Nano-manganese-oxide-modified biomass charcoal, preparation method and method for removing copper citrate

A technology of biomass charcoal and copper citrate, applied in chemical instruments and methods, oxidized water/sewage treatment, water pollutants, etc., can solve problems such as poor removal effect, and achieve the effect of good effect, easy repeatability and efficient removal

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0034] Step 1: Preparation of nano-manganese oxide modified biochar: a preparation method of nano-manganese oxide modified bio-char, comprising the following steps:

[0035](11) Synthesis of nano-manganese oxides: Add coconut shell biochar to 0.15M potassium permanganate solution, keep the liquid-solid ratio at 1 / 10, keep stirring, filter, and dry; after cooling to room temperature, use anhydrous Ethanol impregnation, slowly reducing the potassium permanganate loaded on the biochar, and then filtering and drying;

[0036] (12) Carbonization: the material obtained in step (1) is placed in a tube furnace, roasted at a high temperature in an air atmosphere, and then cooled to room temperature to obtain nano-manganese oxide modified biochar.

Embodiment 1

[0038] This embodiment provides the preparation of nano-manganese oxide modified biochar, including the following steps:

[0039] (1) Material preparation: coconut shell biochar, 0.15M potassium permanganate solution, absolute ethanol;

[0040] (2) Synthesis: 1g of coconut shell biochar was added to 10mL of 0.15M potassium permanganate, magnetically stirred at 300rpm for 4h, filtered and dried in a constant temperature oven at 90°C for 12h; cooled to room temperature, soaked in 10mL of absolute ethanol for 10min, After filtering, dry in a constant temperature oven at 90°C for 12 hours;

[0041] (3) Carbonization: put the material obtained in step (2) into a tube furnace for calcination at 400° C. for 1 h in an air atmosphere; cool to room temperature and take it out for use.

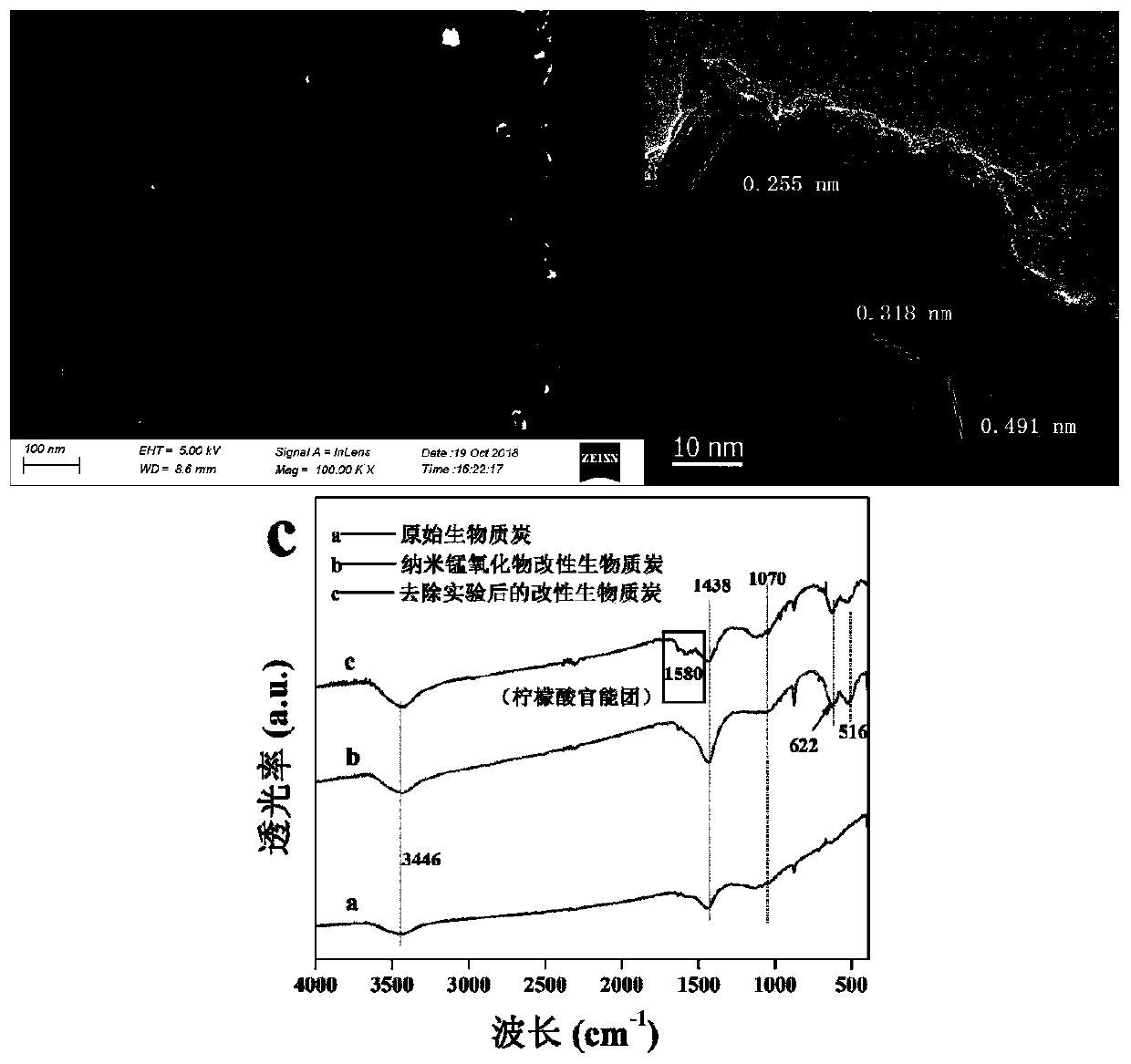

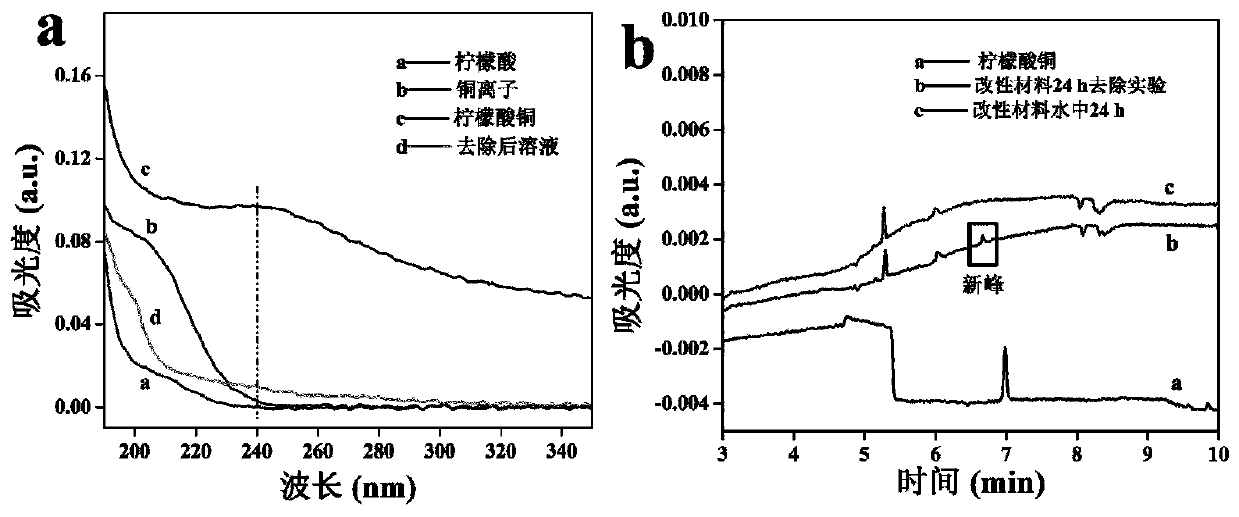

[0042] Such as figure 1 Shown is the morphology of the nano-manganese oxide modified biochar prepared by the present invention. figure 1 Among them, a is the scanning electron microscope image, the su...

Embodiment 2

[0050] The present embodiment provides the method for removing copper citrate by extracting nano-manganese oxide modified biomass charcoal, comprising the following steps:

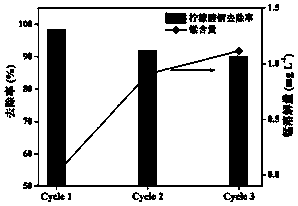

[0051] (1) Determination of the optimum dosage: at room temperature, first take 0.01, 0.05, 0.1, and 0.15 g of the nano-manganese oxide modified biochar obtained in Example 1 and put them into an Erlenmeyer flask; add 100 mL of pH value of about It is a 7.8 copper citrate solution, stirred at a constant speed, in order to achieve full adsorption equilibrium, shake at room temperature for 24 hours, take samples at different time intervals, filter with a 0.45 μm filter membrane, and refrigerate at 4°C for testing. The removal rate of metal copper was analyzed by inductively coupled plasma mass spectrometry, and the optimal dosage was determined to be 1g / L, and this optimal dosage was applied to follow-up research.

[0052] (2) Investigation of influencing factors: Since copper citrate exists stably in a wide...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| clearance rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com