Method for preparing thin-film positive electrode for thermal batteries

A thin-film positive electrode and thermal battery technology, applied to the electrodes of primary batteries, etc., can solve the problems of difficult control of mixing uniformity, cumbersome preparation process, and low productivity of thermal batteries, so as to achieve great military and industrial application value, simplify the preparation process, The effect of improving stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

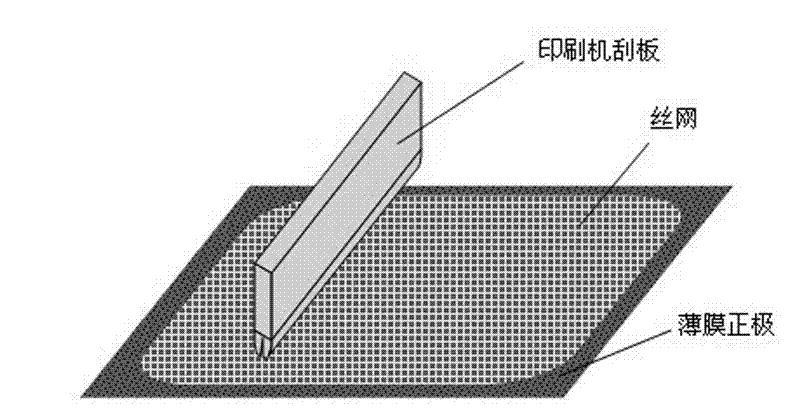

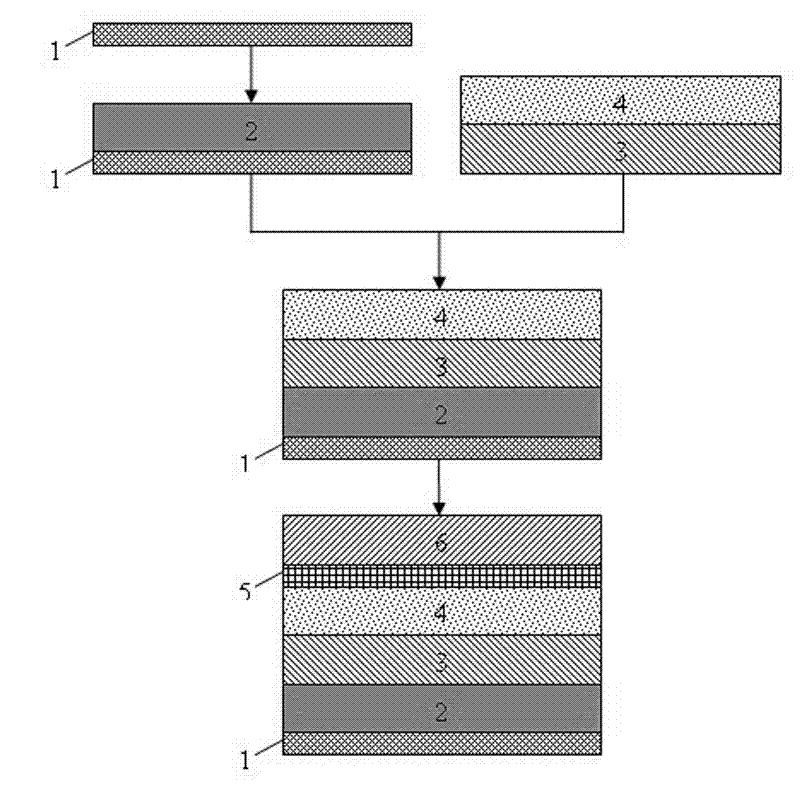

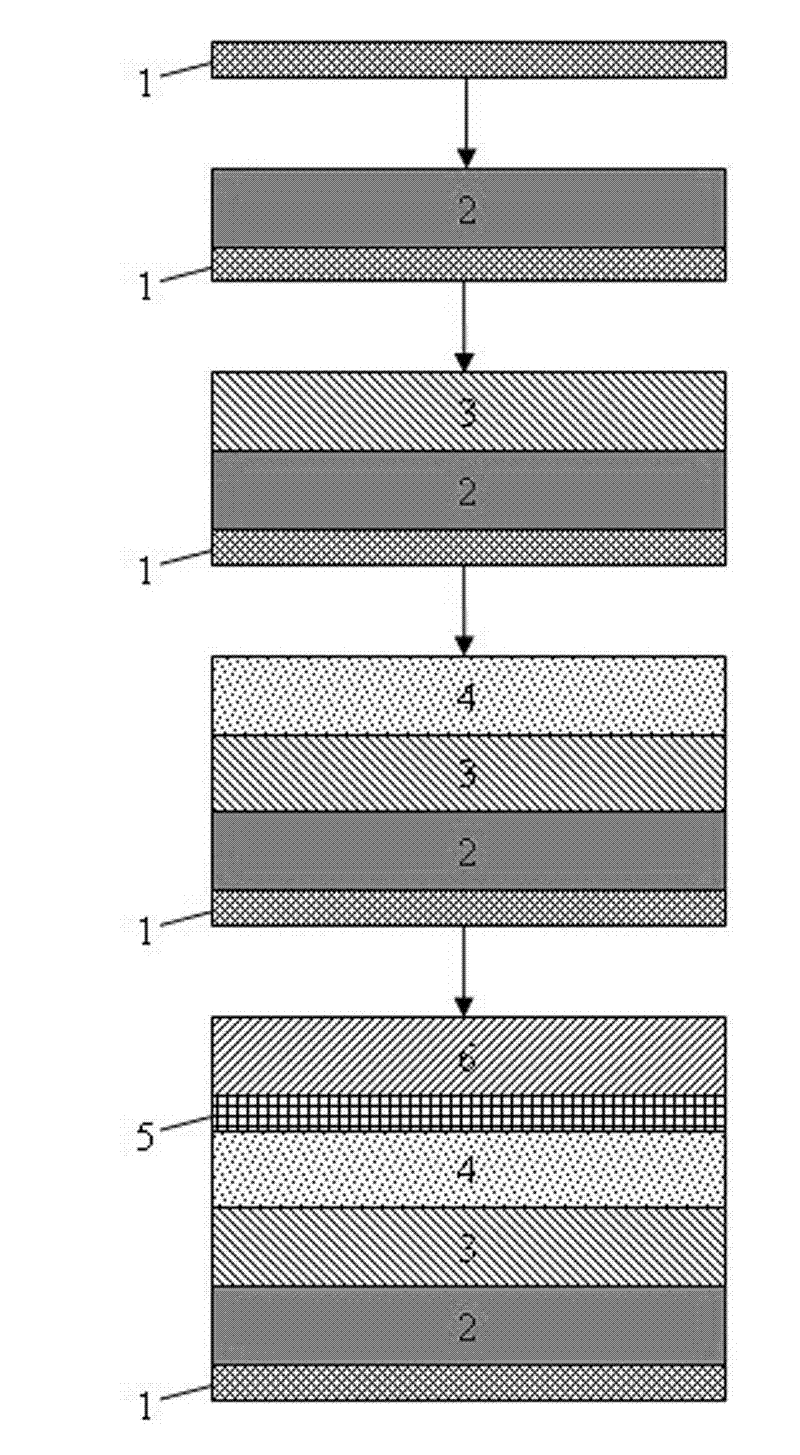

Embodiment 1

[0023] In the positive electrode active material FeS 2 Add 10% LiCl-KCl electrolyte (mass ratio LiCl:KCl=45:55) and 3% carbon nanotubes, mix evenly, add 10ml distilled water, continue stirring for 10min, adjust the viscosity of the mixture to make it a paste with a certain Viscosity, then use a 100-mesh screen printing machine to evenly distribute the paste mixture onto the surface of the porous conductive material, put the substrate covered with the active material into a vacuum drying oven and dry it in vacuum at 250°C for 4 hours to obtain a large-area thermal battery film positive electrode. Under the protection of a dry gas with a relative humidity of 1%, the positive electrode sheet was flat-pressed with an electrode tablet press at 20 MPa, and then punched with an electrode punching machine to obtain several positive electrode sheets with a thickness of 0.4 mm and a diameter of 17 mm.

[0024] Under the protection of dry gas with a relative humidity of 1%, the thermal ...

Embodiment 2

[0027] In the positive electrode active material NiS 2 Add 20% LiCl-KCl electrolyte (mass ratio LiCl:KCl=45:55) and 3% carbon nanotubes, mix evenly, add 3ml distilled water, continue stirring for 10min, adjust the viscosity of the mixture to make it a paste with a certain Viscosity, then use a 100-mesh screen printing machine to evenly distribute the paste mixture onto the surface of the porous conductive material, put the substrate covered with the active material into a vacuum drying oven and dry it in vacuum at 250°C for 4 hours to obtain a large-area thermal battery film positive electrode. Under the protection of a dry gas with a relative humidity of 1%, the positive electrode sheet was flat-pressed with an electrode tablet press at 20 MPa, and then punched with an electrode punching machine to obtain several positive electrode sheets with a thickness of 0.2 mm and a diameter of 17 mm.

[0028] Under the protection of a dry gas with a relative humidity of 1%, the thermal...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com