Composite microbial inoculum for improving settling performance of activated sludge and manufacture method of composite microbial inoculum

A technology of compound bacterial agent and sedimentation performance, applied in the direction of microorganism-based methods, chemical instruments and methods, biochemical equipment and methods, etc., can solve the problems of neurotoxicity, carcinogenicity, secondary pollution, mutagenesis, etc., and achieve improved sedimentation performance , Strong flocculation ability and low price

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] Embodiment 1 improves the composite bacterial agent of activated sludge settling performance

[0029] A composite bacterial agent for improving the settling performance of activated sludge, consisting of Aspergillus sojae CGMCC 3.661, Rhodococcus erythropolis ACCC 02579 and Pseudomonas aeruginosa CGMCC No.1.239; wherein Aspergillus sojae 20-30%, Pseudomonas aeruginosa 40-60%, Rhodococcus erythropolis 20-30%.

Embodiment 2

[0030] The compound microbial agent that the optimization of embodiment 2 improves the settling performance of activated sludge

[0031] The optimal value of the content of the three bacteria: 25% of Aspergillus sojae; 50% of Pseudomonas aeruginosa; 25% of Rhodococcus erythroping. Embodiment 3 improves the preparation method of the composite bacterial agent of activated sludge settling performance

Embodiment 3

[0031] The optimal value of the content of the three bacteria: 25% of Aspergillus sojae; 50% of Pseudomonas aeruginosa; 25% of Rhodococcus erythroping. Embodiment 3 improves the preparation method of the composite bacterial agent of activated sludge settling performance

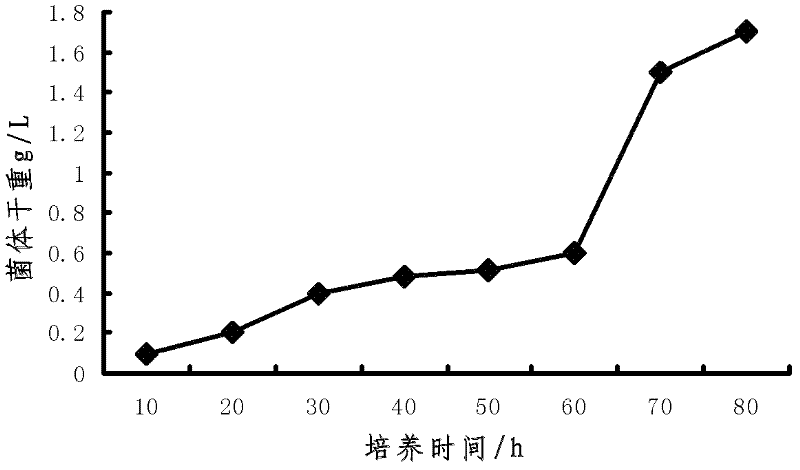

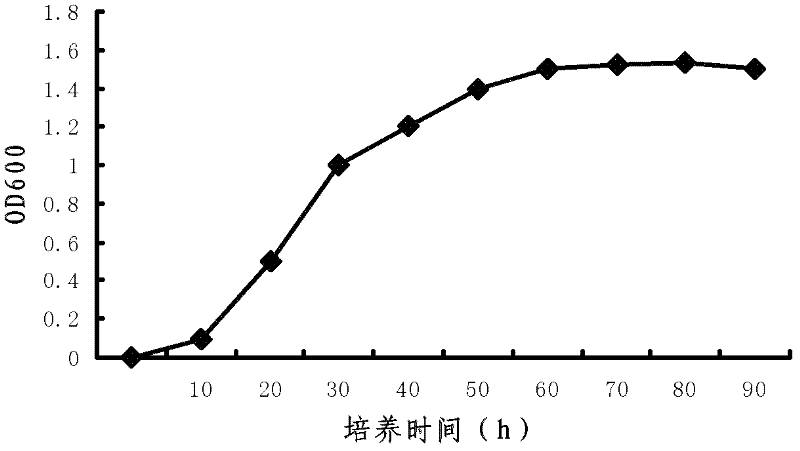

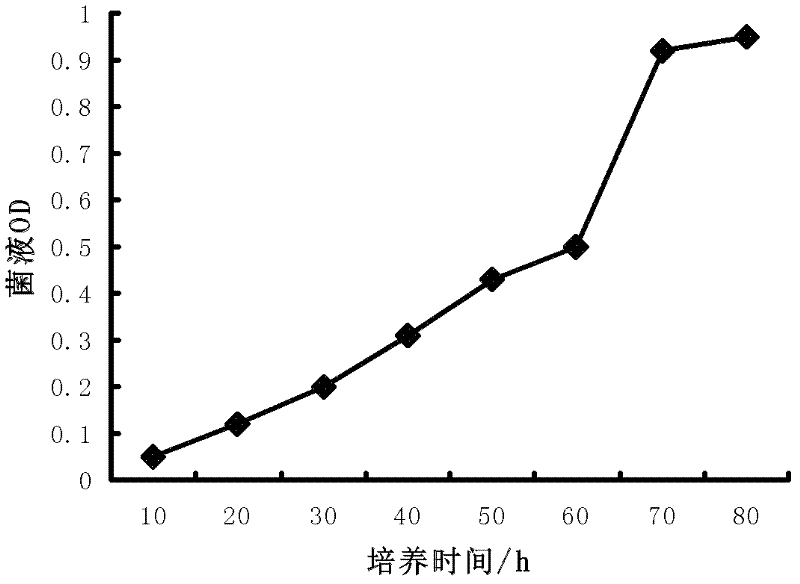

[0032] 1. Activation of strains

[0033] (1) Activation of Aspergillus sojae (Aspergillus sojae) CGMCC 3.661: Take out the strains stored in the refrigerator at -80°C, melt them on ice, inoculate them on the plate medium by aseptic operation, and culture them at 30°C for 24-36 hours. When a single colony appears and the size is suitable for picking and inoculation, seal it with a parafilm and store it in a 4°C refrigerator for later use. Czapek's plate medium: sucrose 30g·L -1 , agar powder 15g·L -1 、NaNO 3 3g·L -1 , MgSO 4 ·7H 2 O 0.5g·L -1 , KCl 0.5g·L -1 , FeSO 4 4H 2 O 0.01g·L -1 、K 2 HPO 4 1g·L -11. After dissolving with deionized water, adjust the pH to 6.5, sterilize at 121°C for 25 minu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com