Electromagnetic field assisted self-assembly with formation of electrical contacts

a technology of electrical contacts and self-assembly, which is applied in the direction of soldering apparatus, sustainable manufacturing/processing, final product manufacturing, etc., to achieve the effect of reducing the repulsive for

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

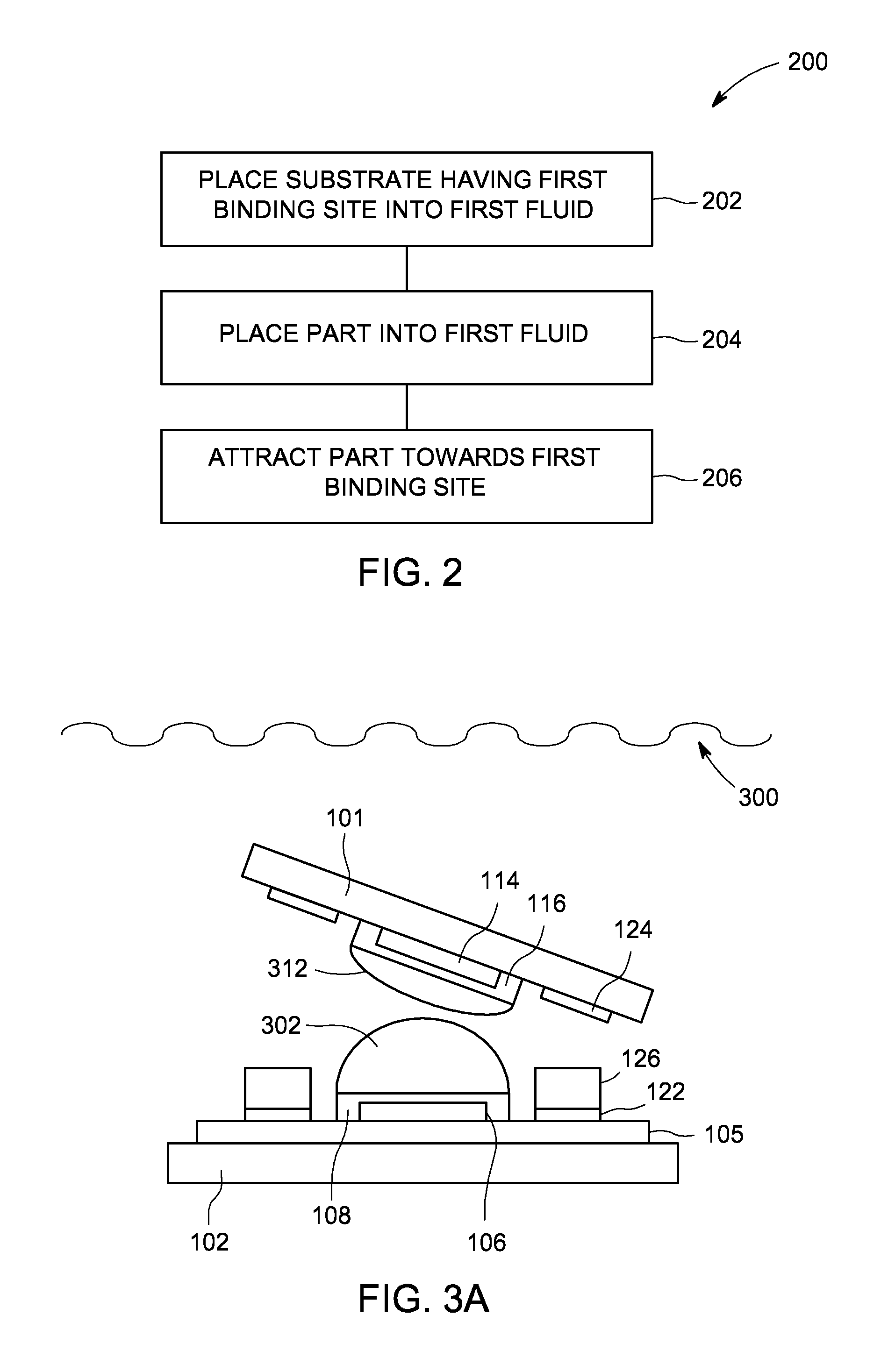

[0012]Embodiments of the present invention comprise methods and apparatus for self-assembling a part on a substrate. The inventive methods and apparatus advantageously facilitate the self-assembly of the part onto the substrate such that the part and the substrate are aligned during the self-assembly process.

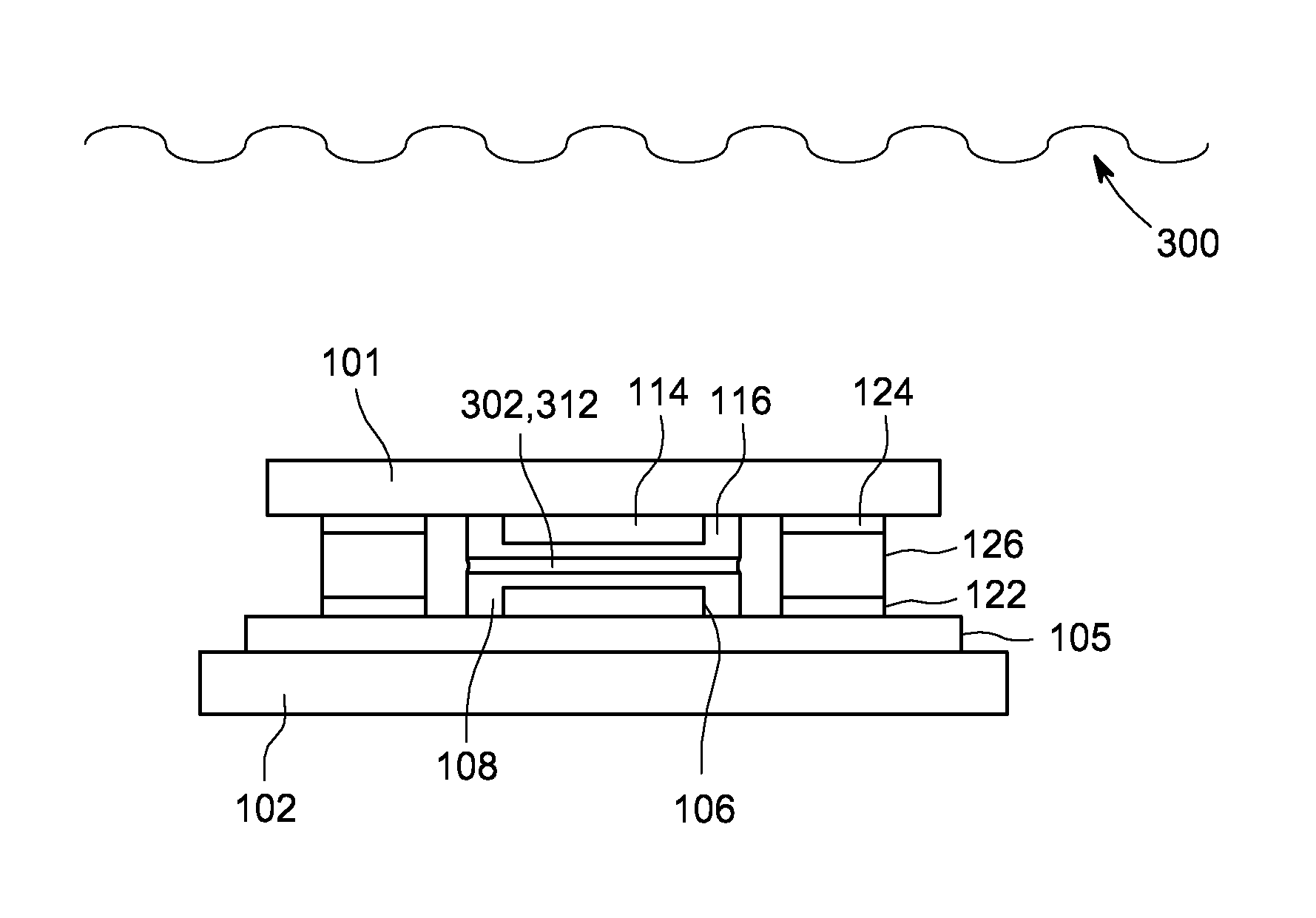

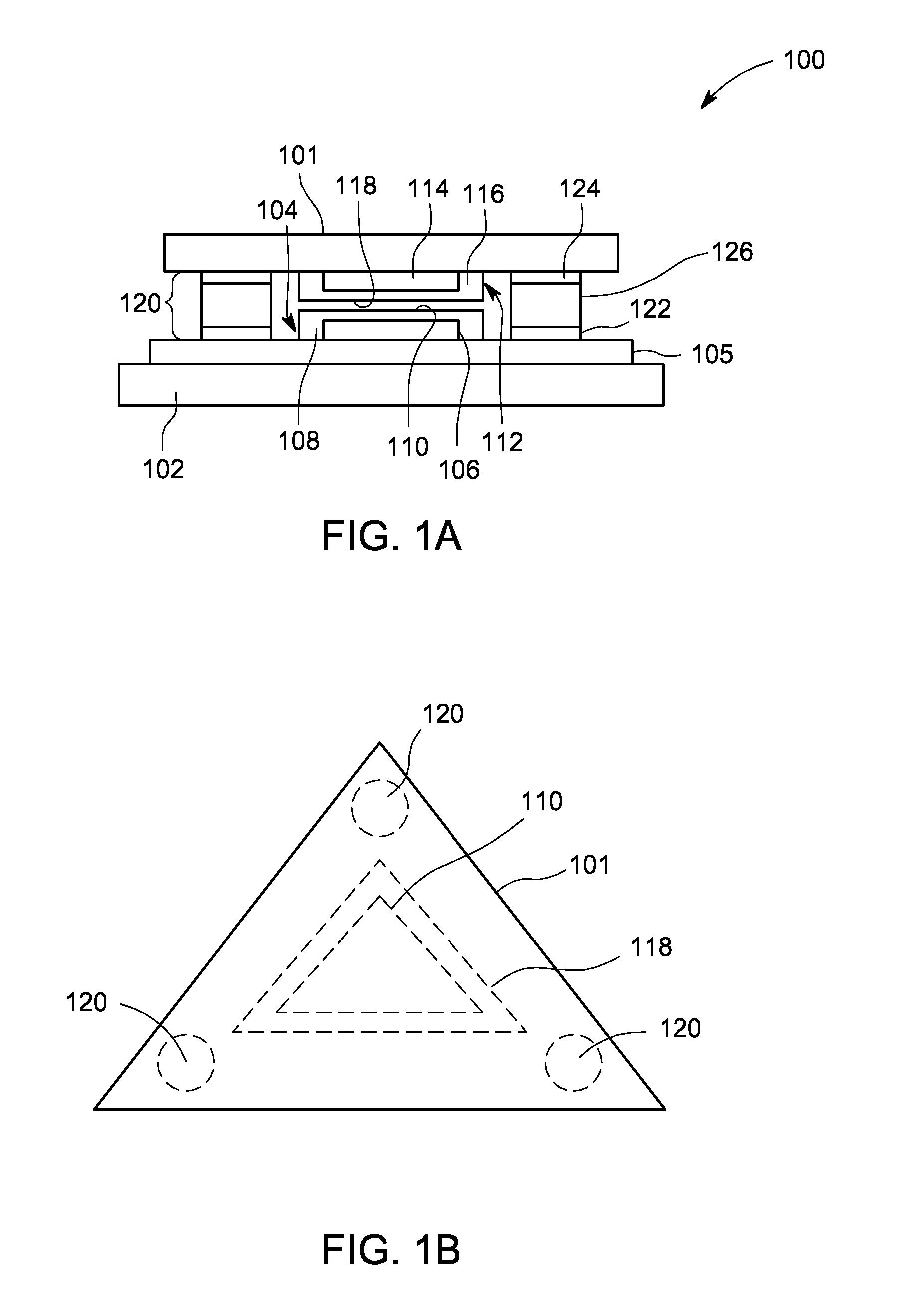

[0013]FIG. 1A depicts a side schematic view of an article 100 in accordance with some embodiments of the present invention. The article 100 includes a part 101 and a substrate 102. For example, the substrate 102 may include one or more of silicon (Si), glass, plastic, or other suitable substrate materials. The substrate 102 includes a first binding site 104. As illustrated in FIG. 1, an electrically conductive layer 105 may be disposed between the substrate 102 and the first binding site 104. For example, the electrically conductive layer 105 may include one or more of gold (Au), copper (Cu), aluminum (Al), or other suitable conductive materials.

[0014]The first binding site 104 ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Boiling point | aaaaa | aaaaa |

| Hydrophobicity | aaaaa | aaaaa |

| Electromagnetic field | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com