Patents

Literature

792 results about "Silk-screen printer" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

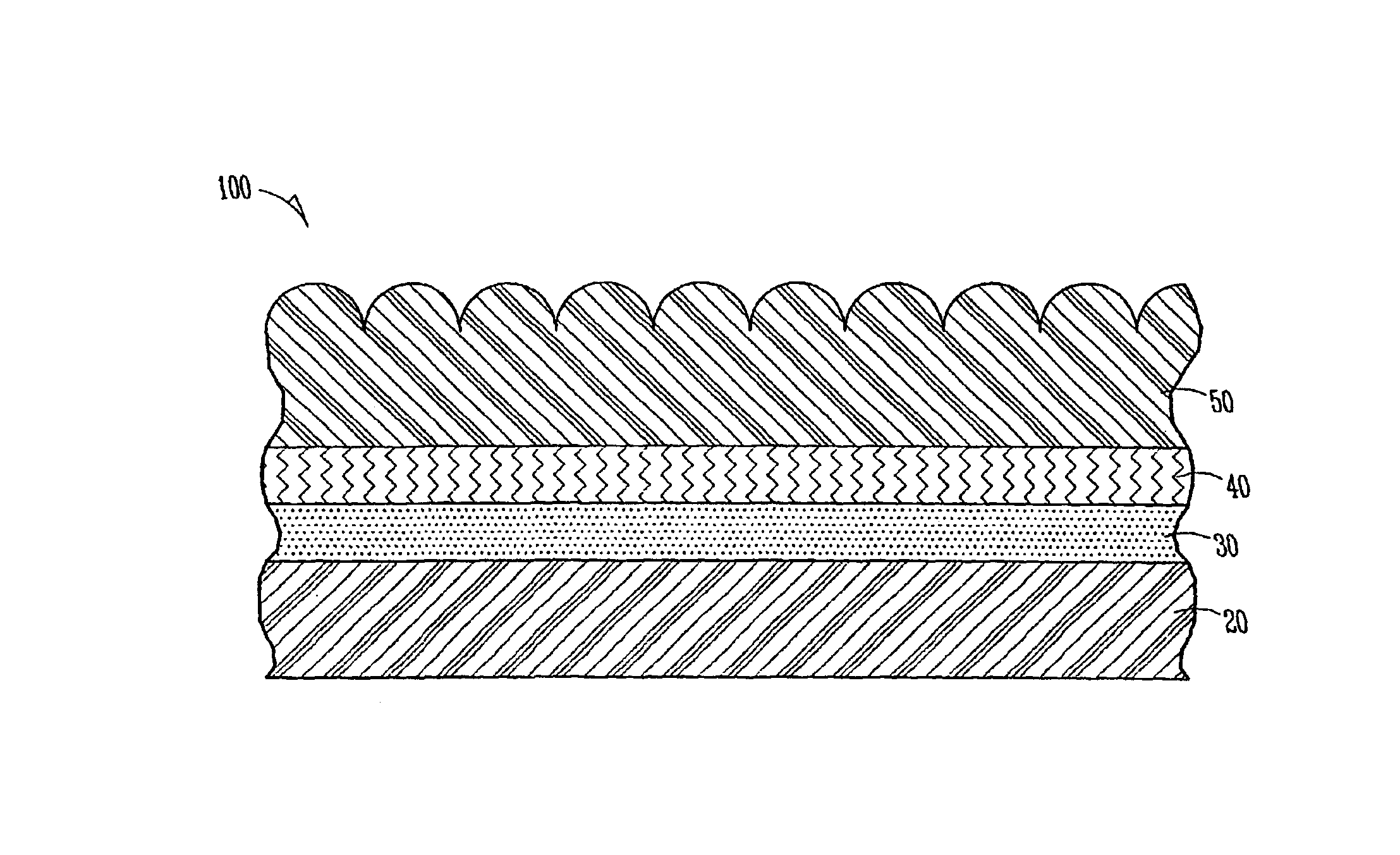

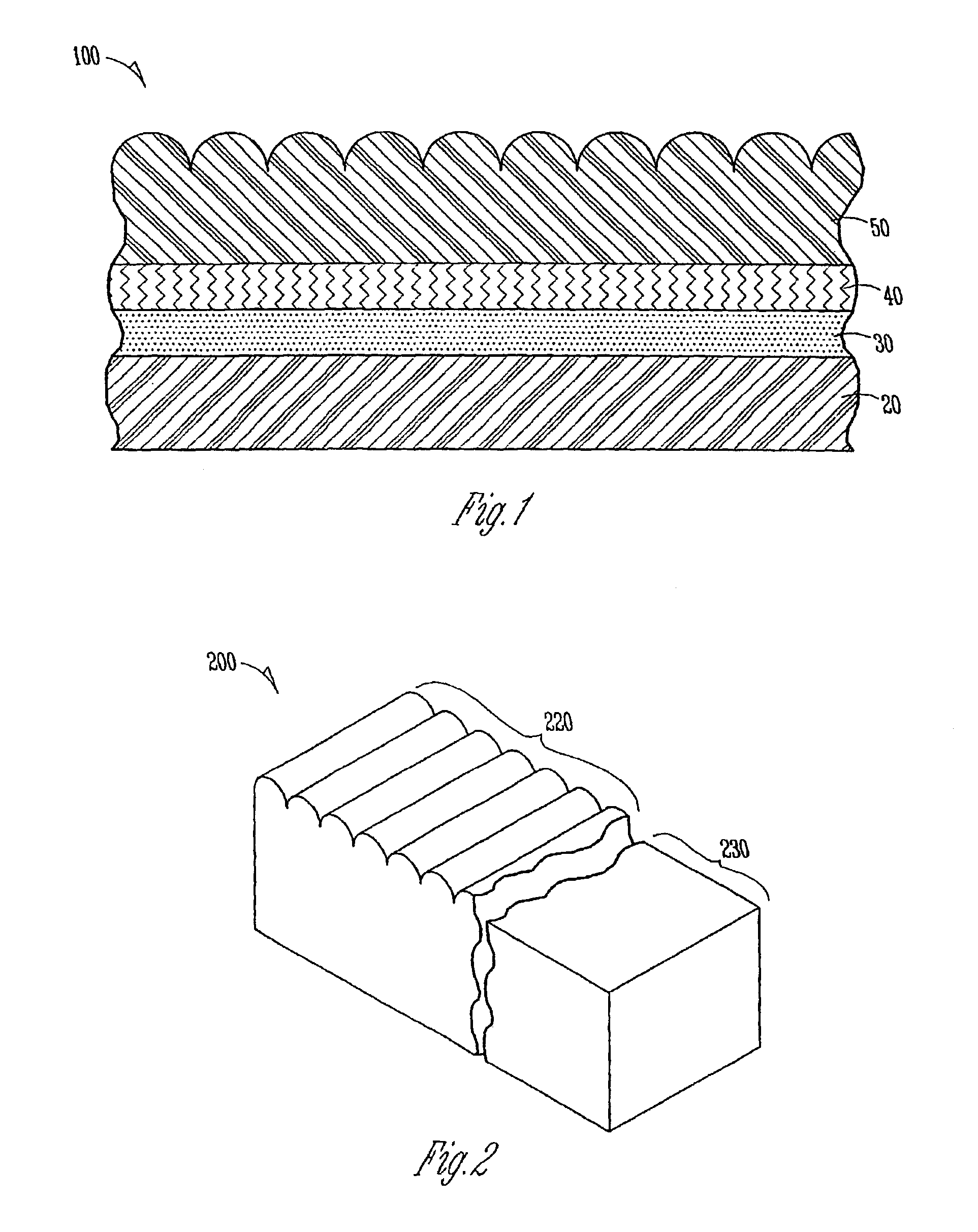

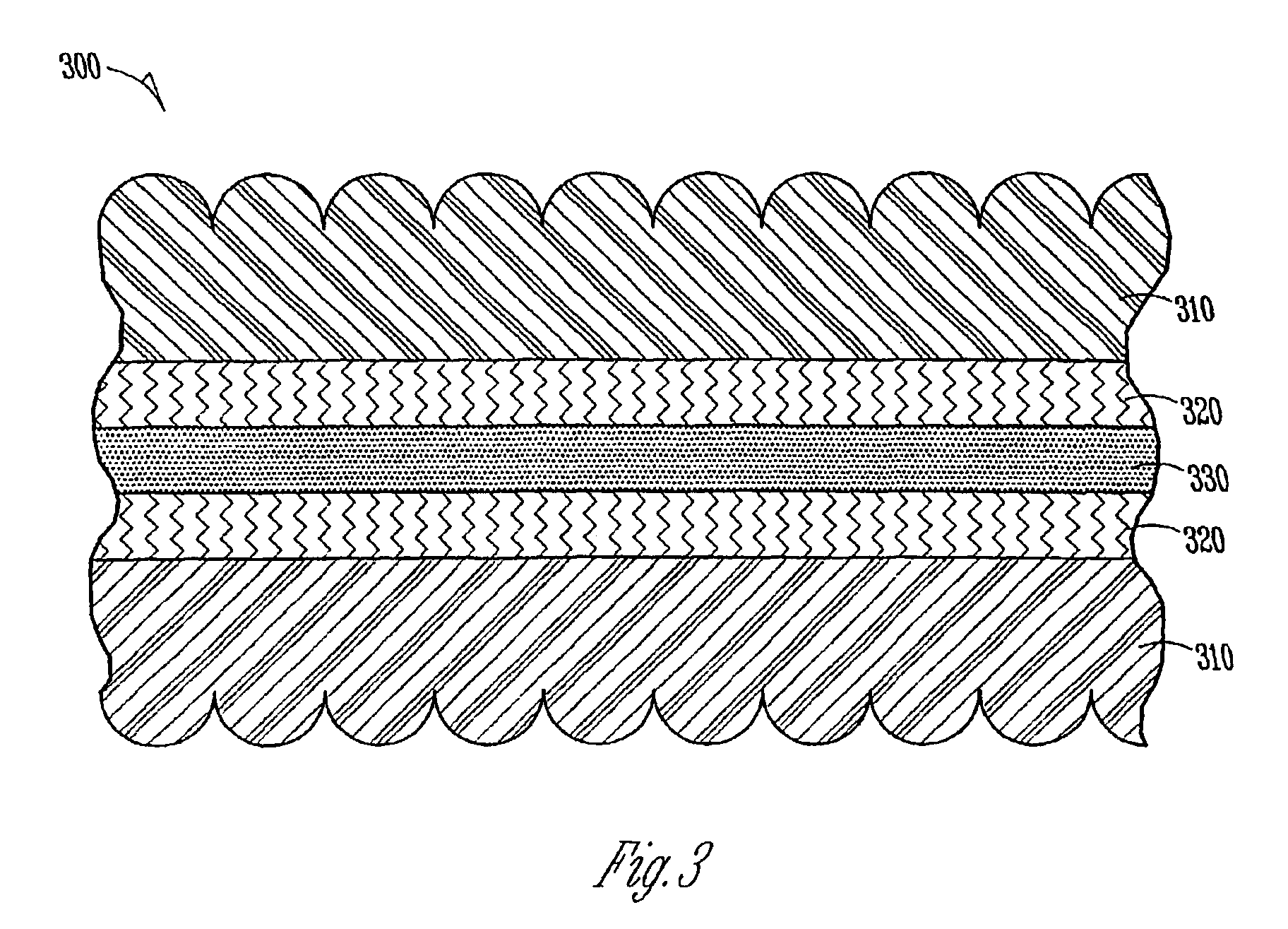

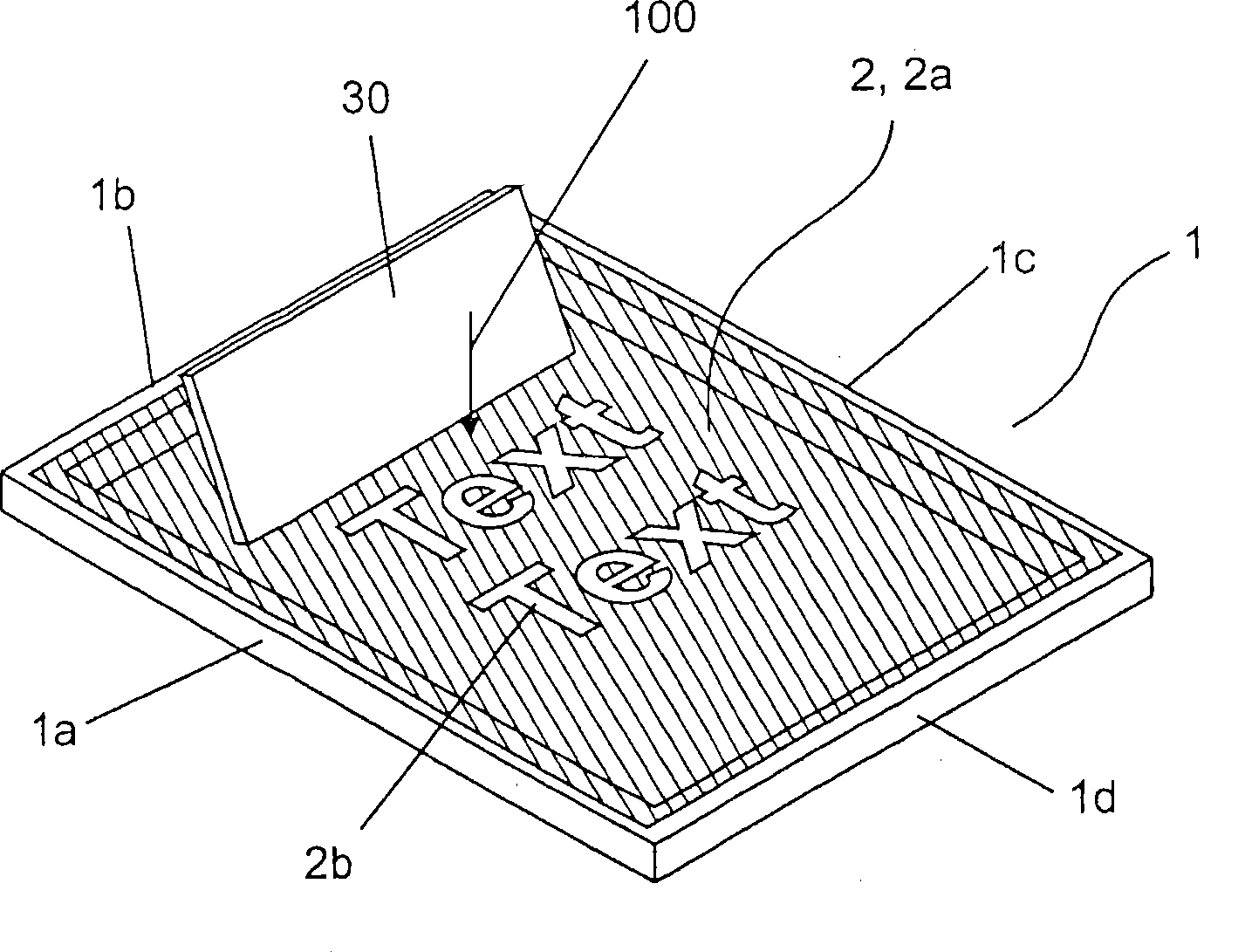

Lenticular card and processes for making

InactiveUS6900944B2Improve propertiesImproved indestructibilityDecorative surface effectsLayered productsAdhesiveEngineering

A process for making a lenticular card including: providing an imaged transparent sheet having a first smooth side and a second side with a lenticulated region, the transparent sheet optionally having at least one printed image area on the first smooth side and a moisture cure adhesive layer over the printed image areas and non-image areas of the first smooth side, and the moisture cure adhesive layer being applied with a screen press through a screen; and combining the imaged transparent sheet on the adhesive layer side of the transparent sheet with a backing sheet by nipping the paired sheets with a nip roller. The invention also provides processes useful for preparing a lenticular card including an optional core sheet, or optional primer layers.

Owner:TRAVEL TAGS

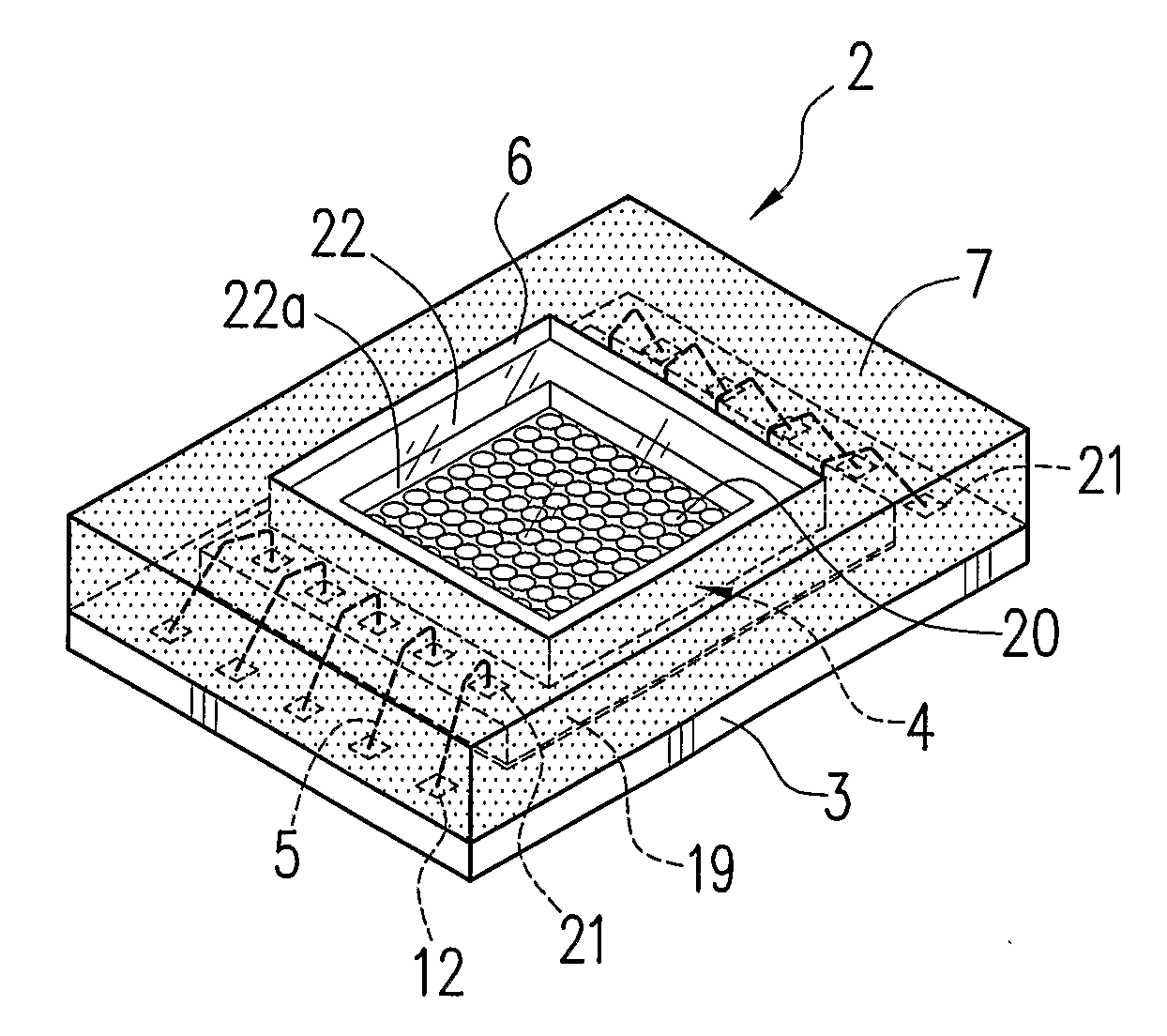

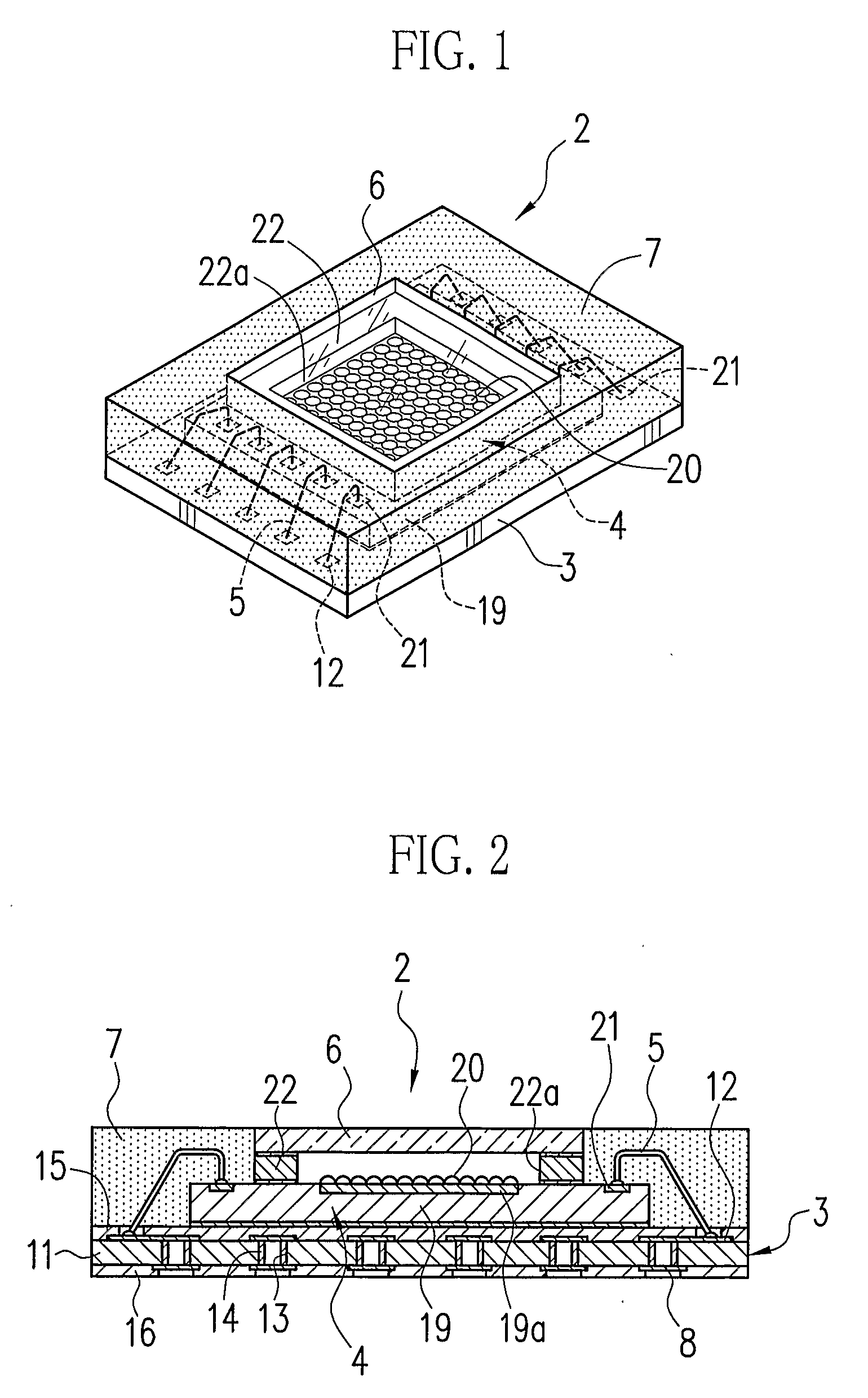

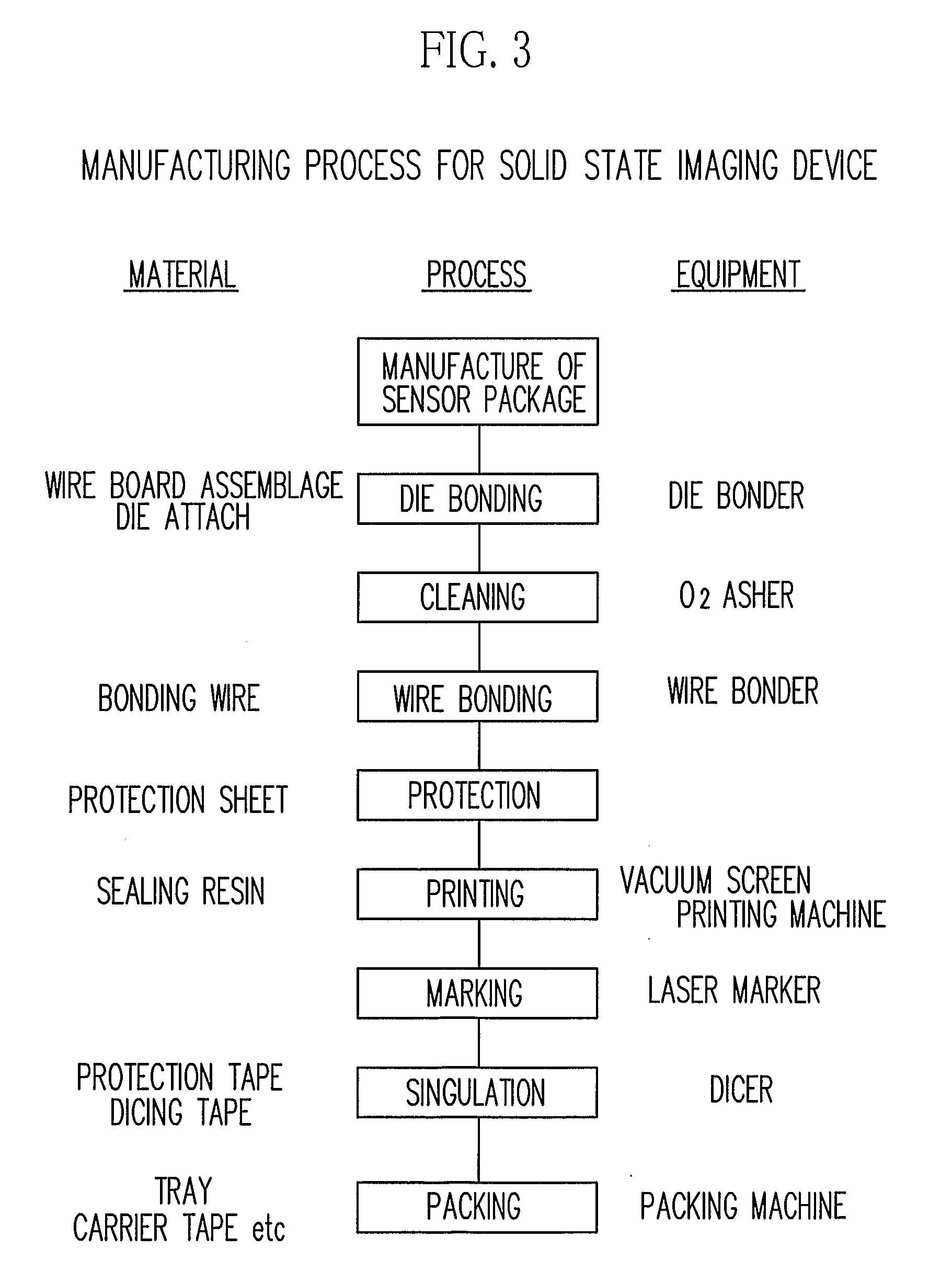

Method of manufacturing solid state imaging device

InactiveUS20090053850A1Avoid corrosionIncrease manufacturing costSolid-state devicesSemiconductor/solid-state device manufacturingCover glassSilk-screen printer

A mask (68) is attached to a circuit assembly board (47) on which a plurality of sensor packages (4) are adhered. An upper face of a cover glass (6) of each sensor package (4) is protected by a mask section (68b) of the mask (68). The circuit assembly board (47) is set in a vacuum screen printing machine and paste of sealing resin (7) is supplied to it. The circuit assembly board (47) is moved in a horizontal direction on a stage with a squeegee (65) pressed onto an upper face of the mask (68). The squeegee (65) presses to fill the sealing resin (7) around each of the sensor packages (4).

Owner:FUJIFILM CORP

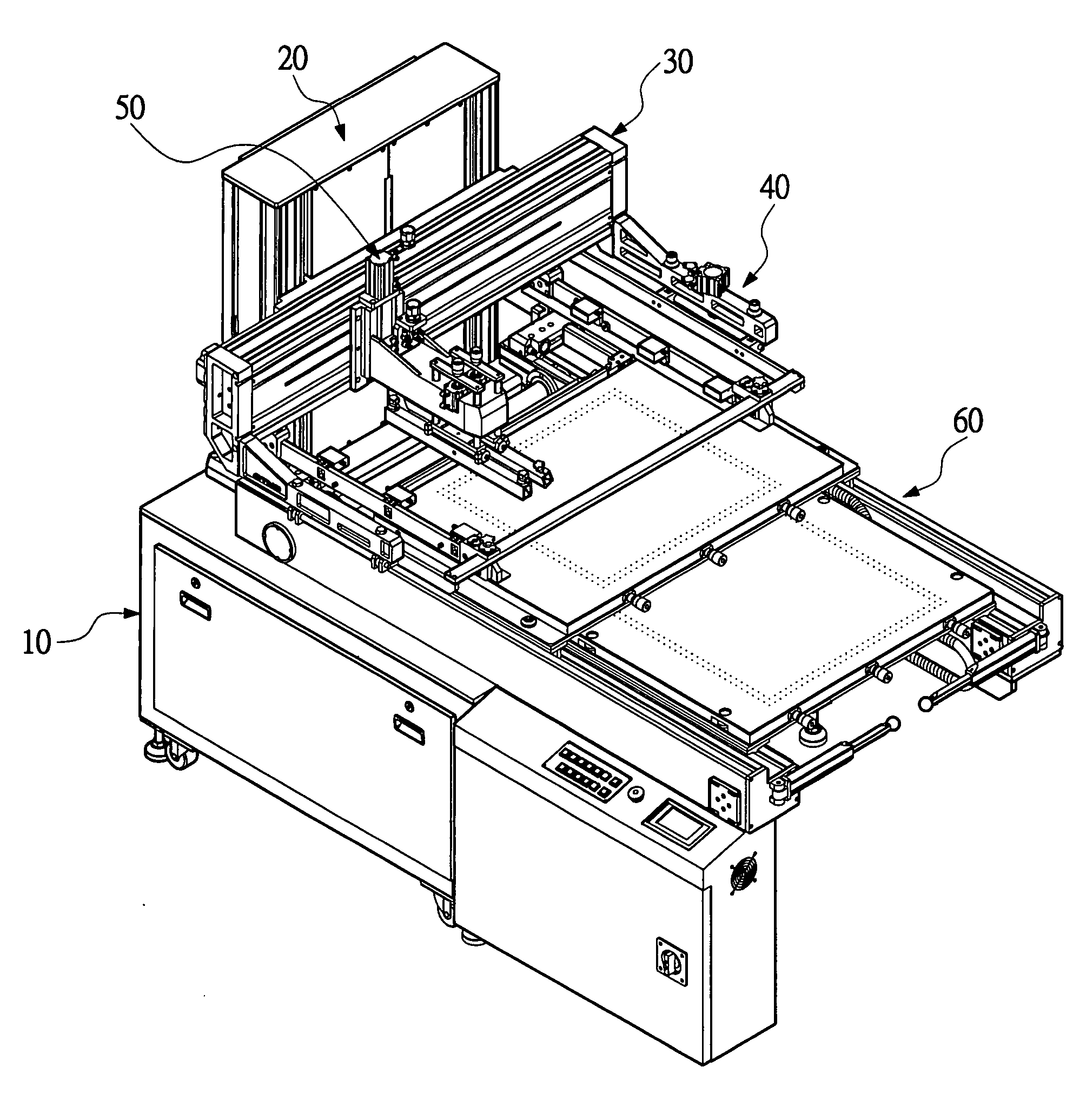

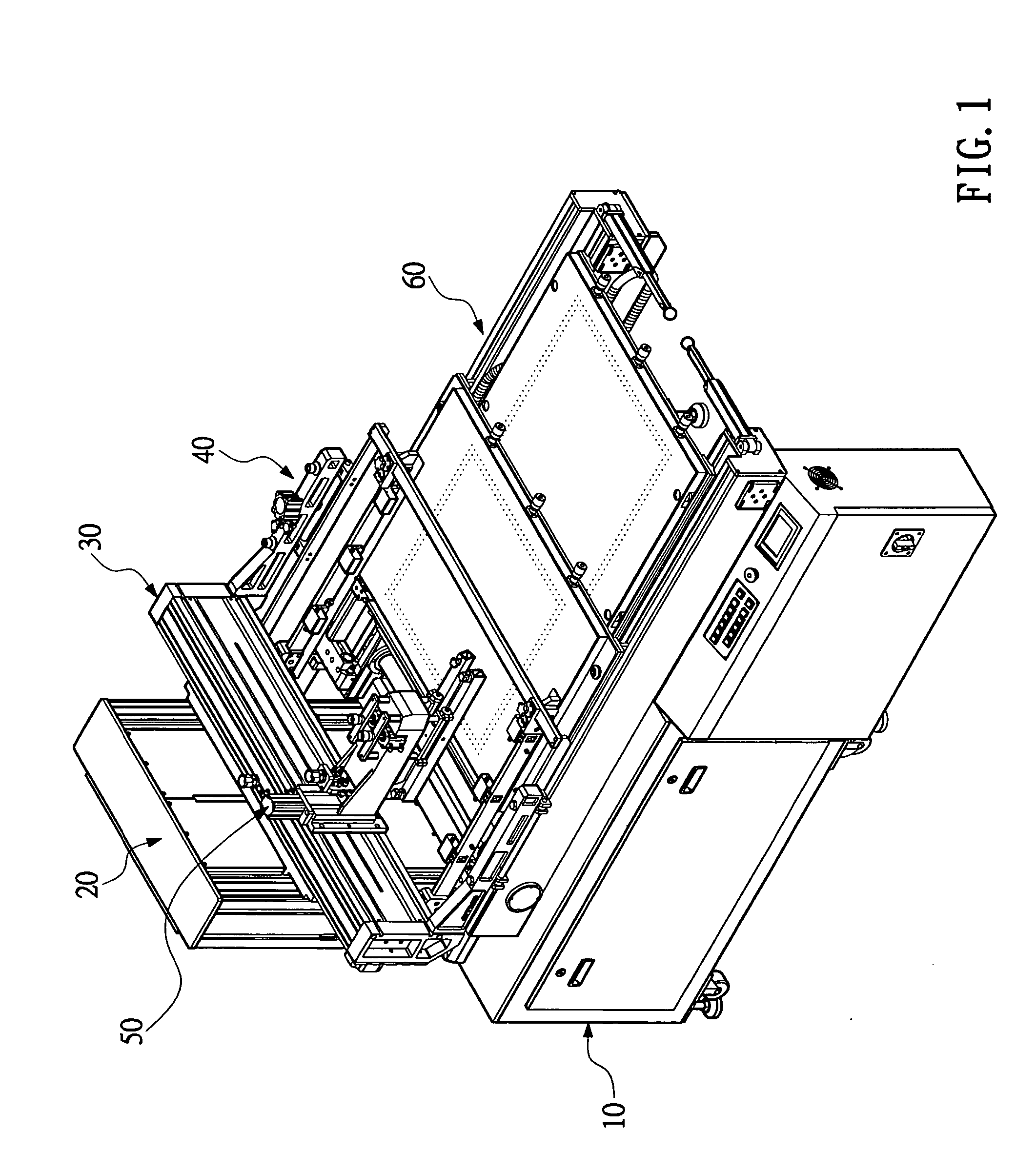

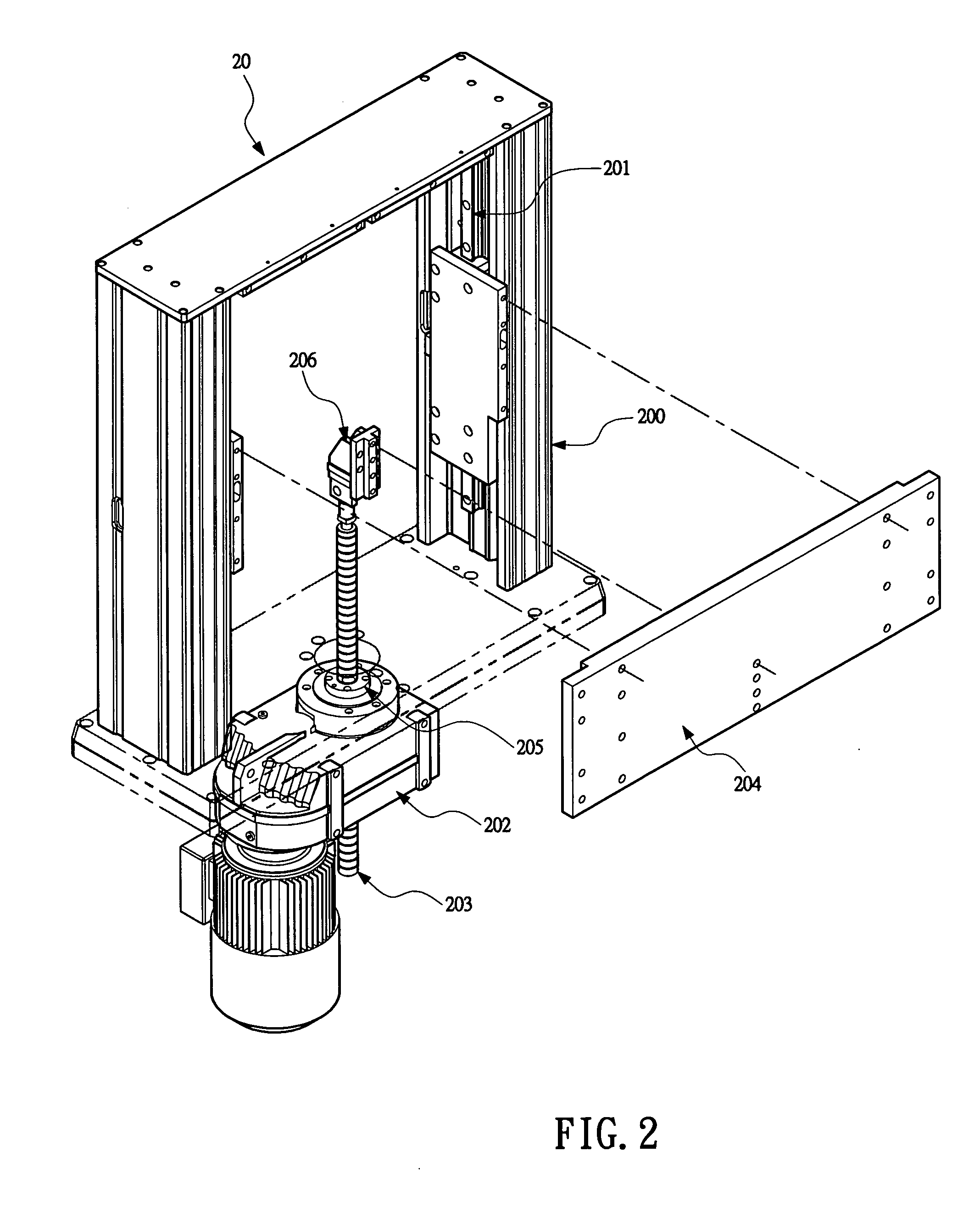

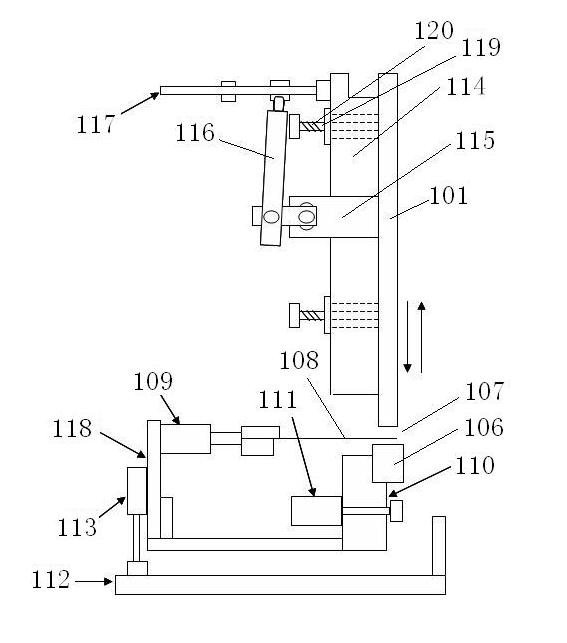

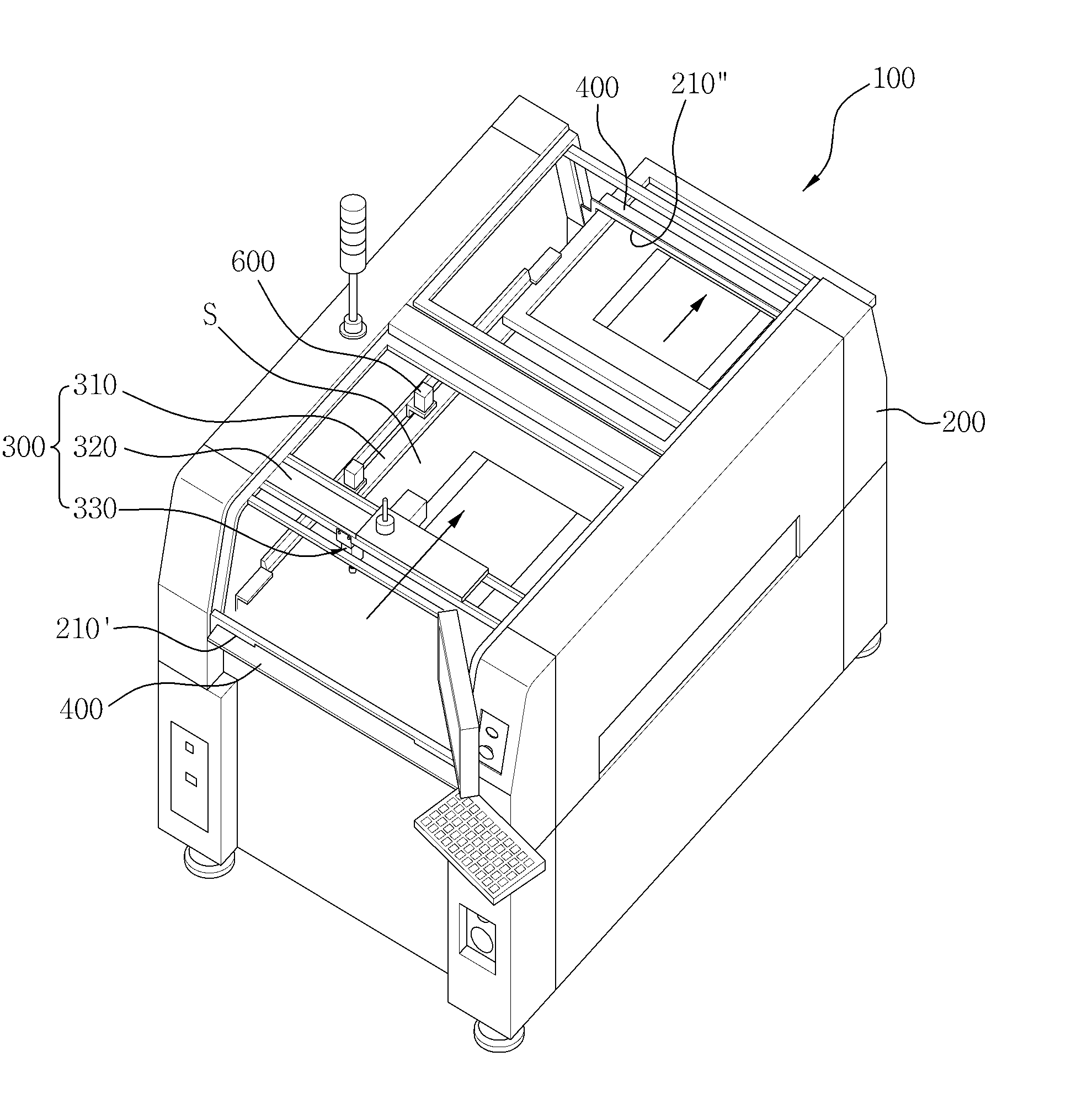

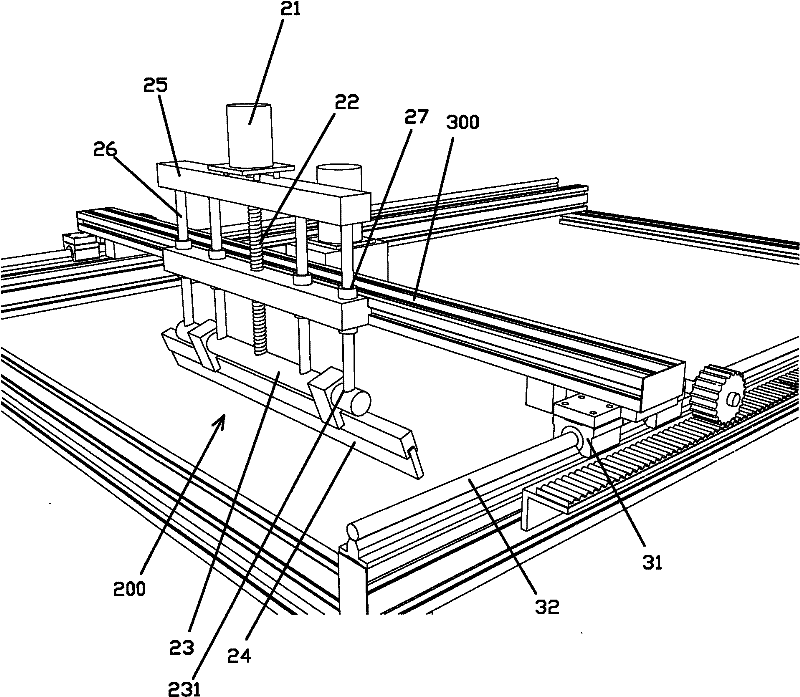

Cantilever type screen-printing machine with double platform

InactiveUS20050263017A1Prevent movementPrecise positioningLiquid surface applicatorsScreen printersGear wheelReducer

The present invention discloses a cantilever type screen-printing machine with double platforms that possess a gear reducer motor with a hollow shaft to rotate a screw of a threaded screw unit and further drive a threaded rod to move upward and downward without rotation inside the hollow shaft thus make a transverse sliding assembly move vertically and synchronously with the threaded rod. Moreover, by a rectangular frame and two sets of horizontal micro adjustable chase clamping mechanism transversely fixed on the rectangular frame, the relative position between the chase and the print materials is adjusted directly. The upper and the lower platforms are driven and powered by two gear reducer motors and a homocentric coaxial-type driving mechanism respectively. By the simplified driving mechanism, the printing efficiency and productivity are enhanced.

Owner:ATMA CHAMP ENTERPRISE

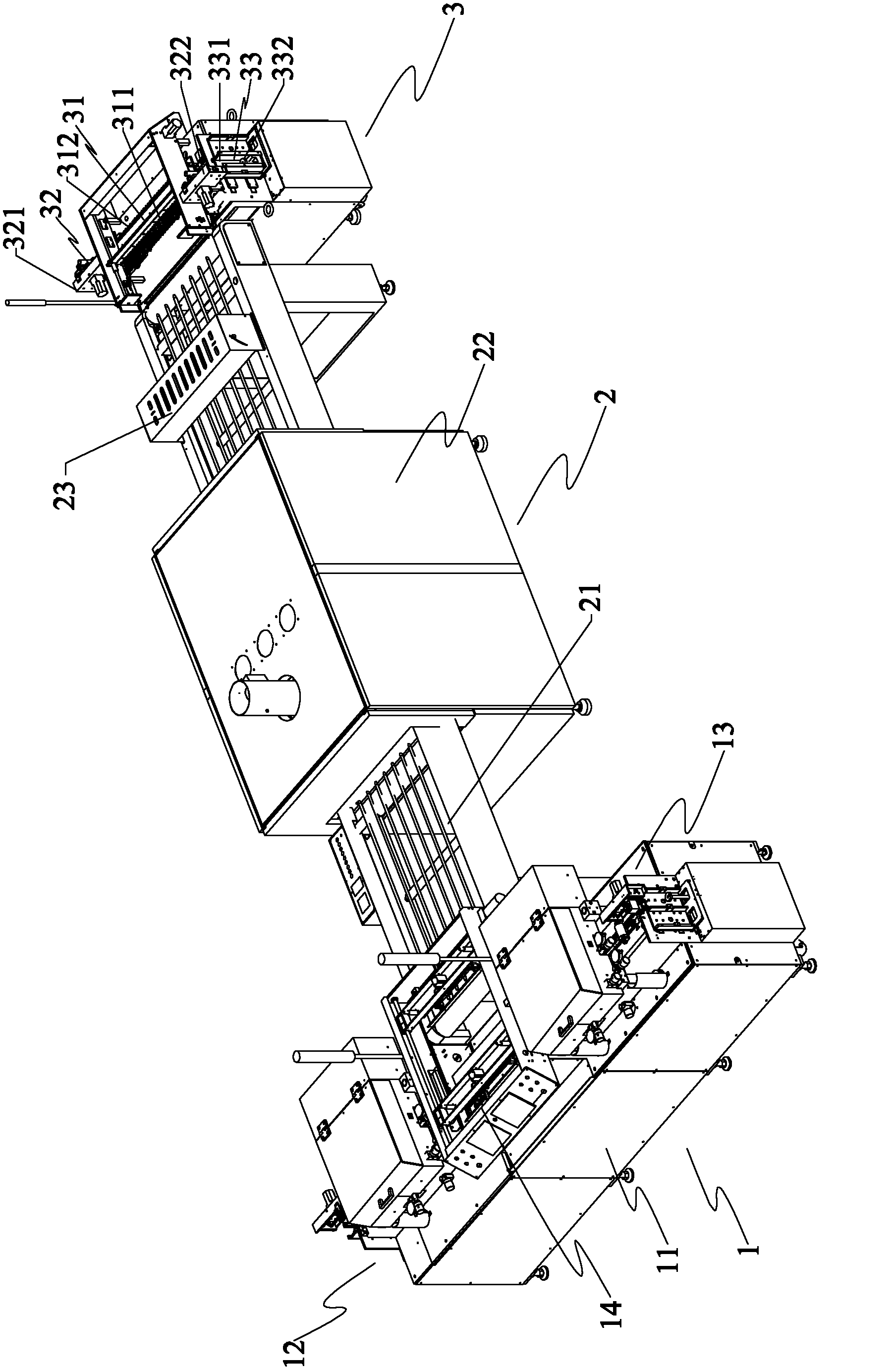

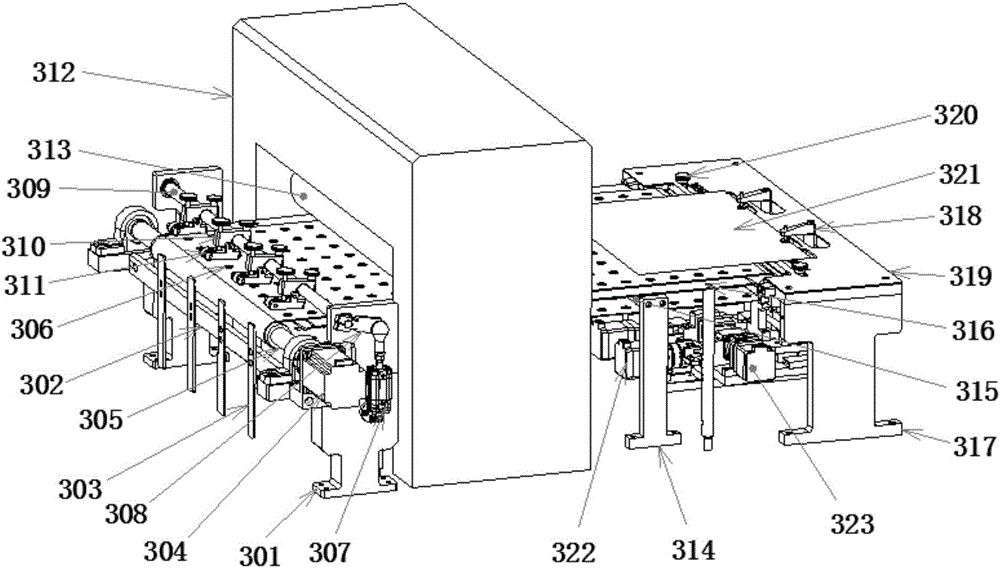

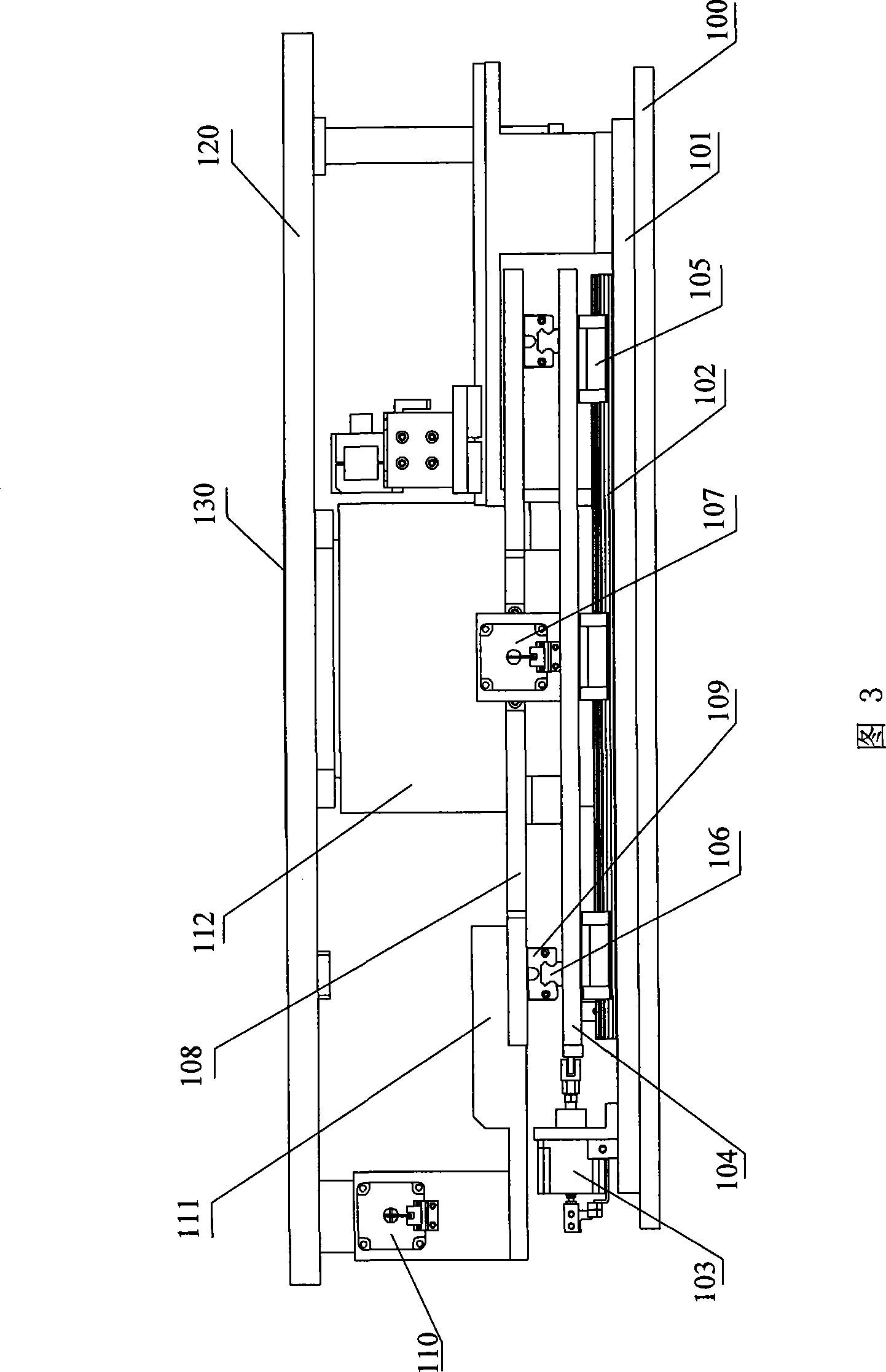

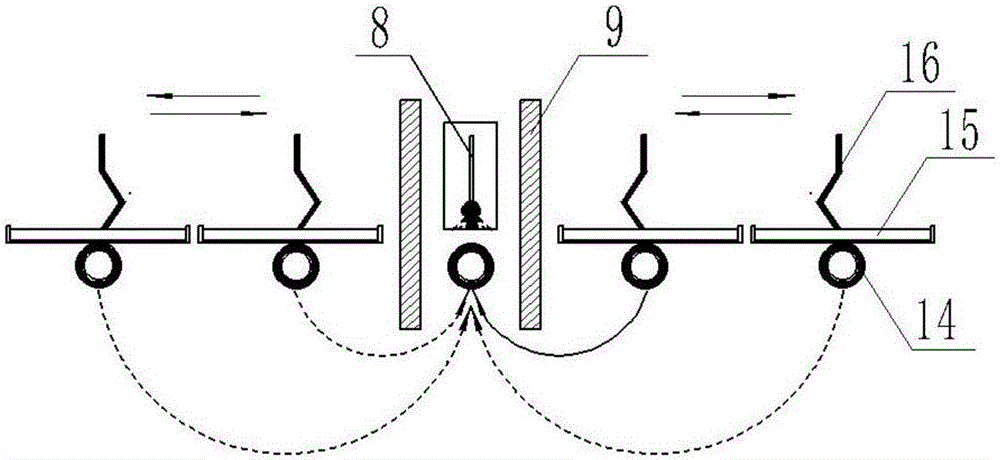

Full-automatic double-work-station screen printing machine

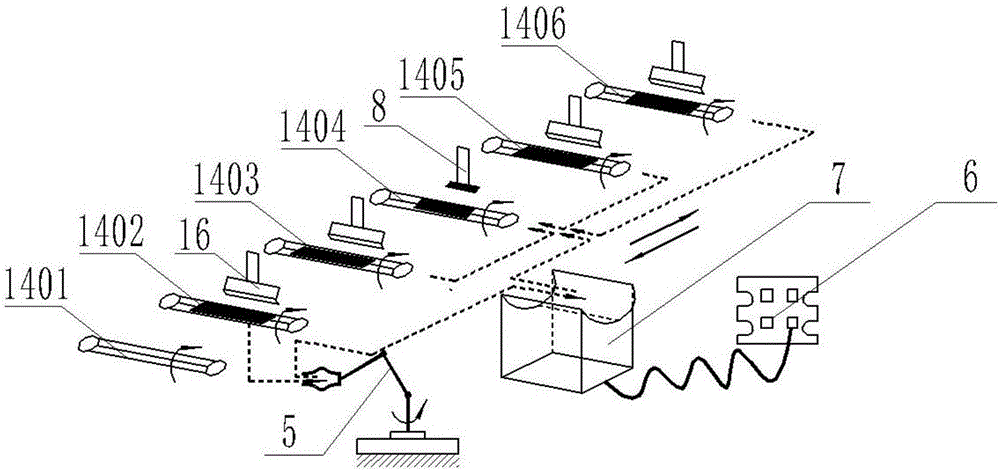

The invention discloses a full-automatic double-work-station screen printing machine, which comprises a printing system, a drying system and an electronic control system, wherein the printing system comprises a base, a left work station printing device, a right work station printing device and a leveling device, wherein the left work station printing device and the right work station printing device are mutually independent and mounted above the base; the leveling device is arranged between the left work station printing device and the right work station printing device; each work station printing device comprises a material loading mechanism, a substrate transmitting and positioning mechanism and a screen printing mechanism which move in a matched manner. Compared with the prior art, the full-automatic double-work-station screen printing machine has the beneficial effects that the full-automatic double-work-station screen printing machine is provided with the left and the right double-work-station printing systems, each work station printing system can independently complete the printing operation, the whole process of material feeding, transmitting, positioning, printing, leveling, drying and collection is automatically controlled at the same time, the efficiency is high, the cost is low, the maintenance is convenient, and the requirements of batch production and the production requirements of high-end products can be effectively met.

Owner:GUANGDONG FENGHUA ADVANCED TECH HLDG

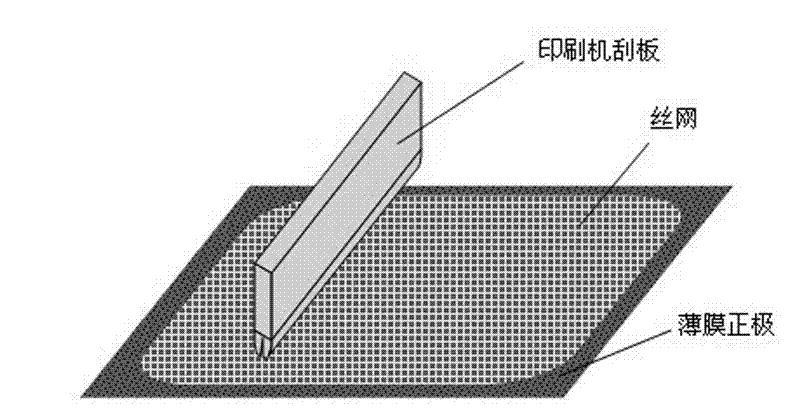

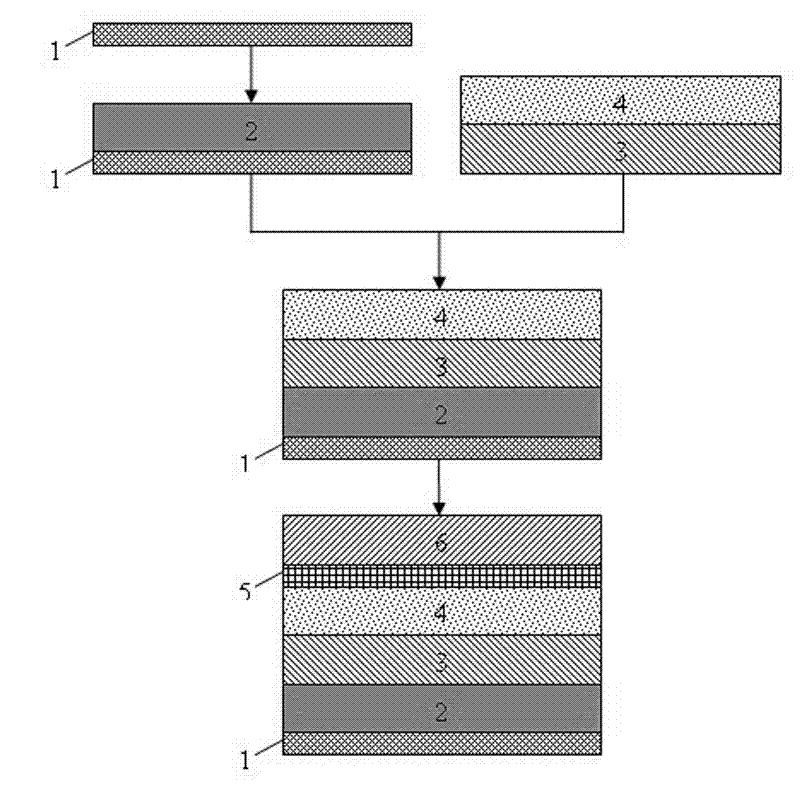

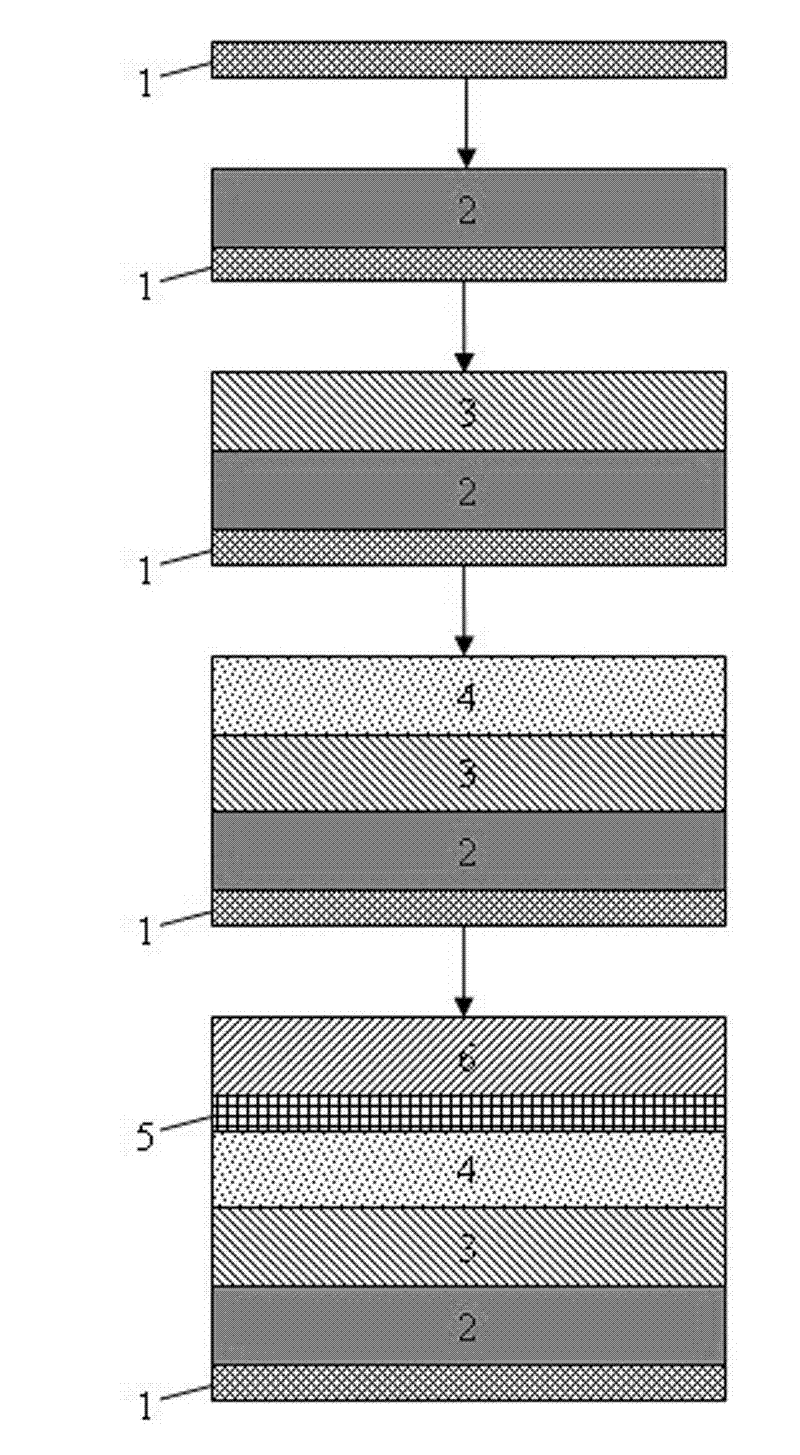

Method for preparing thin-film positive electrode for thermal batteries

InactiveCN102339979AImprove stabilityImprove its discharge performancePrimary cell electrodesElectrical batteryCarbon nanotube

The invention discloses a method for preparing a thin-film positive electrode for thermal batteries and belongs to the technical field of thin-film electrodes for thermal batteries. The method comprises the following steps: uniformly mixing active substances for positive electrodes, an electrolyte and carbon nano tubes in a certain mass ratio; then, adding a certain amount of distilled water, and adjusting the viscosity of the obtained mixture, so that the mixture becomes a pasty mixture and has certain viscosity; and enabling the pasty mixture to be uniformly adsorbed to the surface of a substrate by using a screen process press, and putting the substrate coated with the active substances into a vacuum drying oven to carry out vacuum drying, then obtaining the thin-film positive electrode for the thermal batteries. The thin-film positive electrode disclosed by the invention has the advantages of overcoming multiple defects caused by the existing powder compressing preparation process for the thermal battery electrodes, easily realizing the preparation of large-area or irregularly-shaped electrode plates, simplifying the electrode preparation process, improving the productivity, reducing the cost, and improving the stability and discharge performance of the batteries, therefore, the thin-film positive electrode has greater military and industrial application values.

Owner:SHENYANG LIGONG UNIV

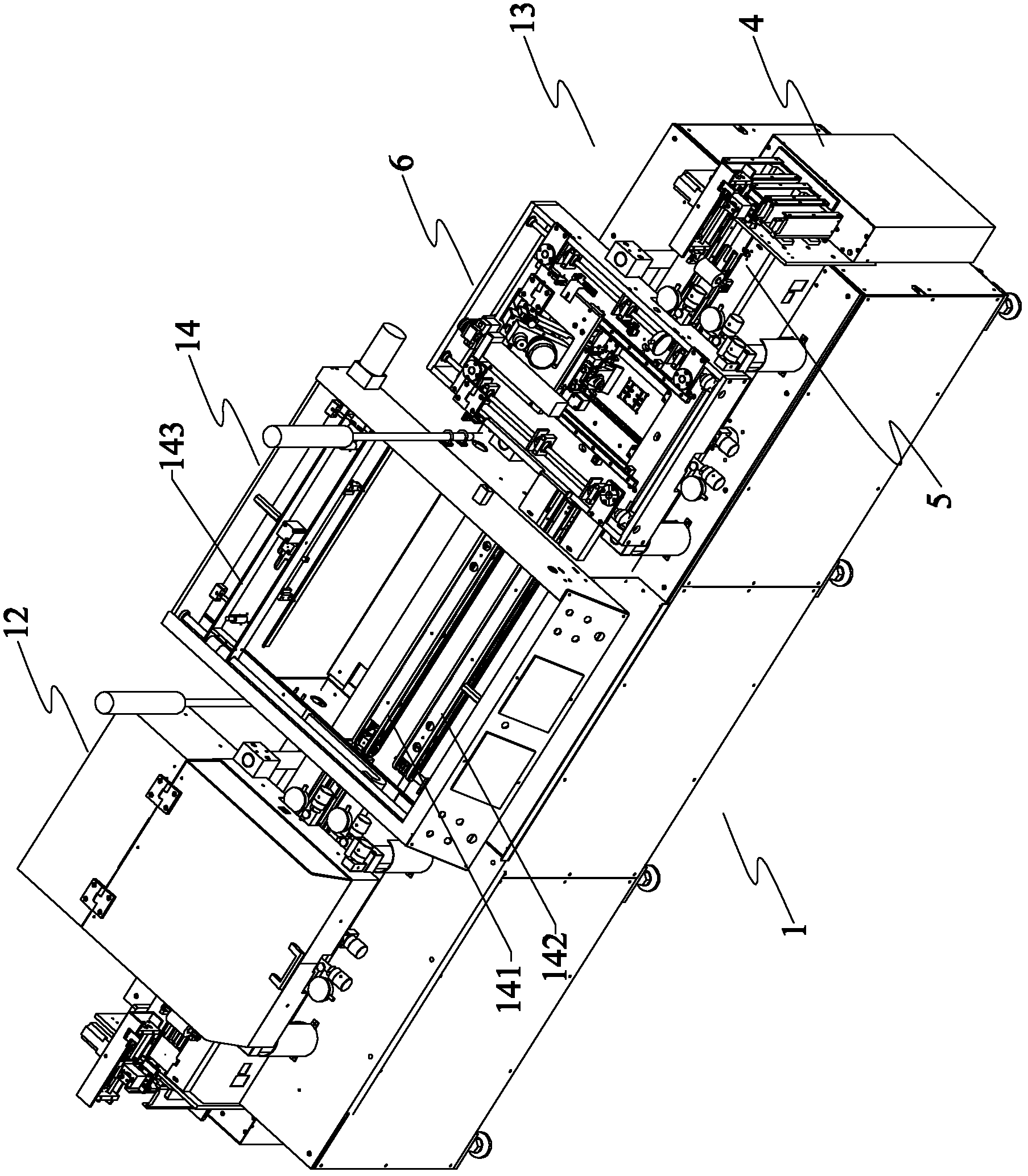

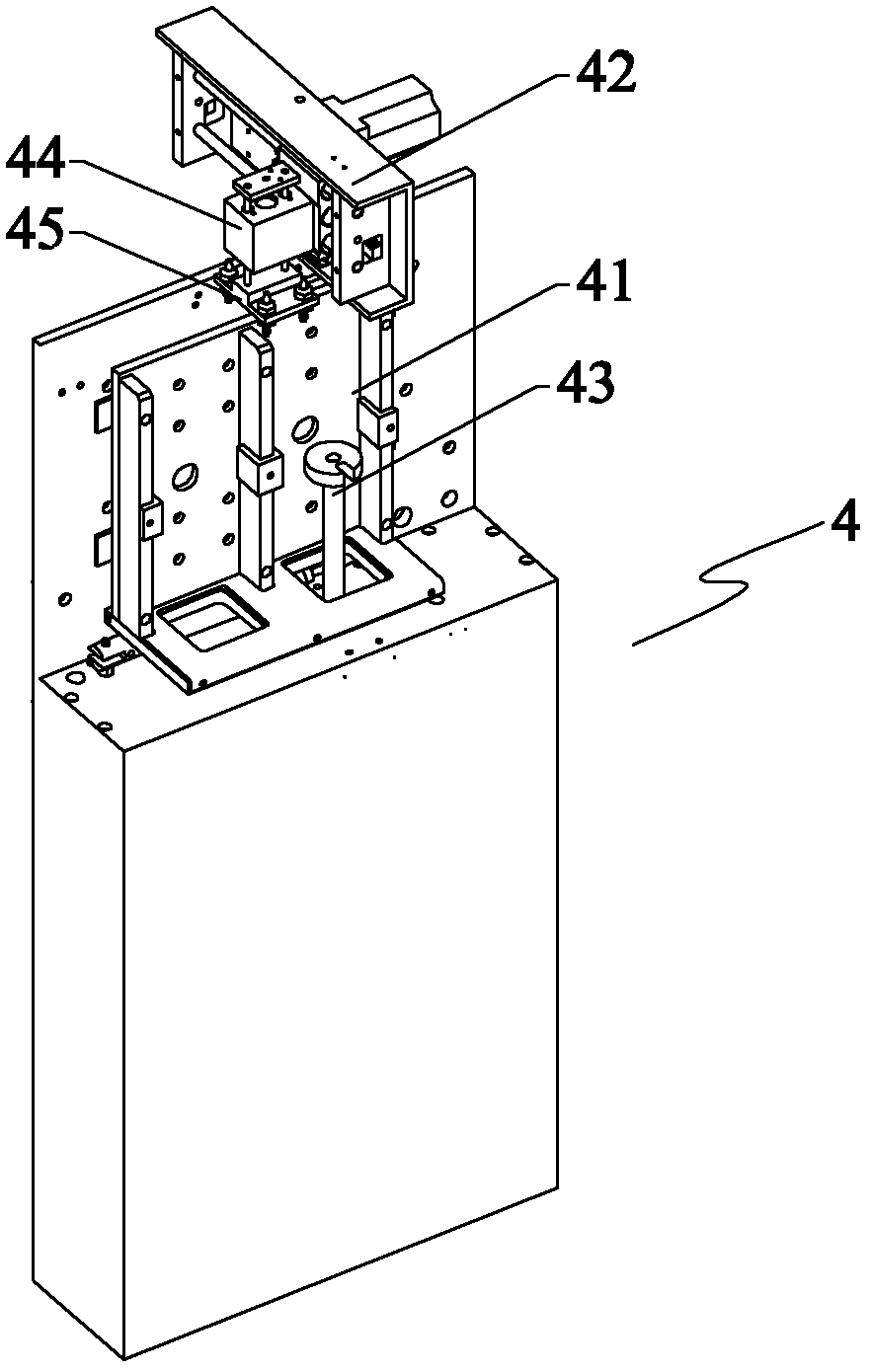

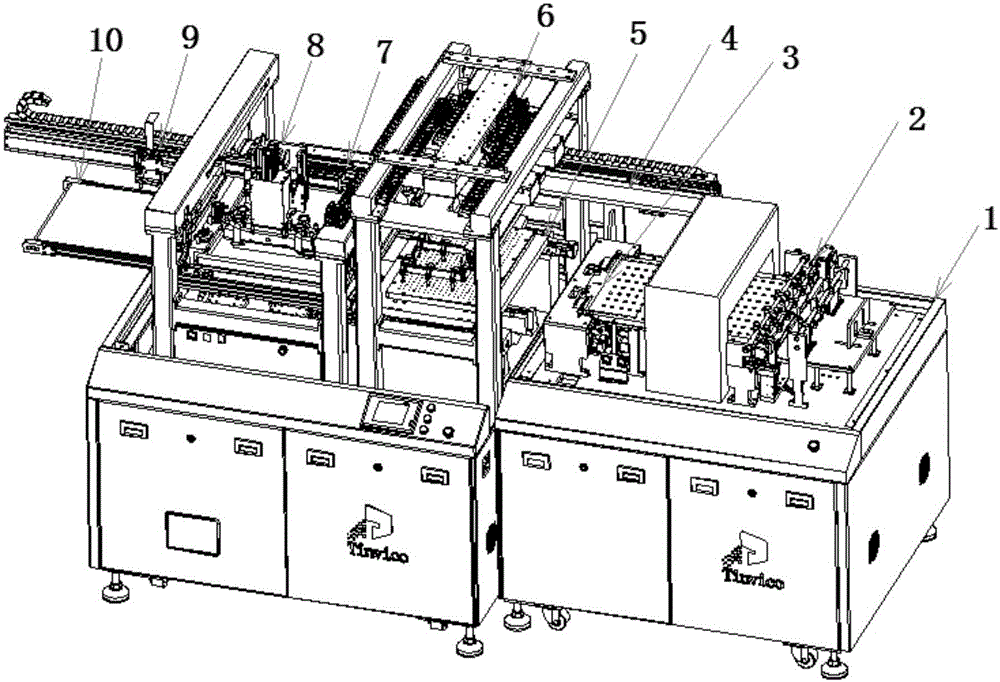

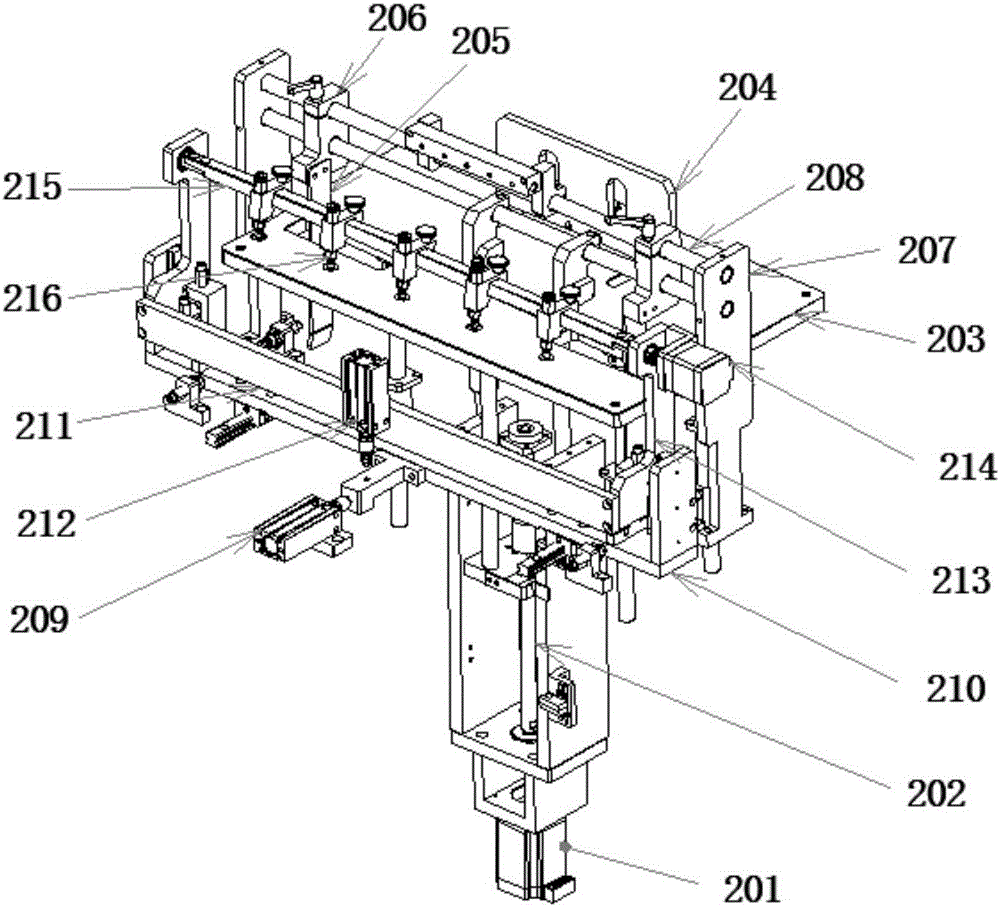

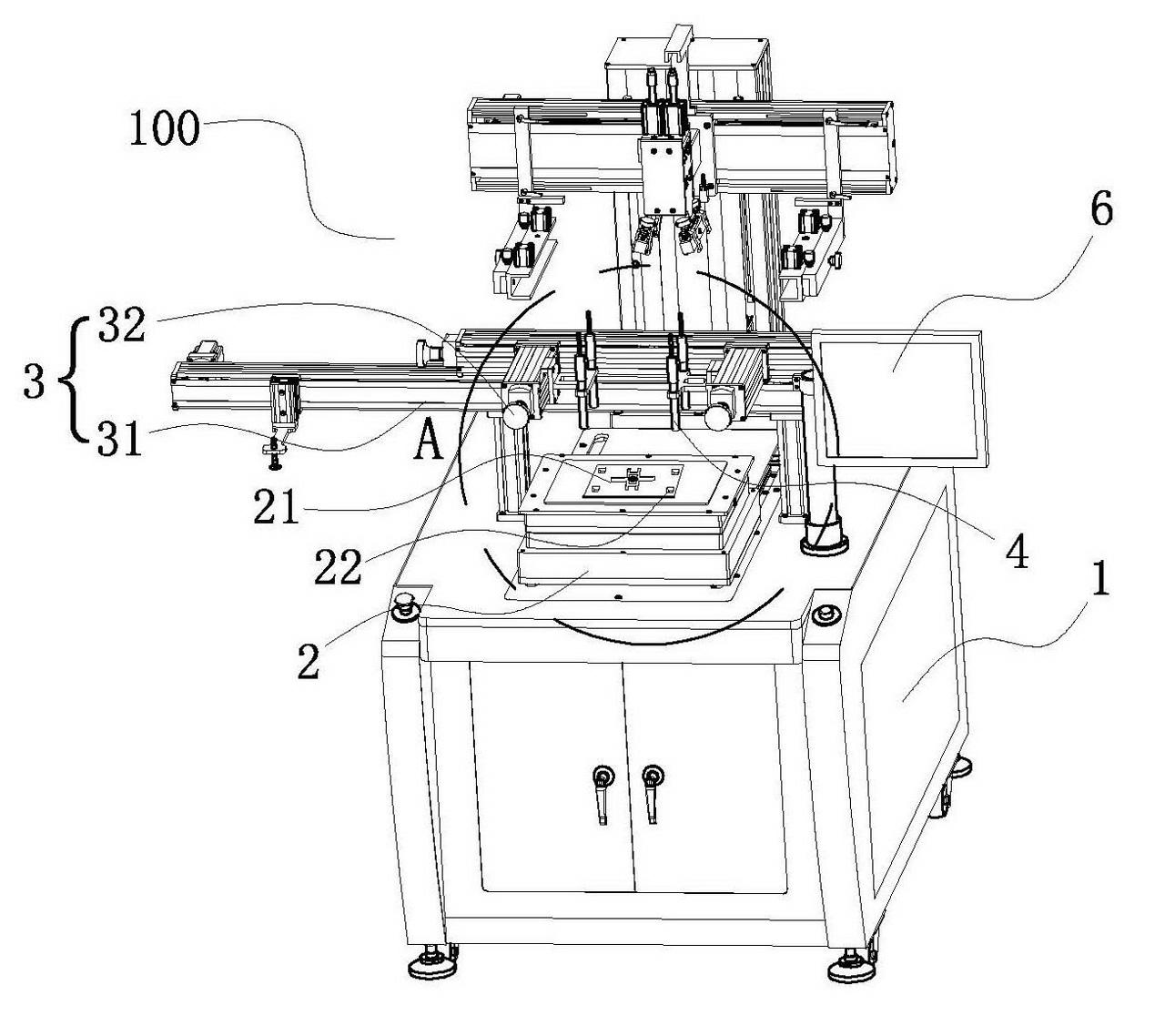

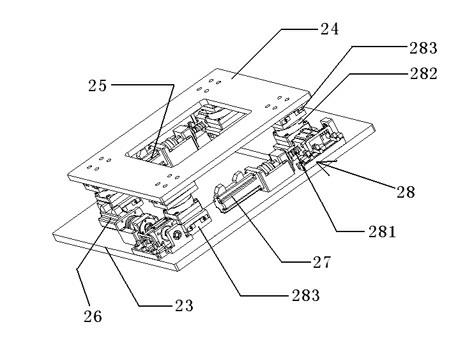

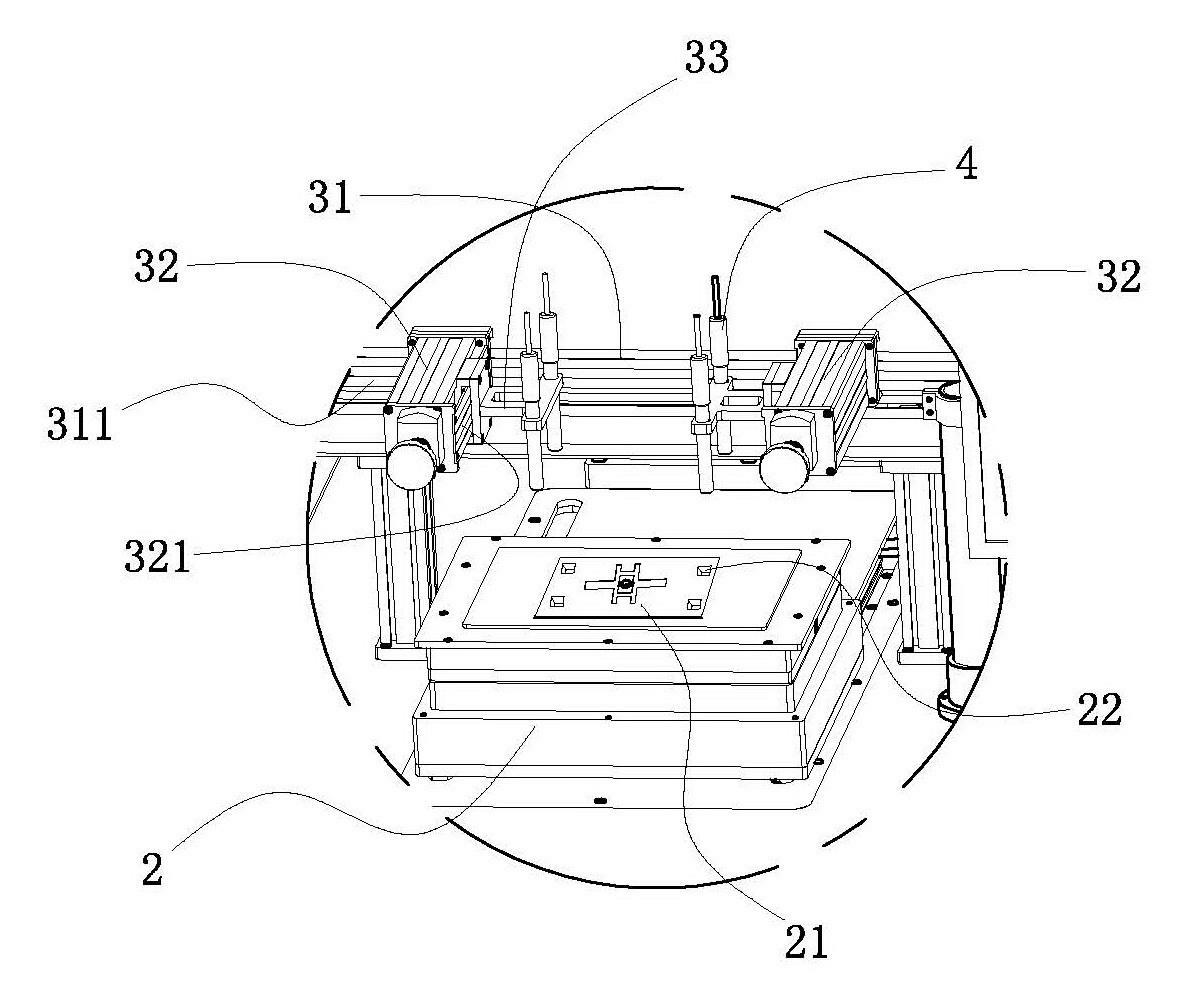

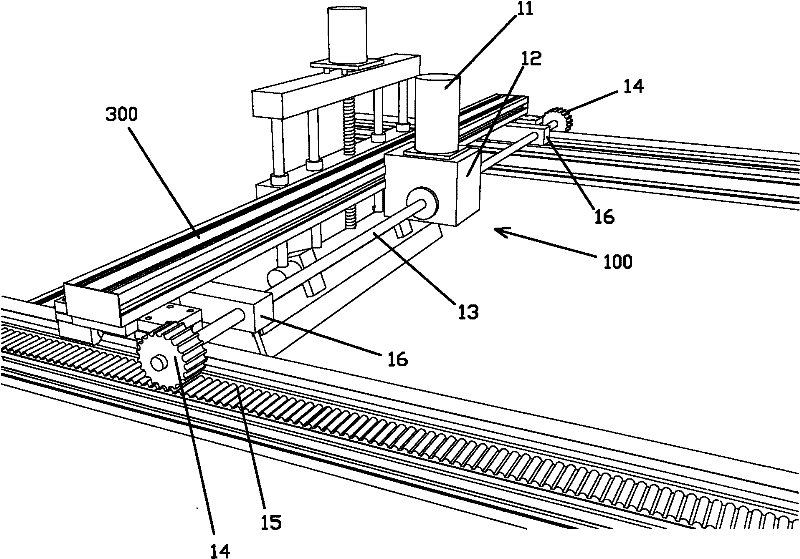

Full-automatic high-precision double-printing-platform screen printing machine

InactiveCN106671579ASolve the problem of manual loading and unloadingReasonable layoutScreen printersConveyor partsEngineeringPrinting press

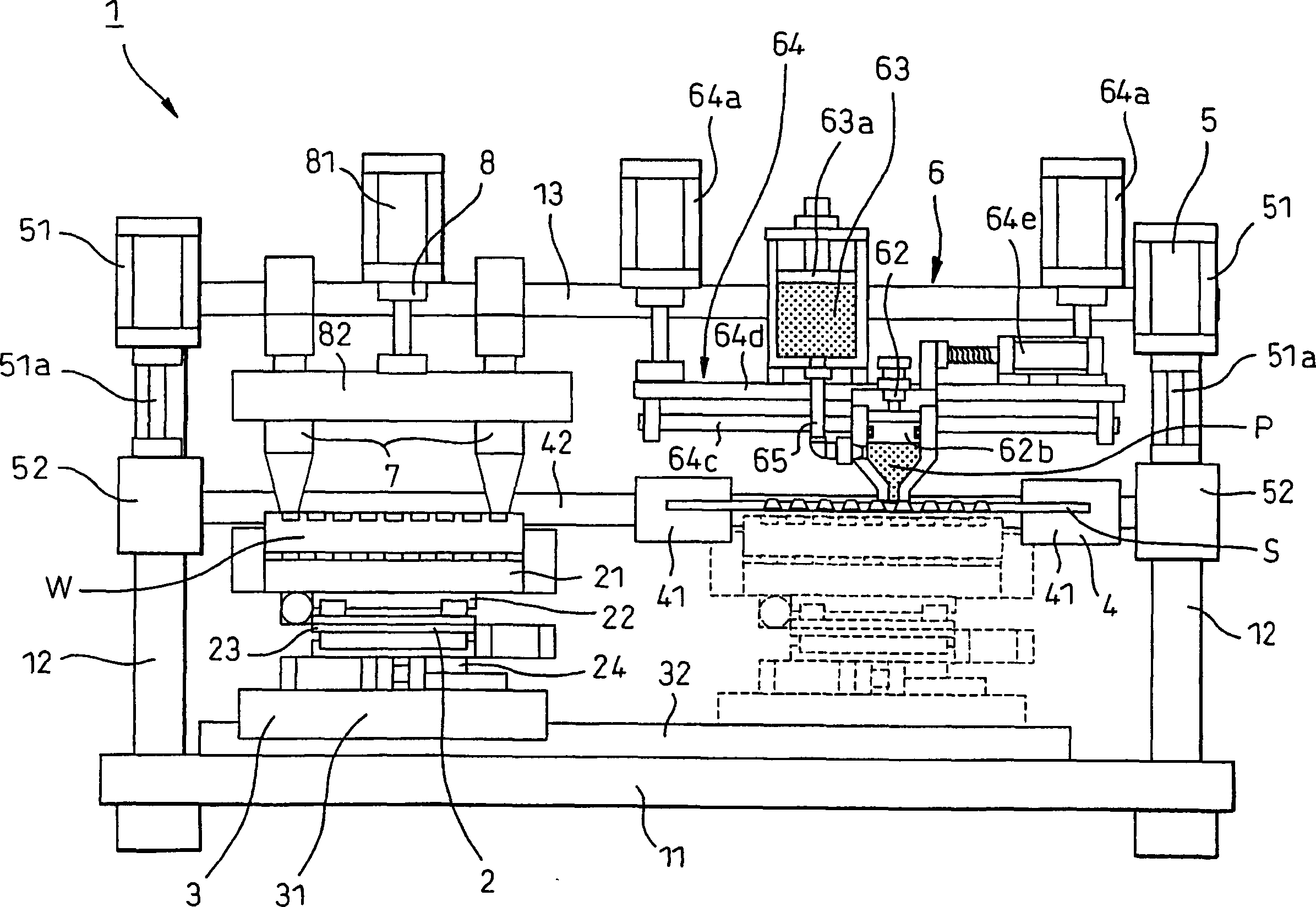

The invention discloses a full-automatic high-precision double-printing-platform screen printing machine. The full-automatic high-precision double-printing-platform screen printing machine comprises a machine frame, material conveying mechanism, a screen printing plate mounting and alignment mechanism and a screen printing mechanism and further comprises a double-printing-platform transfer assembly located on the machine frame, wherein the material conveying mechanism is located on the machine frame; the double-printing-platform transfer assembly comprises a positioning position, a printing position, a lifting printing platform and a printing platform, the lifting printing platform and the printing platform are located in the positioning position or the printing position alternately and switched between the positioning position or the printing position; the material conveying mechanism is used for conveying to-be-printed materials to the positioning position; and the screen printing plate mounting and alignment mechanism and the screen printing mechanism are arranged above the printing position for printing the to-be-printed materials located in the printing position. By means of the full-automatic high-precision double-printing-platform screen printing machine, while one to-be-printed material is printed, another to-be-printed material is automatically fed onto the printing platform and photographed and positioned, and the technical problems that most of existing full-automatic flexible-plate screen printing machine adopts single-platform linear material conveying, and consequently the system efficiency is low are solved.

Owner:SHENZHEN TINVICO TECH CO LTD

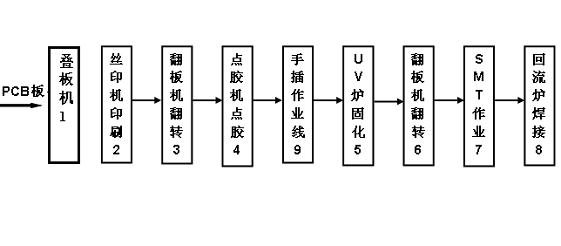

PCB (Printed Circuit Board) production line combining manual in process processing and paster processing

ActiveCN101977484AShorten production timeReduce turnoverPrinted circuit assemblingElectrical componentsProduction lineUV curing

The invention discloses a PCB (Printed Circuit Board) production line combining a manual in process processing and paster processing, which is characterized by comprising a board feeding machine (1), a screen printing machine (2), as well as a first board overturning machine (3), an adhesive dispenser (4), a UV curing oven (5), a second board overturning machine (6), SMT (Surface Mounting Technology) equipment (7) and a reflow soldering heating curing oven (8). The first board overturning machine (3) is responsible for overturning a PCB subjected to low-temperature solder past printing of the screen printing machine (2) and then dispensing an adhesive, and after adhesive dispensing, a UV adhesive with a large long-pin device is cured under UV irradiation; after the PCB is overturned by the second board overturning machine, the step of paster production begins; and finally, PCB heating curing is finished in the reflow soldering heating curing oven (8). The invention combines SMT operation and manual in process operation together to realize a double-faced reflow soldering technology, solves the defects of traditional wave-soldering technology, and saves energy since reflow soldering is performed only twice and elements are heated twice.

Owner:NANJING PANDA ELECTRONICS MFG

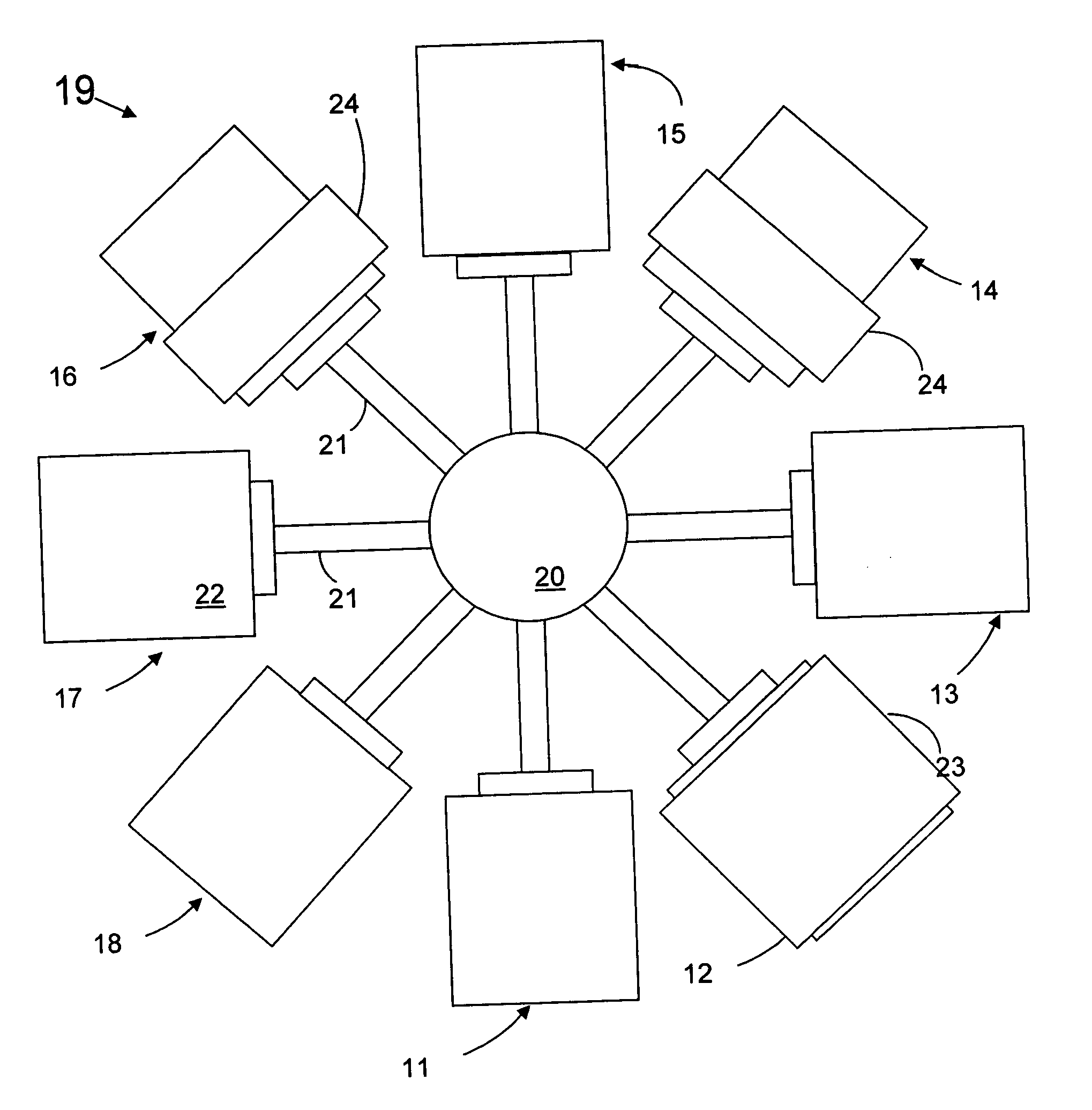

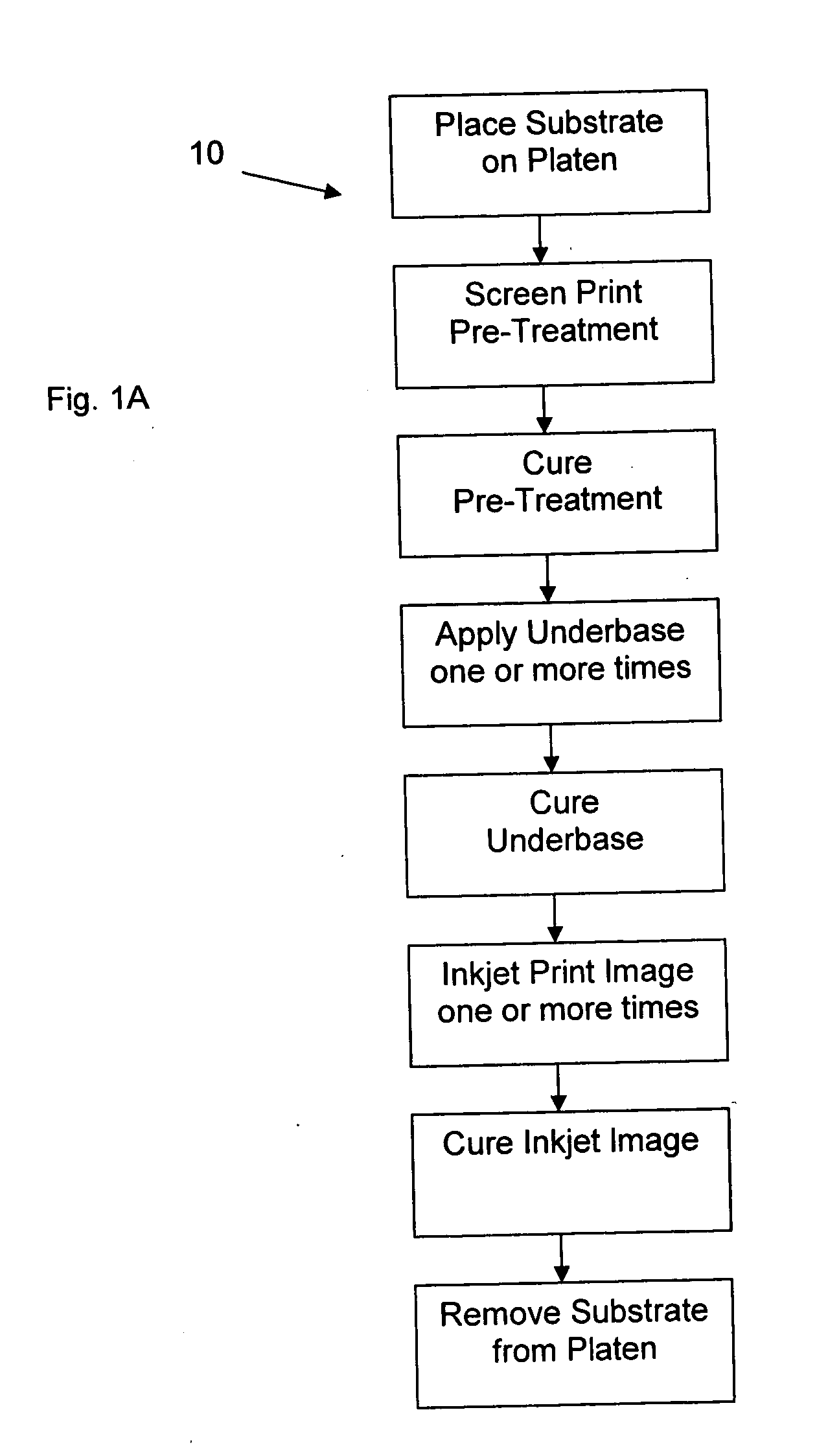

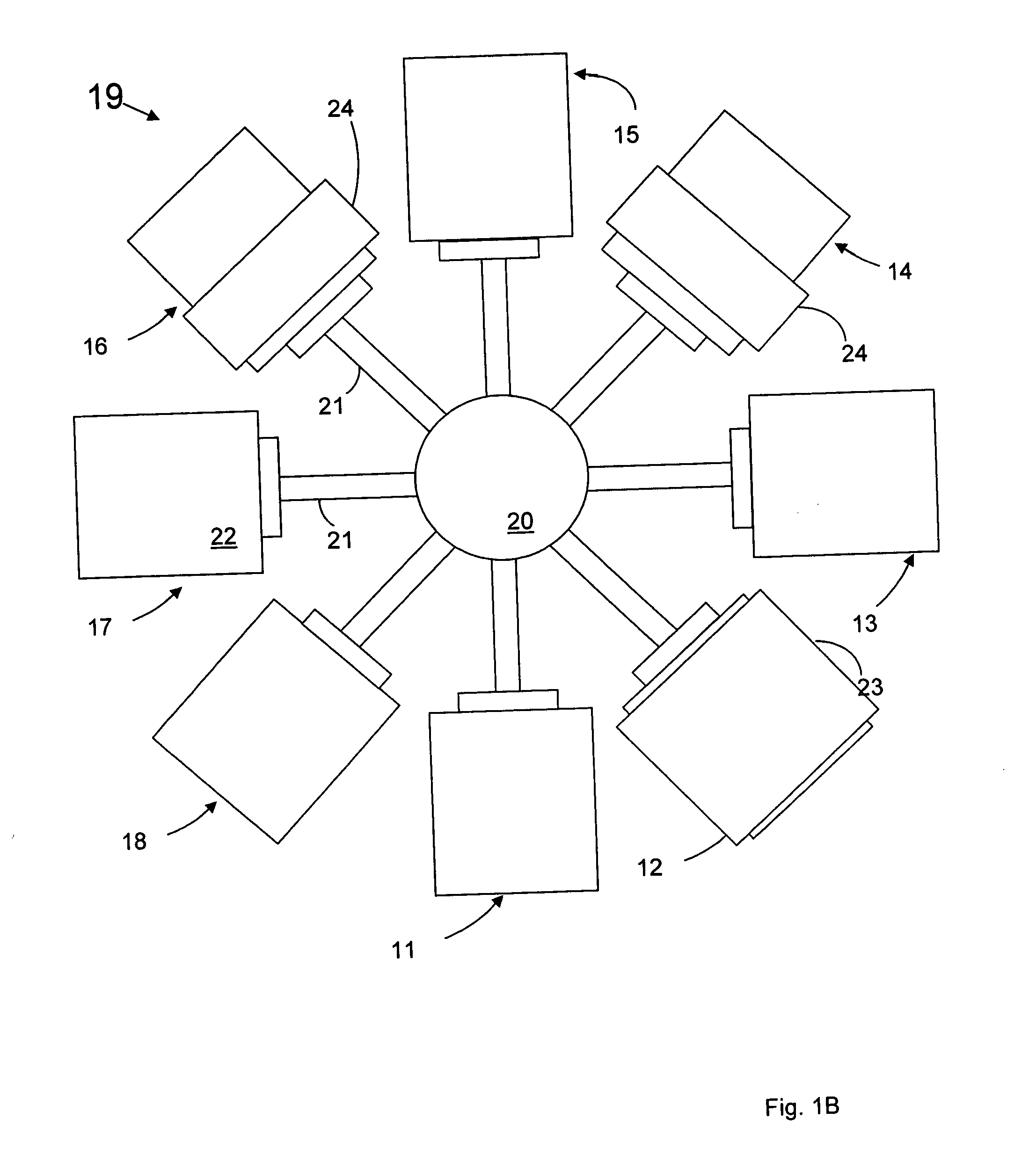

Method for printing white on dark textiles using screen-printers and inkjet printers

A method for printing light colors on dark substrates such as black textiles is disclosed. The method includes screen printing a pre-treatment onto a textile, inkjet printing an underbase on the textile, inkjet printing an image over the underbase, and counting and displaying the number of printings of the underbase and image. In the preferred embodiment, a pre-treatment is screen printed onto a black t-shirt, then a white, opaque underbase is inkjet printed onto the black t-shirt, and finally a white image is inkjet printed over the white underbase. In alternative embodiments, a white image is inkjet printed directly on the black t-shirt without any underbase or is inkjet printed over a screen printed underbase.

Owner:GRAPHIC ARTS ACQUISITION

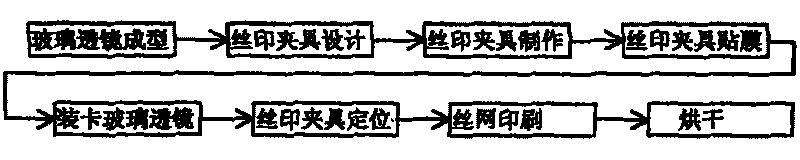

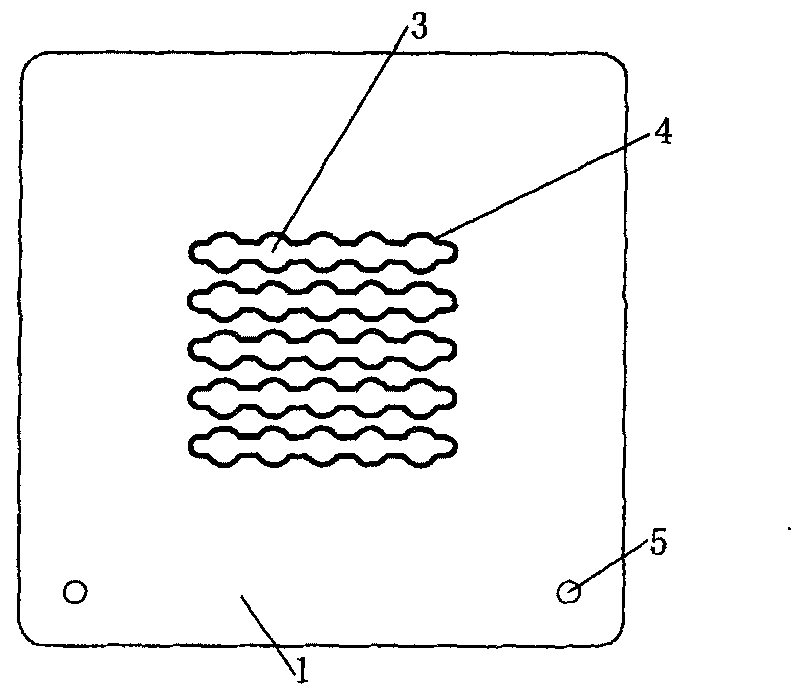

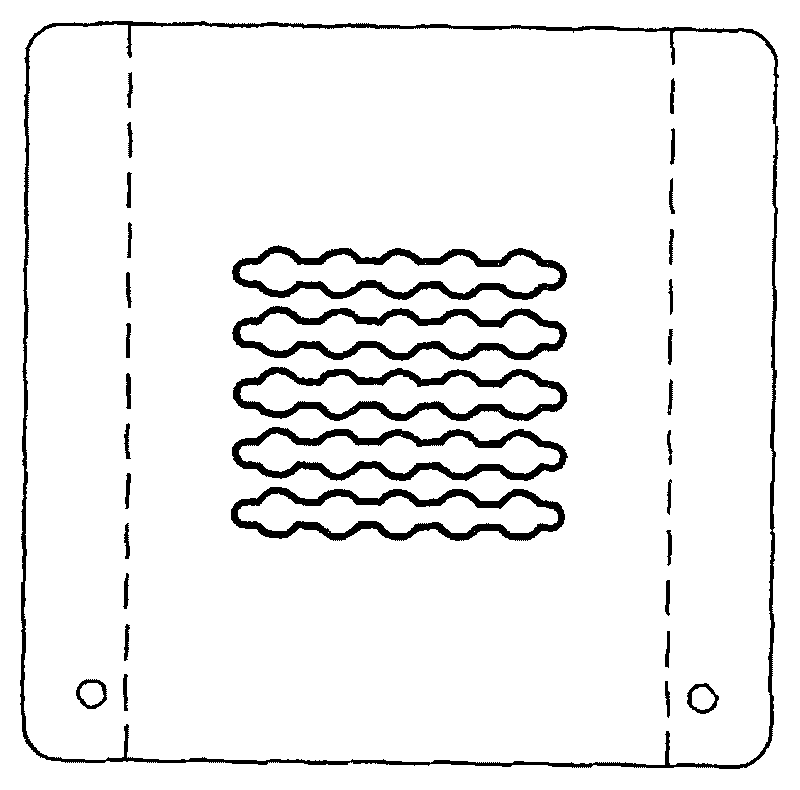

Screen printing process for a plurality of mobile phone glass lenses at one time

InactiveCN101699322ARealize one printingIncrease productivityScreen printersOther printing apparatusNumerical controlTectorial membrane

The invention relates to a screen printing process for a plurality of mobile phone glass lenses at one time, which comprises the following steps: 1, molding the glass lenses, namely, adopting a conventional process for preparing the glass lenses to prepare the glass lenses which meet the requirements; 2, designing screen printing fixtures, namely, designing the sizes and the arrangement mode of the screen printing fixtures according to the appearance of the glass lenses; 3, manufacturing the screen printing fixtures, namely, adopting a numerical control machine to machine the screen printing fixtures; 4, pasting films on the screen printing fixtures, namely, pasting protective films on the backs of the screen printing fixtures; 5, mounting and clamping the glass lenses, namely, mounting and clamping the plurality of glass lenses into the screen printing fixtures; 6, positioning the screen printing fixtures, namely, positioning the screen printing fixtures in which the glass lenses are mounted and clamped onto the surface of a screen printer through positioning posts; 7, performing screen printing, namely, starting the screen printer to perform the screen printing; and 8, drying the screen-printed glass lenses. The process successfully realizes the printing of the plurality of glass lenses at one time on conventional equipment, thereby greatly improving the production efficiency of the glass lenses, reducing the production cost and simultaneously lightening the working intensity of screen printing operators.

Owner:TIANJIN ZHONGHUAN HI TECH

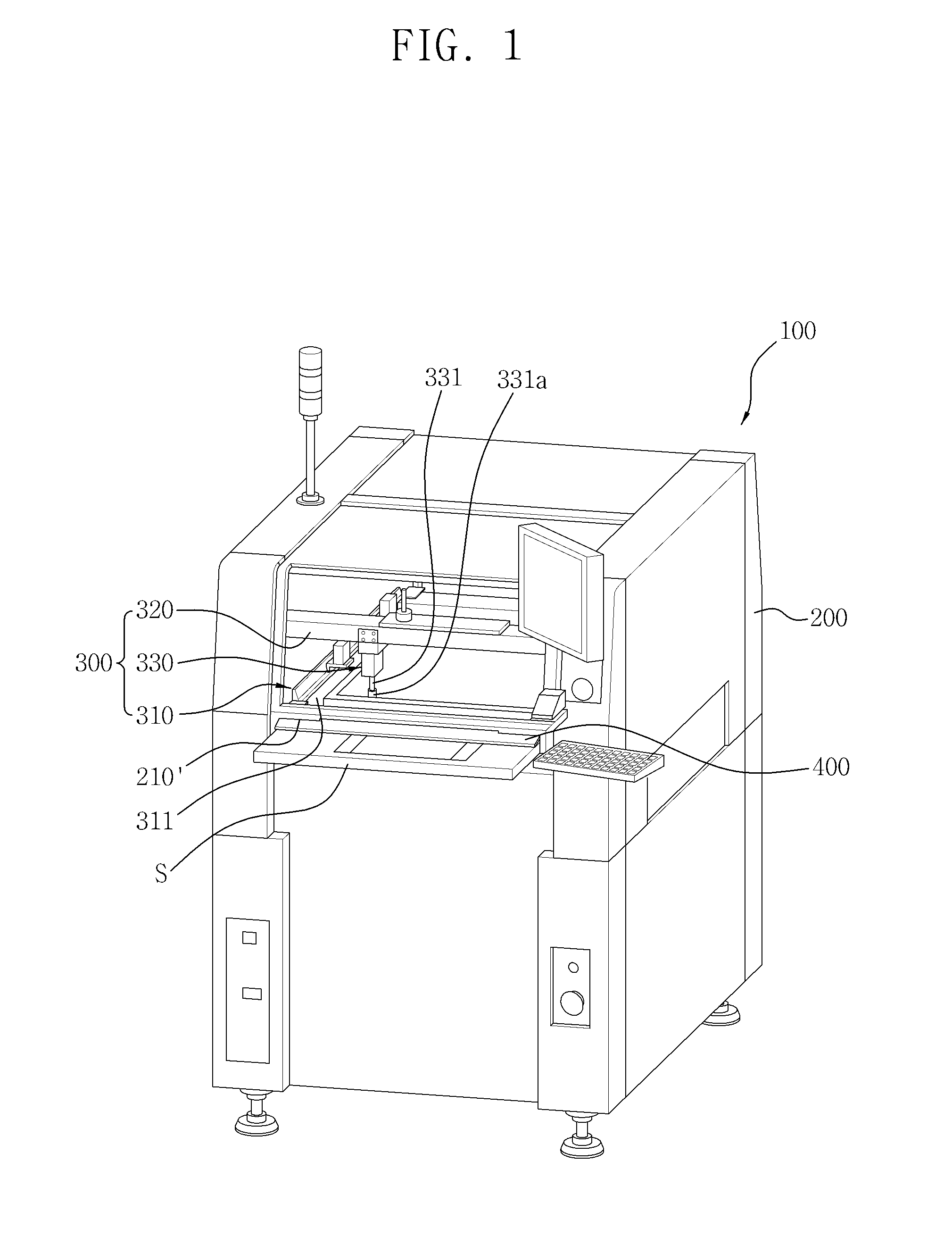

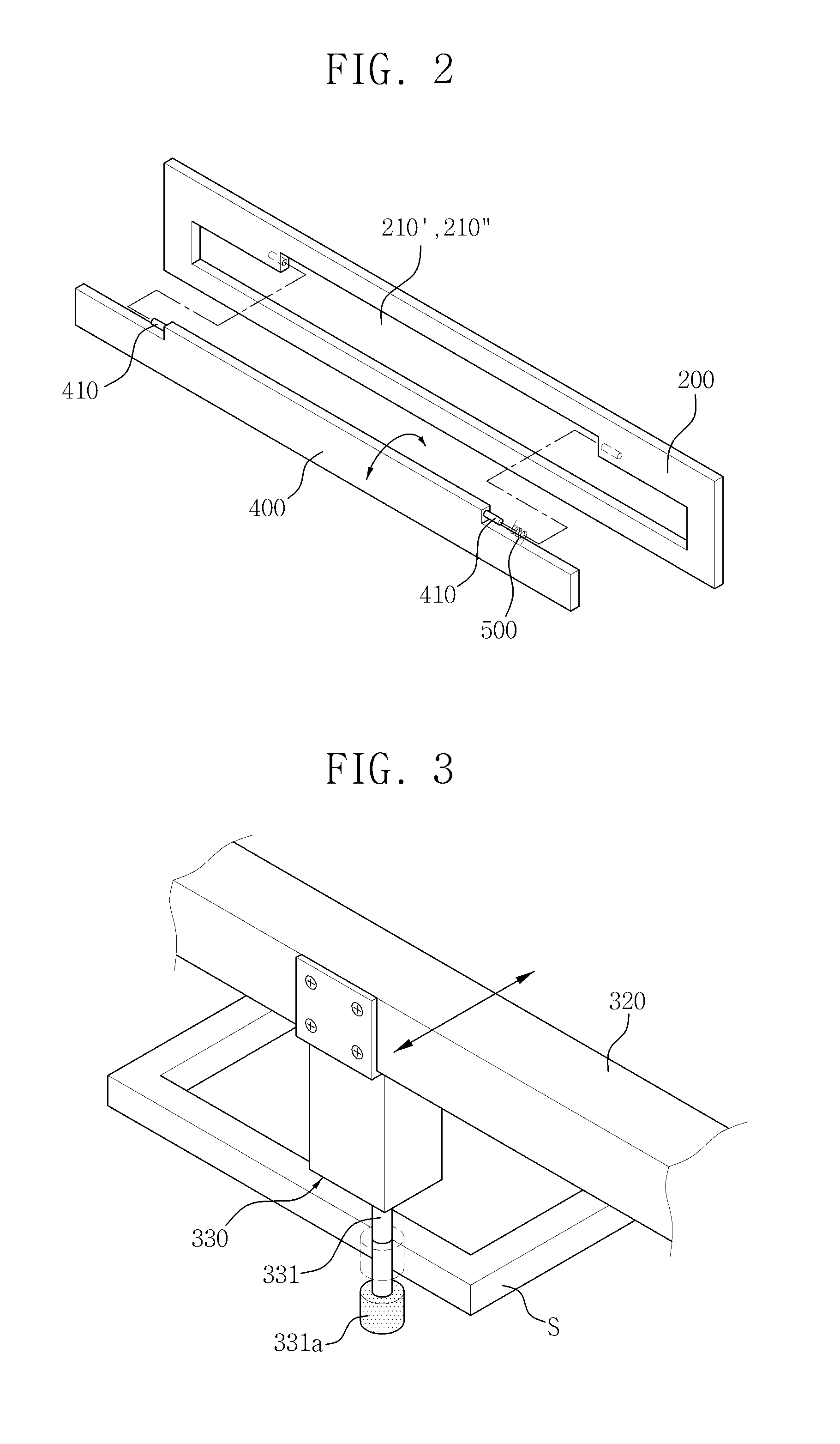

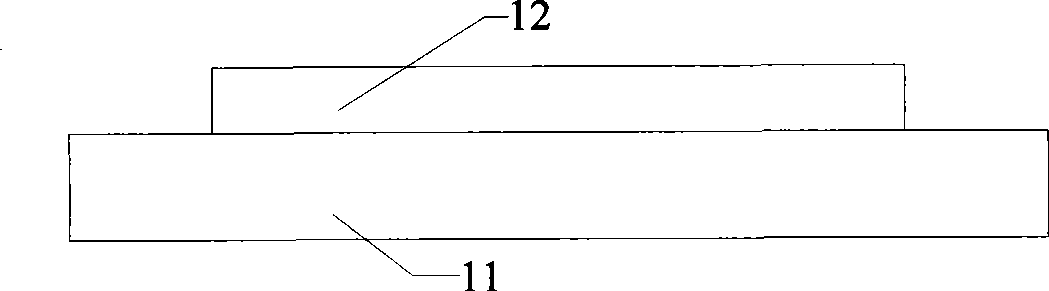

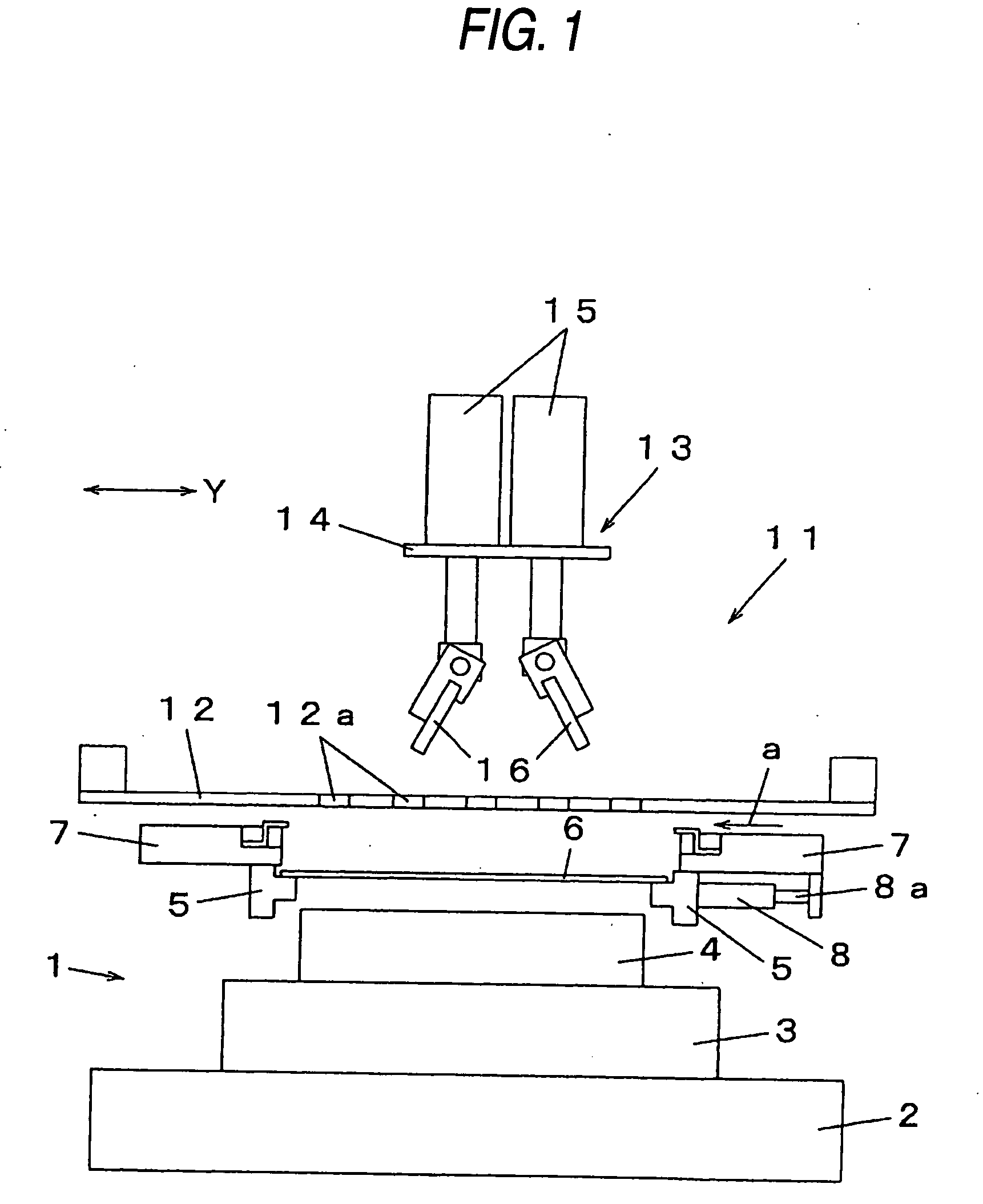

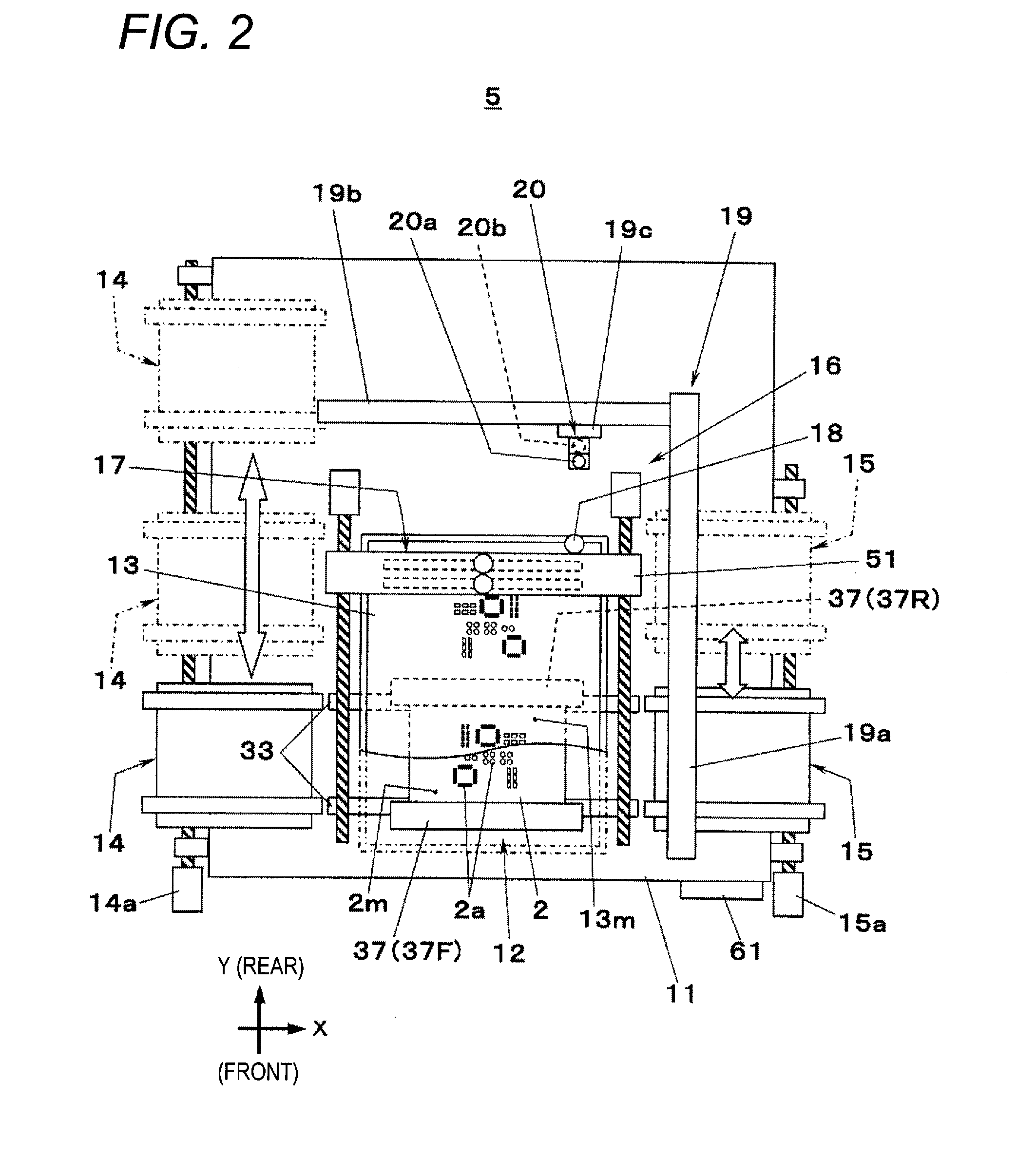

Screen printer

ActiveUS20110192296A1Reduce in quantityLiquid surface applicatorsStencilling apparatusPrinting pressBiomedical engineering

Provided is a screen printer including a main body in which an operation region and at least one introduction and extraction portion are formed, wherein the operation region includes an installation position of a stencil mask therein, and, through the at least one introduction and extraction portion, the stencil mask is introduced into the operation region and is extracted from the operation region to an outside of the main body; and a conveyance unit which conveys the stencil mask introduced into and disposed at the operation region to the at least one introduction and extraction portion when the stencil mask is replaced by a new stencil mask introduced through the at least one introduction and extraction portion, and conveys the new stencil mask to the operation region.

Owner:HANWHA AEROSPACE CO LTD

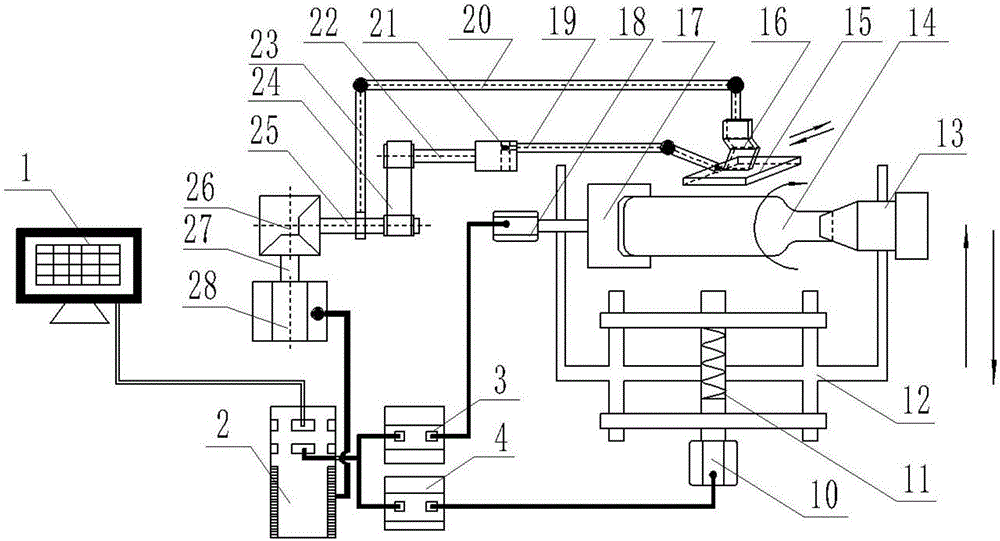

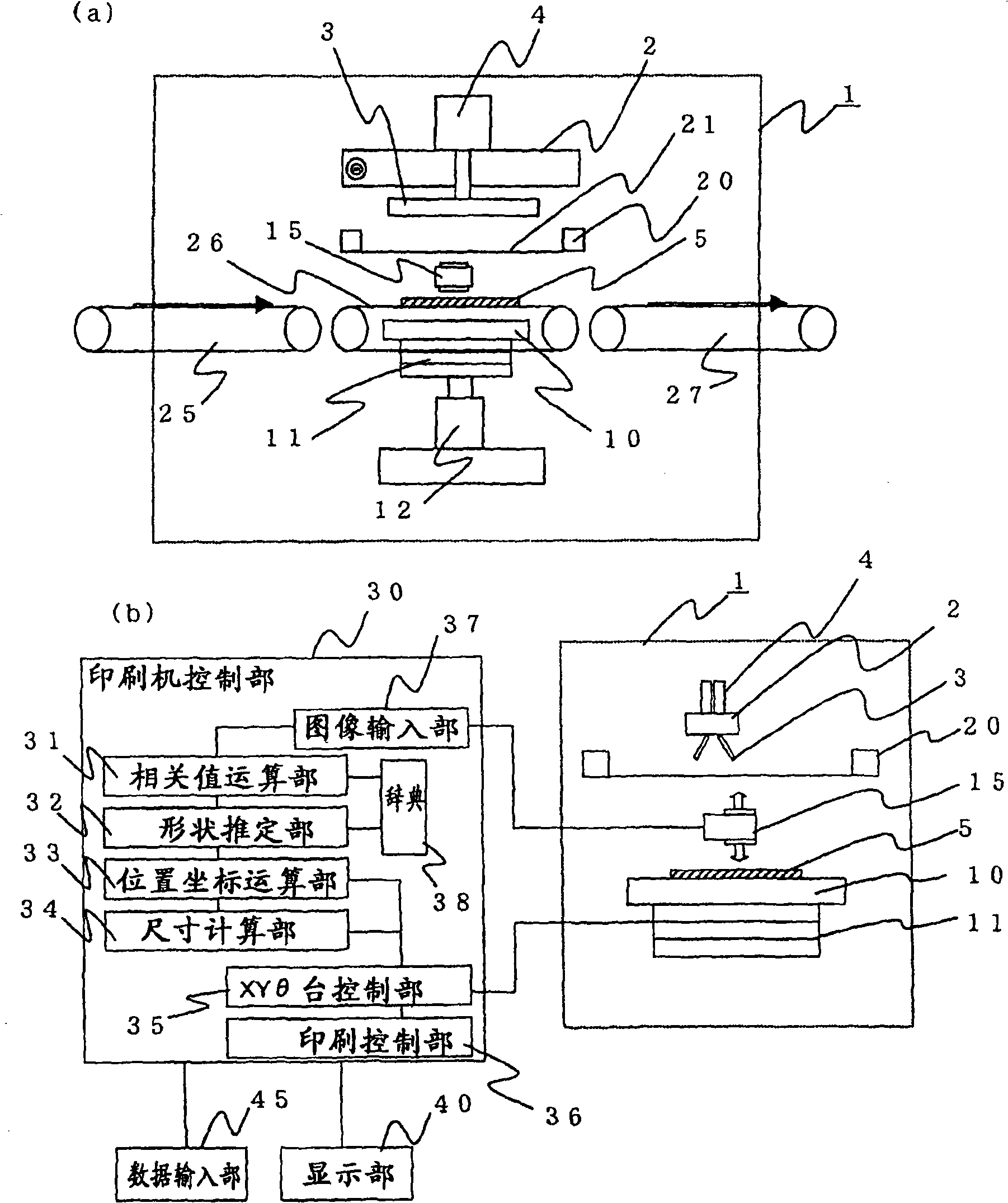

Automatic contraposition method and system for screen process press

InactiveCN101362394ARealize fully automatic alignmentFully automatedScreen printersPrinting press partsEngineeringPrinting press

The invention relates to an automatic aligning method and a system which are used for a screen printing machine. The method comprises the following steps: three lenses are adjusted based on a first piece of printing stock aligned with a halftone screen, to cause the centers of the cross curves of the lenses to be coincided with arbitrary three points on two outer edges of the first piece of printing stock, and the three points are recorded as the reference coordinate points; corrsponding outer edges on a sequent printing stock are captured, three corresponding points intercrossed with the cross curves of the lenses are obtained, and the coordinates of the three points currently captured are calculated based on the three reference coordinate points; the coordinates of the three points currently captured and the recorded three reference coordinate points are compared to determine the movement of a printing platform relative to the halftone screen; based on the determined result, an X axle motor, a Y axle motor and a rotating motor are controlled to respectively drive the printing platform to do linear displacement in X axle direction and Y axle direction and rotate along the Z axle. The invention utilizes the CCD lens to capture the location of the printing stock to adjust the printing platform for automatic aligning, therefore, the accurate alignment is ensured, and the production efficiency is improved.

Owner:SHENZHEN SCREEN STAR PRINTING MASCH CO LTD

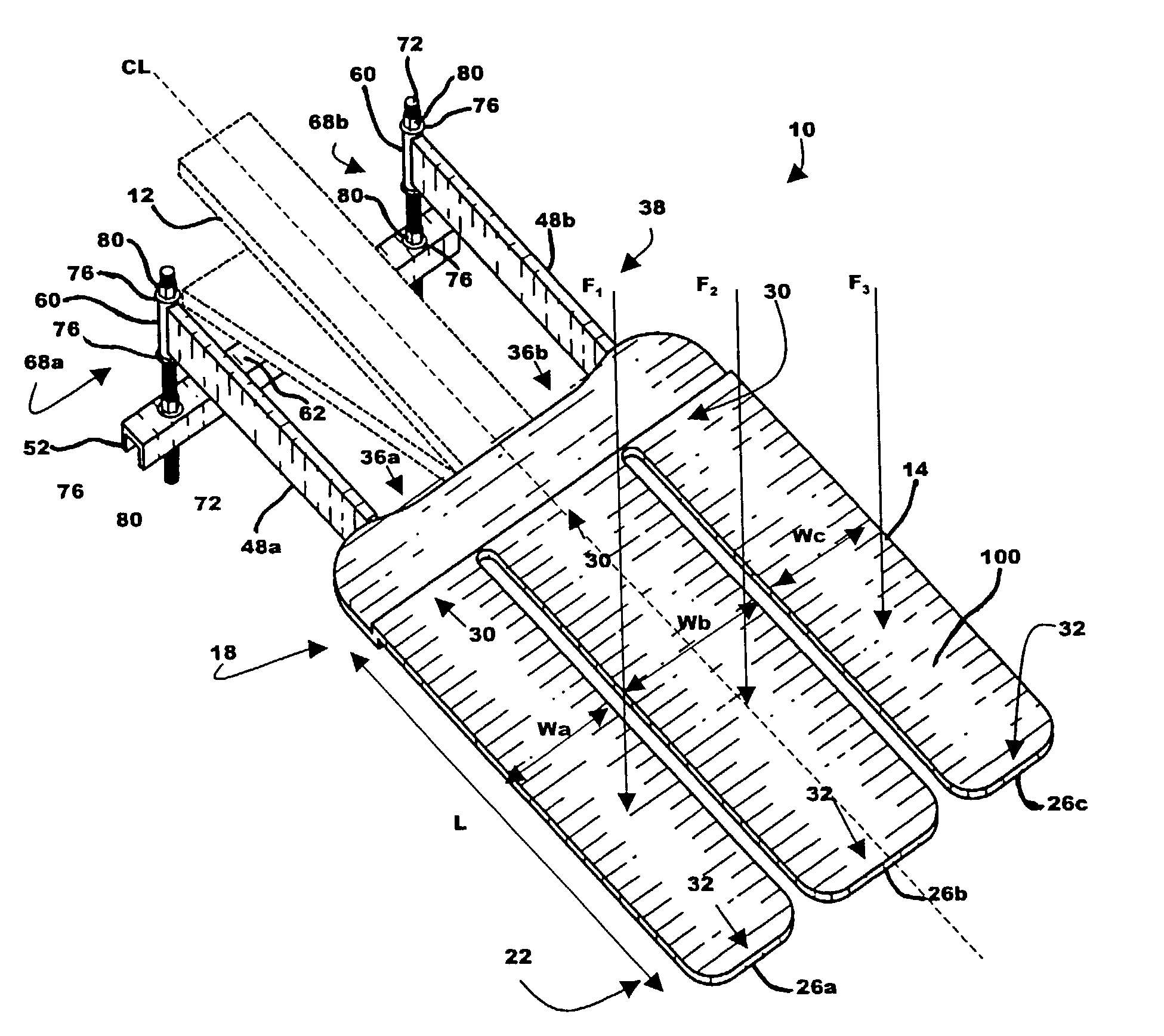

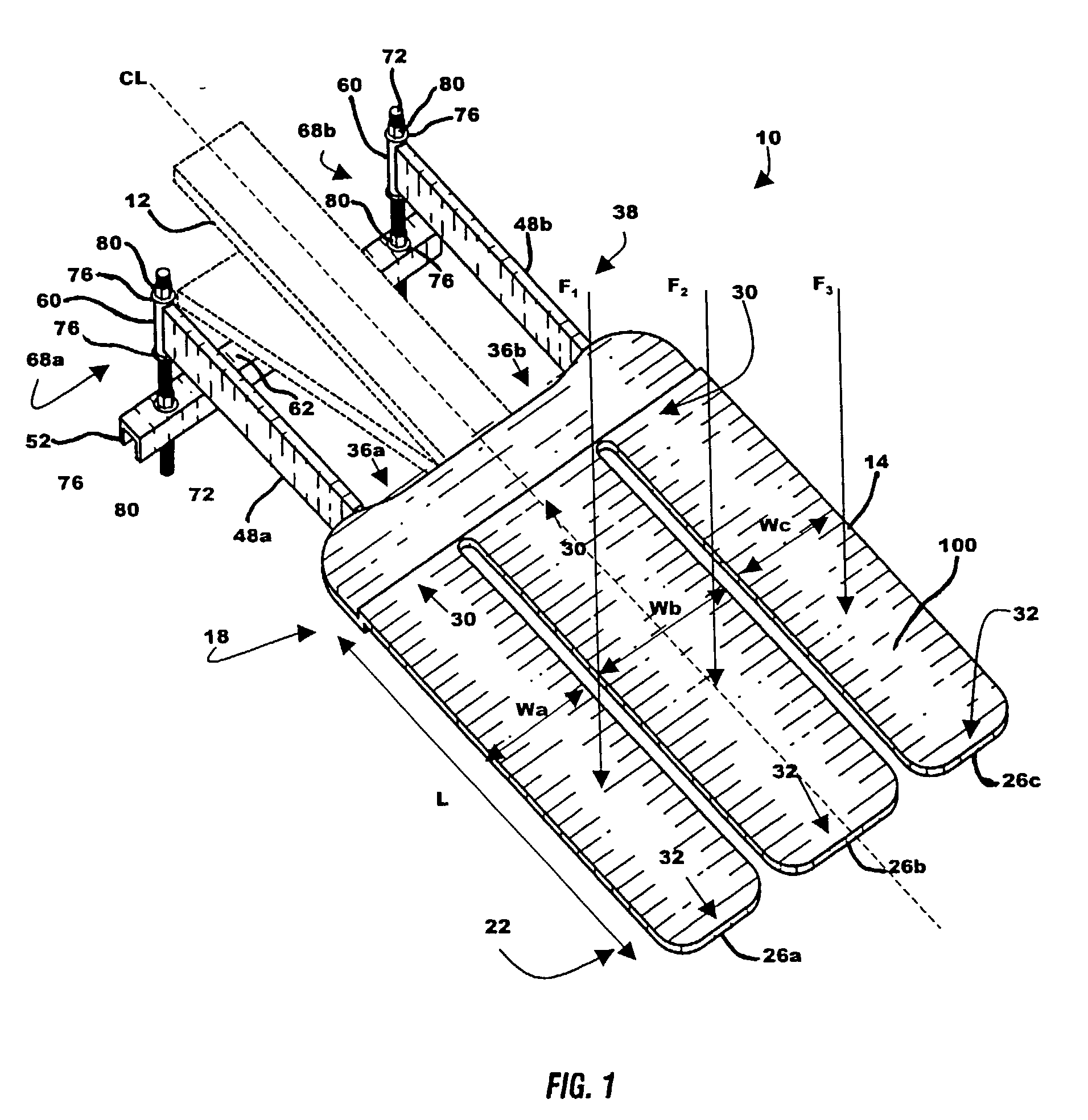

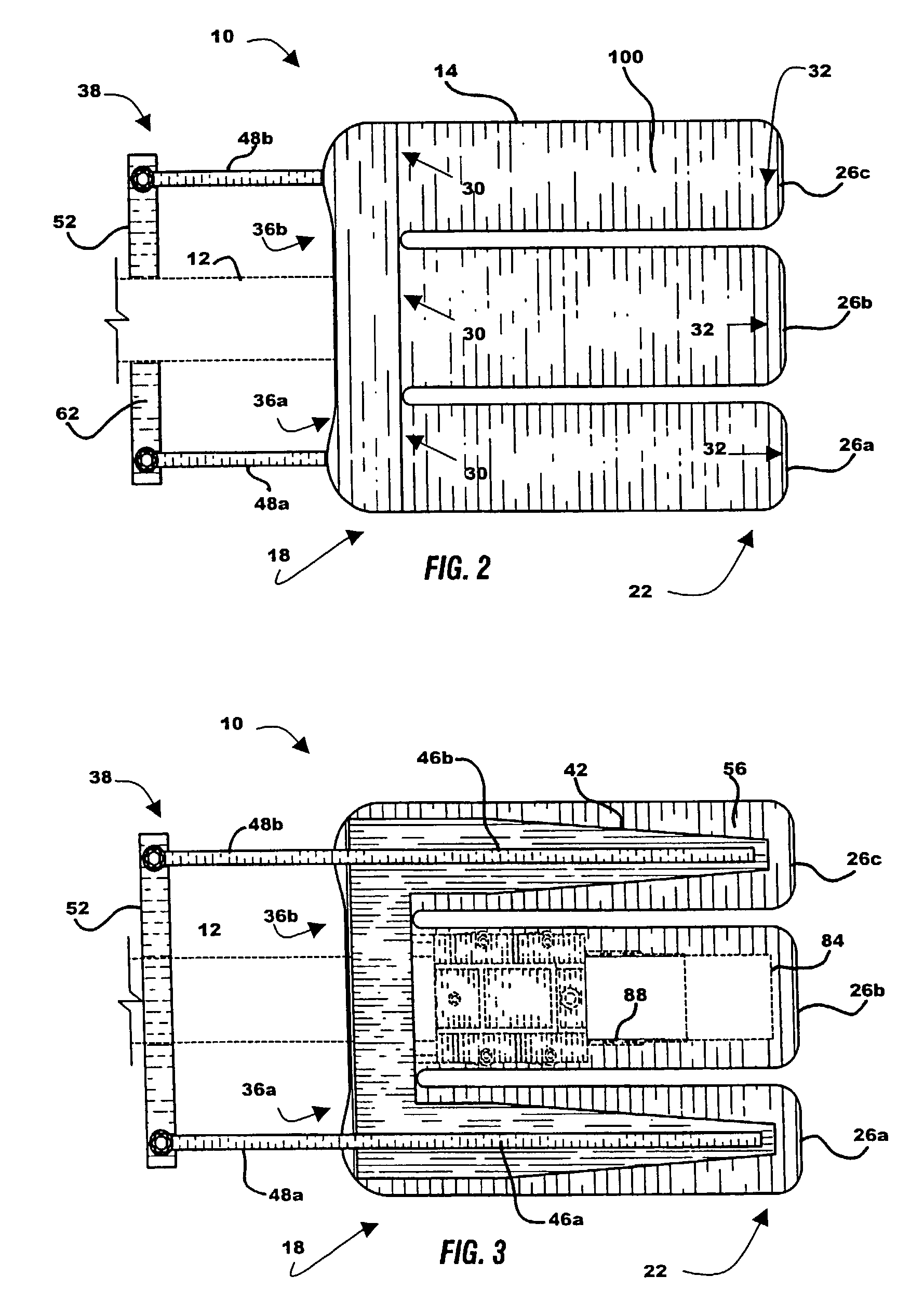

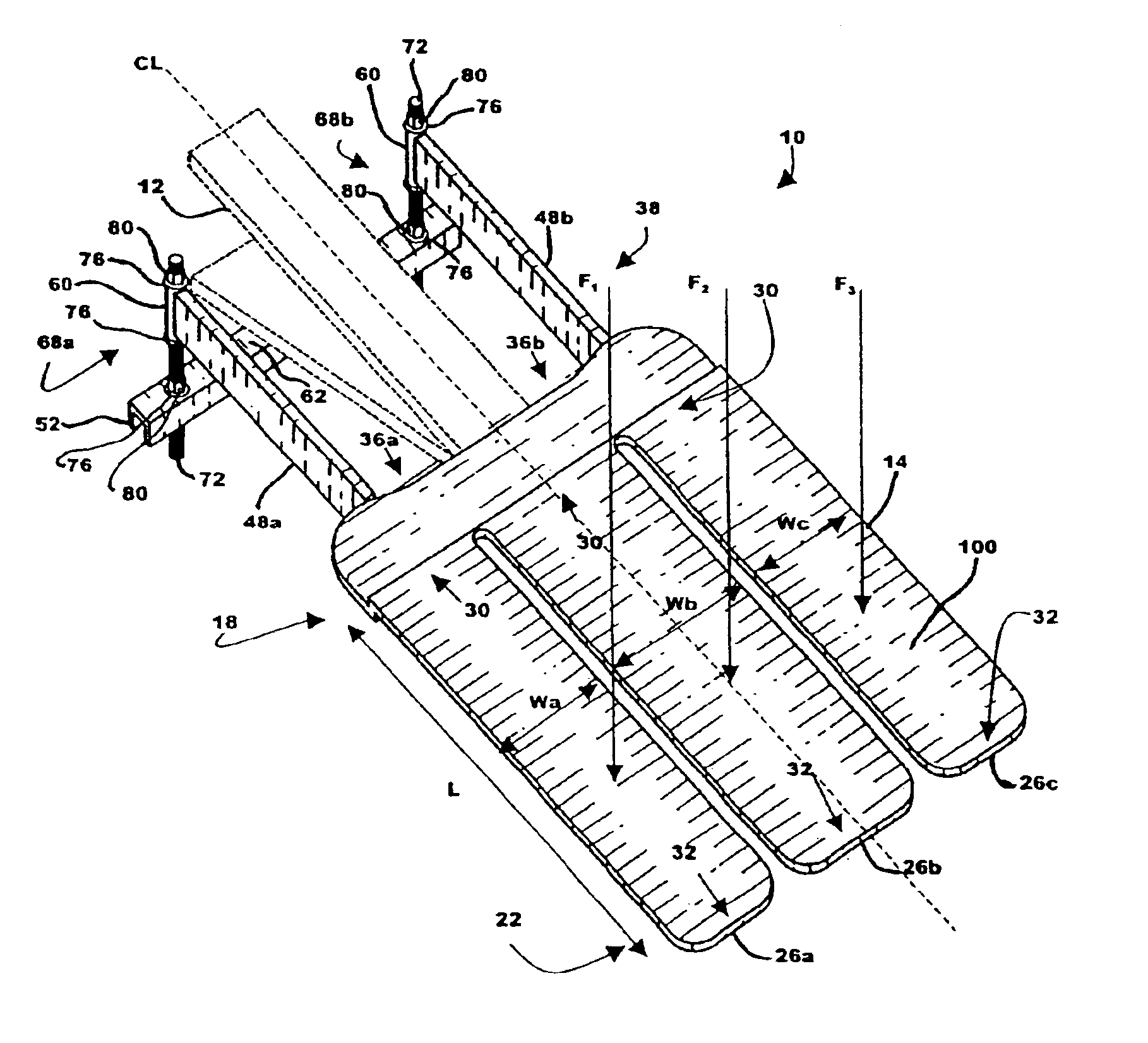

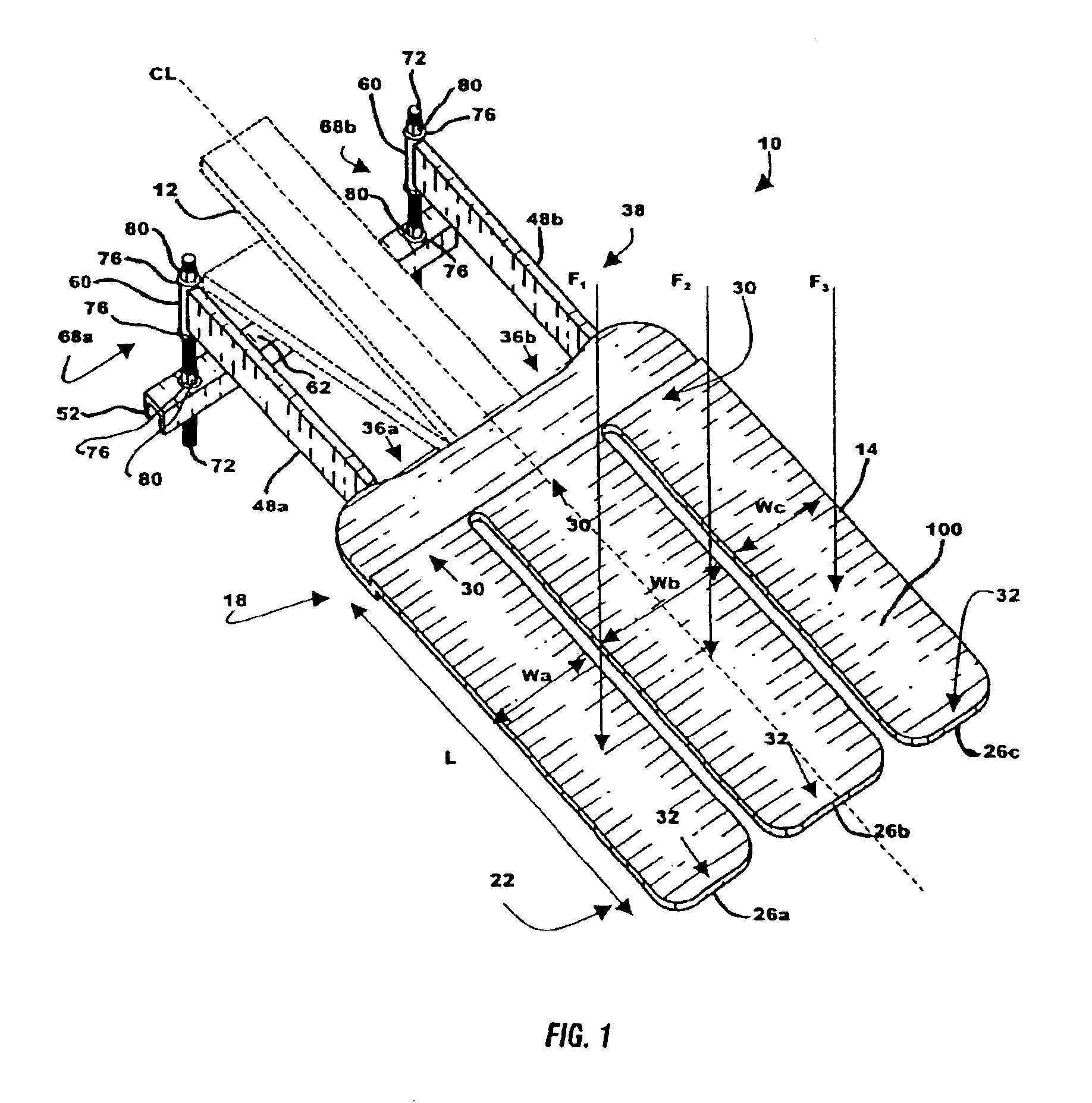

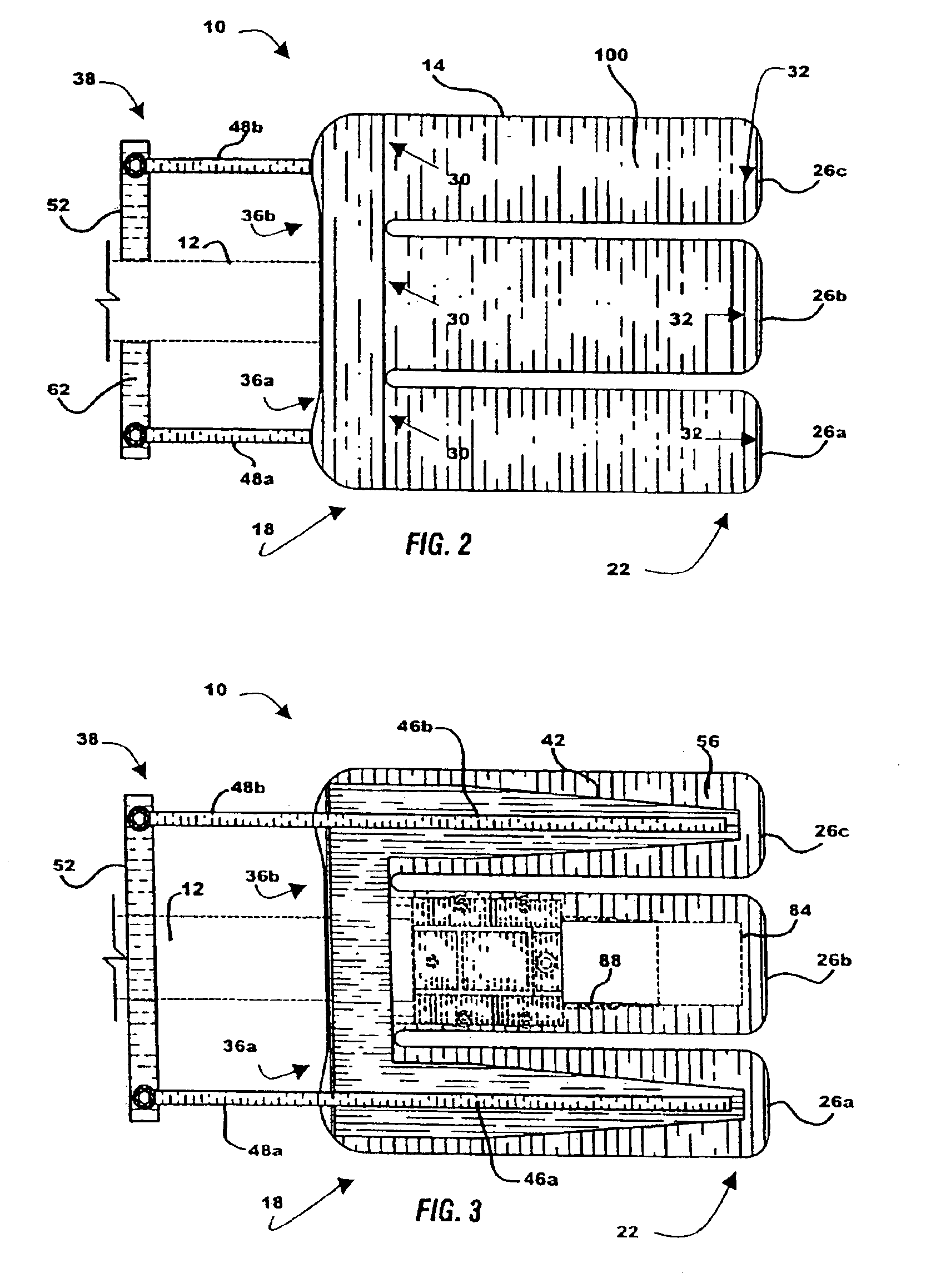

Multi-use pallet with torsion control for a printing machine

A pallet (10) for use with a screen printing apparatus having arms (12) extending outwardly from the printing machine supports an article against a printing force supplied by the screen printing machine. A base portion (14) of the pallet (10) is attachable to the arm (12) of the printing machine and includes a support structure extending therefrom to stabilize and reduce deflection against the printing force.

Owner:M&R PRINTING EQUIP

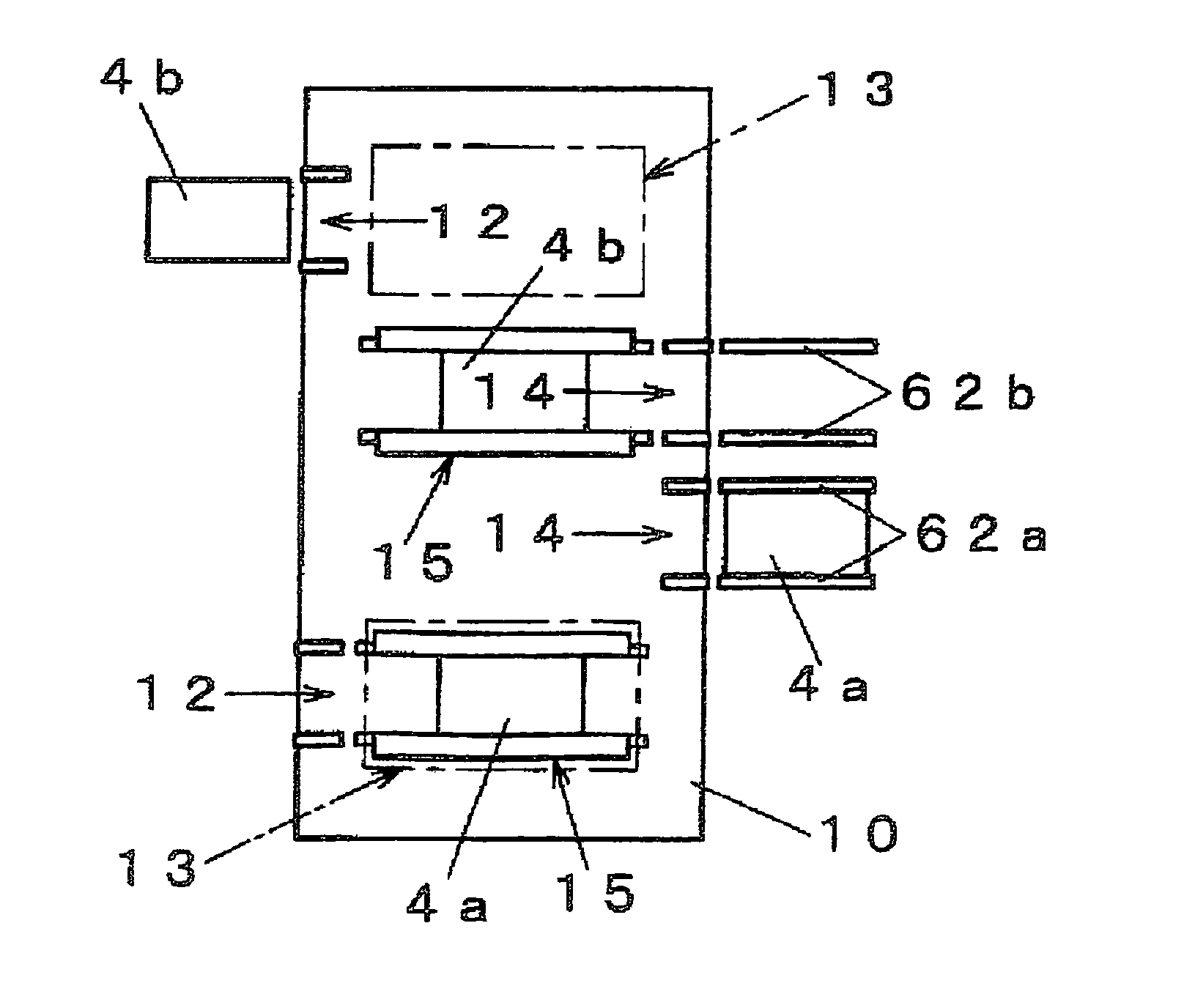

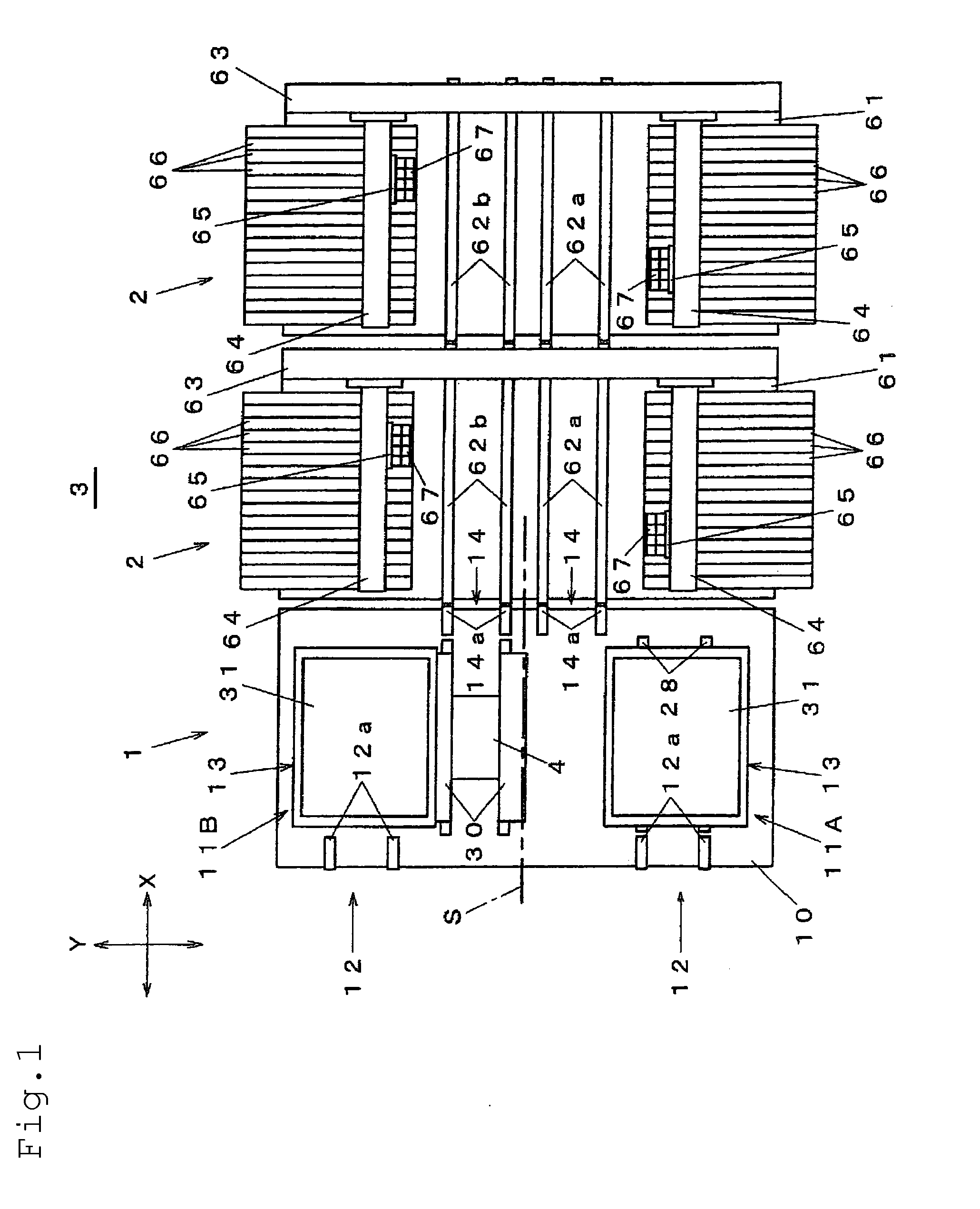

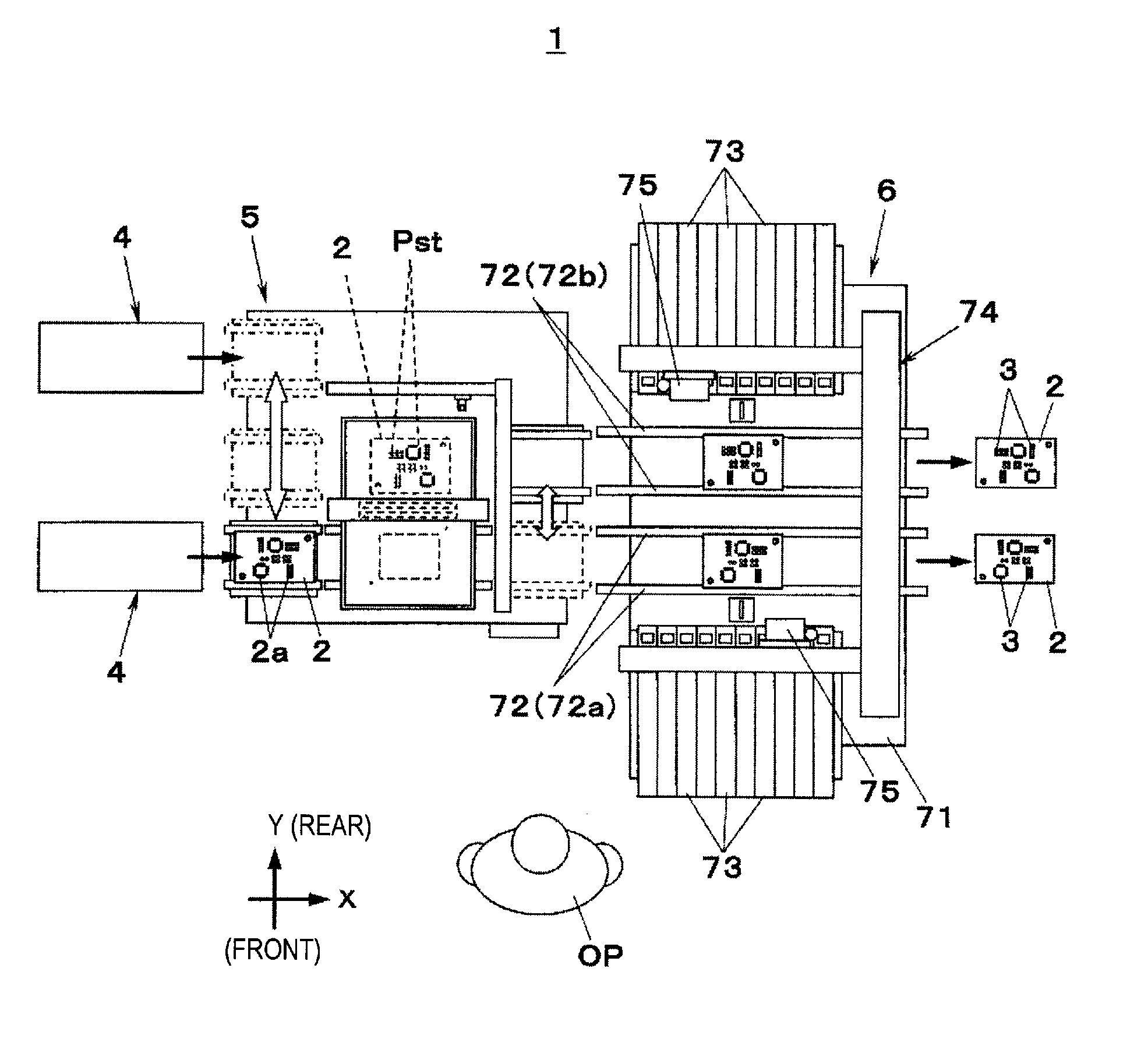

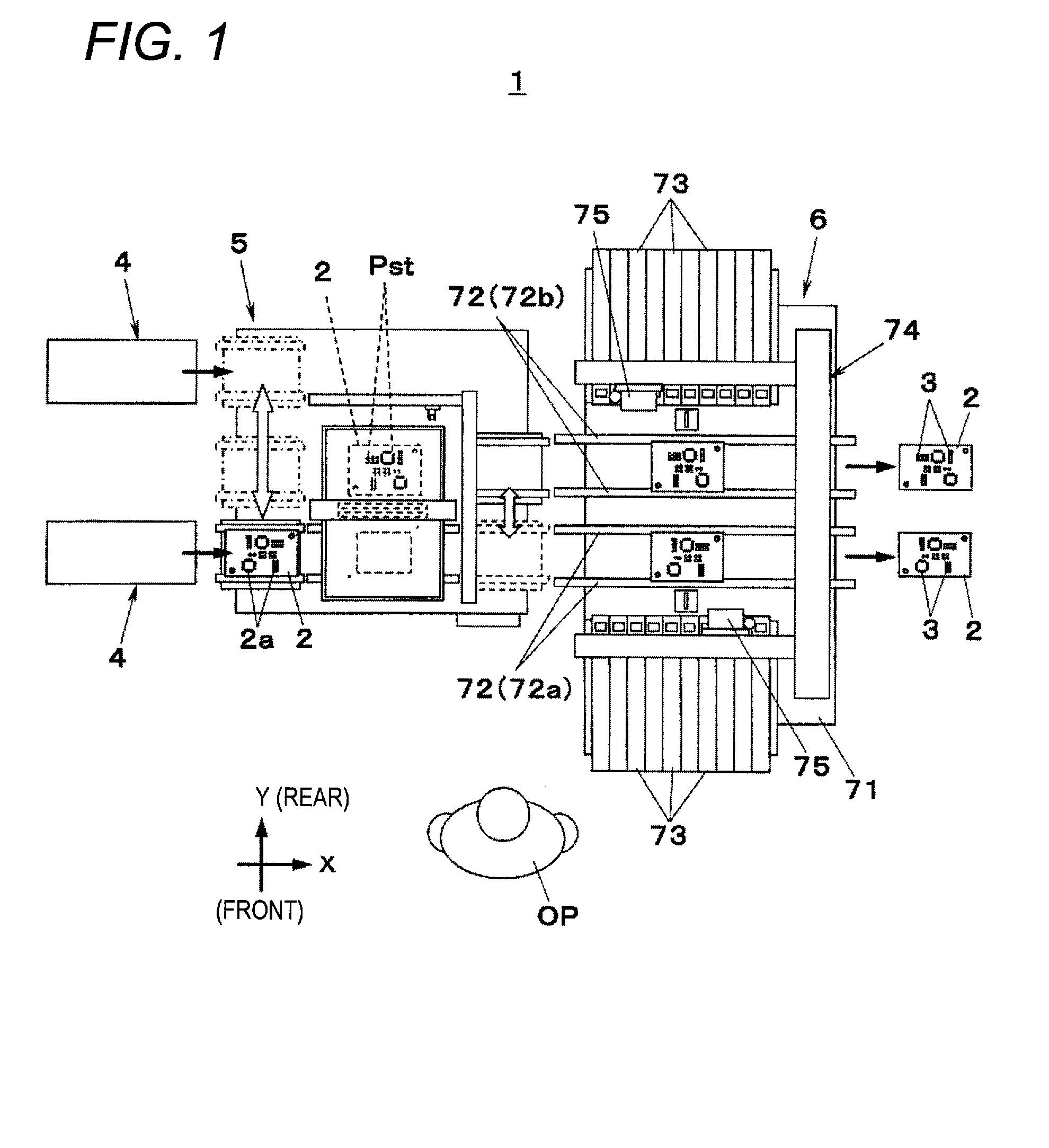

Screen printing apparatus

ActiveUS20100242755A1Convenient ArrangementInterferenceLiquid surface applicatorsScreen printersEngineeringPrinting press

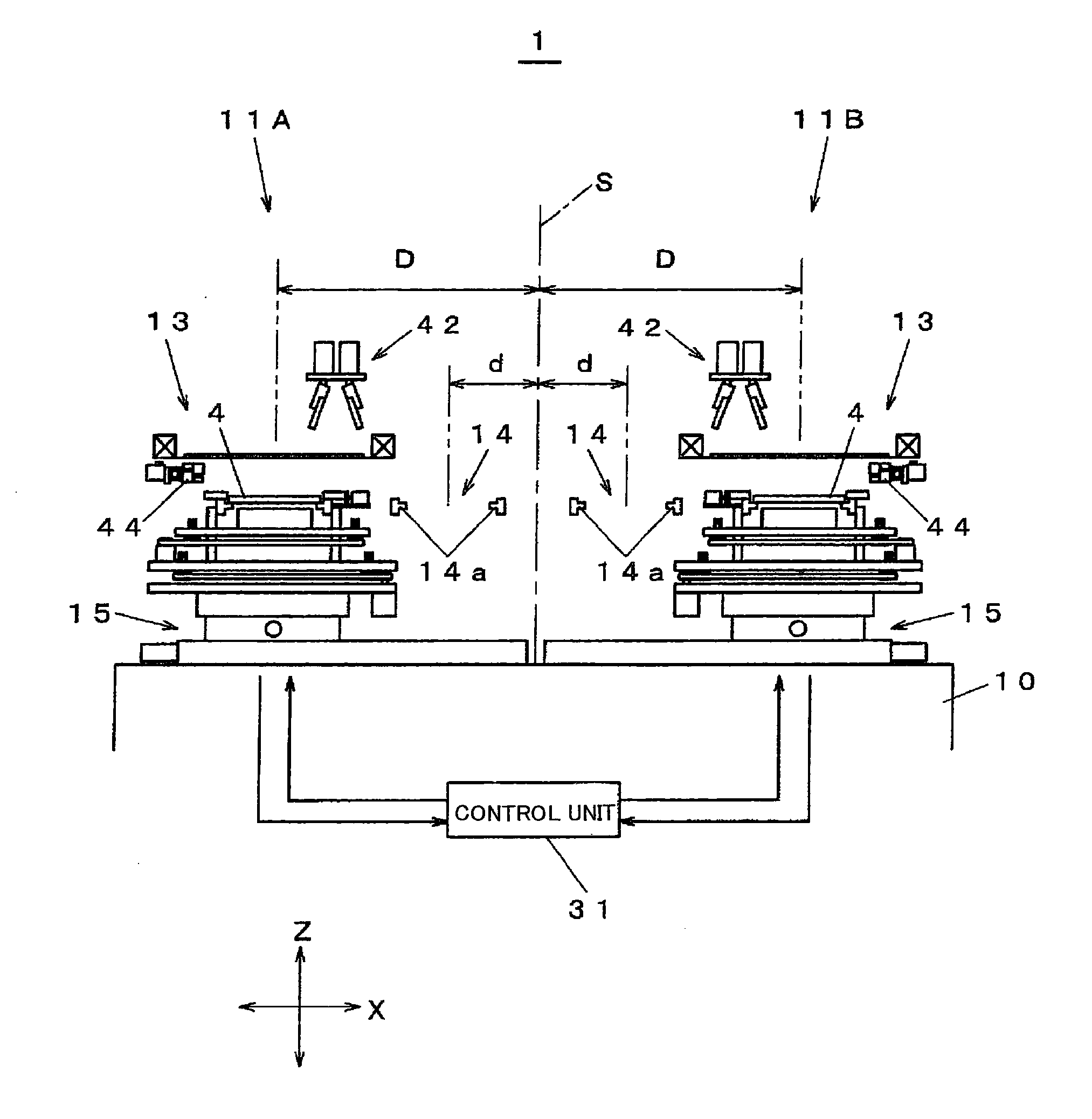

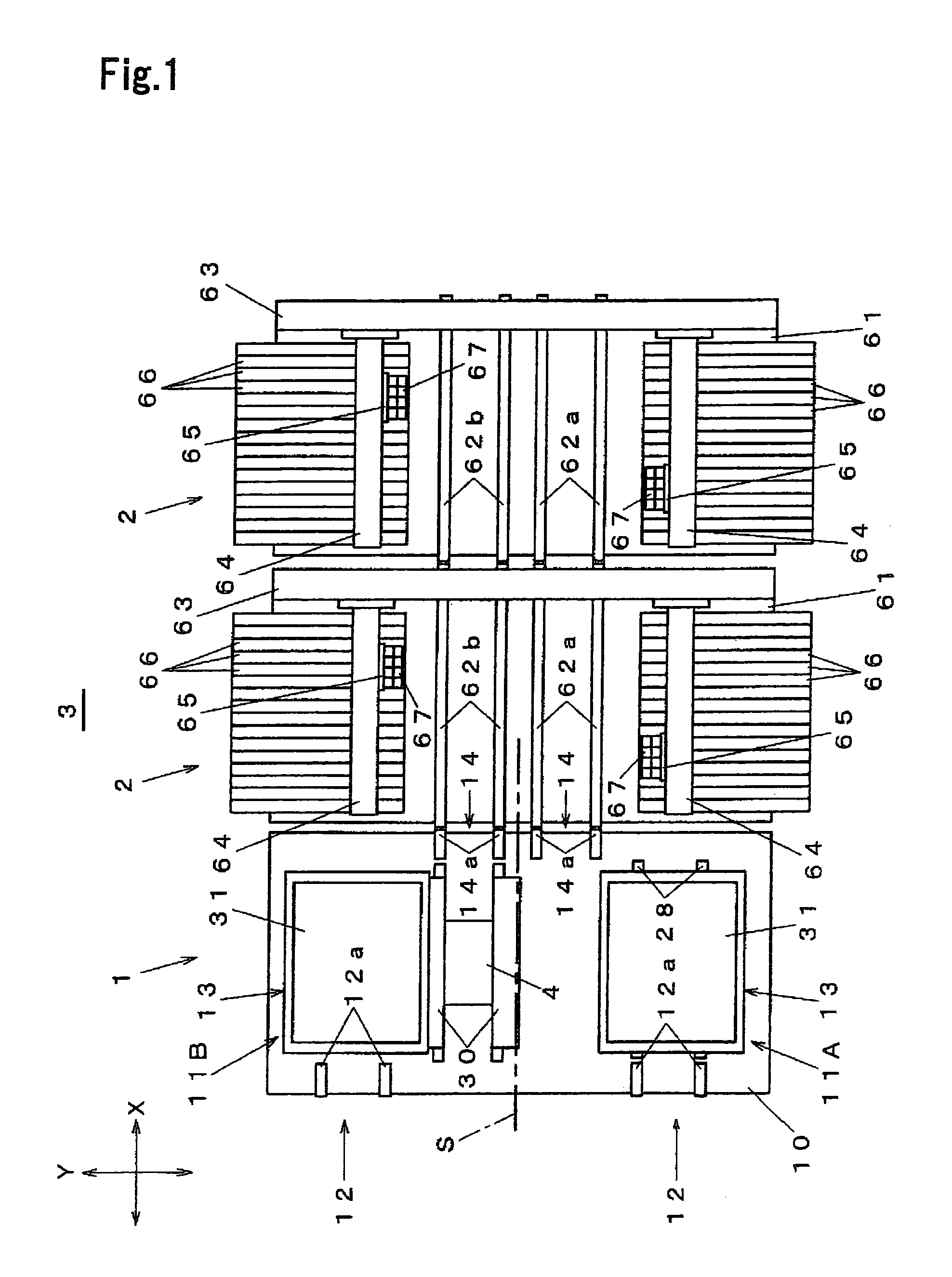

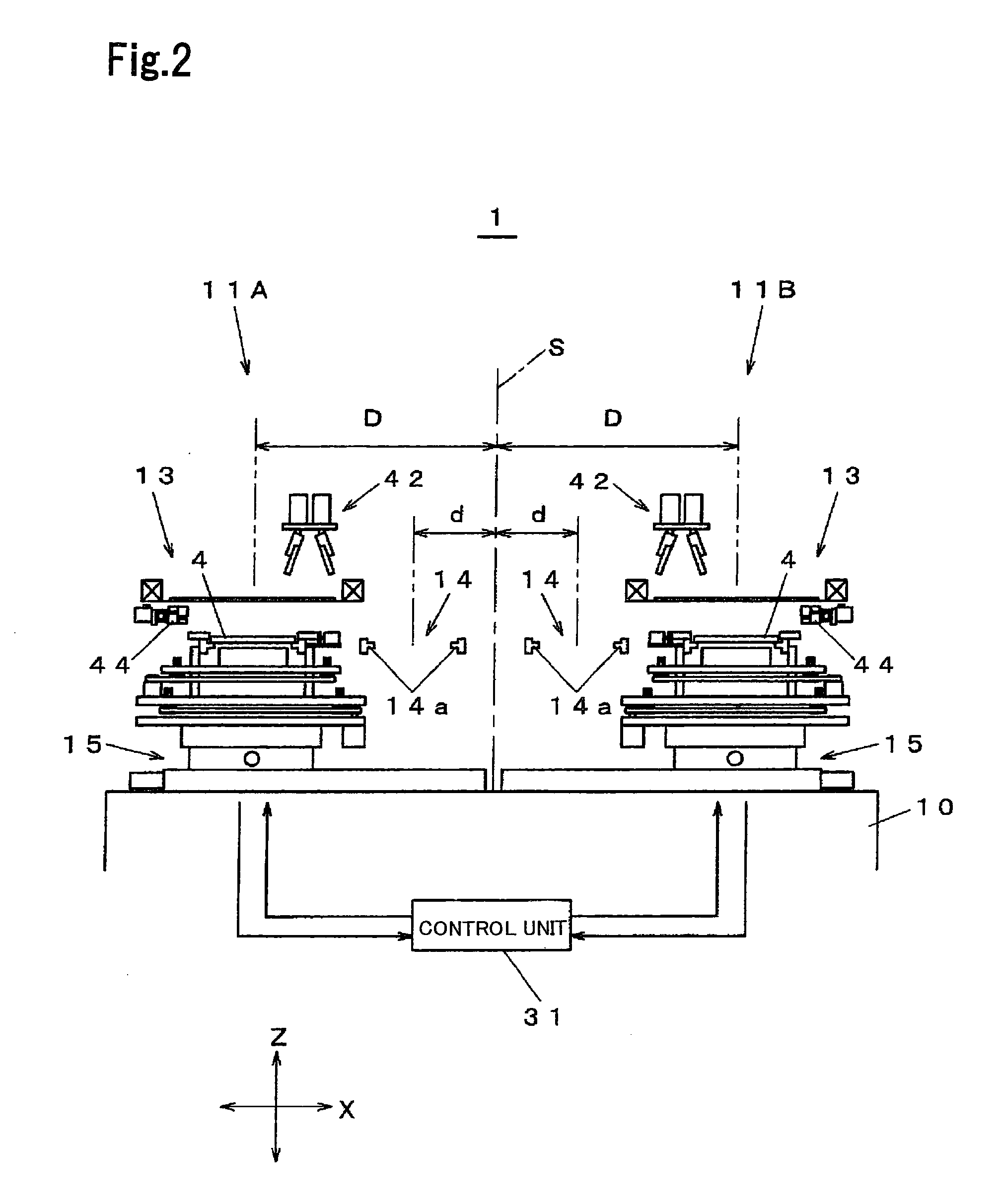

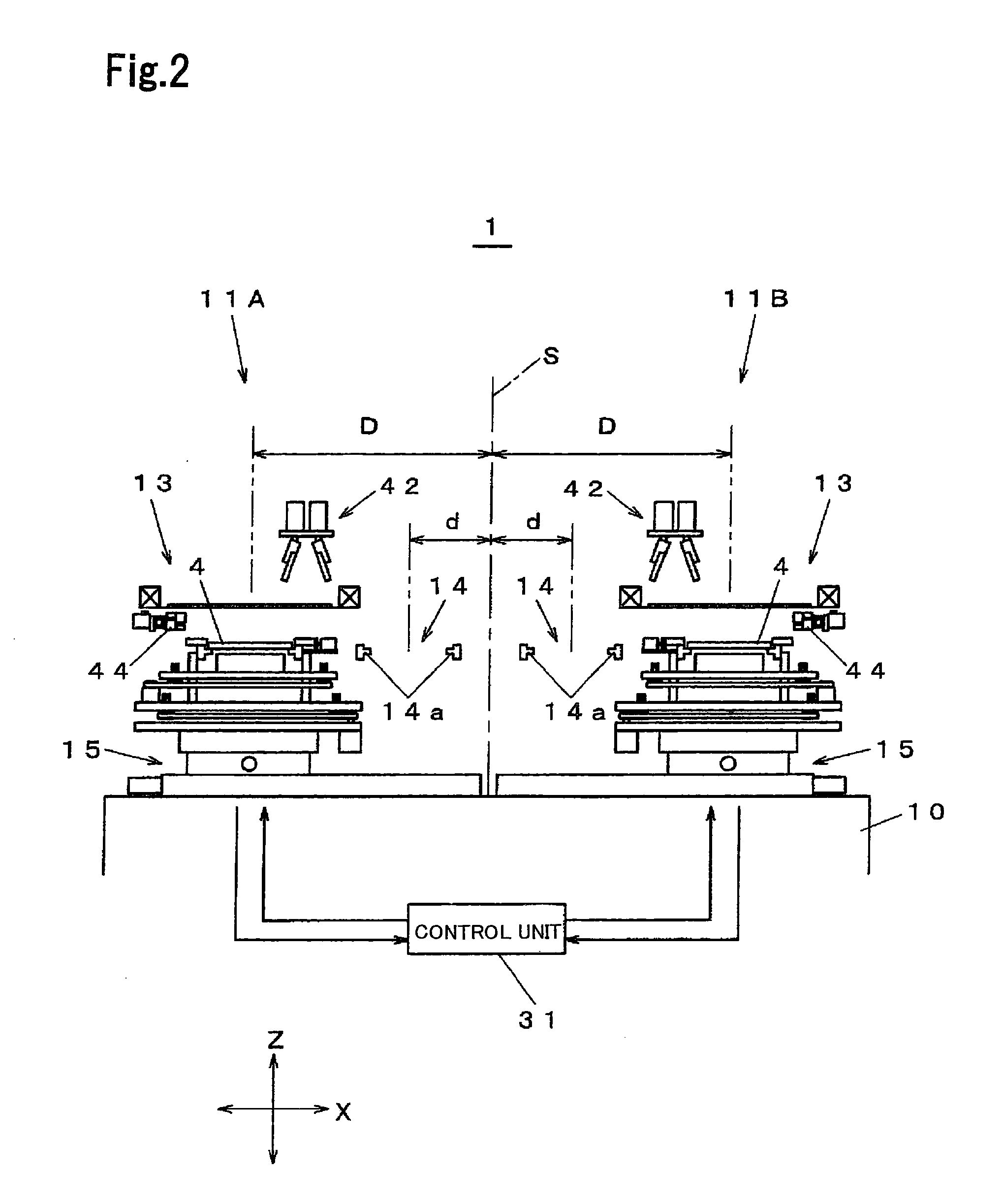

The screen printing apparatus includes two screen printers 11A and 11B each including a substrate introduction portion 12 by which a substrate 4 is introduced from the upstream side of the component mounting line 3, a printing portion 13 which performs a screen printing to the introduced substrate 4, a substrate discharge portion 14 by which the substrate 4 subjected to the screen printing is discharged to the downstream side, and a substrate moving stage 15 which receives the introduced substrate 4 so as to position the substrate 4 with respect to the printing portion 13 and to move the substrate 4 subjected to the screen printing to the substrate discharge portion 14. The two substrate introduction portions 12, the two printing portions 13, and the two substrate discharge portions 14 are arranged symmetrically to each other with respect to a perpendicular symmetrical plane S extending in a transportation direction of the substrate 4 in the component mounting line 3, respectively. Each printing portion 13 is provided at a position further from the perpendicular symmetrical plane S than the substrate discharge portion 14.

Owner:PANASONIC CORP

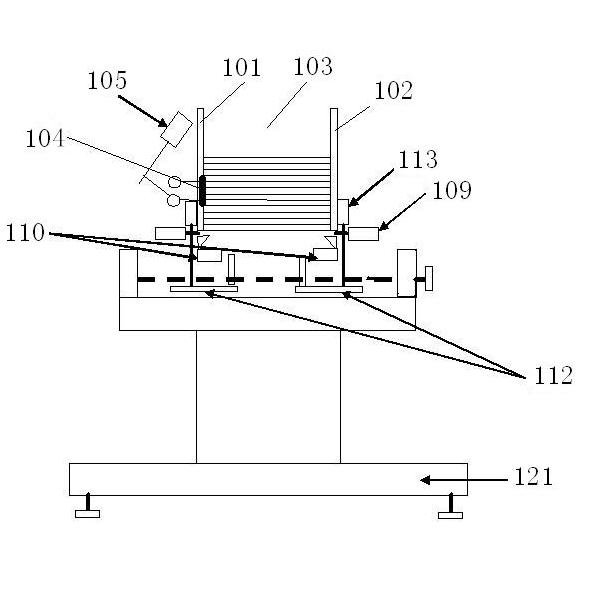

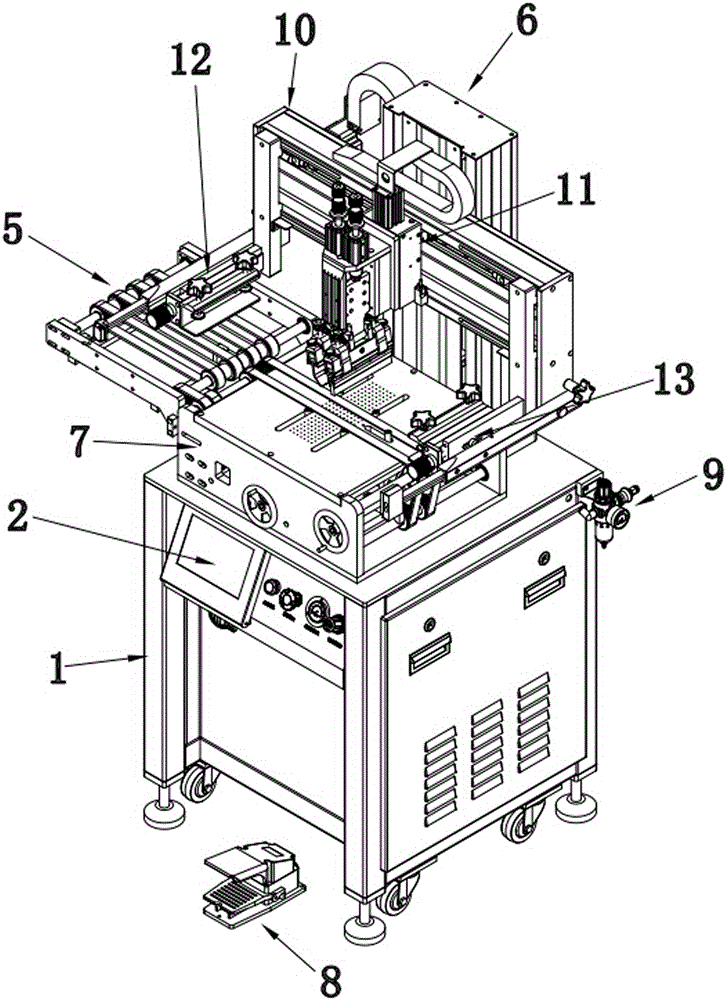

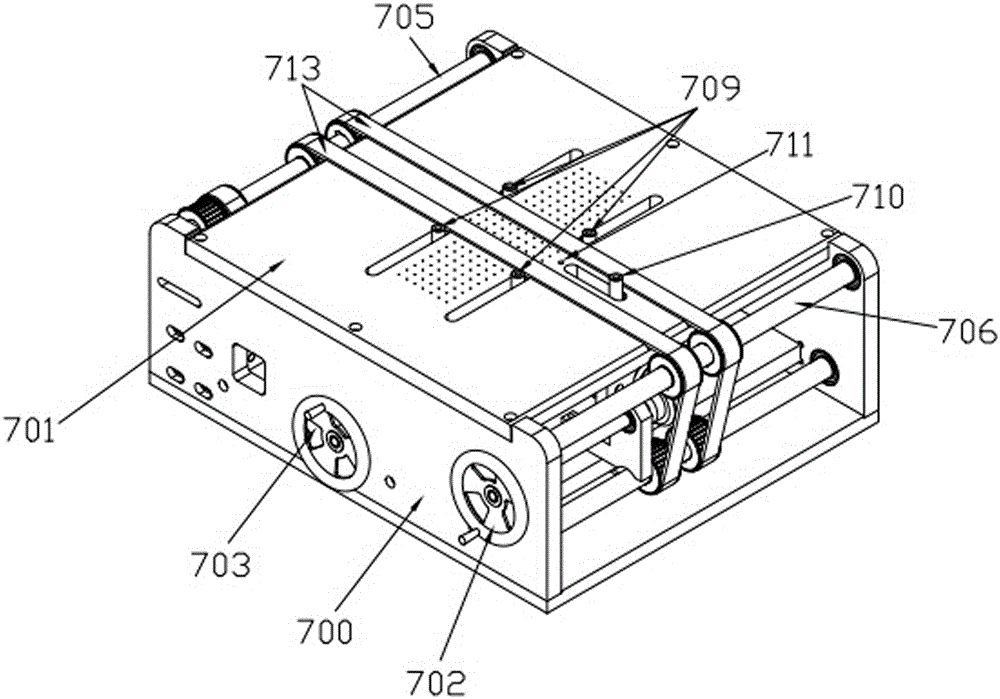

Silkscreen machine with automatic positioning function

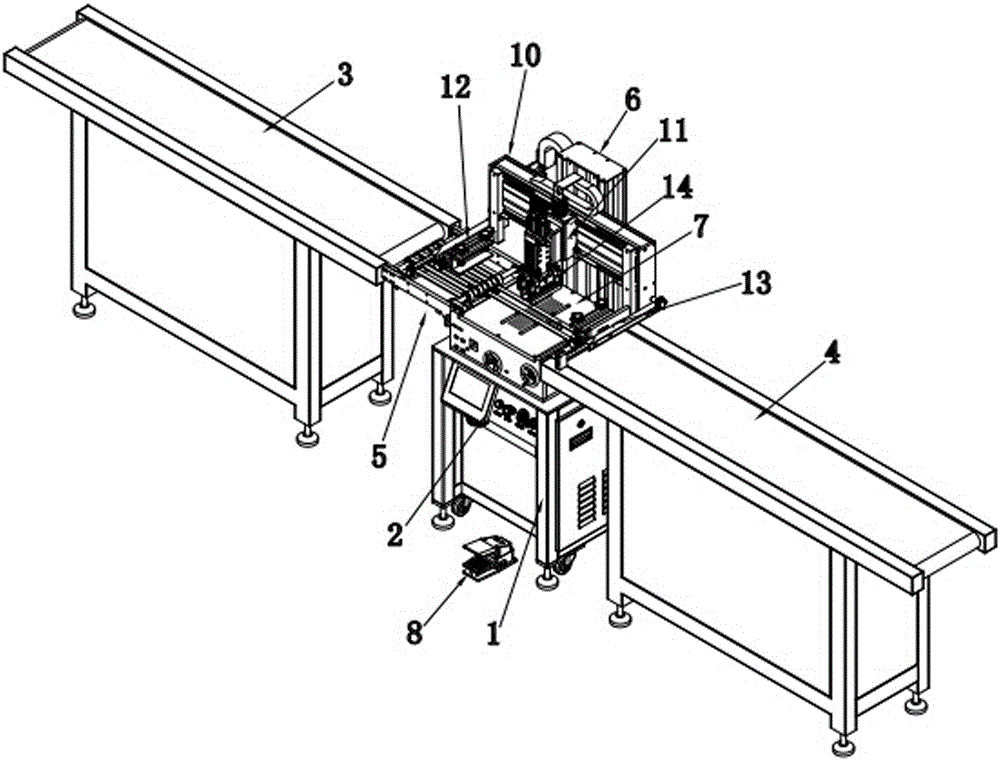

ActiveCN105034554APrecise positioningSize is easy to controlScreen printersHuman–machine interfaceAssembly line

The invention discloses a silkscreen machine with an automatic positioning function and belongs to the technical field of printing equipment. The silkscreen machine comprises a rack of the silkscreen printer and an interface operation system arranged on the rack. At least one feeding conveying belt and at least one discharging conveying belt are arranged on the left side and the right side of the rack. The silkscreen machine further comprises a conveying frame, a lifting column, a positioning workbench, a footbrake switch and an oil mist filter. A printing base transverse beam capable of vertically moving along the lifting column is arranged on the lifting column. A printing base capable of moving leftwards and rightwards along the printing base transverse beam is arranged on the printing base transverse beam. The printing base transverse beam is composed of two symmetrical transverse arm side cover plates, an upper transverse plate and a lower transverse plate, wherein the upper transverse plate and the lower transverse plate are arranged between the two transverse arm side cover plates. A left screen arm and a right screen arm which extend outwards are symmetrically arranged along the bottoms of the two transverse arm side cover plates. Charging is carried out in an assembly-line automatic feeding mode, so that printing precision is improved, the speed is high, and noise is low. A human-computer interface is controlled digitally, and various functions and operation parameters can be set.

Owner:广东恒锦智能装备有限公司

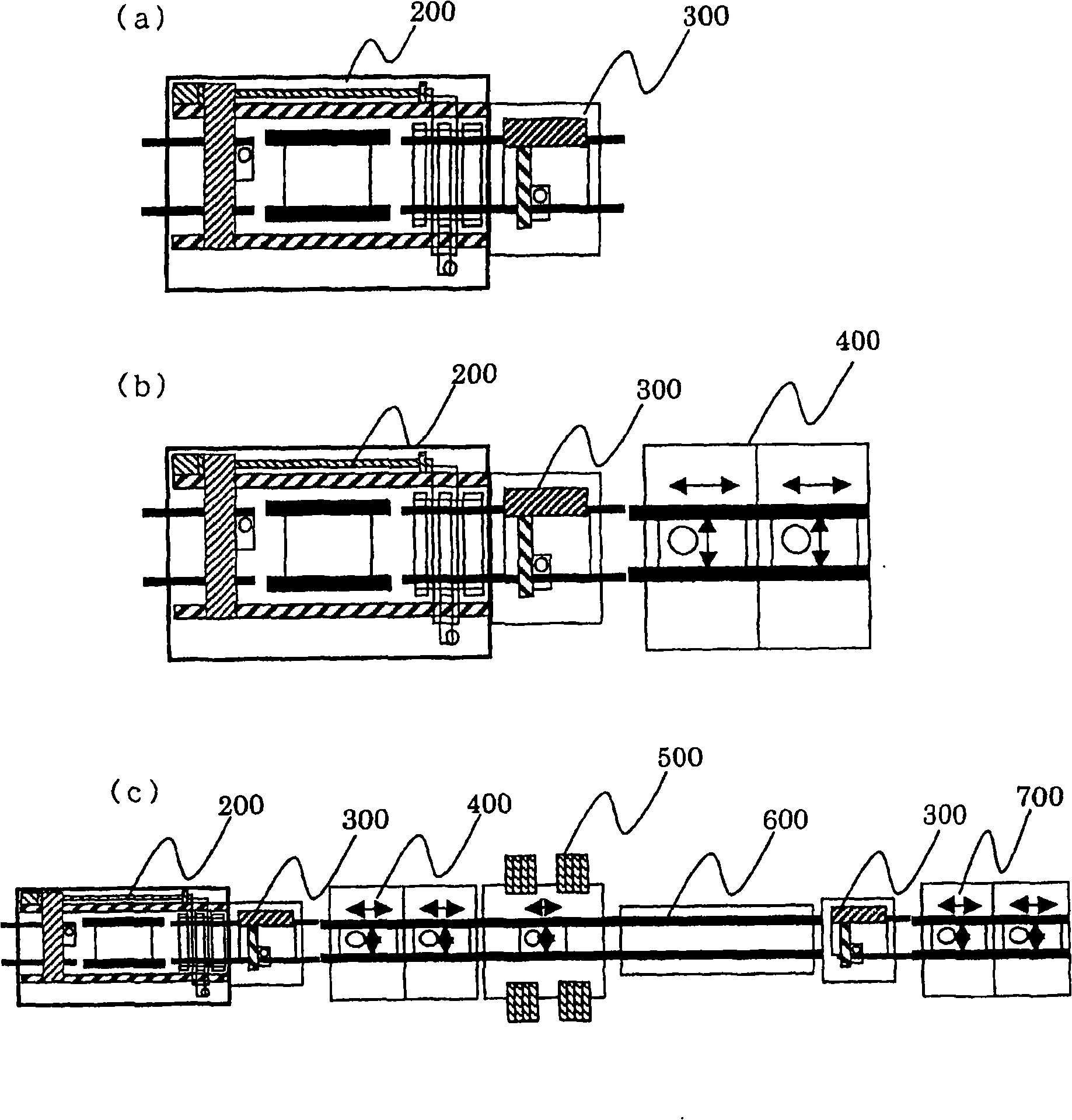

Screen printing apparatus

ActiveUS20120085254A1InterferenceConvenient ArrangementLiquid surface applicatorsScreen printersEngineeringPrinting press

A screen printing apparatus including two screen printers, each including a substrate introduction portion by which a substrate is introduced from an upstream side of a component mounting line, a printing portion which performs a screen printing to the introduced substrate, a substrate discharge portion by which the substrate is discharged to a downstream side, and a substrate moving stage which receives the substrate to position the substrate with respect to the printing portion and to move the substrate to the substrate discharge portion. The two substrate introduction portions, the two printing portions, and the two substrate discharge portions are arranged symmetrically to each other with respect to a perpendicular symmetrical plane extending in a transportation direction of the substrate in the component mounting line, respectively. Each printing portion is provided at a position further from the perpendicular symmetrical plane than the substrate discharge portion.

Owner:PANASONIC CORP

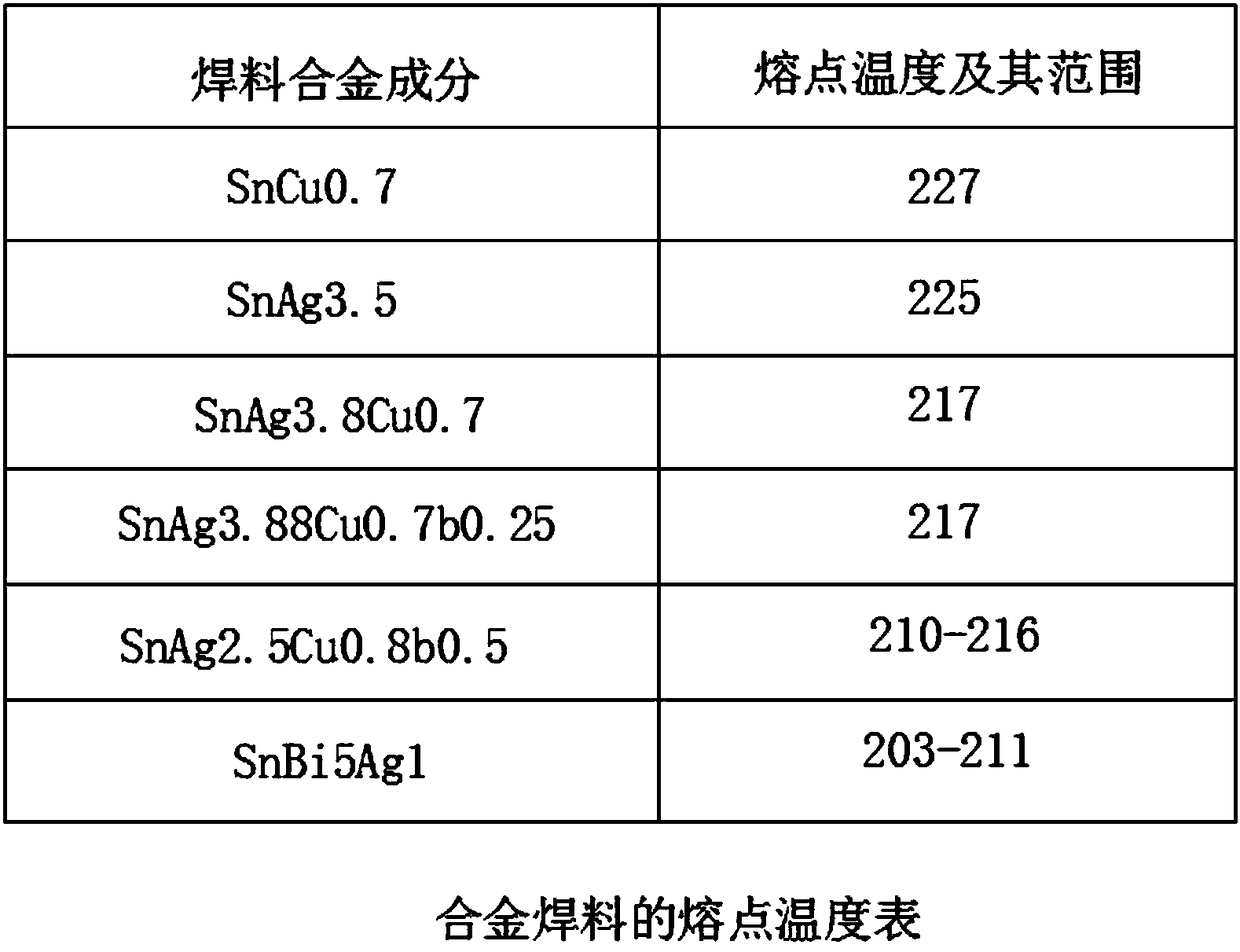

Chip type exploding foil component and production method for same

ActiveCN103868417ASimple structureProduct quality consistency is goodAmmunition fuzesSlapper detonatorCopper foil

The invention discloses a chip type exploding foil component and a production method for the chip type exploding foil component. The chip type exploding foil component comprises exploding foils, flyers and electrodes, wherein the flyers are adhered to the exploding foils; the electrodes are welded on the exploding foils; the exploding foils are rectangular, are arranged on a substrate in an array, and are formed in a scribing way; the electrodes are punched copper foils; the flyers adopt thermoviscous polyimide thin films, and are manually adhered in batches; soldering tin is coated in batches by a small-sized hand-operated screen printer; the exploding foil component is automatically welded in batches in a programmed way by a pulse hot-pressing reflow soldering machine. The chip type exploding foil component belongs to an explosion part of an inline slapper initiator; due to the adoption of chip design, the exploding foil component is simple in structure and favorable for the popularization and application of a slapper detonator, and is suitable to be automatically produced in batches, and a product is high in quality consistency and production efficiency and low in cost.

Owner:INST OF CHEM MATERIAL CHINA ACADEMY OF ENG PHYSICS

Full-automatic, rapid and efficient multi-color rotation hook face silk screen printing machine

The invention discloses a full-automatic, rapid and efficient multi-color rotation hook face silk screen printing machine. The printing machine comprises a control panel, a printing product lifting workbench, a mechanical arm system, a product tool position clamping system and a silk screen control system. Multiple silk screen printing plate control systems and multiple printing scraper control systems are included, wherein product rotating and face changing, printing product lifting workbench driving, surface photoelectric dust removal treatment, a feeding and discharging industrial robot and the arm action of a product transferring mechanical arm system are controlled by a servo motor and a high-precision screw-nut pair, and walking position control is accurate. The full-automatic, rapid and efficient multi-color rotation hook face silk screen printing machine can conduct multi-color silk screen printing on round bottles, double faces of oval bottles and multiple faces of square bottles, a printing product can be closely attached to a silk screen printing plate to be printed through the movement of the lifting workbench in the vertical direction, the horizontal movement of the silk screening printing plate and scrapers and the product rotation movement. The silk screen printing machine is good in printing effect, bottle replacing is convenient, the period is short, and efficiency is high.

Owner:广州市申发机电有限公司

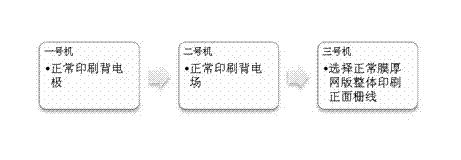

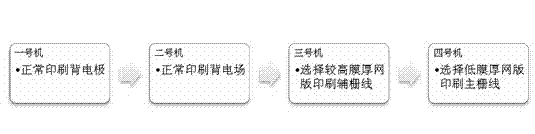

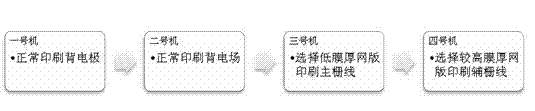

A secondary overprinting process for front electrodes

InactiveCN102270696AImprove the situation of virtual printingUniform printing pressureFinal product manufactureOther printing apparatusEngineeringSolar cell

The invention discloses a secondary overprinting process of the front electrode, which comprises the following steps: using No. 1 screen printing machine to print the back electrode; using No. 2 screen printing machine to print the back electric field; after the back electrode and the back electric field are printed, the battery The pattern printing of the grid lines on the front side of the chip is completed through the secondary overprinting of the main grid lines and the auxiliary grid lines, that is, the main grid lines and the auxiliary grid lines are printed separately. The present invention adopts the secondary overprinting technology for the grid lines on the front of the cell, without affecting the aspect ratio of the auxiliary grid lines, reduces the height of the main grid lines, improves the printing quality, and reduces the consumption of silver paste, so as to reduce the production cost of the battery sheet. cost and improve conversion efficiency.

Owner:HEFEI HAREON SOLAR TECH

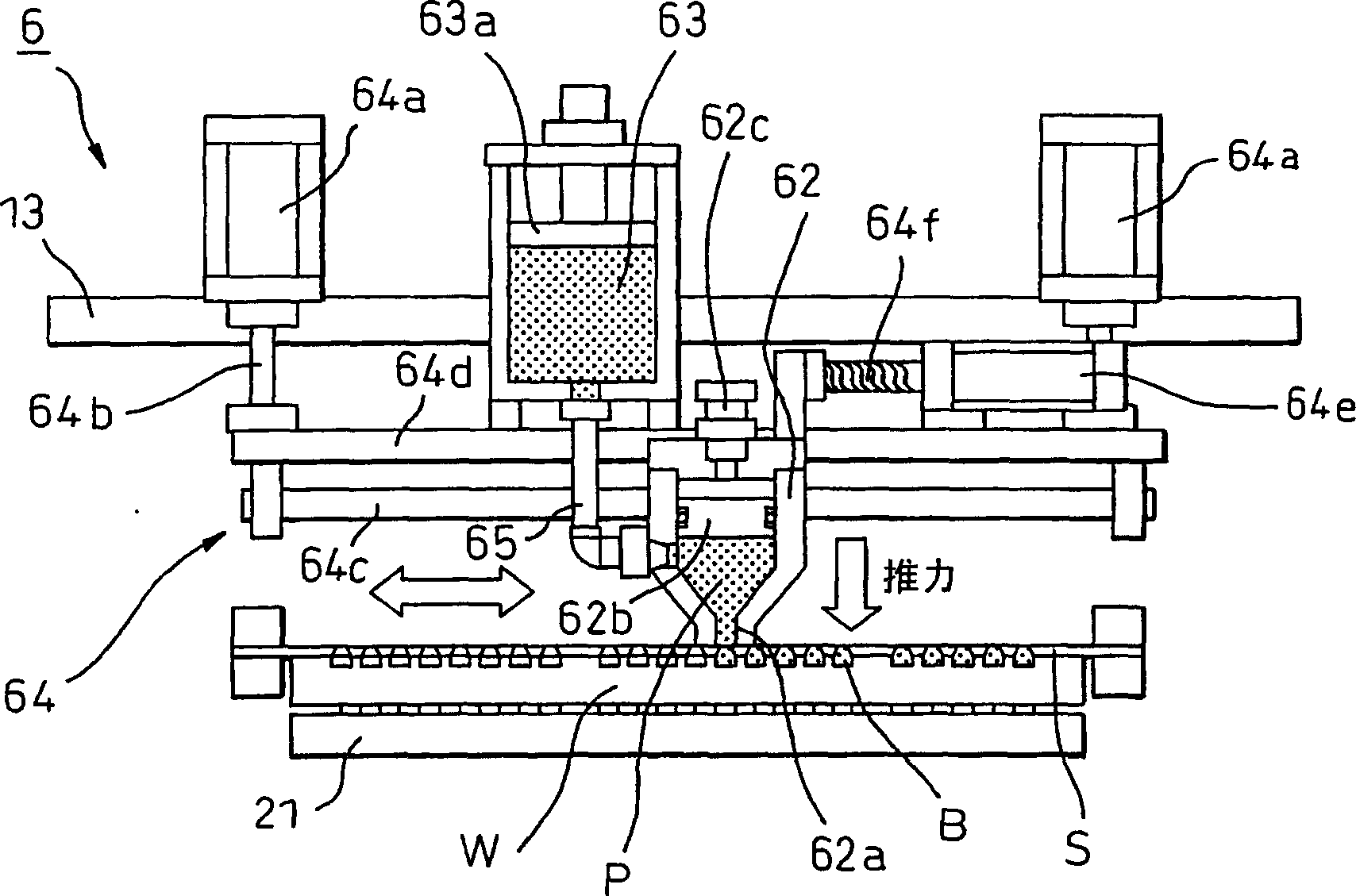

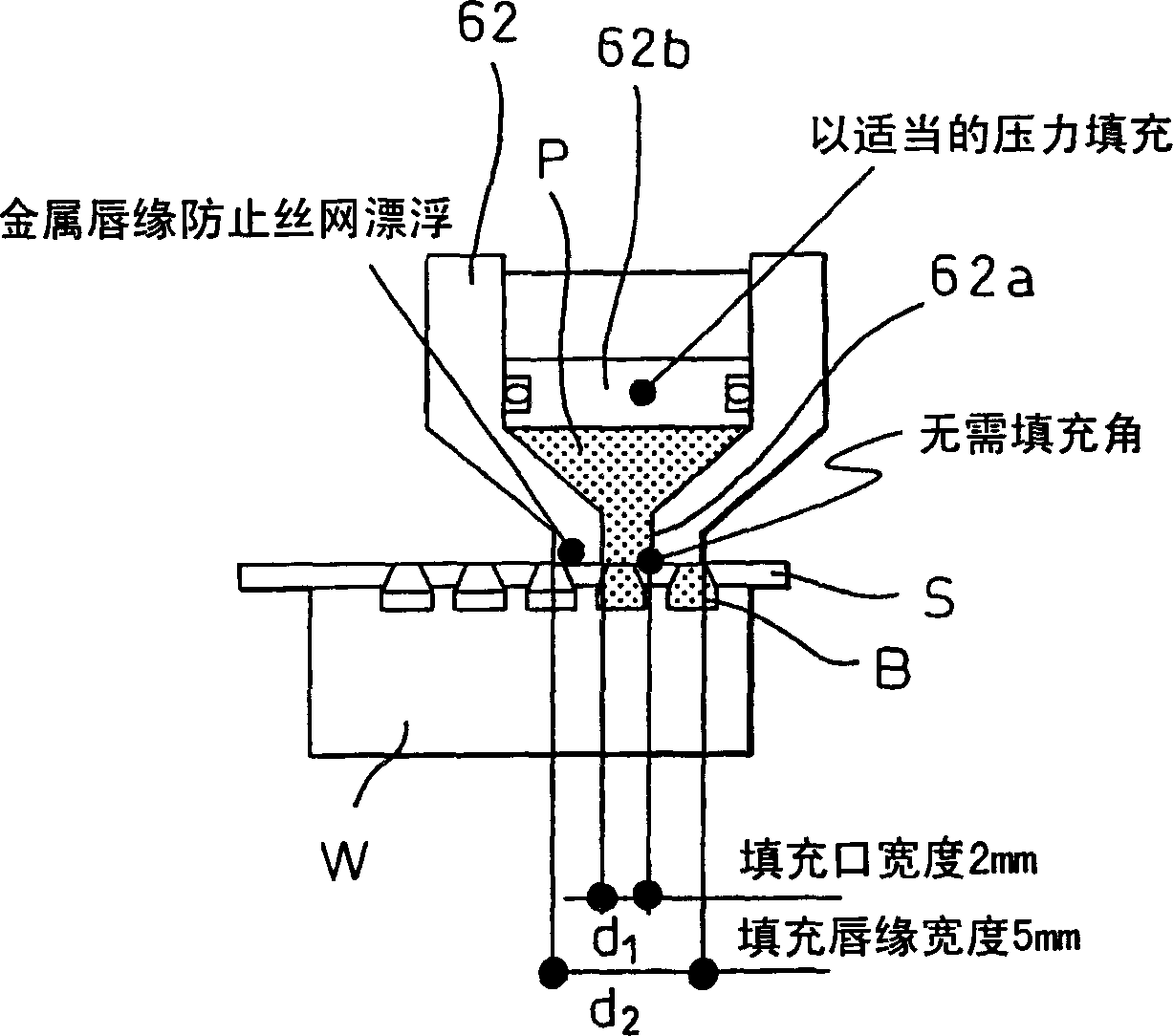

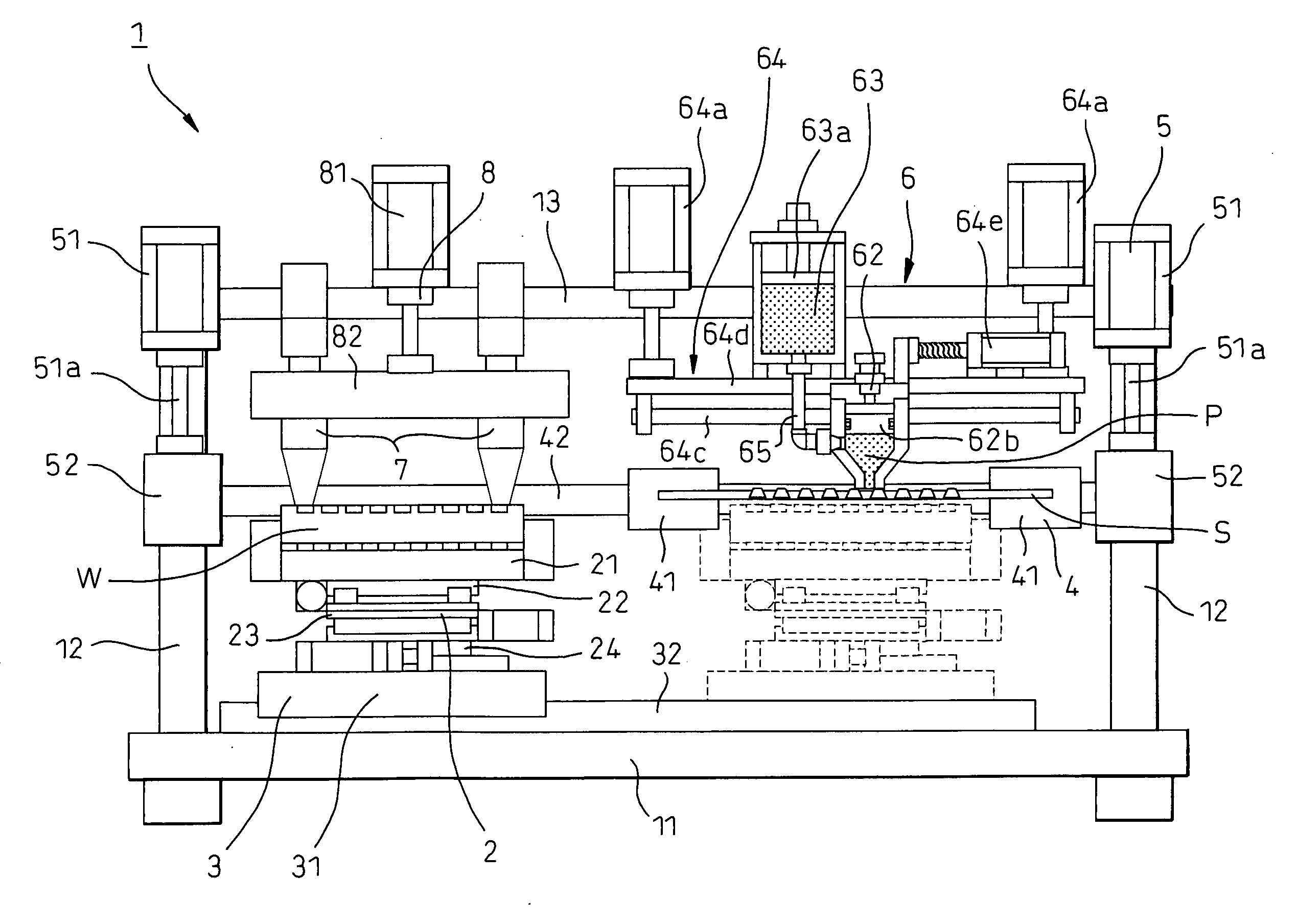

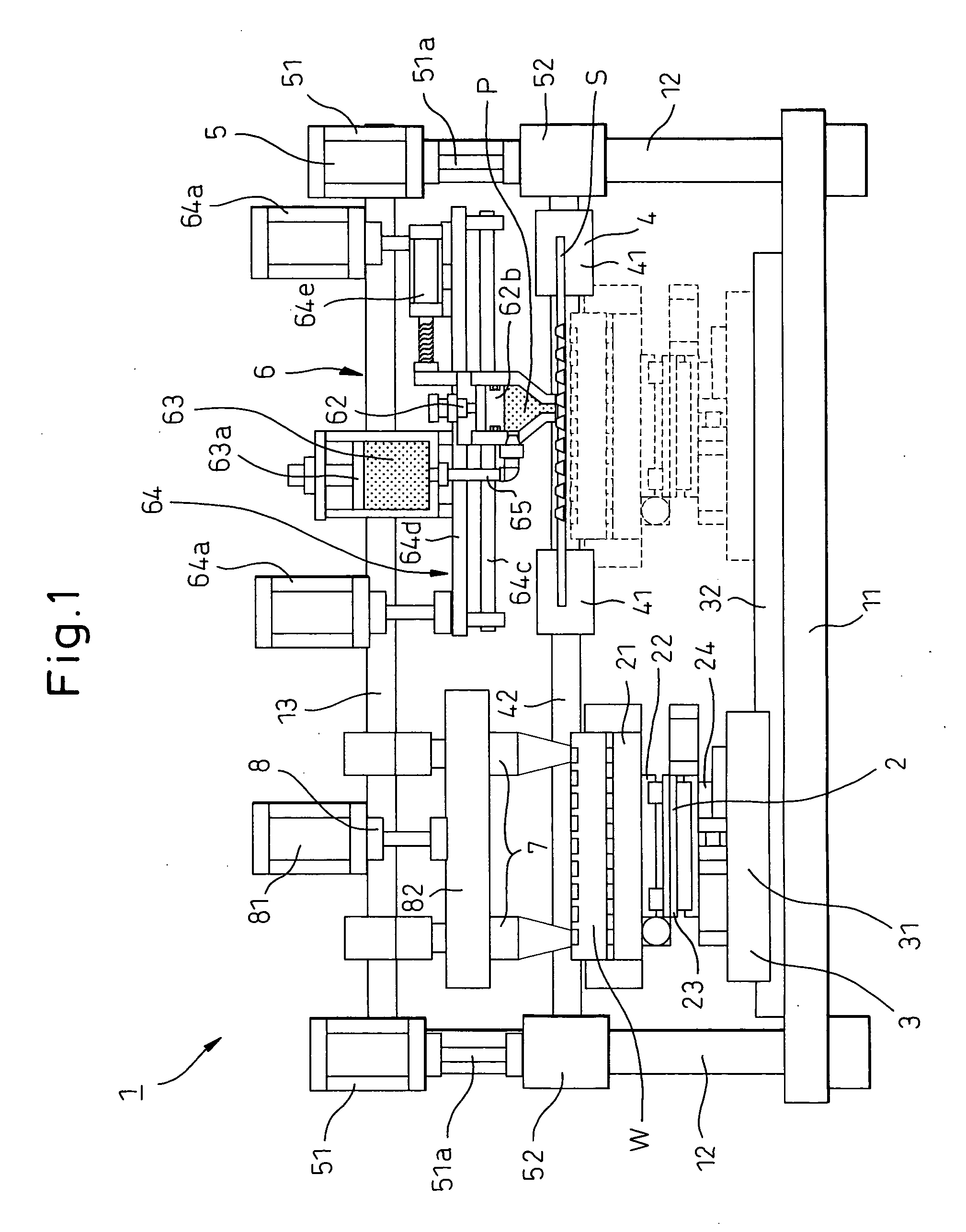

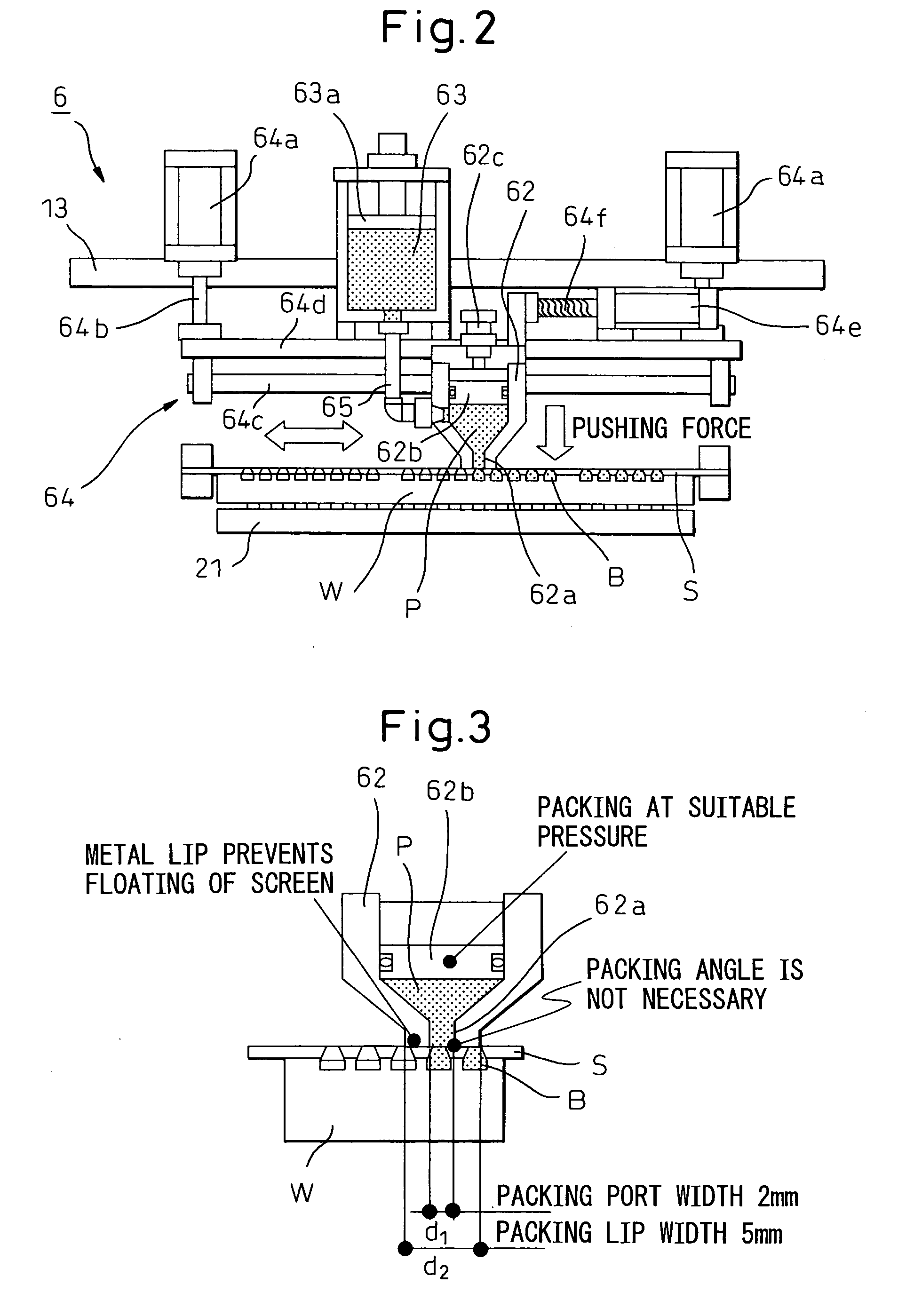

Screen printing machine and printing method thereof

InactiveCN1796109AClose contactSame effectScreen printersConductive pattern formationEngineeringPrinting press

A printing mechanism (6) of a screen printer (1) for printing a paste (P) through a screen (S) onto a workpiece (W) at a printing position comprising: contacting the screen at a distal end A filling nozzle (62), a filling head (62) into which paste consumed during printing is filled, and a feed box (63) for supplying paste into the filling head. There is an extrusion mechanism (62b, 63a) in each of the filling head and the feed box, and the extrusion pressure of the paste to the screen mask can be controlled. The printing mechanism also includes a filling head support mechanism (64), which can support the filling head in such a way that the filling head can move up and down, and can also adjust the thrust of the filling head on the screen.

Owner:DENSO CORP

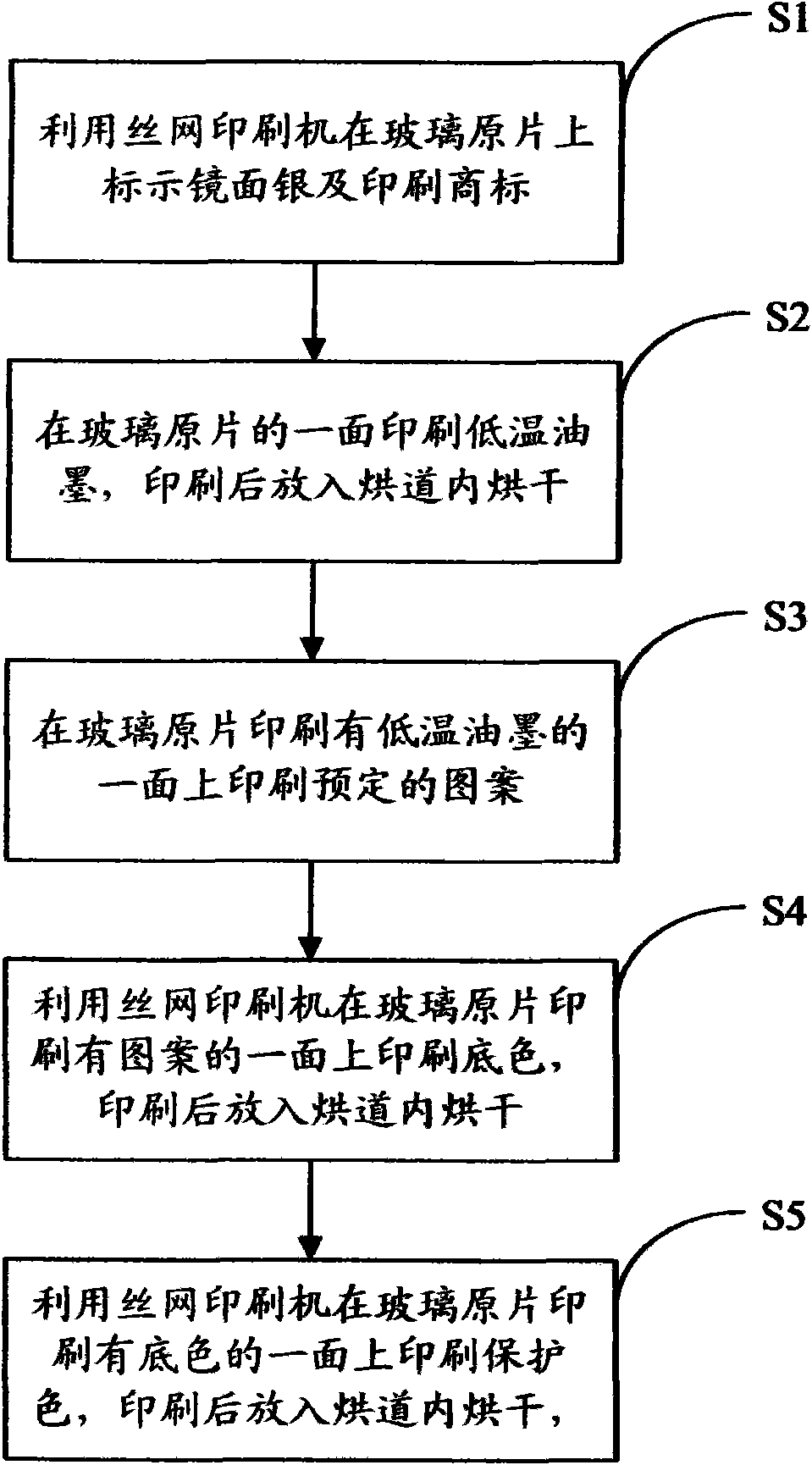

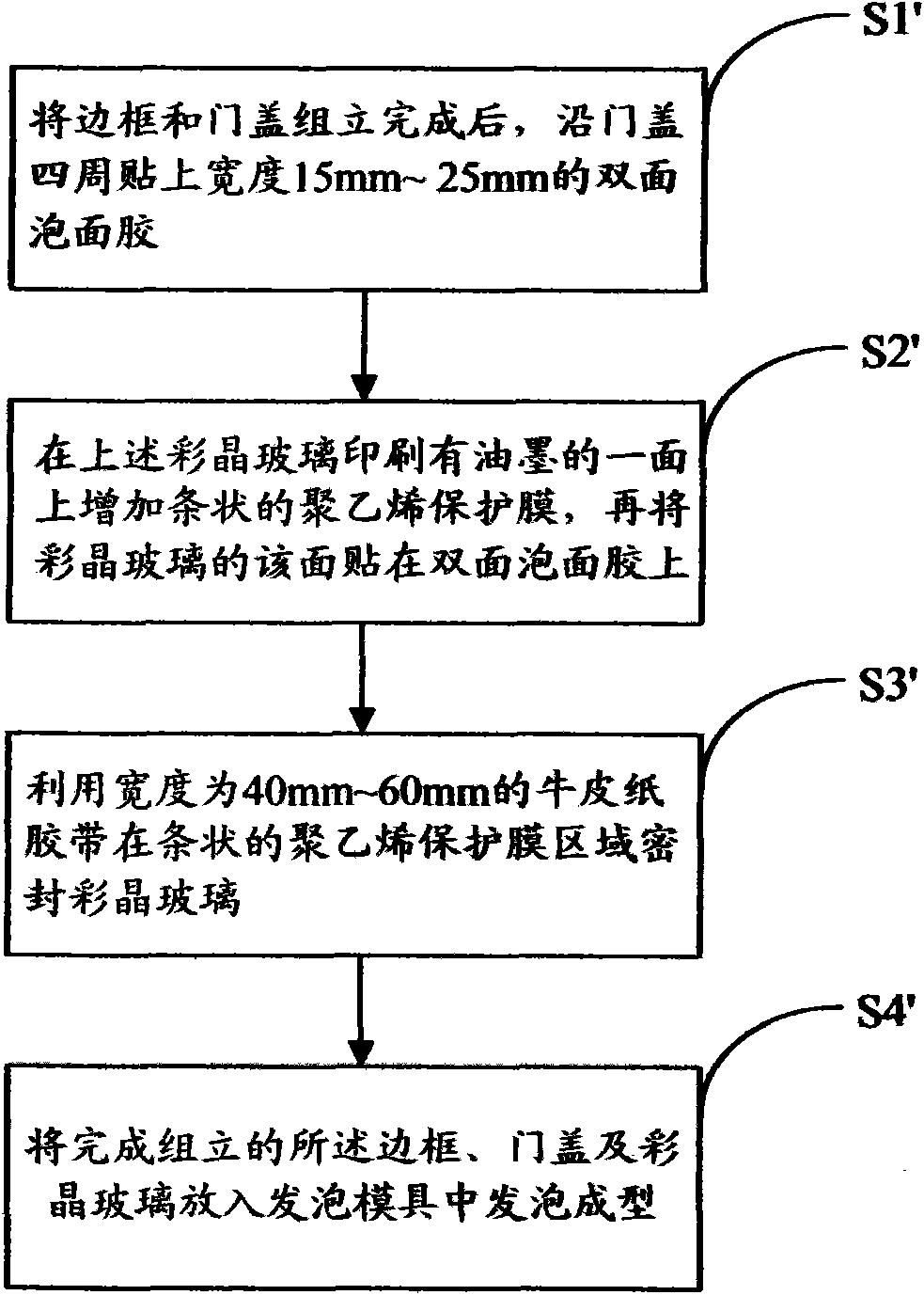

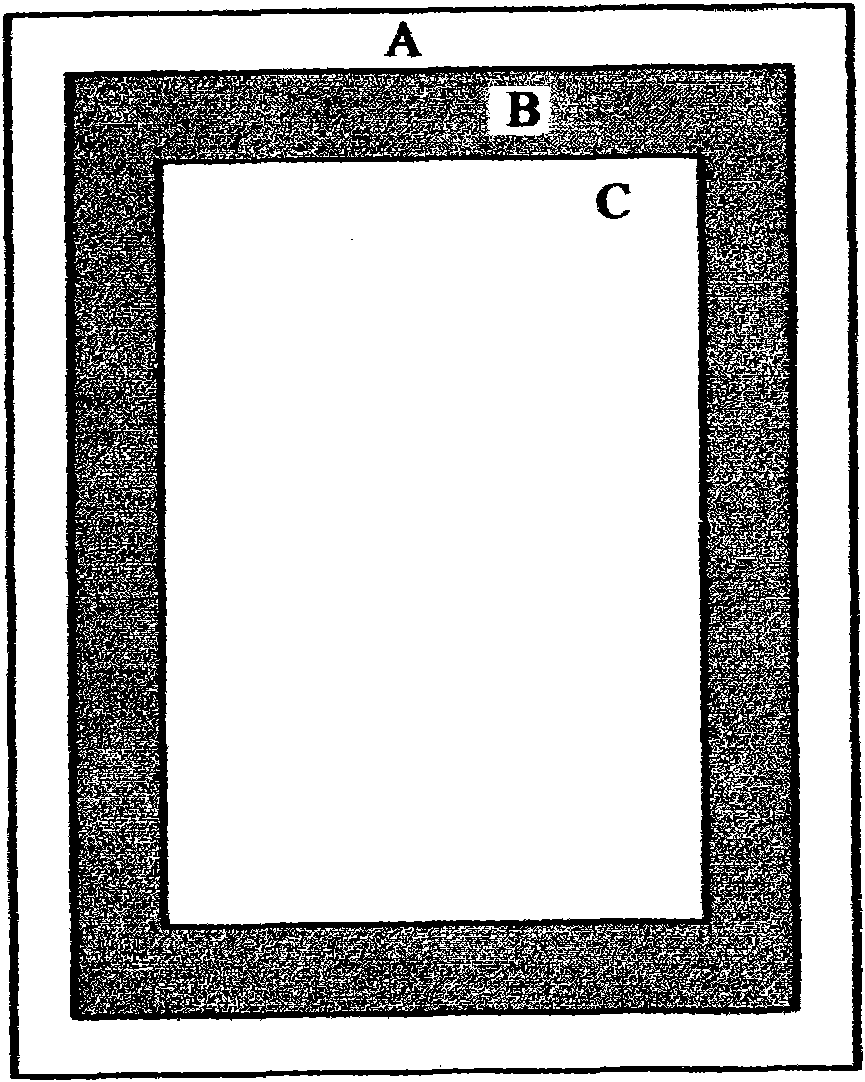

Display glass printing technology and refrigerator door shaping method using finished products formed thereby

InactiveCN101941337AArea maximizationAchieve frameless designDomestic cooling apparatusLighting and heating apparatusRefrigerator carPrinting ink

The invention discloses a display glass printing technology, comprising the following working procedures of: S2, printing low-temperature printing ink on one surface of a glass sheet and then putting the printed glass sheet into a drying channel for drying; S3, printing preset patterns on the glass sheet on the surface printed with the low-temperature printing ink; S4, printing a ground color on the glass sheet on the surface printed with the patterns via a screen printer and then putting the glass sheet into the drying channel for drying; and S5, printing a protective color on the glass sheet on the surface printed with the ground color via the screen printer and then putting the glass sheet into the drying channel for drying. The invention also relates to display glass obtained through the technology and a refrigerator door shaping method using the display glass. The display glass printing technoogy and the refrigerator door shaping method using finished products formed thereby in the technical scheme of the invention can directly foam the low-temperature printing ink and realize a frameless design of the refrigerator door so that the area of the display glass is maximized.

Owner:江苏元隆电器有限公司

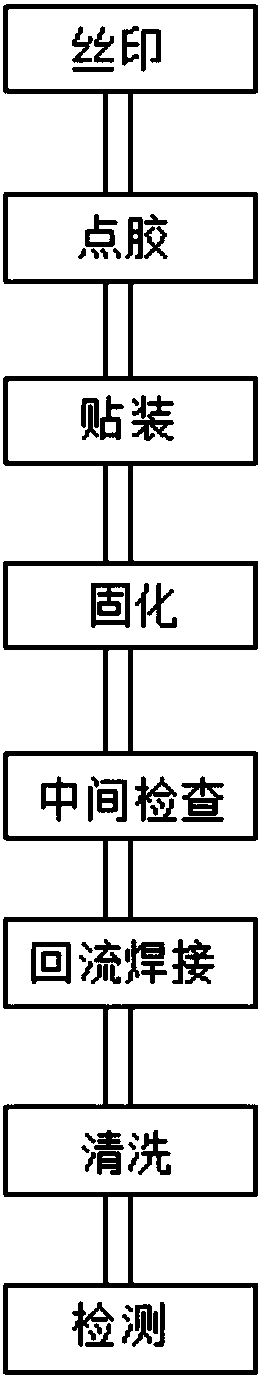

SMT patching process

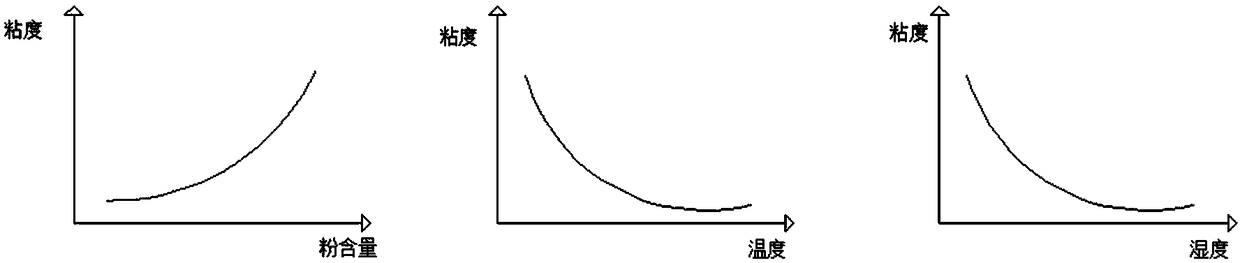

InactiveCN108521722AHigh viscosityGuarantee product qualityPrinted circuit assemblingMetallurgical bondingPrinting pressSolder paste

The invention discloses an SMT patching process which comprises the following steps: S1, silk screening: patching a circuit board to the lower surface of a steel screen after an optical camera detectsthat the circuit board is free of errors, then printing soldering paste or patch leaked glue to a welding plate of a PCB through a screening printer to be prepared for welding of components; S2, gluedispensing: dropping glue to a fixed position of the circuit board after the step of silk screening by means of action of a glue dispenser, wherein the electric components are fixed to the circuit board; and S3, pasting: feeding the circuit board after the step of glue dispensing to a chip mounter. The SMT patching process has the beneficial effects that influence of environmental factors is avoided by controlling the environmental factors in the whole process technology well, so that the viscosity of solder paste can be improved; meanwhile, metal powder in the solder paste is changed to overcome the condition that original cooling speed is small and the surface of the solder paste is not steady; and furthermore, the quality of the circuit board is enhanced.

Owner:贵州贵安新区众鑫捷创科技有限公司

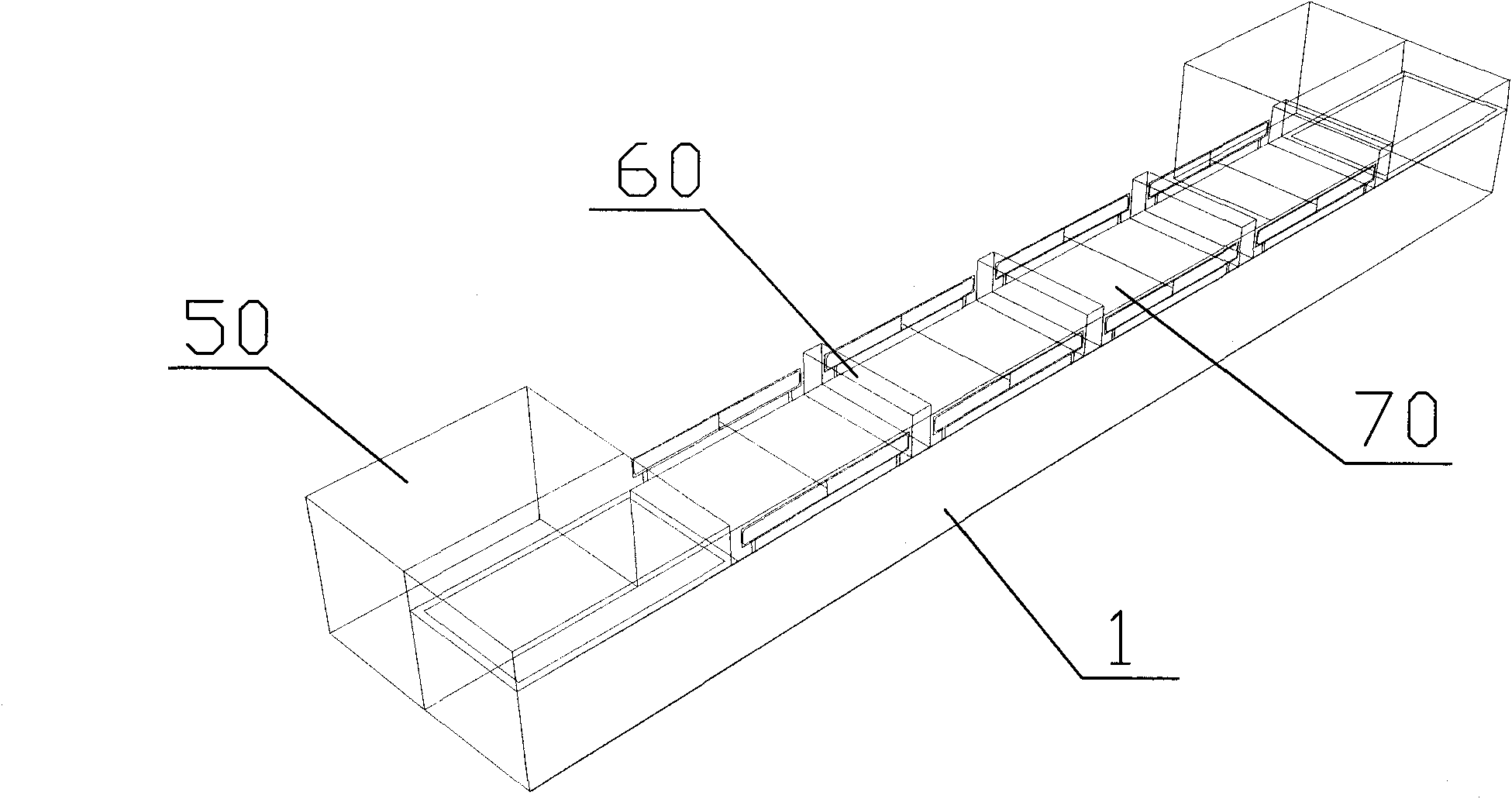

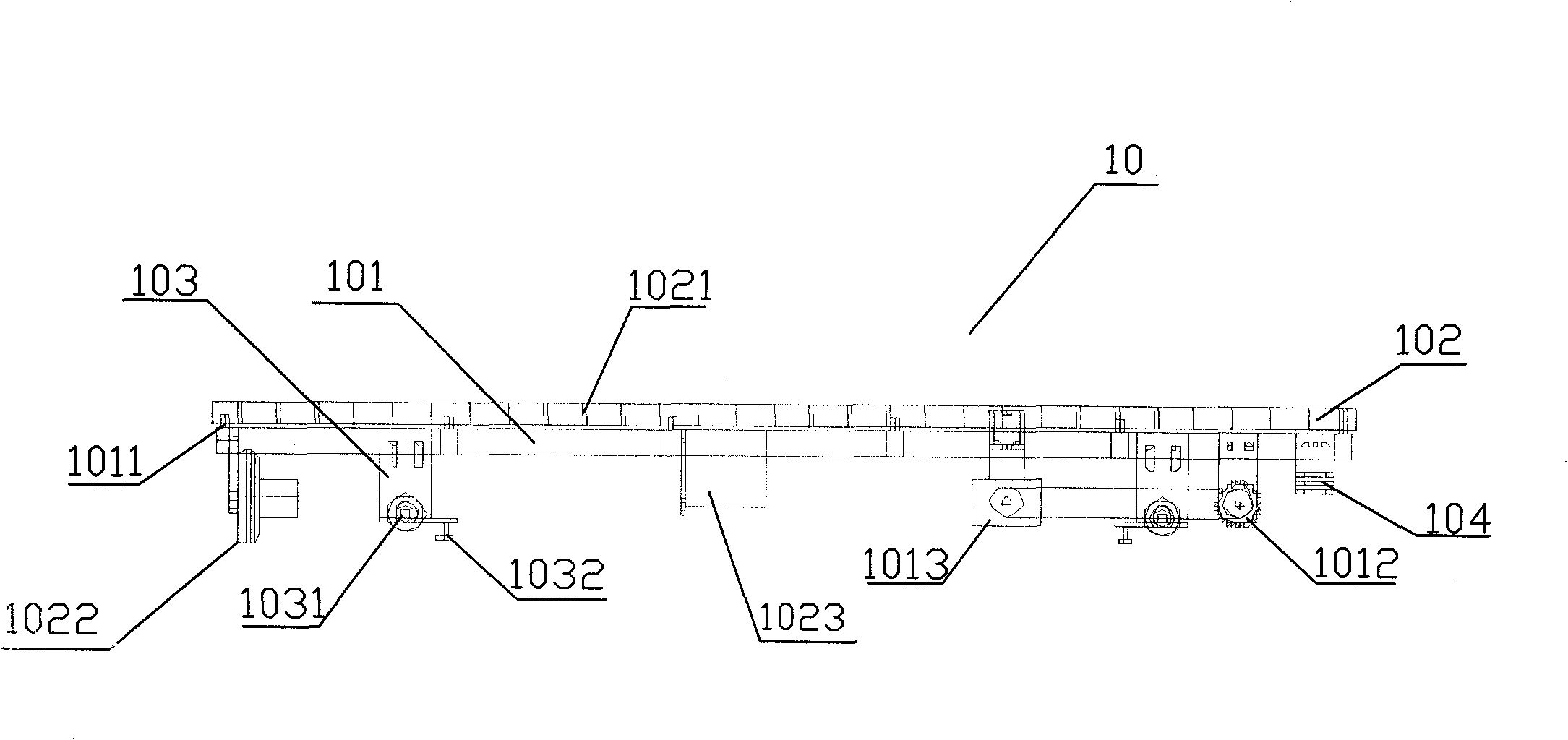

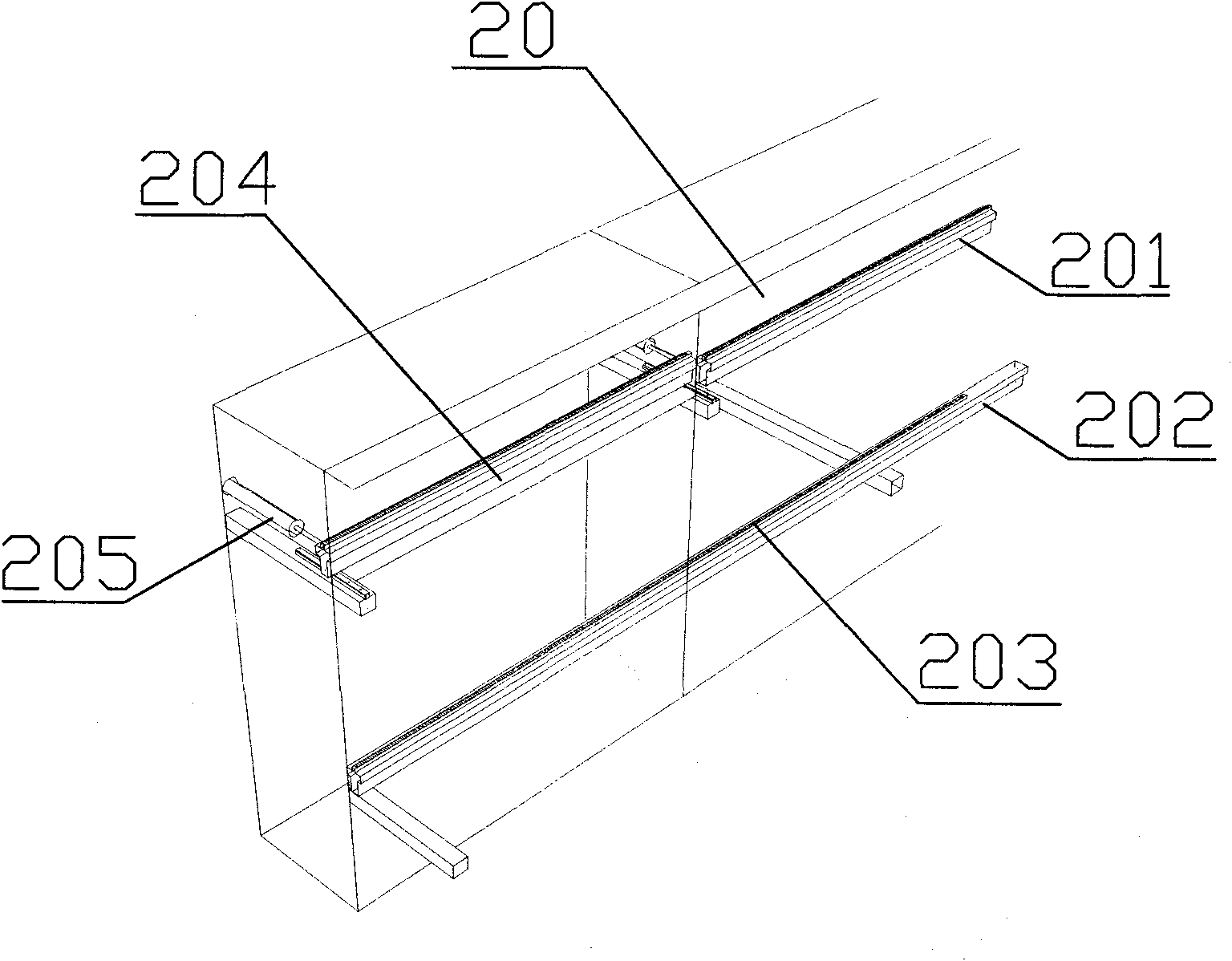

Screen printing machine

InactiveCN101811389AImprove work efficiencyRealize simultaneous workScreen printersAutomatic controlAutomated control system

The invention relates to a printing machine, and provides a screen printing machine. The screen printing machine mainly comprises a machine frame, a plurality of automatically operating air-suction platforms arranged on the machine frame in a movable manner, a plurality of printing devices installed on the machine frame, ink curing and drying devices which are installed on the machine frame and are arranged behind the printing devices, screen printing plate carrying devices which are installed on the machine frame and are arranged opposite to the positions of the printing devices, a turning device installed on the machine frame, a lifting device installed on the machine frame, automatic feeding and reclaiming devices respectively installed at the front and back of the machine frame, a power transmission device used on the automatically operating platforms and an automatic control system for the automatic control in the printing process. By respectively arranging one ink curing and drying device behind each printing device and arranging the turning device and the lifting device, the screen printing machine provided by the invention realizes the simultaneous operation of multiple printing devices, and greatly improves the printing operation efficiency.

Owner:杨国辉

Screen printing equipment and printing system having the same

InactiveCN101318399AReduce distortion distortionStable thicknessPrinted circuit assemblingScreen printersEngineeringPrinting press

The invention provides a silk screen printing device and printing system. In the solder printing system equipped with the silk screen printing device, the invention increases the printing precision of the silk screen printing device while needing to repair the badness not repaired in the system even having printing badness in the silk screen printing device so as to improve the production efficiency of the product. Such that the printing device used in the printing of the silk screen printing device is made in the structure of using the metallic printing device having two stage elasticity and in the structure of the checking unit for checking the printing state after printing and the distributor unit of repairing the badness of the printing substrate according to the checking result, and using the system reflected in the next substrate by using the result sent to the silk screen printing device.

Owner:HITACHI LTD

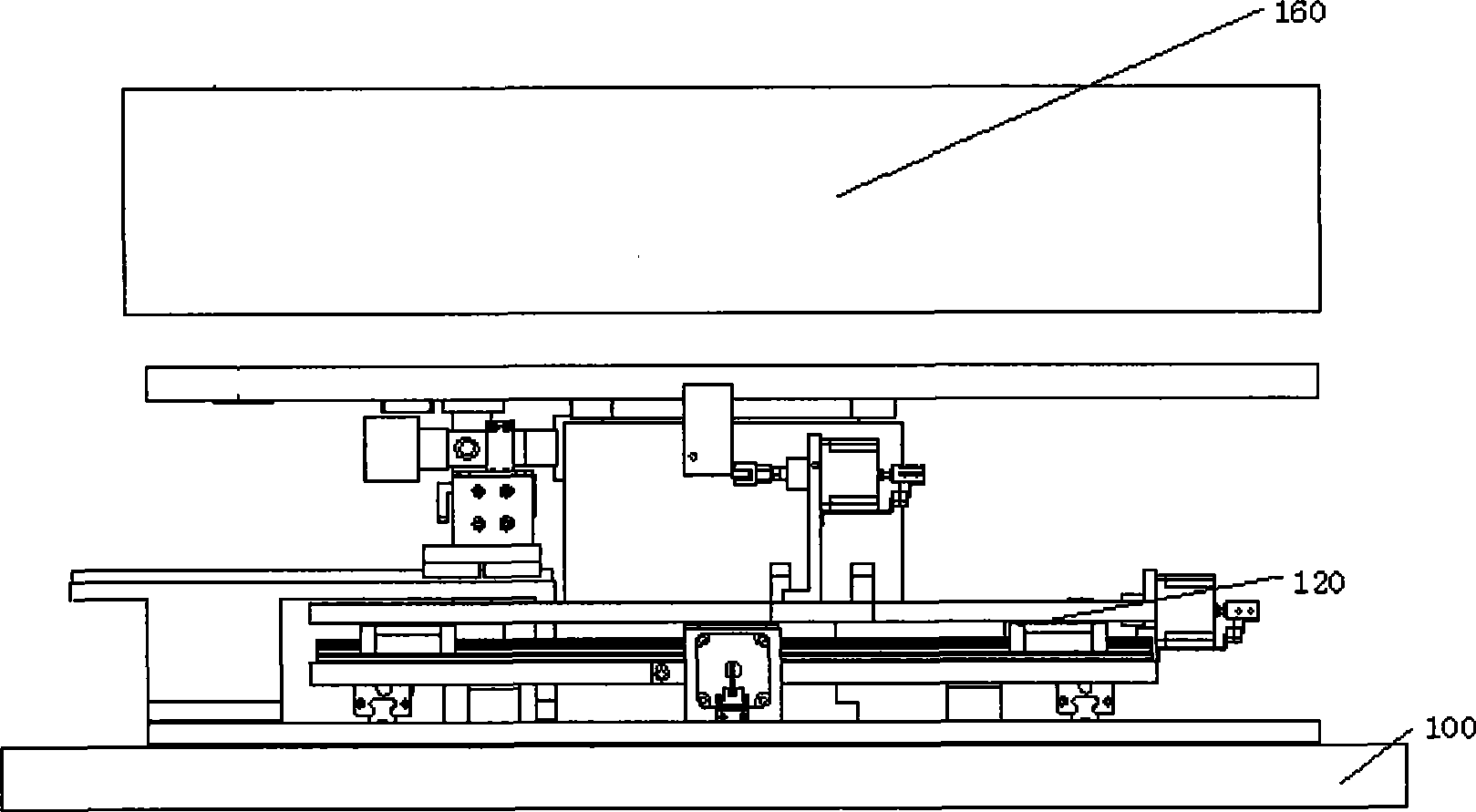

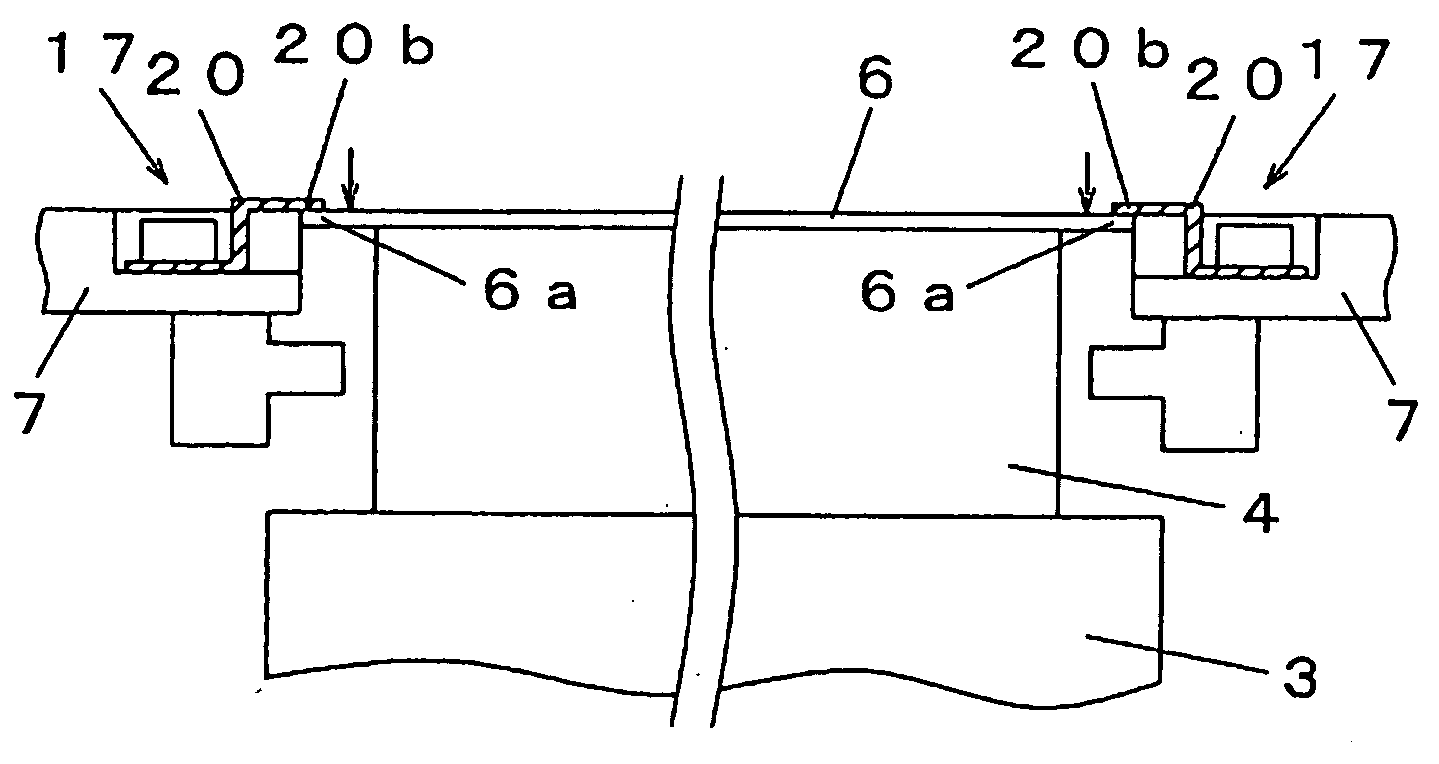

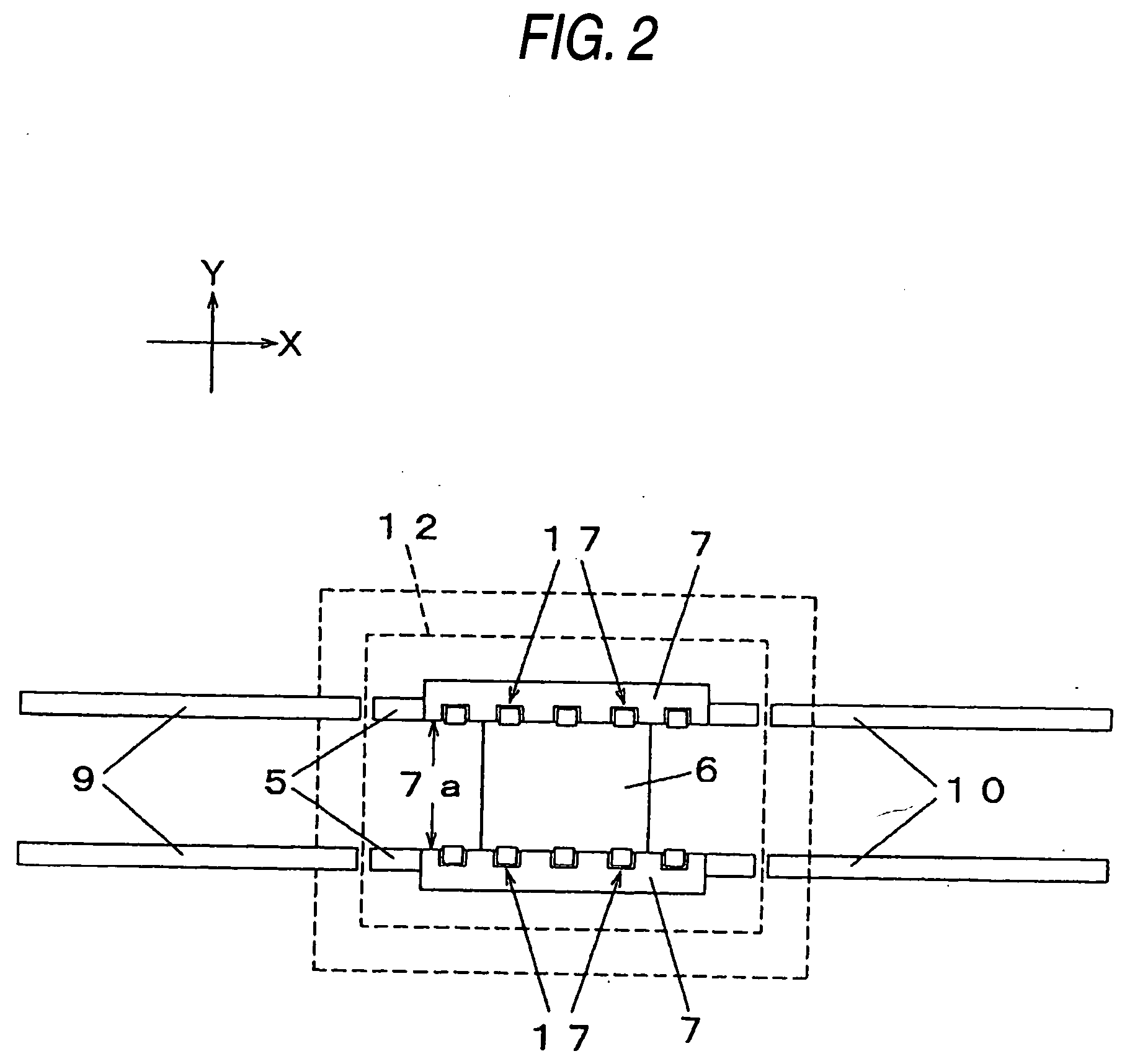

Screen printer

ActiveUS20050155501A1Reliable holdSimple and cheap mechanismPrinted circuit assemblingLiquid surface applicatorsEngineeringSilk-screen printer

In the screen printer for printing paste to the substrate through a pattern hole by abutting a mask plate on the substrate, the end face of a side end portion of the substrate 6 is nipped and held from its both sides by a clamper 7. A warp correcting portion 17 mounting a warp-correcting member 20 constructed by a plate-shaped resilient metal is arranged in the clamper 7. When the substrate 6 held to a substrate holding portion of a Z-axis table 4 is clamped, a free end portion 20b of the warp correcting member 20 is abutted on the upper face side of the side end portion 6a of the substrate 6, and the warp deformation of the substrate 6 is corrected by pressing the free end portion 20b downward. Thus, the warp deformation of the-substrate is corrected by a simple and cheap mechanism, and the clamp state can be reliably held.

Owner:PANASONIC CORP

Multi-use pallet with torsion control for a printing machine

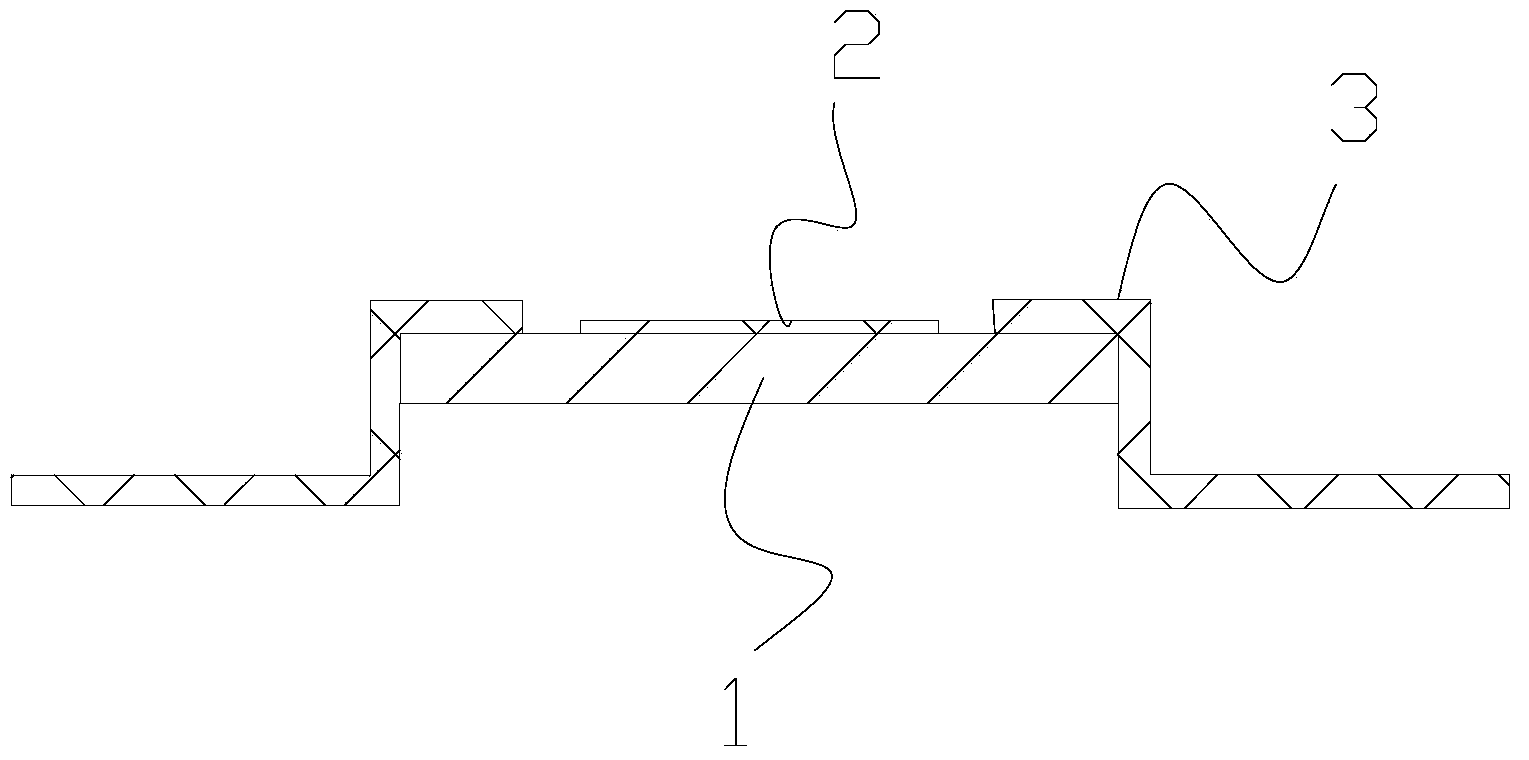

InactiveUS6910419B2Resists deflectionAvoid deflectionLiquid surface applicatorsPlaten pressesEngineeringPrinting press

A pallet (10) for use with a screen printing apparatus having arms (12) extending outwardly from the printing machine supports an article against a printing force supplied by the screen printing machine. A base portion (14) of the pallet (10) is attachable to the arm (12) of the printing machine and includes a support structure extending therefrom to stabilize and reduce deflection against the printing force.

Owner:M&R PRINTING EQUIP

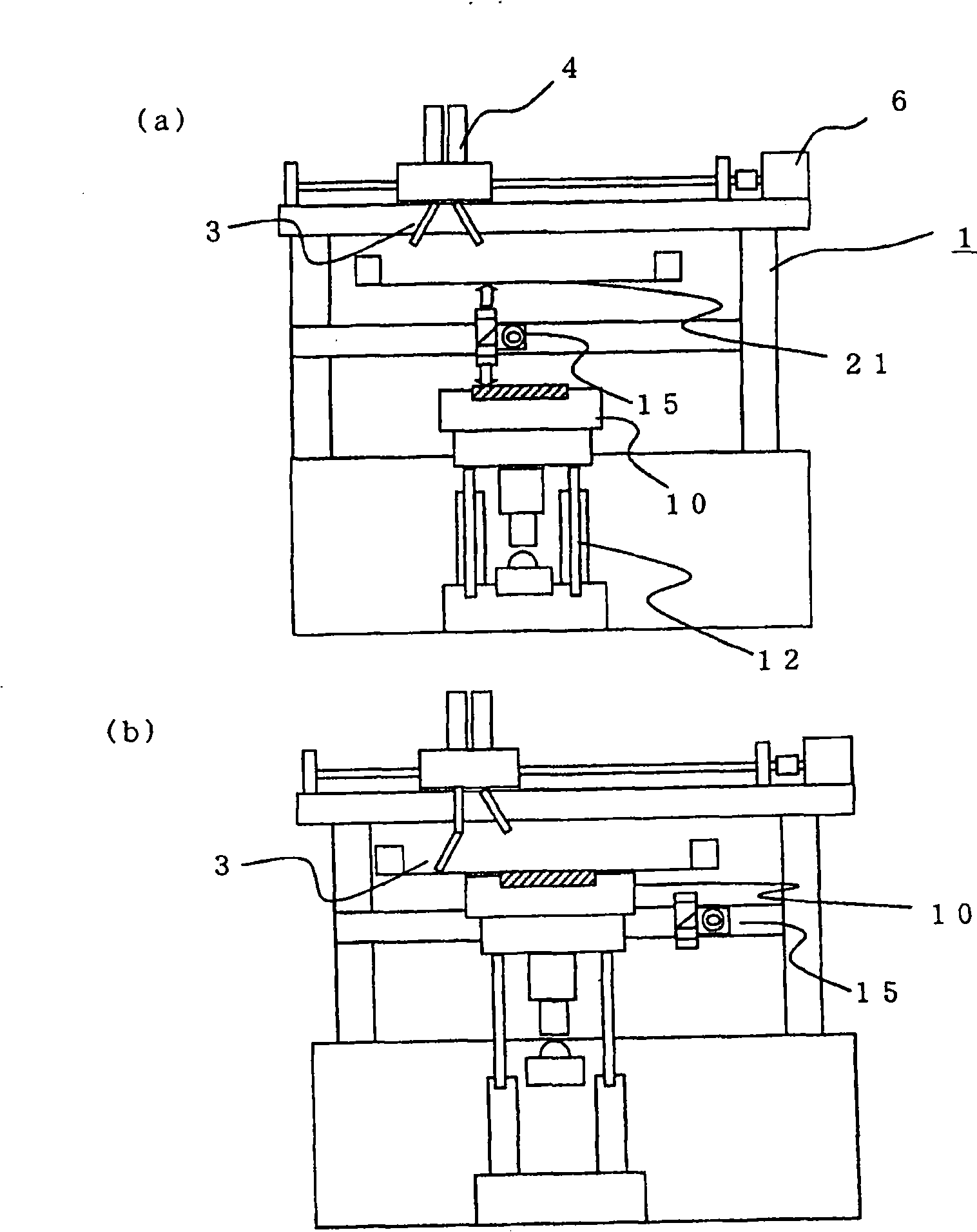

Screen printer and contraposition method for same

ActiveCN102615950AImprove resolutionImprove efficiencyScreen printersPrinting press partsCamera lensEngineering

The invention discloses a screen printer and a contraposition method for the same. The screen printer comprises a screen printer body; the screen printer body is provided with a computer and an XYtheta platform, wherein the computer is electrically connected with the XYtheta platform and can drive the XYtheta platform to move in the X-axis direction, the Y-axis direction and the theta-axis direction; a to-be-printed product placing part is arranged on the upper side of the XYtheta platform; the screen printer body further comprises a light source, a bracket and at least two CCD cameras, wherein the light source is arranged in the XYtheta platform; a light transmitting hole is formed on the edge of the to-be-printed product placing part on the XYtheta platform; the CCD cameras are mounted on the bracket; the camera shots of the two CCD cameras just face the light transmitting hole to enable light emitted by the light source to transmit the light transmission hole to reach the camera shots of the two CCD cameras; and signal output ends of the two CCD cameras are electrically connected with the computer. The two CCD cameras are adopted to conduct the contraposition. The screen printer has the advantages of simple structure, easiness in manufacturing, high contraposition speed and accuracy in contraposition.

Owner:东莞市嘉腾仪器仪表有限公司

Screen printing machine and printing method thereof

InactiveUS20060124003A1High densityImprove rigidityLiquid surface applicatorsInking apparatusEngineeringPrinting press

A printing mechanism 6 of a screen printing machine 1 for printing paste P at a printing position to a work W through a screen S includes a packing nozzle 62 coming into contact, at the distal end thereof, with the screen, a packing head 62 to which the paste consumed during printing is packed and a feed tank 63 for supplying the paste to the filling head. Each of the packing head and the feed tank has therein an extrusion mechanism 62b, 63a and can control an extrusion pressure of the paste to the screen. The printing mechanism further includes a packing head supporting mechanism 64 capable of supporting the packing head in such a manner as to be capable of moving up and down and also capable of regulating the pushing force of the packing head onto the screen.

Owner:DENSO CORP

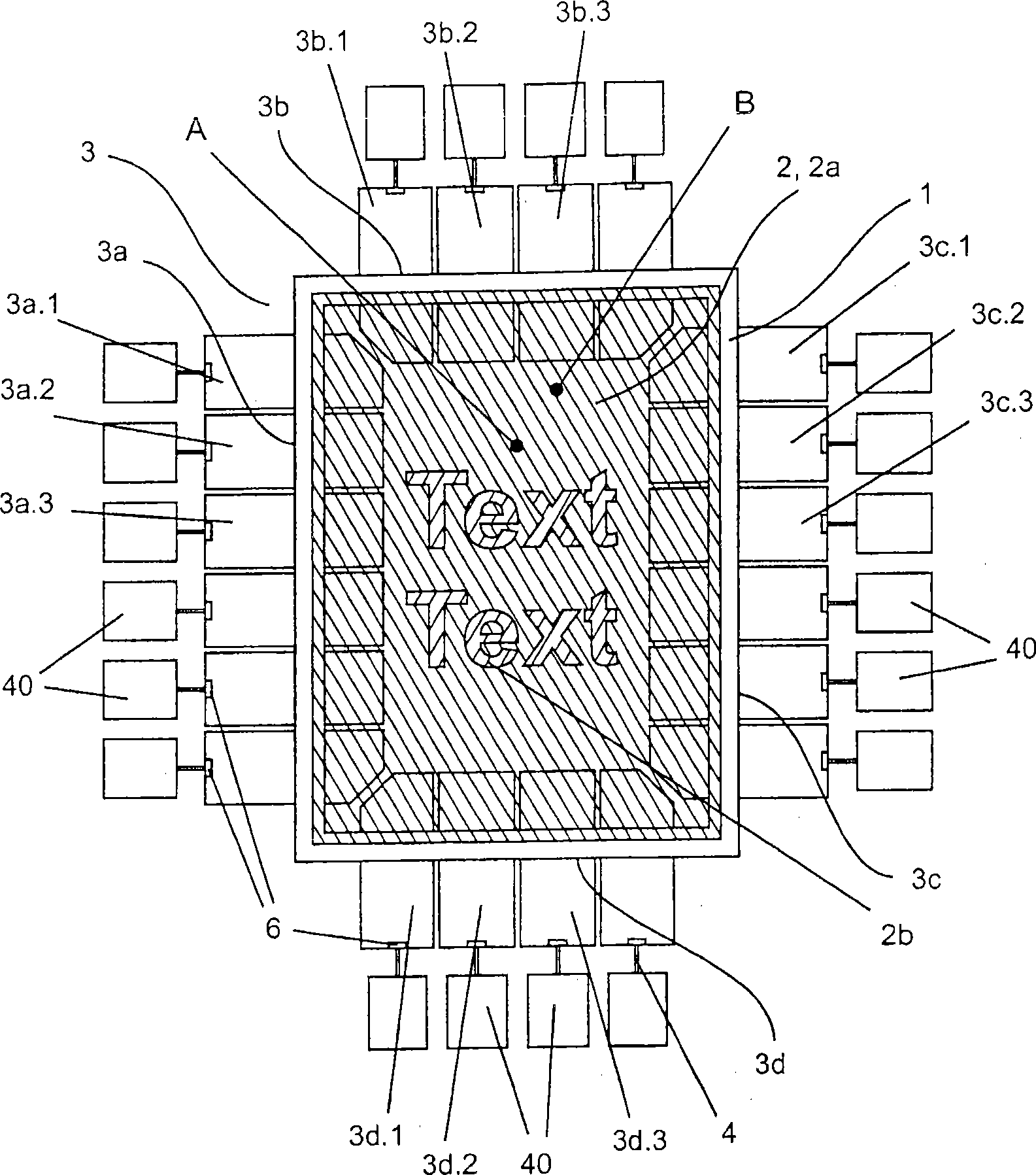

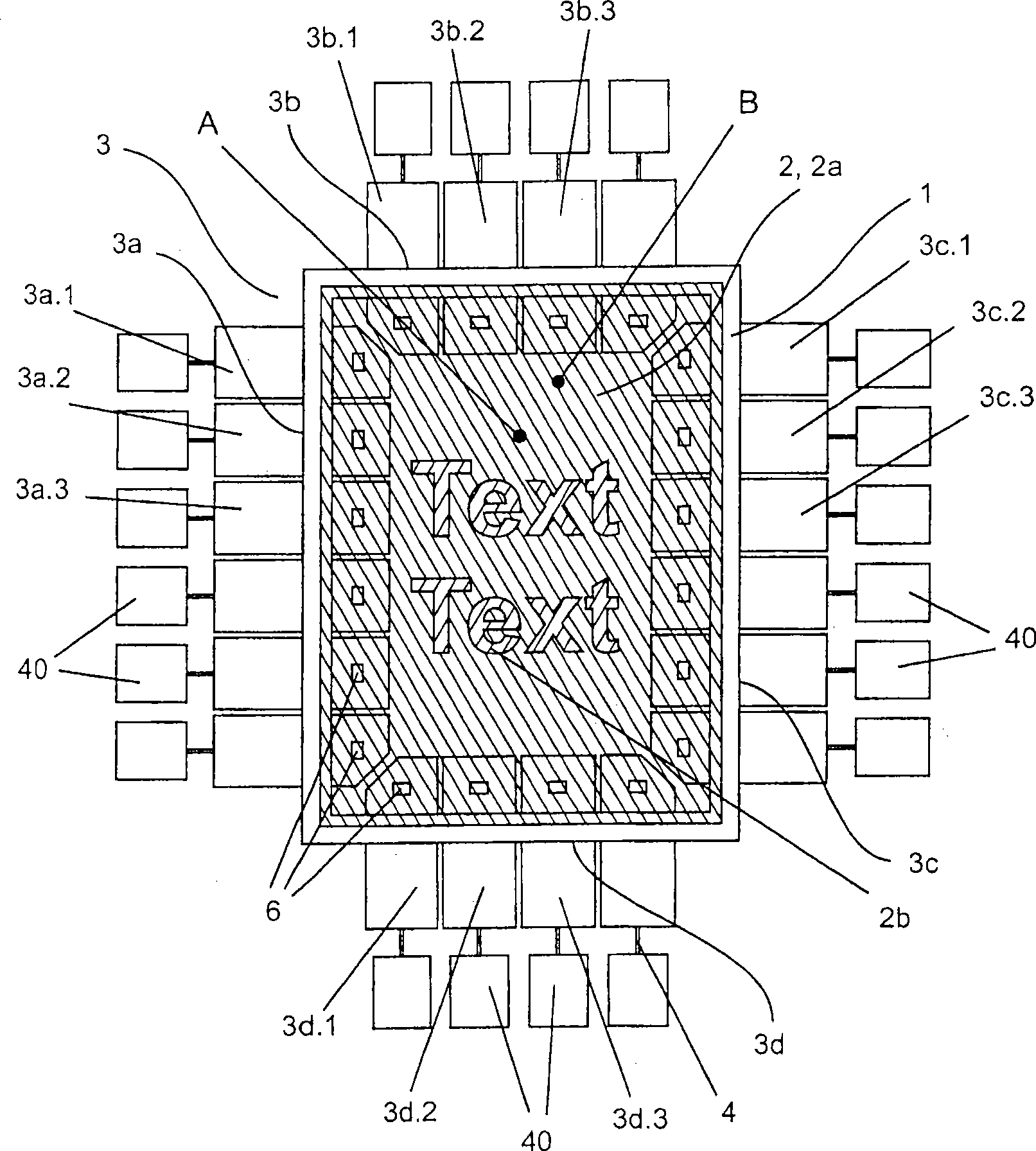

Device and method for measuring the screen tension of the screen fabric in a silk screen frame

InactiveCN101497255AAdjust tensionCompensate for imbalanceScreen printersApparatus for force/torque/work measurementEngineeringTension stress

The inventions relates to an apparatus, in particular for a screen-printing machine, for measuring tension in a printing screen in a frame, characterized in that a holder for the frame (1) has holder bars (3a, 3b, 3c, 3d) each formed of a plurality of sections (3a1, 3a2, . . . , or 3b1, 3b.2, . . . , or 3c1, 3c2, . . . , 3d1, 3d2, . . . , ) each provided with a respective sensor (6) for measuring tension. The invention furthermore relates to a method, in particular for a screen-printing machine, for measuring tension in a screen in a screen frame, characterized in that a screen (2a) mounted in a frame (1) is mounted in a holder (3) having holder bars (3a, 3b, 3c, 3d) each formed by a plurality of sections (3a1, 3a2, . . . , or 3b1, 3b.2, . . . , or 3c1, 3c2, . . . , 3d1, 3d2, . . . ) each provided with a respective sensor (6) that measure forces between the respective section (3a1, 3a2, . . . , or 3b1, 3b.2, . . . , or 3c1, 3c2, . . . , 3d1, 3d2, . . . ) and the frame (1).

Owner:KBA METRONIC AG

Screen printer and component mounting line

InactiveUS20150075721A1Simple configurationReduce the amount requiredInking apparatusLiquid surface applicatorsEngineeringSilk-screen printer

A screen printer includes: a mask having a first area formed with a first pattern and a second area formed with a second pattern; and a print head which forms a past printing on a board and is movable on the mask. When a paste print is formed using the first pattern, the print head moves from a start position located between the first area and the second area to the first area and then returns to the start position. When a paste print is formed using the second pattern, the print head moves from the start position to the second area and then returns to the start position.

Owner:PANASONIC INTELLECTUAL PROPERTY MANAGEMENT CO LTD

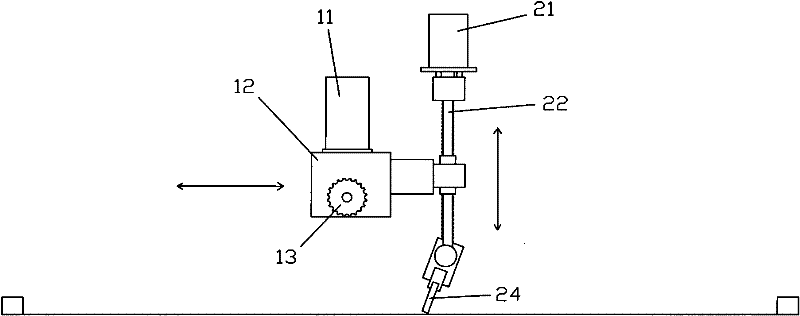

Direct drive screen CNC scraper device

The present invention relates to a screen printing machine, in particular to a direct-drive screen CNC scraper device, which includes a printing stroke unit for controlling the horizontal movement of the scraper and a scraper stroke unit for controlling the vertical movement of the scraper. The scraper stroke unit is controlled by a The connecting piece is arranged on the printing stroke unit; the scraper stroke unit includes a scraper servo motor, the output end of the scraper servo motor is connected with a ball screw, and the end of the ball screw is fixedly connected to the scraper through the scraper connecting piece. Compared with the existing technology, the present invention can adopt full digital control, precise motion control, direct drive of servo motor for motion power drive, eliminating many intermediate transmission parts, simple and reliable mechanical structure; it can be realized by changing the upper motion control code The required printing movement mode is digitized as the reference data of machine production, and the operation and control are easy.

Owner:晋江市联盟服装织造有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com