Red strontium magnesium phosphate fluorescent material as well as preparation method and application thereof

A technology of strontium magnesium phosphate and fluorescent materials, which is applied in the field of red phosphate fluorescent materials and its preparation, can solve the problems that limit the wide application and promotion of fluorescent powder, and achieve good chemical stability, good matching, and good thermal stability Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0037] (1) According to the chemical formula Sr 19 Mg 2 (PO 4 ) 14 : 0.005Eu 2+ (Sr 18.905 Eu 0.095 Mg 2 (PO 4 ) 14 ) composition Weigh 0.9153gSrCO 3, 0.0264g MgO, 0.6063g (NH 4 ) 2 HPO 4 and 0.0054g Eu 2 o 3 , and grind for 30 minutes to mix the raw materials evenly to obtain a mixed powder;

[0038] (2) Put the mixed powder into a corundum crucible, put it into a tube-type atmosphere furnace, and feed the mixed reducing gas, that is, flowing N 2 / H 2 (The volume ratio is 9 / 1) in a reducing atmosphere, raise the temperature at a rate of 5 °C / min to 900 °C for 4 hours, then increase the rate of temperature at 5 °C / min to 1200 °C, keep it at 6 hours, and then heat at 5 °C The rate per minute is lowered to 500°C and then naturally cooled to room temperature, and the obtained powder is taken out and ground into powder to obtain the required phosphor material.

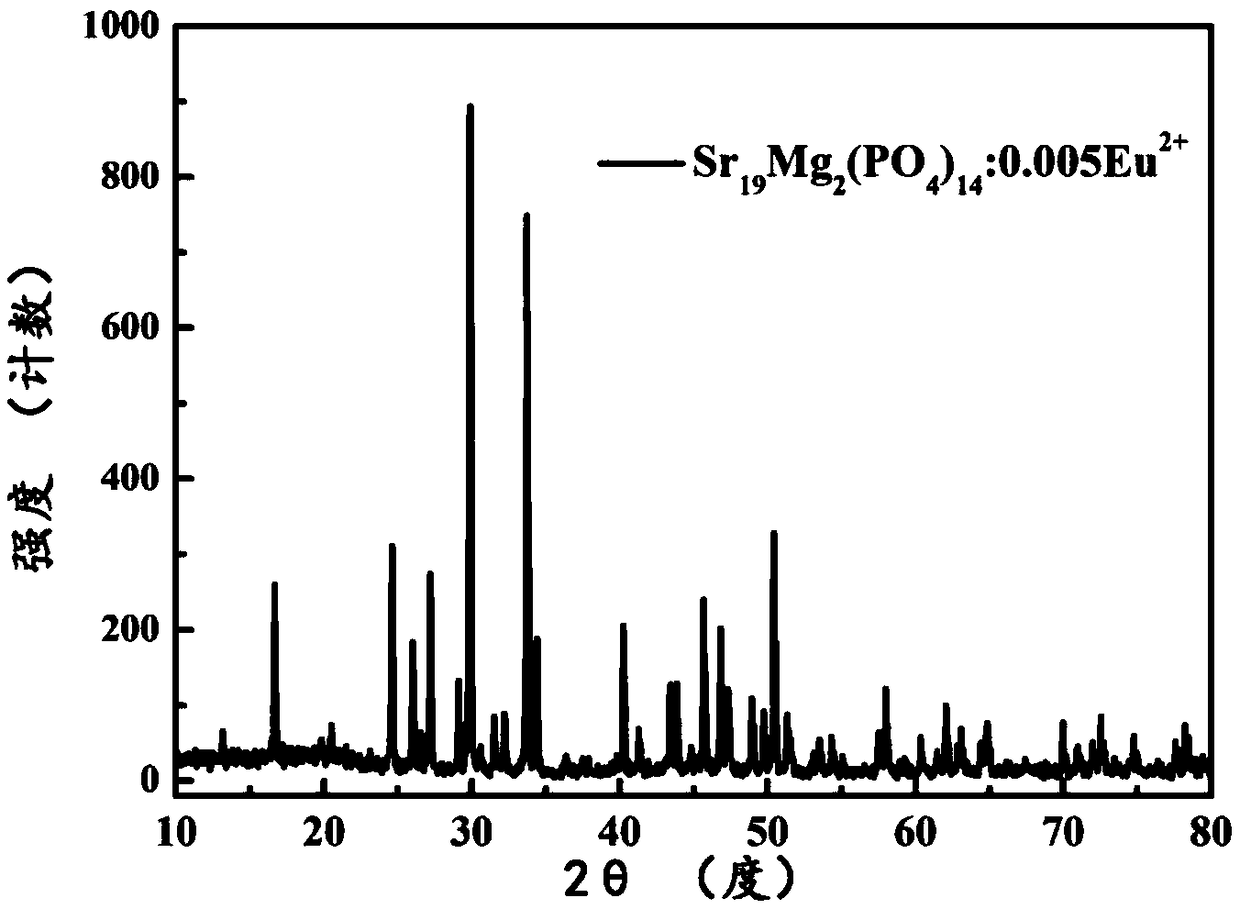

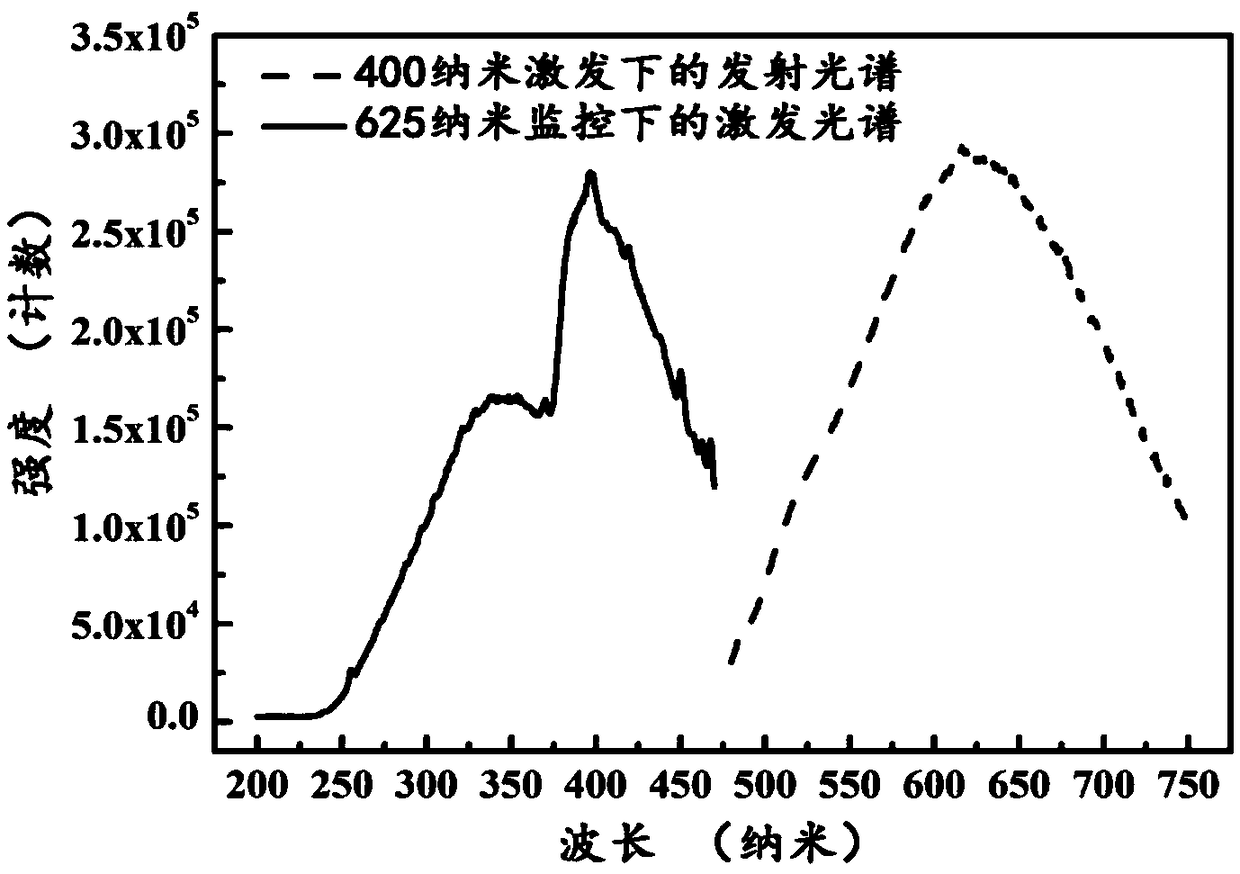

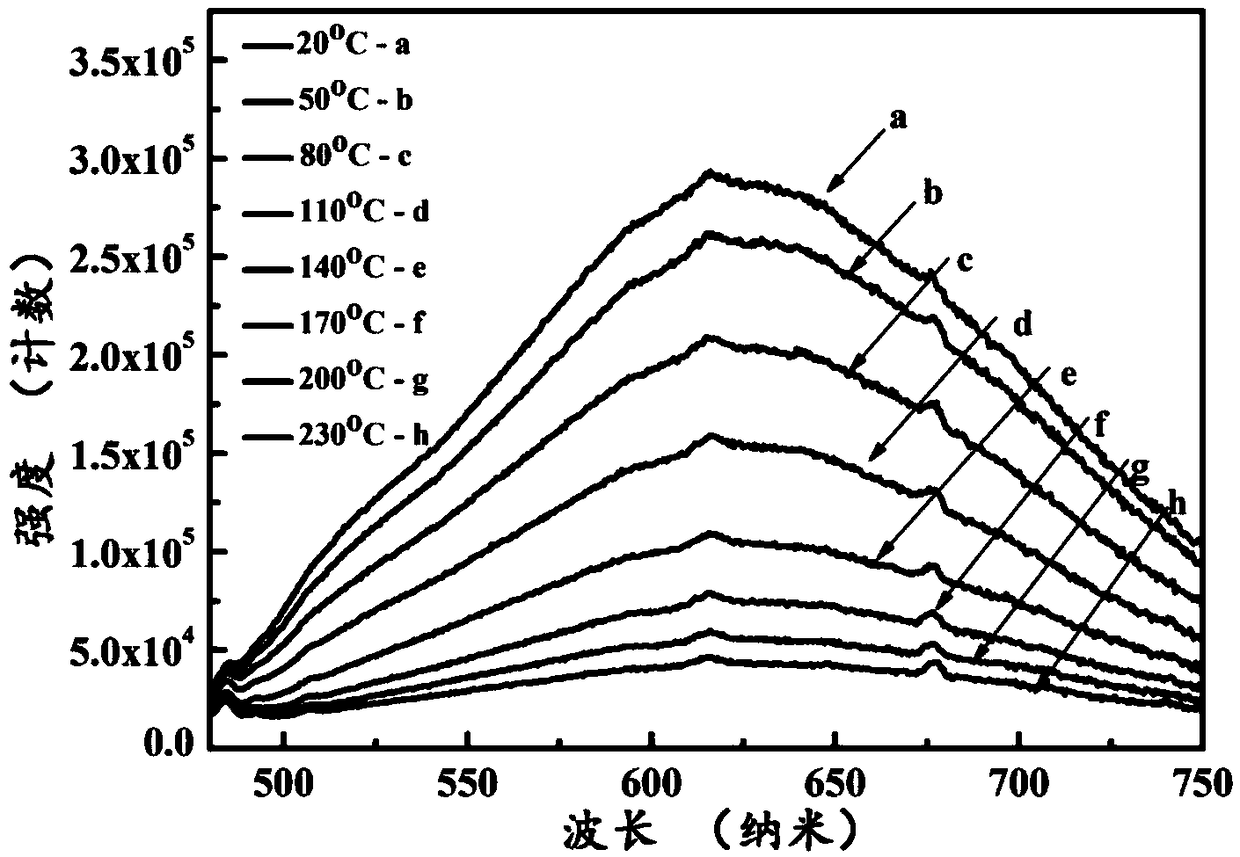

[0039] as the picture shows, figure 1 The sample Sr obtained in Example 1 is shown 18.905 Eu 0.095 M...

Embodiment 2

[0044] (1) According to the chemical formula Sr 19 Mg 2 (PO 4 ) 14 :0.01Eu 2+ (Sr 18.81 Eu 0.19 Mg 2 (PO 4 ) 14 ) composition Weigh 1.7465g Sr(NO 3 ) 2 4H 2 O, 0.0636g 4MgCO 3 ·Mg(OH) 2 ·5H 2 O, 0.4490g H 3 PO 4 and 0.0109g Eu 2 o 3 , grind for 45min to make the raw materials mix evenly;

[0045] (2) Put the mixed powder into a corundum crucible, put it into a tube-type atmosphere furnace, and feed the mixed reducing gas, that is, flowing N 2 / H 2 In a reducing atmosphere in a mixed atmosphere (the volume ratio of nitrogen and hydrogen is 9 / 1), raise the temperature at a rate of 5 °C / min to 900 °C for 4 hours, then increase the rate of temperature to 1200 °C at a rate of 5 °C / min, and keep the temperature for 6 hours. Then cool down to 500° C. at a rate of 5° C. / min, then cool naturally to room temperature, take out the obtained powder and grind it into powder to obtain the required phosphor material. Figure 4 The sample Sr obtained in embodiment 2 is sho...

Embodiment 3

[0047] (1) According to the chemical formula Sr 19 Mg 2 (PO 4 ) 14 :0.02Eu 2+ (Sr 18.62 Eu 0.38 Mg 2 (PO 4 ) 14 ) composition Weigh 0.6290gSrO, 0.0263g MgO, 0.5250g NH 4 h 2 PO 4 and 0.0552g Eu(NO 3 ) 3 ·6H 2 O, grind for 60min to make the raw materials mix evenly;

[0048] (2) Put the mixed powder into a corundum crucible, put it into a tube-type atmosphere furnace, and feed the mixed reducing gas, that is, flowing N 2 / H 2 (The volume ratio is 9 / 1) in a reducing atmosphere, raise the temperature at a rate of 5 °C / min to 900 °C for 4 hours, then increase the rate of temperature at 5 °C / min to 1200 °C, keep it at 6 hours, and then heat at 5 °C The rate per minute is lowered to 500°C and then naturally cooled to room temperature, and the obtained powder is taken out and ground into powder to obtain the required phosphor material. Figure 7 The sample Sr obtained in embodiment 3 is shown 18.62 Eu 0.38 Mg 2 (PO 4 ) 14 Its XRD pattern shows that its basic str...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com