SMT patching process

A process and patch technology, applied in metallurgical bonding, electrical components, printed circuit manufacturing, etc., can solve the problems of heat resistance and different cooling speeds, affecting the welding quality of circuit boards, etc., to overcome slow cooling speed and ensure production quality , the effect of improving quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

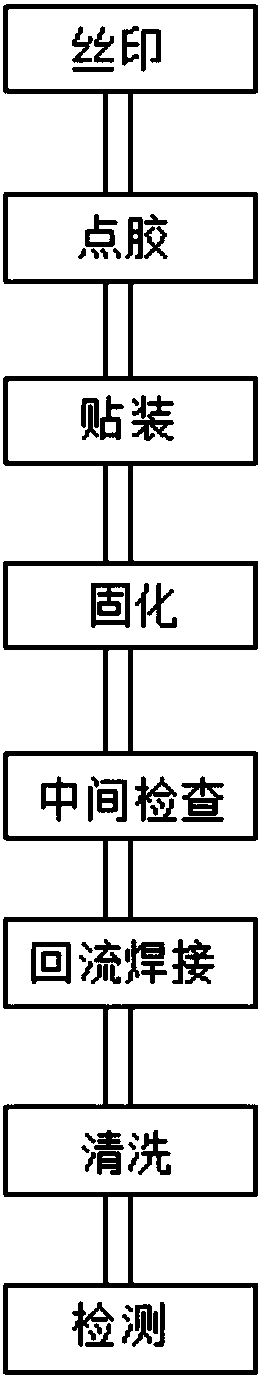

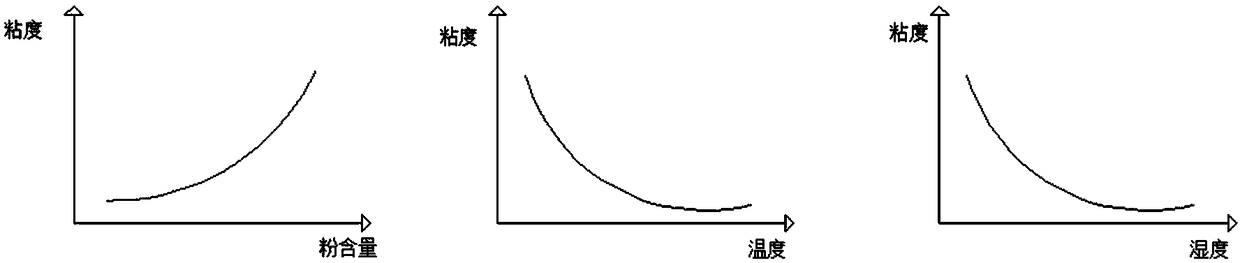

[0028] Such as Figure 1-3 As shown, a SMT patching process includes the following steps: S1, silk screen, after the circuit board is detected correctly by an optical camera, the circuit board is pasted under the stencil, and then the screen printing machine applies the solder paste or patch glue Missing printing on the pad of PCB to prepare for the soldering of components;

[0029] S2, glue dispensing, the circuit board after the screen printing step is completed, the glue is dripped onto the fixed position on the circuit board through the action of the glue dispenser, so that the electrical components are fixed on the circuit board;

[0030] S3, Mounting, sending the circuit board after the dispensing step into the placement machine, and the placement machine accurately installs the assembled components on the circuit board to a fixed position on the circuit board;

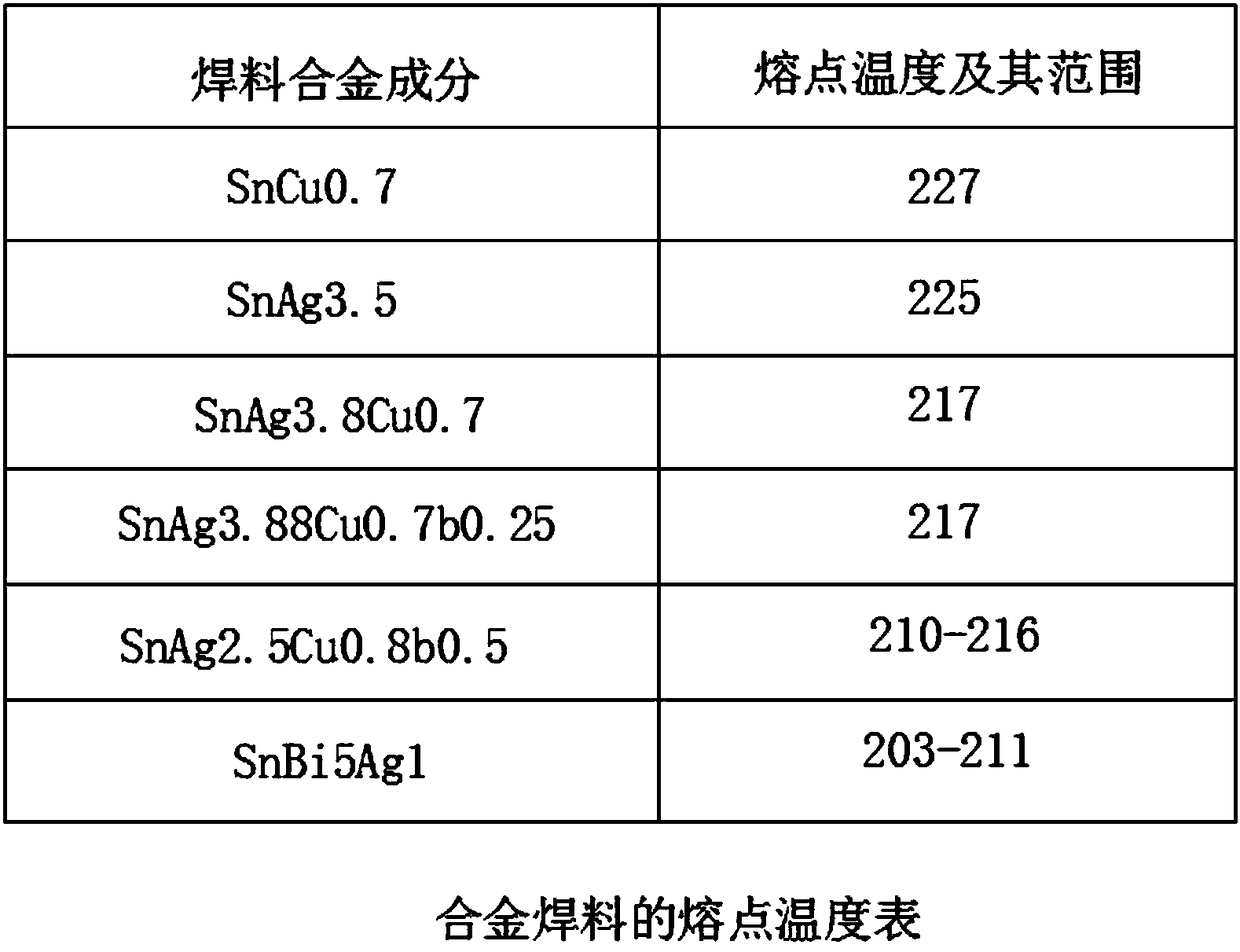

[0031] S4, curing, sending the mounted circuit board into the curing furnace, the curing furnace melts the p...

Embodiment 2

[0038] A kind of SMT placement process, comprising the following steps: S1, silk screen, after the circuit board is detected by an optical camera, the circuit board is pasted under the stencil, and then the silk screen printing machine leaks the solder paste or patch glue onto the On the pad of PCB, prepare for the soldering of components;

[0039] S2, glue dispensing, the circuit board after the screen printing step is completed, the glue is dripped onto the fixed position on the circuit board through the action of the glue dispenser, so that the electrical components are fixed on the circuit board;

[0040] S3, Mounting, sending the circuit board after the dispensing step into the placement machine, and the placement machine accurately installs the assembled components on the circuit board to a fixed position on the circuit board;

[0041] S4, curing, sending the mounted circuit board into the curing furnace, the curing furnace melts the patch adhesive, and bonds the assembl...

Embodiment 3

[0048] A kind of SMT placement process, comprising the following steps: S1, silk screen, after the circuit board is detected by an optical camera, the circuit board is pasted under the stencil, and then the silk screen printing machine leaks the solder paste or patch glue onto the On the pad of PCB, prepare for the soldering of components;

[0049] S2, glue dispensing, the circuit board after the screen printing step is completed, the glue is dripped onto the fixed position on the circuit board through the action of the glue dispenser, so that the electrical components are fixed on the circuit board;

[0050] S3, Mounting, sending the circuit board after the dispensing step into the placement machine, and the placement machine accurately installs the assembled components on the circuit board to a fixed position on the circuit board;

[0051]S4, curing, sending the mounted circuit board into the curing furnace, the curing furnace melts the patch adhesive, and bonds the assembly...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com