Organic macromolecular flocculating agent for polymer-bearing sewage and preparation method for organic macromolecular flocculating agent

An organic polymer, sewage treatment technology, applied in the direction of flocculation/sedimentation water/sewage treatment, etc., can solve the problems of subsequent process and adverse environmental impact, large on-site environmental impact, large amount of sludge, etc., to achieve high-efficiency water purification effect and cost. Inexpensive, less flocculent effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

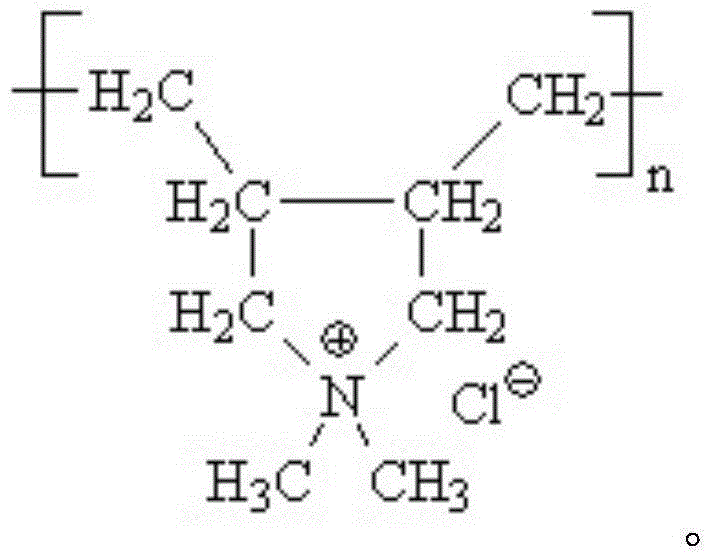

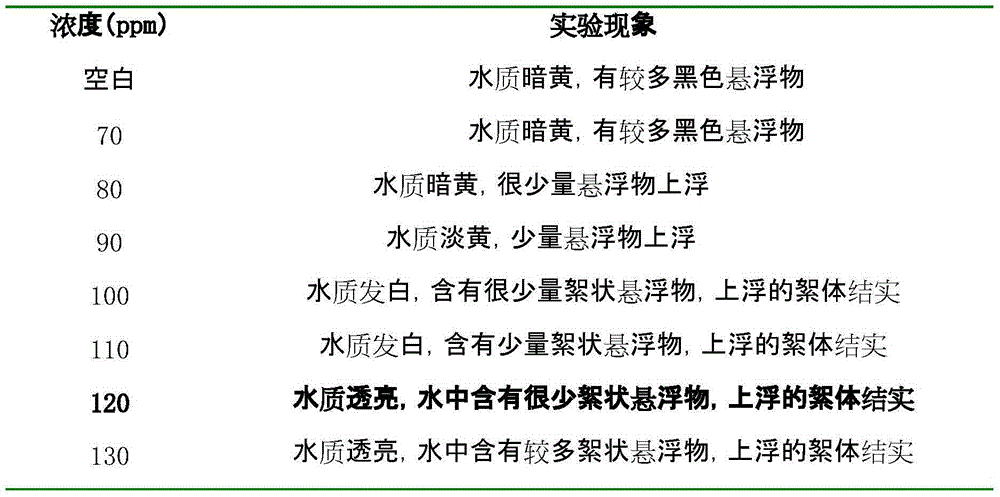

[0019] Each raw material component is selected according to mass percentage: polyaluminum chloride is 30%, and the mass of nonionic polyacrylamide is 5% of the mass of polyaluminum chloride; The mass ratio is 1:2; use absolute ethanol and distilled water to prepare a polyaluminum chloride solution with a mass percent concentration of 40% at room temperature (the volume ratio of distilled water to absolute ethanol is 3:1), and put it into a four-hole container with a stirrer. In the bottle, heat up to 50°C, add a certain amount of non-ionic polyacrylamide; fully stir at constant temperature for 20 minutes to fully dissolve; then use a separatory funnel to slowly add polydimethyldiallylammonium chloride dropwise, and Raise the temperature to 65°C, the polymerization reaction occurs, and control the temperature, the dropwise addition is completed within 3 hours; then raise the temperature to 80°C, add an appropriate amount of dilute sulfuric acid dropwise to adjust the pH value to...

Embodiment 2

[0026] Select each raw material component according to mass percentage: polyaluminum chloride is 35%, and the mass of nonionic polyacrylamide is 5% of polyaluminum chloride mass; Polydimethyl diallyl ammonium chloride and polyaluminum chloride The mass ratio is 1:3; use absolute ethanol and distilled water to prepare a polyaluminum chloride solution with a mass percent concentration of 40% at room temperature (the volume ratio of distilled water to absolute ethanol is 3:1), and put it into a four-hole container with a stirrer. In the bottle, heat up to 50°C, add a certain amount of non-ionic polyacrylamide; fully stir at constant temperature for 20 minutes to fully dissolve; then use a separatory funnel to slowly add polydimethyldiallylammonium chloride dropwise, and Raise the temperature to 65°C, the polymerization reaction occurs, and control the temperature, the dropwise addition is completed within 3 hours; then raise the temperature to 80°C, add an appropriate amount of di...

Embodiment 3

[0034] Select each raw material component according to mass percentage: polyaluminum chloride is 35%, and the mass of nonionic polyacrylamide is 5% of polyaluminum chloride mass; Polydimethyl diallyl ammonium chloride and polyaluminum chloride The mass ratio is 2:3; use absolute ethanol and distilled water to prepare a polyaluminum chloride solution with a mass percent concentration of 40% at room temperature (the volume ratio of distilled water to absolute ethanol is 3:1), and put it into a four-hole container with a stirrer. In the bottle, heat up to 50°C, add a certain amount of non-ionic polyacrylamide; fully stir at constant temperature for 20 minutes to fully dissolve; then use a separatory funnel to slowly add polydimethyldiallylammonium chloride dropwise, and Raise the temperature to 65°C, the polymerization reaction occurs, and control the temperature, the dropwise addition is completed within 3 hours; then raise the temperature to 80°C, add an appropriate amount of di...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com