Wafer fixing surface paste method, SMT printing steel mesh and wafer fixing device

A technology of wafer fixing and printing stencil, which is applied in printed circuit, printed circuit manufacturing, printed circuit assembly of electrical components, etc., can solve the problems of wafer cracking, product scrapping, complicated packaging process, etc., and reduce the size of bubbles Quantity, the effect of reducing voids

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] In order to describe the technical content, structural features, achieved goals and effects of the present invention in detail, the following will be described in detail in conjunction with the embodiments and accompanying drawings.

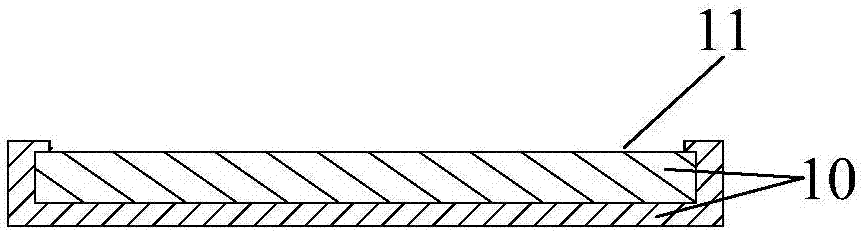

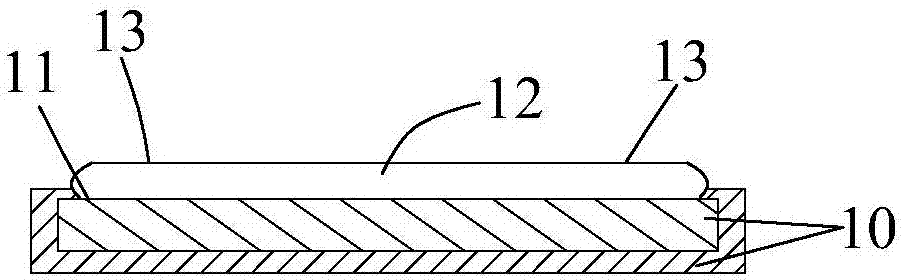

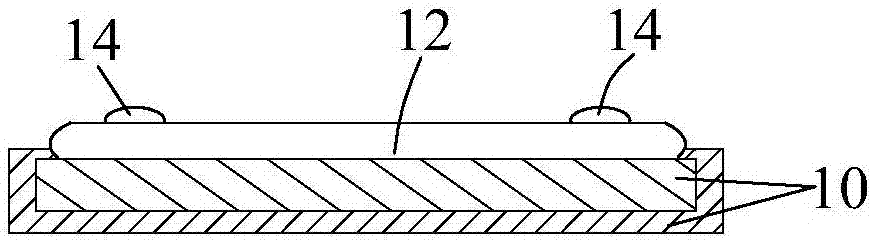

[0037] refer to Figure 1a to Figure 1e , the invention discloses a surface-attaching method for fixing a wafer, comprising the following steps: (1) referring to Figure 1a to Figure 1b , printing solder paste on the primary solder paste printing area 11 on the substrate 10 to form a primary solder paste layer 12; (2) heating and cooling the substrate 10 to volatilize the flux in the primary solder paste layer 12; (3) Reference Figure 1b with Figure 1c , printing solder paste on the secondary solder paste printing area 13 on the cooled primary solder paste layer 12 to form a secondary solder paste layer 14, the area of the secondary solder paste layer 14 is smaller than the primary solder paste layer Layer 12; (4) Ref Figure 1d , t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com