Patents

Literature

94results about How to "Great industrial application value" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

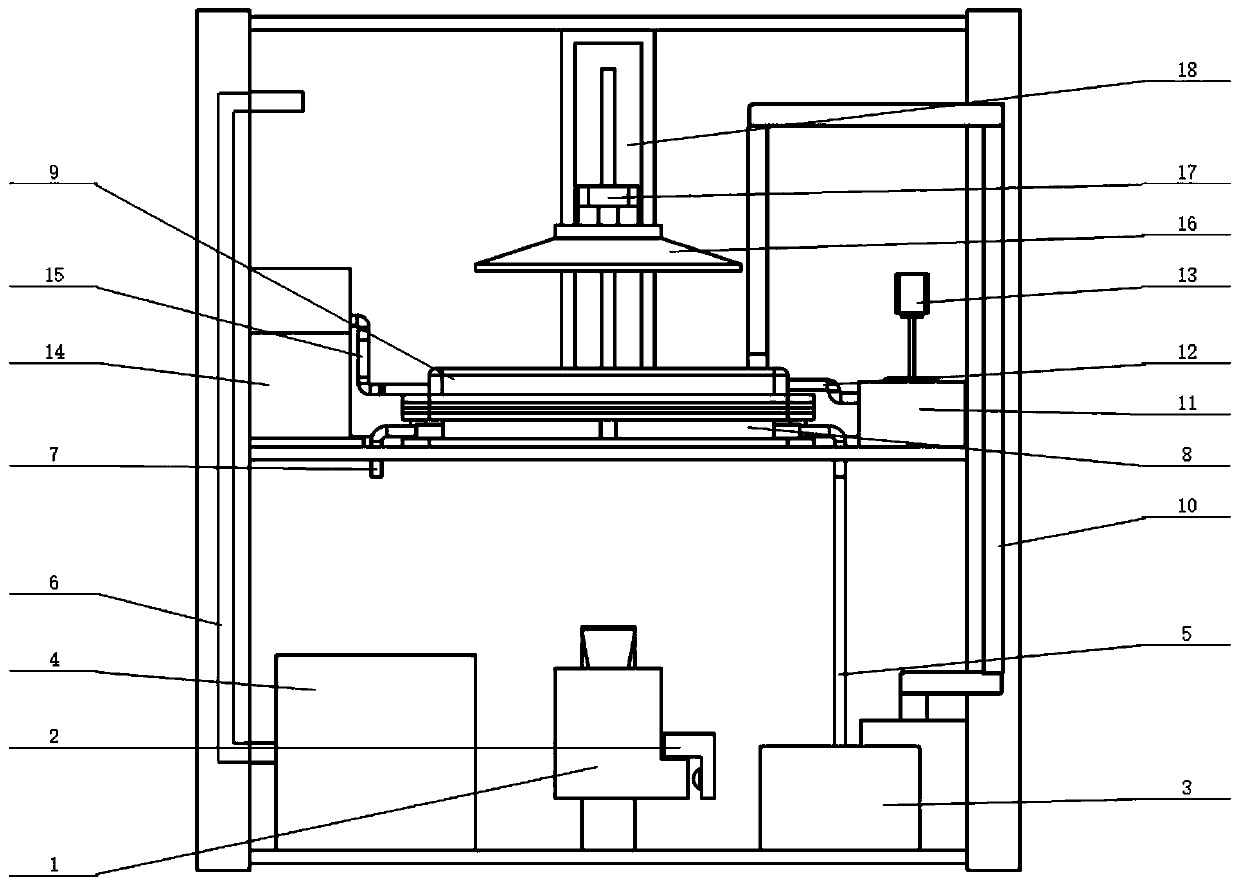

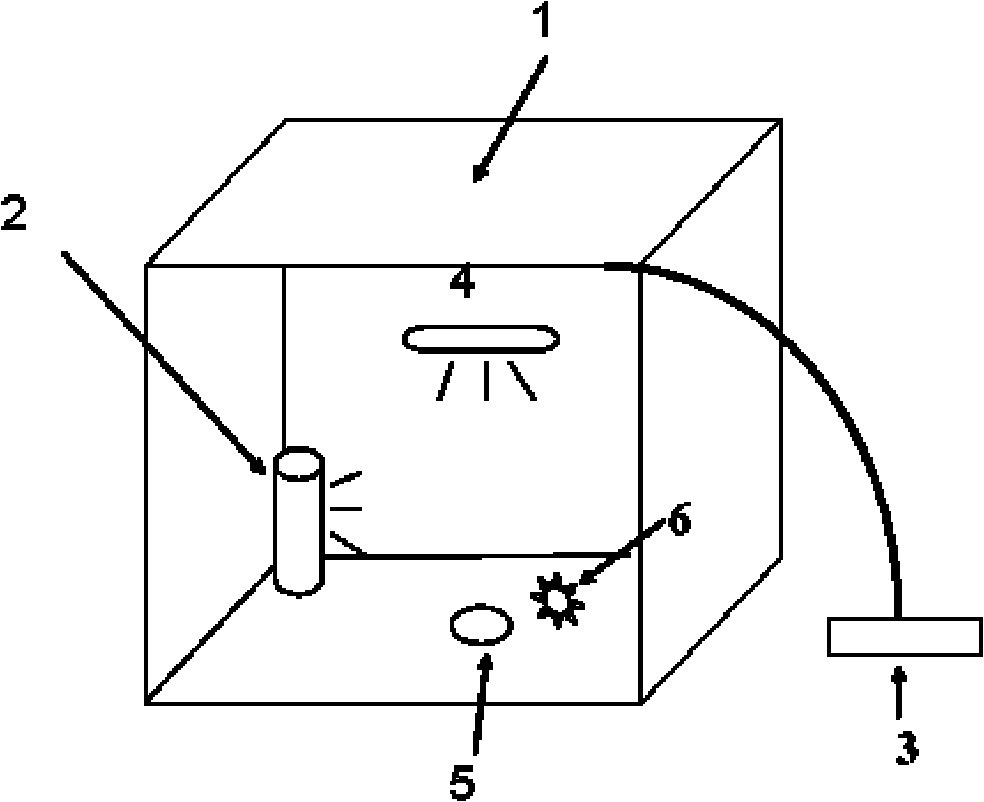

High-speed continuous photocuring type 3D printing device and working method thereof

ActiveCN106426915ALow costEfficient continuous printingManufacturing irradiation arrangementsManufacturing material handlingLiquid surfacesOxygen rich

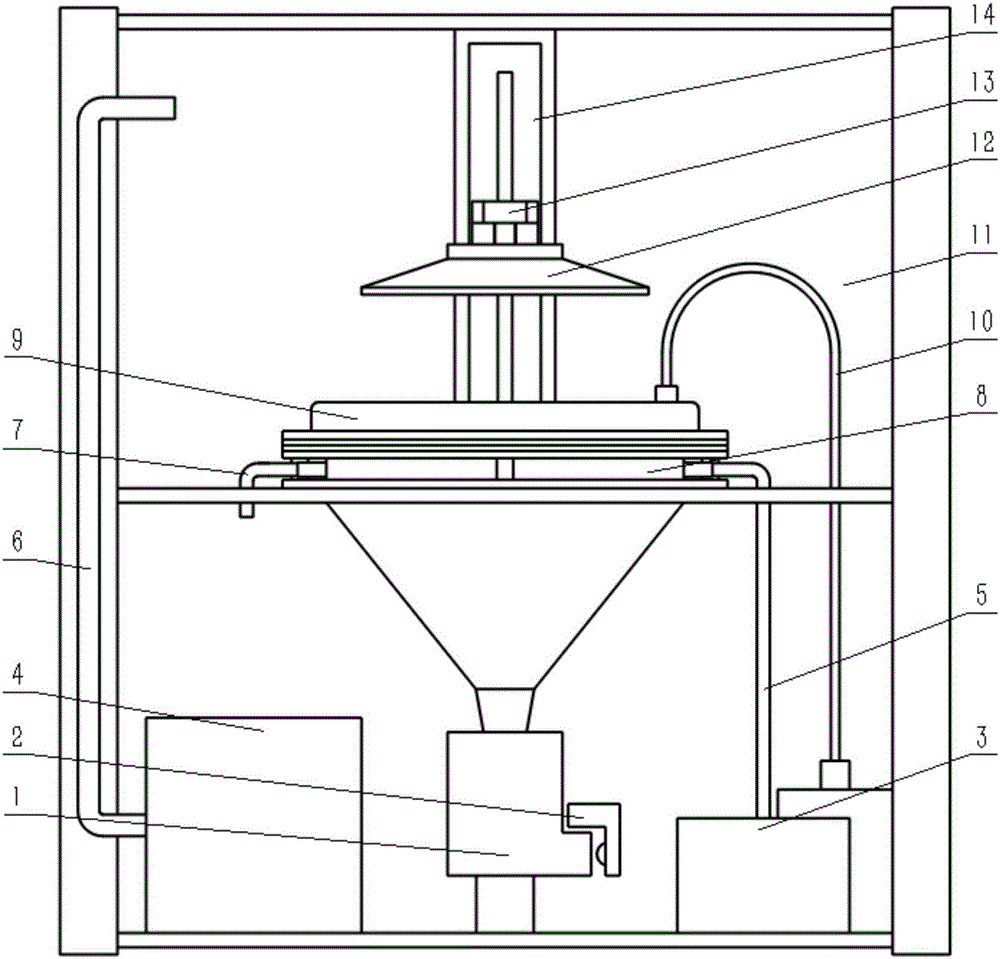

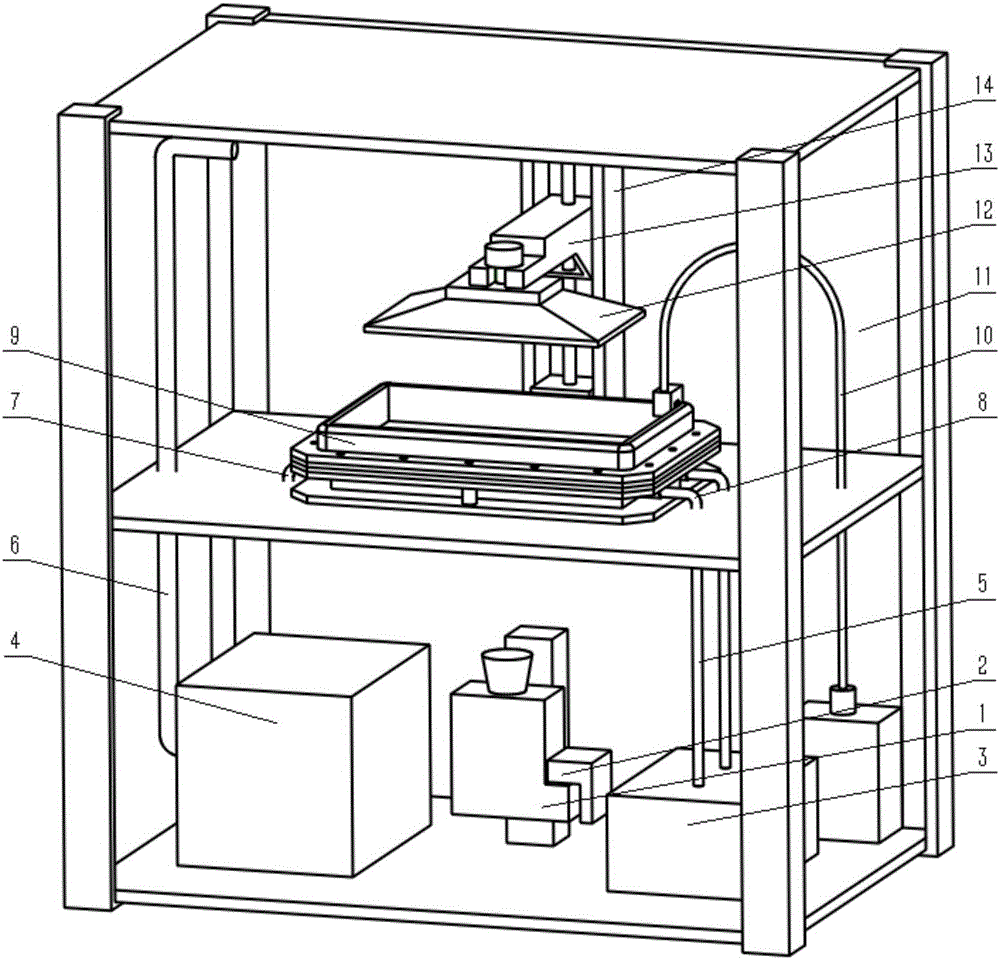

The invention discloses a high-speed continuous photocuring type 3D printing device and a working method thereof. The 3D printing device comprises a machine case body which is divided into an upper cavity and a lower cavity by a middle partition board, wherein an image forming module is arranged in the lower cavity, a window box and an oxygen supply cooling module are arranged in the upper cavity and are combined to be fixedly mounted on the middle partition board, the oxygen supply cooling module is arranged right below the window box, and the image forming module I is arranged right below the window box; a printing platform is arranged right above the window box and is mounted on a Z-direction worktable; and the window box is connected with a raw material feeding unit. The 3D printing device is integrated with the advantages of a compound oxygen-rich film, oxygen supply cooling and liquid surface auxiliary pressurization of the window box, so that the low-cost and efficient continuous printing of large-sized products with arbitrary shapes is realized, the range of applicable materials is wide, the printed products are high in precision and quality and good in uniformity, and the process is stable and reliable. An industrial-grade solution is provided for the high-speed continuous photocuring type 3D printing.

Owner:SHENZHEN ELEGOO TECH CO LTD

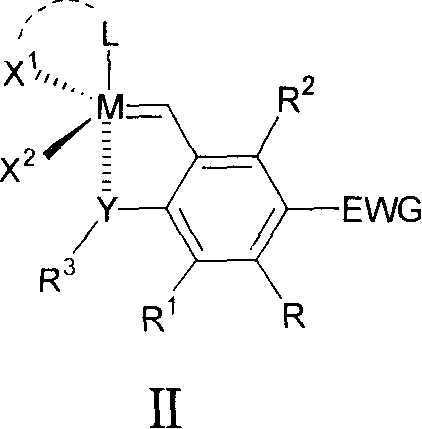

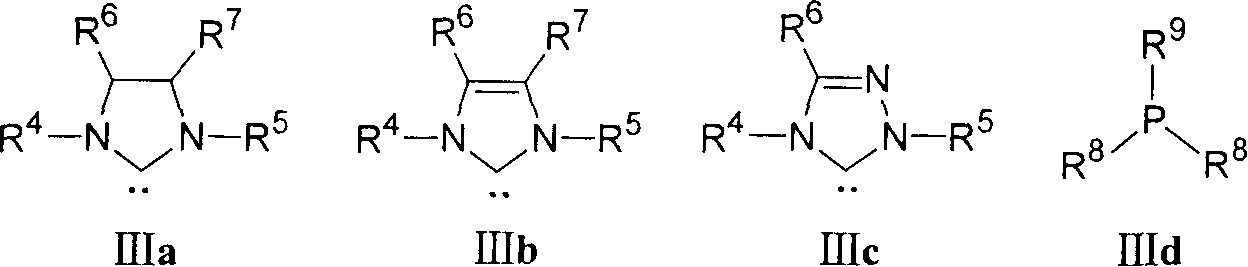

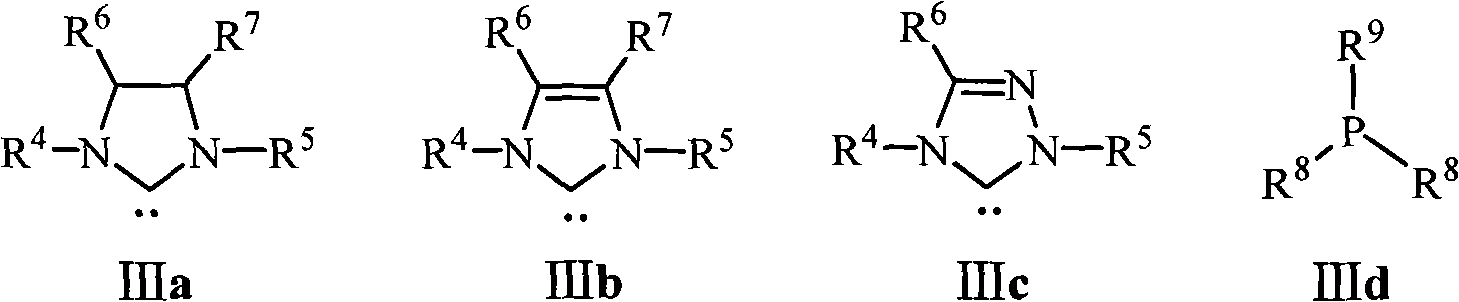

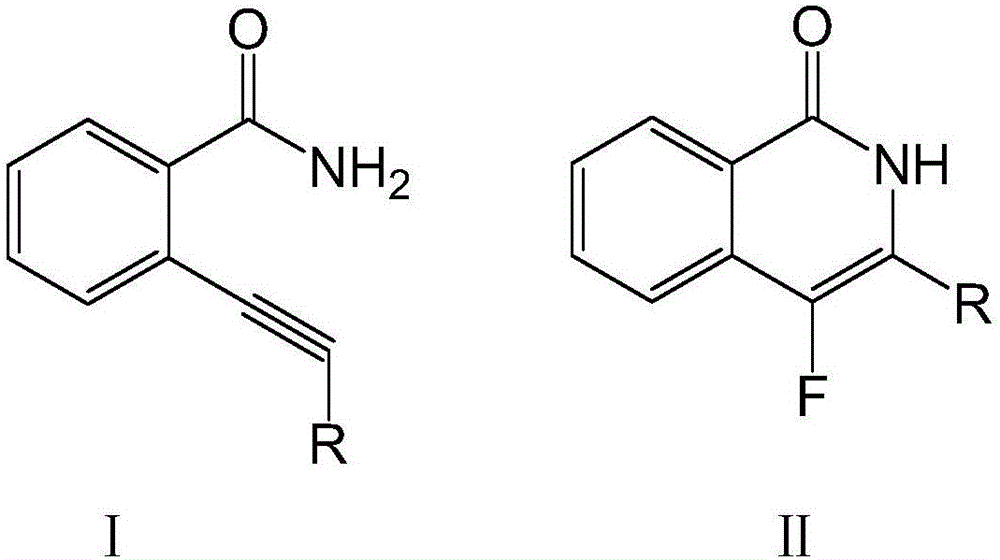

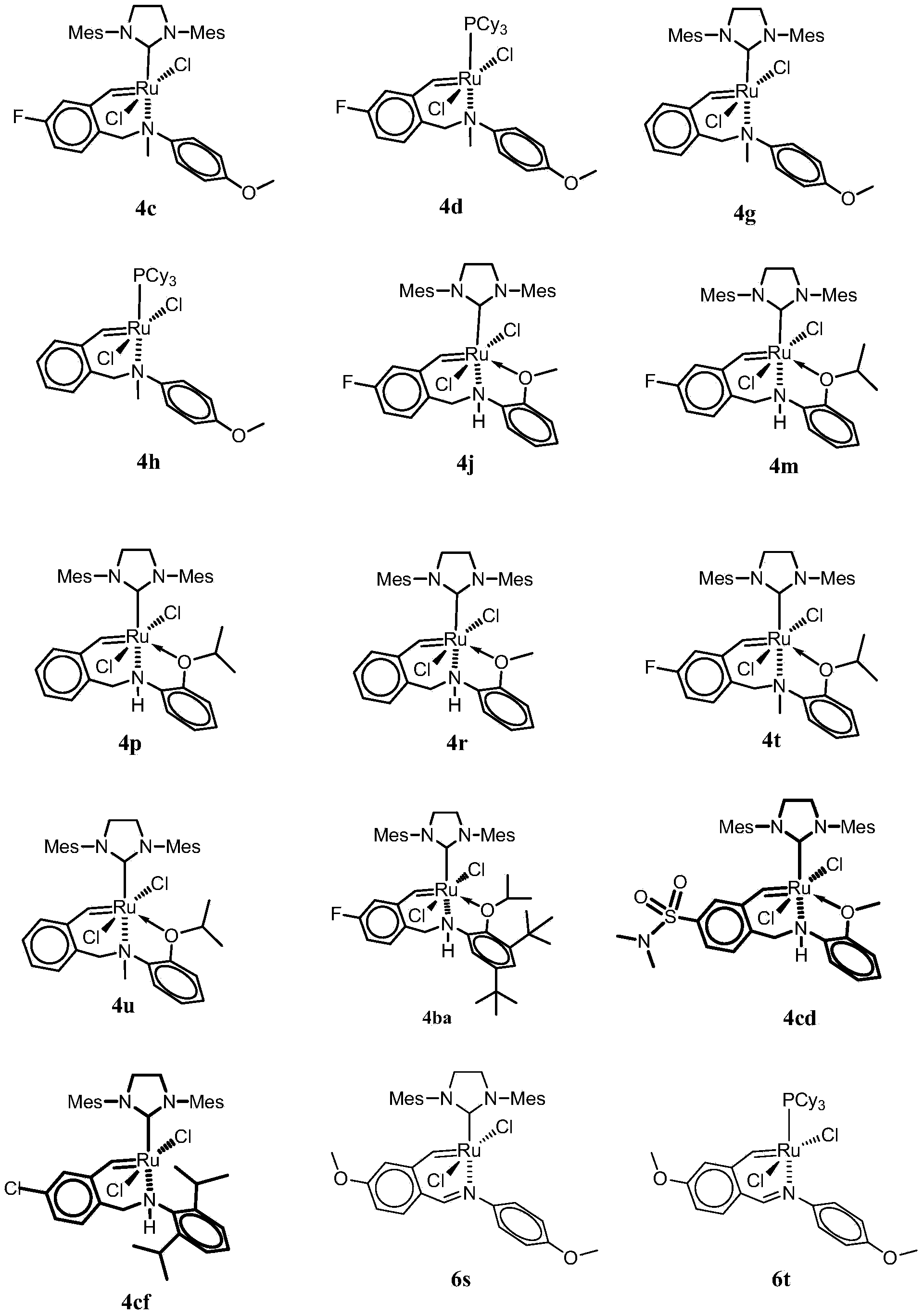

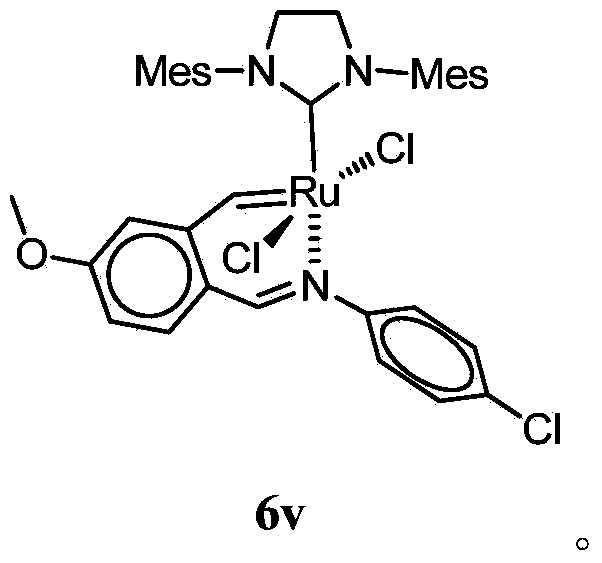

Ruthenium complex compound ligand, ruthenium complex compound, solid carrying ruthenium complex catalyst and preparation method and use thereof

ActiveCN1907992AHigh catalytic activityImprove catalytic stabilityOrganic-compounds/hydrides/coordination-complexes catalystsGroup 5/15 element organic compoundsRutheniumStructural formula

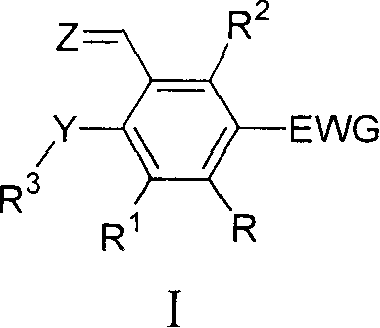

The invention discloses a ruthenium complex compound ligand,fixed-carrying ruthenium complex compound catalyst and preparing method and utility, wherein the structural formula of ruthenium complex compound ligand I and II is displayed in the graph I and II; the structural formula of fixed-carrying ruthenium complex compound catalyst IV is as displayed in the right graph IVa-IVb.

Owner:ZANNAN SCITECH

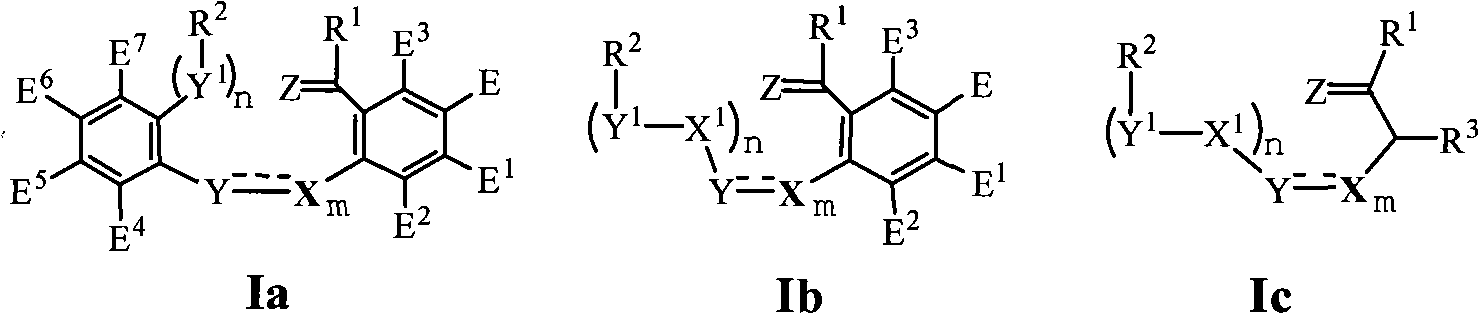

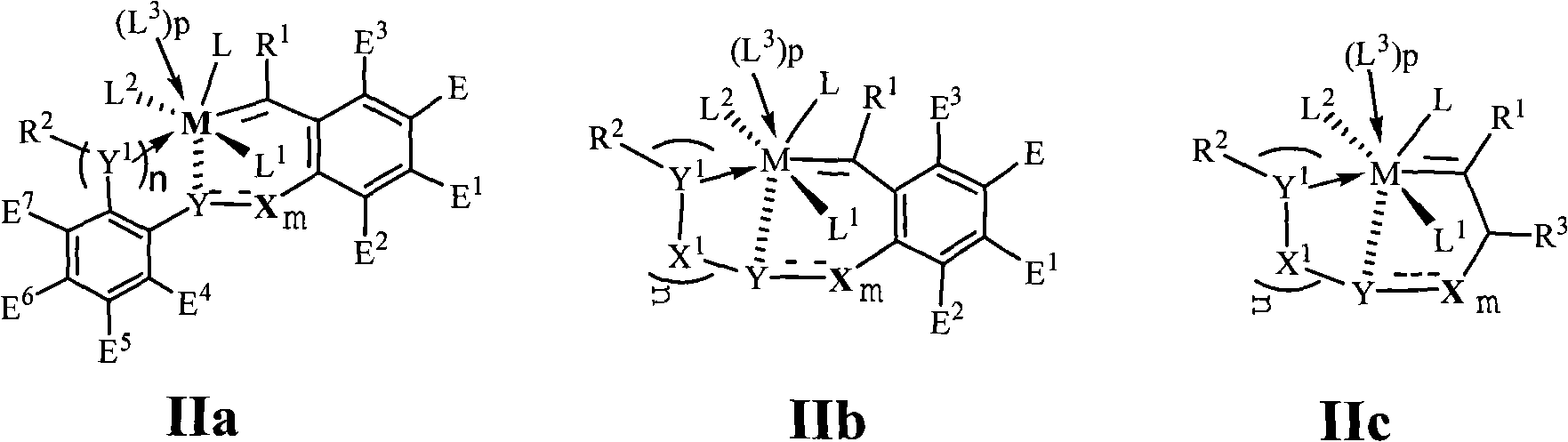

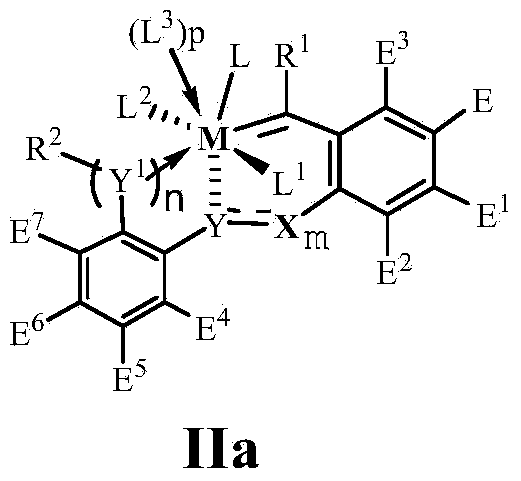

Metal complex ligand, metal complex, preparation method and application thereof, high molecular polymer, preparation method and application thereof

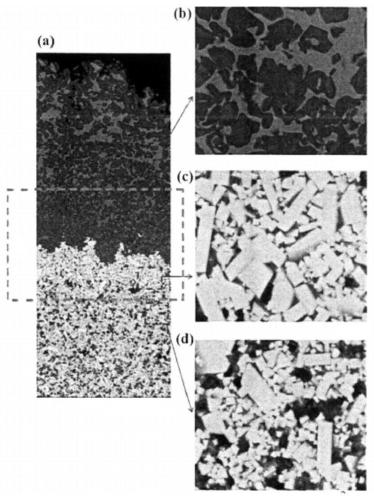

ActiveCN101684075AHigh catalytic activityImprove catalytic stabilityLiquid crystal compositionsGroup 4/14 element organic compoundsStructural formulaNew materials

The invention discloses a metal complex ligand, a metal complex, a preparation method and application thereof. Structural formulas of the metal (M) complex ligand Ia-Ic and the metal complex IIa-IIc thereof are shown. The metal complex has the advantages of higher catalytic activity, diversity of structures and physical properties and the like, and provides diverse optimal selection to catalytic application of various raw materials. The invention also discloses various novel functional polymer materials generated by ring-opening metathesis polymerization (ROMP) of different types of small molecular cycloolefines and application thereof, and structures of the materials are shown above.

Owner:ZANNAN SCITECH

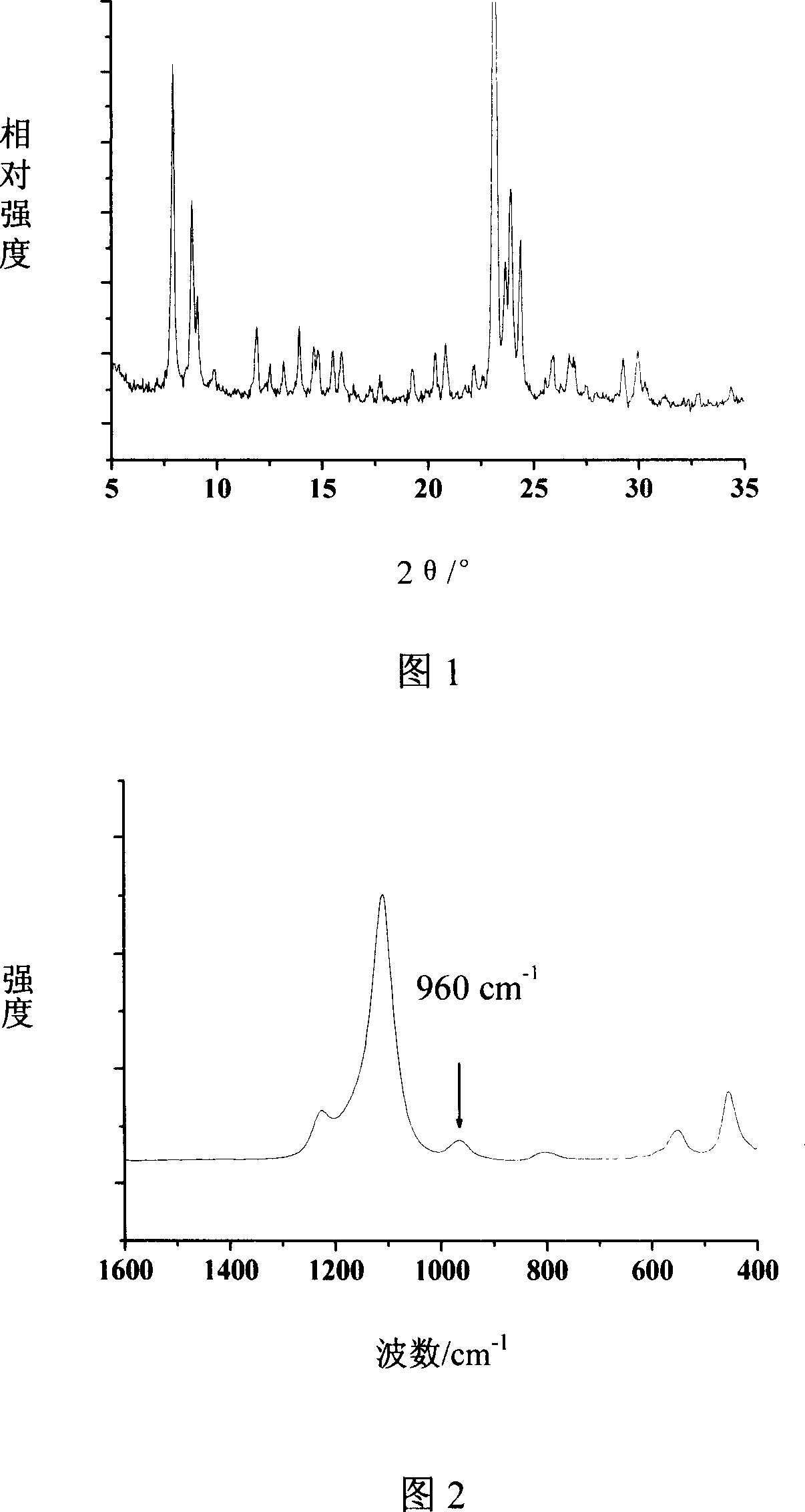

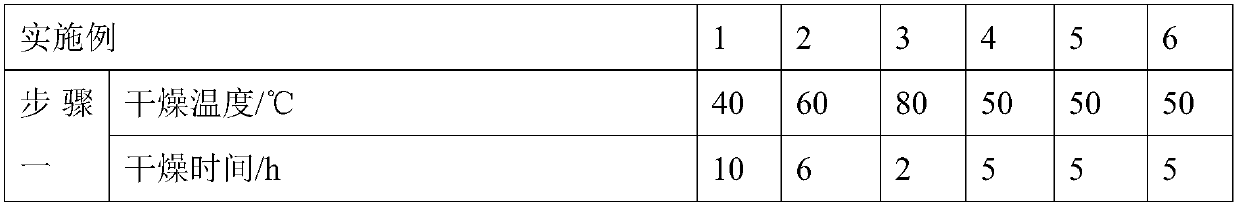

Method for preparing titanium-containing molecular sieve

InactiveCN1935651AIncrease loading capacityHigh yieldCrystalline aluminosilicate zeolitesInorganic ChemicalTitanium

The invention is a Ti-containing molecular sieve, namely TS-1 molecular sieve preparing method, belonging to inorganic chemical synthesis technical field. Multiple Si-Al molecular sieves have been successfully synthesized by the existing dry glue process, such as ZSM-5, FER, MOR, CHA, ZSM-48 and other zeolite molecular sieves, and Ti-Beta and Ti-MWW molecular sieves. And the preparing method synthesizes TS-1 molecular sieve by dry glue process, firstly hydrolyzing TBOT in a template TPAOH, then adding in inorganic silicon sources to form uniform gel, heating and evaporating the gel to dryness and obtaining dry glue, and finally transferring the dry glue into a crystallizing kettle with water jacket isolation layer for crystallization, and obtaining the TS-1 molecular sieve by routine filtering, washing, drying and baking processes. And the TS-1 molecular sieve product has high activity and high yield.

Owner:EAST CHINA NORMAL UNIVERSITY

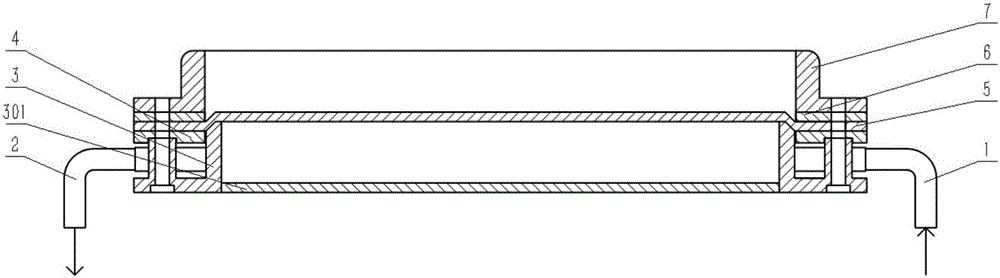

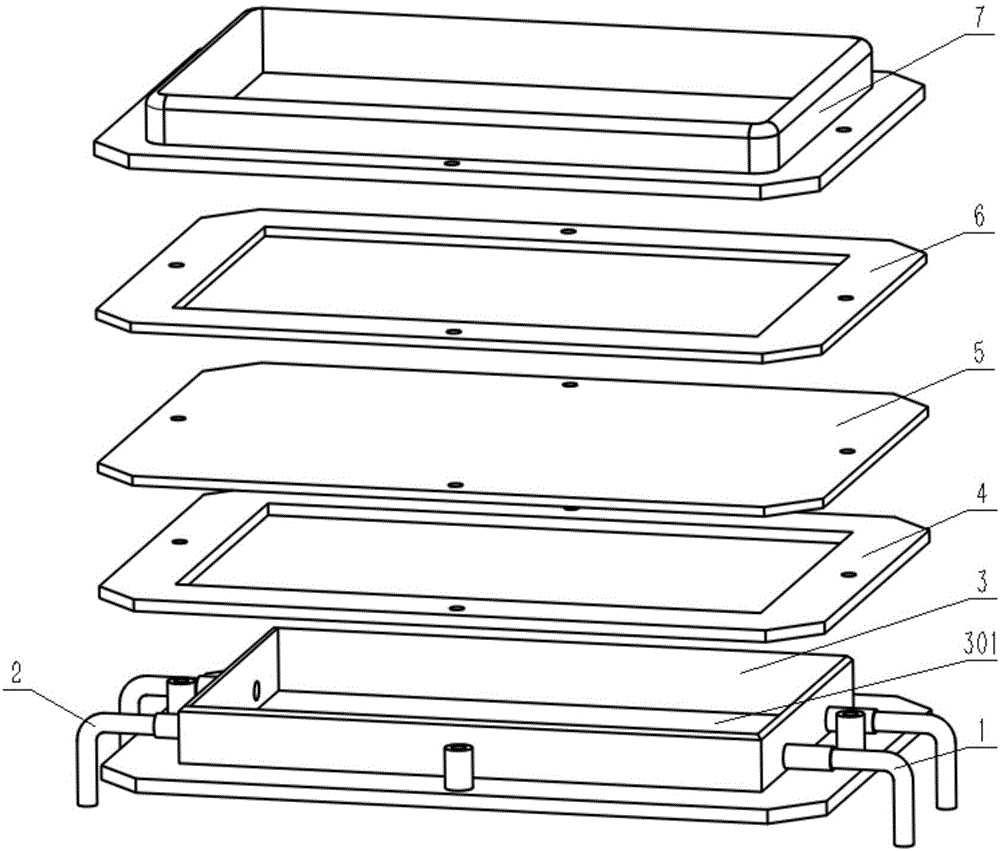

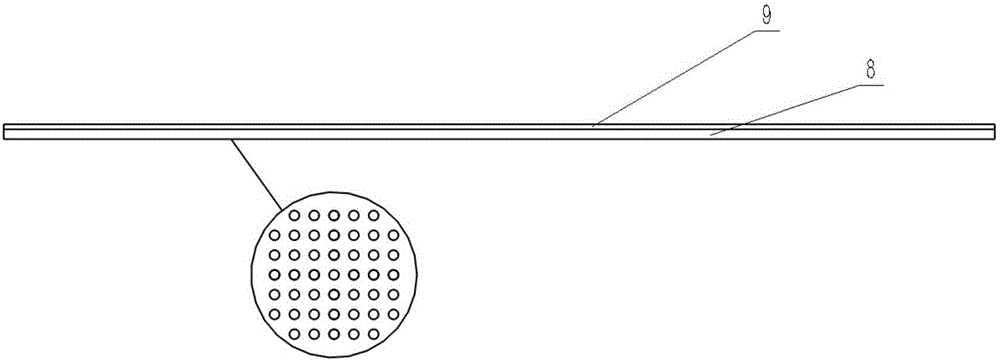

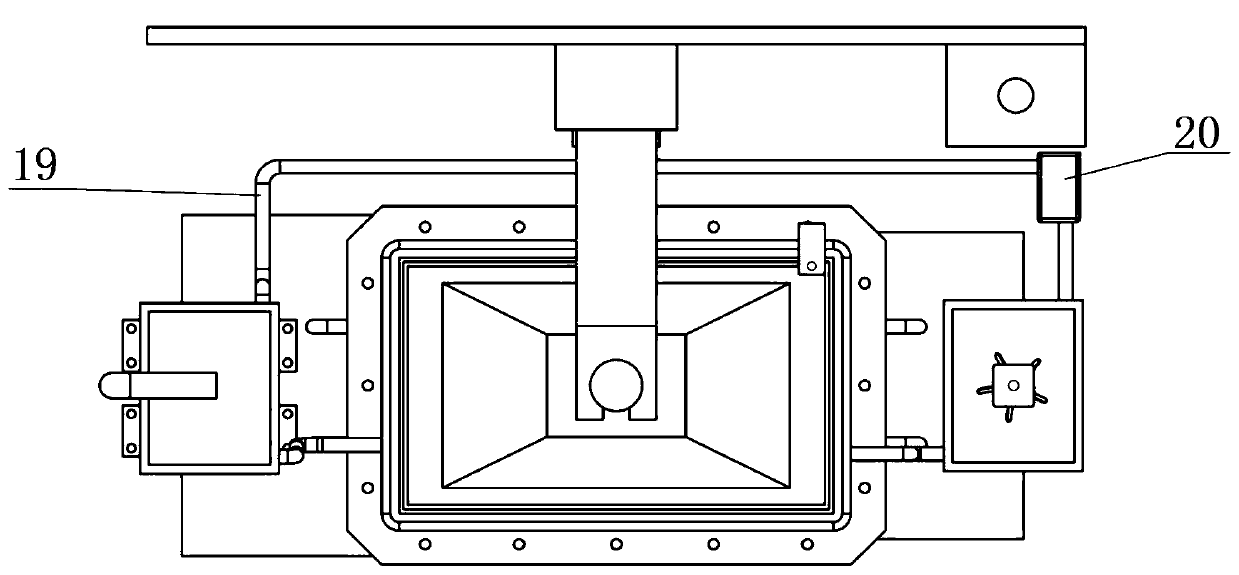

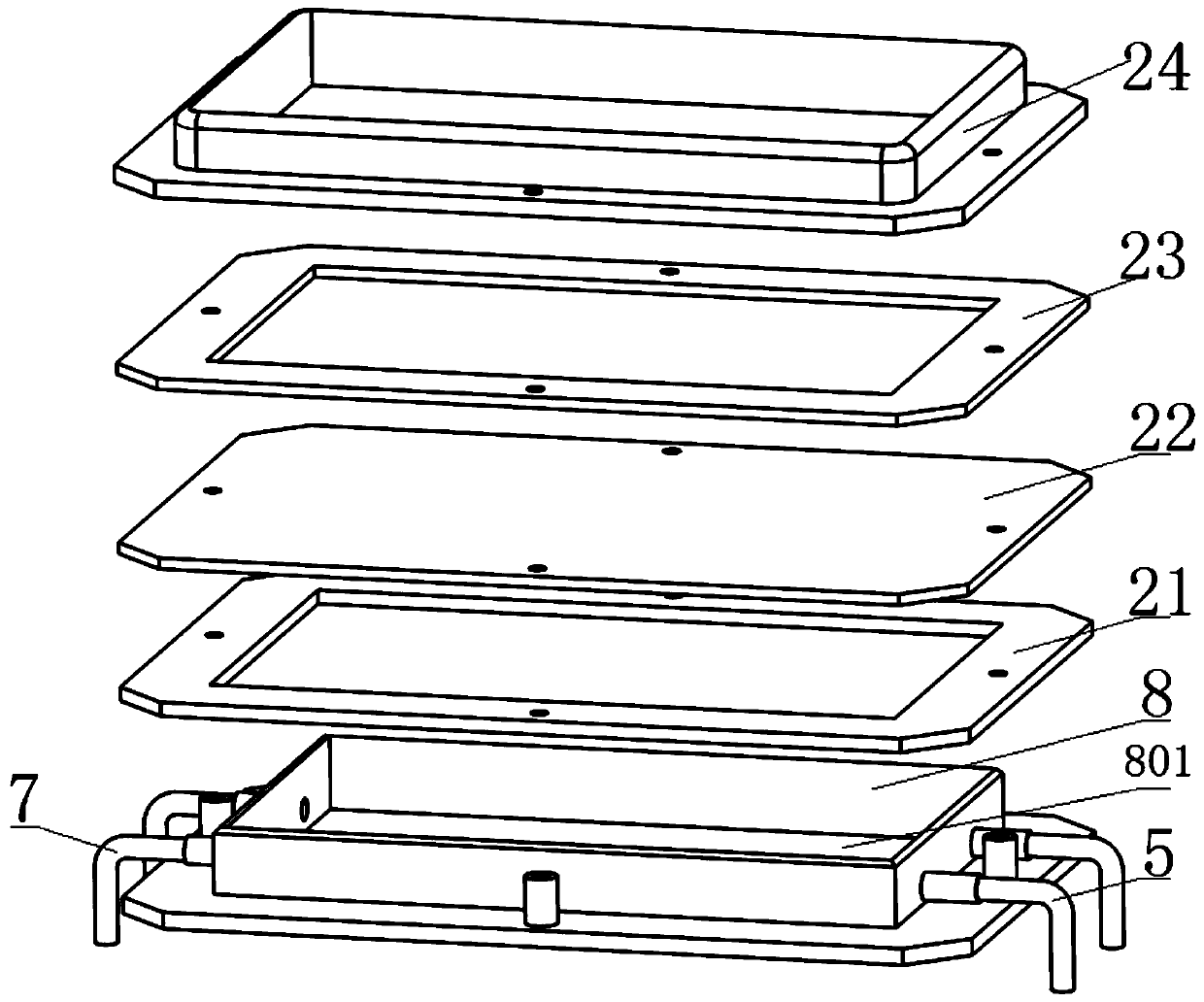

Forming window for high-speed continuous photocuring 3D printing

ActiveCN106273516AEfficient printingTroubleshoot quick fixesAdditive manufacturing apparatusCooling chamberEngineering

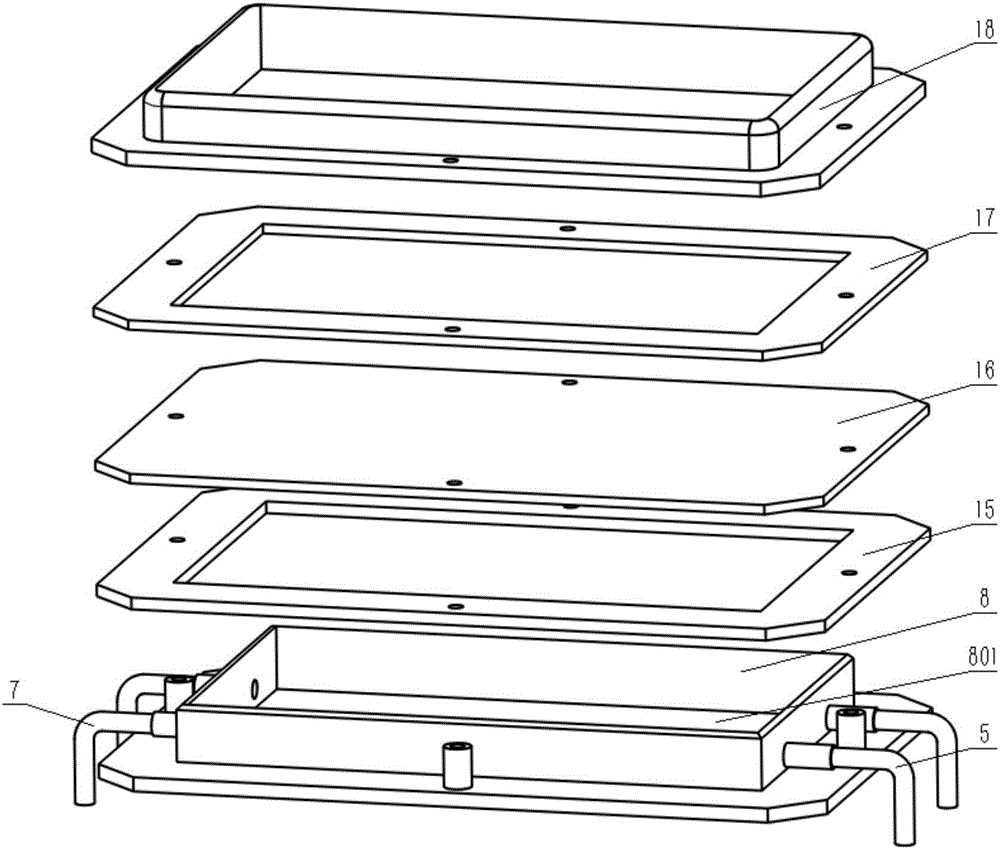

The invention discloses a forming window for high-speed continuous photocuring 3D printing. The forming window applied to a photocuring 3D printer comprises a window box and an oxygen supply cooling module. The photocuring 3D printer is divided into an upper cavity and a lower cavity through a middle partition. The window box and the oxygen supply cooling module are arranged in the upper cavity of the case of the photocuring 3D printer. The window box and the oxygen supply cooling module are fixedly mounted on the middle partition in a combined manner. Two ends of an oxygen supply cooling chamber are respectively connected with a cooling gas inlet pipeline and a cooling gas outlet pipeline, and the oxygen supply cooling chamber, the o cooling gas inlet pipeline and the cooling gas outlet pipeline form the oxygen supply cooling module. The forming window has the advantages that low-cost and efficient continuous printing of large-size optional-shape parts can be achieved, the forming window is wide in applicable materials, the precision and quality of the printed parts are high, the printed parts are good in consistency, and process stability and reliability are achieved. In addition, the forming window is high in industrial application value and applicable to a desktop-level 3D printer and industrial 3D printing.

Owner:QINGDAO TECHNOLOGICAL UNIVERSITY

Continuous surface exposure ceramic 3D printing device and working method thereof

ActiveCN109795010ARealize continuous surface exposure printingSolve layeringAdditive manufacturing apparatusFeeding arrangmentsLiquid storage tankSlurry

The invention discloses a continuous surface exposure ceramic 3D printing device and a working method thereof. Before printing, a raw material feeding unit pours ceramic slurry into a window box; after a water pump pulls out the ceramic slurry in a first slurry tank, the ceramic slurry is conveyed into a second slurry tank through a second slurry conveying pipeline, the ceramic slurry in the second slurry tank flows into aliquidstorage tank of the window box through the second slurry conveying pipeline, the ceramic slurry in the liquid storage tank of the window box flows into the first slurrytank through the first slurry conveying pipeline, and the circulation flow of ceramic slurry in the first slurry tank, the liquid storage tank, and the second slurry tank is realized throughthe waterpump; and the continuous surface exposure technology is adopted, continuous molding of ceramic 3D printing is realized, and continuous printing is realized.

Owner:QINGDAO TECHNOLOGICAL UNIVERSITY

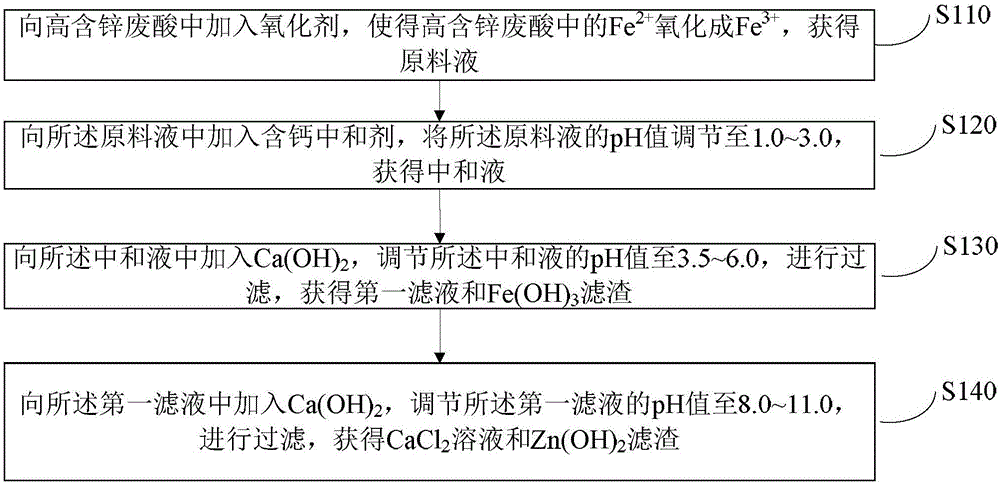

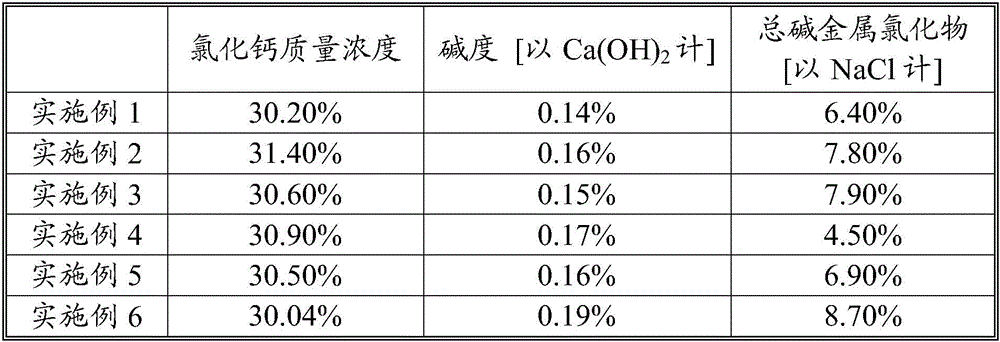

Method for comprehensive treatment and utilization of high-zinc-content waste acid

ActiveCN106745151ARealize processing utilizationEfficient separationZinc halidesCalcium/strontium/barium chloridesChlorideZinc

The invention relates to a method for comprehensive treatment and utilization of high-zinc-content waste acid. By reasonably designing process steps and reaction agents of the method for comprehensive treatment and utilization of the high-zinc-content waste acid, effective separation, recycling and reutilization of iron and zinc are achieved, iron and zinc resource waste is avoided, a by-product industrial calcium chloride solution having a wide industrial application value and meeting the national quality standard is also obtained, comprehensive treatment and utilization of the high-zinc-content waste acid is successfully achieved, and the method is simple in process, lower in cost, green and environmentally friendly.

Owner:TANGSHAN 3R CHEM CO LTD

Preparation method of batch preparation of boron nitride nanotube

InactiveCN102849694AWide variety of sourcesLow costMaterial nanotechnologyNitrogen compoundsAlkaline earth metalShielding gas

The invention relates to a method for batch preparation of boron nitride nanotubes. The method comprises the steps of sufficiently mixing a boron source, a transition metal compound and alkaline-earth metal compounds; heating the mixture to 1000-1100 DEG C under the protection of nitrogen or argon; stopping supplying a protective gas, beginning supplying a mixture gas of the nitrogen and the argon, reacting and continuing to heat to 1200-1400 DEG C, keeping the temperature for 0.5-4 hours, stopping the supply of the gas after the heat preservation, closing the gas inlet and the gas outlet and decreasing the temperature to the room temperature so as to obtain white rough products, heating the rough products in the air to 600 DEG C and subsequently pickling and drying. The diameter of the prepared boron nitride nanotube is 50-300nm, and the length can be more than 100 microns. By introducing an alkaline-earth metal as a catalyst, a great quantity of boron nitride nanotubes can grow at a lower temperature; the cost is lower, the material resource is wide, the preparation process is simple, and the batch production can be realized easily.

Owner:JINGDEZHEN CERAMIC INSTITUTE

Special treating agent for galvanizing surface chemical conversion and treating technique thereof

ActiveCN104498921AReduce pollutionSimple methodMetallic material coating processesSodium phosphatesActive agent

The invention discloses a special treating agent for galvanizing surface chemical conversion and a treating technique thereof, belonging to the field of surface protection of transmission and transformer equipment components. The conversion treating method mainly comprises the steps of pretreatment, water washing, chemical conversion, water washing, natural drying and the like. The pretreatment agent is composed of Na2CO3, NaH2PO4, NaHPO4, sodium pyrophosphate, copper salt, nickel salt and titanium salt. In the treatment process, the conversion agent is composed of H3PO4 and ZnO, the corrosion inhibitor is one or both of thiocarbamide and hexamethylenetetramine, the complexing agent is composed of one or more of citric acid, tartaric acid and monobutyric acid, the surfactant is composed of one or more of OS-15, OP-10 and sodium dodecyl benzene sulfonate, and the accelerator is composed of one or more of sodium nitrate, sodium nitrate, hydrogen peroxide, potassium permanganate and potassium chlorate. The galvanizing substrate surface treated by the technique is a compact corrosion-resistant film with insulation resistance. The treating agent and treating technique can effectively enhance the corrosion resistance of the material and enhance the corrosion resistance and service life of the transmission and transformer equipment metal components.

Owner:STATE GRID CORP OF CHINA +1

Zinc layer surface conversion film forming liquid, and application method thereof

InactiveCN102234799AReduce pollutionImprove performanceMetallic material coating processesFluorosilicate saltPhosphate

The invention discloses a zinc layer surface conversion film forming liquid, and an application method of the film forming liquid. The prepared zinc layer surface conversion film forming liquid is an aqueous solution with a pH value of 0.5 to 2, where in the pH value is regulated by nitric acid or sulfuric acid. The film forming liquid is prepared from cerium salt, halide, phosphate, meta-vanadate, fluorosilicate and water. The method comprises the steps that: a surface oxide layer of a galvanized material is removed through alkali washing and desmutting treatments; the treated galvanized material is immersed in the zinc layer surface conversion film forming liquid for 30 seconds to 30 minutes under a temperature of 10 DEG C to 70 DEG C; such that a conversion film is formed on the surface of the galvanized material. The formed conversion film has a uniform color and an excellent anti-corrosion performance. The film forming liquid and the method provided by the invention have values to be widely applied in industrial productions.

Owner:北京小铱新材料科技有限公司

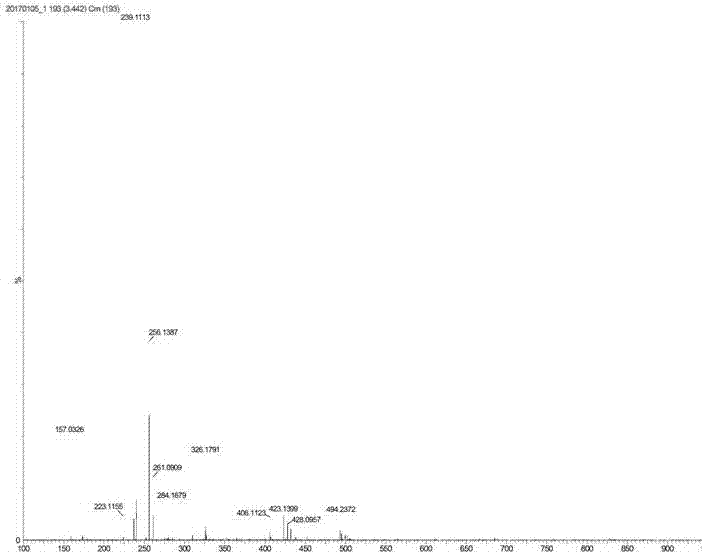

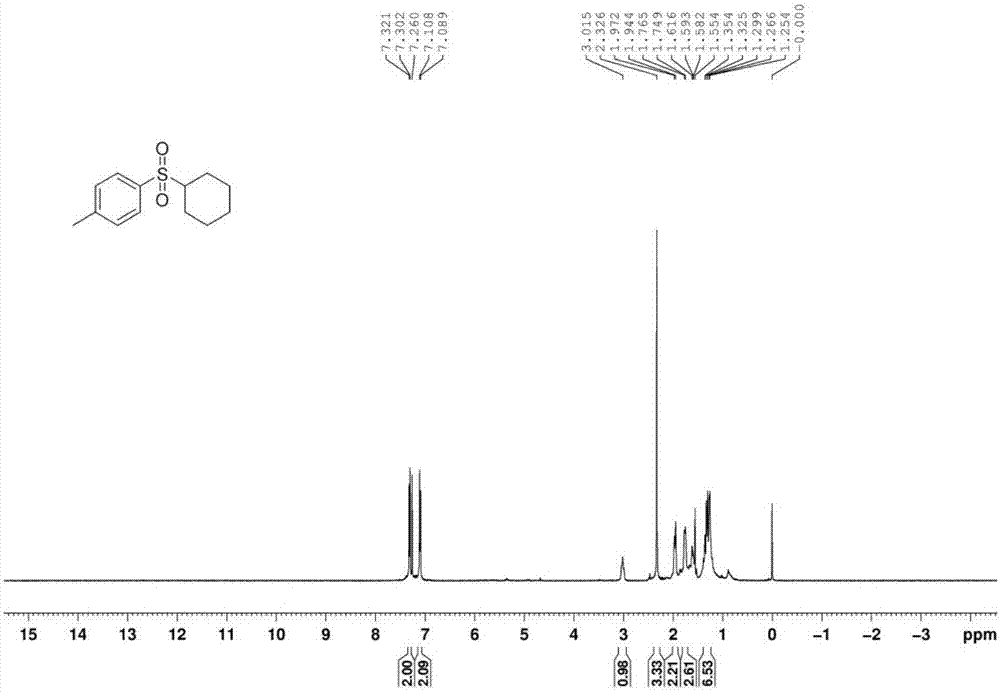

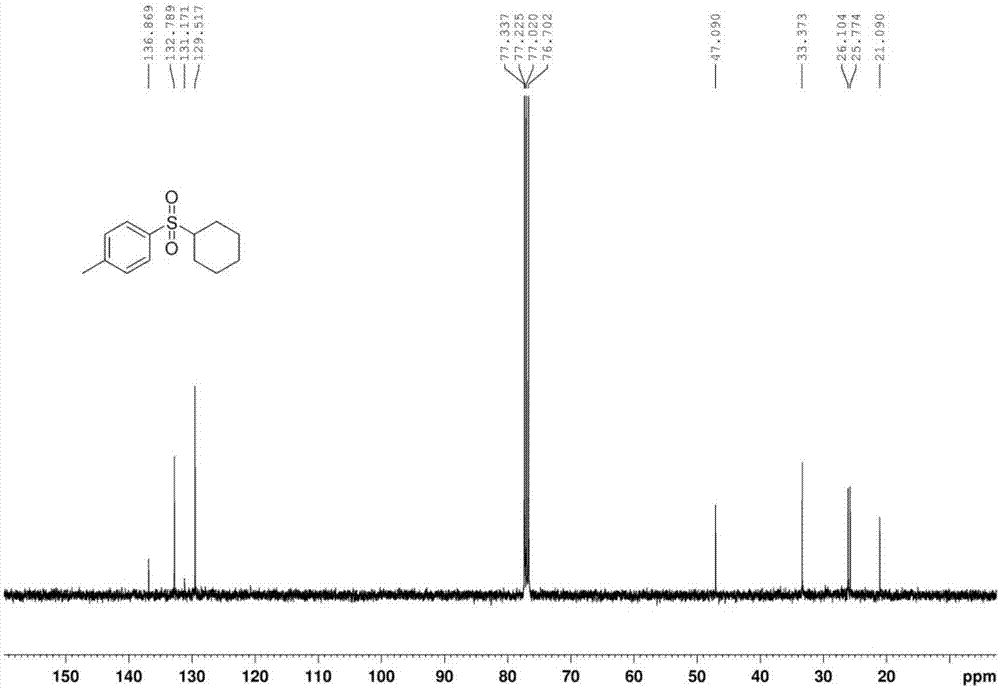

Preparation method of sulfone compound

InactiveCN107445874AMild reaction conditionsEasy to operateOrganic chemistryOrganic compound preparationSolventSulfone

The invention discloses a preparation method of a sulfone compound. The method concretely comprises the following steps of (a) dispersing benzenesulfonyl hydrazide of a structure (I) into a cyclane solvent of a structure (II) (The structure (I) and the structure (II) are shown in the description); (b) adding catalysts of ferric salts and oxidants of peroxides into the mixture obtained in the step (a); then, performing reaction for 6 to 12h at the temperature being 90 to 130 DEG C to obtain the sulfone compound of a structure (III) (the structure (III) is shown in the description); R is aryl or substitutional aryl; the n is 1, 2, 3 or 4. The reaction conditions related by the synthesis method are mild; the cheap and easy-to-obtain ferric salts and peroxides are respectively used as catalysts and oxidants. The preparation method provided by the invention has the advantages that the cost is low; the operation is simple; mass production can be easily realized. Experiment results show that the yield of the obtained sulfone compound can reach a value as high as 80 percent.

Owner:XINYANG NORMAL UNIVERSITY

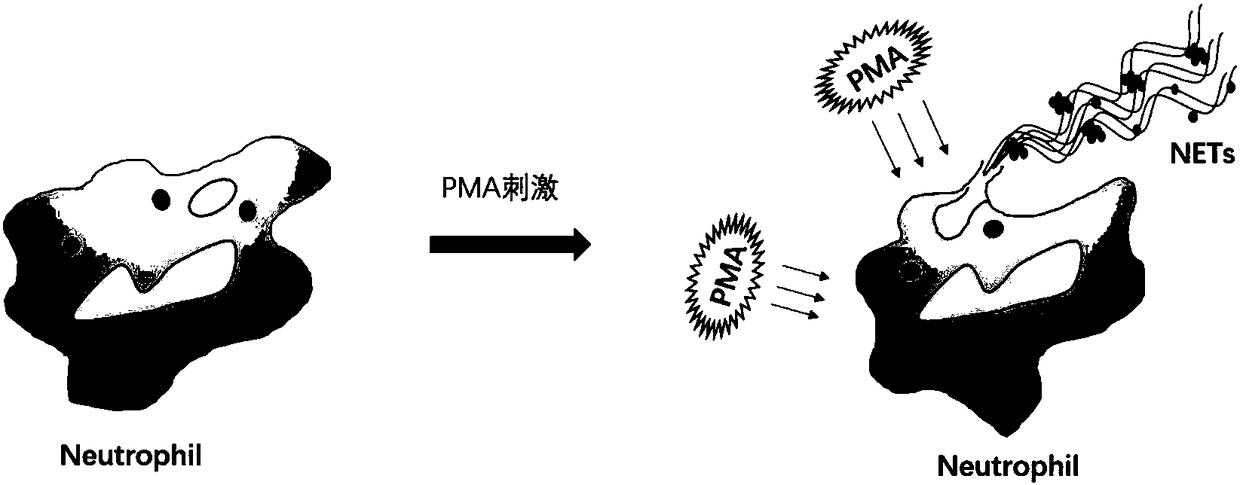

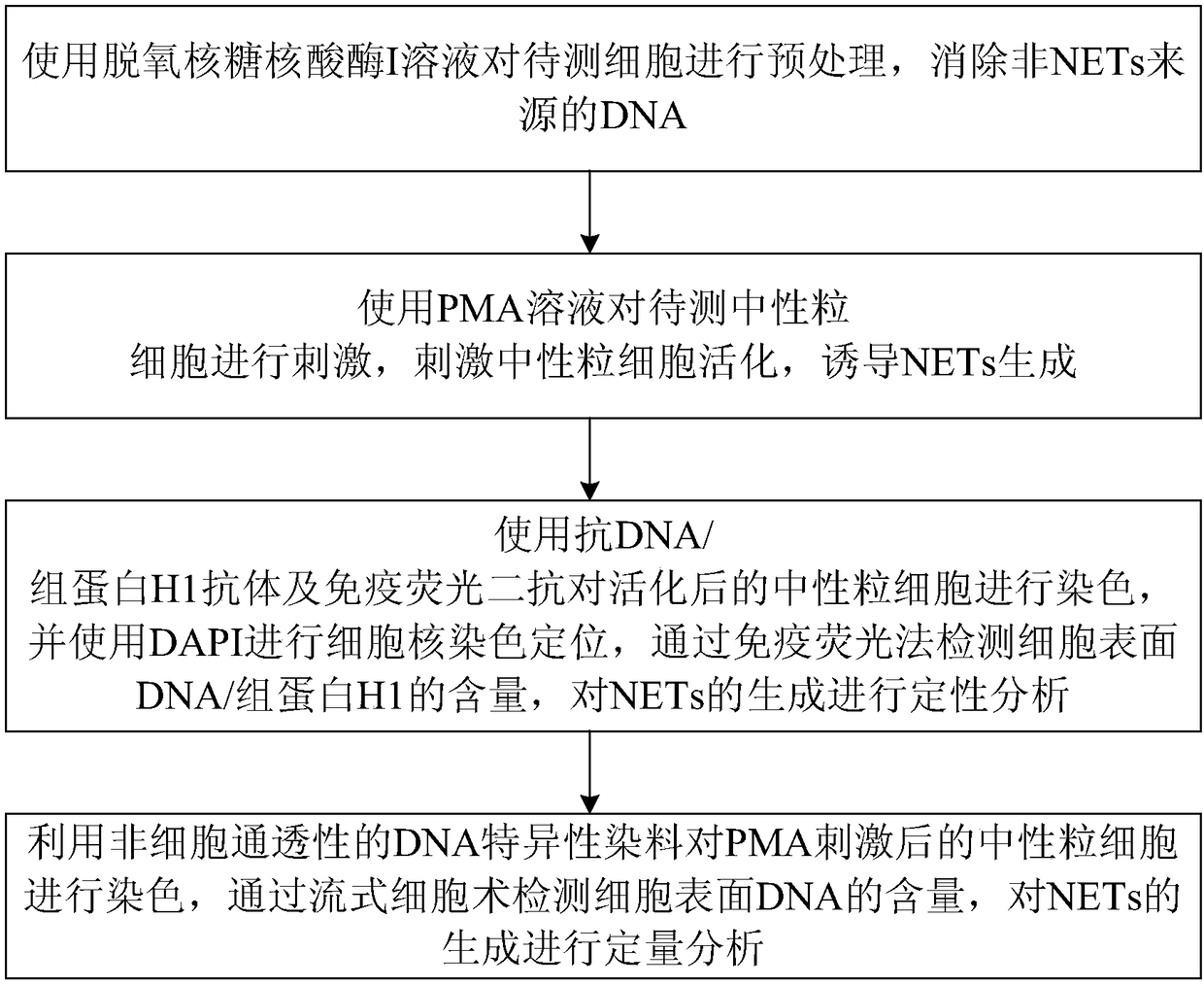

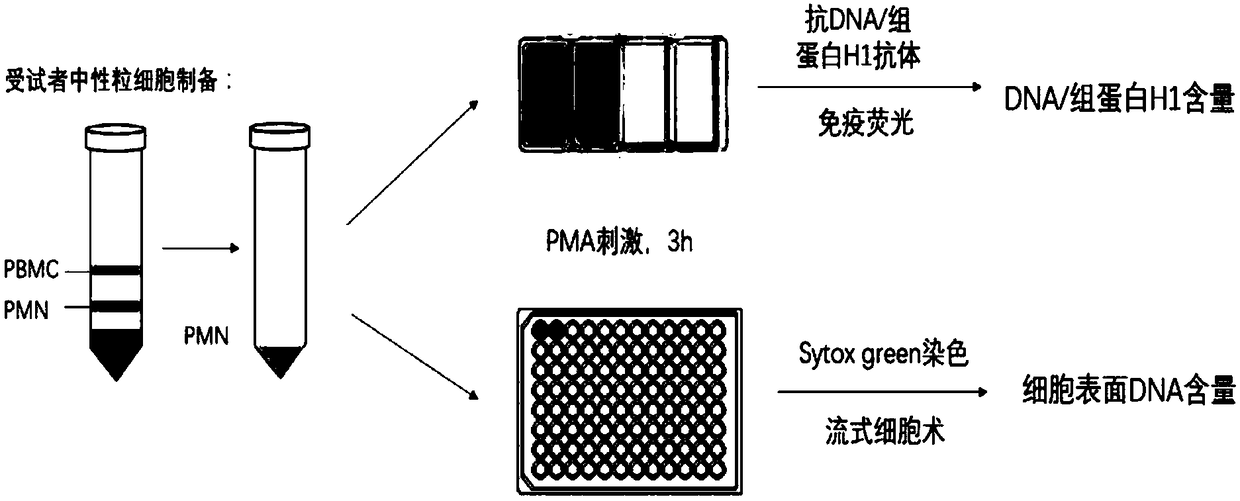

Kit and method for detection of NETs (neutrophil extracellular traps)

InactiveCN108362871AGreat industrial application valueBiological particle analysisIndividual particle analysisExperimental researchGenerating capacity

The invention provides a kit and a method for detection of NETs (neutrophil extracellular traps). The NETs are produced by in-vitro simulation induction and subjected to qualitative and quantitative detection. The kit is suitable for detecting NET generating capacity of subjects under physiological or pathological conditions and applied to screening of drugs for promoting or inhibiting generationof NETs and other immunological experiment studies related to the NETs; the kit not only is used for detection of human samples, but also can be used for detection of the NETs of other species such asmice, rats, rabbits, dogs, cattle, pigs and the like, and has wide industrial application value.

Owner:YUANJIAN BIOTECH SHANGHAI CO LTD

Visible light-based hydroxyl radical generator and trapping method

InactiveCN101940905AStrong oxidation and sterilization abilityReduce lossesDispersed particle separationLavatory sanitoryTrappingOzone Sterilization

The invention belongs to the technical field of ozone sterilization and discloses a visible light-based hydroxyl radical generator and a trapping method. The visible light-based hydroxyl radical generator comprises a testing box, an ozone generator, an ozone online monitor, a light source, a culture dish and a fan, and is characterized in that: the ozone generator, the light source, the culture dish and the fan are respectively fixed in the testing box; the light source is fixed above the culture dish; the fan is fixedly arranged in the testing box and opposite to the culture dish; the ozone online monitor is positioned outside the testing box; and a probe of the ozone online monitor is positioned in the testing box. Under the condition of visible light, ozone is photolyzed to generate hydroxyl radical, and the generated hydroxyl radical is subjected to spin trapping and ESR detection, and the hydroxyl radical generated in the ozone photolyzing process can be accurately detected, and can be analyzed by combining the ESR spectrum.

Owner:SHANGHAI JIAO TONG UNIV

Polyether-ether-ketone composite material surface chemical plating pre-treatment technology

ActiveCN109652787AHigh bonding strengthImprove bindingLiquid/solution decomposition chemical coatingEtchingChemical plating

The invention belongs to the technical field of surface modification and electroplating of special materials, and particularly relates to a polyether-ether-ketone composite material surface chemical plating pre-treatment technology. The polyether-ether-ketone composite material surface chemical plating pre-treatment technology comprises the following steps of stress removal, oil removal, pretreatment, etching, adjustment activation and peptizing chemical plating. The polyether-ether-ketone composite material surface chemical plating pre-treatment technology solves the problems of the low bonding strength and the low product qualification rate in the prior art; and a metal plating layer obtained after the chemical plating pre-treatment technology is high in bonding strength, is not prone tofalling off, is high in product qualification rate and is suitable for industrial application.

Owner:镇江阿尔法特种镀膜科技有限公司

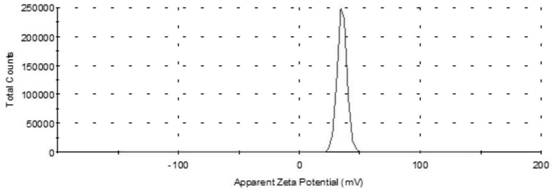

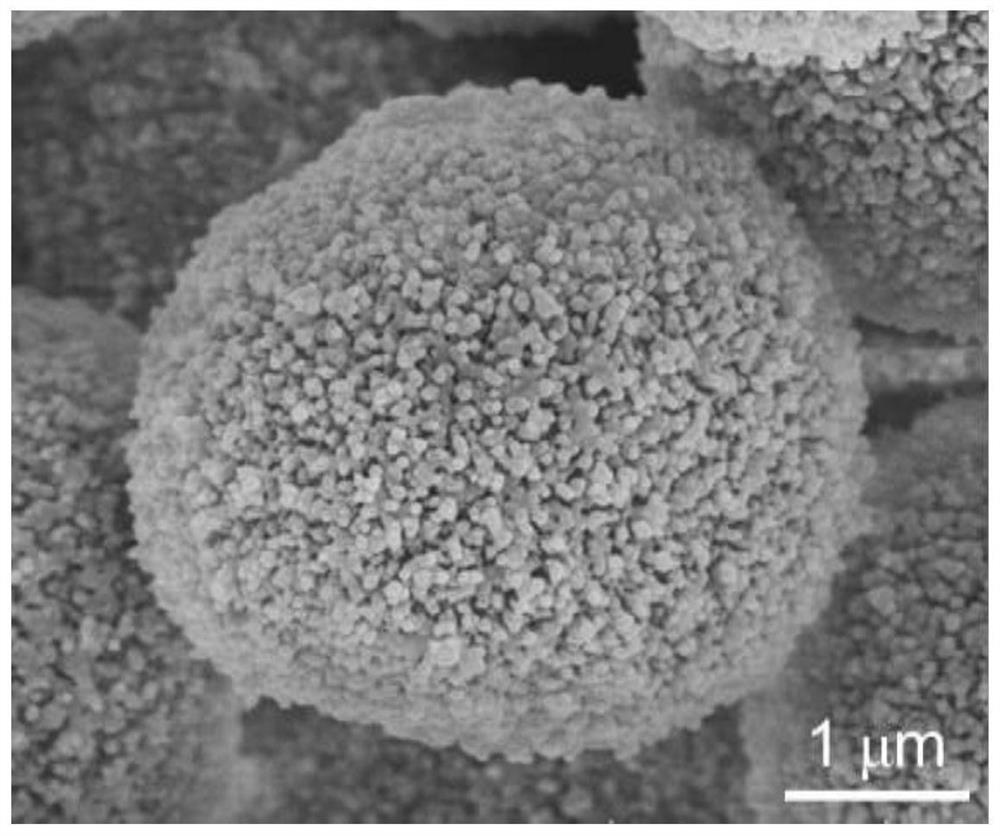

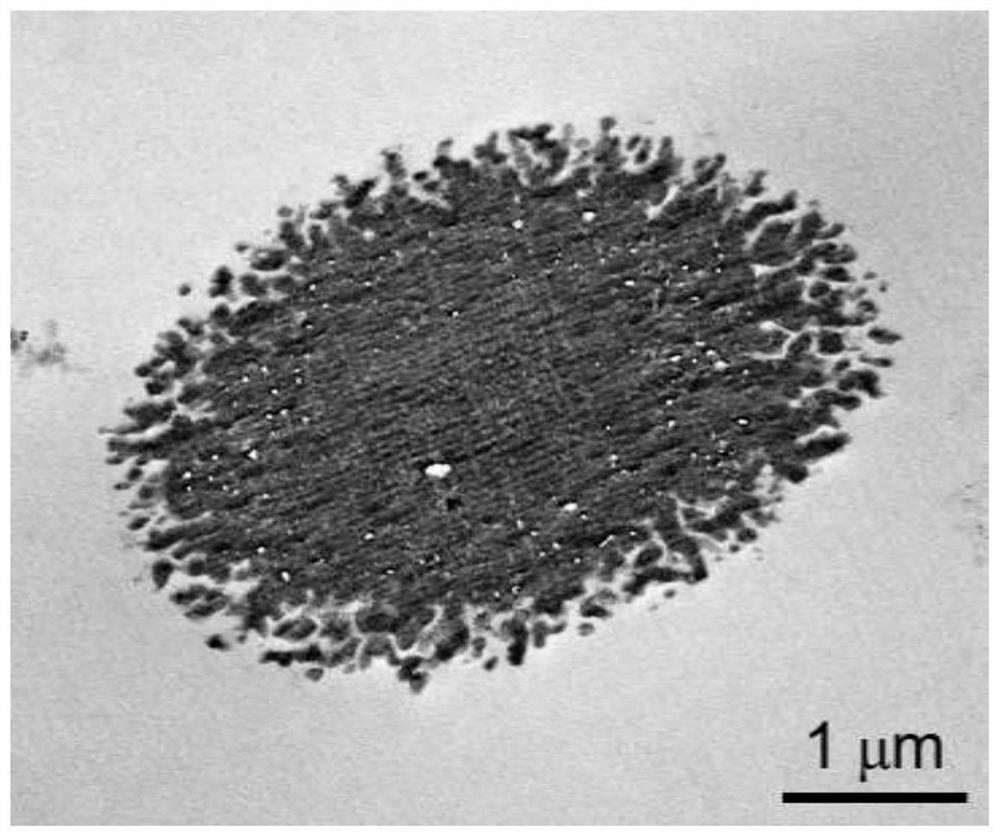

Ion exchange polymer microsphere and synthesis method thereof

PendingCN114805657AThe reaction process is simpleExperimental conditions are simpleMicroballoon preparationMicrocapsule preparationIon exchangeHydrophilic polymers

The invention relates to an ion exchange polymer microsphere and a synthesis method thereof. The microsphere has a micron size, is internally composed of a hydrophobic polymer, and has a solid and compact structure; and the outer part is composed of a charged hydrophilic polymer and has a nano-porous structure. By changing the types of the hydrophobic polymer and the charged hydrophilic polymer, the chemical components and the surface appearance of the microspheres can be regulated and controlled. The microspheres have uniform size and morphology, the preparation method is simple, large-scale production is easy, and the microspheres have wide industrial application value. The ion exchange polymer microsphere with the micro-nano hierarchical heterostructure has great value in adsorption and separation of various molecules, ions and particles, and is expected to be applied to the fields of medicine purification, food detection, environmental governance and the like.

Owner:DALIAN INST OF CHEM PHYSICS CHINESE ACAD OF SCI

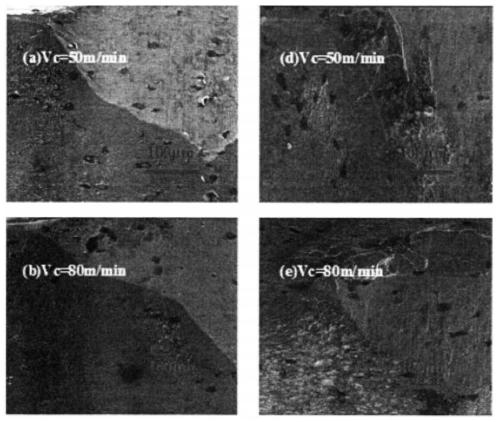

Argon-arc welding-brazing composite welding method

InactiveCN108161263AImprove performanceReduce performanceWelding apparatusCopperUltimate tensile strength

The invention provides an argon-arc welding-brazing composite welding method. The argon-arc welding-brazing composite welding method is characterized in that welding for a to-be-welded magnesium alloyplate and a copper plate is realized by adopting a Mg-Nb intermediate layer, so that relatively great stress in a joint and deformation, which are caused by direct welding two kinds of parent metal,are avoided, and the problem that strength of the joint is affected and toughness of the joint is not good as the two kinds of parent metal are in direct contact to easily form an intermediate compound is solved, and therefore, an obtained welded part is excellent in comprehensive performance. An argon-arc welding-brazing composite welding mode is adopted to overcome the defects of independently adopting argon-arc welding or brazing, so that the argon-arc welding-brazing composite welding method has a very good effect, and a wide industrial application value.

Owner:XUZHOU VOCATIONAL COLLEGE OF BIOENG

Method for improving settling property of activated sludge

ActiveCN106396271AAccelerated settlementImprove settlement performanceWater/sewage treatment by centrifugal separationFatty/oily/floating substances removal devicesActivated sludgeCyclone

The invention discloses a method for improving settling property of activated sludge. The method comprises steps as follows: wastewater containing the activated sludge is pretreated; activated sludge solids with good settling property are separated through gravity settling; the activated sludge with poor settling property is conveyed to an aeration tank for aeration treatment, and an oxygen bearing solid-liquid mixture is obtained; the oxygen bearing solid-liquid mixture is subjected to gravitational separation by a hydraulic cyclone, and coarse particle substances, a concentrated liquid and liquid-solid suspended matter are obtained; activated sludge with the improved settling property is obtained through gravity settling of the coarse particle substances and the concentrated liquid; the activated sludge with the improved settling property and the activated sludge solids with the good settling property are combined. According to the method, BOD (biochemical oxygen demand) load of the separated activated sludge with the poor settling property is improved by the aid of the aeration tank, meanwhile, excessive organic matter and nitrogen are consumed through aerobic bacteria, and the sludge is prevented from anaerobic fermentation; finally, colloidal components and tiny particles capable of causing membrane pollution and inducing scaling of a membrane air diffuser are removed through gravitational separation, and the settling property of the activated sludge is effectively improved; the process is simple, and the method has quite broad industrial application value.

Owner:SOUTH CHINA INST OF ENVIRONMENTAL SCI MEP

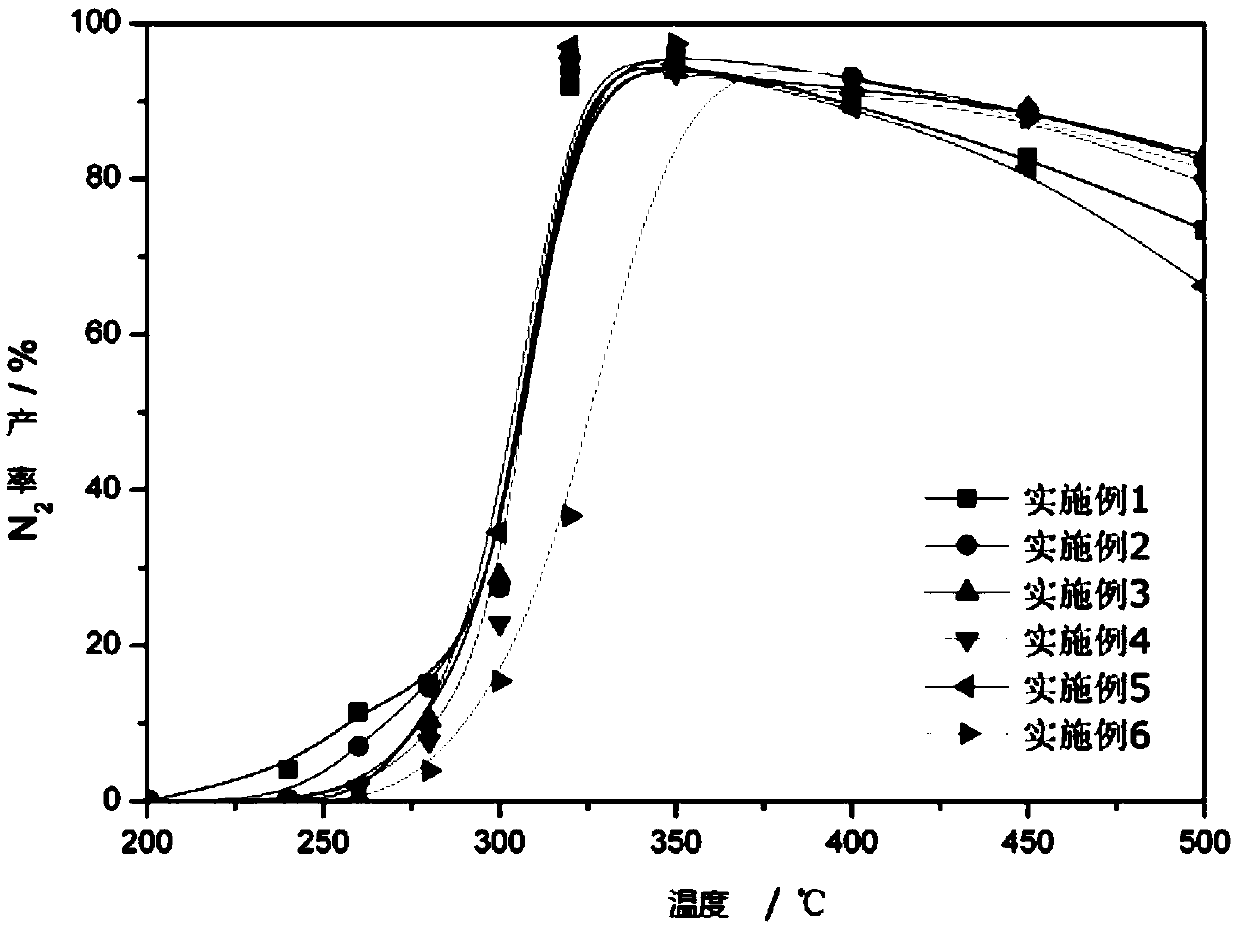

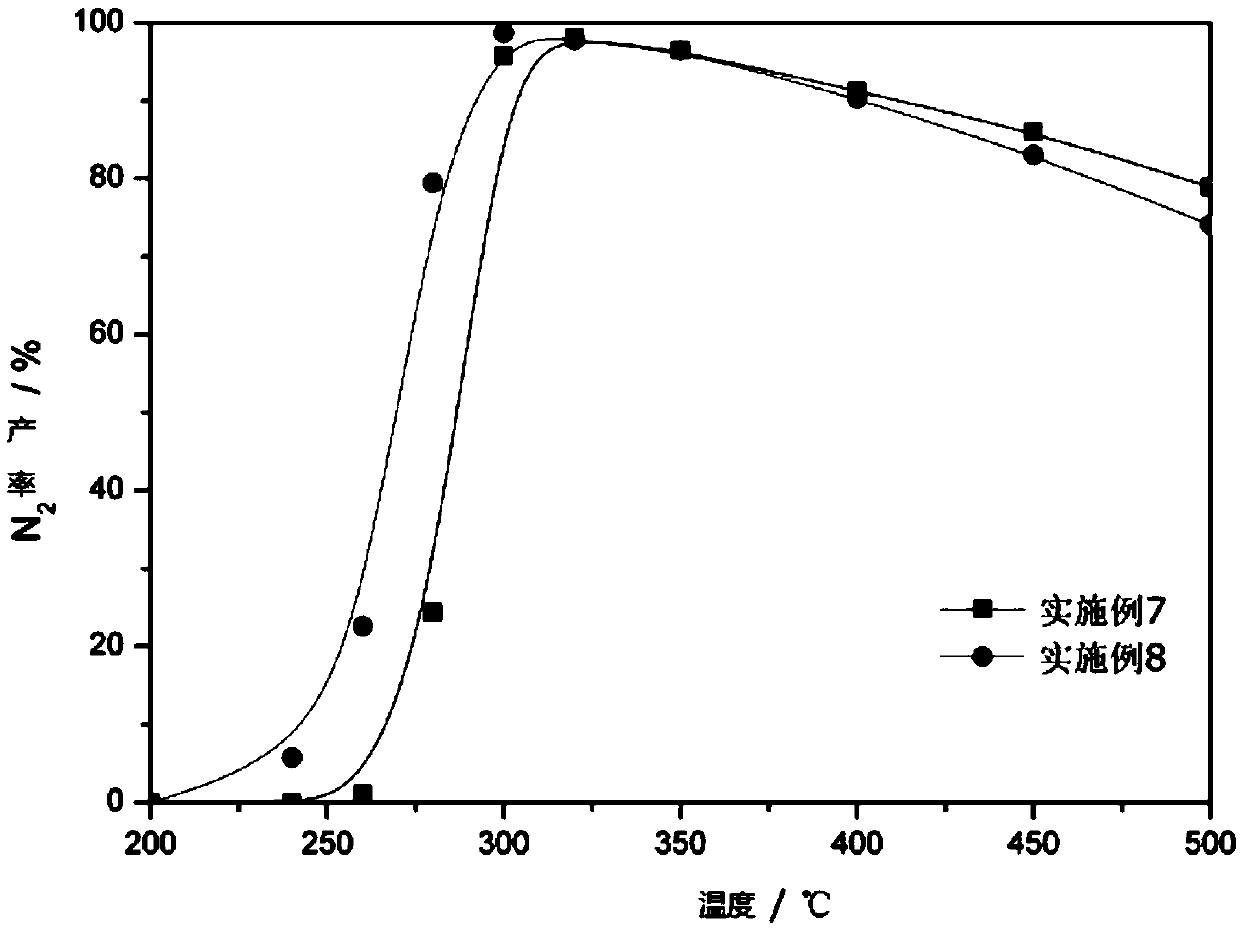

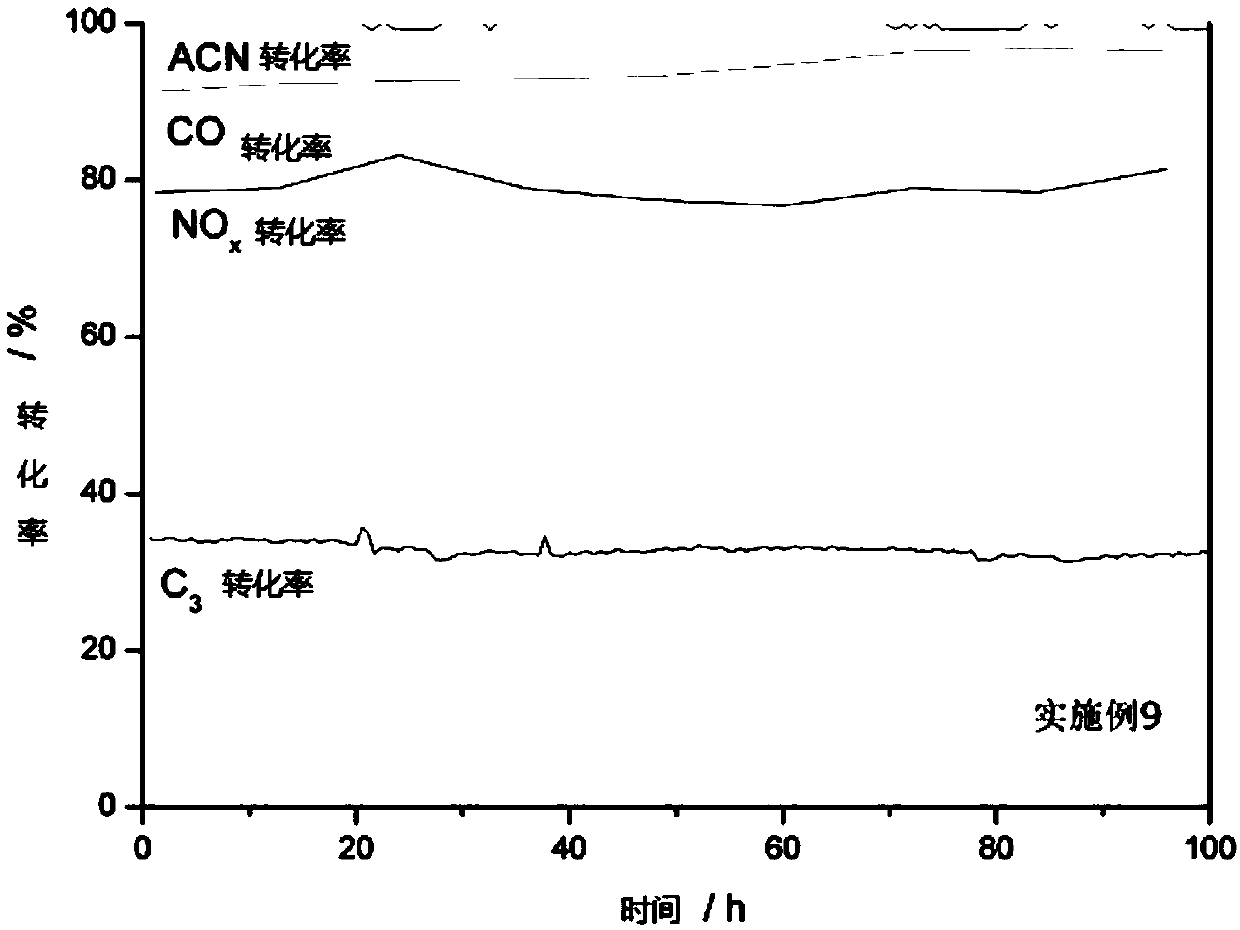

Supported honeycomb catalyst, and preparation method and application thereof

InactiveCN111151265AHigh catalytic activityImprove catalytic selectivityCatalyst carriersDispersed particle separationPtru catalystPhysical chemistry

The invention discloses a supported honeycomb catalyst, a preparation method thereof, and an application of the supported honeycomb catalyst in treatment of acrylonitrile-containing waste gas. The catalyst comprises a catalytic coating and a honeycomb carrier; the catalytic coating comprises an active component and a mesoporous metal oxide carrier; and the active component comprises an active metal element, and the active metal element is selected from at least one of Cu, Ag and Ce. The catalyst has very high catalytic activity and selectivity, and the catalyst is simple in preparation process, low in raw material price, basically free of byproducts, low in energy consumption and wide in industrial application value.

Owner:DALIAN INST OF CHEM PHYSICS CHINESE ACAD OF SCI

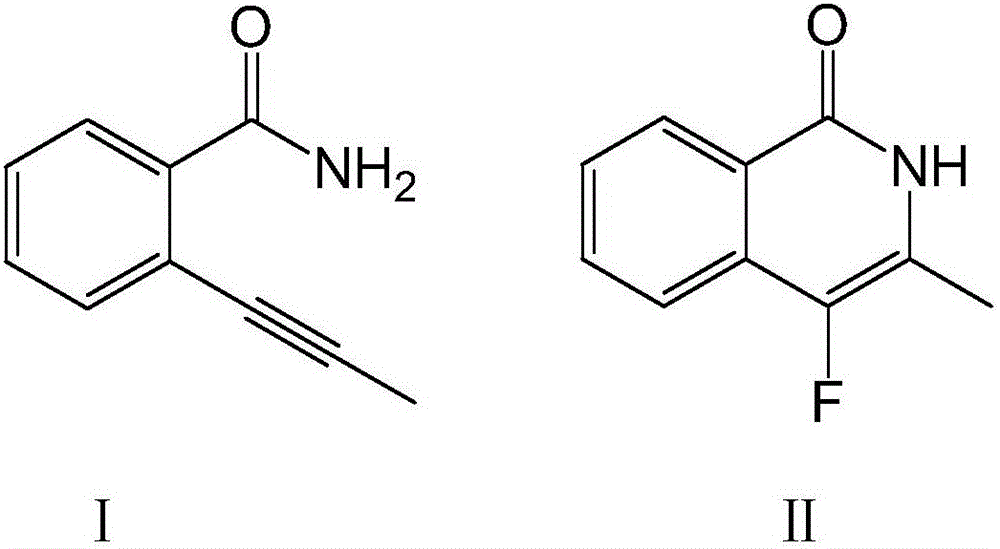

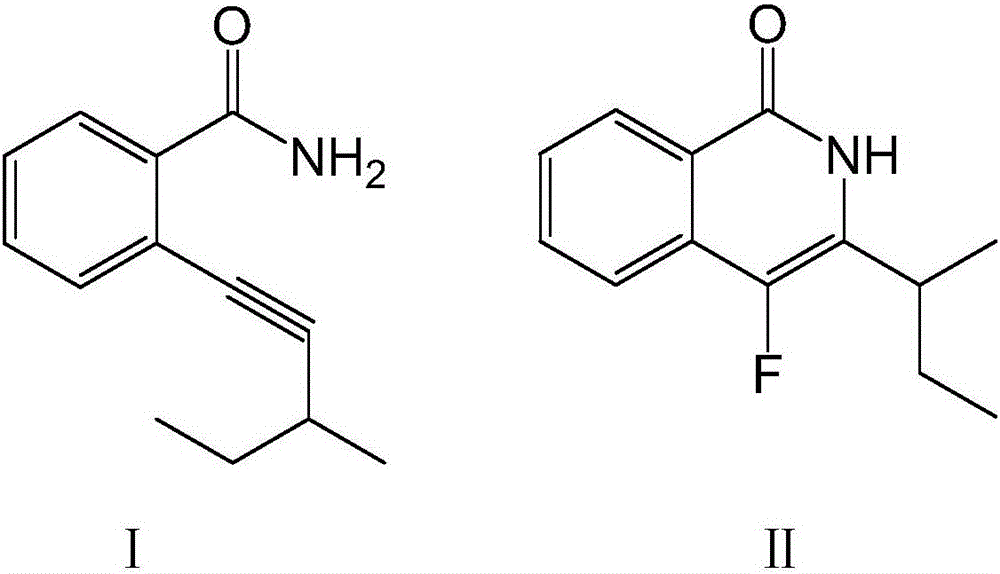

Fluoroisoquinolone compound and synthesis method thereof

InactiveCN105859617AHigh selectivityHigh yieldOrganic chemistryOrganic-compounds/hydrides/coordination-complexes catalystsArylSynthesis methods

The invention discloses a fluoroisoquinolone compound and a preparation method thereof. The reaction mechanism of the method is characterized in that a compound I reacts with a fluorating agent under the catalysis of a catalyst to generate a ring closing effect in order to generate the compound II, and R in the formulas of the compound I and the compound II is a C1-C6 alkyl group, a C1-C6 alkyloxy group, an aryl group or a heteroaryl group. A high-efficiency multi-component catalyst system is adopted, so the selectivity of an intramolecular cyclization reaction is improved, and the yield of the target product is improved. The preparation method has the advantages of simple steps, simple operation, high production efficiency, mild environment conditions needed by the reaction, and wide industrial application values.

Owner:叶芳

Scouring agent for silk fabric and application method of scouring agent

InactiveCN107287889AProtective silk fibroinGood refining effectAnimal fibresDiphenyl etherReaction temperature

The invention discloses a scouring agent for a silk fabric and an application method of the scouring agent. The scouring agent is prepared from the following components in parts by weight: a liquid A, including 100 parts of potassium octyl diphenyl ether disulfonate, 20-40 parts of octadecyl alcohol polyoxyethylene ether, 8-12 parts of sodium diethylhexyl sulfosuccinate, 2-5 parts of a chelating dispersant and 4-6 parts of propargyl alcohol, and a liquid B, including 10 parts of papain and 80-110 parts of a buffering agent. The invention further provides an application method of the scouring agent for the silk fabric. The scouring agent is relatively low in reaction temperature, mild in pH and good in scouring effect. The scouring agent is capable of preventing the fabric from being damaged, and the fabric is capable of maintaining relatively good hand feeling and improving the commercial value of the silk fabric.

Owner:SUZHOU WILDER IND & TRADE

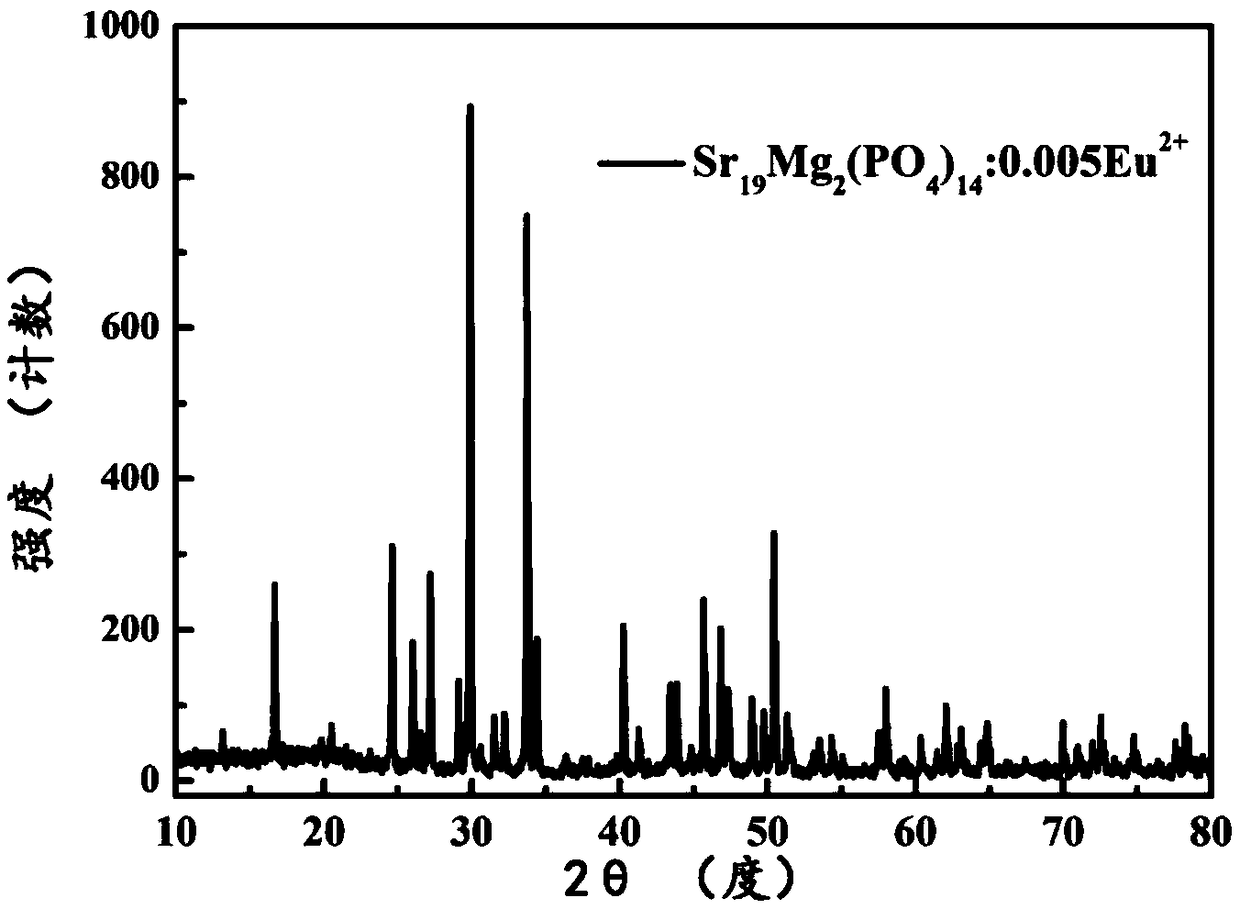

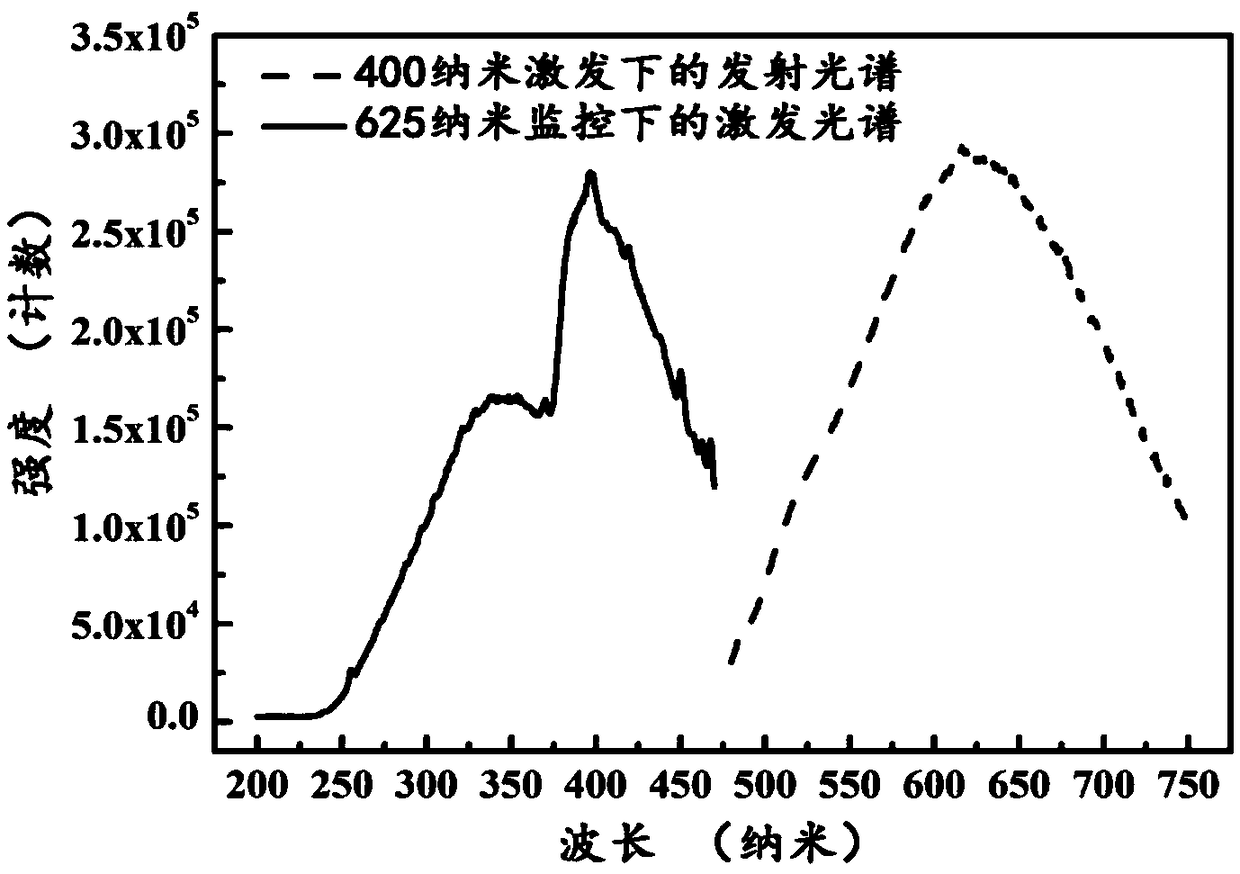

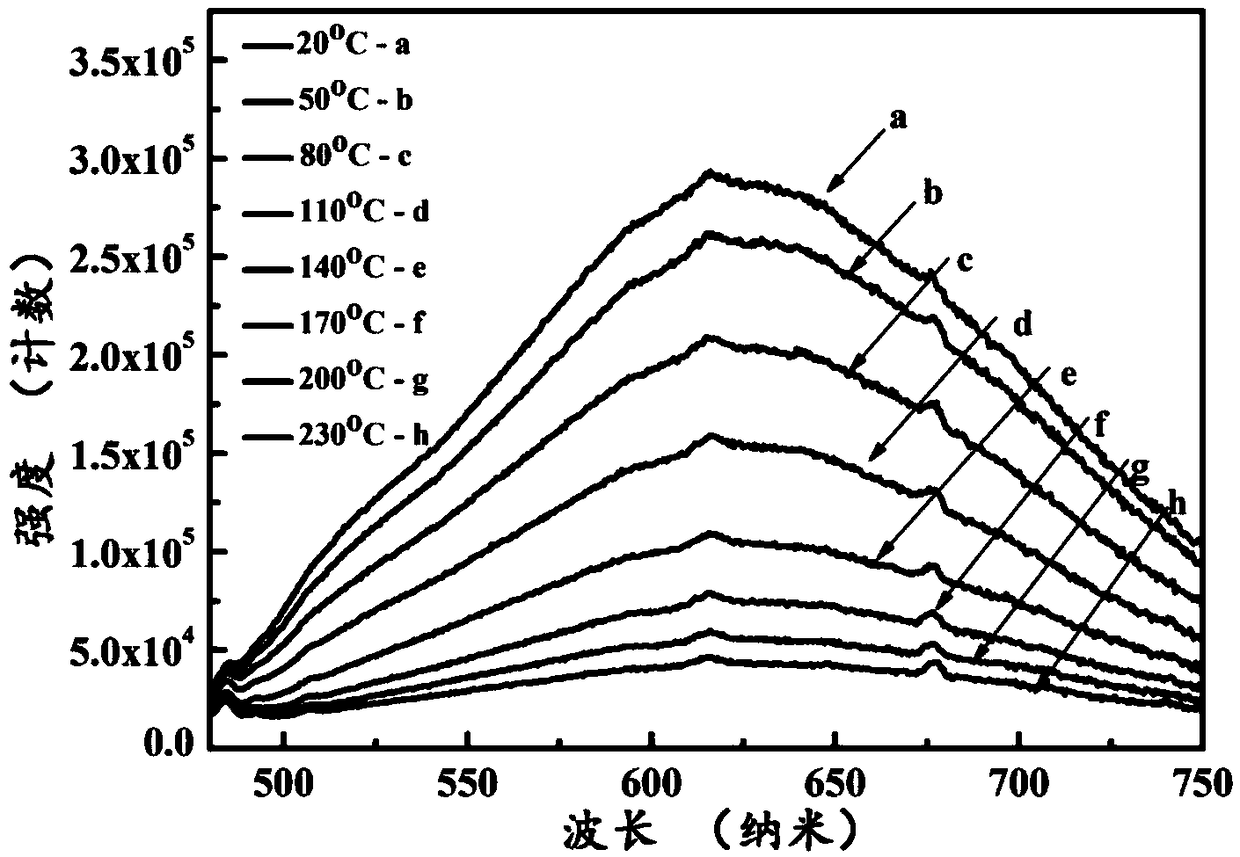

Red strontium magnesium phosphate fluorescent material as well as preparation method and application thereof

ActiveCN108822842AGood physical and chemical stabilityCalcination temperature is lowEnergy efficient lightingLuminescent compositionsMagnesium phosphateMagnesium orthophosphate

The invention discloses a red strontium magnesium phosphate fluorescent material as well as a preparation method and application thereof. The red strontium magnesium phosphate fluorescent material isSr19(1-X)Eu19xMg2(PO4)14, and raw materials are weighed according to the molar ratio of each element in Sr:Eu:Mg=19(1-X):19x:2 and Mg:P=1:7, mixed under a reducing atmosphere, heated to 900 DEG C andmaintained the temperature for 4 hours, then heated to 1200 DEG C and maintained the temperature for 6 hours, and finally cooled to room temperature along with a furnace. The invention has the advantages that Eu2+ can obtain red light with emission wavelength of 625 nm at excitation wavelength of 400 nm after Eu2+ is dopped with Sr19Mg2 (PO4) 14 icons, which provides the red spectrum required by high color rendering in semiconductor lighting, and has high luminescence efficiency, good thermal stability and excellent chemical stability. The preparation method provided by the invention is simple, mild in synthetic conditions and suitable for mass production, and has great industrial application value.

Owner:DALIAN NATIONALITIES UNIVERSITY

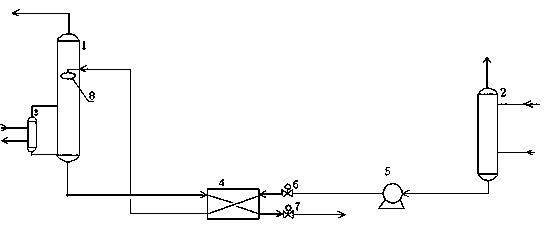

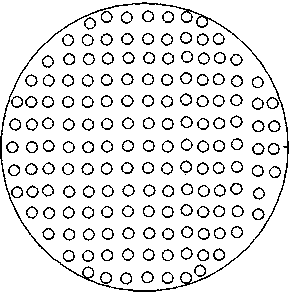

Method for recovering methanol from tail gas washing water in low-temperature methanol washing technology

ActiveCN103524298ARaise the pHReduce steam usageOrganic compound preparationHydroxy compound separation/purificationAcid washingWastewater

The invention provides a method for recovering methanol from tail gas washing water in a low-temperature methanol washing technology. The method comprises the following flows: exchanging heat of washing water from a tail gas washing tower and wastewater at the bottom of a methanol / water separating tower in a heat exchanger, and sending the wastewater out of a boundary region for processing after cooling; heating the washing water to about 100 DEG C, feeding the washing water into the methanol / water separating tower, providing a distributor in the methanol / water separating tower, evenly distributing the heated washing water on a tower tray through the distributer; distilling and separating the washing water in the methanol / water separating tower after quickly releasing the dissolved CO2, and recovering methanol after condensing an overhead component. By adopting the method for recovering methanol from the tail gas washing water in the low-temperature methanol washing technology disclosed by the invention, corrosion of acid washing water on the wall of the methanol / water separating tower is reduced to the lowest extent; the service life of the methanol / water separating tower can be prolonged; meanwhile, the device and operation costs are reduced.

Owner:NANJING CHENGZHI CLEAN ENERGY CO LTD

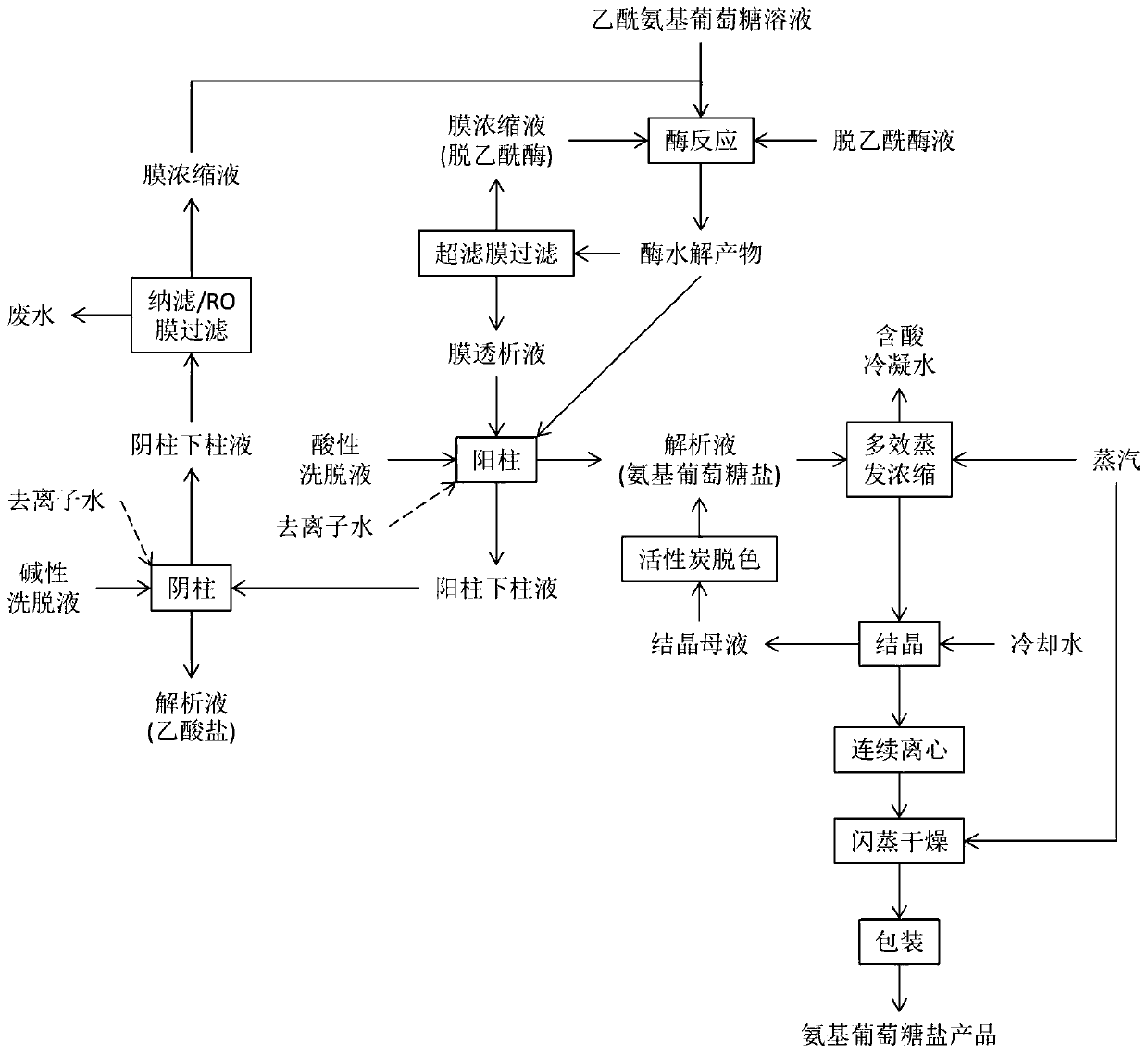

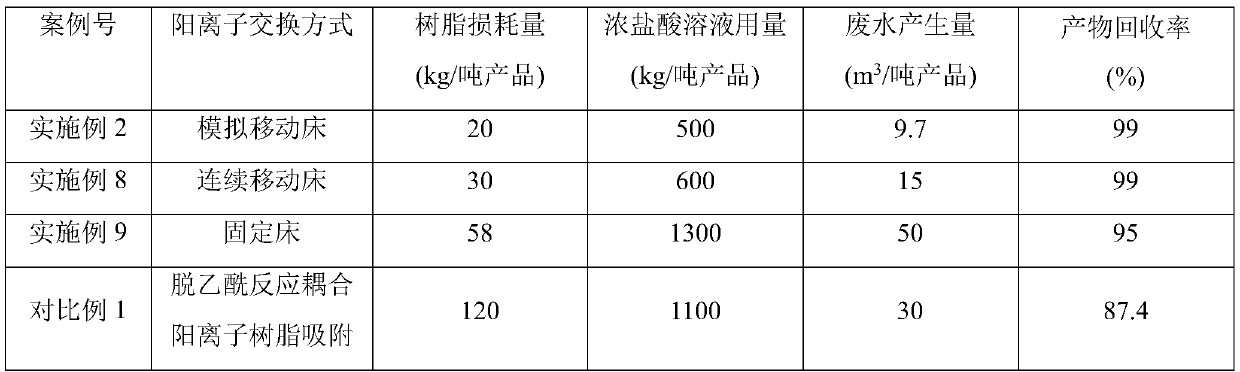

Method for producing GlcNAc salts by enzymic method and purifying GlcNAc salts

PendingCN111518857AHigh purity crystalReduce consumptionSugar derivativesChemical industrySodium acetateAcetic acid

The invention discloses a method for producing GlcNAc salts by an enzymic method and purifying the GlcNAc salts, and belongs to the technical field of bioengineering. According to the method, N-acetyl-D-(+)-glucosamine is used as a raw material and is hydrolyzed by deacetylase to obtain GlcNAc and acetic acid; then, the GlcNAc salts are obtained through separation by eluting cation exchange columns by an acid solution; and meanwhile, a byproduct of sodium acetate is obtained through anion exchange recovery. The obtained GlcNAc salts are subjected to concentration, crystallization, decoloring and drying to obtain high-purity GlcNAc salt crystals. According to the method, a cyclic utilization process of enzymes, a cyclic recovery process of residue substrates and a recovery process of aceticacid are combined. The conversion rate of the N-acetyl-D-(+)-glucosamine and the total yield of the GlcNAc salt product are improved, and meanwhile, enzymes are cyclically utilized, so that the residue substrates circulate to be sufficiently converted, and the acetic acid is utilized as resources. Through operation conditions at the normal temperature, the resin loss rate is low; the generation quantity of hydrochloric acid waste liquid is very small; and the economic benefits of energy saving and consumption reduction and the effects of environment protection and safety are realized.

Owner:JIANGSU HEVI BIOTECH CO LTD +1

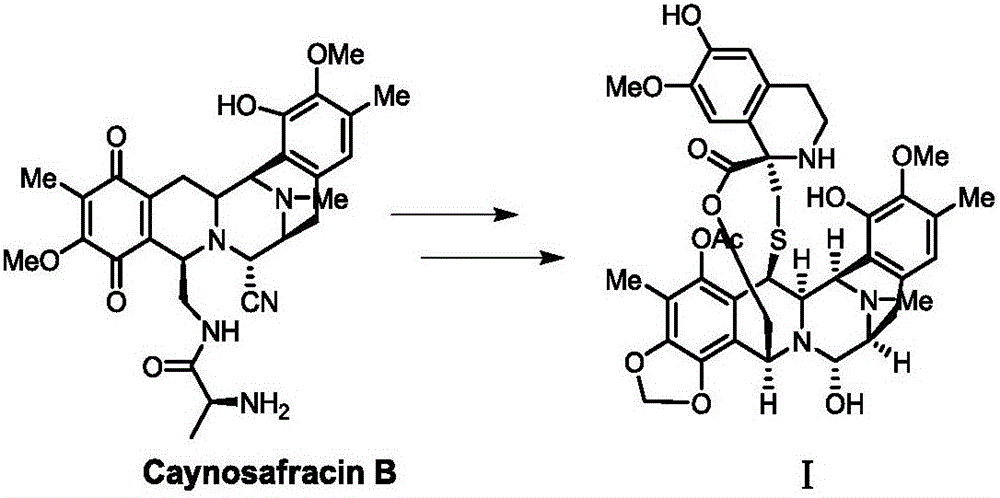

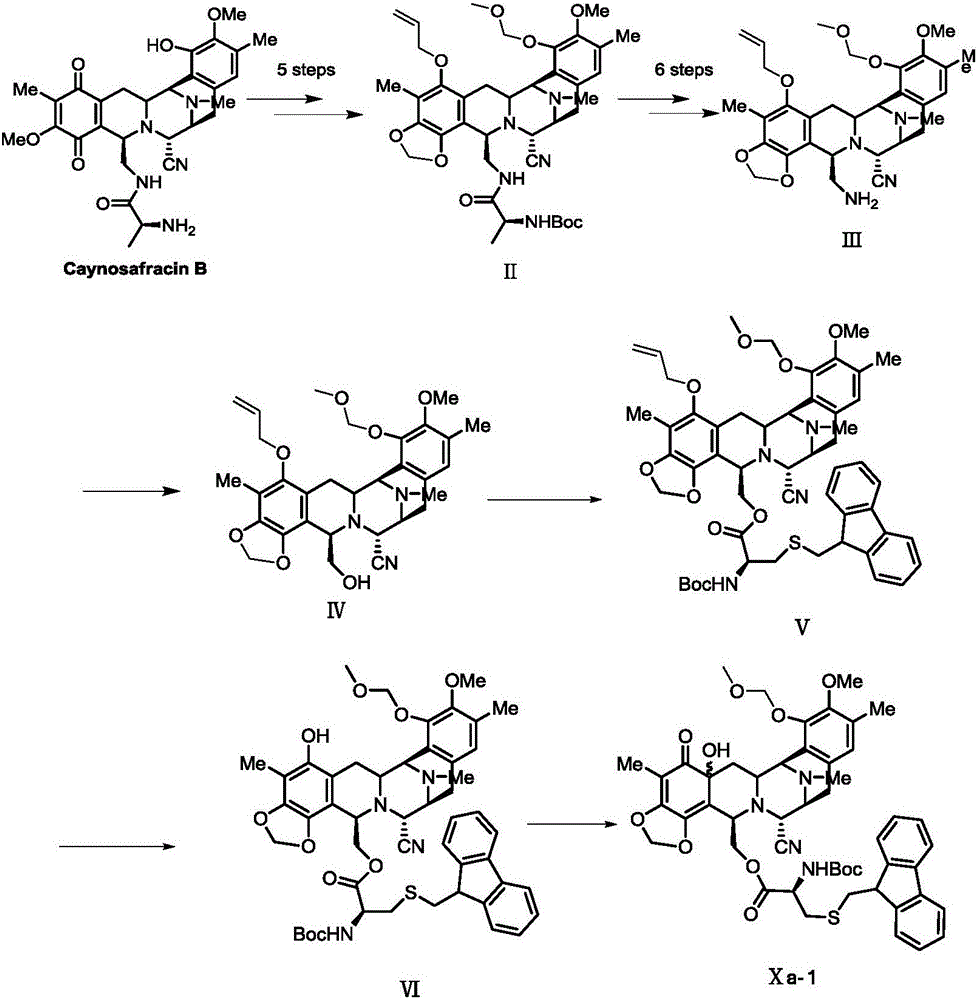

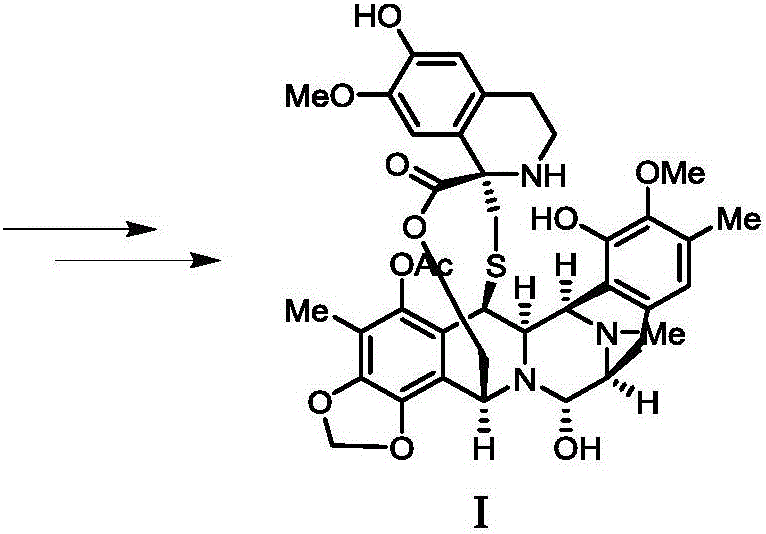

Preparation method and intermediate of trabectedin

ActiveCN107522698AEasy to synthesizeHigh industrial application valueOrganic chemistryBulk chemical productionSafracin BTrabectedin

The invention provides a novel preparation method for trabectedin. According to the method, safracin B is used as a starting raw material and undergoes a series of reactions to synthesize trabectedin. The raw material used in the method is easily available; the method is few in synthesis steps; a highly toxic organotin reagent is not used in the method, so the method is safe and low in cost; and the method has good industrial application value.

Owner:ZHEJIANG HISUN PHARMA CO LTD +1

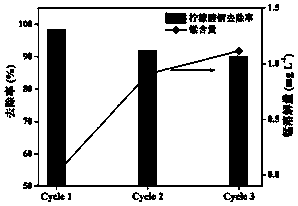

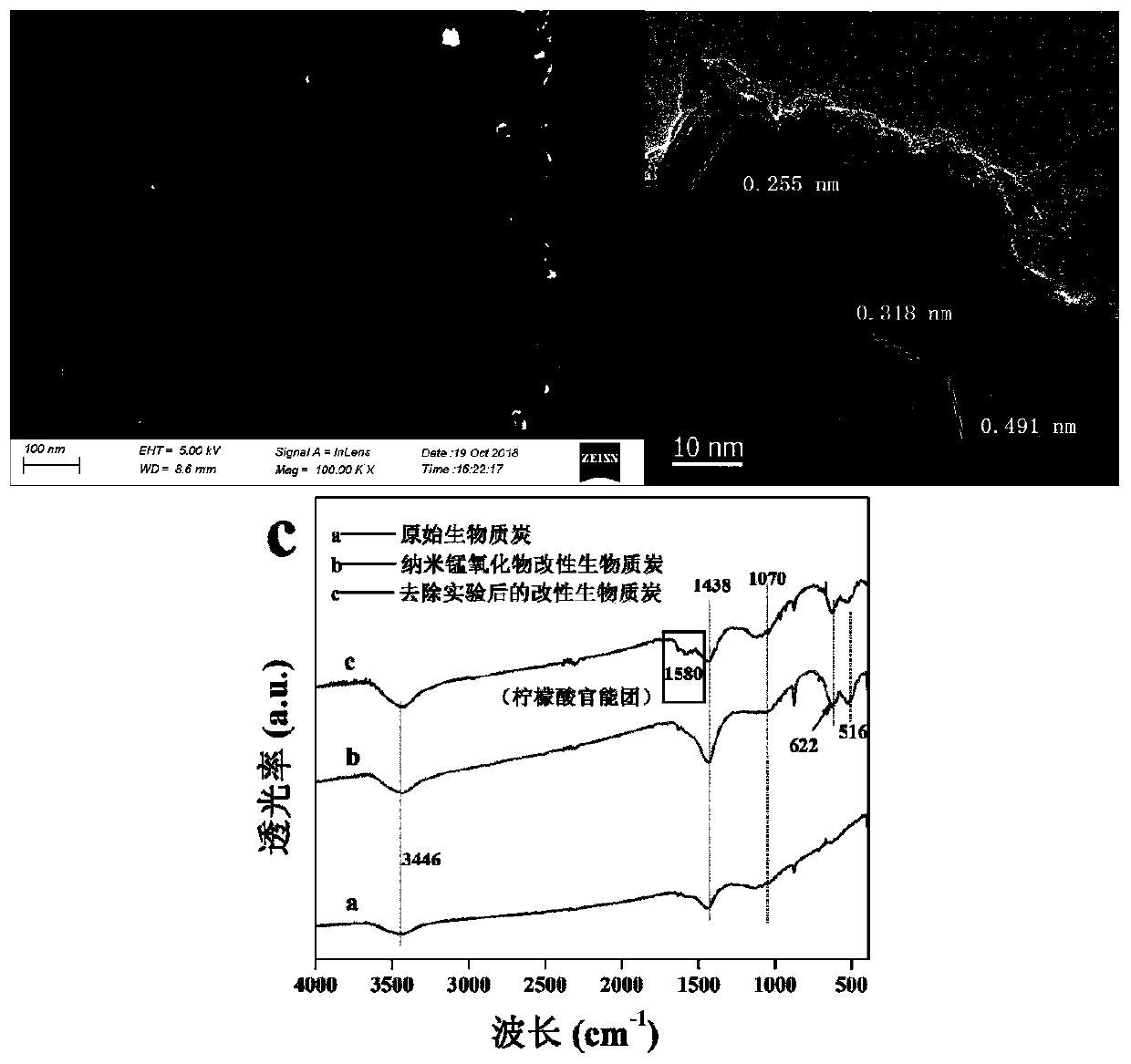

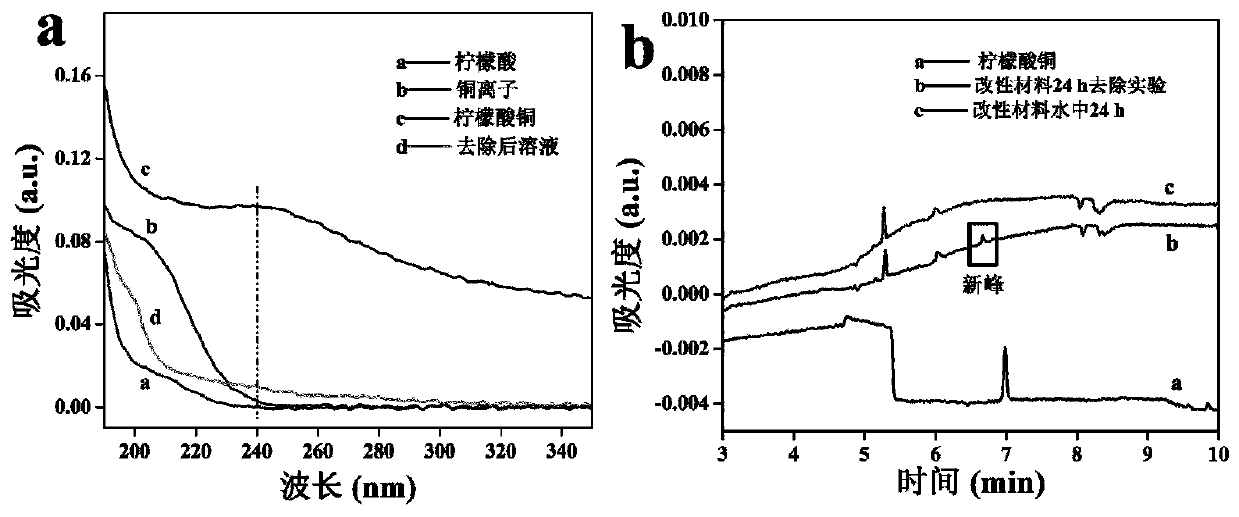

Nano-manganese-oxide-modified biomass charcoal, preparation method and method for removing copper citrate

ActiveCN110743495AEfficient removalLow mobilityOther chemical processesWater contaminantsSorbentCarbonization

The invention discloses a nano-manganese-oxide-modified biomass charcoal and a preparation method. A nano-manganese-oxide-modified biomass charcoal composite material is synthesized as an adsorbent bycombining the advantages of each of the biomass charcoal and manganese oxide, good stability and oxidability are achieved, and the treatment of contaminated water containing complex heavy metal has low cost, high-efficiency and no secondary pollution. The invention further discloses a method for removing copper citrate by using nano-manganese-oxide-modified biomass carbon and a mechanism study. The preparation method of the nano-manganese-oxide-modified biomass charcoal comprises the steps that (11) nano manganese oxide is synthesized, coconut shell biomass charcoal is added to a 0.15M potassium permanganate solution, a liquid-solid ratio of 1 / 10 is maintained, the mixture is continued to be stirred, filtered and dried; after the mixture is cooled to a room temperature, the mixture is impregnates with absolute ethyl alcohol, then filtered and dried; and (12) carbonization is carried out, the material obtained in the step (11) is placed in a tube furnace, and the mixture is roasted atair atmosphere and then cooled to the room temperature.

Owner:BEIHANG UNIV

Method for utilizing coal gangue waste

The invention relates to a comprehensive utilization method for coal gangue waste combined with spent cathode carbon blocks in the aluminum electrolysis industry. The method comprises the following concrete steps: smashing coal gangue and the spent cathode carbon blocks into powder, drying, then burdening in a certain proportion, removing alkaline soluble impurities in a mixed material by using astrong alkali liquid, washing to be neutral with hot water, drying, then in an inert or reducing atmosphere, heating to 1400-1700 DEG C, carrying out heat preservation for a period of time, so that mixed powder containing silicon carbide is obtained, then oxidizing and combusting the powder in an oxidizing atmosphere for removing residual carbon powder, dispersing the obtained powder into hydrofluoric acid for removing residual silicon dioxide, cleaning, and drying, so that silicon carbide powder can be obtained. The obtained silicon carbide product is high in purity and small in particle sizeand has extremely high industrial application value; meanwhile, industrial solid wastes coal gangue and spent cathode carbon blocks are taken as raw materials, so that the method provided by the invention has positive significance in directions of reducing waste pollution, protecting the environment and recycling resources.

Owner:CENT SOUTH UNIV

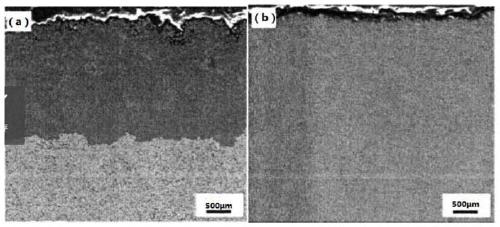

Double-layer structure hard alloy with cubic phase-rich surface layer and preparation method thereof

ActiveCN111363963AImprove solubilityGreat industrial application valueSolid state diffusion coatingAlloyTitanium carbide

The invention belongs to the technical field of alloy materials, and specifically relates to a double-layer structure hard alloy with a cubic phase-rich surface layer and a preparation method thereof.The double-layer structure hard alloy with the cubic phase-rich surface layer comprises the following ingredients and the mass percentage thereof: 4 to 6% of titanium carbide, 6 to 10% of cobalt, 0.1to 1.0% of vanadium carbide, 0.1 to 1.0% of scandium, and 82 to 89.8% of tungsten carbide; and the double-layer structure hard alloy is made by a series of process steps such as ball milling, drying,granulation, compacting and low-pressure high-temperature sintering, etc. According to the double-layer structure hard alloy with the cubic phase-rich surface layer provided by the invention, by adding rare earth metal scandium in the formula, the solubility of nitrogen in a metal binding phase is greatly improved, and the thickness of the cubic phase-rich surface layer of the hard alloy is increased, and the hard alloy has excellent wear resistance; and by controlling the heating rate in the low-temperature sintering process, defect generation is reduced, so that the alloy structure is compact and is more suitable for industrial application.

Owner:广东正信硬质材料技术研发有限公司

Radiation-orientated sintered magnetic ring processing method

ActiveCN108922764AUniform penetrationPenetration controllableInductances/transformers/magnets manufactureRemanenceMacroscopic scale

The invention discloses a radiation-orientated sintered magnetic ring processing method. In a penetration process, except for atomic diffusion motion of a target permeation source relative to a magnetic ring, the target permeation source and the magnetic ring have macroscopic relative motion rather than relative fixation in macroscopic position, wherein the macroscopic relative motion does not include ball milling motion and refers to rotating or stirring motion between the magnetic ring and the target permeation source. The magnetic ring is obtained by radiation orientated forming through a rotating magnetic field. By adoption of the method, magnetic performances of the radiation-orientated sintered magnetic ring are improved, coercivity is remarkably improved under the condition that evident reduction of remanence is avoided, magnetic flux thermal decay is remarkably reduced, and excellent magnetic performances and thermal stability are achieved.

Owner:SHENZHEN RADIMAG TECH CO LTD

Preparation method of silicon carbide from blast furnace water quenching slag and waste activated carbon

ActiveCN107934969AHas an activation effectLower the activation energy of the reactionSilicon carbideActivated carbonSlag

The invention discloses a preparation method of silicon carbide from blast furnace water quenching slag and waste activated carbon. The preparation method comprises the following steps: preparing materials of the blast furnace water quenching slag and the waste activated carbon in a mass ratio of 1: (0.5 to 2) and mixing uniformly to obtain a mixture A; placing the mixture A in an acid solution Bin a mass ratio of 1: (5 to 10), stirring at least for 4 h at the temperature of 70 to 90 DEG C, filtering and cleaning filter residues; and drying the filter residues to obtain backup filter residues, heating the backup filter residues to the temperature of 1400 to 1700 DEG C in inert or reducing atmosphere and carrying out heat preservation for 3 to 10 h and then lowering the temperature to 600to 900 DEG C, carrying out heat preservation for 3 to 5 h in oxidizing atmosphere, and performing acid pickling to obtain silicon carbide powder. The silicon carbide obtained by the invention has highpurity, small particle size, narrow distribution, and good industrial application values. Furthermore, the blast furnace water quenching slag and the waste activated carbon are taken as the raw materials, thereby being of positive significance in the aspects of reducing waste pollution, protecting environments and recycling resources.

Owner:CENT SOUTH UNIV

Metal complex ligand, metal complex, preparation method and application thereof, high molecular polymer, preparation method and application thereof

ActiveCN101684075BHigh catalytic activityImprove catalytic stabilityLiquid crystal compositionsGroup 4/14 element organic compoundsStructural formulaNew materials

The invention discloses a metal complex ligand, a metal complex, a preparation method and application thereof. Structural formulas of the metal (M) complex ligand Ia-Ic and the metal complex IIa-IIc thereof are shown in the description. The metal complex has the advantages of higher catalytic activity, diversity of structures and physical properties and the like, and provides diverse optimal selection to catalytic application of various raw materials. The invention also discloses various novel functional polymer materials generated by ring-opening metathesis polymerization (ROMP) of different types of small molecular cycloolefines and application thereof, and structures of the materials are shown below.

Owner:ZANNAN SCITECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com