Method for preparing titanium-containing molecular sieve

A molecular sieve and titanium source technology, applied in the field of inorganic chemical synthesis, can solve the problems of high cost, complicated production operation process, large amount of template agent TPAOH, etc., and achieve the effect of reducing production cost, avoiding organic pollution, and reducing the amount of consumption.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] In the first step, the silicon source is fumed silica gel, and the SiO in the silicon source 2 : Organic base template: TiO in titanium source 2 :H 2 The molar ratio of O is 1: 0.15: 0.02: 12; in the second step, the weight ratio of water: dry glue is 0.5: 1, and quantitative water is added at the bottom of the interlayer of the crystallization kettle, and the crystallization temperature and time are respectively 180 °C and 2 days.

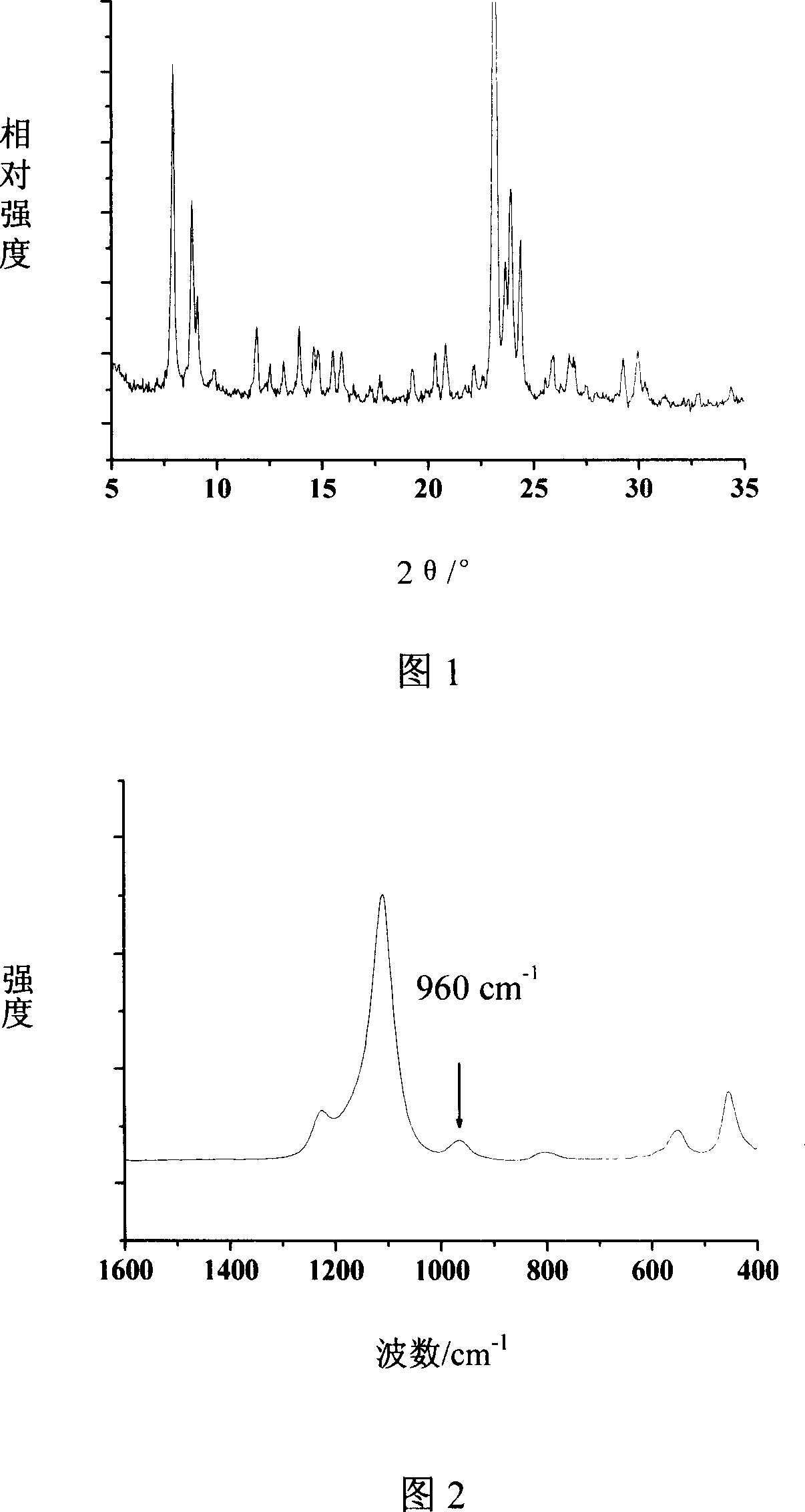

[0027] The XRD spectrum and IR spectrum of the product TS-1 molecular sieve of this example are shown in Figure 1 and Figure 2 respectively.

Embodiment 2

[0029] Implementation process is except following difference, and all the other are all the same with embodiment 1:

[0030] In the first step, the SiO in the silicon source 2 : Organic base template: TiO in titanium source 2 :H 2 The molar ratio of O is 1:0.1:0.005:8.

[0031] The XRD spectrum and IR spectrum of the product TS-1 molecular sieve in this example are similar to those shown in Figure 1 and Figure 2 respectively.

Embodiment 3

[0033] Implementation process is except following difference, and all the other are all the same with embodiment 1:

[0034] In the first step, the silicon source is solid silica gel; in the second step, the crystallization temperature and time are 170° C. and 3 days, respectively.

[0035] The XRD spectrum and IR spectrum of the product TS-1 molecular sieve in this example are similar to those shown in Figure 1 and Figure 2 respectively.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com