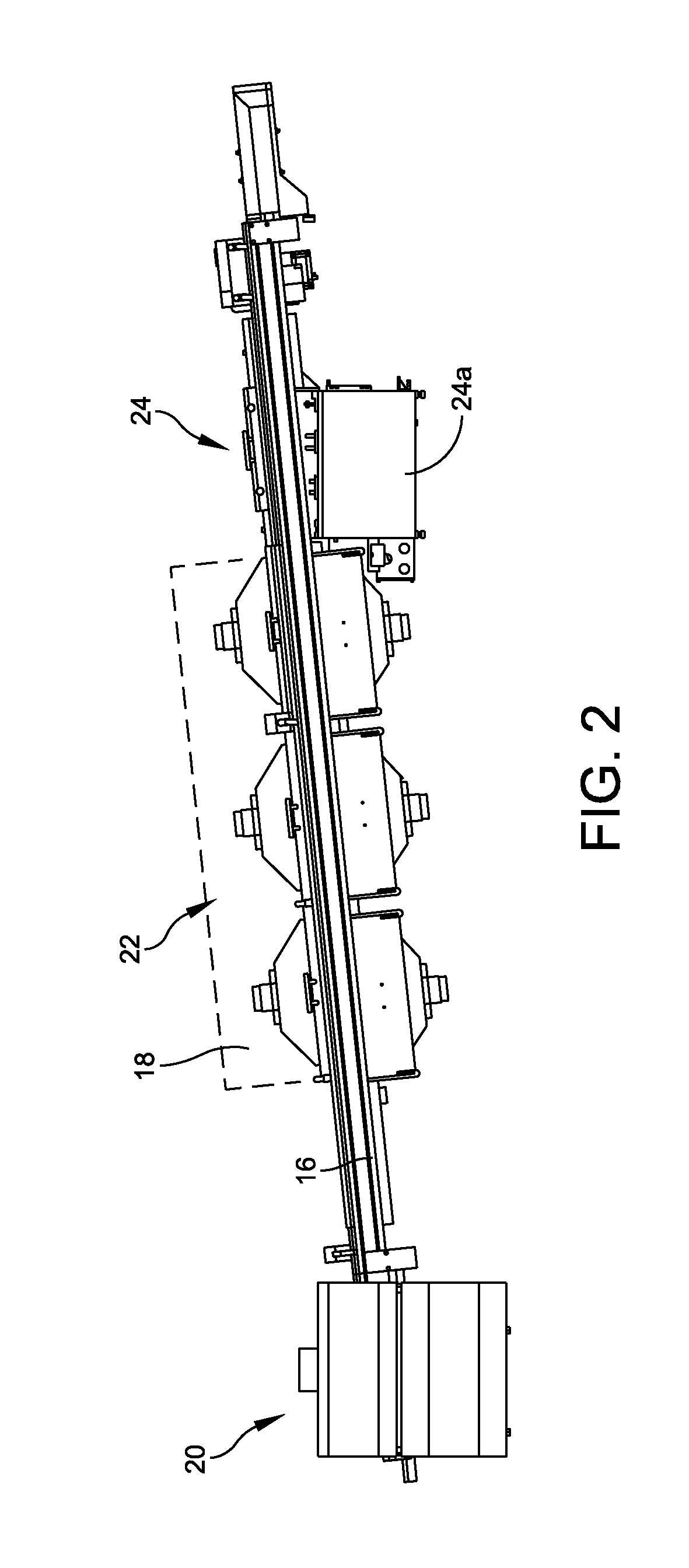

Pre-heater latch and seal mechanism for wave solder machine and related method

A wave solder machine includes a pre-heating station, a wave soldering station, and a conveyor to transport substrates through a tunnel passing through the pre-heating station and the wave soldering station. The tunnel has a substantially oxygen-free environment. The pre-heating station includes a pre-heater including a support frame assembly, and a heater assembly supported by the support frame assembly. The heater assembly is slidably coupled to the support frame assembly between an operational position and a non-operational position. The pre-heater further includes a seal disposed between the heater assembly and the support frame assembly. The seal provides a gas-tight seal when the heater assembly is in the operational position to prevent atmosphere from entering the tunnel thereby preserving the substantially oxygen-free environment within the tunnel.

Owner:ILLINOIS TOOL WORKS INC

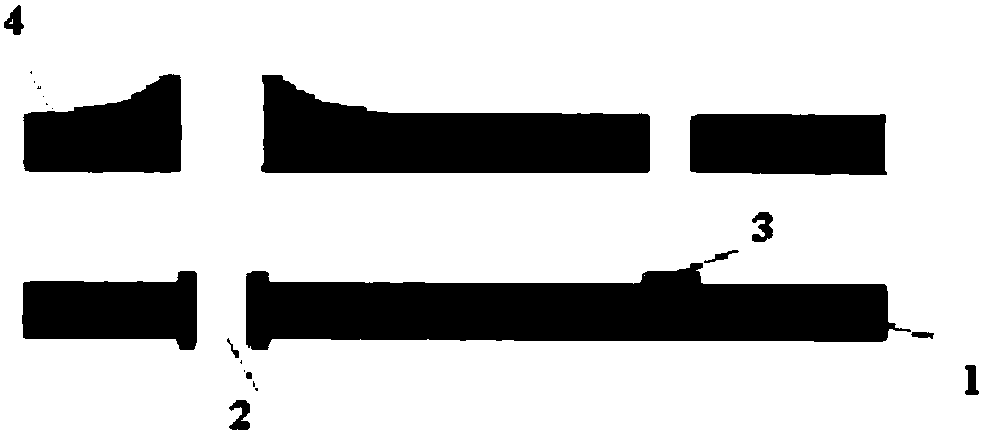

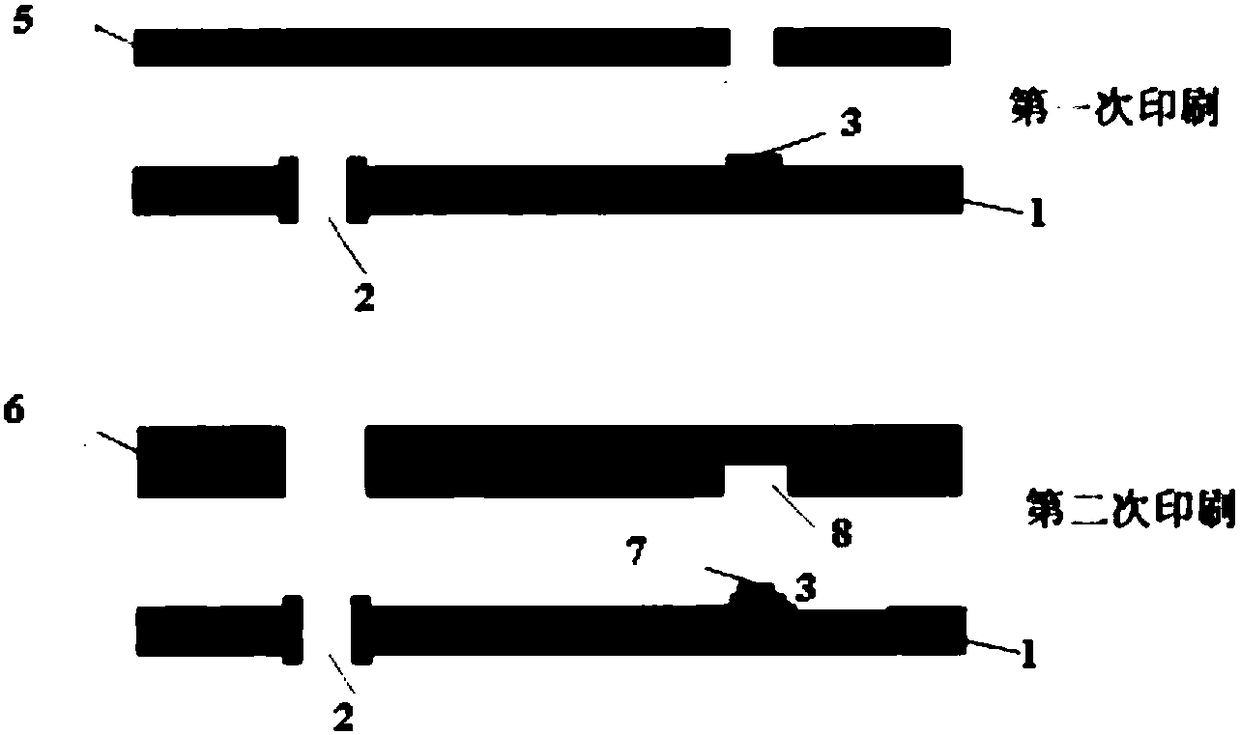

Wafer fixing surface paste method, SMT printing steel mesh and wafer fixing device

PendingCN107347232AReduce the number of sizesEasy heating operationPrinted circuit assemblingMetallurgical bondingWaferSolder paste

The invention discloses a wafer fixing surface paste method to fix and attach a wafer on a substrate. The method comprises the steps that solder paste is printed in a primary solder paste printing area on the substrate to form a primary solder paste layer; the substrate is heated and cooled to volatilize a flux in the primary solder paste layer; solder paste is printed in a secondary solder paste printing area on the cooled primary solder paste layer to form a secondary solder paste layer, wherein the area of the secondary solder paste layer is smaller than the area of the primary solder paste layer; the wafer is attached on the substrate through the secondary solder paste layer; and reflow soldering is carried out on the substrate on which the wafer is attached to fix and attach the wafer on the substrate. Compared with the prior art, the method provided by the invention has the advantages that a part of the solder paste which is not attached is heated to volatilize the flux, which effectively reduces the size and number of the bubbles generated by heating after sticking; and the method can be used for fixing and attaching a thin wafer. The invention further discloses an SMT printing steel mesh and an SMT wafer fixing device.

Owner:UTAC DONGGUAN

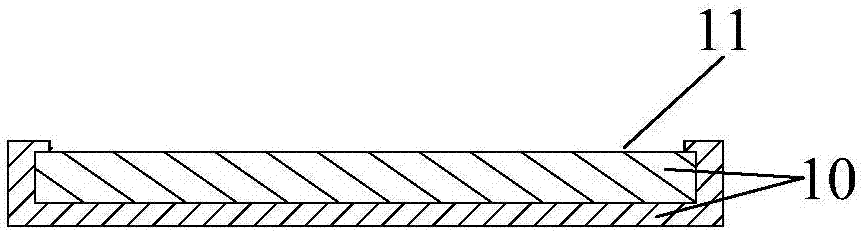

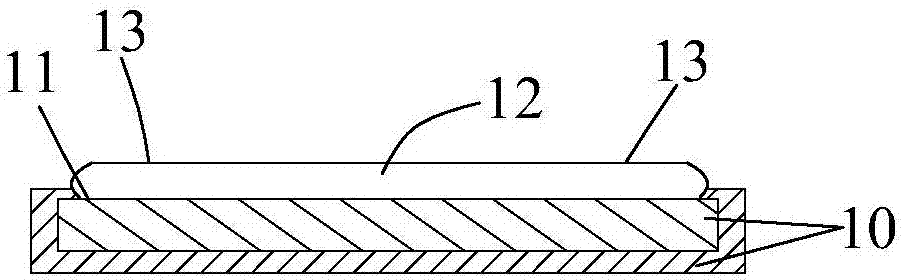

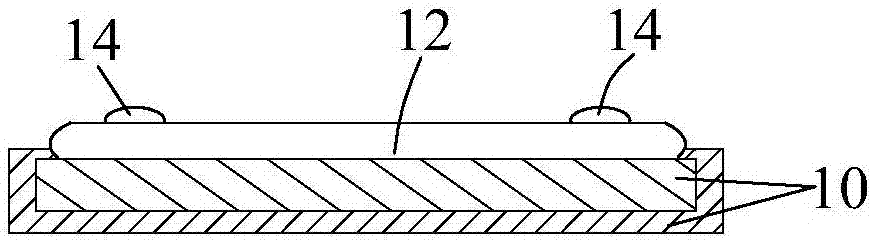

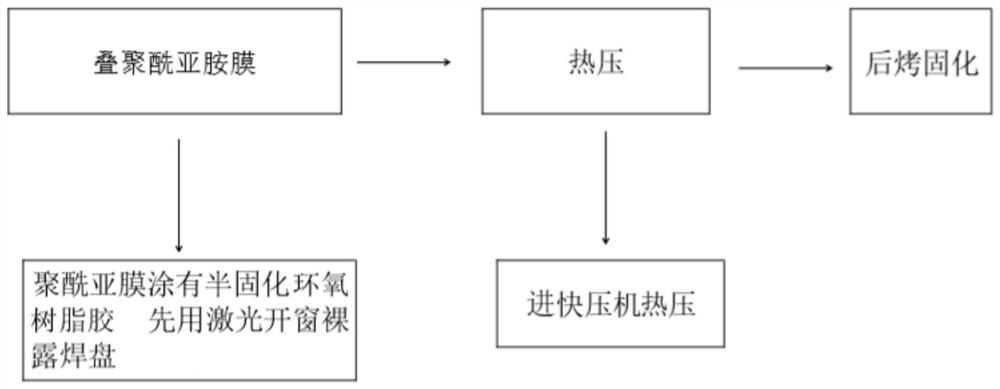

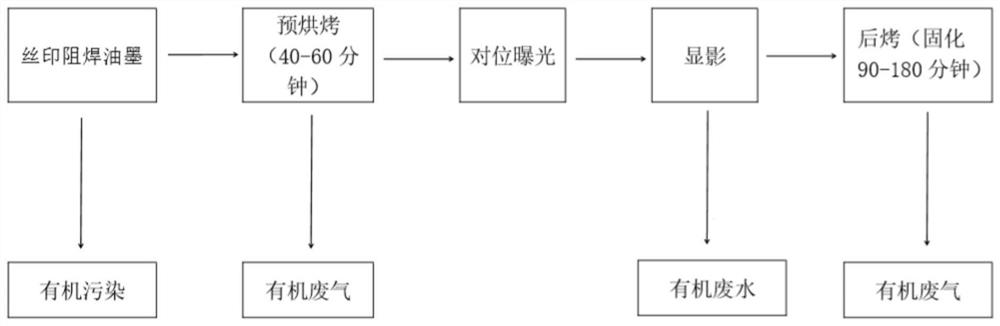

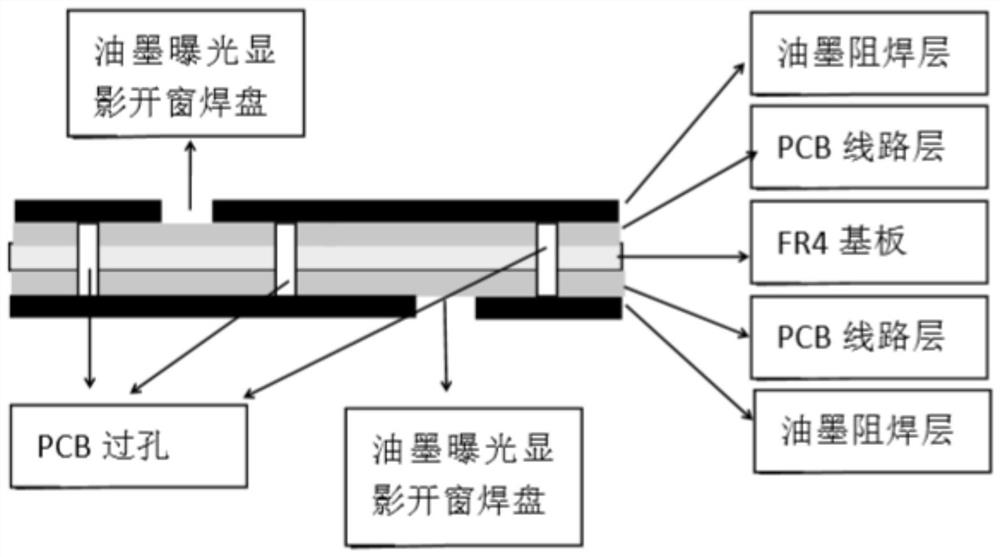

PCB solder mask production process

InactiveCN111642081AQuite flexibleIncrease productivityPrinted circuit assemblingMetallurgical bondingEpoxySolder mask

The invention discloses a PCB solder mask production process. The PCB solder mask production process comprises the following steps of: raw material preparation, bonding pad exposing, film stacking, stacked film fixing, high-temperature hot press molding, baking and curing. Compared with the traditional PCB production process, the PCB solder mask production process provided by the invention has theadvantages that zero emission is realized through the solder mask process, water and electricity are saved, and the production cycle of the process can be greatly shortened; the PCB can be enabled tohave a considerable bending property; the production process comprises the following steps of: coating one sides of polyimide films (PI) with a semi-cured epoxy resin adhesive (or semi-solid acrylicacid), cutting windowing positions of PCB bonding pads on the polyimide films (PI) by processes like laser or die punching, then stacking and fixing the windowed polyimide films (PI) on a PCB body ina stacking mode, and performing pressing and forming in a high-temperature fast pressing mode, thus finally obtaining a solder mask superior to printing ink. The process saves water, electricity and labor, improves the production efficiency, and is environment-friendly and pollution free.

Owner:江西兆信精密电子有限公司

Popular searches

Welding/cutting media/materials Welding/soldering/cutting articles Metal working apparatus Soldering media Semiconductor devices Semiconductor/solid-state device manufacturing Electrical connection printed elements Printed circuits structural associations Electrical components Printed electric component incorporation

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com