Metal complex ligand, metal complex, preparation method and application thereof, high molecular polymer, preparation method and application thereof

A metal complex, complex technology, applied in the direction of organic compound/hydride/coordination complex catalyst, one-component synthetic polymer rayon, non-metallic conductor, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

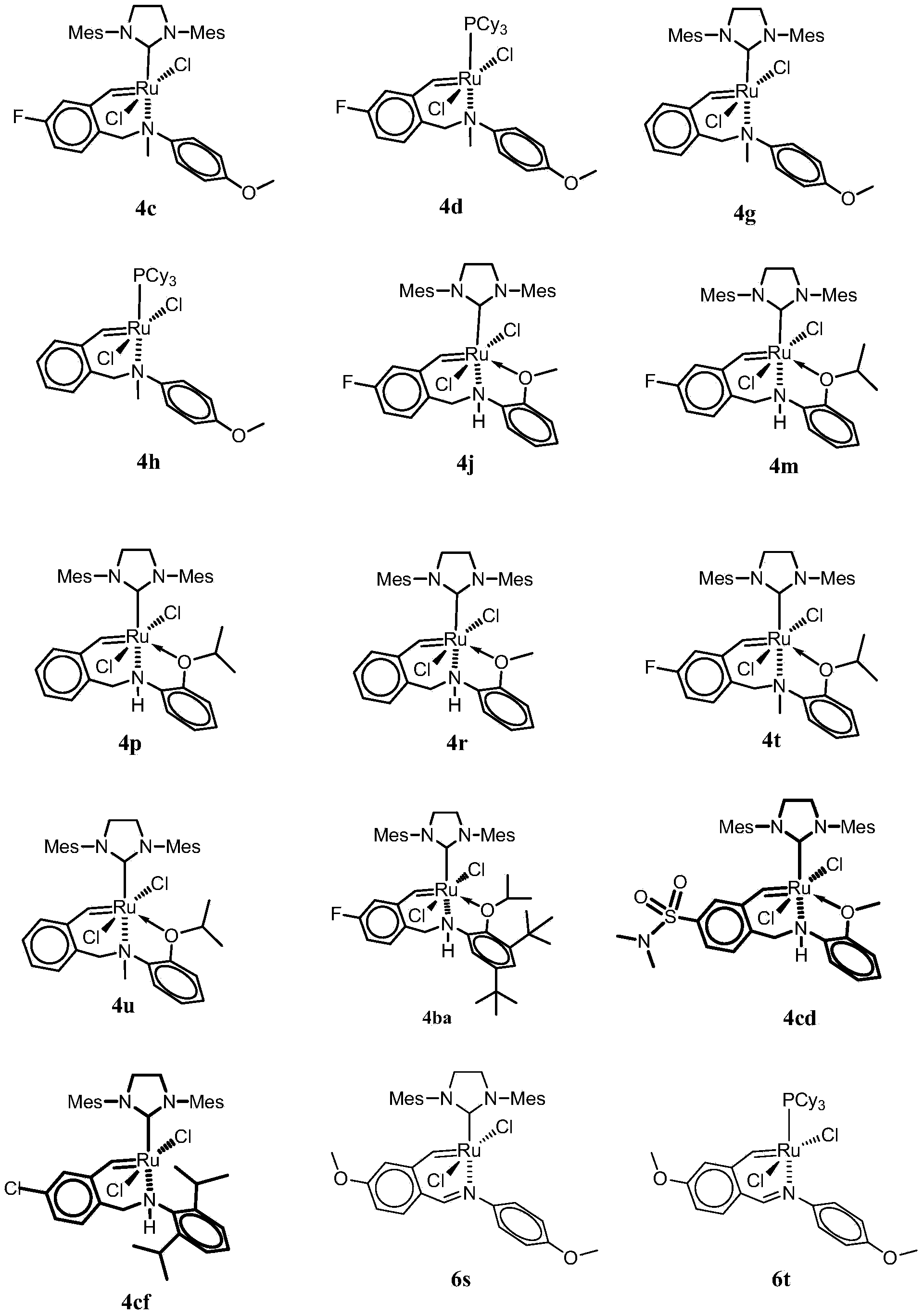

[0263] The synthesis of embodiment 1 ruthenium complex 4a

[0264] A 50mL two-neck flask was replaced with argon, and then added ligand 3a (10mmol), CuCl (30mmol, 3eq) and 30mL of dry DCM in sequence, and then replaced with argon three times, and then protected the closed system with an argon balloon. Ruthenium complex 1b (12 mmol) was added under the protection of argon, and reacted at room temperature for 0.5 hours. After the reaction was completed, silica gel was added to the filtrate to make sand, and the crude product was obtained by silica gel column chromatography, and then washed with methanol or pentane-DCM to obtain the green solid product 4a, the yield: 32%.

[0265] After detection, the ruthenium complex (4a) 1 HNMR (400MHz, CDCl 3 ): δ18.68 (s, Ru=CH), 7.23-6.65 (m, 10H, aromatic H), 6.36 (dd, J=2.8, 9.6Hz, 1H, aromatic H), 6.03 (d, J=12.8Hz , 1H, NCH 2 ), 4.14-3.90 (m, 4H, NCH 2 CH 2 N), 3.85(s, 3H, OCH 3 ), 3.47 (d, J=12.8Hz, 1H, NCH 2 ), 2.89-1.62 (m, 1...

Embodiment 2

[0266] The synthesis of embodiment 2 ruthenium complexes 4b:

[0267] A 50mL two-necked flask was replaced with argon, and then added ligand 3b (10mmol), CuCl (30mmol, 3eq) and 30mL of dry DCM in sequence, and then replaced with argon three times, and then protected the closed system with an argon balloon. Ruthenium complex 1a (12 mmol) was added under the protection of argon, and reacted at room temperature for 0.5 hours. After the reaction was completed, silica gel was added to the filtrate to make sand, and the crude product was obtained by silica gel column chromatography, and then washed with methanol or pentane-DCM to obtain the green solid product 4b, the yield: 35%.

[0268] After detection, the ruthenium complex (4b) 1 HNMR (400MHz, CDCl 3 ): δ19.28 (d, J = 8.4Hz, Ru = CH), 7.45 (d, J = 8.8Hz, 2H, aromatic H), 7.31-7.16 (m, 3H, aromatic H), 6.83 (d, J =8.8Hz, 2H, aromatic H), 5.13(t, J=12.4Hz, 1H, NH), 7.96(d, J=12.4Hz, 1H, NCH 2 ), 3.85 (d, J=12.4Hz, 1H, NCH 2 )...

Embodiment 3

[0269] The synthesis of embodiment 3 ruthenium complex 4c:

[0270]A 50mL two-necked flask was replaced with argon, and then added ligand 3c (10mmol), CuCl (30mmol, 3eq) and 30mL of dry DCM in sequence, and then replaced with argon three times, and then protected the closed system with an argon balloon. Ruthenium complex 1b (12 mmol) was added under the protection of argon, and reacted at room temperature for 0.5 hours. After the reaction was completed, silica gel sand was added to the filtrate after filtration, and the crude product was obtained by silica gel column chromatography, and then washed with methanol or pentane-DCM to obtain the green solid product 4c, the yield: 14%.

[0271] After detection, the ruthenium complex (4c) 1 HNMR (400MHz, CDCl 3 ): δ18.99 (s, Ru=CH), 7.483-7.444 (m, 1H, aromatic H), 7.192-6.862 (m, 7H, aromatic H), 6.715-6.662 (m, 1H, aromatic H), 5.293 (t, J=13.2Hz, 1H, NHCH 2 ), 4.19-3.58 (m, 8H, NHCH 2 , NCH 2 CH 2 N, NCH 3 ), 2.52-2.37 (m,...

PUM

| Property | Measurement | Unit |

|---|---|---|

| hardness | aaaaa | aaaaa |

| modulus | aaaaa | aaaaa |

| modulus | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com