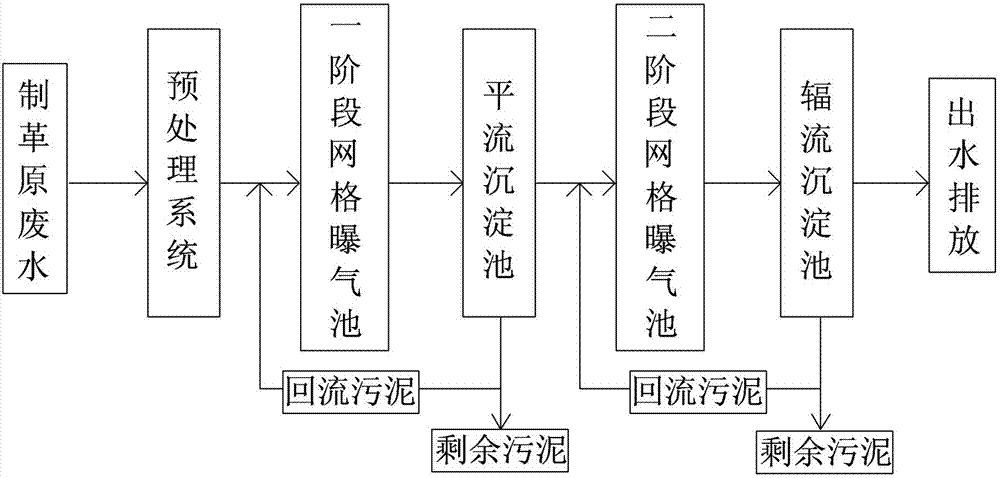

Biological tannery wastewater treatment system and treatment method thereof

A technology for biological treatment and tanning wastewater, applied in animal processing wastewater treatment, water/sewage multi-stage treatment, water/sludge/sewage treatment, etc., to achieve significant economic and social benefits, low energy consumption, convenient operation and maintenance Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

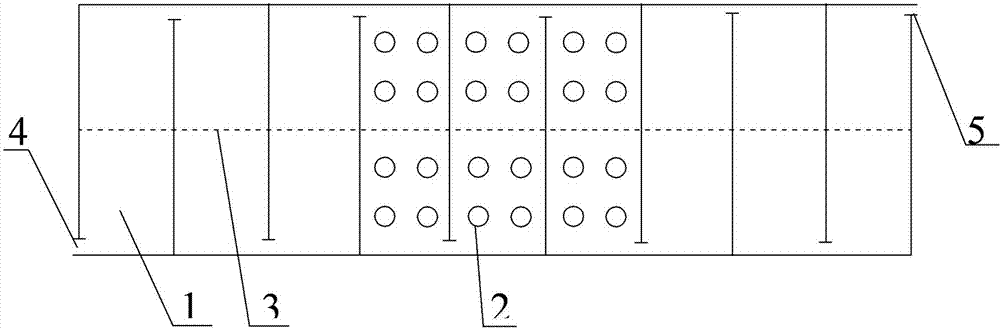

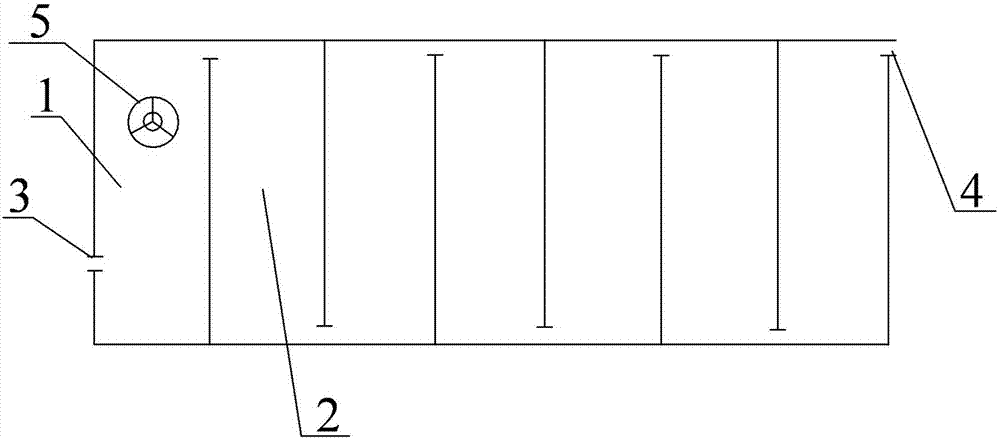

[0043] see figure 2 and image 3 The biological treatment system for tannery wastewater in this embodiment includes a one-stage grid aeration tank, an advection sedimentation tank, a second-stage grid aeration tank and a radial flow sedimentation tank connected in sequence, wherein the bottom of the advection sedimentation tank passes through The reflux pump is connected to the feed port of the first-stage grid aeration tank, and the bottom of the radial flow sedimentation tank is connected to the feed port of the second-stage grid aeration tank through the reflux pump.

[0044] The first-stage grid aeration tank is a grid-shaped multi-stage aeration tank, which is equipped with 9 series treatment grids. The liquid inlet and liquid outlet of each treatment grid are arranged diagonally, and a half wall is set in the middle of the treatment grid. The height is 1 / 3~1 / 2 of the wall height of the treatment cell, and the half wall divides the lower part of the treatment cell into ...

Embodiment 2

[0048] The biological treatment system for tannery wastewater in this embodiment includes a first-stage grid aeration tank, an advection sedimentation tank, a second-stage grid aeration tank, and a radial flow sedimentation tank connected in sequence, wherein the bottom of the advection sedimentation tank is passed through the back flow The pump is connected to the feed port of the first-stage grid aeration tank, and the bottom of the radial flow sedimentation tank is connected to the feed port of the second-stage grid aeration tank through a return pump.

[0049] The first-stage grid aeration tank is a grid-shaped multi-stage aeration tank, which is equipped with 3 series treatment grids, the liquid inlet and liquid outlet of each treatment grid are arranged diagonally, and a half wall and a half wall are set in the middle of the treatment grid. The height is 1 / 3~1 / 2 of the wall height of the treatment cell, and the half wall divides the lower part of the treatment cell into t...

Embodiment 3

[0053] The biological treatment system for tannery wastewater in this embodiment includes a first-stage grid aeration tank, an advection sedimentation tank, a second-stage grid aeration tank, and a radial flow sedimentation tank connected in sequence, wherein the bottom of the advection sedimentation tank is passed through the back flow The pump is connected to the feed port of the first-stage grid aeration tank, and the bottom of the radial flow sedimentation tank is connected to the feed port of the second-stage grid aeration tank through a return pump.

[0054] The first-stage grid aeration tank is a grid-shaped multi-stage aeration tank, which is equipped with 6 serial treatment grids. The liquid inlet and liquid outlet of each treatment grid are arranged diagonally, and a half wall is set in the middle of the treatment grid. The height is 1 / 3~1 / 2 of the wall height of the treatment cell, and the half wall divides the lower part of the treatment cell into two disconnected s...

PUM

| Property | Measurement | Unit |

|---|---|---|

| surface load factor | aaaaa | aaaaa |

| surface load factor | aaaaa | aaaaa |

| surface load factor | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com