Microorganism bacterium agent for treating leather wastewater and preparation method thereof

A technology for microbial inoculants and leather wastewater, applied in the directions of microorganism-based methods, biochemical equipment and methods, microorganisms, etc., can solve the problems of difficult removal of COD and ammonia nitrogen, and achieve improved sedimentation performance, simple operation and management, and strong impact resistance. Effects of Sexuality and Adaptability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

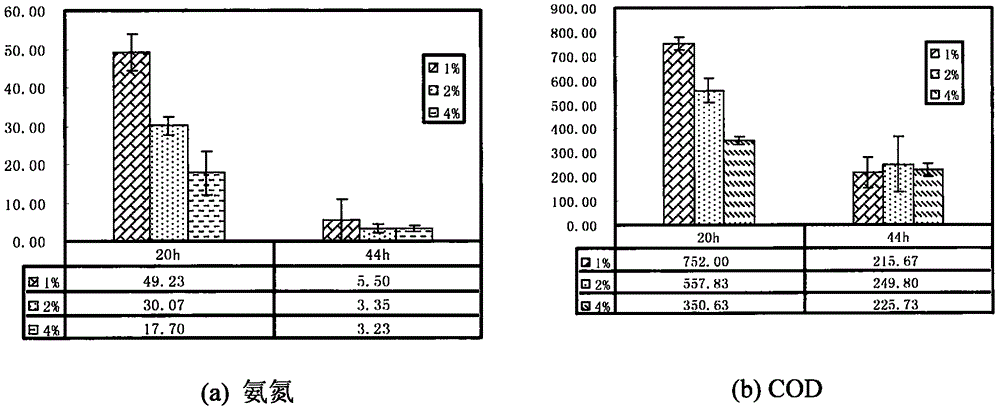

[0035] The effect of embodiment 1 microbial bacterial agent in synthetic waste water

[0036] Put the microbial agent in the medium containing molasses, incubate at 30°C, 110rpm for 12-24 hours, then centrifuge at 10,000rpm for 5min, discard the supernatant, wash twice with sterile water, centrifuge in the same steps, and remove the lower layer Bacteria were placed in synthetic wastewater at concentrations of 1%, 2%, and 4% (v / v) respectively. Synthetic wastewater components (g / L): glucose 1.0; ammonium sulfate 0.3; peptone 0.1; sodium bicarbonate 0.6; Potassium hydrogen 0.15; Magnesium sulfate heptahydrate 0.03; Manganese sulfate 0.01; Trace elements 1ml; Distilled water 1L. Three sets of parallel samples were made for each concentration. Put the synthetic waste water in the Erlenmeyer flask, inoculate the microbial agent into the synthetic waste water, place the Erlenmeyer flask in a shaker, shake the Erlenmeyer flask at a speed of 110rpm to make it oxygenated, and measure ...

Embodiment 2

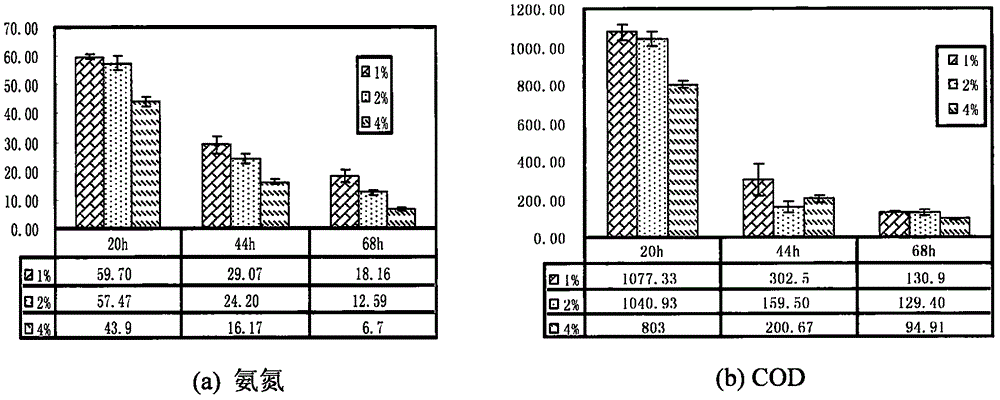

[0038] Application effect of embodiment 2 microbial bacterial agents in leather wastewater

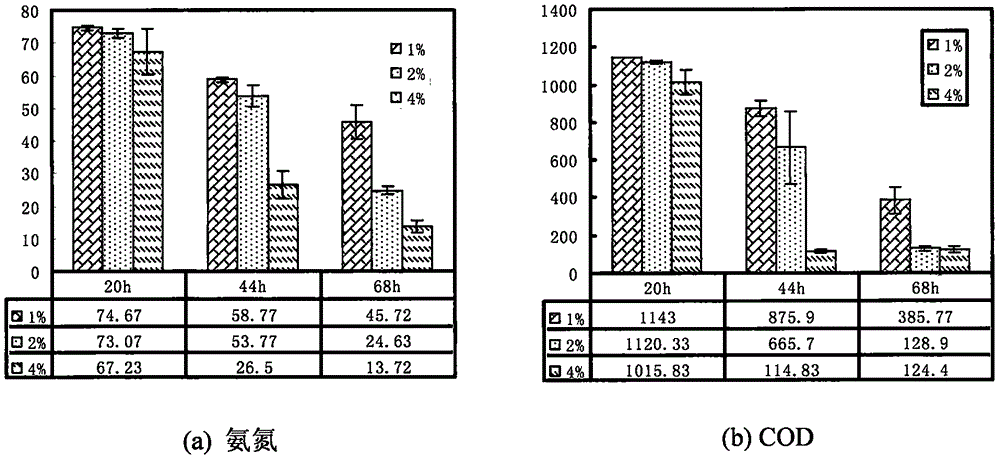

[0039] The embodiment provides a method for the enhanced treatment of actual leather wastewater by microbial agents. The main steps of this method are the same as in Example 1, except that the actual leather wastewater is used instead of synthetic wastewater for experimental research. At 30°C, the degradation conditions of ammonia nitrogen and COD are as follows: Figure 4 shown. Dilute the leather wastewater by 5 times, at 30°C, the degradation of ammonia nitrogen and COD are as follows: Figure 5 shown.

[0040] The results show that: the original ammonia nitrogen concentration of leather wastewater is 168.6mg / L, and the COD is 3326mg / L. Within 67 hours, the highest removal rate of the microbial agent to the ammonia nitrogen concentration is close to 50%, indicating that the microbial agent can achieve the highest removal rate in the actual leather wastewater. Effective degradatio...

Embodiment 3

[0041] Example 3 Treatment of high-concentration leather wastewater with high-efficiency and enhanced bio-activated carbon technology with microbial agents

[0042] Example utilizes Figure 6 The method of water treatment in the experimental device is as follows: the microbial bacterial liquid is added to the biological activated carbon filter 3, and at the same time, the air compressor 4 is used to aerate under the activated carbon in the biological activated carbon filter 3 to realize the rapid loading of activated carbon by the microbial bacterial agent. The dissolved oxygen (DO) is 2-6mg / L, the temperature is 25-30°C, and after 10-16 hours of aerated film-hanging culture, the aerobic biological activated carbon filter is successfully constructed.

[0043] The leather waste water to be treated is placed in the water tank 1, pumped into the bioactive carbon filter 3 by the water inlet pump 2, and at the same time, the bioactive carbon filter 3 is continuously aerated to keep...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com