Patents

Literature

1043results about How to "Improve settlement performance" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

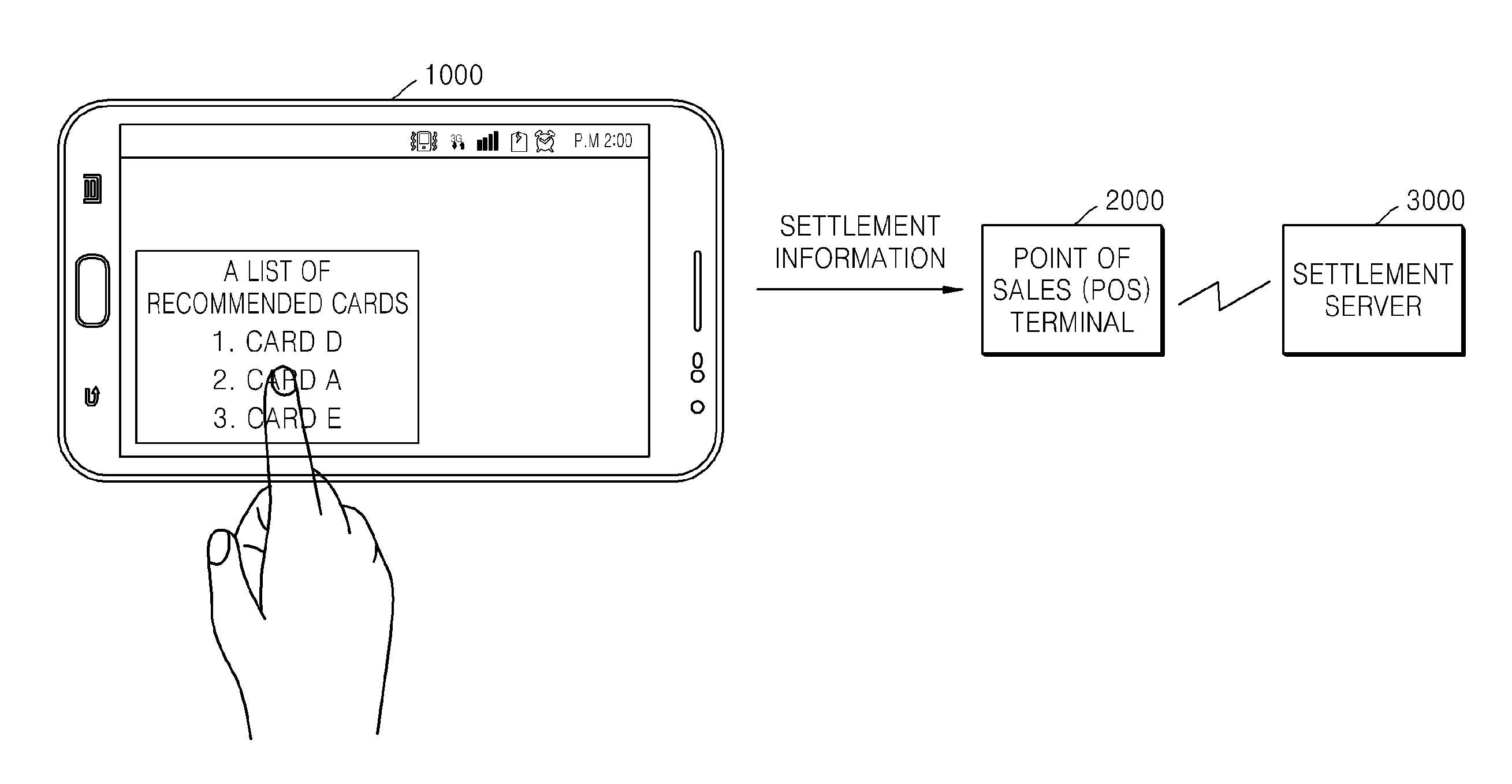

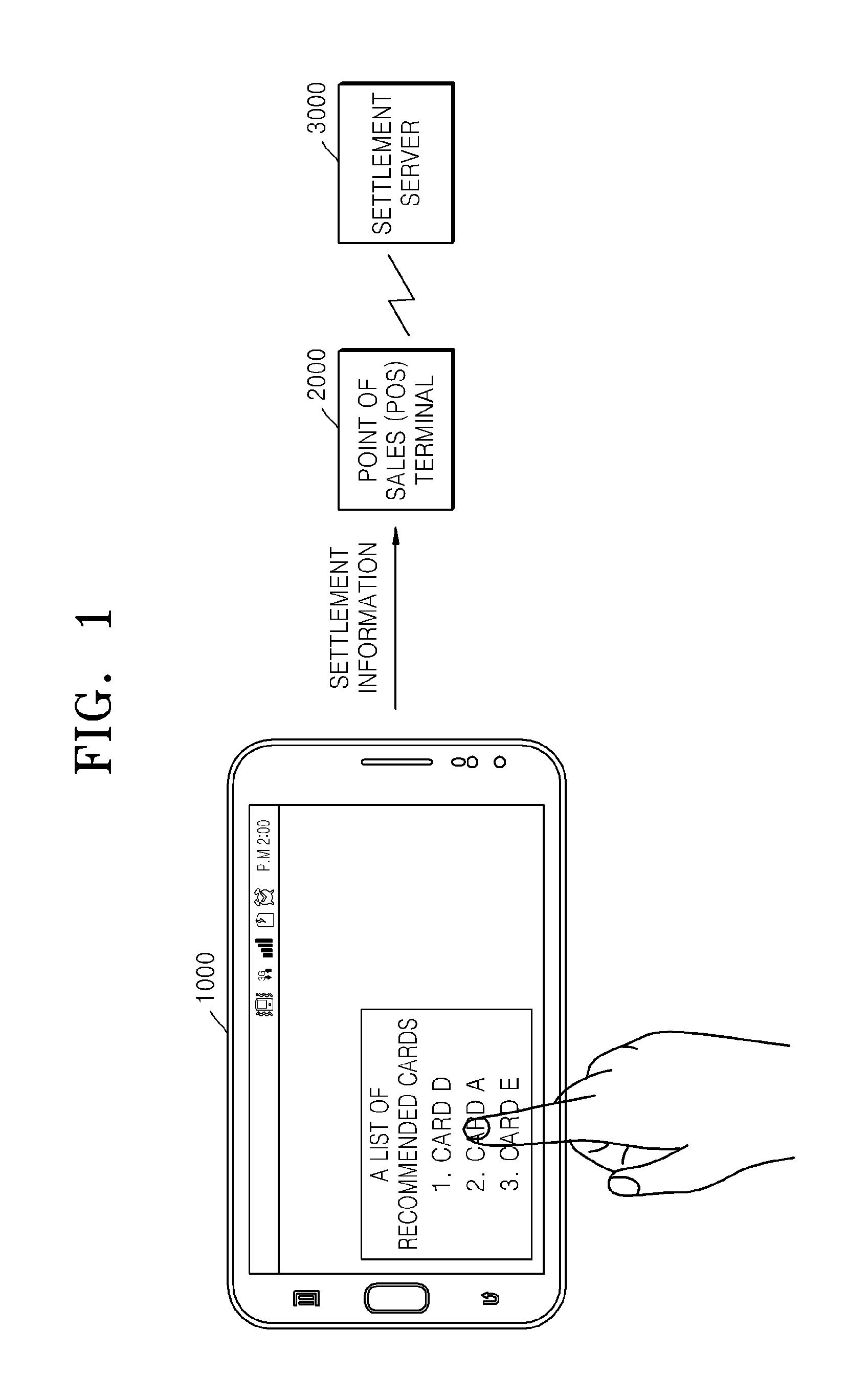

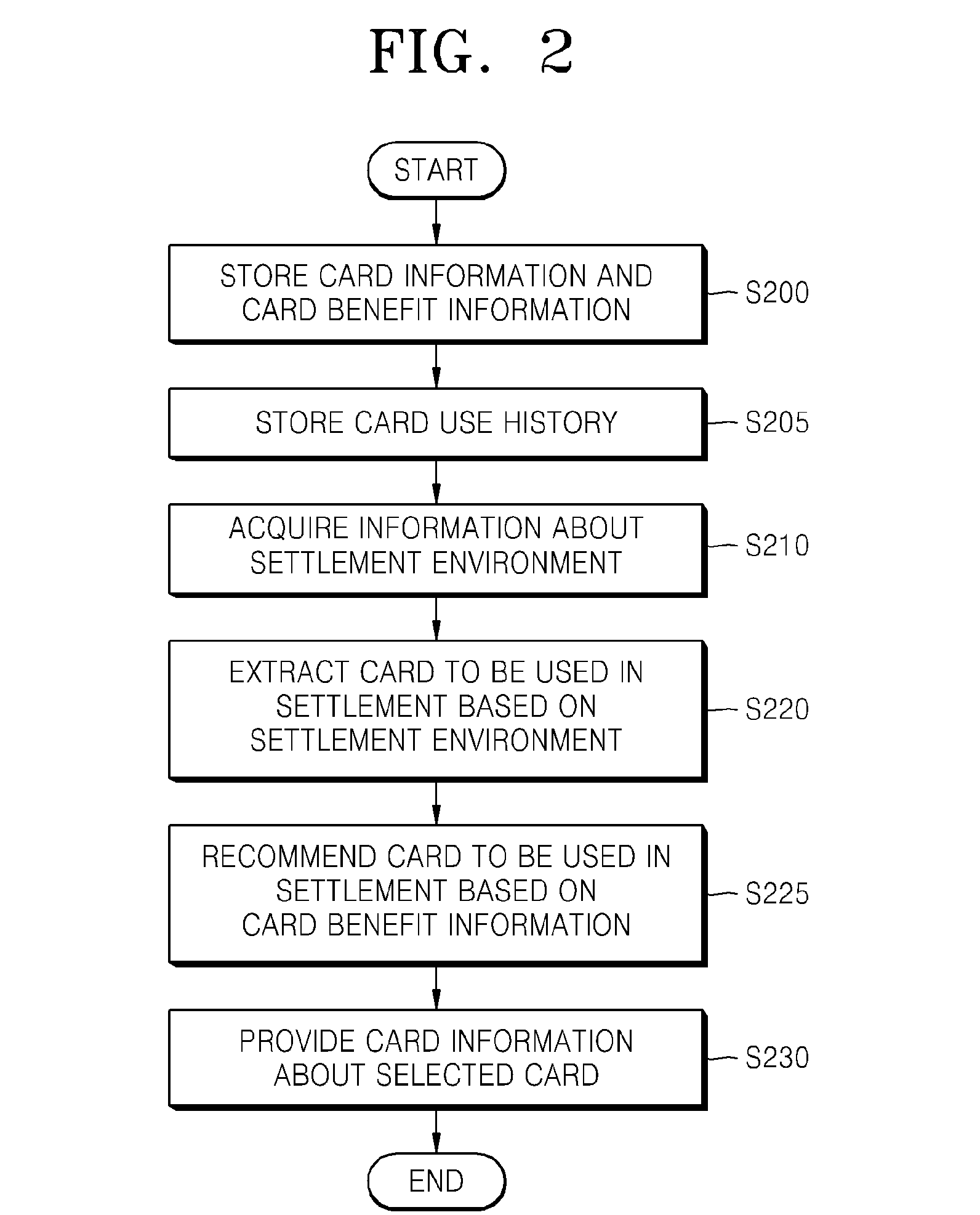

Method and apparatus for determining item based on interaction environment

ActiveUS20140058860A1Improve settlement performanceImprove performancePoint-of-sale network systemsPayment schemes/modelsComputer hardwareRelevant information

A method and an apparatus for using a device to determine an item, such as, for example, a card based on an interaction environment, such as, for example, a settlement environment, are provided. The method by which a device determines a card to be used in a settlement includes: acquiring a card use history of a card, which is stored in the device; acquiring information which relates to a settlement environment of the device; determining a card to be used in the settlement, based on the acquired information relating to the settlement environment and the acquired card use history; and providing settlement information which relates to the determined card to a point of sale (POS) terminal.

Owner:SAMSUNG ELECTRONICS CO LTD

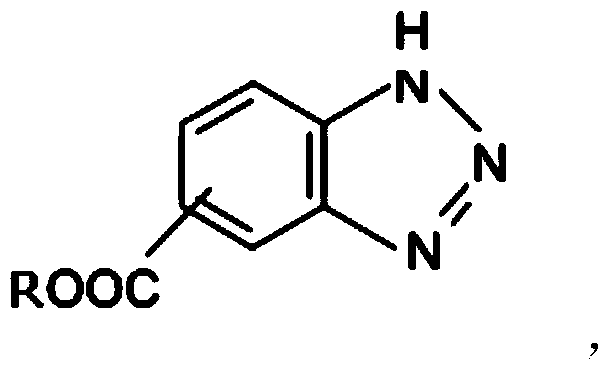

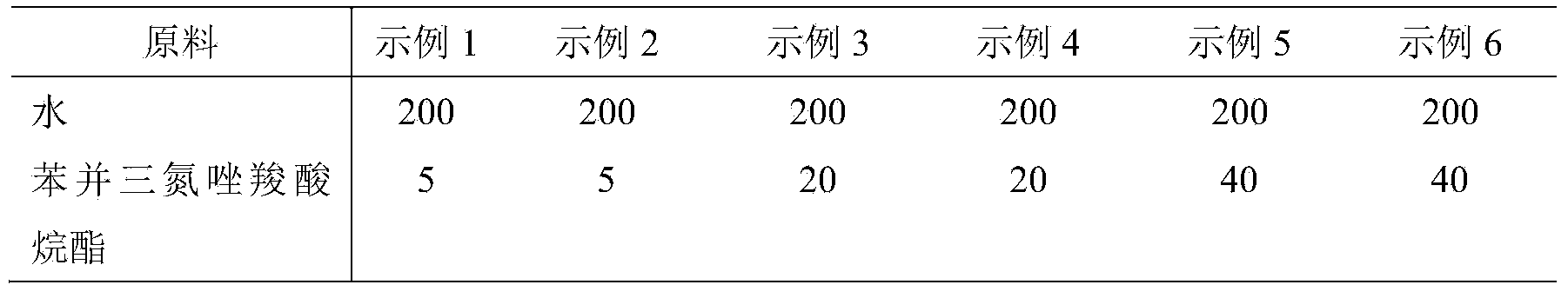

Water soluble full-alloy metal grinding fluid

ActiveCN104017636ALubricity achievedImprove stabilityLubricant compositionOrganic EsterNonferrous metal

The invention discloses a water soluble full-alloy metal grinding fluid which belongs to the technical field of metal grinding fluids. The metal grinding fluid is prepared from the following components in percentage by weight: 5-40wt% of an antirust agent, 1-20wt% of a cleaning agent, 0.1-10wt% of a lubricating corrosion inhibitor, 1-20wt% of a penetrant, 1-20wt% of a solubilizer, 10-40wt% of a PH adjustor, 0.5-5wt% of a defoamer and the balance of water. Based on the total weight of the water soluble full-alloy metal grinding fluid, the pH value of the water soluble full-alloy metal grinding fluid is 7-11. The lubricating corrosion inhibitor is long chain nitrogen heterocyclic ring organic ester. The water soluble full-alloy metal grinding fluid has excellent lubricating, rust-preventing, cleaning and cooling performances and can be widely applied to grinding of ferrous metals and nonferrous metals.

Owner:TSINGHUA UNIV

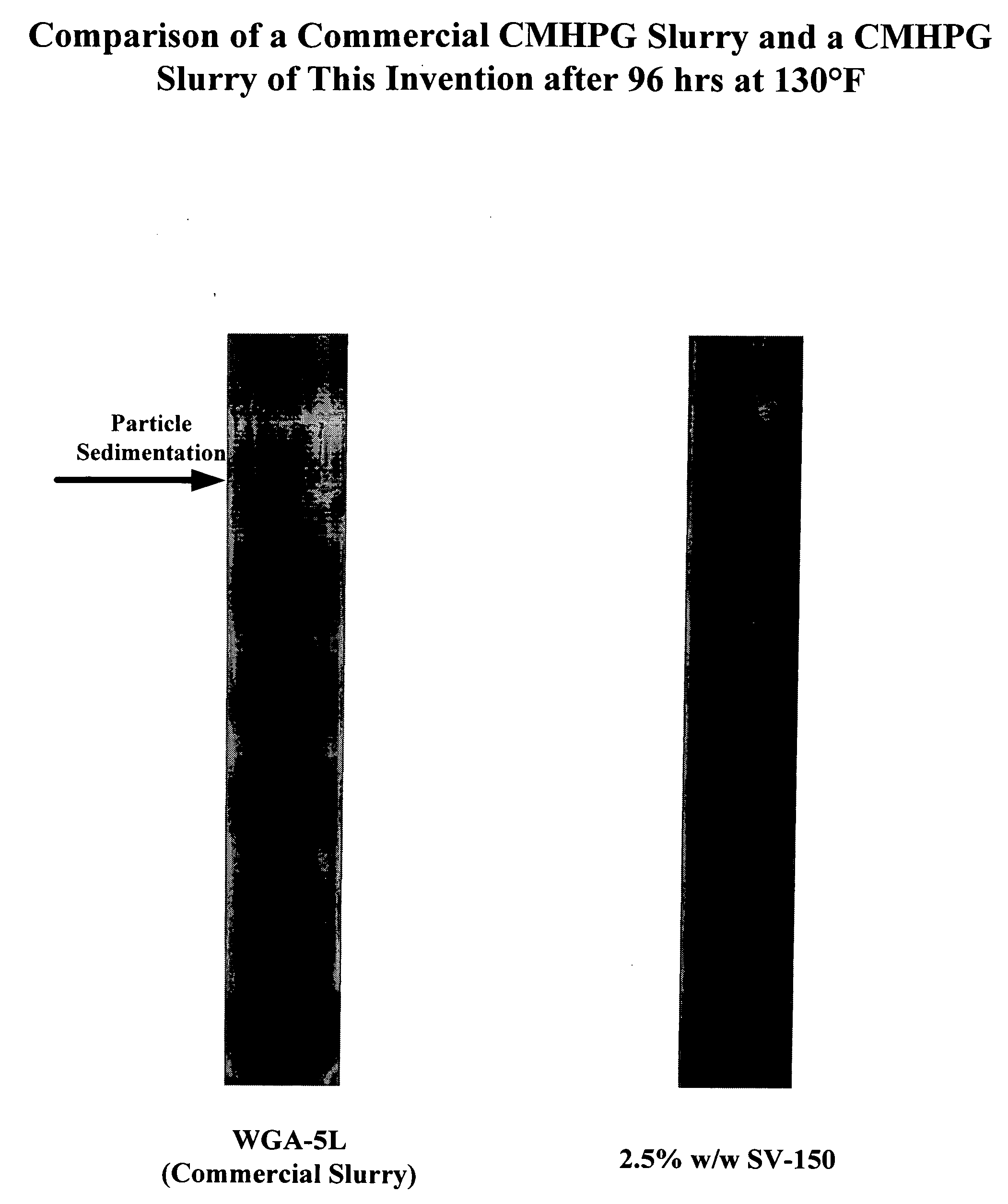

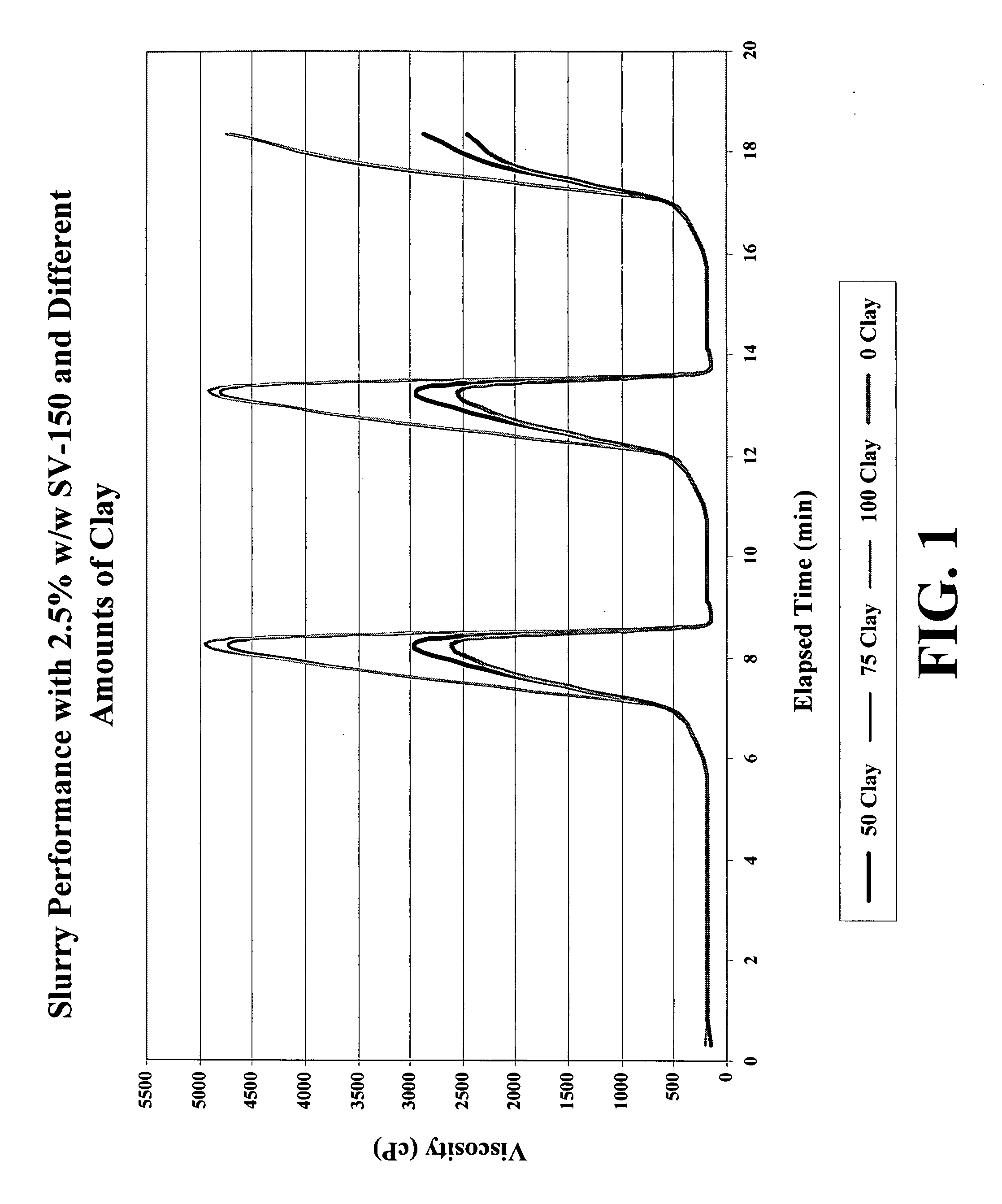

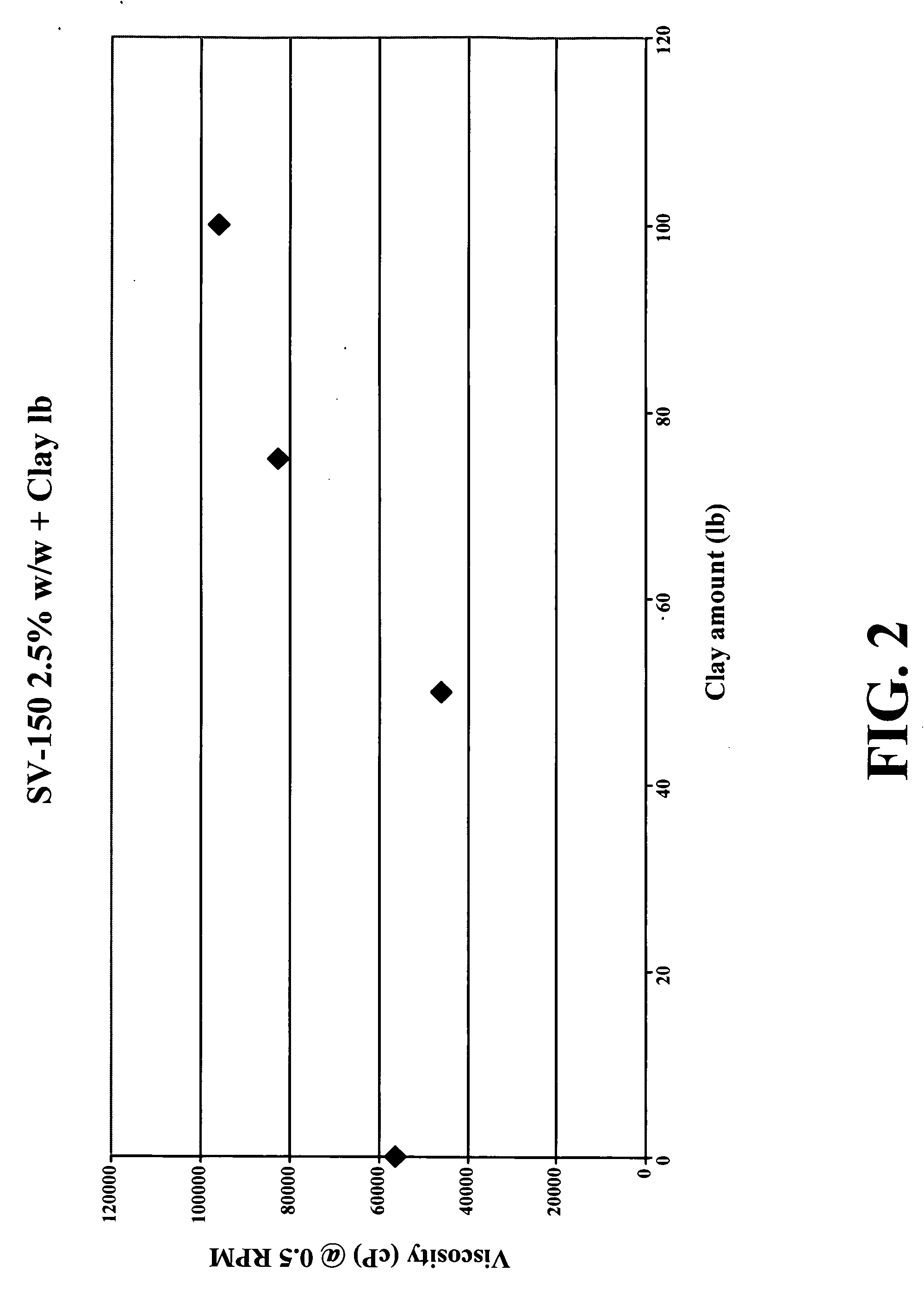

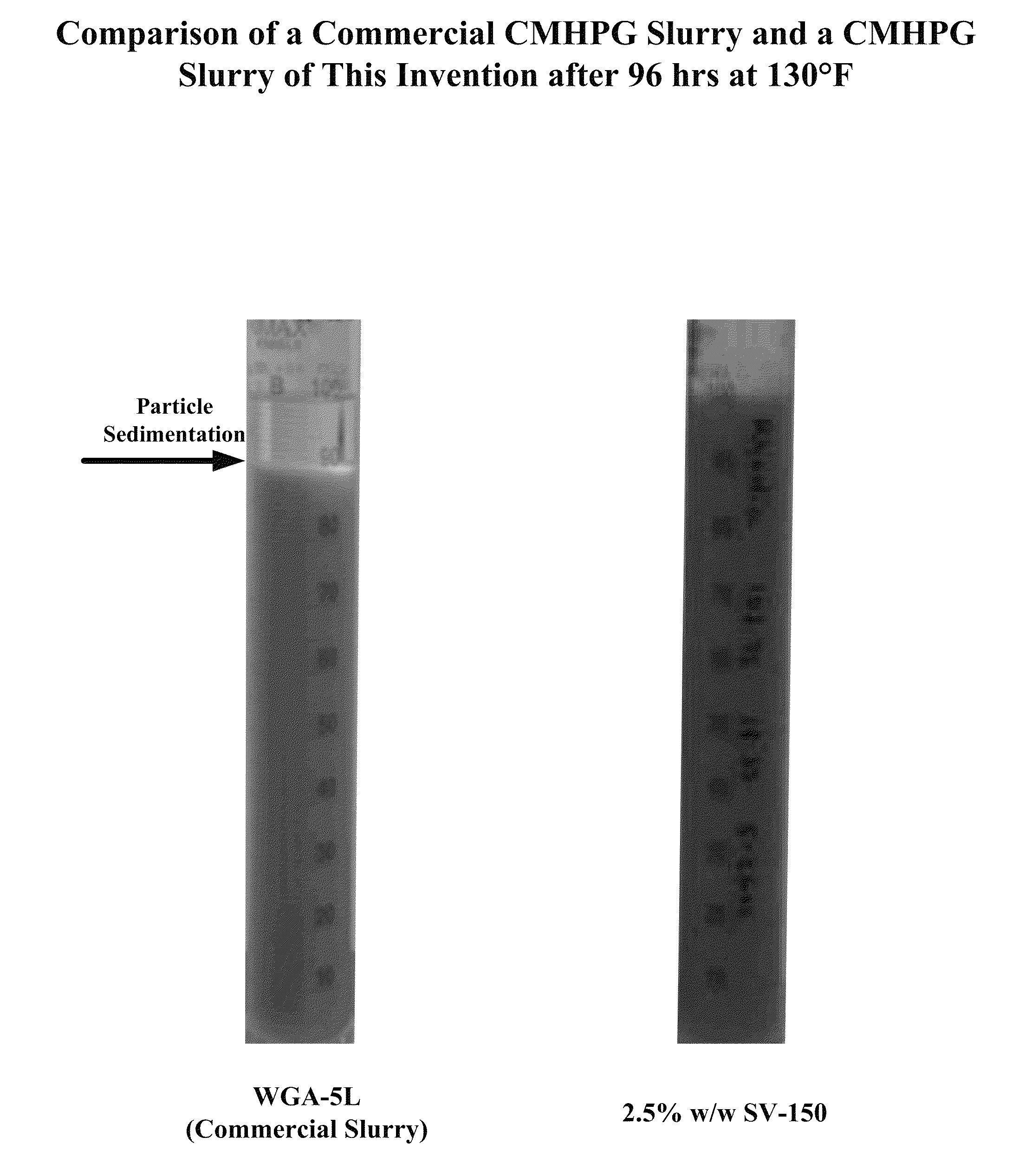

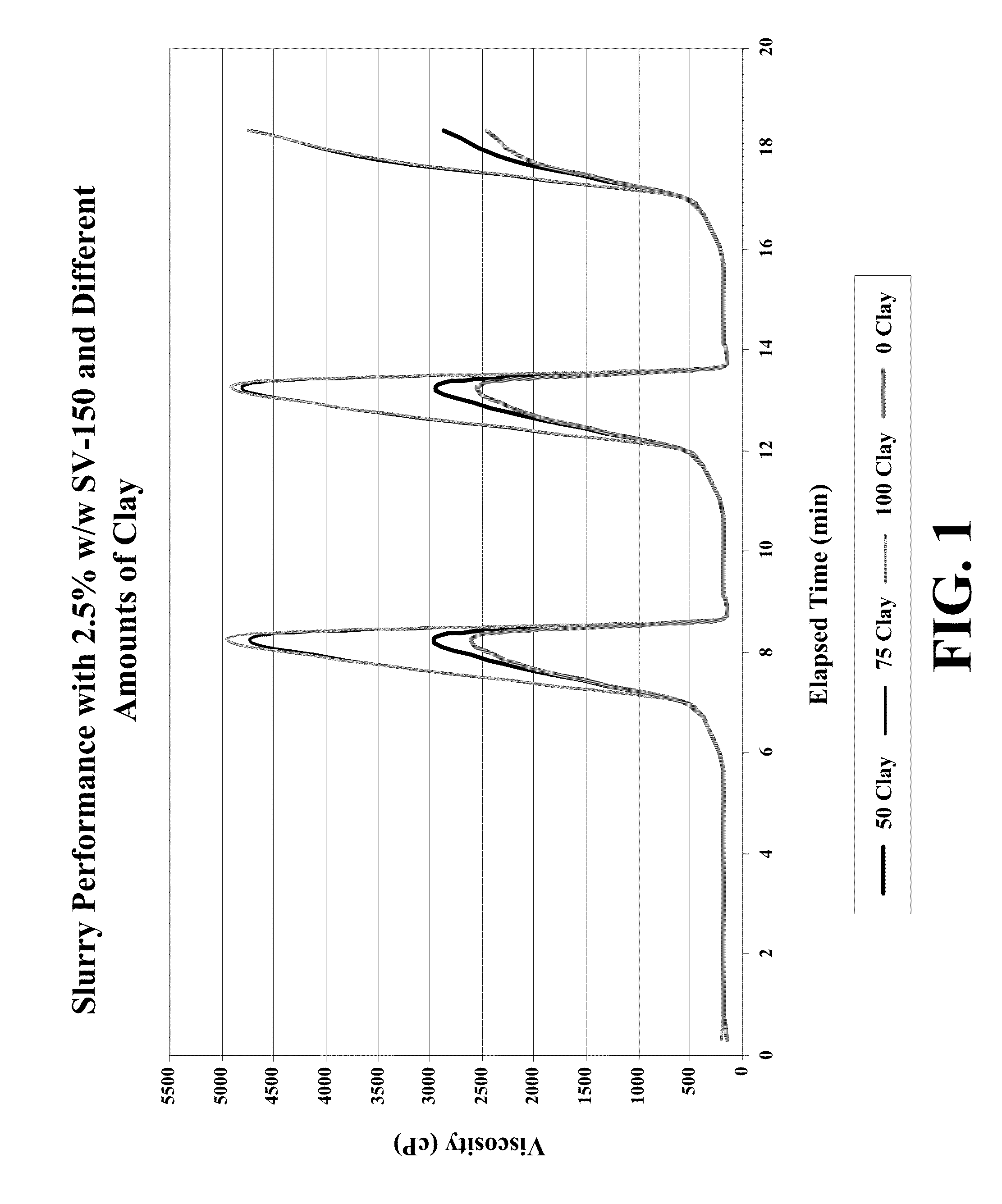

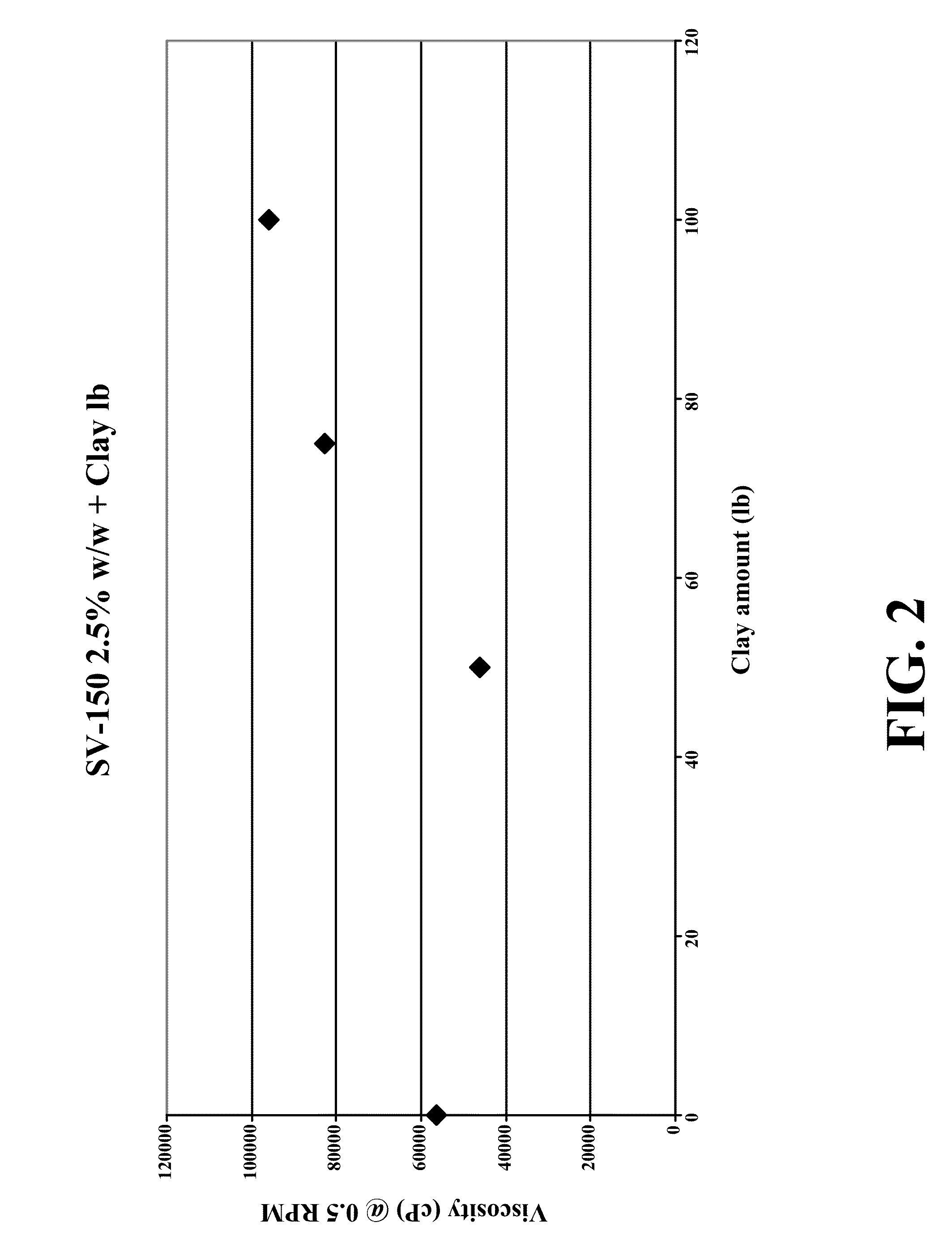

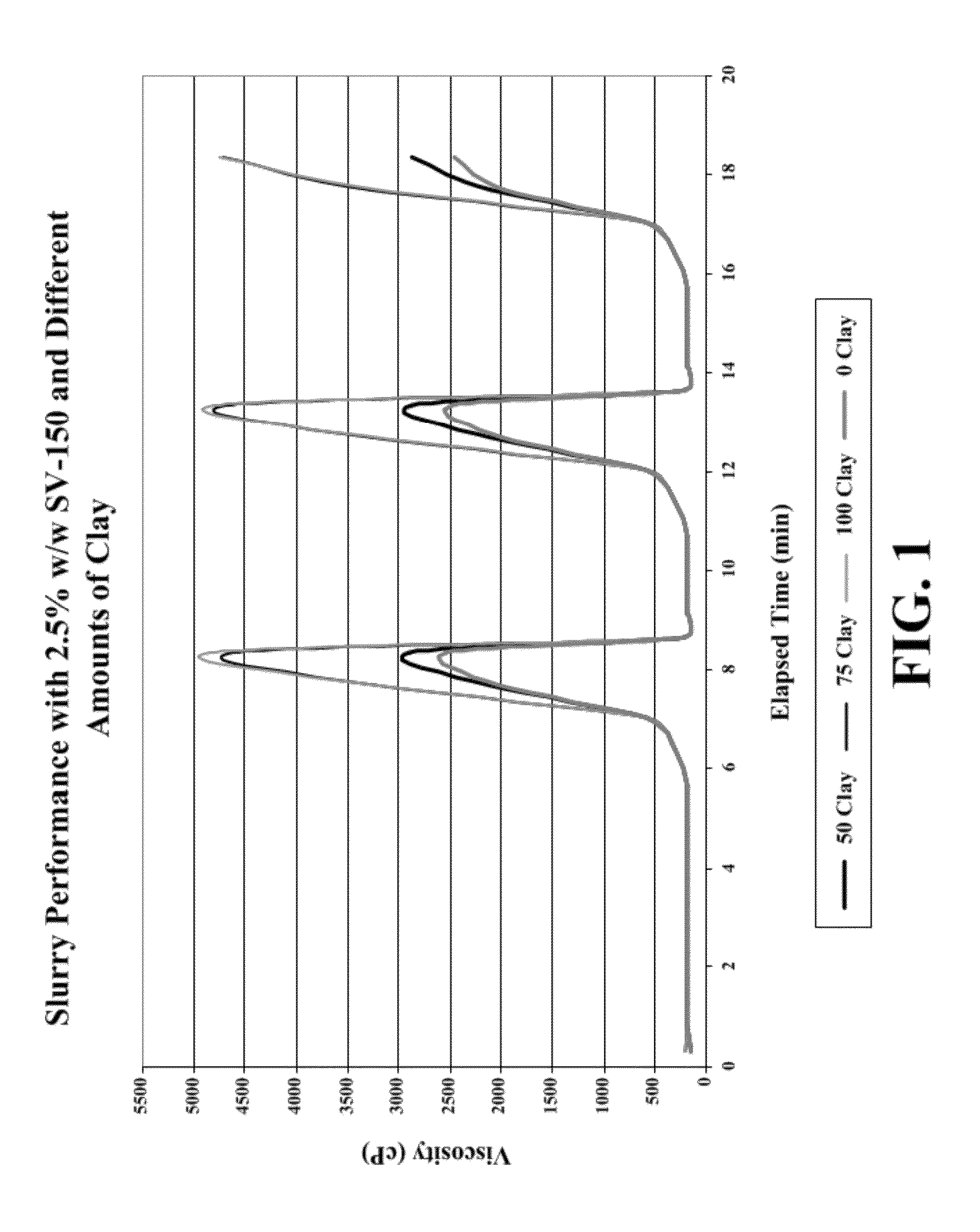

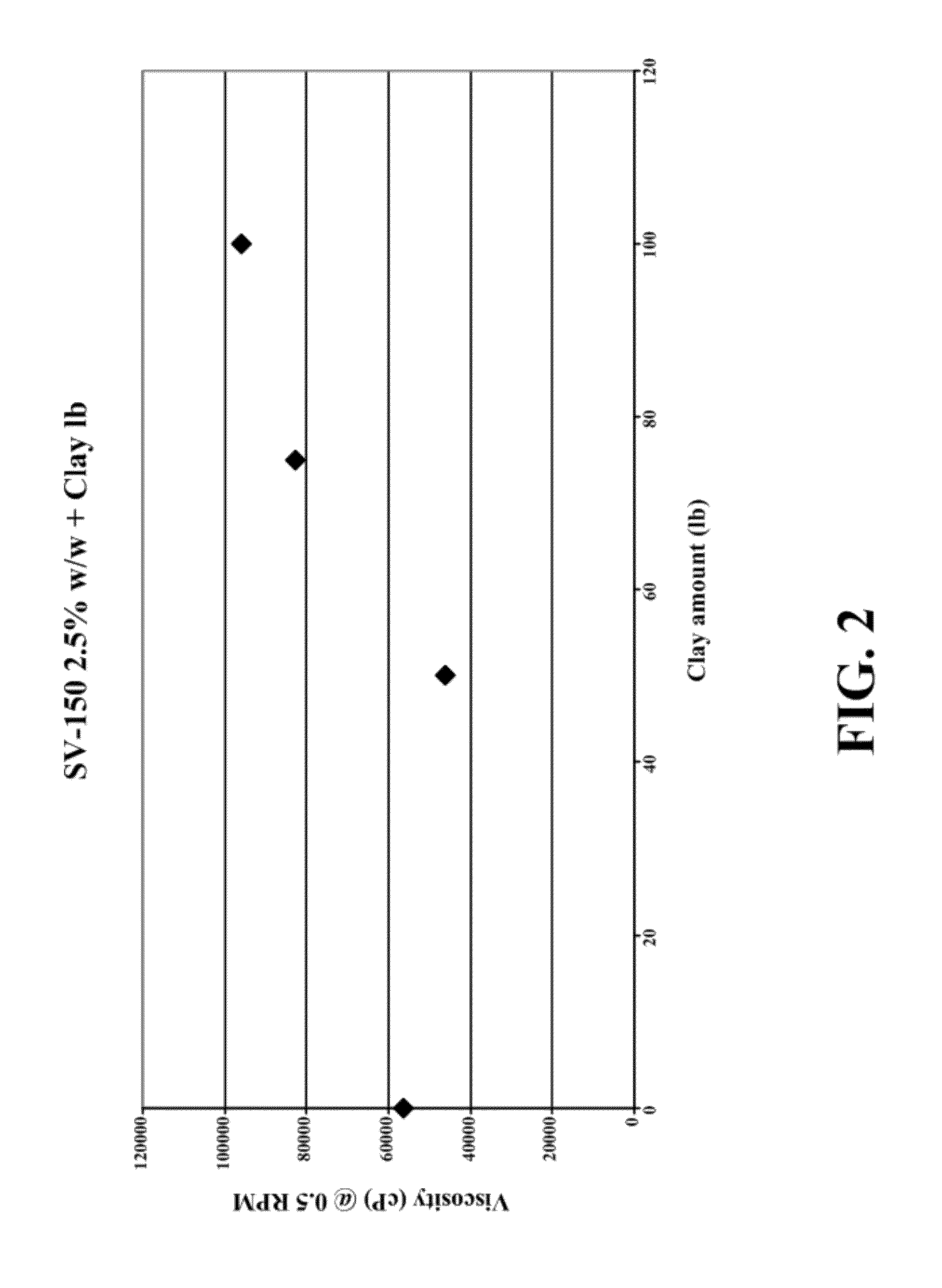

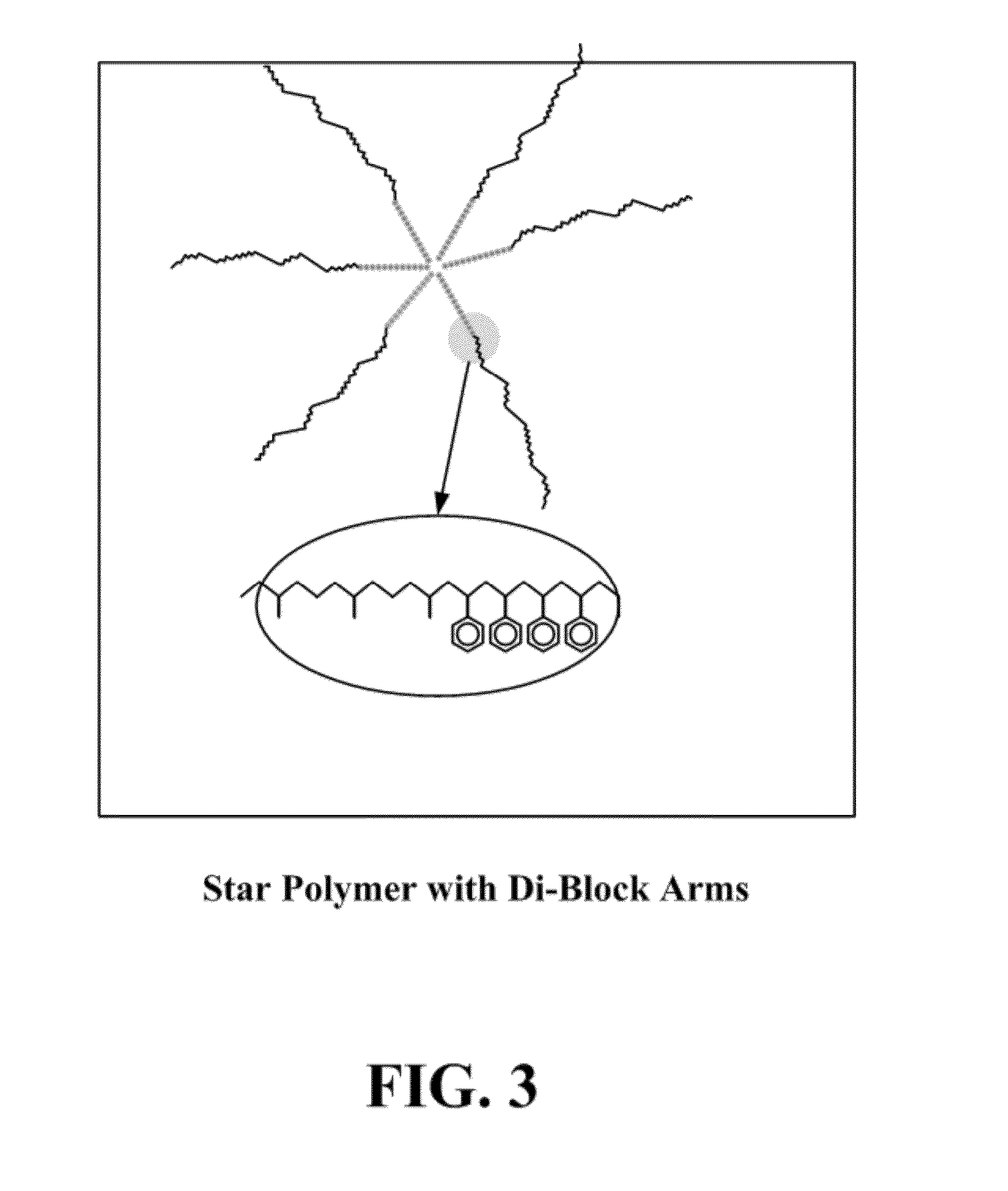

Oil based concentrated slurries and methods for making and using same

InactiveUS20080318812A1Reduce sedimentation rateReduce settlementFluid removalFlushingParticulatesSlurry

New hydrocarbon based slurry compositions and drilling, fracturing, completion and production fluids including the hydrocarbon based slurry composition are disclosed, where the composition includes a hydrocarbon soluble polymer adapted to decrease particle settling rates of particulate materials present in the fluids and in the case of fluids that include hydratable materials to increase hydration properties of such materials.

Owner:WEATHERFORD TECH HLDG LLC

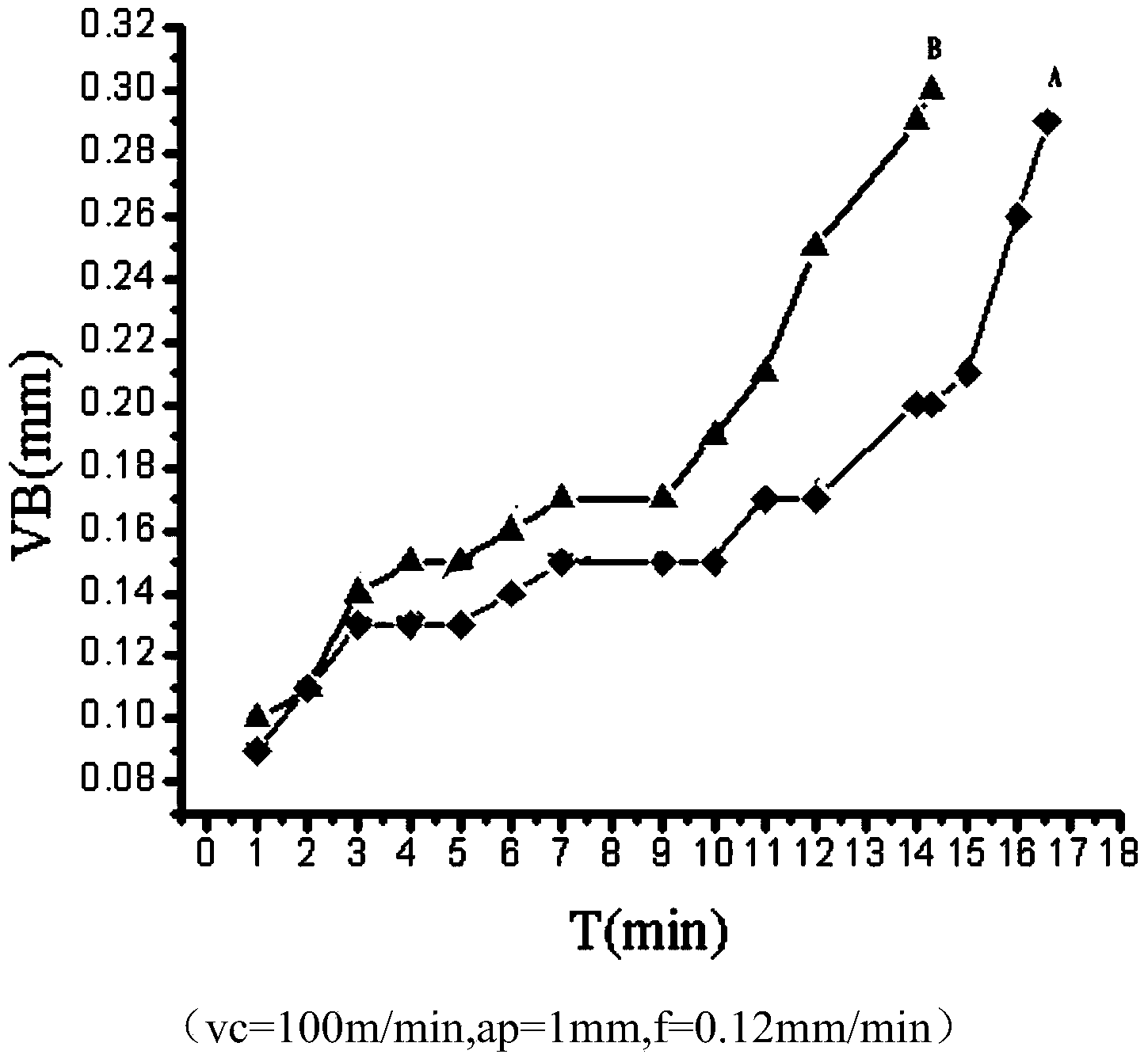

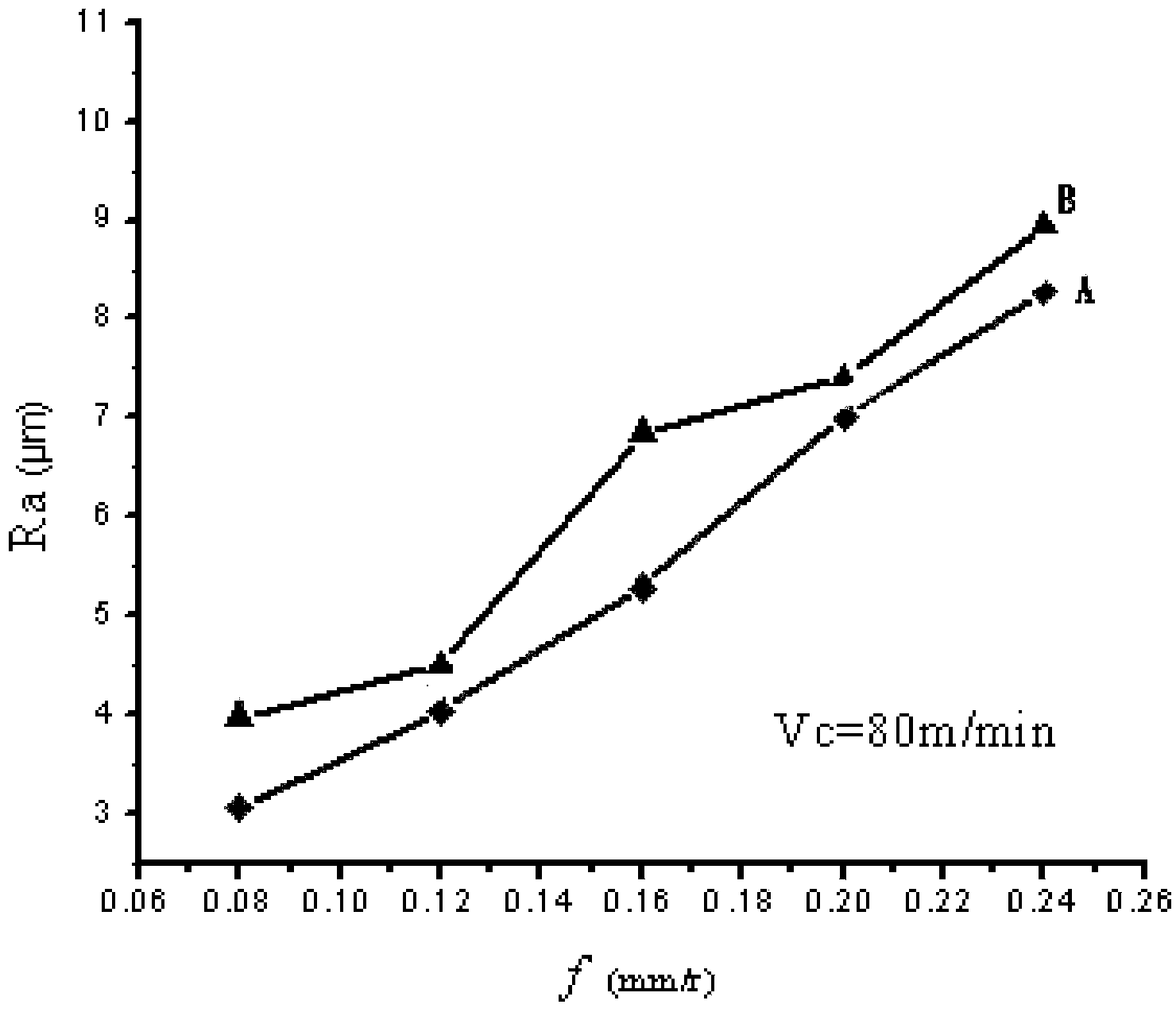

Water-based cutting fluid used in slice machining of hard brittle crystal material and preparation method of water-based cutting fluid

InactiveCN102618374AGuaranteed lubrication effectGuaranteed anti-rust performanceAdditivesWater basedTool wear

The invention discloses a water-based cutting fluid used in slice machining of a hard brittle crystal material, comprising the following compositions: base oil, organic amine, organic acid, synthetic ester, emulsifier, rust and corrosion inhibitor, dispersion flocculation and hard-water resisting agent, antiseptic bactericide, antifoaming agent, coupling agent, adjuvant and a proper amount of water. Aiming at the machining techniques of inner circle slicing and outer circle slicing, the water-based cutting fluid has good generality, lubricity, strong antirust property and a long service life; when the cutting fluid is used, the machining situation can be observed easily, the cooling property is good, the cleaning and the permeability are strong, cuttings subside easily, and the machining problems of machining error, crack and the like caused by cutter blocking, abrasion and the like are solved; according to the invention, the problems that cuttings are easy to adhere and suspend, a cutter is seriously abraded, a machined product cracks easily, the accuracy is not high, the machining efficiency is low, the later period cleaning is complex and the like existing in the current slice machining of the hard brittle crystal material are solved, and further, a machine bed is protected, and the cost is reduced.

Owner:AMER TECH CO LTD

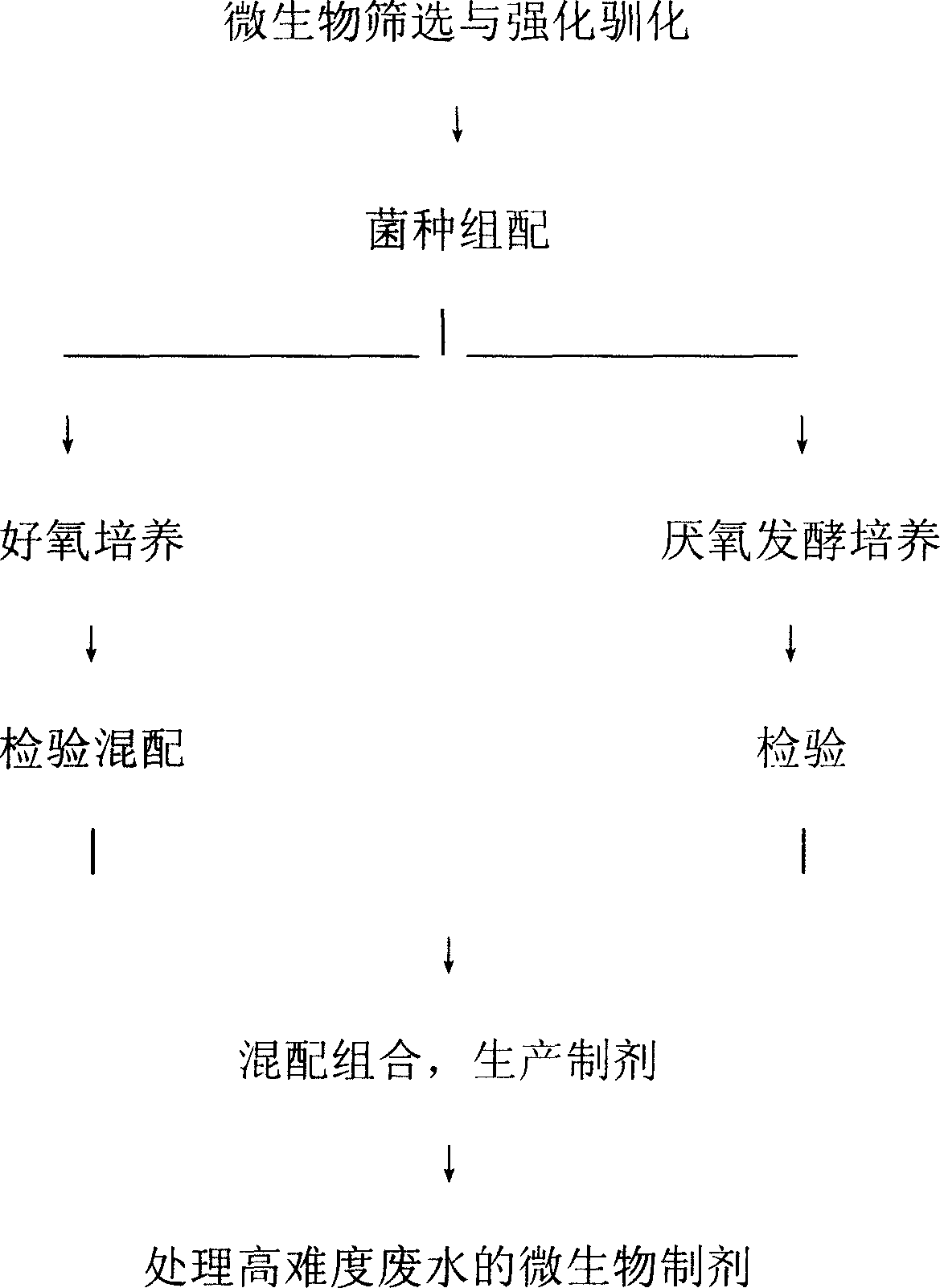

Microbe preparation in use for treating high difficult wastewater and preparation method

InactiveCN1563342ARich varietyComplete transformation and decompositionMicroorganism separationBiological water/sewage treatmentWastewaterMicrobiologic agent

A microbiological preparation made from 105 types of acclimatized and integrated microorganisms belonging to 47 genuses can be used to process highly difficult waste waters of coking waste water, gourment powder waste water, antibiotic waste water, pigment waste water, paper making waste water and fluorating waste water.

Owner:凌亮

Water-based cutting fluid used for processing neodymium-iron-boron material slices and application method thereof

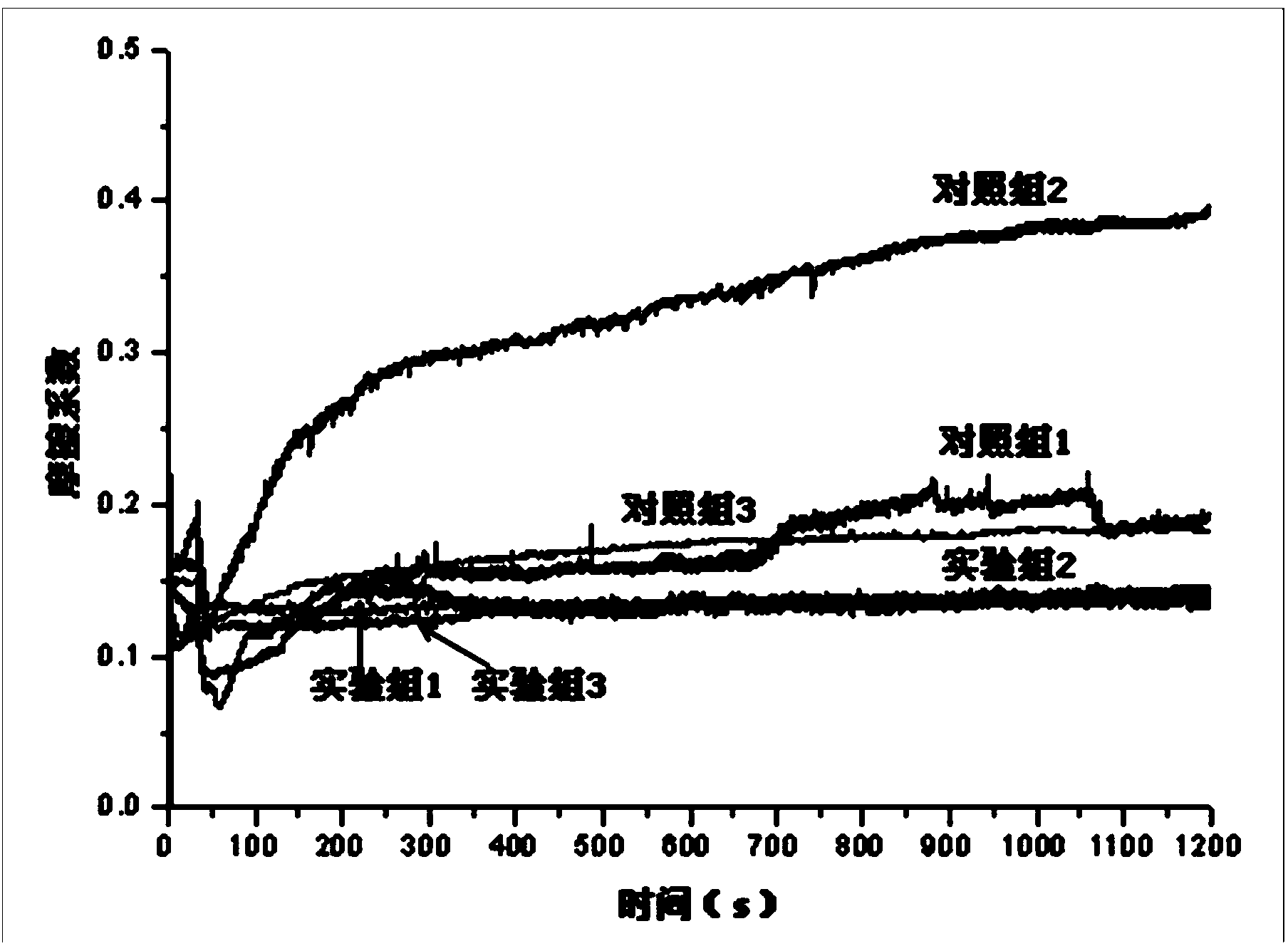

ActiveCN102311860AGuaranteed lubrication effectGuaranteed anti-rust performanceLubricant compositionSolubilityWater based

The invention discloses a water-based cutting fluid used for processing neodymium-iron-boron material slices and an application method thereof. The cutting fluid comprises the following components in parts by weight: organic amine, organic acid, water-soluble phosphate, polyether, antirust corrosion inhibitor, dispersing agent and surfactant, antiseptic bactericide, anti-hard-water agent, defoaming agent, auxiliary agent and water, wherein environmentally-friendly lubricating agent, extreme-pressure agent and antirust agent are reasonably matched in the cutting fluid disclosed by the invention, thus the lubricating property, extreme pressure property and antirust property of the cutting fluid are guaranteed; organic base, organic acid and special auxiliary agent are reasonably matched, thus the corrosion dissolution phenomenon of the cutting fluid to adhesive is greatly weakened; the dispersing agent and the surfactant are used for reducing surface tension of solution, thus permeability and settlement performance of the cutting fluid are enhanced; pH value of a final product is 7.5-8.5; and solubility of the cutting fluid to adhesive used for binding neodymium-iron-boron material in a processing cycle is extremely low, and the condition that product processing accuracy error is large or a tool is damaged as the adhesive is dissolved by the cutting fluid can not be caused.

Owner:AMER TECH CO LTD

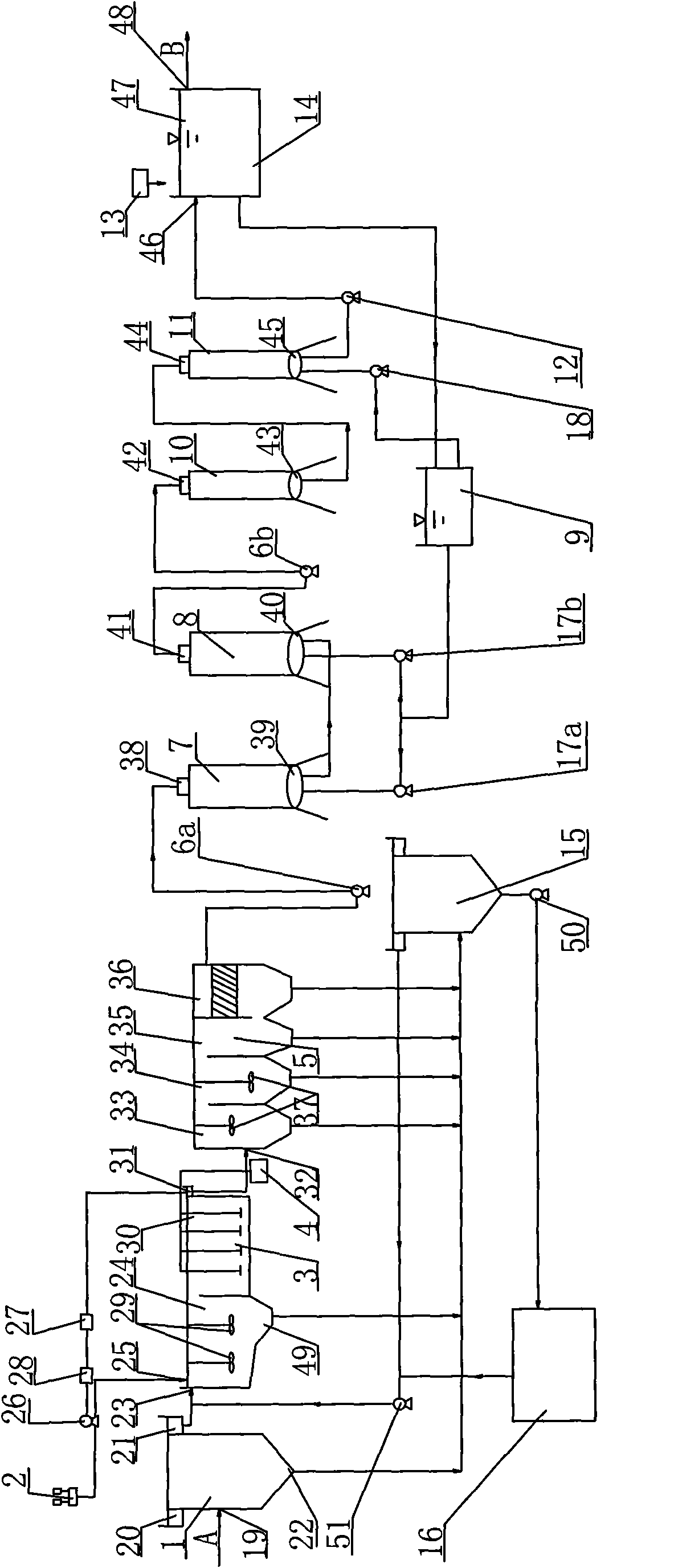

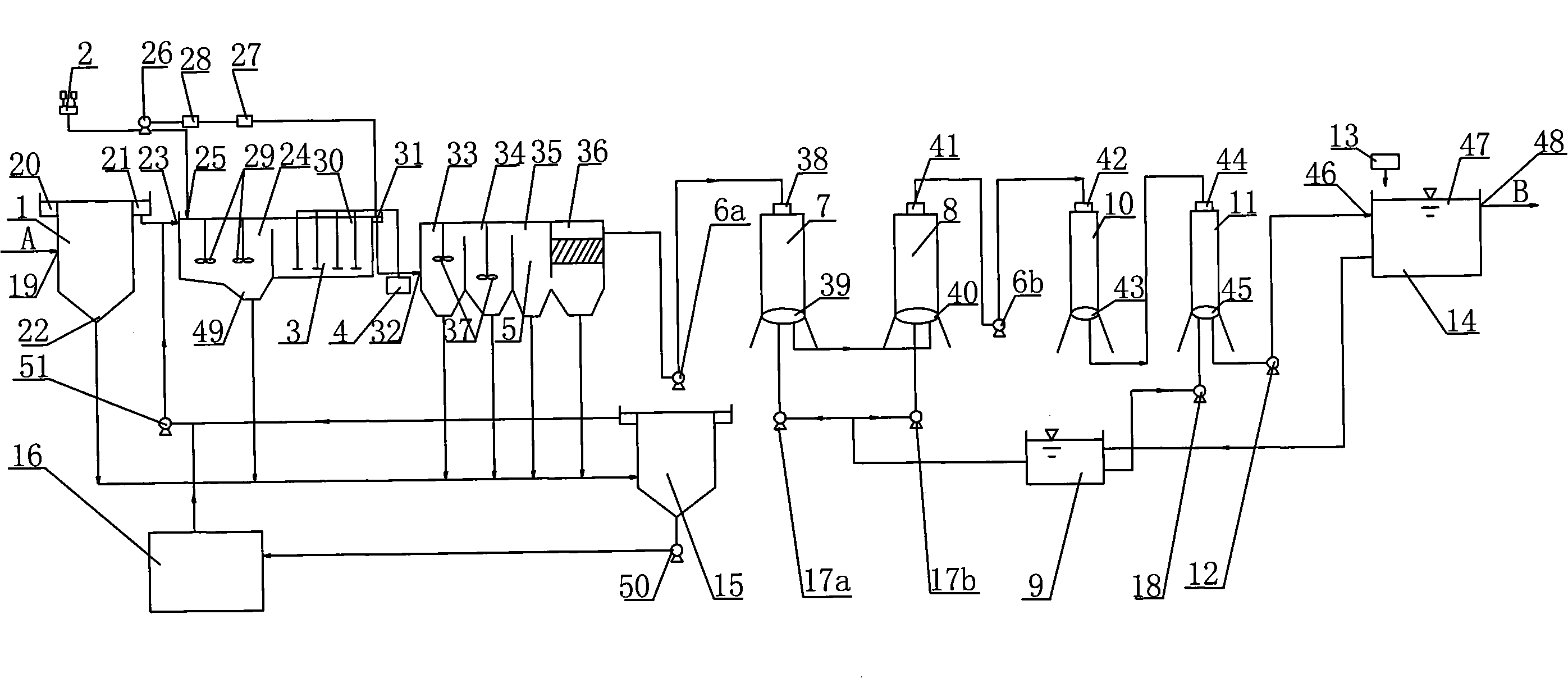

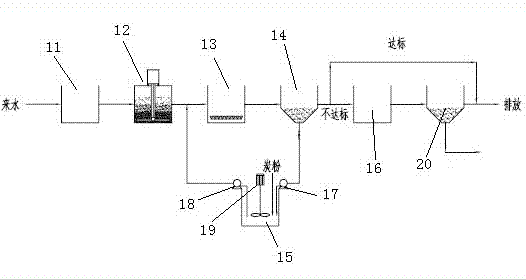

Acid mine water treatment system

InactiveCN101830585ALarge specific surface areaImprove settlement performanceWaste water treatment from quariesMultistage water/sewage treatmentWater treatment systemManganese

The invention discloses an acid mine water treatment system and belongs to the field of water treatment. The system consists of a neutralization system, a coagulation sedimentation system, a filtration system, a reverse osmosis system and a sterilization system which are connected in turn, wherein the coagulation sedimentation system comprises a mixing region, a reaction region, a transition region and a settling region; the mixing region is communicated with the reaction region, the transition region and the settling region in turn; the water inlet of the mixing region is communicated with the water outlet of the neutralization system; the water outlet of the settling region is communicated with the water inlet of the filtration system; and the filtration system comprises a manganese sand filter in which a modified manganese sand filter material modified by 1 to 7 mass percent potassium permanganate solution is arranged. Four regions are arranged in the coagulation sedimentation system of the system, so coagulation treatment effect is enhanced; and the modified manganese sand filter material is adopted in the manganese sand filter, so the effect of removing ferro-manganese ions in the mine water is enhanced and the aim of treating and recycling the acid mine water with high turbidity, high ferro-manganese content and high mineralization is fulfilled.

Owner:CHINA UNIV OF MINING & TECH (BEIJING)

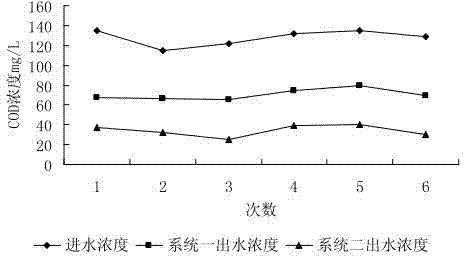

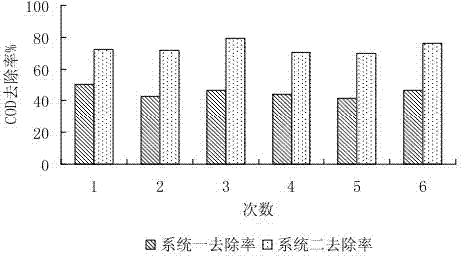

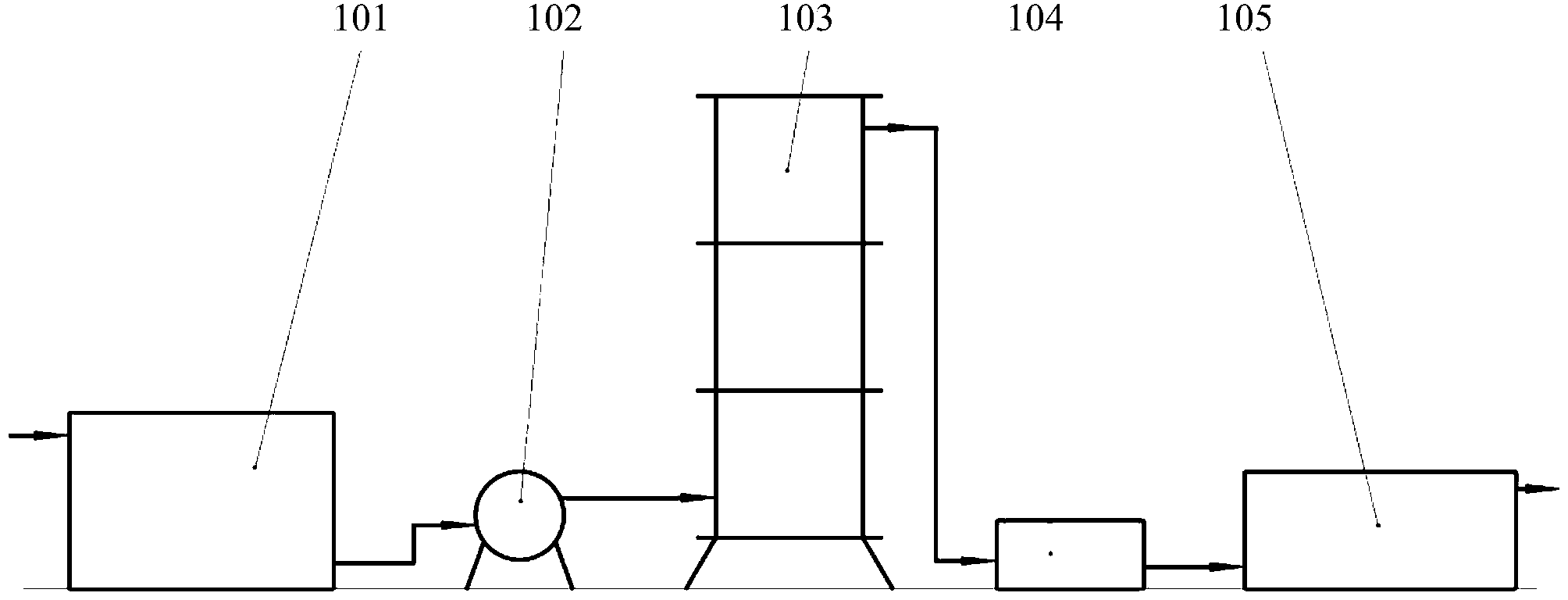

PACT (powdered activated carbon treatment) process and device, and activated carbon-microbial zoogloea culture method using same

ActiveCN103086503AImprove settlement performanceProportionally largeSustainable biological treatmentWater/sewage treatment by sorptionZoogloeaWater treatment system

The invention relates to a PACT (powdered activated carbon treatment) process and an PACT process device. The activated carbon-microbial zoogloea culture method comprises the following steps: selecting activated sludge, and culturing until the activated sludge is mature; and adding powdered activated carbon to ensure that the powdered activated carbon serving as a core is wrapped by microorganisms to form activated carbon-microbial zoogloea floccules, and acclimating, thus increasing the specific gravity of the powdered activated carbon and enhancing the precipitability. In the PACT process device, a sludge return tank is added, and the powdered activated carbon is added into the sludge return tank, so that the powdered activated carbon and the microorganisms can form activated carbon-microbial zoogloeae in the sludge return tank, thereby prolonging the retention time of the powdered activated carbon in a water treatment system; and sludge in the sludge return tank is lifted into a sewage inlet at the front end of an aerobic tank through a lifting pump, so that the sludge and sewage can be better mixed, thereby prolonging the retention time of the powdered activated carbon in the aerobic tank and enhancing the treatment effect. On the basis of prolonging the water retention time of the aerobic tank, the invention does not need to increase the volume of the original aerobic tank, and is small in occupied area and easy to implement.

Owner:GUANGDONG XINDAYU ENVIRONMENTAL PROTECTION TECH CO LTD +1

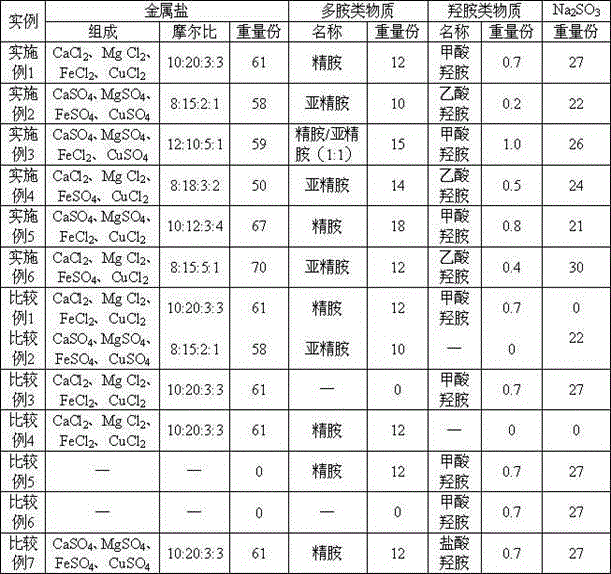

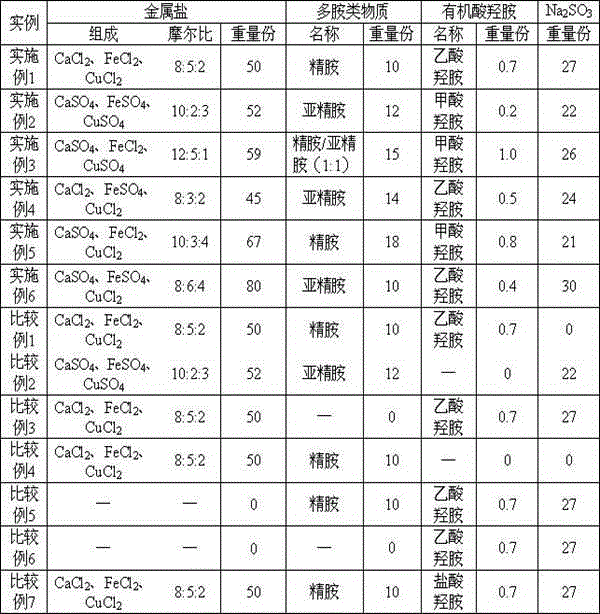

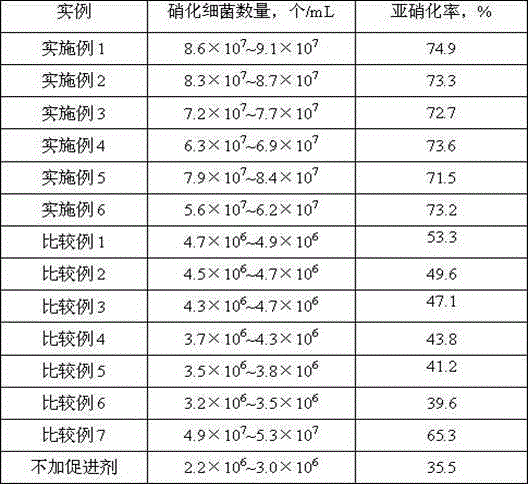

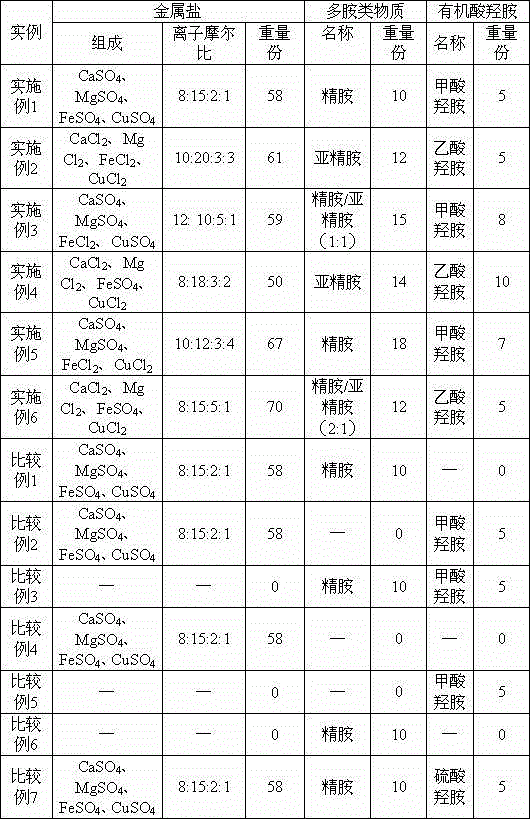

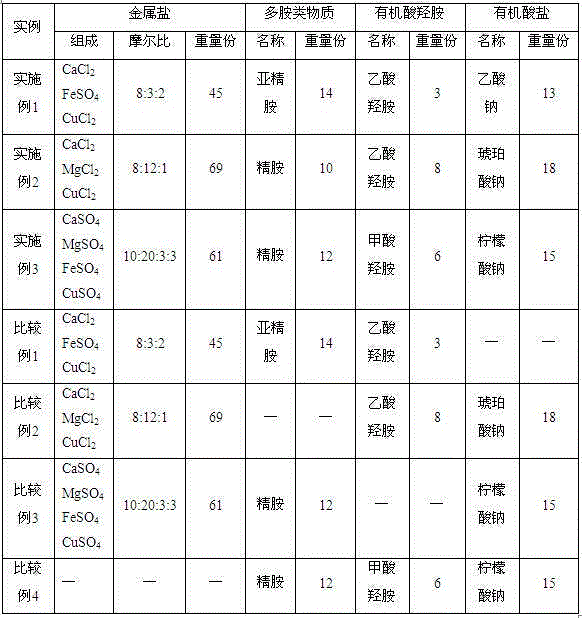

Nitrite bacteria growth promoter and preparation method thereof

ActiveCN105621625AImprove settlement performanceImprove stabilityBiological water/sewage treatmentBacteroidesHydroxylamine

The invention discloses a nitrite bacteria growth promoter including the components: 40-100 parts by weight, preferably 50-80 parts by weight, of metal salts; 5-30 parts by weight, preferably 10-20 parts by weight, of an amine substance; 0.05-1.5 parts by weight, preferably 0.1-1.0 part by weight, of organic acid hydroxylamine; and 10-40 parts by weight, preferably 20-30 parts by weight, of Na2SO3; the metal salts comprise a calcium salt, a magnesium salt, a ferrous salt and a copper salt, and the molar ratio of Ca<2+> to Mg<2+> to Fe<2+> to Cu<2+> is (5-15) to (5-25) to (1-8) to (0.5-5), preferably (8-12) to (10-20) to (2-6) to (1-4). The promoter has the advantages of simple formula and easy preparation, can be used in the cultivation process of nitrite bacteria, can also be directly added into a sewage treatment system, accelerates starting of short-cut nitrification-denitrification and short-cut nitrification-anaerobic ammonium oxidation processes and achieves stable operation.

Owner:CHINA PETROLEUM & CHEM CORP +1

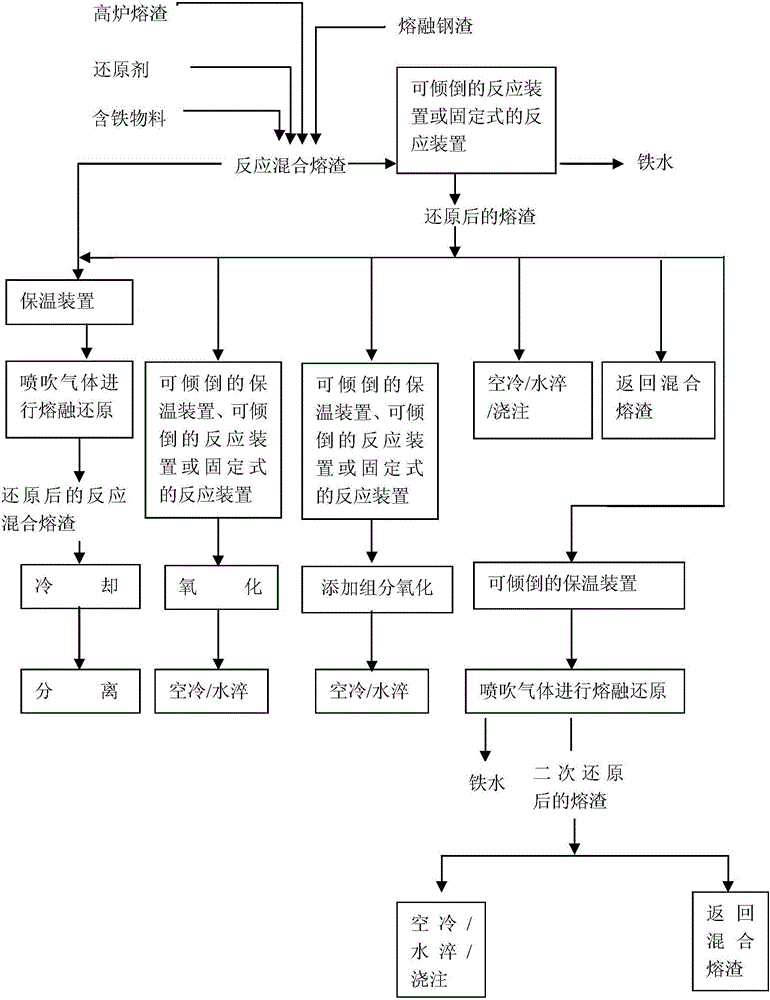

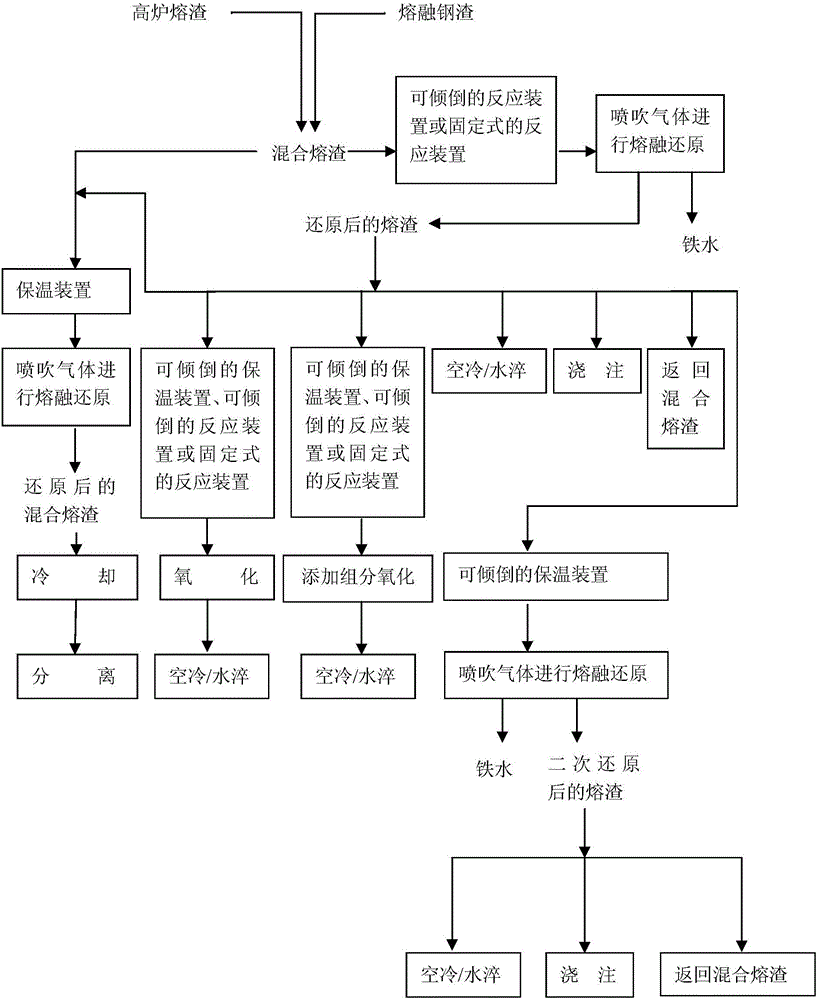

Mixed slag smelting reduction production and thermal refining method

ActiveCN106191344AEasy to removeTake advantage ofRecycling and recovery technologiesProcess efficiency improvementMolten stateReducing agent

The invention discloses a mixed slag smelting reduction production and thermal refining method, and belongs to the field of non-blast furnace iron smelting and comprehensive utilization of resources. The method comprises the following steps: 1) an iron-contained material and a reducing agent are added in mixed slag of blast furnace slag and molten steel slag for heating to reach a molten state; and oxide gas is sprayed for iron smelting by smelting reduction to treat most iron-contained material; and 2) an iron component, a calcium silicon component and a phosphorus component in the mixed slag are separated and recovered according to a reaction device. After smelting reduction, the reduced slag can serve as a cement additive, a cement regulator, a cement clinker or a cement clinker with high production additional value, so that the method realizes efficient comprehensive utilization of the resources, and is a new smelting reduction iron making method. The method uses smelting reduction of the mixed slag for production of pig iron or steel and phosphorus-enriched phases and thermal refining, is short in reaction time, high in metal recovery rate, low in production cost, high in raw material adaptability, high in handling quantity, environment-friendly and high in economic benefit, and can effectively achieve the goal of efficient recycling of metallurgic resources and heat energy.

Owner:NORTHEASTERN UNIV

Nitrite bacterium culture promoter and preparation method thereof

ActiveCN105624093AImprove settlement performanceImprove stabilityBacteriaTreatment with aerobic and anaerobic processesHydroxylamineFerrous salts

The invention discloses a nitrite bacterium culture promoter, which consists of metal salts, polyamine substances, organic acid hydroxylamine and Na2SO3, wherein in parts by weight, the content of the metal salts is 40-100 parts by weight, preferably 50-80 parts by weight; the content of the polyamine substances is 5-30 parts by weight, preferably 10-20 parts by weight; the content of the organic acid hydroxylamine is 0.05-1.5 parts by weight, preferably 0.1-1.0 part by weight; and the content of the Na2SO3 is 10-40 parts by weight, preferably 20-30 parts by weight; the metal salts include calcium salt, ferrous salt and copper salt; and the molar ratio of Ca<2+> to Fe<2+> to Cu<2+> is (5-15) to (1-8) to (0.5-5), and preferably (8-12) to (2-6) to (1-4). The promoter is simple in formula and easy for preparing; and the promoter can be applied to the culture process of the nitrite bacteria and the promoter can be also directly added to a sewage treatment system, so that the starting of partial nitrification-denitrification and partial nitrification-anaerobic ammonia oxidation processes is accelerated and the stable running of the processes is achieved.

Owner:CHINA PETROLEUM & CHEM CORP +1

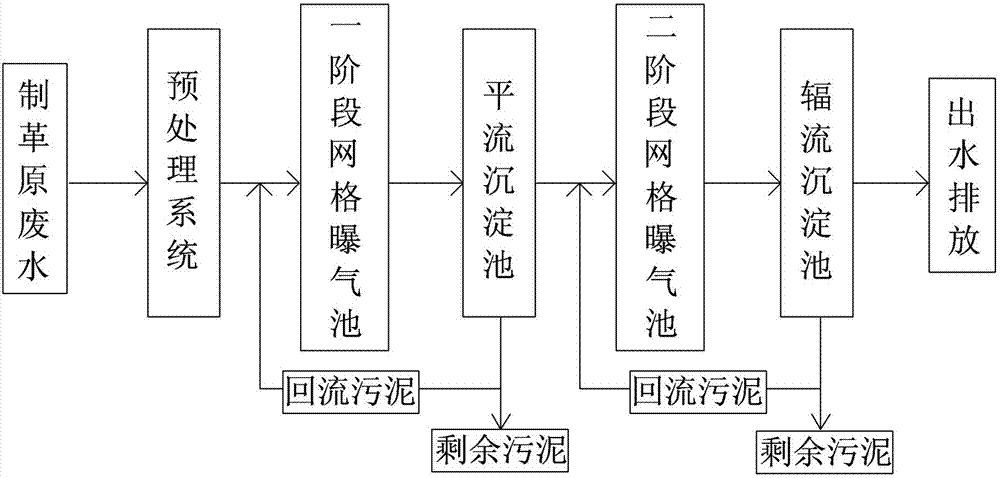

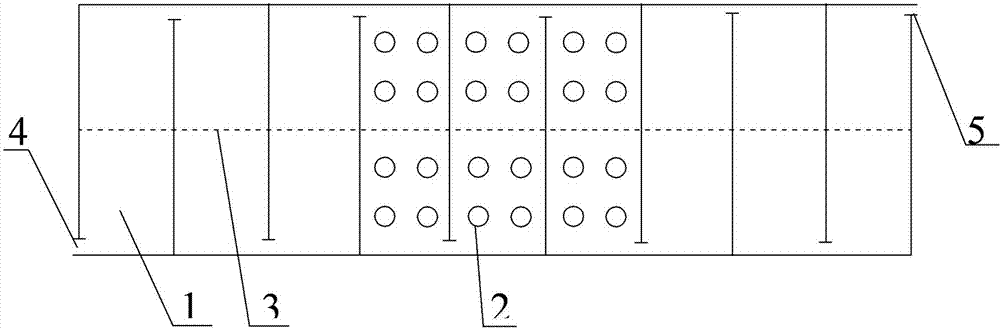

Biological tannery wastewater treatment system and treatment method thereof

ActiveCN103787548AEasy to handleEasy to operate and maintainWaste water treatment from animal processingMultistage water/sewage treatmentAmmoniacal nitrogenSewage treatment

The invention belongs to the field of sewage treatment and relates to a biological treatment method for high-concentration wastewater with high ammonia nitrogen content, in particular to a biological tannery wastewater treatment system and a treatment method thereof. The biological tannery wastewater treatment system comprises a first-stage gridding aeration tank, a horizontal flow sedimentation tank, a second-stage gridding aeration tank and a radial flow sedimentation tank which are communicated sequentially, wherein the bottom of the horizontal flow sedimentation tank is communicated with a material inlet of the first-stage gridding aeration tank through a backflow pump; and the bottom of the radial flow sedimentation tank is communicated with a material inlet of the second-stage gridding aeration tank through the backflow pump. According to the treatment method, the organic degrading proportion and the denitration function of the system are enhanced by two-stage aeration. The treatment system and the treatment method which are disclosed by the invention has the advantages that the treatment effect is obvious, running maintenance is facilitated, the energy consumption is low, and the treatment cost is low; and obvious economical and beneficial benefits are realized.

Owner:ZHONGNIU GRP

Nitrifying bacterium culture promoter as well as preparation method and application thereof

ActiveCN105624094AImprove settlement performanceImprove stabilityTreatment with aerobic and anaerobic processesChemical cell growth stimulationHydroxylamineMagnesium salt

The invention discloses a nitrifying bacterium culture promoter, which consists of metal salts, polyamine substances and organic acid hydroxylamine, wherein in parts by weight, the content of the metal salts is 40-100 parts by weight, preferably 50-80 parts by weight; the content of the polyamine substances is 5-30 parts by weight, preferably 10-20 parts by weight; and the content of the organic acid hydroxylamine is 0.5-15 parts by weight, preferably 2-10 part by weight; the metal salts include calcium salt, magnesium salt, ferrous salt and copper salt; and the molar ratio of Ca<2+> to Mg<2+> to Fe<2+> to Cu<2+> is (5-15) to (5-25) to (1-8) to (0.5-5), and preferably (8-12) to (10-20) to (2-6) to (1-4). The promoter is simple in formula and easy for preparing; and the promoter can be applied to the culture process of the nitrifying bacteria and the promoter can be also directly added to a sewage treatment system, so that the rapid growth and reproduction of nitrifying bacteria can be achieved within a short time; and the cultured nitrifying bacteria are high in activity and strong in impact resistance.

Owner:CHINA PETROLEUM & CHEM CORP +1

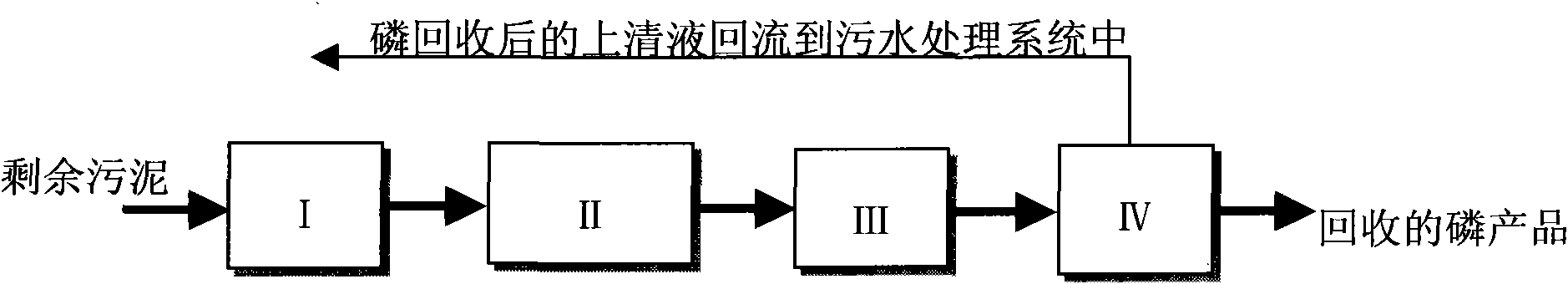

Method for recovering sludge phosphorus from urban sewage treatment plant

ActiveCN101580334ACost-effective recyclingReach reductionSludge treatment by de-watering/drying/thickeningPhosphorus compoundsCalcium biphosphateMunicipal sewage

The invention relates to a method for recovering sludge phosphorus from an urban sewage treatment plant, belonging to the technical fields of sludge treatment and resources. The method comprises the following steps: respectively carrying out gravity thickening on sludge releasing sludge phosphorus, sludge phosphorus releasing on sludge after the gravity thickening, solid-liquid separation on sludge after the sludge phosphorus releasing, sludge phosphorus recovery on supernatant fluid rich of phosphorus after the solid-liquid separation, and the like; the sludge phosphorus releasing on sludge after the gravity thickening is realized by treating the sludge by an acidification and normal-pressure microwave radiation combination method; and the sludge phosphorus recovery on supernatant fluid rich of phosphorus after the solid-liquid separation is realized by treating the supernatant fluid rich of phosphorus by a calcium phosphate crystallization process to obtain the deposit containing calcium phosphate crystal, then filtering the deposit containing calcium phosphate crystal and finally recovering the sludge phosphorus. The method not only can efficiently recover the phosphorus in the sludge from the urban sewage treatment plant, but also can achieve the aims of reducing the sludge and improving the depositing performance of the sludge.

Owner:RES CENT FOR ECO ENVIRONMENTAL SCI THE CHINESE ACAD OF SCI

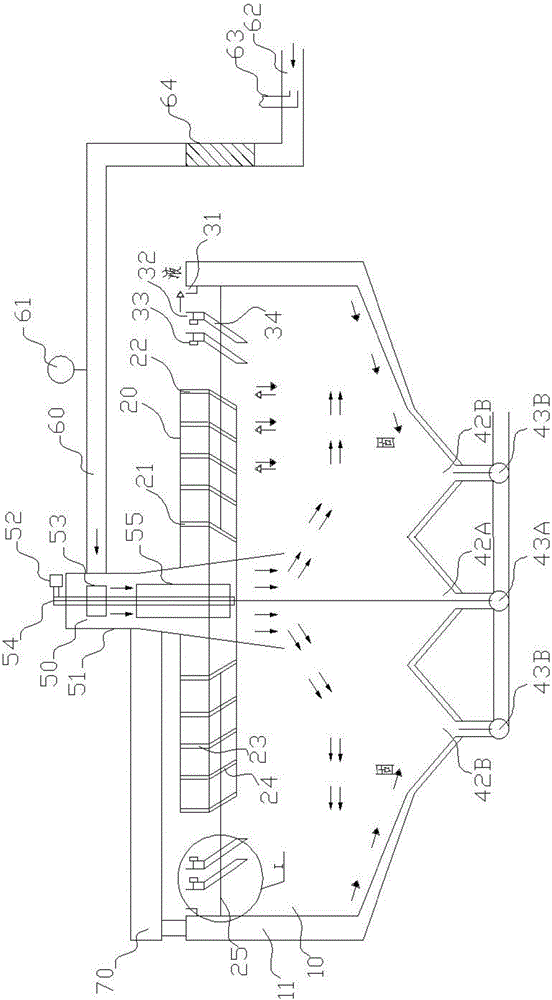

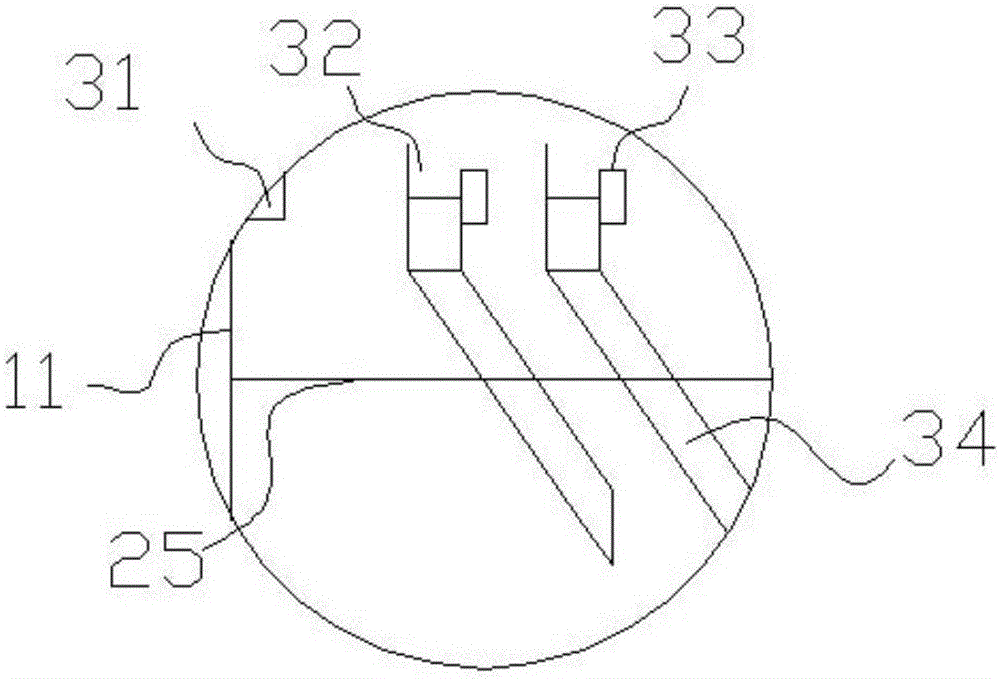

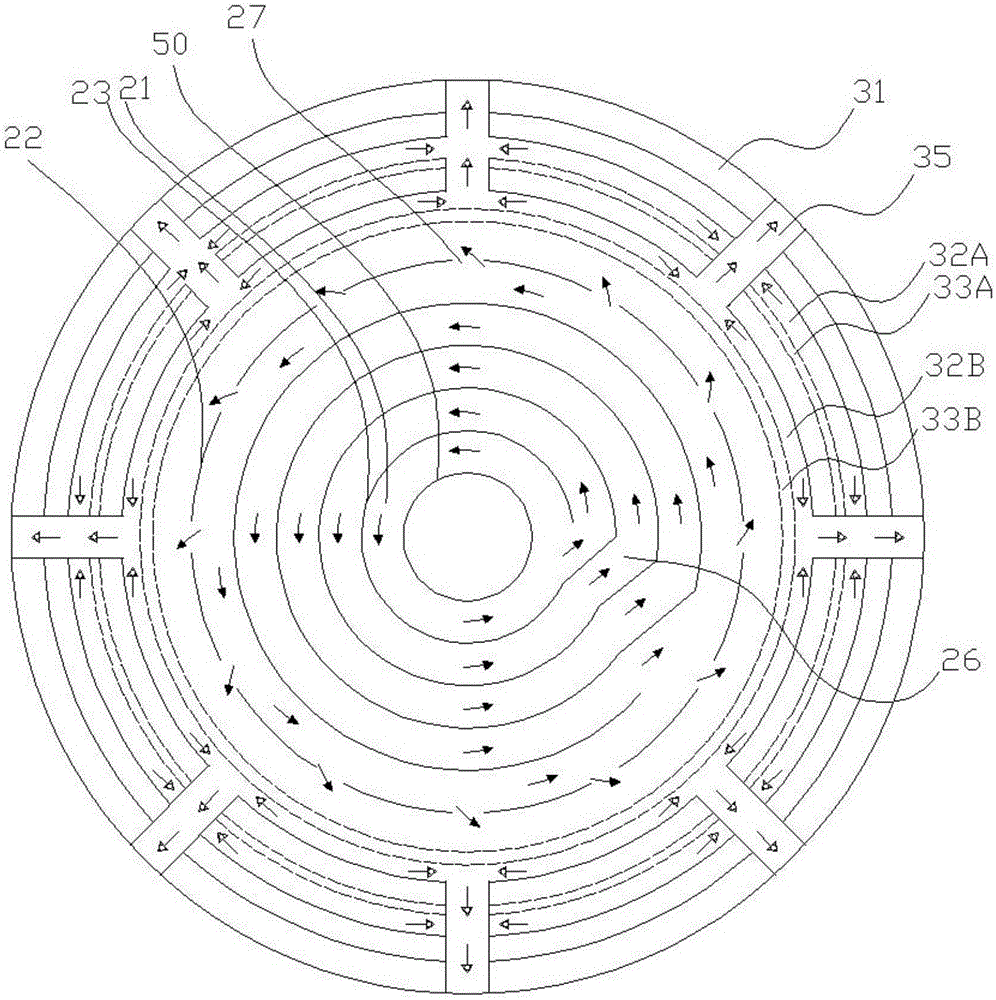

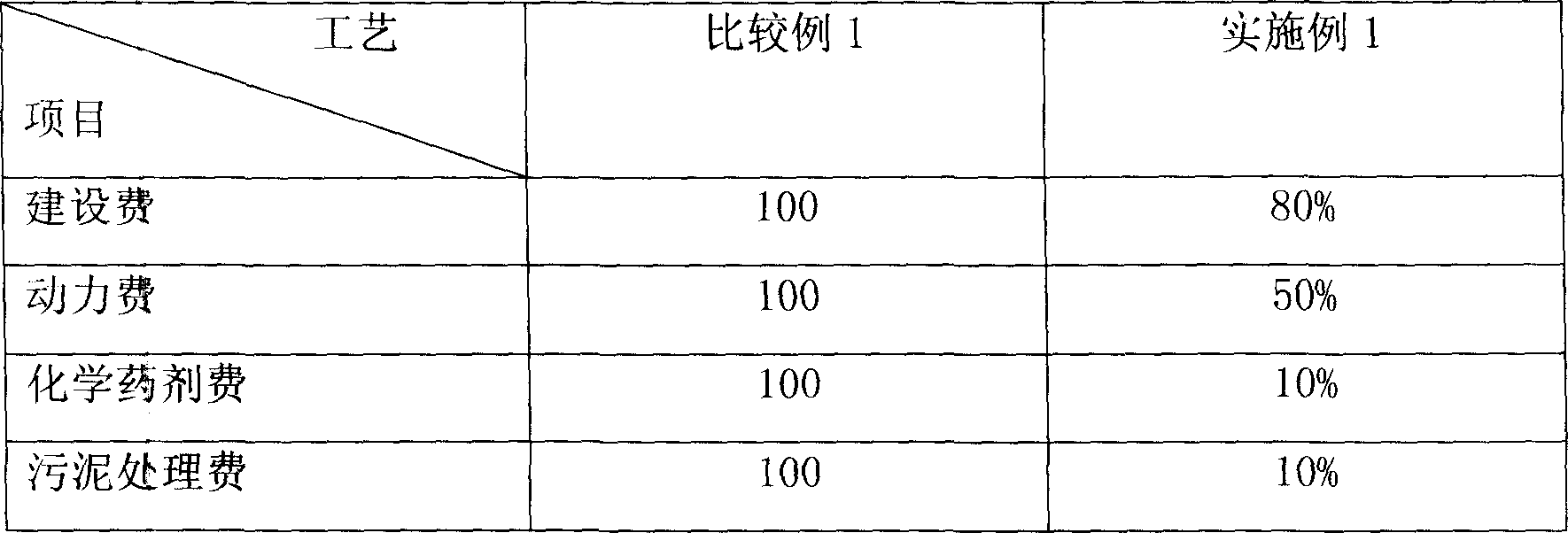

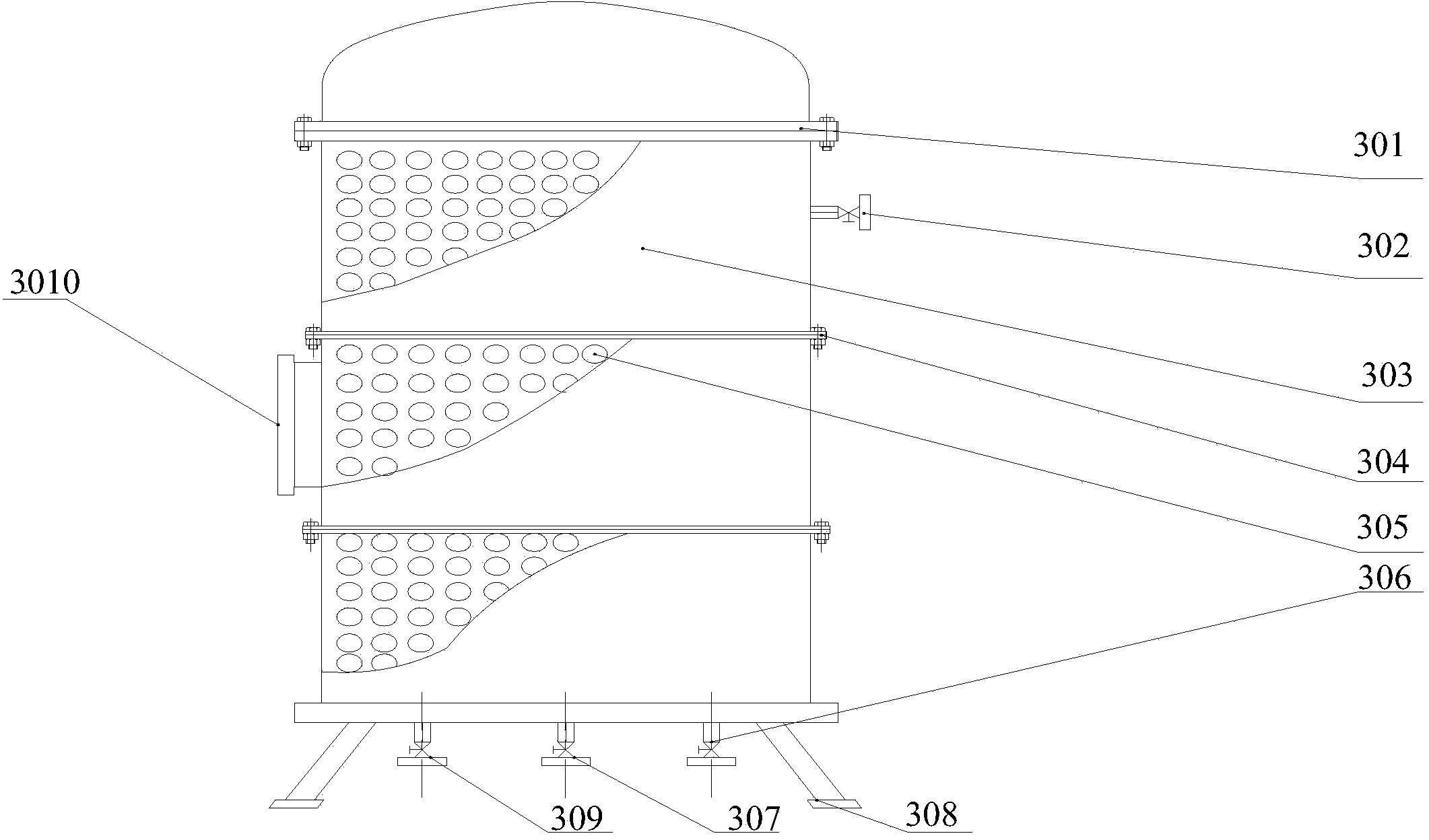

Rake-free thickener with rotary annular channels

ActiveCN105944407AEnsure stabilityImprove settlement performanceSedimentation regulating devicesSettling tanks feed/dischargeWater concentrationEngineering

The invention relates to the field of slime water concentration and clarification, in particular to a rake-free thickener with rotary annular channels. The rake-free thickener at least comprises a thickener body, and further comprises rotary annular channels, wherein the rotary annular channels are used for constraining upper-layer ore pulp inside the thickener to do reciprocatory motion; the rotary annular channels consist of a plurality groups of annular channels of which the diameters are increased gradually; adjacent annular channels are mutually communicated through connecting channels; each group of the annular channels comprises an upper annular partitioning plate and a lower inclined settlement plate; overflowing ore pulp is discharged out from overflow weirs; the overflow weirs comprise annular overflow weirs and composite overflow weirs; settled granules are fed into a bottom flow discharge system; the bottom flow discharge system consist of bottom flow collecting cabins, bottom flow holes and corresponding bottom flow pumps; the rake-free thickener further comprises a feeding pipeline and a driving stirring mechanism; a stirring machine is driven by residual power of the feeding pipeline conveying the ore pulp to rotate so as to uniformly mix the ore pulp with medicines. The rake-free thickener has the characteristics of being low in energy consumption, low in repairing workload, low in medicine consumption and free of rake.

Owner:ANHUI UNIV OF SCI & TECH

Method of producing composite and highly effective microorganism preparation for waste water treatment

InactiveCN101033450ANo toxicityNon-pathogenicMicroorganismsTreatment with aerobic and anaerobic processesEffective microorganismSludge

This invention relates to a preparation method for a compound high efficient microbe preparation used in processing waste water including: A, selecting and cultivating, B, fermenting and cultivating the preparation of oxygen and anaerobic compound microbes, C, fermenting and cultivating the preparation of aerobic microbes, D, mixing them. 1, the preparation prepared in this invention is avirulent and will not cause second time pollution, 2, microbes in this preparation can degradate organics and ammonia nitrogen pollutant factors thoroughly due to multikind of microbes and quick speed to degradate pollutants in waste water, 3, output of mud is less, the life time is long and its settlement is good, 4, the preparation method is simple.

Owner:赵志龙 +1

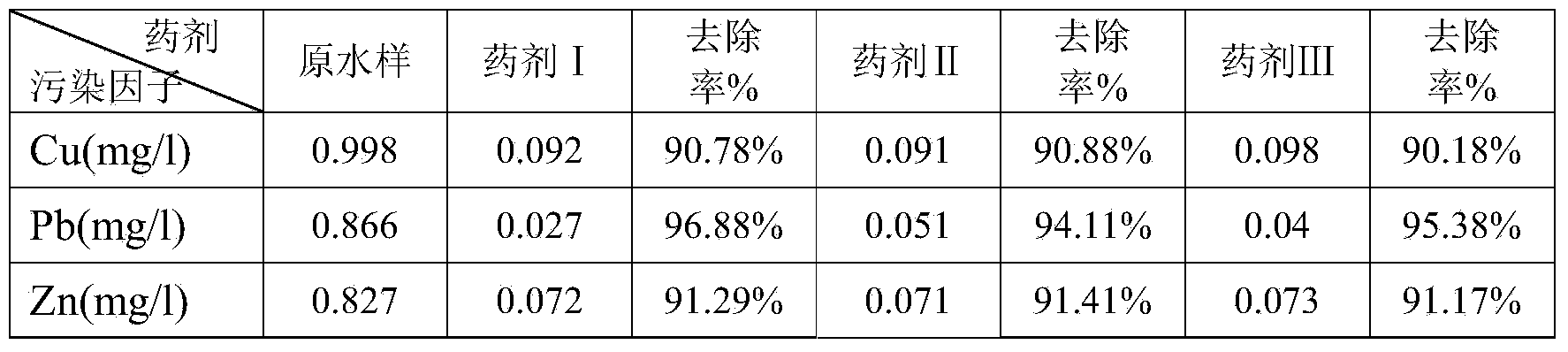

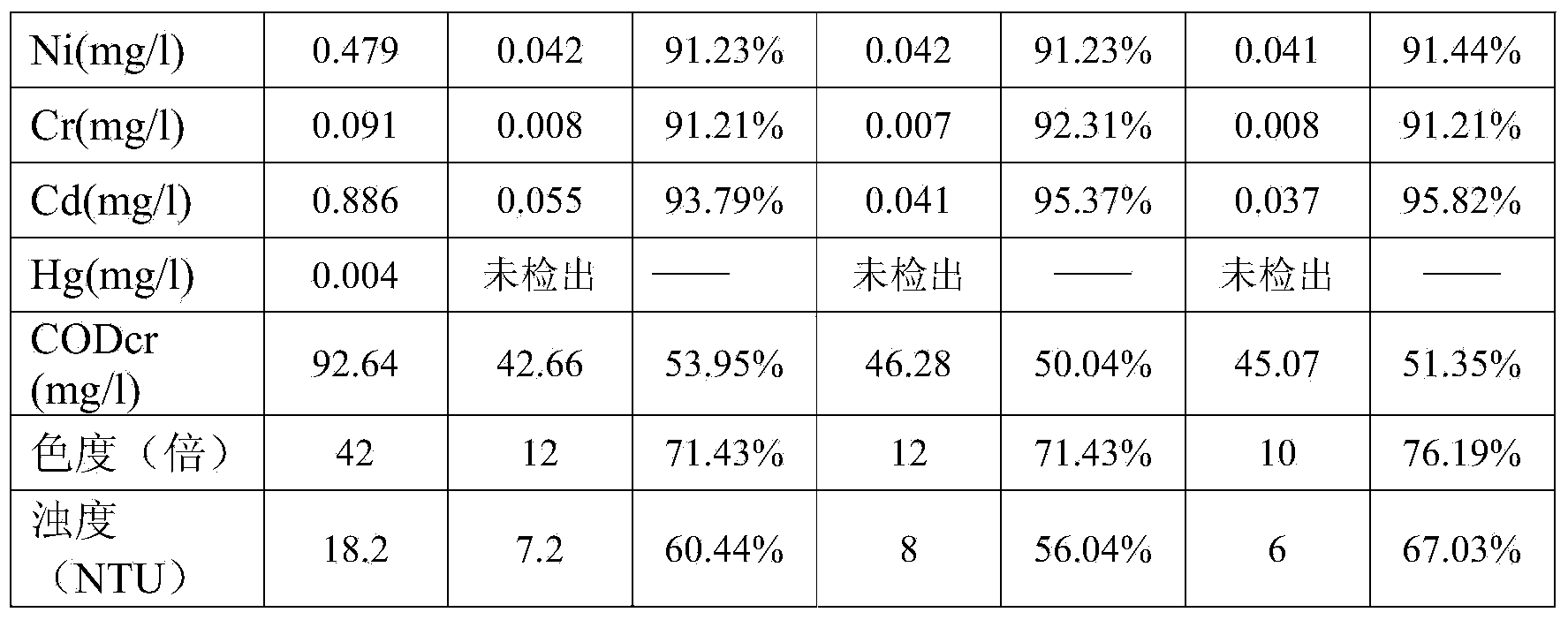

Composite reagent for deep removal of heavy metals in wastewater and preparation method thereof

ActiveCN103482750AImprove adsorption capacityStrong chelationWater/sewage treatment by flocculation/precipitationWater/sewage treatment by sorptionFlocculationChemical oxygen demand

The invention discloses a composite reagent for deep removal of heavy metals in wastewater and a preparation method thereof. The composite reagent is prepared from the following raw materials in parts by weight: a component A including 20-30 parts of modified attapulgite powder, 30-50 parts of a modified natural high molecular polymer and 0-3 parts of a surfactant; a component B namely an inorganic flocculating agent, wherein the weight ratio of the component A to the component B is (2.5-8.3):1. The composite reagent disclosed by the invention has very strong adsorption, chelating and flocculation performances on heavy metal ions in water, has a plurality of effects of auxiliary reduction of COD (chemical oxygen demand), decoloration, dephosphorization and the like at the same time, and is good in treatment effect, and the preparation method is simple and easy.

Owner:ENVIRONMENTAL SCI RES & DESIGN INST OF ZHEJIANG PROVINCE

Method for mixed slag smelting reduction recycling and thermal refining

ActiveCN106048109ARealize smelting reduction ironmakingEasy to removeCement productionRecycling and recovery technologiesThermal energyEconomic benefits

The invention discloses a method for mixed slag smelting reduction recycling and thermal refining, and belongs to the field of non-blast furnace iron making and comprehensive utilization of resources. With the method, pig iron or steel and a phosphorus-rich phase are recycled from mixed slag, and slag thermal refining is carried out. The method comprises the following steps that (1) blast furnace slag and molten steel slag are mixed; (2) gas blowing is carried out to carry out smelting reduction; and (3) separation and recycling are carried out. According to the method, blast furnace slag and the molten steel slag are mixed, then, oxidizing gas is blown to carry out molten reduction iron making, the iron in the mixed slag is recycled, phosphorus-rich phase recycling and slag thermal refining are achieved, and the reduced slag can serve as slag cement or a cement regulator or an additive in cement production or cement clinker, or be used for producing high-value-added cement clinker. The method for mixed slag smelting reduction recycling and thermal refining is short in reaction time, high in metal recycling rate, low in production cost, high in material adaptability, high in handling capacity, friendly to the environment, high in economic benefit, and capable of effectively achieving the purpose of high-efficiency recycling of metallurgical resources and thermal energy, and is a new smelting reduction technology.

Owner:NORTHEASTERN UNIV

Oil based concentrated slurries and methods for making and using same

InactiveUS8728989B2Reduce sedimentation rateReduce settlementFluid removalFlushingParticulatesSlurry

New hydrocarbon based slurry compositions and drilling, fracturing, completion and production fluids including the hydrocarbon based slurry composition are disclosed, where the composition includes a hydrocarbon soluble polymer adapted to decrease particle settling rates of particulate materials present in the fluids and in the case of fluids that include hydratable materials to increase hydration properties of such materials.

Owner:WEATHERFORD TECH HLDG LLC

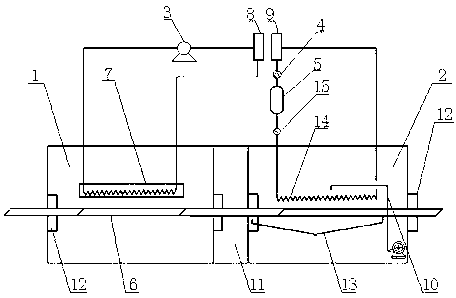

Sludge freeze thawing dewatering treating system and treating method using system

ActiveCN103011550AEfficient use ofReduce consumptionSludge treatment by thermal conditioningFreeze thawingWater pipe

The invention discloses a sludge freeze thawing dewatering treating system and a treating method using the system, solving the problems of poor sludge dewatering effect and higher cost in the prior art. The sludge freeze thawing dewatering system comprises a freezing chamber for freezing sludge and a thawing chamber communicated with the freezing chamber and used for heating the sludge, wherein an evaporator for cooling the sludge is arranged in the freezing chamber; a hot water pipe for heating the sludge is arranged in the thawing chamber; a conveyer belt for conveying the sludge is arranged in the freezing chamber and the thawing chamber and extends out of the thawing chamber; and the conveyor belt is arranged below the evaporator and the hot water pipe. The invention also provides a treating method using the sludge freeze thawing dewatering treating system. The sludge freeze thawing dewatering treating system is simple in structure, low in price, convenient for operation and excellent in sludge dewatering effect.

Owner:SICHUAN YISITONG TECH ENG

Zero-emission treatment system and method of epoxy ethane

InactiveCN103706233AFully dissolveImprove liquidityDispersed particle separationChemicalsEpoxyTreatment system

The invention discloses a zero-emission treatment system and method of epoxy ethane. The method comprises the following steps: firstly, a chemical combination treatment is carried out on an epoxy ethane waste gas in a chemical combination device; the epoxy ethane waste gas generates a sulfonation reaction with a sulfonation reaction agent in the chemical combination device; the epoxy ethane is oxidized to generate carbon dioxide and ethylene glycol; the generated carbon dioxide and the residual epoxy ethane waste gas are discharged into a turbulence ball tower; the residual epoxy ethane waste gas is output to the turbulence ball tower by a gas-liquid pump and is fully mixed and dissolved in hot water pumped by the gas-liquid pump in the turbulence ball tower; then, the epoxy ethane waste gas dissolved in the wastewater is treated on the basis of an aeration tank, a sedimentation tank and a filter tank, and meanwhile, organic matters in the wastewater can be treated as well, wherein micro-biological degradation is mainly used for carrying out oxygenation degradation on the epoxy ethane waste gas dissolved in the water through microbial communities forming flocculating constituents in the aeration tank; finally, CO2, H2O, NH3, SO42 and the like are generated and are discharged with the water, so that the epoxy ethane waste gas is treated.

Owner:杨亮月 +1

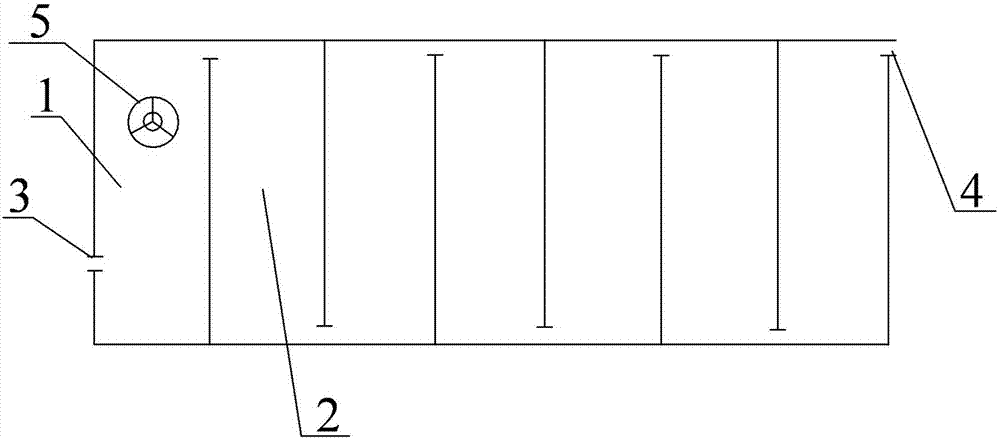

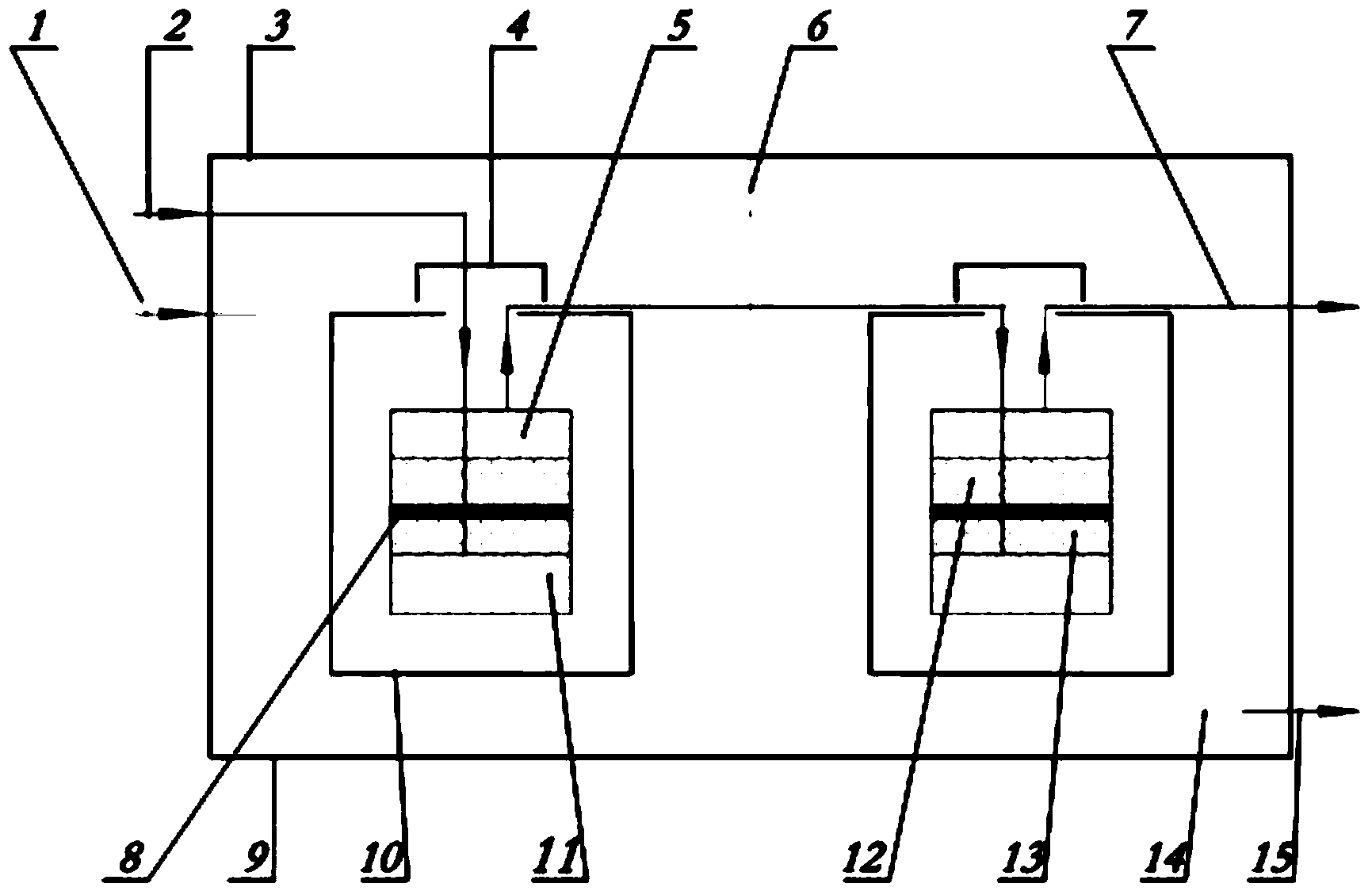

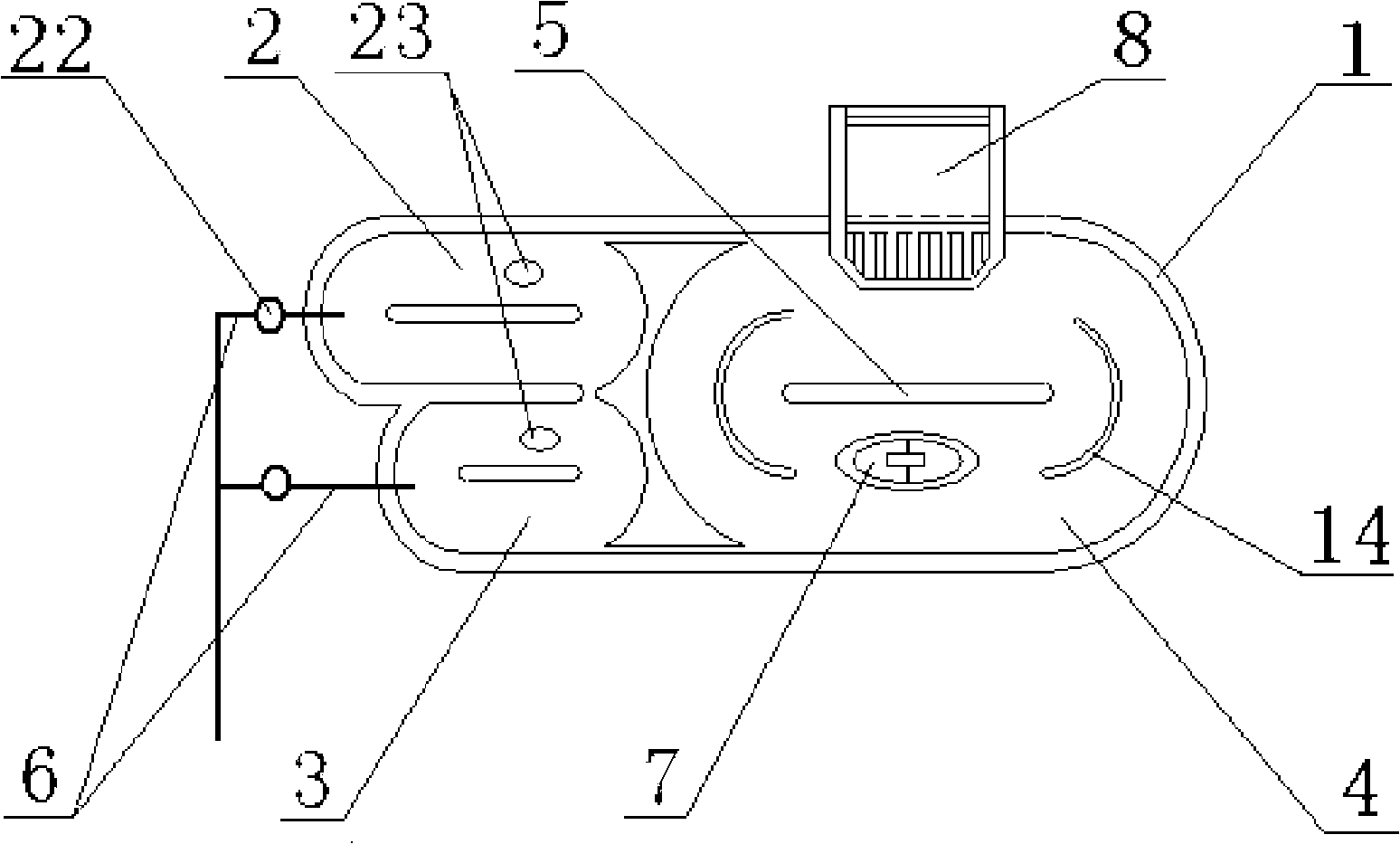

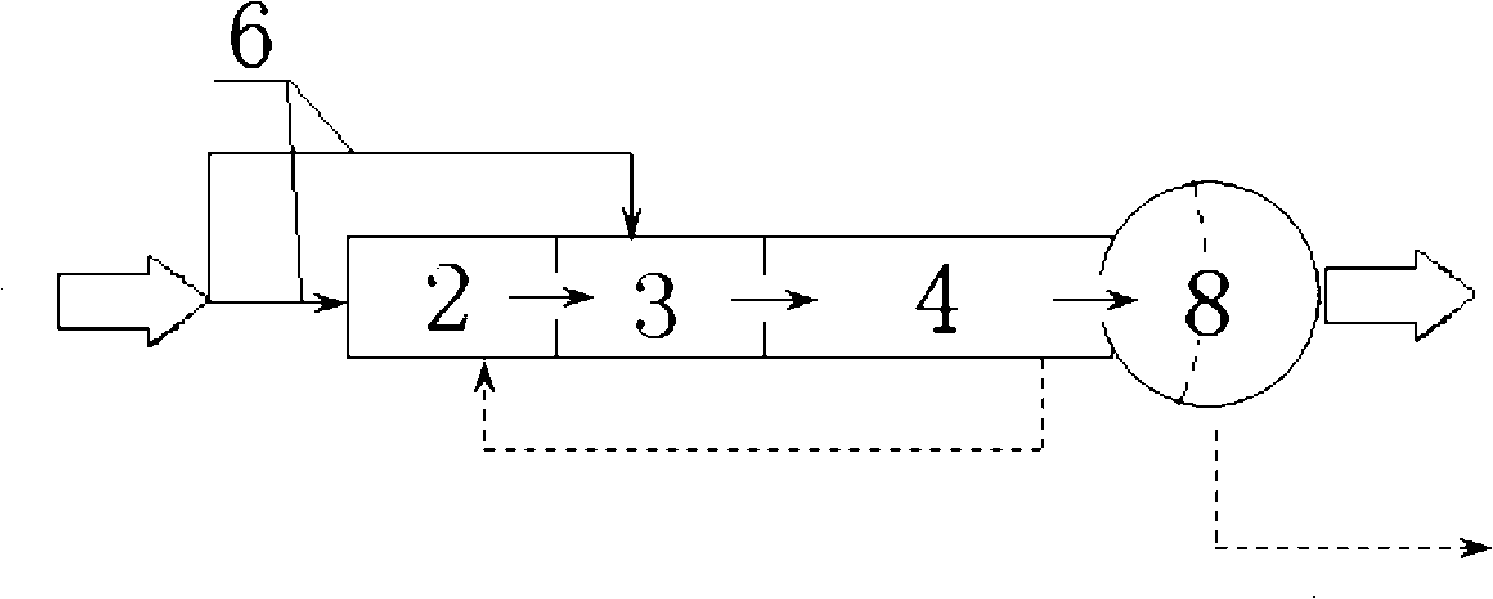

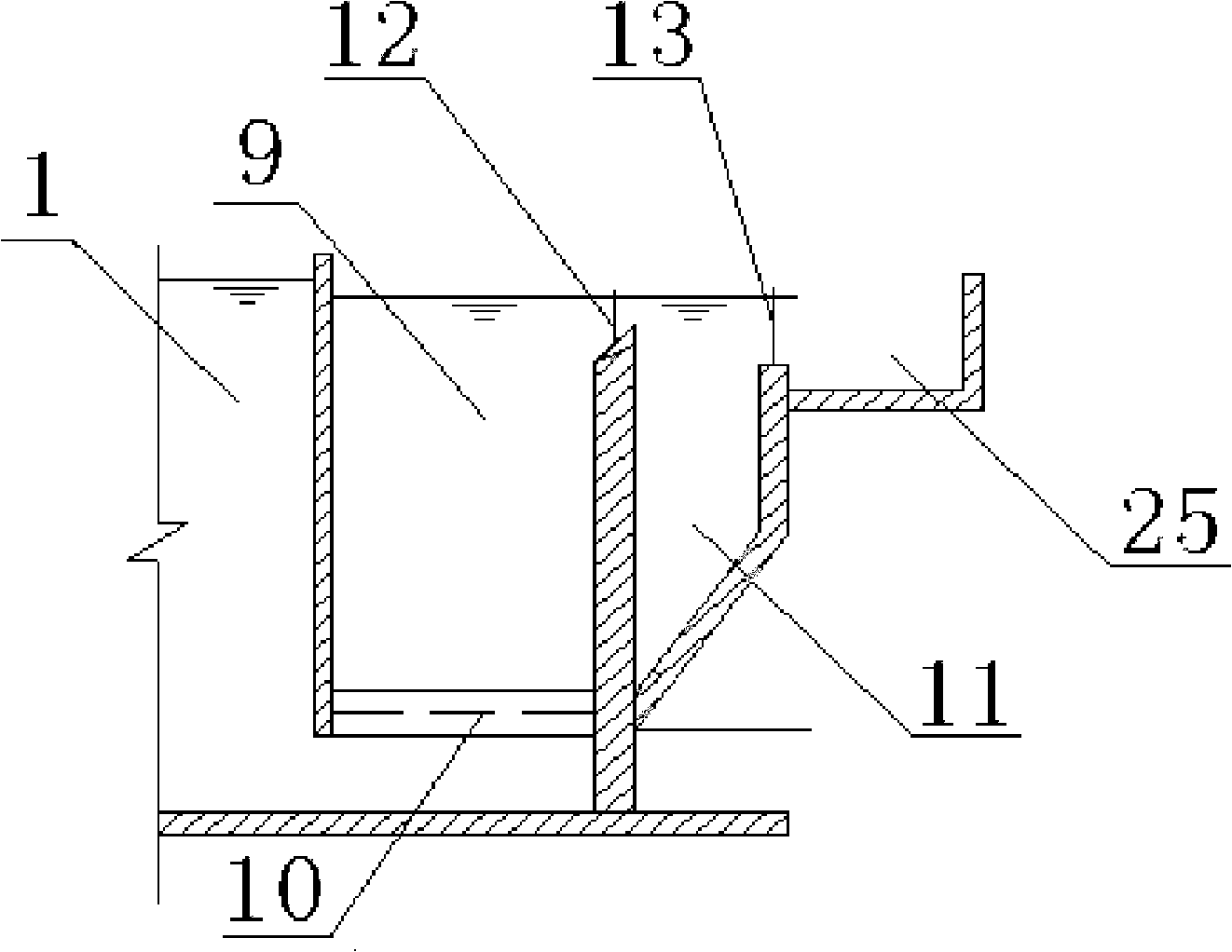

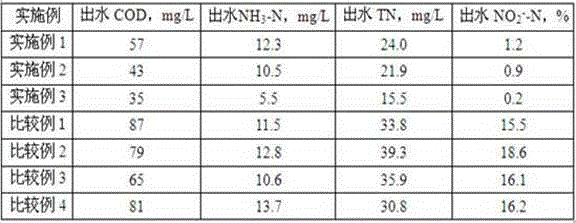

Integrated oxidation ditch, construction and operation method

InactiveCN101269882AImprove settlement performanceIncrease concentrationTreatment with aerobic and anaerobic processesSewageSmall footprint

The invention discloses an integrated oxidation ditch and a construction and operation method thereof. The construction and operation method has the technical proposal that the integrated oxidation ditch is divided into an anoxic zone, an anaerobic zone and an aerobic zone, which are communicated mutually, the anoxic zone and the anaerobic zone are arranged at one end of the integrated oxidation ditch in common, the aerobic zone is arranged at the other end of the integrated oxidation ditch, and a water-retaining wall is arranged at the middle part of each zone to cause each zone to be formed a single annular channel, water inlet pipes used for feeding water by the division point way are arranged at the anoxic zone and the anaerobic zone, an aeration device is arranged in a circulation channel at one side of the aerobic zone communicated with the anoxic zone, and a mud-water separation device used for the mud-water separation and the water emission is built on the side wall of the aerobic zone for the water emission. The aeration device is started, and the sewage passes through the anoxic zone, the anaerobic zone, the aerobic zone, and the mud-water separation device in sequence, so the dephosphorization and the denitrification as well as the decarbonization treatments of the sewage are realized. The integrated oxidation ditch has the advantages of simple structure, lower cost, small occupation area, and good sewage treatment effect, and can particularly and effectively perform the dephosphorization and the denitrification simultaneously.

Owner:ARCHITECTURAL DESIGN RES INST OF GUIZHOU +1

Denitrification microorganism culture accelerator, preparation method and applications thereof

ActiveCN106754450AHigh activityImprove settlement performanceBacteriaWater contaminantsHydroxylamineMagnesium salt

The present invention discloses a denitrification microorganism culture accelerator, which comprises a metal salt, a polyamine substance, an organic acid hydroxylamine and an organic acid salt, wherein the metal salt comprises a calcium salt, a copper salt, a magnesium salt and / or a ferrous salt. The preparation method comprises: (1) preparing a metal salt solution according to a certain composition and a certain weight part ratio; and (2) adding a polyamine substance, an organic acid hydroxylamine and an organic acid salt into the metal salt solution before use. According to the present invention, the denitrification microorganism culture accelerator has advantages of simple formula and easy preparation, the cultured denitrifying microorganisms have characteristics of high activity and strong impact resistance, and can perform denitrogenation reactions by using nitrite nitrogen as the electron acceptor, and the accelerator can be used in the denitrification microorganism culture process using nitrite nitrogen as the electron acceptor and can further be directly poured into the existing sewage treatment system so as to promote the smooth operating of the short-term nitrification and denitrification process.

Owner:CHINA PETROLEUM & CHEM CORP +1

Oil based concentrated slurries and methods for making and using same

ActiveUS20140315763A1Reduce sedimentation rateReduce settlementFluid removalFlushingParticulatesSlurry

New hydrocarbon based slurry compositions and drilling, fracturing, completion and production fluids including the hydrocarbon based slurry composition are disclosed, where the composition includes a hydrocarbon soluble polymer adapted to decrease particle settling rates of particulate materials present in the fluids and in the case of fluids that include hydratable materials to increase hydration properties of such materials.

Owner:WEATHERFORD TECH HLDG LLC

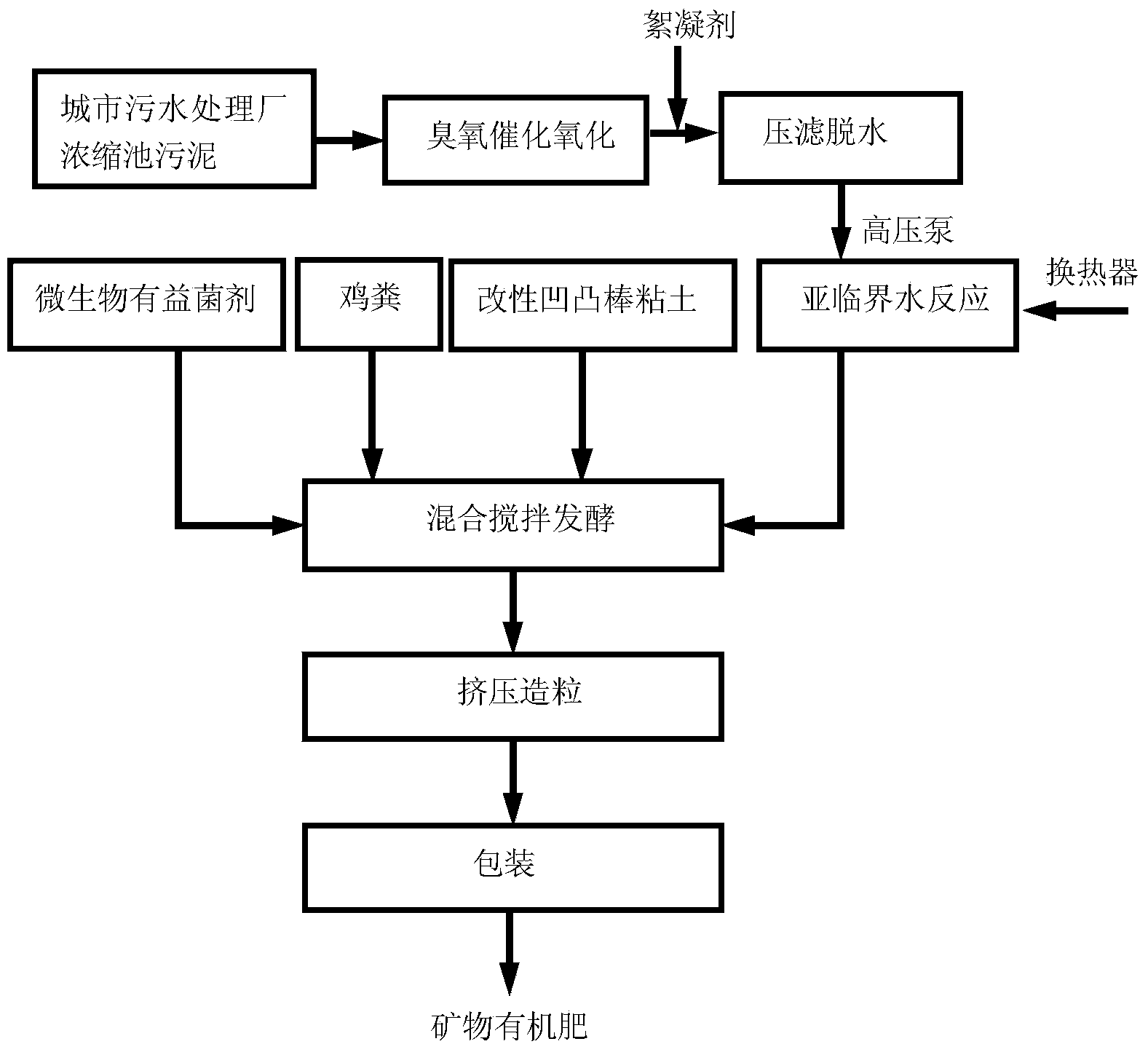

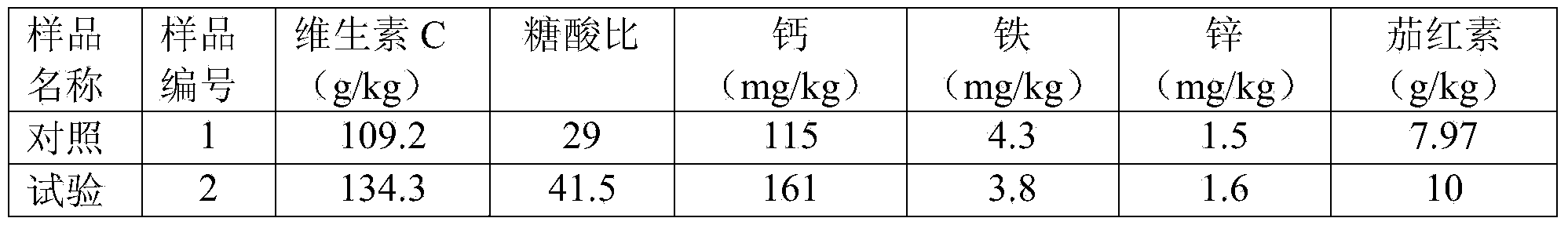

Method for preparing mineral organic fertilizer by using surplus sludge in municipal sewage plants

InactiveCN103755400AImprove oxidation activityIncreased redox potentialBio-organic fraction processingFertiliser formsMicroorganismControlled release

The invention discloses a method for preparing mineral organic fertilizer by using surplus sludge in municipal sewage plants. The method mainly comprises the following three steps: firstly reducing sludge in a sludge thickening tank, dehydrating the reduced sludge by adopting a catalytic ozonation method, carrying out subcritical water reaction on the dehydrated sludge, and discharging solids subjected to harmless treatment; finally mixing modified attapulgite clay with the sludge subjected to harmless treatment, chicken manure and microorganism beneficial microbial agents, and fermenting the mixture to obtain the mineral ecological organic fertilizer. The method is green and environment-friendly and realizes the harmless and resourceful treatment of the sludge; the obtained mineral organic fertilizer is capable of obviously improving the structure of soil, enabling the volume-weight of soil to be reduced, the holes of soil to be increased and the ventilation and water permeability of the soil to become good and adjusting the uniform growth of crops and has a good controlled release effect, thus the quality of the crops is improved.

Owner:安徽乐农环保科技有限公司

Totally-synthesized water-based stainless steel cutting liquid, and preparation method and using method thereof

ActiveCN103865622AGood instant solubilityEasy to cleanLubricant compositionWater basedPolyethylene glycol

The invention discloses a totally-synthesized water-based stainless steel cutting liquid. The cutting liquid contains the following components: a stainless steel water-based extreme-pressure agent, caprylic-capric acid, boric acid triethanolamine ester, polyethylene glycol, a cation quaternary ammonium salt metal filings settling agent, a dicarboxylic compound antirusting agent, a monobutyl ether coupling agent, a hard-water-resisting agent, a defoamer and distilled water. By virtue of an environmental-friendly total-synthesis formula, the cleaning and settling properties of the cutting liquid are enhanced; an environmental-friendly special water-based extreme-pressure lubricant is used to substitute for the traditional synthetic ester, thereby ensuring the long-time stability of the cleaning and settling properties of the cutting liquid. The cutting liquid plays a very good role in protecting non-ferrous metal and ferrous metal; by virtue of the cation quaternary ammonium salt settling agent, the problem of iron filings settling during the processing of stainless steel is eliminated, and the transparency and stability of the cutting liquid in long-time use are guaranteed.

Owner:苏州安美润滑科技有限公司

Composite high polymer flocculant for coking wastewater and preparation method thereof

InactiveCN106335988AReduce secondary pollutionWide variety of sourcesWater/sewage treatment by flocculation/precipitationCoking wastewaterIron(II) chloride

The invention discloses a composite high polymer flocculant for coking wastewater and a preparation method thereof. The composite high polymer flocculant adopts non-ionic modified starch, cationic modified starch, anionic modified starch, and amphoteric modified starch as the raw materials, in the presence of an initiator and under a weak acid condition, the raw materials undergo graft copolymerization with acrylamide, acrylic acid, methacrylic acid, acrylonitrile, acrylic ester, styrene, methylene acrylamide, maleic anhydride and other monomers to obtain a modified starch graft copolymer, and the copolymer is blended with an inorganic flocculant ferric sulfate, ferric silicate, ferric chloride, ferrous sulfate and ferrous chloride to obtain the composite high polymer flocculant. The composite high polymer flocculant has the characteristics of long molecular chain, compact floccules, wide source of raw materials, low price, biodegradability, and little secondary pollution, etc., and is a real efficient and environment-friendly flocculant. During use, the dosage of the composite high polymer flocculant accounts for 0.1-1% of the volume fraction of the treated coking wastewater, the COD removal rate of the treated coking wastewater reaches 85% or more, the decolorization rate is 95% or more, and the removal rate of suspended solids reaches 95% or more.

Owner:TIANJIN ZHONGFU ENG TECH

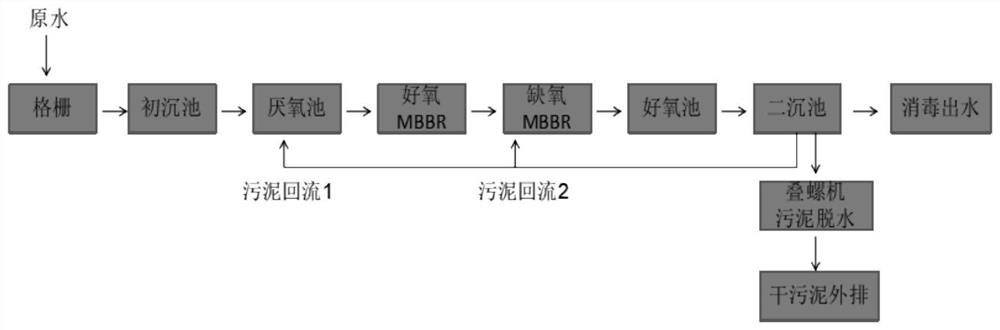

Municipal domestic sewage AOA mud-membrane mixed deep nitrogen and phosphorus removal system

InactiveCN113173642AImprove settlement performanceEasy to useWater contaminantsTreatment with aerobic and anaerobic processesActivated sludgeDenitrifying bacteria

The invention discloses a municipal domestic sewage AOA mud-membrane mixed deep nitrogen and phosphorus removal system, which comprises the following operation steps that municipal domestic sewage enters a biochemical system and is mixed with first reflux sludge in an anaerobic tank, phosphorus-accumulating bacteria and glycogen-accumulating bacteria in the sludge utilize a carbon source in raw water to synthesize an internal carbon source in vivo, then the sludge enters an aerobic zone, phosphorus-accumulating bacteria in the aerobic zone perform aerobic excessive phosphorus absorption to completely absorb phosphorus in the domestic sewage while activated sludge in the aerobic zone and nitrifying bacteria on a filler perform nitrification under the aerobic condition, at the moment, the mixed liquid and the sludge reflux to enter the anoxic zone, and the activated sludge and endogenous denitrifying bacteria on the filler perform deep denitrification on nitrate nitrogen in the sewage by utilizing an internal carbon source accumulated in the anaerobic zone. According to the invention, the system consists of a pretreatment unit, an AOA mud-membrane mixed reactor, a secondary sedimentation tank and a disinfection system, and the effluent reaches the four-class standard.

Owner:JIANGSU YULONG ENVIRONMENTAL PROTECTION

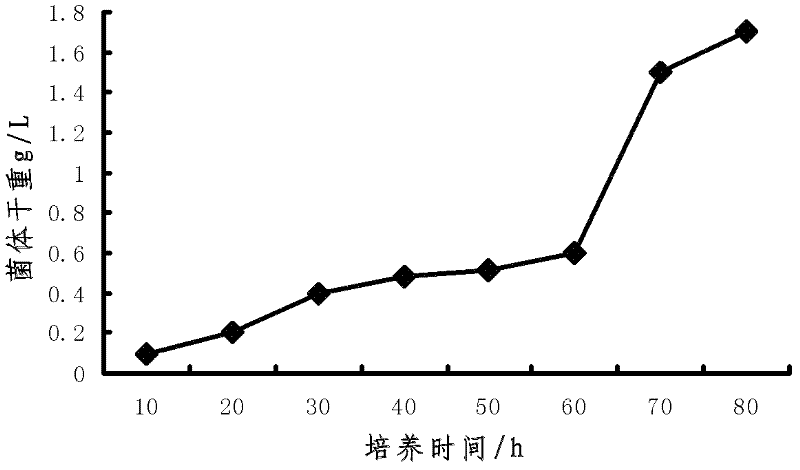

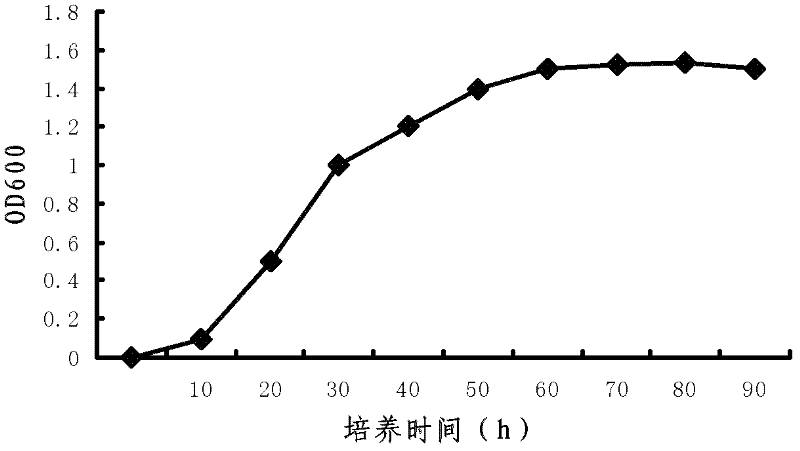

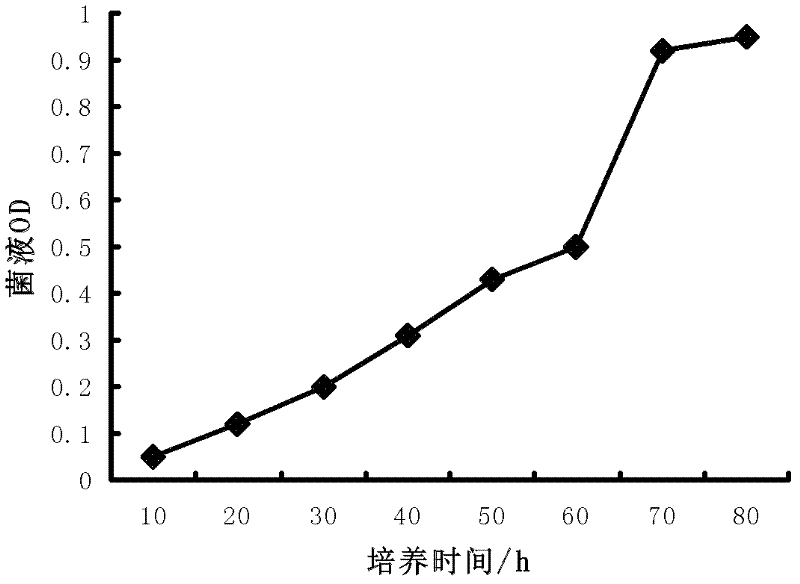

Composite microbial inoculum for improving settling performance of activated sludge and manufacture method of composite microbial inoculum

InactiveCN102399694AStrong flocculation abilityImprove settlement performanceFungiBacteriaBiologyCulture mediums

The invention discloses composite microbial inoculum for improving the settling performance of activated sludge, which consists of Aspergillussojae CGMCC3.661, Rhodococcuserythropolis ACCC02579 and Pseudomonasaeruginosa CGMCCNo.1.239. The composite microbial inoculum has the advantages that the flocculating capability is high, no public hazard exists, a good synergistic effect with original microbes of activated sludge can be generated, the settling performance of the activated sludge is improved, the activated sludge expansion is effectively prevented, and the secondary settling pool treatment efficiency is improved. In addition, the culture medium designed in the composite microbial inoculum has low price and meets the industrial high-intensity fermentation requirement of the composite microbial inoculum, the designed fermentation process control condition reaches the high-intensity production requirement of the composite microbial inoculum (the dry weight of thalli in fermentation liquid reaches 30 g.L<-1> or higher after the fermentation is completed), the investment saving of production factors such as equipment and the like is realized, and the basis is laid for the scale production and the application of the composite microbial inoculum.

Owner:JIANGSU SHANGDA WATER AFFAIR

Microorganism bacterium agent for treating leather wastewater and preparation method thereof

PendingCN106834158APromote degradationStrong resistance to changeFungiBacteriaBiotechnologyPichia pastoris

The invention discloses a microorganism bacterium agent and a preparation method thereof, and relates to a composite bacterium agent and a preparation method thereof. The composite bacterium agent can be used for efficiently removing a large amount of COD (chemical oxygen demand), ammonia and nitrogen in leather wastewater. The composite bacterium agent is prepared from mycobacterium, microbacterium, acinetobacter, pichia pastoris, lactobacillus, klebsiella oxytoca and a liquid culture medium. The preparation method comprises the following steps of 1, activating the bacteria strains of raw materials; 2, enriching and culturing; 3, mixing the bacterium strains according to a weight ratio, and adding into the liquid culture medium, so as to obtain the composite bacterium agent. The composite bacterium agent has the advantages that the biological activity is high, the growth speed is high, the leather wastewater can be treated under the low temperature condition, the removal rate of organic matter can be obviously increased, the contents of COD, ammonia and nitrogen in the leather wastewater are effectively decreased, and the effect is obvious.

Owner:北京市科学技术研究院资源环境研究所

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com