Patents

Literature

214results about How to "Improve flocculation ability" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Method of preparing high-purity vanadium pentoxide from roasting-method vanadium solution

The invention discloses a method of preparing high-purity vanadium pentoxide from roasting-method vanadium solution. The method comprises the following steps: adding a purifying agent into the roasting-method vanadium solution, wherein the purifying agent is polyaluminium chloride, magnesium chloride or calcium chloride, or the purifying agent is polyaluminium chloride and magnesium chloride, or polyaluminium chloride and calcium chloride; uniformly stirring the roasting-method vanadium solution containing the purifying agent, standing for settling, then filtering, and adding ammonium salt into the filtrate to precipitate vanadium; and finally, calcining meta-ammonium and deaminizing to prepare vanadium pentoxide with the purity being higher than 99.5%. Polyaluminium chloride serving as the purifying agent can be used for polymerizing jellies with several molecules into large particles with several tens of thousands of molecules, even hundreds of thousands of molecules. The large-particle molecular polymer is easy to settle in the vanadium solution and can be separated from the solution. The method provided by the invention has the advantages that the consumption of polyaluminium chloride is low, the flocculation process is simple, the flocculation capacity is strong, the flocculation speed is high, pollution is hardly caused and the cost is low.

Owner:贵州义信矿业有限公司

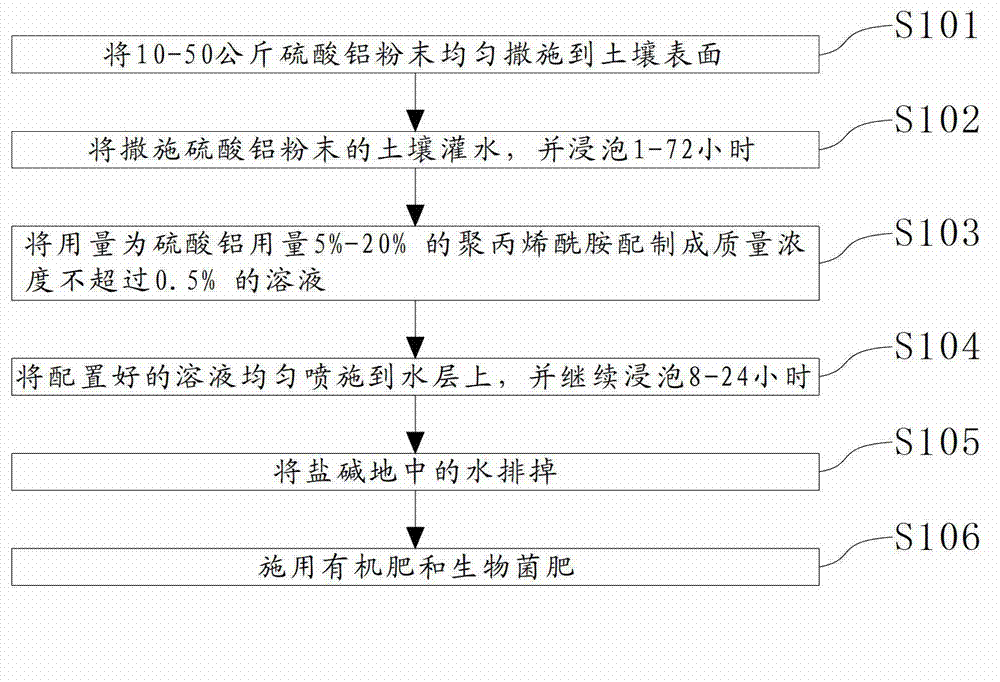

Improvement method for saline-alkali soil

ActiveCN103109615AImprove propertiesImprove permeabilitySoil-working methodsAlkali soilPolyacrylamide

The invention relates to the agricultural field, in particular to an improvement method for saline-alkali soil. The improvement method for the saline-alkali soil comprises the following steps: sprinkling 10 to 50 kilograms of aluminum sulfate powders on the surface of the saline-alkali soil evenly; irrigating the soil with the aluminum sulfate powders and soaking the soil with the aluminum sulfate powders for 1 hour to 72 hours; compounding polyacrylamide with a dosage which is 5% to 20% of the dosage of the aluminum sulfate powders into a solution, wherein the mass concentration of the solution is no more than 0.5%; evenly spraying the compounded solution onto the water layer, and continuing to soak the soil with the aluminum sulfate powders for 8 hours to 24 hours; draining the water in the saline-alkali soil; and applying organic fertilizer and biological bacterial fertilizer to the saline-alkali soil. The improvement method for the saline-alkali soil can improve the sodium ions, the carbonate ions and the bicarbonate radical ions in the soil, so that the potential of hydrogen (pH) value of the solution of the soil can be reduced. The aluminum sulfate is increased, so that the soluble salts released by the soil particles are also increased, so that the salt materials in the soil can be reduced remarkably. Due to the fact that the macromolecule polyacrylamide is added, the soil can congeal into bigger particles like pea grains, so that permeability and water and fertilizer preserving capability of the soil can be improved.

Owner:黑龙江省汉通生物工程有限公司

Method for decoloring burned waste water by using zero-valent iron/ultrasonic wave synergistic reaction

InactiveCN101234812AImprove biodegradabilityEasy to handleWater/sewage treatment with mechanical oscillationsWater/sewage treatment by reductionUltrasound - actionReaction temperature

The invention relates to environmental chemistry, in particular to a method for decolorizing coking wastewater by using synergetic effect of zero-valent iron / ultrasonic waves, which specifically comprises the following steps: wastewater and zero-valent iron chips / powders are added into a reactor; the pH value of the wastewater is adjusted to be 1 to 6; then stirring is carried out under the effect of the ultrasonic waves with the power of 150 to 200W; the reaction is lasted for 30 to 60 minutes; the wastewater is decolorized and COD is removed. During the process, the use amount of zero-valent iron in each liter of wastewater is 2 to 500g, and the reaction temperature is 10 to 80 DEG C. By applying the method for decolorizing coking wastewater by using synergetic effect of zero-valent iron / ultrasonic waves, the chromaticity of the coking wastewater can drop from 1,500 times to 140 times, and the removal efficiency can reach over 90 percent; in addition, after the synergetic effect of the zero-valent iron and ultrasonic waves, the removal efficiency of COD in the coking wastewater is higher than the efficiency under the signal effect of the zero-valent iron and the ultrasonic waves. The obtained BOD5 / COD is increased from 0.08 to 0.36, and the biodegradability of the wastewater is also increased remarkably.

Owner:SHENYANG INST OF APPL ECOLOGY CHINESE ACAD OF SCI

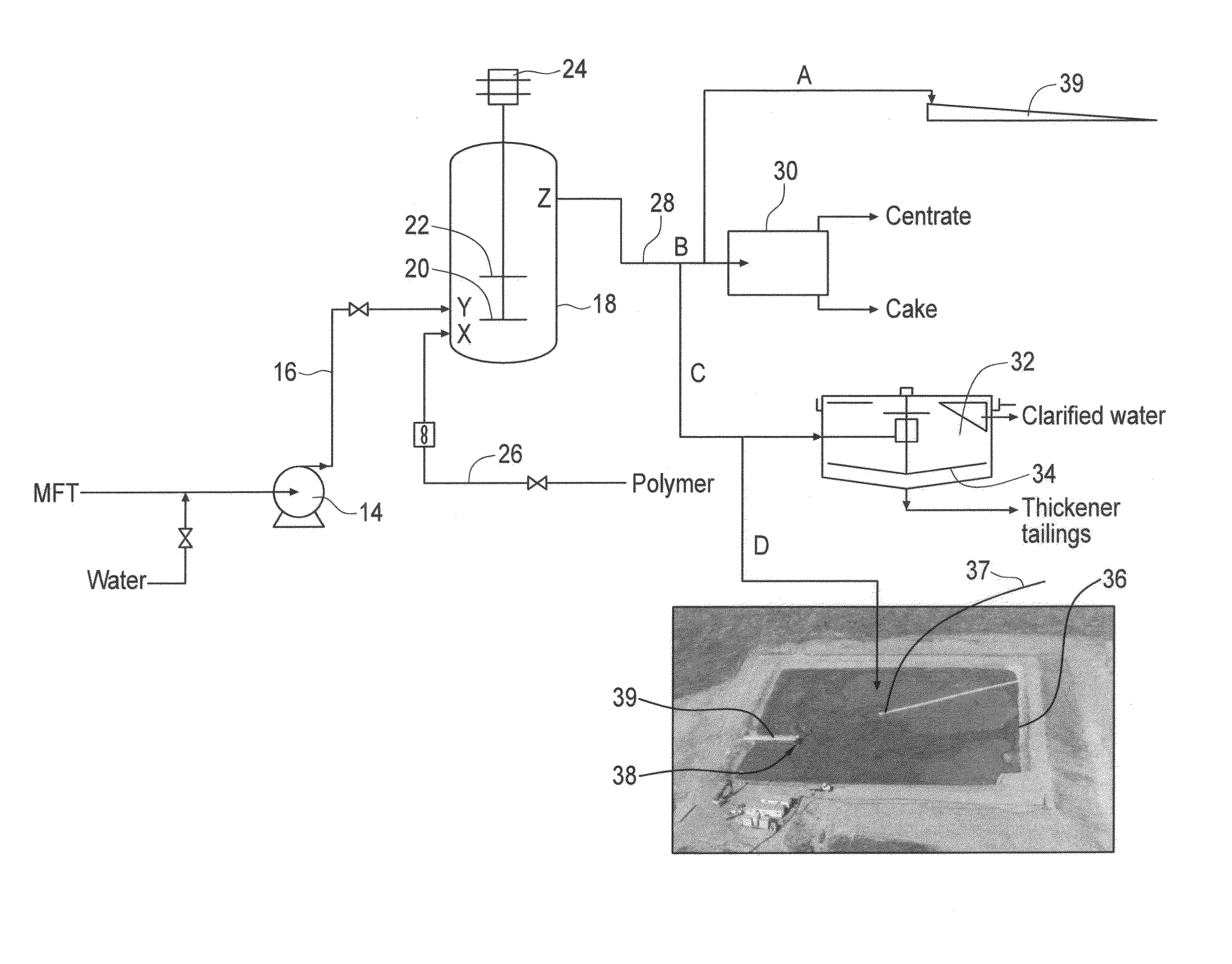

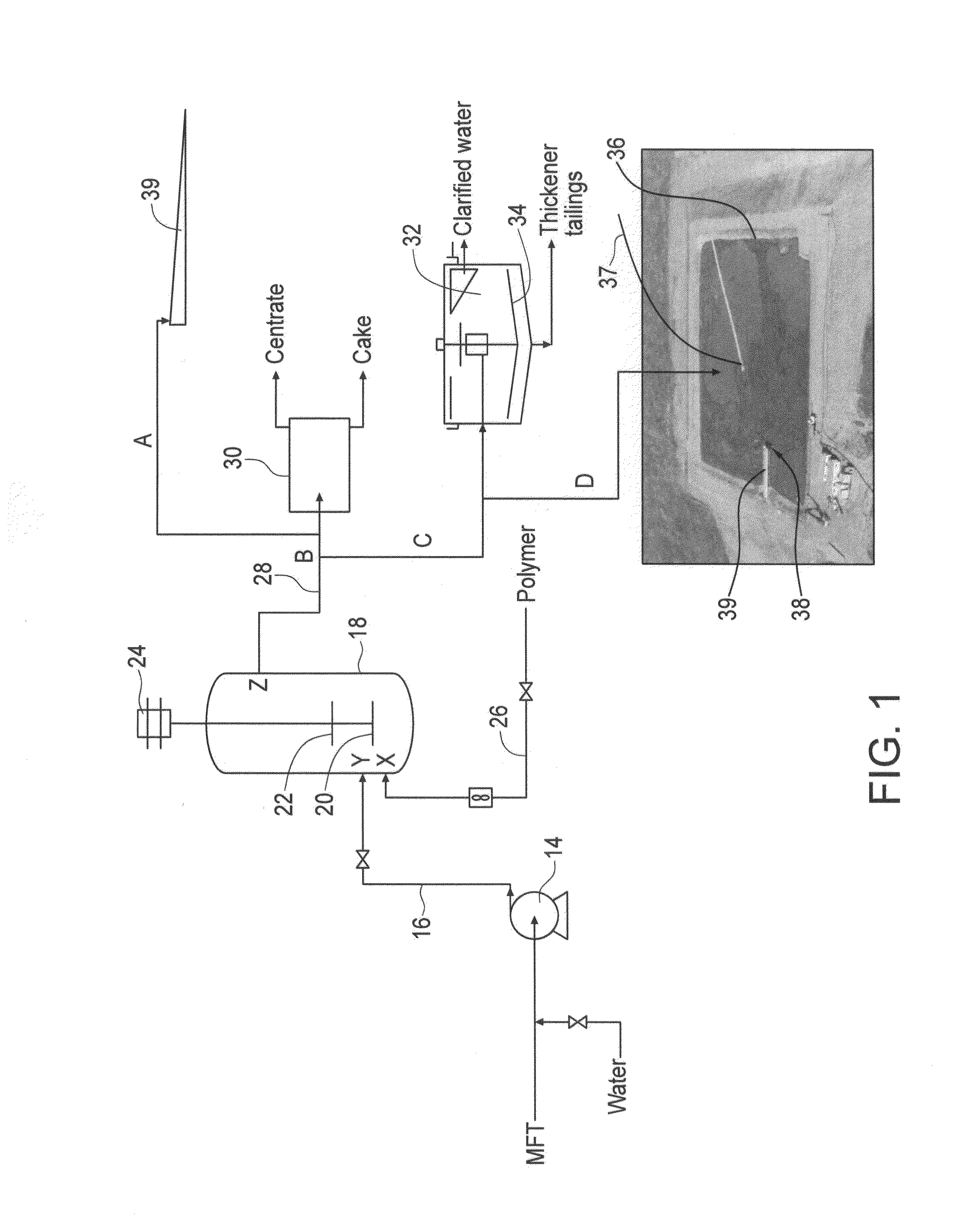

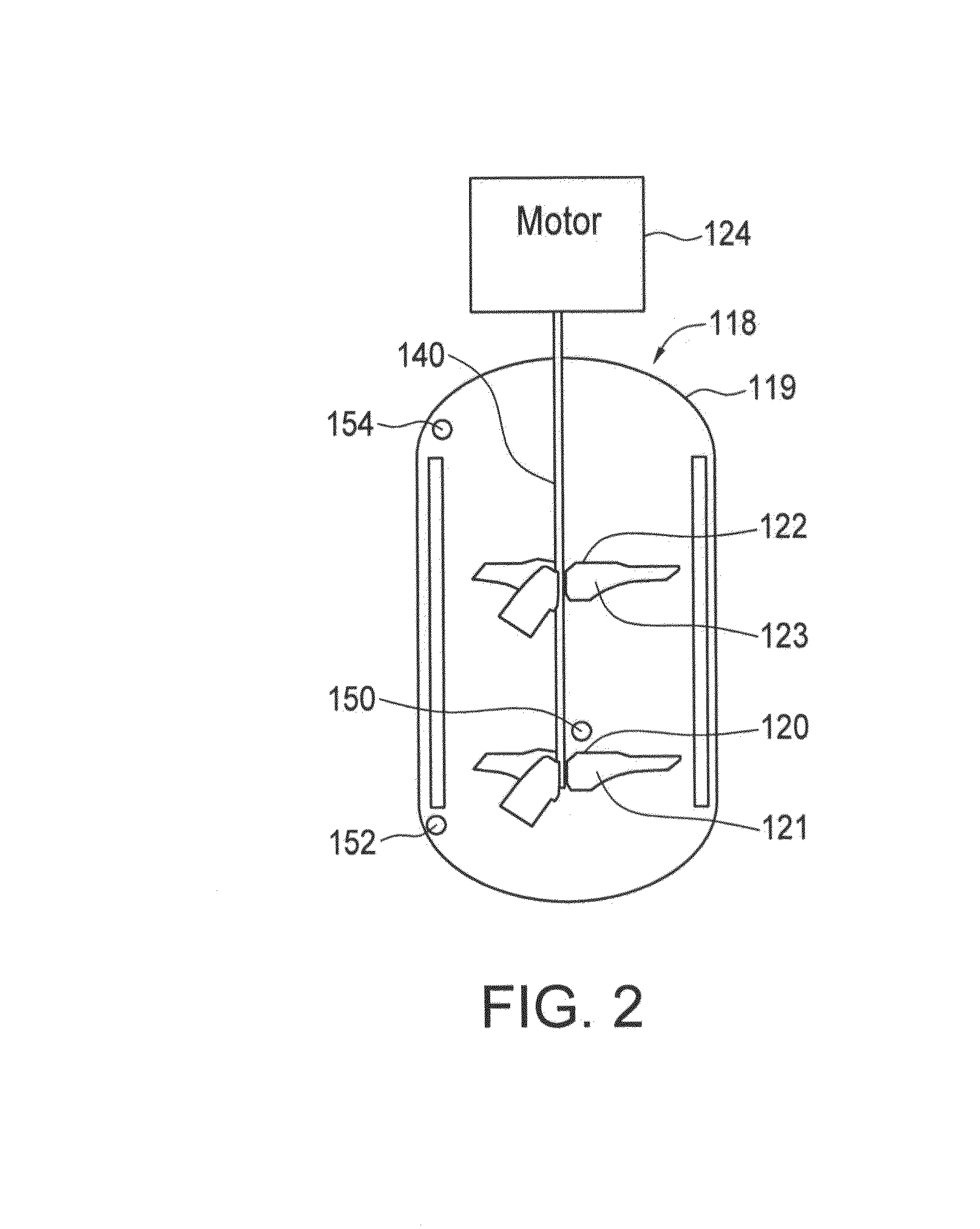

Oil sands fine tailings flocculation using dynamic mixing

InactiveUS20130075340A1Dehydration fastBetter dewateringWaste water treatment from quariesWater/sewage treatment by centrifugal separationFlocculationSlurry

A process for flocculating and dewatering oil sands fine tailings is provided, comprising: adding the oil sands fine tailings as an aqueous slurry to a stirred tank reactor; adding an effective amount of a polymeric flocculant to the stirred tank reactor containing the oil sands fine tailings and operating the reactor at an impeller tip speed for a period of time that is sufficient to form a gel-like structure; subjecting the gel-like structure to shear conditions in the stirred tank reactor for a period of time sufficient to break down the gel-like structure to form flocs and release water; and removing the flocculated oil sands fine tailings from the stirred tank reactor when the maximum yield stress of the flocculated oil sands fine tailings begins to decline but before the capillary suction time of the flocculated oil sands fine tailings begins to substantially increase from its lowest point.

Owner:SYNCRUDE CANADA LTD

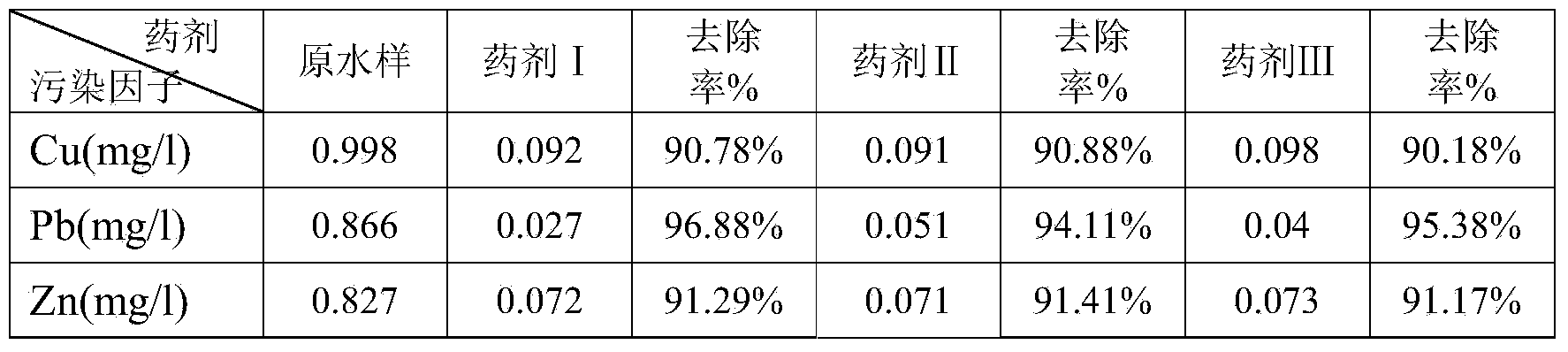

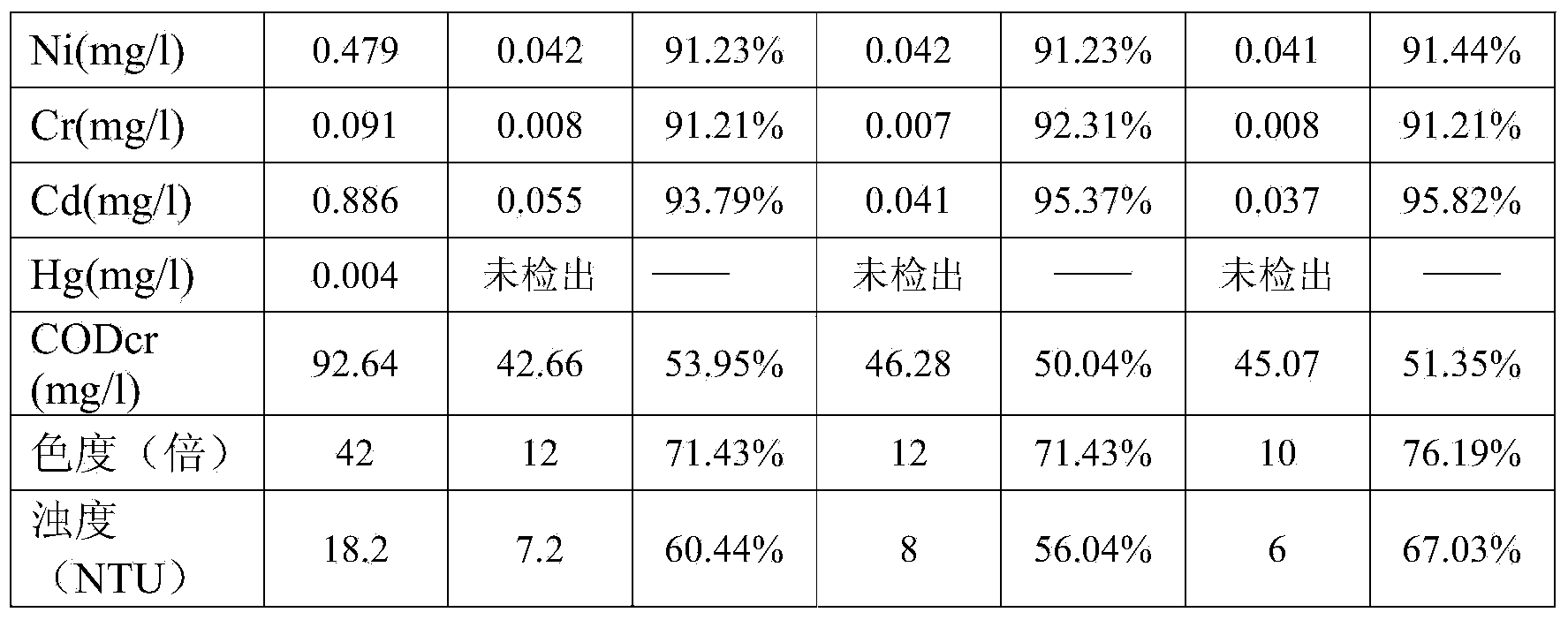

Composite reagent for deep removal of heavy metals in wastewater and preparation method thereof

ActiveCN103482750AImprove adsorption capacityStrong chelationWater/sewage treatment by flocculation/precipitationWater/sewage treatment by sorptionFlocculationChemical oxygen demand

The invention discloses a composite reagent for deep removal of heavy metals in wastewater and a preparation method thereof. The composite reagent is prepared from the following raw materials in parts by weight: a component A including 20-30 parts of modified attapulgite powder, 30-50 parts of a modified natural high molecular polymer and 0-3 parts of a surfactant; a component B namely an inorganic flocculating agent, wherein the weight ratio of the component A to the component B is (2.5-8.3):1. The composite reagent disclosed by the invention has very strong adsorption, chelating and flocculation performances on heavy metal ions in water, has a plurality of effects of auxiliary reduction of COD (chemical oxygen demand), decoloration, dephosphorization and the like at the same time, and is good in treatment effect, and the preparation method is simple and easy.

Owner:ENVIRONMENTAL SCI RES & DESIGN INST OF ZHEJIANG PROVINCE

Preparation of polymer composite gelling agent for grouting and application method thereof

The invention belongs to the technical field of a gelling agent for geologic hazard control as well as filling control of goaf and waste laneway or collapse craters after exploitation of other mines, and provides a formula and a method of a novel polymer composite gelling agent for grouting. The gelling agent comprises the following components in percentage by weight: 10-25% of bentonite, 5-20% of cellulose, 5-20% of vegetable gum, 10-15% of calcium hydroxide, 10-25% of inorganic hygroscopic agent, 0.5-1.5% of inorganic dispersant, 0.5-2% of inorganic flocculent, 6-18% of organic flocculent, and 5-15% of alkali metal carbonate. The gelling agent is used for processing and crushing, mixing with water, and injecting to slurry for gelling. According to the invention, the characteristics of high-hydroscopicity mineral matters and hydroscopic synthetic resin are sufficiently absorbed and utilized, and various ion groups are introduced and adjusted to obtain specific performance, so that the gelling agent has strong water solubility, can form hydrophile and water-insoluble gel in the slurry, and has excellent adhesion force to solids and dissolved matters in the slurry, good gelling property, strong water control function, high and adjustable jelling speed, low cost and no pollution.

Owner:JICHANG XIANDAO ENG MATERIAL

Cationic polyacrylamide-modified Fe3O4 magnetic flocculant and preparation method thereof

InactiveCN103073101AReduce dosageFast flocculationOrganic/organic-metallic materials magnetismWater/sewage treatment by flocculation/precipitationFlocculationSuperparamagnetism

The invention relates to a magnetic flocculant and a preparation method thereof, wherein the magnetic flocculant is cationic polyacrylamide-modified magnetic nanometer Fe3O4 particles. The magnetic flocculant provided by the invention retains the advantages of low dosage of organic high molecular flocculant, high flocculation speed, coexistence of salts, low pH value and temperature influence, low total amount of flocculating constituent and the like; and the superparamagnetism of the flocculant enables the flocculant to quicken the precipitation under the effect of an applied magnetic field and to realize quick and efficient separation of residual flocculant and flocculation. The magnetic flocculant provided by the invention has the advantages of simple preparation technique, low cost, easiness in amplification and no secondary pollution, and facilitates realizing efficient and economic flocculation operation.

Owner:INST OF PROCESS ENG CHINESE ACAD OF SCI

Aquaculture water purifying agent

InactiveCN103508553AImprove biodegradation effectImprove securityWater/sewage treatment by flocculation/precipitationBiological water/sewage treatmentCelluloseWater quality

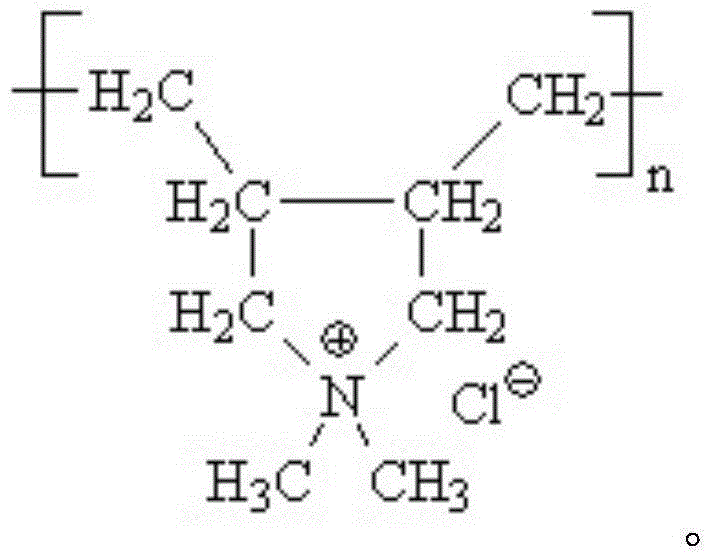

The invention relates to a water purifying agent, in particular to a water purifying agent for purifying an aquaculture water environment. The water purifying agent comprises the following components in parts by mass: 12 to 15 parts of poly dimethyl diallyl ammonium chloride, 25 to 40 parts of a microbial flocculant, 5 to 8 parts of an aquaculture oxygen supply agent, 9 to 12 parts of a biological enzyme and 7 to 10 parts of cellulose. After the formula is adopted, the microbial flocculant has the characteristics of biodegradability, safety, high efficiency, no toxicity and no secondary pollution, and overcomes the defects of inorganic polymer and synthetic organic polymer flocculants, and finally non-pollution discharge is realized. The poly dimethyl diallyl ammonium chloride is used as the organic water purifying agent and has the characteristics of small use amount, strong flocculation capacity, high efficiency and the like. The oxygen supply agent can rapidly and effectively increase dissolved oxygen in water, improves water quality, adsorbs and degrades organisms in the water and also can effectively sterilize the water.

Owner:丹阳市现代生态水产养殖场

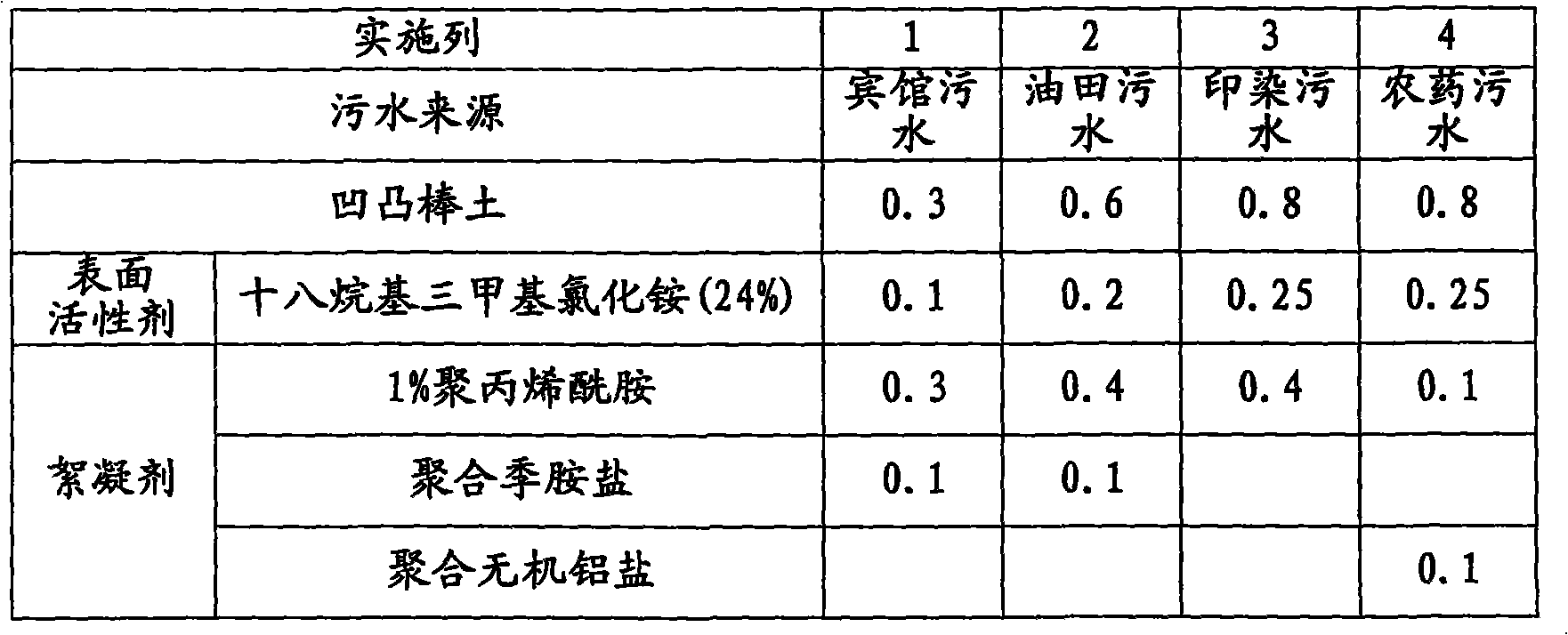

Attapulgite sewage water treating method

InactiveCN101254958AReduce typesEasy to purchaseWater/sewage treatment by flocculation/precipitationWater/sewage treatment by sorptionFlocculationSewage

An attapulgite sewage handling method is to grind the attapulgite powder into attapulgite of 101 to 600 meshes and then pour the attapulgite into the awaiting sewage to stir. Then, 24 percent of octadecyl trimethyl ammonium chloride is poured into the sewage and stirred; then a flocculent is poured into the sewage and stirred and settled, and the water-soil separation, microorganism treatment and standard discharge are carried out. The weight ratio of the sewage and the attapulgite is 1000:0.1 to 1000:1.5; the dosage ratio of the attapulgite and the octadecyl trimethyl ammonium chloride is 4:1 to 4:3; the dosage ratio of the attapulgite and the flocculent is 1:1 to 4:1. The method can be used for treating hotel sewage, dyeing sewage, pesticide sewage and oilfield sewage and has the advantages of low treatment cost, saved time and labor, strong flocculation and easy raw material attainment.

Owner:浙江华特新材料有限公司

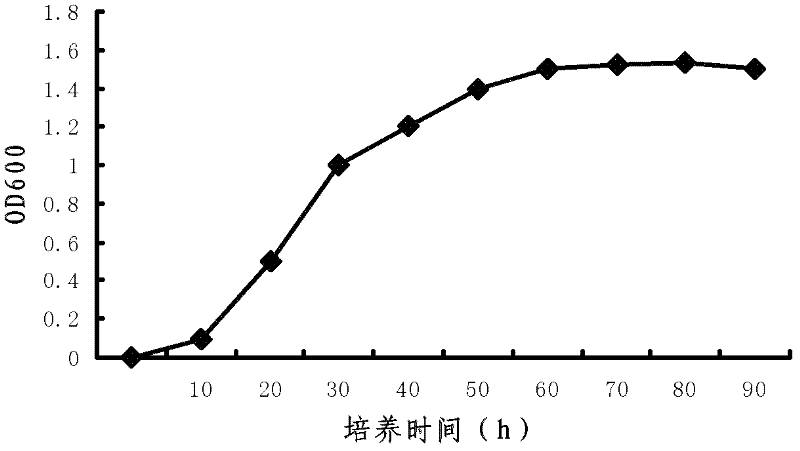

Composite microbial inoculum for improving settling performance of activated sludge and manufacture method of composite microbial inoculum

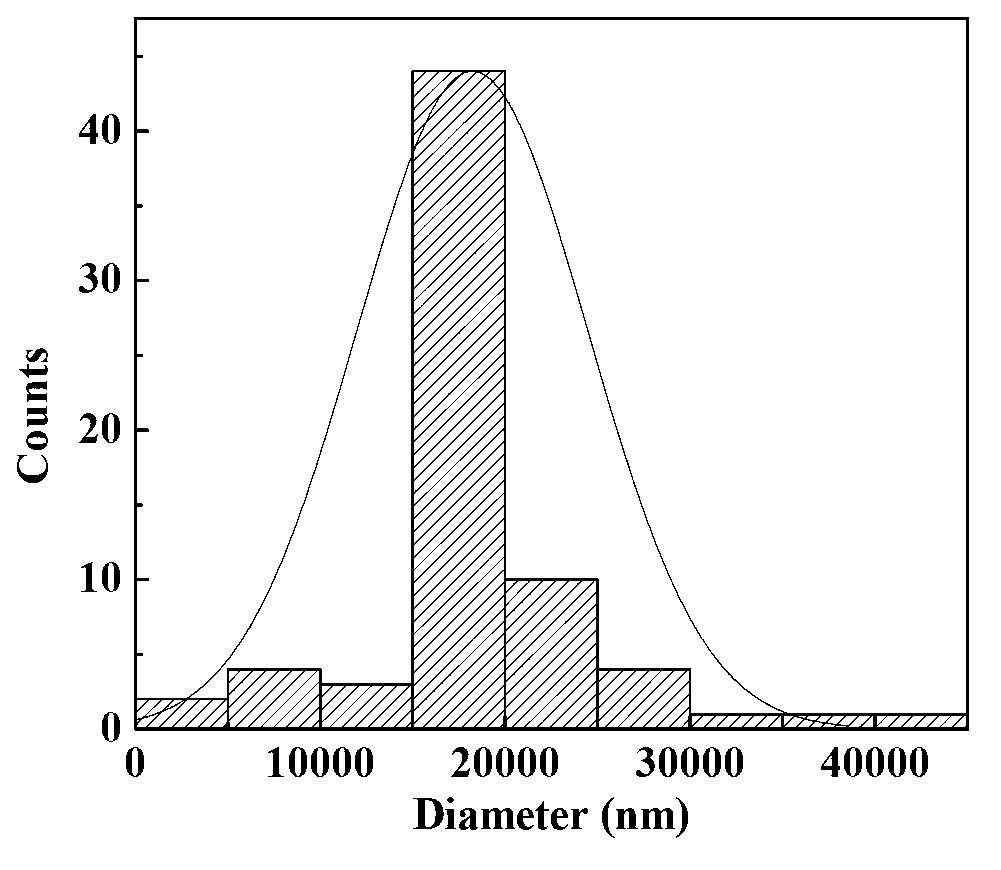

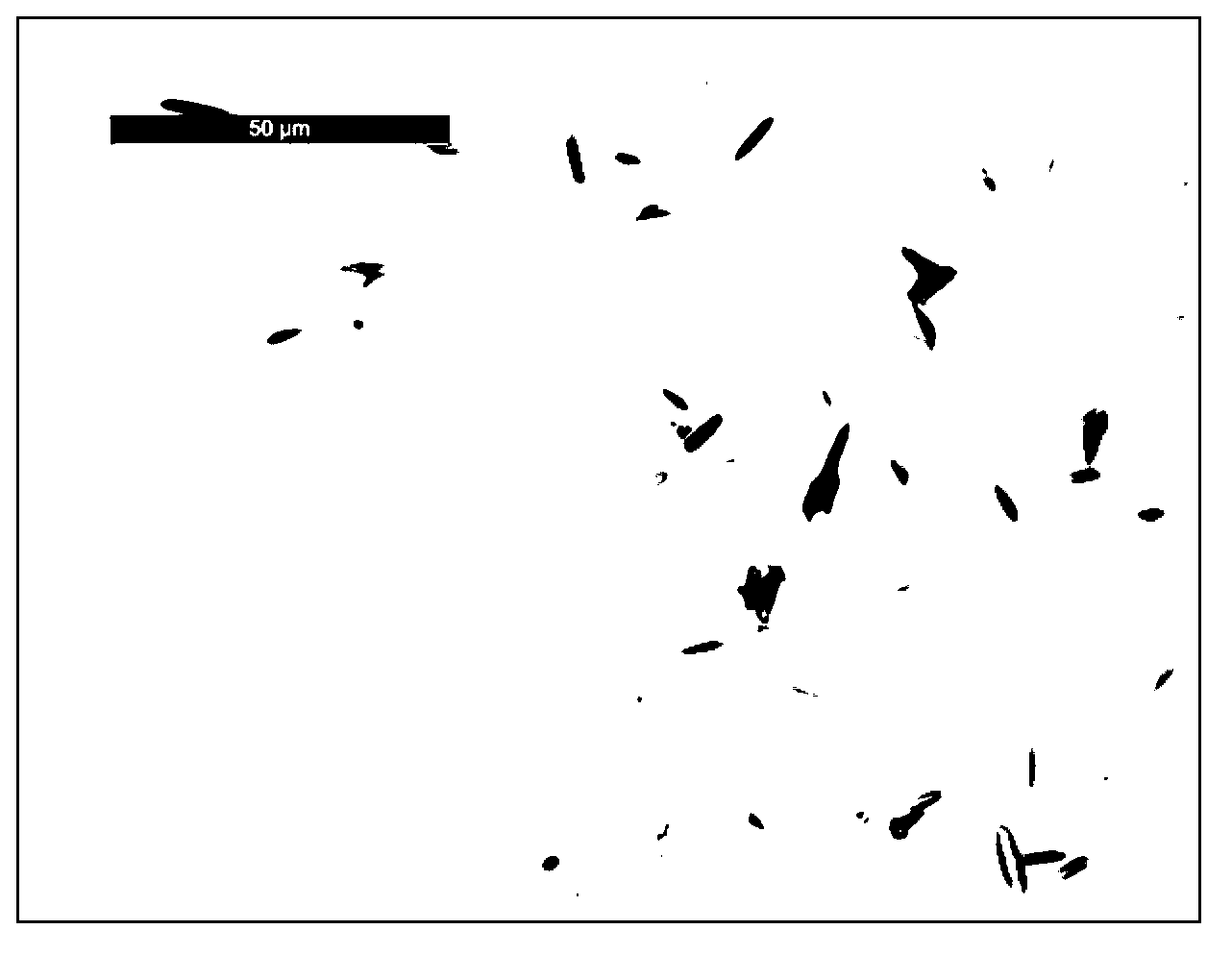

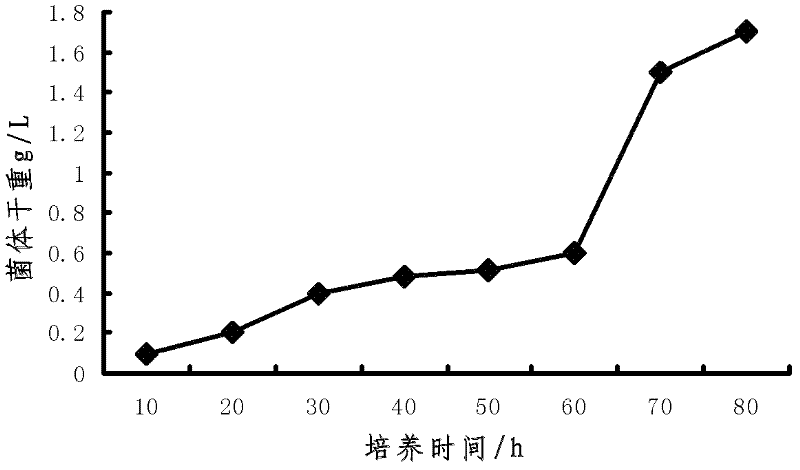

InactiveCN102399694AStrong flocculation abilityImprove settlement performanceFungiBacteriaBiologyCulture mediums

The invention discloses composite microbial inoculum for improving the settling performance of activated sludge, which consists of Aspergillussojae CGMCC3.661, Rhodococcuserythropolis ACCC02579 and Pseudomonasaeruginosa CGMCCNo.1.239. The composite microbial inoculum has the advantages that the flocculating capability is high, no public hazard exists, a good synergistic effect with original microbes of activated sludge can be generated, the settling performance of the activated sludge is improved, the activated sludge expansion is effectively prevented, and the secondary settling pool treatment efficiency is improved. In addition, the culture medium designed in the composite microbial inoculum has low price and meets the industrial high-intensity fermentation requirement of the composite microbial inoculum, the designed fermentation process control condition reaches the high-intensity production requirement of the composite microbial inoculum (the dry weight of thalli in fermentation liquid reaches 30 g.L<-1> or higher after the fermentation is completed), the investment saving of production factors such as equipment and the like is realized, and the basis is laid for the scale production and the application of the composite microbial inoculum.

Owner:JIANGSU SHANGDA WATER AFFAIR

Improved fertilizer for saline and alkaline land and preparation method of improved fertilizer

InactiveCN106187581ALower pHSuitable for plantingSuperphosphatesExcrement fertilisersAlkali soilMicrobial agent

The invention discloses an improved fertilizer for saline and alkaline land and a preparation method of the improved fertilizer. The improved fertilizer for the saline and alkaline land is prepared from the following raw materials in parts by weight: 25-28 parts of maleic anhydride, 15-20 parts of citric acid, 20-30 parts of calcium superphosphate, 10-12 parts of a sodium ion adsorbent, 2-4 parts of a microbial agent, 25-32 parts of fulvic acid, 15-20 parts of a trace element fertilizer, 30-38 parts of a chicken manure fermentation fertilizer, 20-35 parts of peat, 3-5 parts of perlite, 5-8 parts of vermiculite and 20-25 parts of smashed straw particles. The invention further provides the preparation method of the improved fertilizer for the saline and alkaline land. According to the improved fertilizer for the saline and alkaline land, various soil improving measures can be synthesized, effects of reducing salt and alkali for the saline and alkaline land are good, the water content of the soil is high, the water retention property and the fertilizer retention property of the soil are good, besides, the survival rate of planted plants is high, and virtuous cycle of the soil of the saline and alkaline land is realized.

Owner:SHANDONG SUNWAY LANDSCAPE TECH

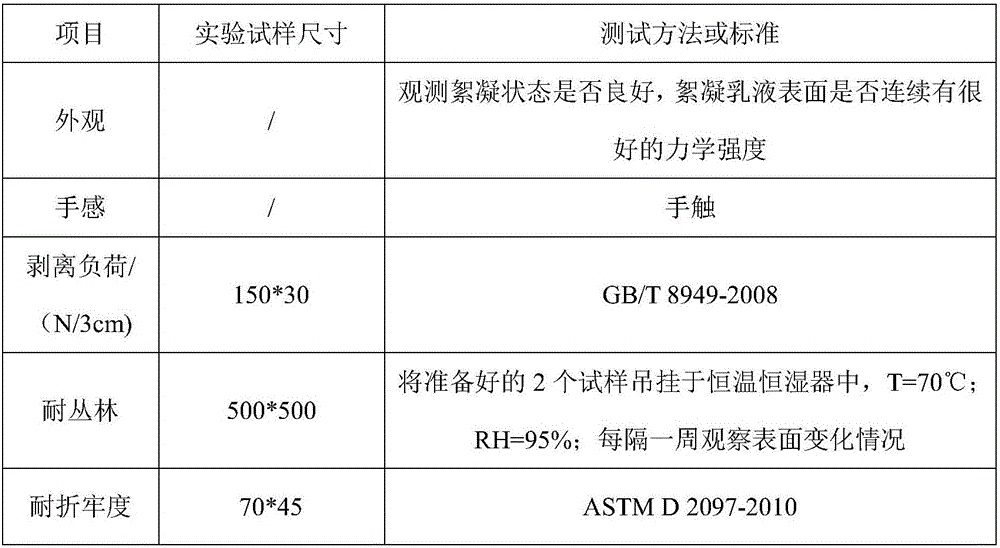

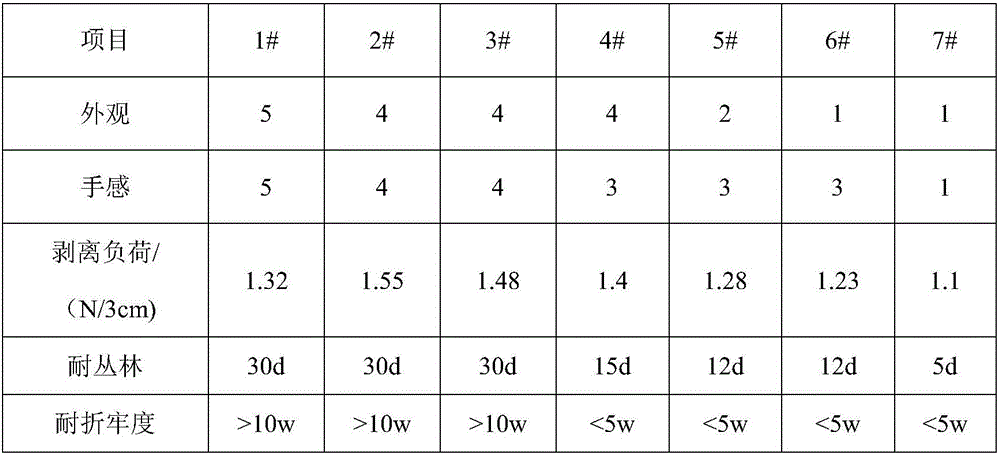

Water-soluble polyurethane dispersoid slurry and method for preparing wet method base thereof

ActiveCN106543406AImprove flocculation abilityPrevent penetrationPolyurea/polyurethane coatingsTextiles and paperEnvironmental resistanceFlocculation

The invention discloses water-soluble polyurethane dispersoid slurry and a method for preparing a wet method base thereof. Water-soluble polyurethane dispersoid in the slurry is negative non-ionic type polyurethane dispersoid prepared by an acetone method; after foaming, the water-soluble polyurethane dispersoid slurry is smeared on a base cloth, and then a flocculation and solidification process is conducted; the flocculation ability of the water-soluble polyurethane dispersoid slurry is good in flocculation liquid; and the water-soluble polyurethane base which is dense in surface and good in handfeel is obtained. The preparation method for the water-soluble wet method base is similar to a preparation method of a solvent type wet method base, except that DMF in the flocculation liquid is replaced with water, and the preparation method is an ecological leather synthetic method. The production process is environmentally friendly and free of pollution, continuous production is achieved, operation is easy, the preparation method is efficient, and meanwhile, the obtained water-soluble wet method base is comparable to the solvent wet method base in leather texture and can replace an oiliness wet method base.

Owner:WANHUA CHEM GRP CO LTD +1

Method for preparing net-shaped cationic polyacrylamide

ActiveCN102532409AStrong adsorption and capture abilityImprove flocculation abilityWater/sewage treatment by flocculation/precipitationSuspended particlesPolymer science

The invention relates to the field of water-soluble polymer auxiliary chemicals, in particular to a method for preparing net-shaped cationic polyacrylamide, wherein raw materials are selected from the followings: 200-270 parts of nonionic monomer, 80-170 parts of cationic monomer, 0.006-0.01 part of structure modifier, 600-700 parts of deionized water, 0.08-0.12 part of initiator in parts by weight. The preparation method comprises the steps of: preparing a mixed solution of the nonionic monomer, the cationic monomer and the deionized water, adding the structure modifier into the solution, introducing nitrogen into the solution to remove oxygen, adjusting the pH value to 4- 5, and adding the initiator into the solution to perform polymerization at the temperature of 2-5 DEG C; after the reaction, granulating the polymer, drying the colloidal particles at the temperature of 70-80 DEG C and finally crushing to obtain a product with a net-shaped structure. The product is stronger in the absorption and capture capabilities for colloid and suspended particles in the water, better flocculation effect can be achieved with fewer amount of the product, in addition, flocculation blocks are firm, the shear resistance performance is stronger, and the influence of large shearing force of a centrifugal machine on the flocculation effect is smaller.

Owner:东营市诺尔化工有限责任公司 +1

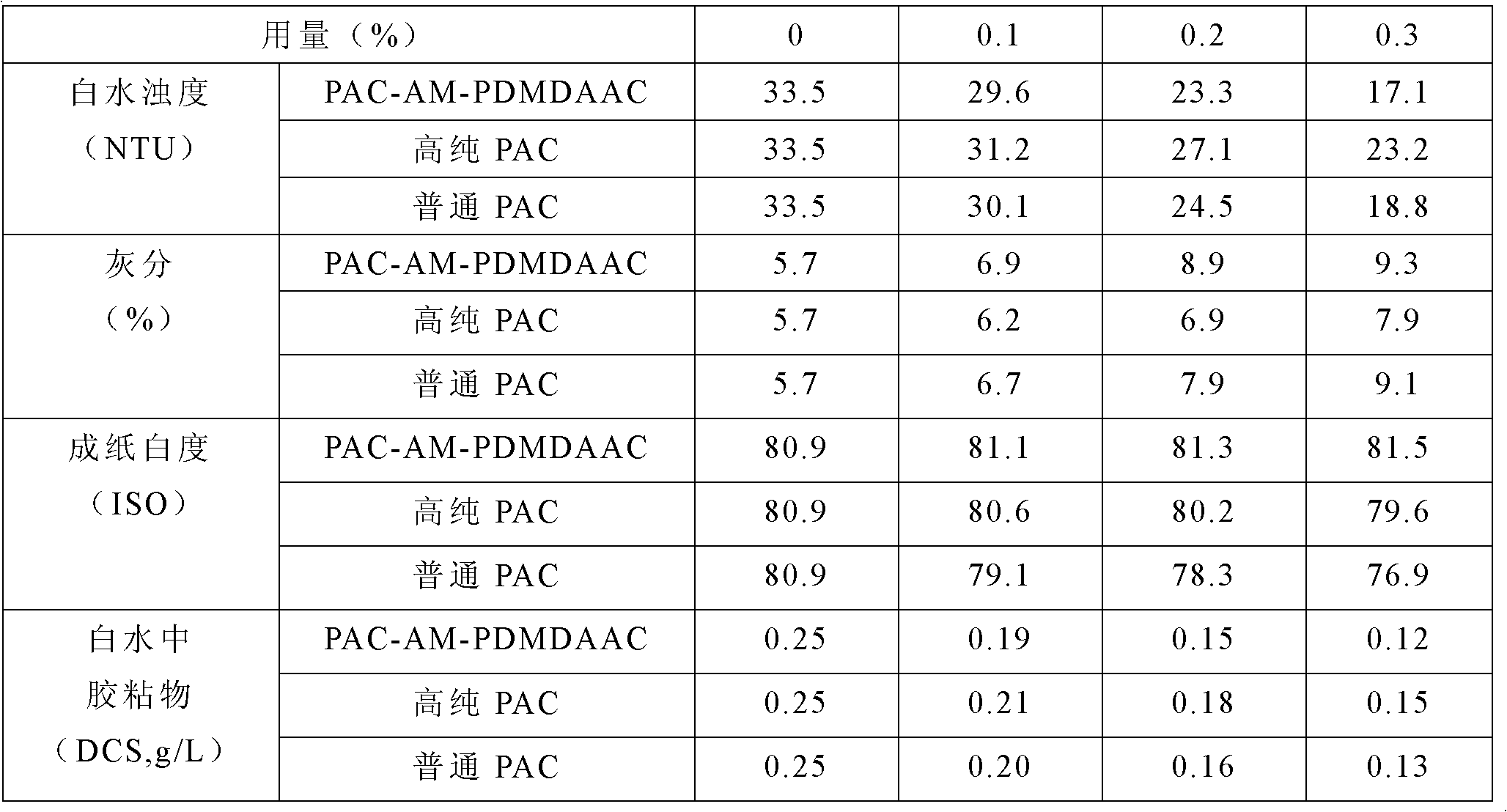

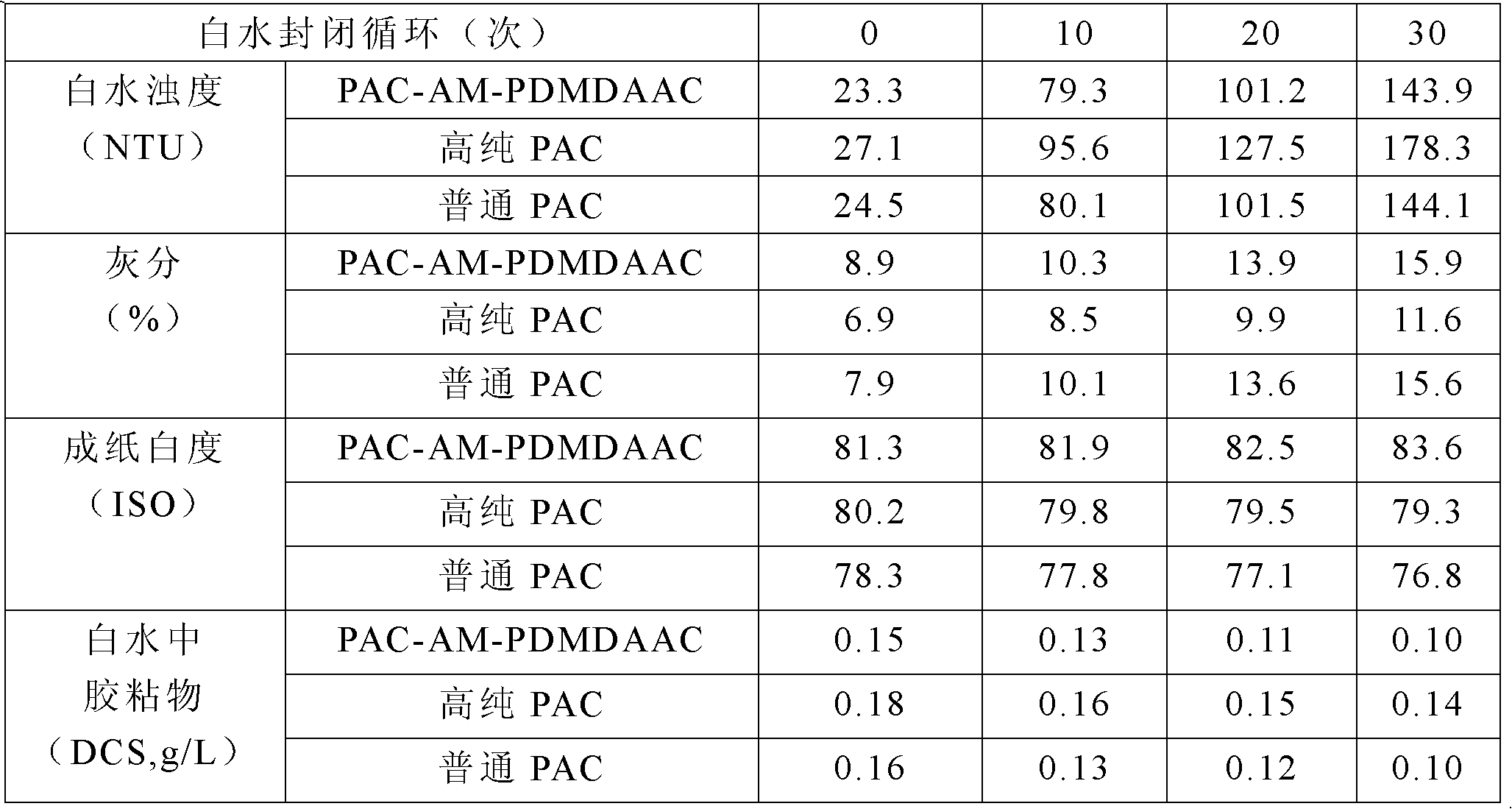

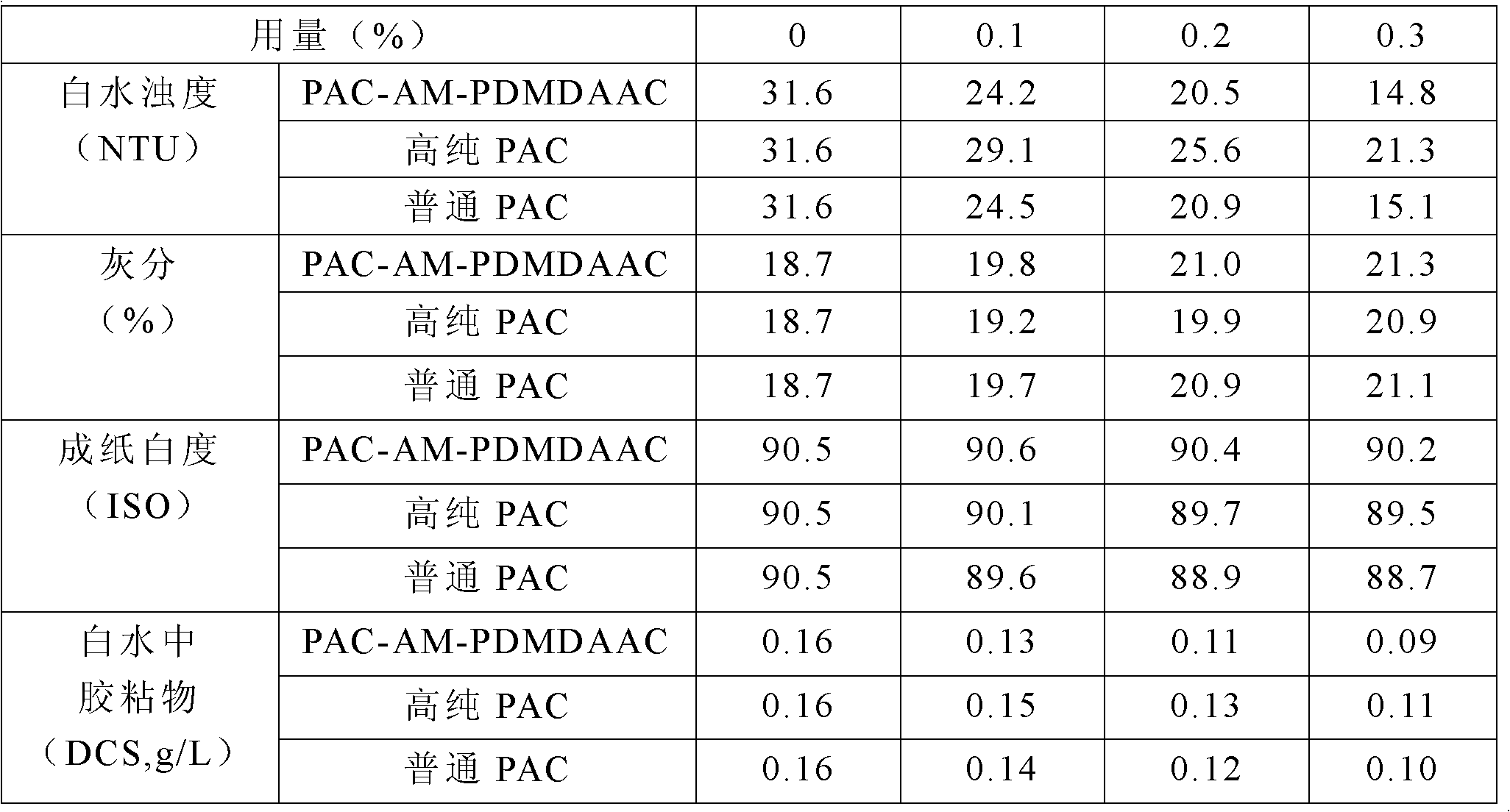

Powdery high-whiteness polyaluminium chloride complex and preparation method thereof

InactiveCN101885528AImprove flocculation abilityConvenient amountWater/sewage treatment by flocculation/precipitationFiberWater insoluble

The invention discloses a powdery high-whiteness polyaluminium chloride complex and a preparation method thereof. The mass content of alumina is 28 to 30 percent, the mass content of acrylic amide-dimethyldiallylammoniumchloride copolymer is 1 to 5 percent, the alkalinity is 55 to 85 percent, the whiteness is 80 to 90 percent, the mass content of water-insoluble substance is 0.5 to 1.5 percent, and the mass content of iron ions is less than 0.01 percent. When the complex is used for papermaking white water treatment, the complex controls fin fiber, filler and gooey and the like in the papermaking white water with small using amount and low using cost; when the complex is used for treating the papermaking white water, the sediment floccule is recycled for papermaking and the adding amount of the sediment floccule in papermaking reaches 5 percent, the whiteness of the formed paper is still not reduced; when the complex is added into the papermaking pulp, the complex has strong charge neutralization capability for pulp fiber, and can obviously improve the retention rate of the fiber and the inorganic filler and reduce the turbidity of the papermaking white water; when the using amount of the complex reaches 3 percent, the whiteness of the formed paper is still not reduced; and when newspaper is manufactured by de-inking, bleaching and pulping waste paper and the white water is recycled, the complex can improve the whiteness of the formed paper.

Owner:广东名桂环保有限公司

Polyacrylamide composite modified macromolecule poly silicon iron flocculant and preparing method thereof

InactiveCN103073099AGood storage stabilityGood COD removal rate and turbidity removal rateWater/sewage treatment by flocculation/precipitationIron(III) sulfateSilicon iron

The invention discloses a polyacrylamide composite modified macromolecule poly silicon iron flocculant, which comprises polysilicon ferric sulfate and non-ionic polyacrylamide. The mass ratio between the polysilicon ferric sulfate and the non-ionic polyacrylamide is 21-2120:1. The method for preparing the flocculant comprises the following steps: (i) dissolving sodium silicate in distilled water and blending to obtain sodium silicate solution, and adjusting the pH value of the sodium silicate solution so as to obtain polysilicic acid solution; (ii) dissolving ferric sulfate in distilled water and blending to obtain ferric sulfate solution, mixing the ferric sulfate solution and the polysilicic acid solution, adding alkaline liquor and aging to obtain polyferric silicate sulfate; and (iii) mixing the polyferric silicate sulfate and nonionic polyacrylamide according to the mass ratio, stirring and aging. The flocculant provided by the invention is not only good in storage stability but also high in flocculating activity and high in COD removal rate when being used for pharmacy waste water treatment, and can be widely used for the treatment of waste water produced by large-scale pharmaceutical enterprises.

Owner:HEBEI UNIVERSITY

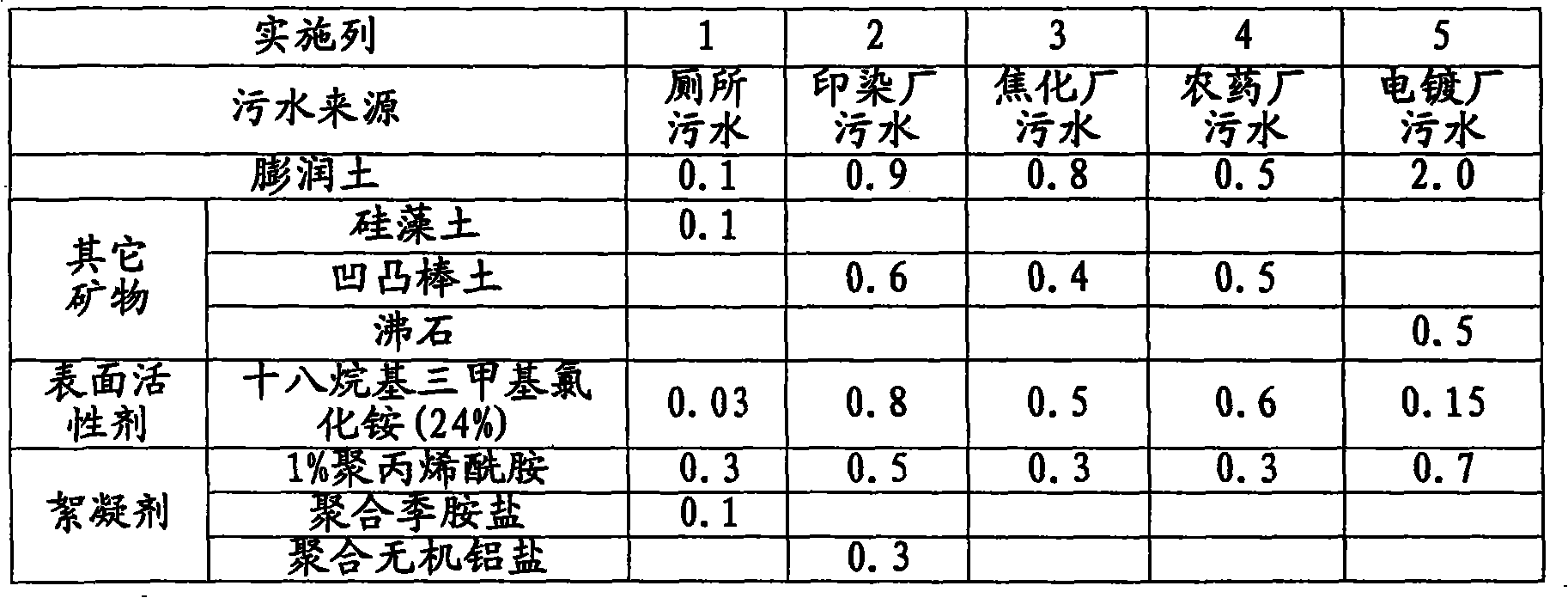

Mineral complex sewage treating method

ActiveCN101254994ALow costImprove adsorption capacityMultistage water/sewage treatmentWater/sewage treatment by flocculation/precipitationSodium BentoniteSludge

The invention relates to a mineral composite sewage treatment method. calcium based, sodium based or acidic bentonite is crushed into 101 to 600 mesh, other minerals are crushed into 60 to 600 mesh, the bentonite and other kinds of minerals form a mineral composite, the mineral composite is poured into sewage to be treated, and is blended, then 24% octadecyl trimethyl ammonium chloride is poured into the sewage and stirred, then a flocculating agent is poured into the sewage and stirred for subsiding, and then soil and water separation and micro-organism treatment are performed , and satisfying drainage standard can be reached; the weight ratio of the sewage and the added mineral composite is (1000:0.2)-(1000:2.5), the ratio of the dosage of the bentonite and the dosage of any another mineral is (1:1)-( 4:1), the dosage ratio of the mineral composite and the octadecyl trimethyl ammonium chloride is (2:1)-(17:1), and the dosage ratio of the mineral composite and the flocculating agent is (0.5:1)-(4:1). The method can be used for the treatment of toilets, printing and dyeing, coking, agricultural chemicals and galvanization sewage, and has the advantages of low treatment cost, wide application range and smaller sludge deposit, and has no influence on the subsequent microorganism treatment.

Owner:浙江华特新材料有限公司

Method for treating degradation-resistant organic pollutants in waste water

InactiveCN103420530AGood dispersionExpand the radiation rangeWater/sewage treatment with mechanical oscillationsWater contaminantsIron nanoparticlePersistent organic pollutant

The invention provides a method for treating degradation-resistant organic pollutants in waste water and overcomes the defect that iron nanoparticles are prone to agglomeration when the iron nanoparticles are subjected to waste water treatment in the prior art. In order to solve the technical problem, the technical scheme includes that the method includes the following steps: under the pneumatic ultrasonic action, adjusting pH to be 1-5, adding ferrous ion salt, casting the iron nanoparticles in, adding hydrogen peroxide, performing solid-liquid separation after the pneumatic ultrasonic action, and discharging the waste water after the waste water reaches the standard. Comparing a pneumatic ultrasonic field with a common electric ultrasonic field, dispersion and radiation range can be widened, and the iron nanoparticles can be dispersed in the waste water more easily; air serves as a medium generating the pneumatic ultrasonic field, functions of an oxidizing agent (O2), stirring and cutting are provided for a waste water treating system, but only an air compressor generating the pneumatic ultrasonic field is energy-consuming equipment, so that energy-saving effect is achieved.

Owner:CHANGSHU CITY YUHENG KNITTING

Industrial wastewater purifying agent

ActiveCN105565452AImprove flocculation abilityGood biocidal effectSpecific water treatment objectivesWater contaminantsSilicon dioxidePolyacrylamide

The invention discloses an industrial wastewater purifying agent which is prepared from the following components in parts by weight: 5-12 parts of polyaluminum chloride, 3-7 parts of polyferric sulfate, 2-5 parts of magnesium chloride, 6-9 parts of polyacrylamide, 4-8 parts of sodium hypochlorite, 8-15 parts of calcium oxide, 4-6 parts of sulfur, 11-15 parts of silicon dioxide, 13-18 parts of surfactant, 7-10 parts of biological degerming agent and 80-90 parts of anhydrous ethanol. The wastewater purifying agent has the advantages of high flocculation effect, high removal rate for suspended substances and heavy metals and favorable biological sterilizing effect, lowers the hazard of secondary pollution, and is more environment-friendly.

Owner:佛山市顺德区绿点废水回收处理有限公司

Pulp

InactiveCN103485233ANo reduction in mechanical strengthNot easy to turn yellowNon-fibrous pulp additionPaper/cardboardEpoxyFiber

The invention discloses a pulp. The pulp comprises the following raw material components at weight ratio: 50-60 straw pulp, 10-20 raphioid hardwood fiber, 1-10 silkworm cocoon, 2-8 debregeasia edulis, 3-8 agar, 1-2 adhesive, 1-2 flexibilizer, 1-2 waterproof agent and 1-2 adjuvant. The pulp enables the paper whitenness to meet the requirement of paper without lowering the mechanical strength of paper, and ensures low yellowing probability and stable quality of paper. A Sirain high-side-chain-density paper-making retention and filtration aid, which has higher flocculation capability than linear molecules and particularly extremely strong retention capability to fiber fines, is adopted. The high-strength positive charge density also helps to retain more fillers. The common raw materials, such as straw pulp, silkworm cocoon, raphioid hardwood fiber, debregeasia edulis and the like, are adopted, epoxy resin and other flexibilizers are added to increase the tenacity, and agar is added to increase the smoothness of paper, so that an embroidery picture book prepared from the pulp has a certain glossiness and nice color.

Owner:句容市植保植检站

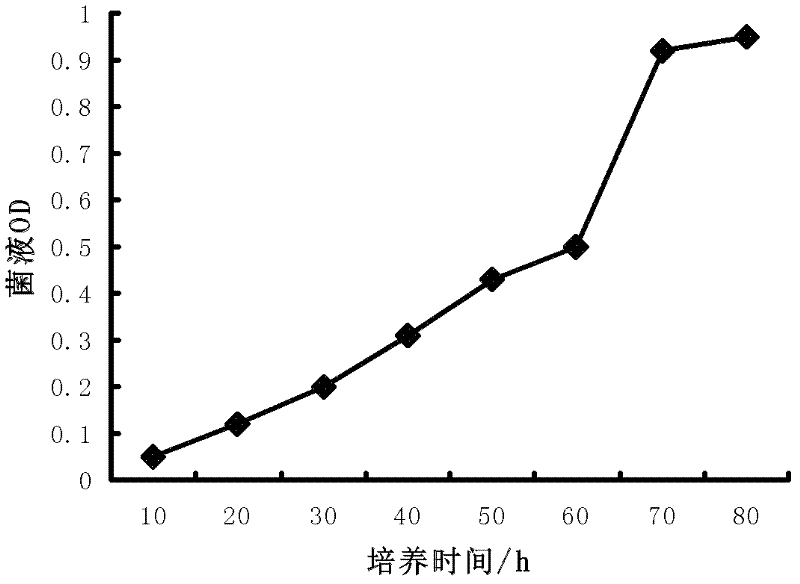

Halomonas taeanensis and method for preparing flocculants by same

ActiveCN107641610AImprove flocculation abilityAccelerated settlementBacteriaMicroorganism based processesShort-necked clamSludge

The invention relates to the technical field of water treatment, in particular to Halomonas taeanensis and a method for preparing flocculants by the same. Bacterial strain Halomonas sp.GHF11 of the Halomonas taeanensis is separated and purified from sludge spitted by short-necked clams, cultures of the bacterial strain are subjected to amplification culture to obtain culture liquid, the culture liquid is subjected to fermenting culture to secrete exopolysaccharides, flocculation carriers are added into fermentation bacteria solutions in later period of fermentation to provide adhesion places for thalli, the thalli are adhered to cluster and settle, and the exopolysaccharides completely settle under the further action of ethyl alcohol. The exopolysaccharides secreted by the bacterial strainHalomonas sp.GHF11 has high flocculation effect; the carriers are added during preparation of the flocculants, exopolysaccharide sedimentation is accelerated, and consumption of the ethyl alcohol isreduced; the obtained flocculants have high flocculation capability and stable performance.

Owner:ZHEJIANG OCEAN UNIV

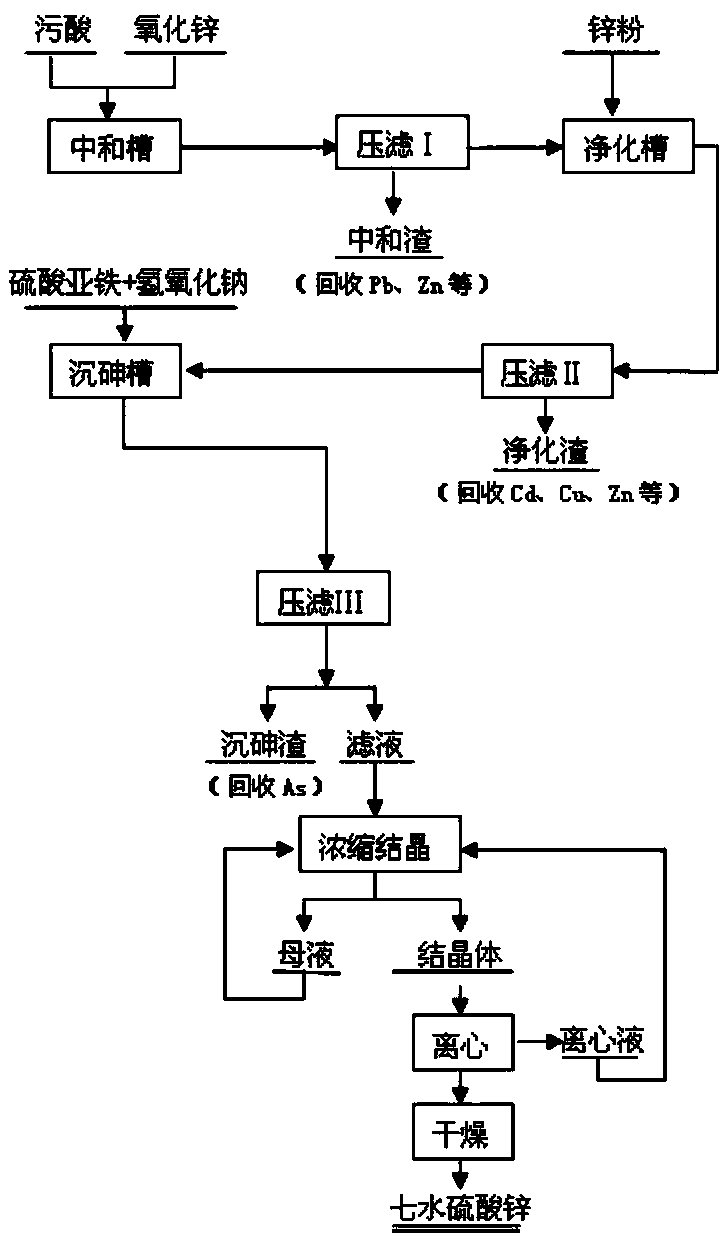

Green utilization method of waste acid

ActiveCN103588240ALow costImprove adsorption capacityZinc sulatesChemical industryZINC SULFATE HEPTAHYDRATE

The invention discloses a green utilization method of a waste acid, and belongs to the fields of the metallurgy and the chemical industry. The method comprises the following steps: adding zinc oxide powder to neutralize sulfuric acid in the waste acid and generate zinc sulfate; adding zinc powder to replace heavy metal ions comprising lead ions, cadmium ions, copper ions and the like in the waste acid to enrich most heavy metals in the waste acid; adding ferrous sulfate to precipitate arsenic, and utilizing the strong adsorption and flocculation capability characteristics of hydroxide of iron to further remove a small amount of harmful heavy metal ions comprising lead ions, cadmium ions, copper ions and the like residual in the waste acid; and carrying out concentrating crystallization, centrifugation and drying of an arsenic-precipitated filtrate to obtain zinc sulfate heptahydrate. The method has the advantages of short process flow, reduction of the waste acid treatment cost of traditional methods, economic benefit and good application prospect.

Owner:CHENZHOU CITY JINGUI SILVER IND CO LTD

Forsterite bio-filter material for sewage treatment and preparation method of forsterite bio-filter material

InactiveCN104071891AStrong oxidation abilityImprove flocculation abilitySustainable biological treatmentBiological water/sewage treatmentBiofilmPolystyrene

The invention particularly relates to a forsterite bio-filter material for sewage treatment and a preparation method of the forsterite bio-filter material. The technical scheme is as follows: the preparation method comprises the following step: uniformly mixing 45-55wt% of forsterite raw ore fine powder, 20-30wt% of talc fine powder, 15-25wt% of magnesium oxide fine powder and 2-6wt% of dravite micropowder as raw materials with additional 2-6wt% of starch to prepare a mixed material; then, putting the mixed material and polystyrene balls in a pelletizer in a volume ratio of the polystyrene balls and the mixed material of (1.5-2.0) to 1; then, adding 10-20wt% of water to prepare particles with the grain size being 5-13mm; and then, roasting the prepared particles for 16-24 hours at 110-150 DEG C, and sintering for 2-4 hours at 1300-1500 DEG C to prepare the forsterite bio-filter material for sewage treatment. The forsterite bio-filter material for sewage treatment is simple in process and wide in source of raw materials and the prepared forsterite bio-filter material for sewage treatment has the characteristics of good flora biofilm culturing effect, high flora survival rate, good decoloring effect and high strength.

Owner:XIXIA HONGTAI FORSTERITE +1

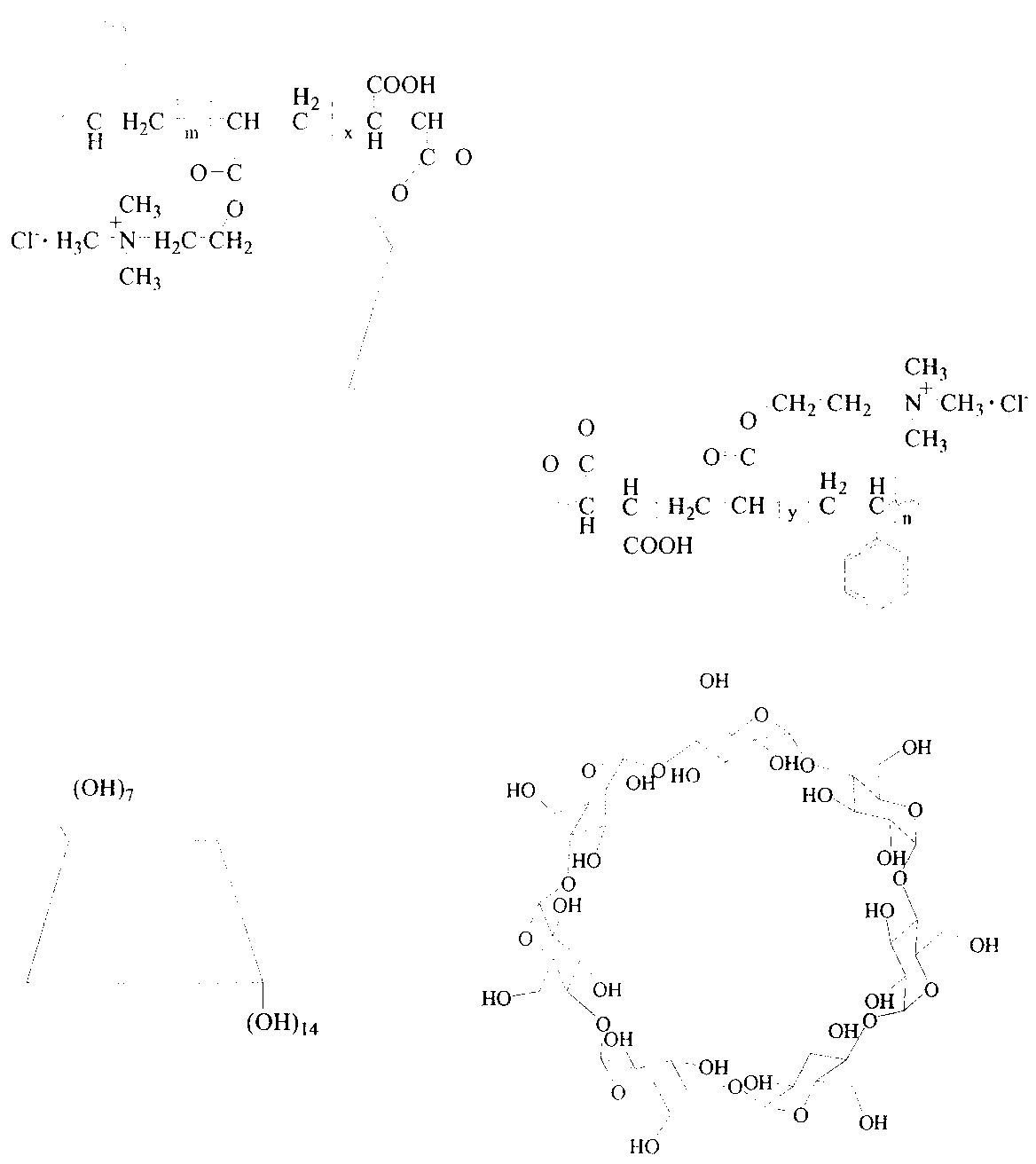

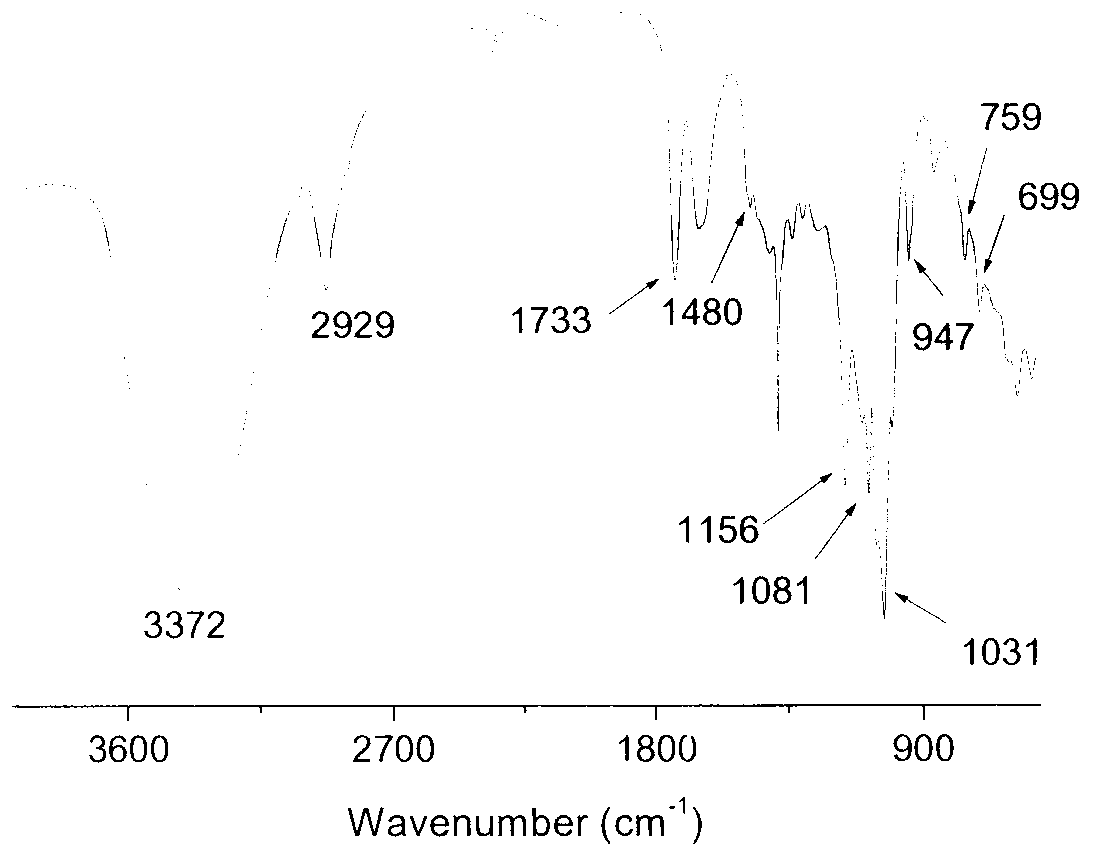

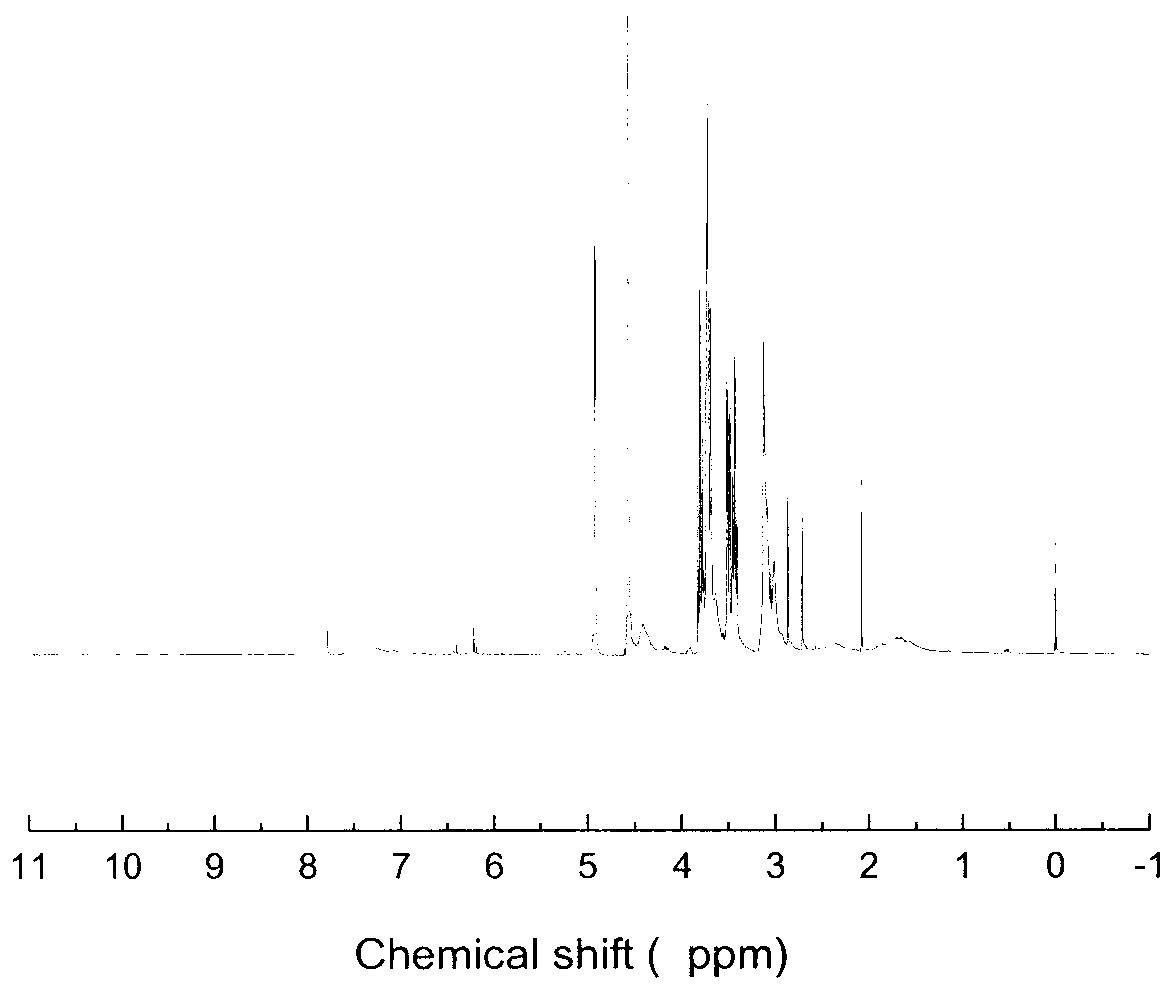

Preparation method and application of hydrophobization beta-cyclodextrin cation polyelectrolyte

InactiveCN103289026AStable structureSimple structureWater/sewage treatment by flocculation/precipitationSolubilityCationic polyelectrolytes

The invention discloses a preparation method and an application of hydrophobization beta-cyclodextrin cation polyelectrolyte. In a water phase, three monomers, namely polymerizable beta-cyclodextrin derivatives, acryloyl oxyethyl trimethyl ammonium chloride and styrene, are subjected to a free radical copolymerization reaction under an oxidation / reduction (potassium peroxodisulfate / sodium hydrogen sulphite) initiating system to obtain the hydrophobization beta-cyclodextrin cation polyelectrolyte product. The hydrophobization beta-cyclodextrin cation polyelectrolyte product is white powder solids and is stable in structure and convenient to store and transport, hydrophilcity is reduced and better solubility is still maintained; the preparation method of the hydrophobization beta-cyclodextrin cation polyelectrolyte product is simple, and low in energy consumption; no other auxiliaries such as a surface active agent is added in an aqueous solution polymerization process, and environmental pollution is less; and the hydrophobization beta-cyclodextrin cation polyelectrolyte product can serve as a novel flocculating agent for decoloration, the specific structure of beta-cyclodextrin (beta-CD) is reserved, toxicity and cost are low, flocculation capacity is strong, decoloration speed is high, an applicable pH range is wider (2-12), and salt tolerance is high.

Owner:JIANGNAN UNIV

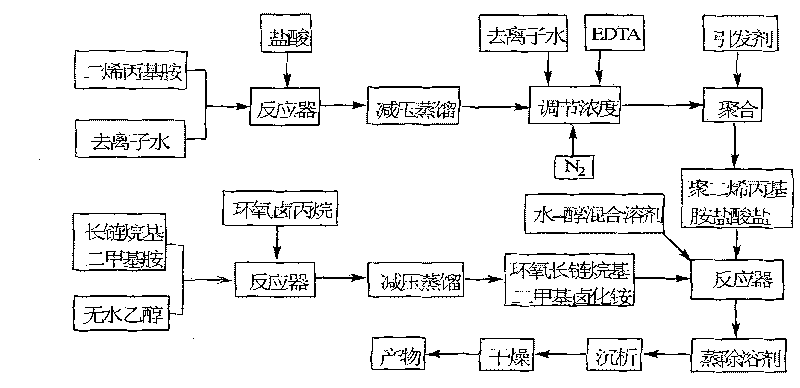

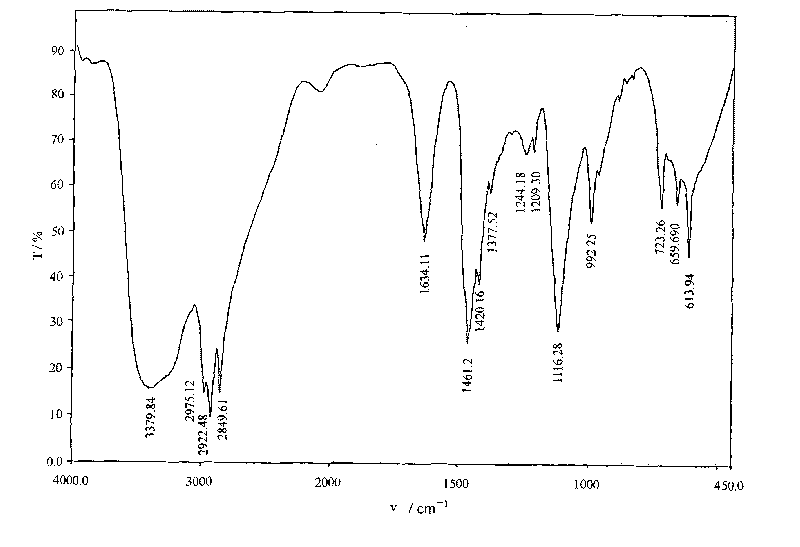

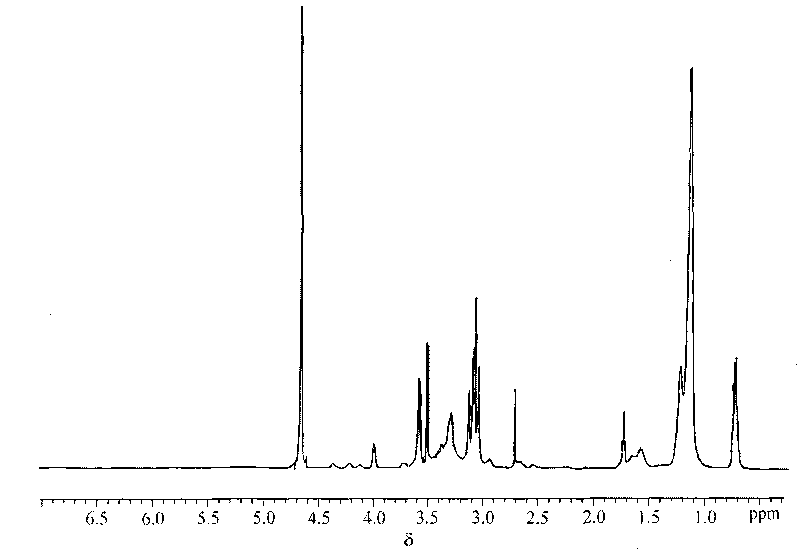

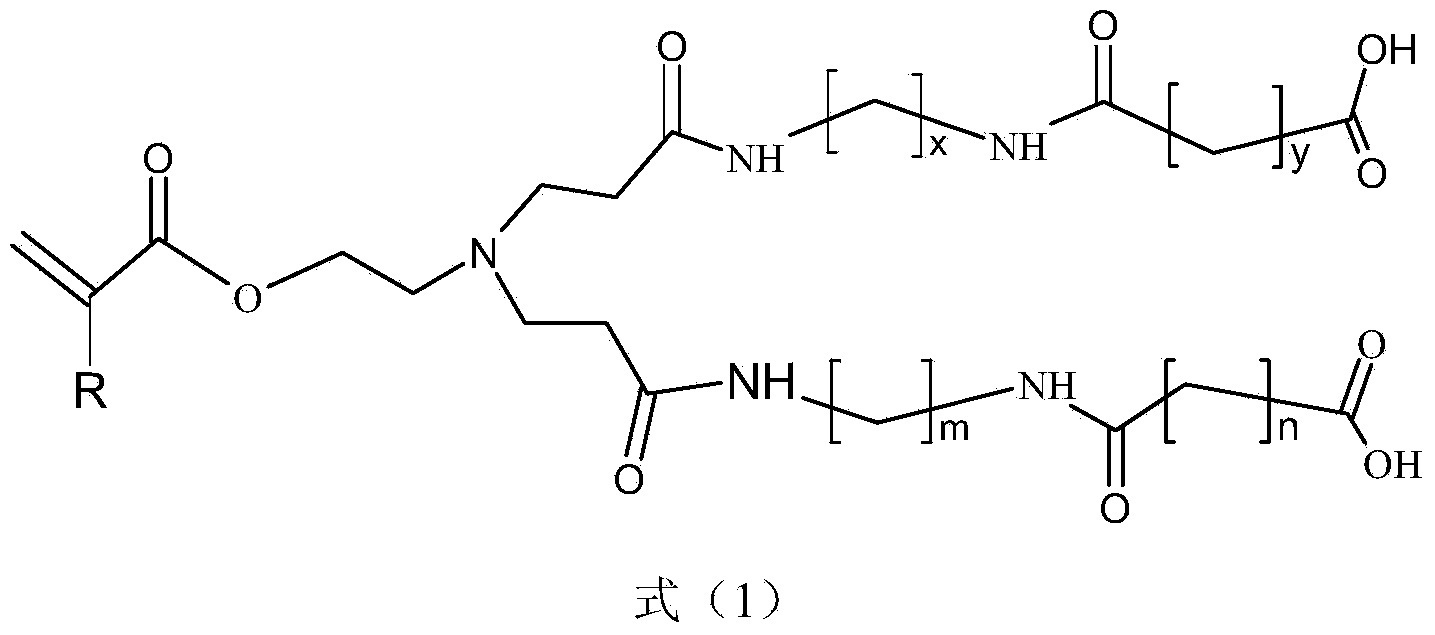

Flocculation-sterilization double-effect macromolecule and preparation method thereof

InactiveCN101747460AHigh charge densityStrong electrical neutralization abilityWater/sewage treatment using germicide/oligodynamic-processWater/sewage treatment by flocculation/precipitationSolventAllylamine

The invention relates to a flocculation-sterilization double-effect macromolecule and a preparation method thereof. Diallyl amine and hydrochloric acid are adopted as raw materials to firstly synthesize diallyl amine hydrochloride, the diallyl amine hydrochloride is polymerized to poly-diallyl amine hydrochloride under the effect of a free radical initiator, and the poly-diallyl amine hydrochloride is reacted with epoxy long chain alkyl dimethyl ammonium halides which is obtained by Long-chain alkyl dimethyl amine and epoxy propane halogen in absolute ethyl alcohol in a water-alcohol mixed solvent to prepare the flocculation-sterilization double-effect macromolecule. The flocculation-sterilization double-effect macromolecule overcomes the weaknesses that the conventional flocculant does not have the sterilization function, the bactericide is lack of flocculation capacity, the flocculation and the sterilization are always separated in the application, the residual flocculant is reacted with the oxidization bactericide in the sterilization procedure to a harmful substance, and the bacteria dirty after the sterilization cannot be eliminated through the flocculation. The product of the invention can realize the flocculation and the sterilization functions at the flocculation procedure, so the traditional water treatment process can be simplified, and the cost can be reduced. The flocculation-sterilization double-effect macromolecule is suitable for being used as a processing agent for original water, waste water and drinking water.

Owner:HUNAN UNIV OF SCI & TECH

Industrial wastewater treating agent

InactiveCN103663579AImprove adsorption capacityImprove flocculation abilityWater/sewage treatment by flocculation/precipitationWater/sewage treatment by sorptionSodium BentoniteSludge

The invention relates to an industrial wastewater treating agent, and belongs to the field of sewage treatment. The industrial wastewater treating agent comprises raw materials of flue ash, bentonite, corn starch, citric acid, sodium chloride, saccharide and activated carbon. According to the industrial wastewater treating agent, the flue ash and the bentonite are taken as main raw materials for sewage treatment, so that the sewage treatment cost is reduced; the absorption and flocculation capacity of the bentonite is high, the sedimentation time is shorter, and less sludge exists, so that the effect and the efficiency of sewage treatment are further improved; and corn starch, saccharide and activated carbon are added, so that the absorption and flocculation capacity is further improved, and no chemical agent is left in treated water.

Owner:栾晓健

Purificant for purifying oily sewage

InactiveCN101538082ABreak interface energyFloating fastWater/sewage treatment by flocculation/precipitationEmulsionChemistry

The invention relates to a water purification agent, in particular to an oily sewage purificant used for treating oily sewage in oil fields, which consists of the following components according to weight percentage: 30 to 40 percent of aluminum chloride hexahydrate, 10 to 25 percent of epoxypropyl polyquaternary amine and 35 to 50 percent of poly(diallyldimethylammonium chloride. The oily sewage purificant is mainly used for the emulsion breaking and oil removing of oily sewage emulsion liquid or other 0 / W sewage, has enough strong electrophilicity to neutralize negative charge formed by an emulsifier, has enough strong flocculation capability to flocculate particles in the emulsion liquid for facilitating the formation of large vanadium flowers, and has enough strong surface activity to break the interfacial energy of the emulsion liquid. The purificant is characterized by high deoiling rate, limpid water of dehydration, quick floating upwards of oil clots and even oil-water boundary. In addition, the purificant has the advantages of low dosage, low cost and broad application prospect.

Owner:唐山市金沙工贸有限公司

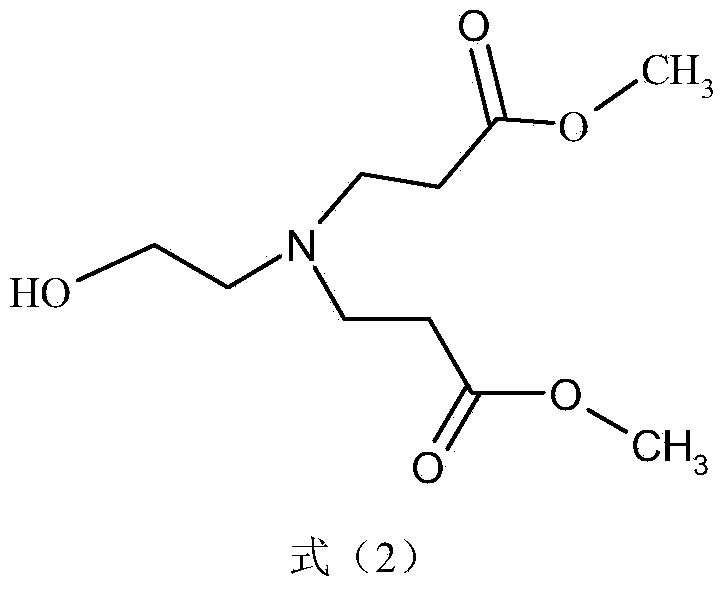

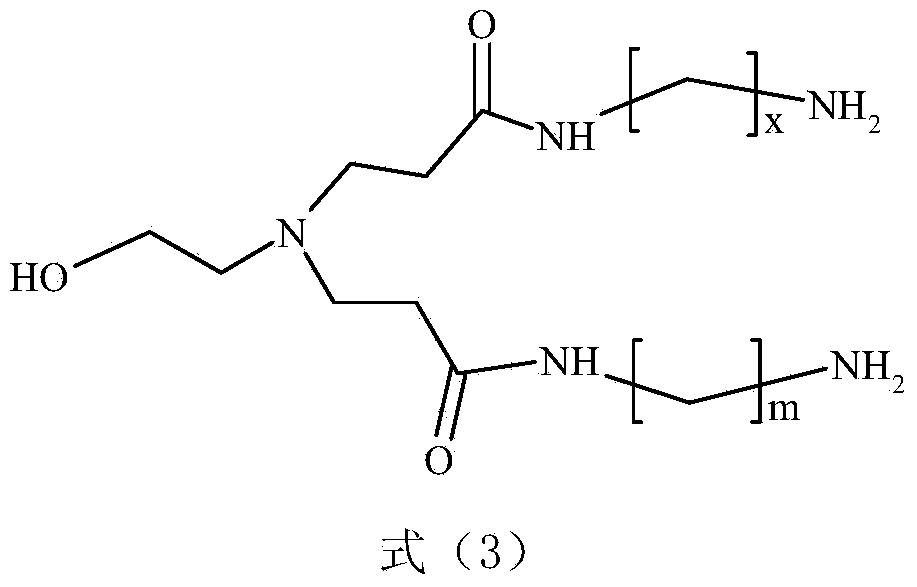

Alkenyl-branched monomers and preparation method thereof

ActiveCN104311449AIncrease viscosityGood viscosity increaseOrganic compound preparationCarboxylic acid amides preparationOrganic synthesisPolyamide

The invention discloses alkenyl-branched monomers and a preparation method thereof, and belongs to the field of organic synthetic chemistry. The monomers are prepared by the steps of reacting a hydroxyethyl-containing branched polyamide intermediate and acryloyl chloride at a room temperature in presence of an organic solvent and an acid-trapping agent; standing; separating an organic phase; washing for a plurality of times by neutralizing with a saturated sodium bicarbonate solution; drying by using anhydrous sodium sulfate; steaming the organic solvent out to obtain a crude product; and further purifying the crude product to obtain a polymer grade product. The monomers can be used as co-polymerization monomers to prepare hyperbranched polymers used for oilfields and to prepare branched water-soluble polymers for other applications and emulsifiers for emulsion polymerization.

Owner:CHINA PETROCHEMICAL CORP +1

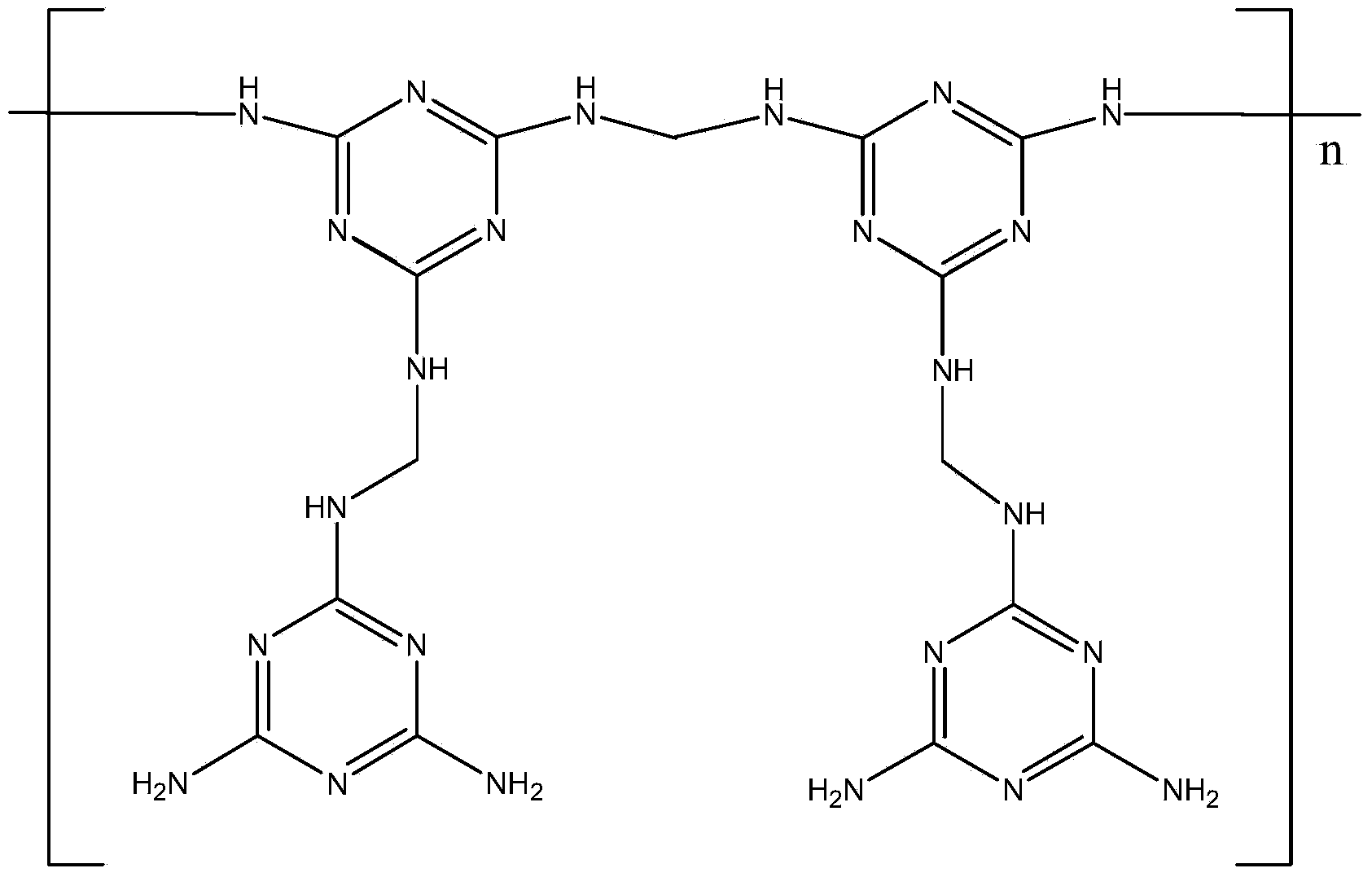

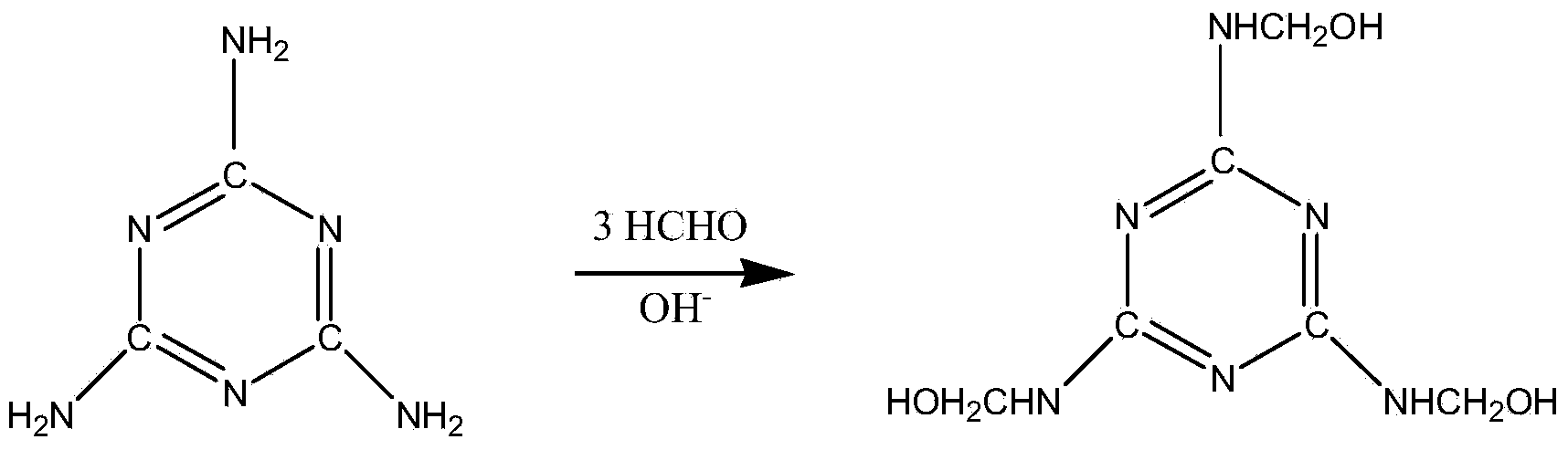

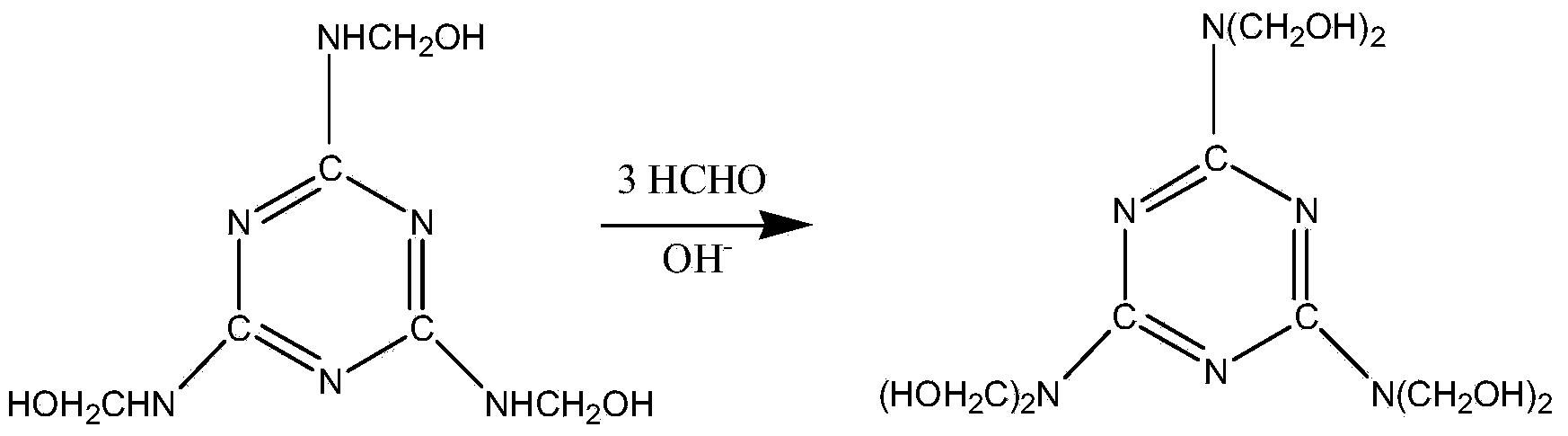

Cationic polymer as well as preparation method and application thereof

ActiveCN103450430AHigh cationic degreeHigh molecular weightFatty/oily/floating substances removal devicesLiquid separationTextile fiberDemulsifier

The invention discloses a cationic polymer as well as a preparation method and application thereof. The cationic polymer is prepared by the following five process steps in sequence: metering and mixing, hydroxymethylation reaction, polycondensation, inhibition reaction and free formaldehyde elimination. The cationic polymer has the advantages of high cationic degree, high molecular weight, long storage life and low formaldehyde content, and can serve as a flocculating agent, a reverse-phase demulsifier, a water reducing agent for concrete or a treating agent of textile fibers.

Owner:GUANGZHOU ZHENQING ENVIRONMENTAL PROTECTION TECH

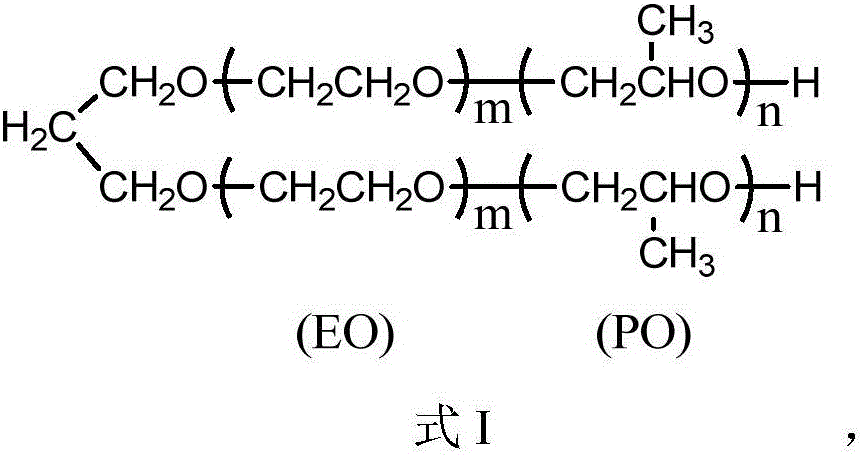

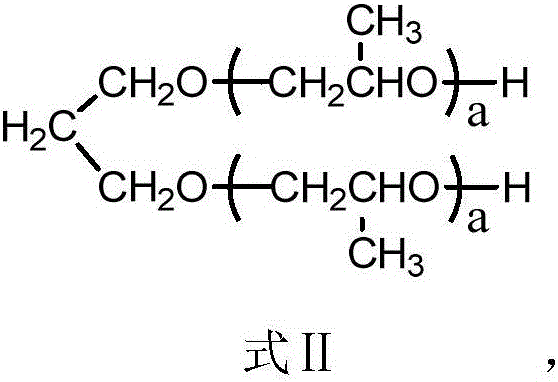

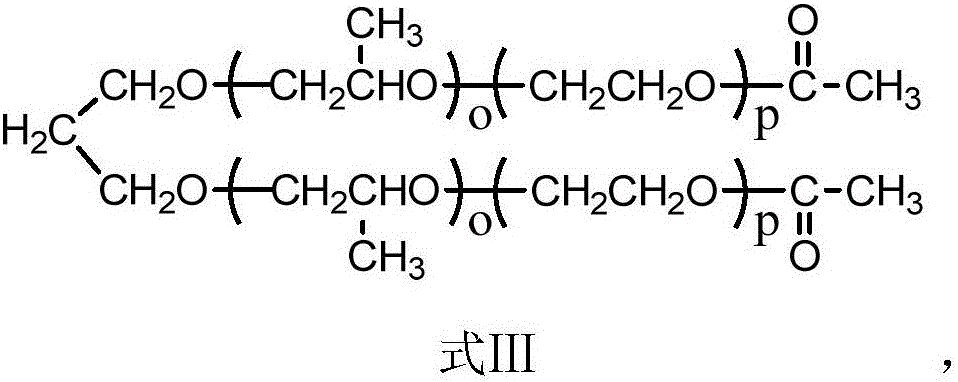

Demulsification water purifying agent for combination-flooding produced fluid and preparation method for demulsification water purifying agent

ActiveCN106044940AAchieve the effect of one dose and two usesImprove surface propertiesWaste water treatment from quariesFatty/oily/floating substances removal devicesPolyethylene oxidePetroleum

The invention discloses a demulsification water purifying agent for combination-flooding produced fluid and a preparation method for the demulsification water purifying agent and belongs to the technical field of petroleum extraction. The demulsification water purifying agent is prepared from the following ingredients in percentage by mass: 45% to 50% of polyether block copolymer, 30% to 40% of polyether polyol and 10% to 20% of esterification-terminated polyether surfactant, wherein the polyether block copolymer is multiblock polyether of polyoxyethylene and polyoxypropylene which takes propylene glycol as an initiator, the polyether polyol is polyethylene oxide ether which takes propylene glycol as an initiator, and the esterification-terminated polyether surfactant is diblock esterification-terminated polyether of polyoxyethylene and polyoxypropylene which takes propylene glycol as an initiator. The demulsification water purifying agent has the actions of demulsification, agglomeration-flocculation, adsorption-displacement and the like. By adding the demulsification water purifying agent into the combination-flooding produced fluid, other flocculation water purifying agents are not required to be added during the treatment of dehydrated sewage, and thus the effect of achieving two purposes by one agent can be achieved.

Owner:CHINA PETROLEUM & CHEM CORP +1

Organic macromolecular flocculating agent for polymer-bearing sewage and preparation method for organic macromolecular flocculating agent

ActiveCN105060446AImprove flocculation abilityEfficient removalWater/sewage treatment by flocculation/precipitationSide effectPoly(diallyldimethylammonium chloride)

The invention discloses an organic macromolecular flocculating agent for polymer-bearing sewage and a preparation method for the organic macromolecular flocculating agent. Before a mixing reaction, the organic macromolecular flocculating agent comprises the following components in percentage by mass: 30-40 percent of polymeric aluminum, wherein the mass of non-ion polyacrylamide is 5 percent of the mass of polymeric aluminum; the mass ratio of poly diallyldimethylammonium chloride to the polymeric aluminum is 1-2: 2-3. After a polymerization reaction, the weak cation type organic macromolecular flocculating agent can be obtained; an extremely good flocculating effect is achieved, and organic impurities and emulsified oil in polymer-bearing crude oil wastewater can be effectively removed; furthermore, a small quantity of produced floccules are produced, and the form is stable; the organic macromolecular flocculating agent is prepared by a compounding method and has the advantages of simple technology, readily available raw material, good water purification effect, low cost, small use amount and the like, and has no toxic and side effects.

Owner:E TECH ENERGY TECH DEV CORP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com