Double-layer structure hard alloy with cubic phase-rich surface layer and preparation method thereof

A technology with rich cubic phase and double-layer structure, applied in coating, solid-state diffusion coating, metal material coating process, etc., can solve the problem that the surface layer of rich cubic phase is difficult to have industrial application value and cannot reach industrial value. , the nitriding effect is not ideal, etc., to achieve the effect of extensive industrial application value, less defects, and increased thickness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0036] Example 1. A double-layer structured cemented carbide with rich cubic phase on the surface

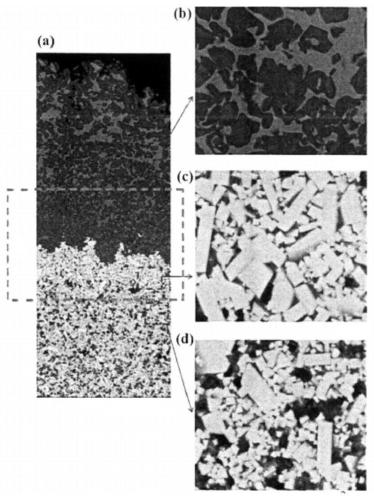

[0037] The double-layer structured cemented carbide with rich cubic phase in the surface layer includes the following components and their mass percentages: titanium carbide 5%, cobalt 8%, vanadium carbide 0.5%, scandium 0.5%, tungsten carbide 86%; the surface layer rich cubic phase The particle size of each component in the double-layer structure cemented carbide raw material is 1μm, expressed as WC-8Co-5TiC-0.5VC-0.5Sc; the structure diagram is as follows figure 1 As shown in the figure: (a)-alloy surface surrounding structure, (b)-alloy rich cubic phase surface layer, (c)-alloy transition layer, (d)-alloy inner layer.

[0038] The preparation method of the double-layer structure cemented carbide with rich cubic phase on the surface layer specifically includes the following steps:

[0039] S1. Weigh all the raw materials according to the formula, mix them evenly, add the ball milling...

Embodiment 2

[0049] Example 2. A double-layer structure cemented carbide with a surface layer rich in cubic phase

[0050] A hard alloy with a double-layer structure with a rich cubic phase on the surface layer includes the following components and their mass percentages: 4% titanium carbide, 6% cobalt, 0.1% vanadium carbide, 0.1% scandium, and 89.8% tungsten carbide. The particle size of each component in the double-layered cemented carbide raw material with rich cubic phase in the surface layer is: titanium carbide 0.8 μm, cobalt 1.0 μm, vanadium carbide 1.0 μm, scandium 1.0 μm, and tungsten carbide 0.2 μm.

[0051] The preparation method of the double-layer structure cemented carbide with rich cubic phase on the surface layer specifically includes the following steps:

[0052] S1. Weigh titanium carbide, cobalt, vanadium carbide, scandium and tungsten carbide according to the formula, mix them evenly, add ball milling media and place them in a ball mill for ball milling to obtain wet mixture A...

Embodiment 3

[0062] Example 3. A double-layer structure cemented carbide with rich cubic phase on the surface

[0063] A hard alloy with a double-layer structure with a cubic-rich surface layer includes the following components and their mass percentages: 6% titanium carbide, 10% cobalt, 1.0% vanadium carbide, 1.0% scandium, and 82% tungsten carbide; The particle size of each component in the double-layer structure cemented carbide raw material is: titanium carbide 1.0 μm, cobalt 1.0 μm, vanadium carbide 1.0 μm, scandium 1.0 μm, and tungsten carbide 2.5 μm.

[0064] The preparation method of the double-layer structure cemented carbide with rich cubic phase on the surface layer specifically includes the following steps:

[0065] S1. Weigh titanium carbide, cobalt, vanadium carbide, scandium and tungsten carbide according to the formula, mix them evenly, add ball milling media and place them in a ball mill for ball milling to obtain wet mixture A; the ball milling media is anhydrous alcohol 99.2 W...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com