Patents

Literature

84results about How to "High cationic degree" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

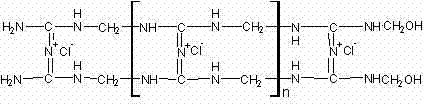

Flocculant and preparation method therefor

ActiveCN107805292AHigh viscosityHigh cationic degreeWater/sewage treatment by flocculation/precipitationMannich reactionWastewater

The invention discloses a flocculant and a preparation method therefor and belongs to the technical field of wastewater. The preparation method comprises the following steps: adding acrylamide, a quaternary ammonium salt monomer, amine, aldehyde, a complexing agent, a cosolvent and water, and carrying out stirring and mixing; sequentially adding an initiator A and an initiator B, and carrying outa Mannich reaction and a methylolation reaction; and after the reaction, sequentially adding a catalyst and an etherifying agent, carrying out a polycondensation reaction and amino resin molecule terminal hydroxymethyl-terminating, thereby finally obtaining the cationic liquid flocculant. The flocculant prepared by the preparation method is good in decoloring and flocculating effect and wide in applicable range, and the secondary pollution caused by free formaldehyde can be reduced.

Owner:广州安达净水材料有限公司

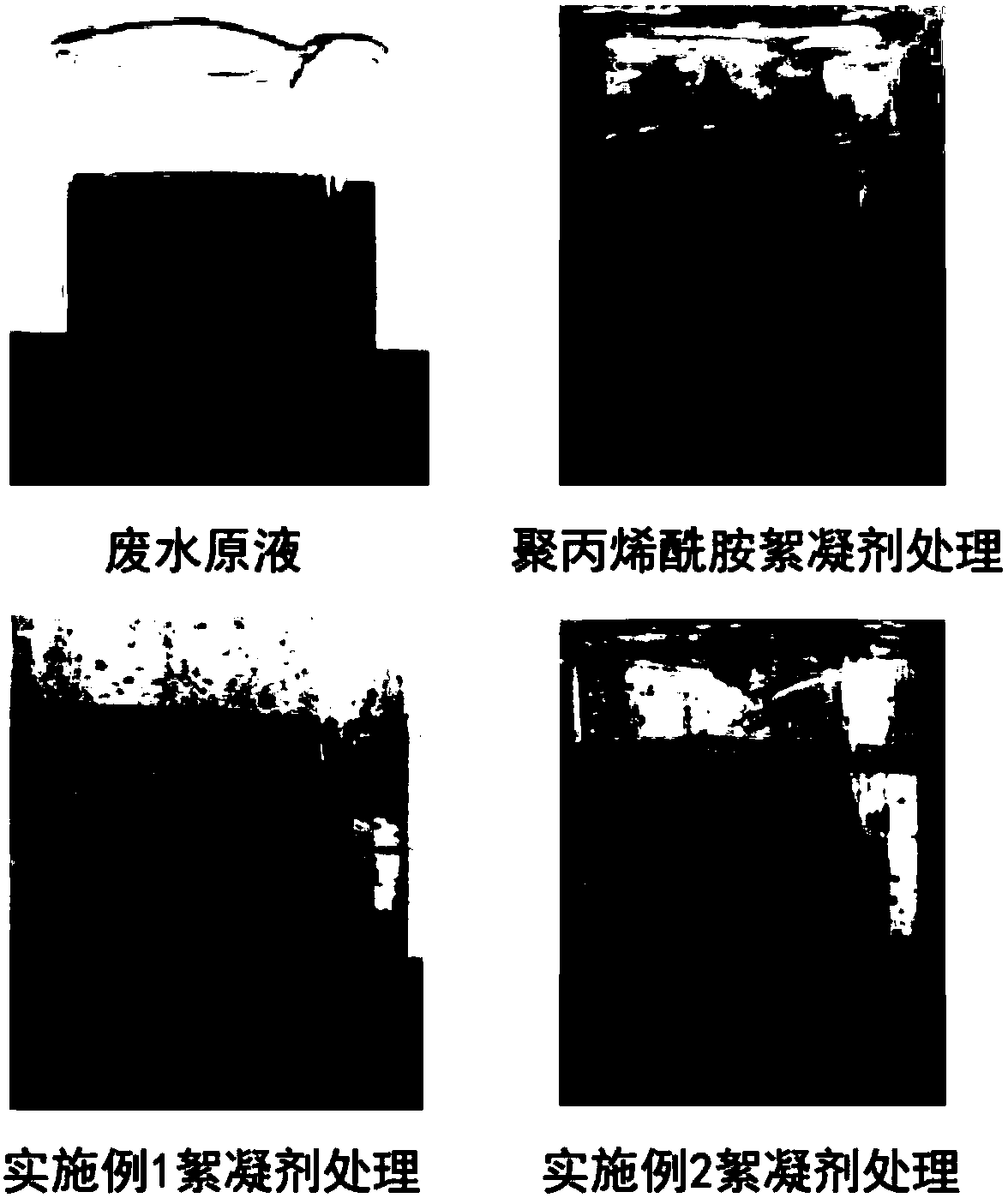

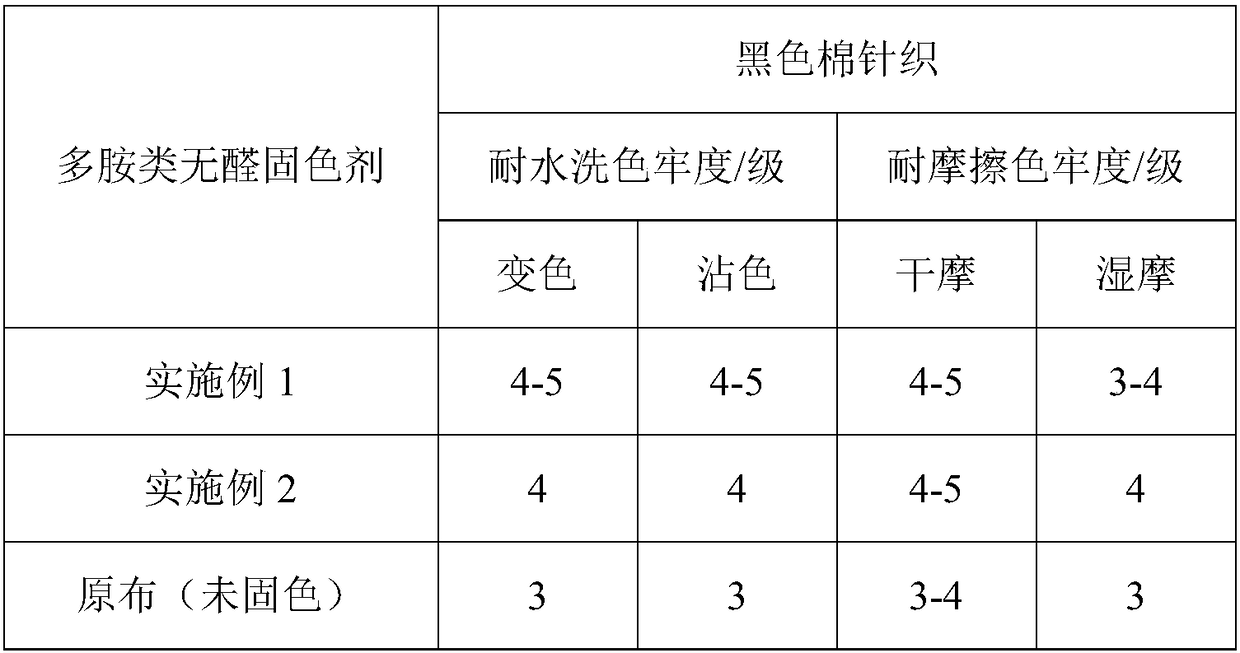

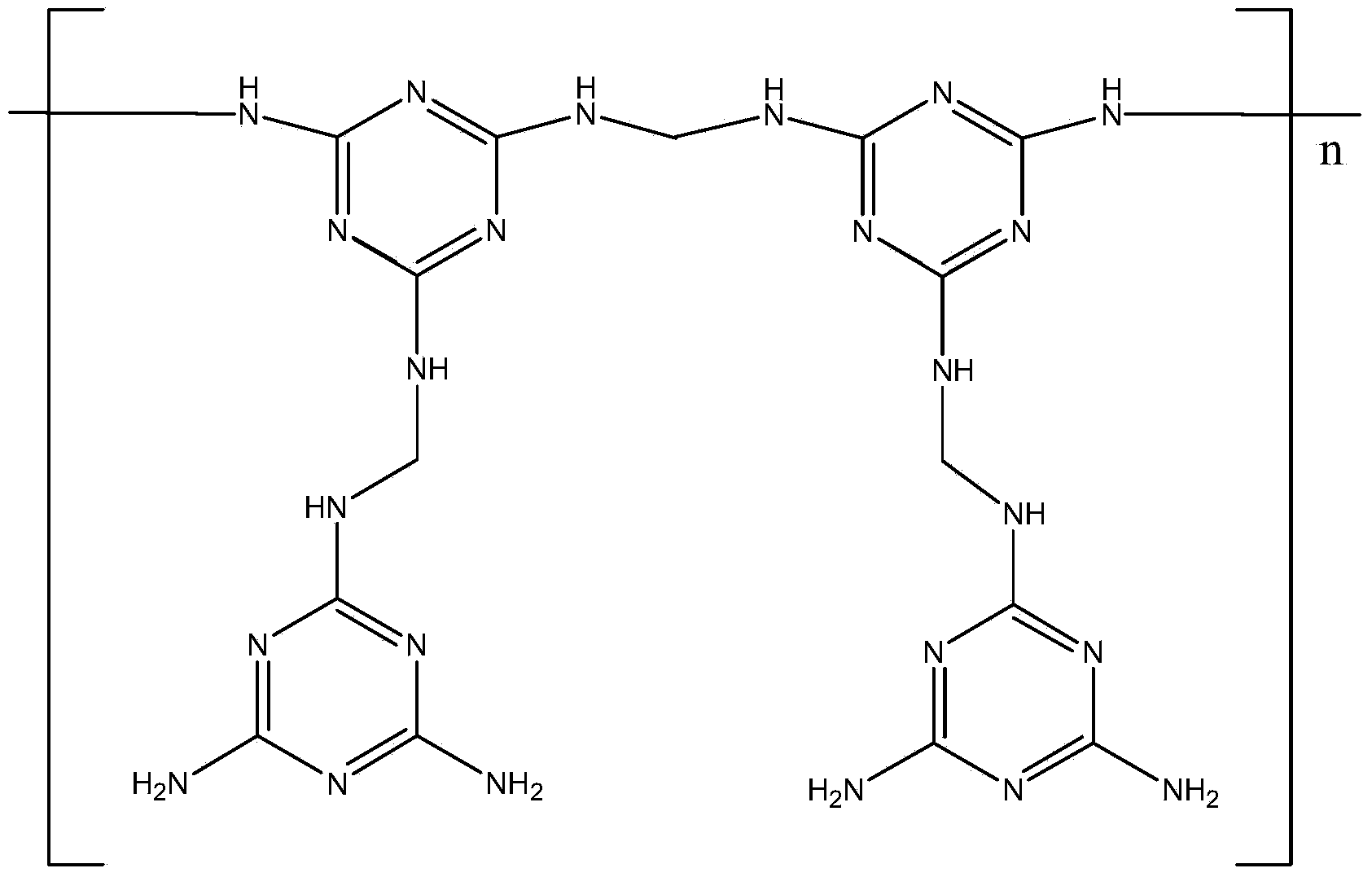

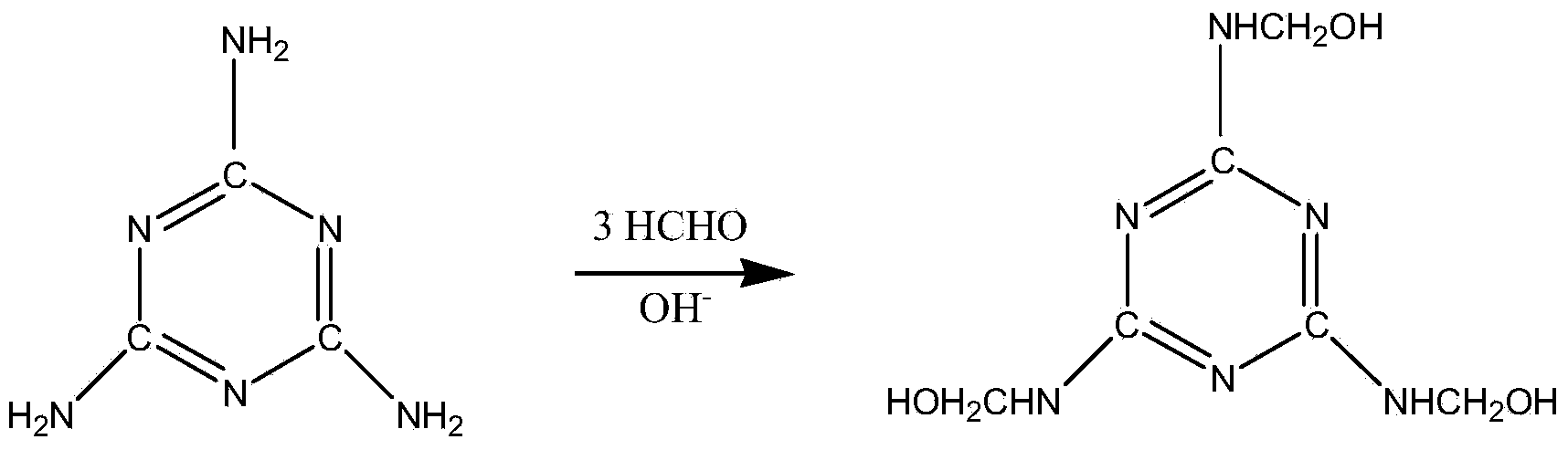

Polyamine formaldehyde-free fixing agent as well as preparation and application method thereof

InactiveCN108660810APrevent falling offImprove color fastnessDyeing processQuaternary ammonium surfactantIon

The invention provides a polyamine formaldehyde-free fixing agent as well as preparation and application method thereof. The polyamine aldehyde-free fixing agent is prepared from the following components in parts by weight: 8 to 15 parts of organic amine monomer, 5 to 15 parts of N-aminoethyl piperazine, 10 to 20 parts of quaternary ammonium cationizing agent, 15 to 25 parts of dicyandiamide, 2 to5 parts of organic acid, 8 to 15 parts of organic solvent, 5 to 15 parts of epichlorohydrin, 10 to 20 parts of cationic etherifying agent, 5 to 10 parts of polyvinyl alcohol (PVA) and 40 to 60 partsof deionized water. The polyamine formaldehyde-free fixing agent provided by the invention is green and environmentally friendly, and can eliminate reddish color produced during dyeing while fixing, thus avoiding repairing dyeing, and effectively improving various color fastnesses of fabrics, such as washing fastness, friction fastness and boiling water fastness.

Owner:苏州联胜化学有限公司

Method for preparing cationic polyacrylamide through photo-initiating system

ActiveCN107151289AChain growth proceeds uniformly and orderlyGood linearityWater/sewage treatment by flocculation/precipitationSolventIon

The invention relates to a method for preparing cationic polyacrylamide through a photo-initiating system. The method comprises the following steps of sequentially adding deionized water, acrylamide monomer, cationic monomer and cosolvent into a quartz reaction device until the materials are completely dissolved; adjusting a pH value of a solution; sequentially adding an azo initiator and a redox initiator into the reaction device while introducing high-purity nitrogen; sealing the reaction device and then putting the reaction device on an ultrasonicscope to be evenly oscillated; putting the reaction device on a rotary disk which rotates at a constant speed; utilizing a control method of low light intensity at first and then high light intensity to react; curing, washing, refining, drying and grinding generated polyacrylamide colloid to obtain a final product. The method can keep a certain concentration of free radicals in a reaction system and guarantees that chain growth proceeds evenly and orderly; the prepared polyacrylamide has good solubility and good flocculating performance; furthermore, an ultraviolet photo-initiating method has the advantages of low production energy consumption, high production efficiency, simpleness to operate, easiness to control and the like; the method disclosed by the invention has a good market application prospect.

Owner:SHENGLI OIL FIELD FANGYUAN CHEM IND

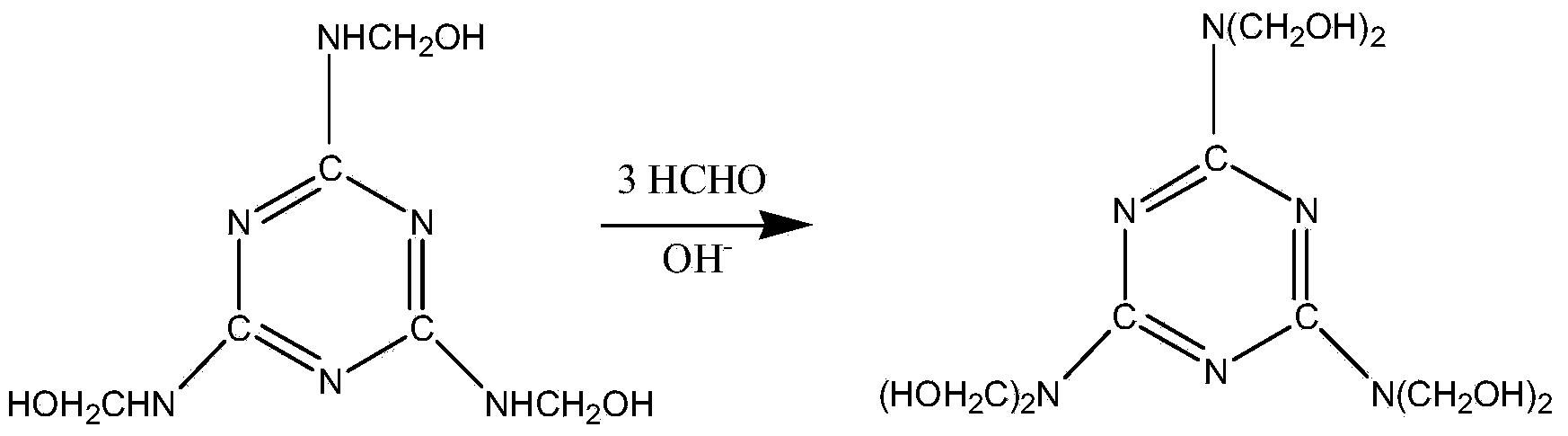

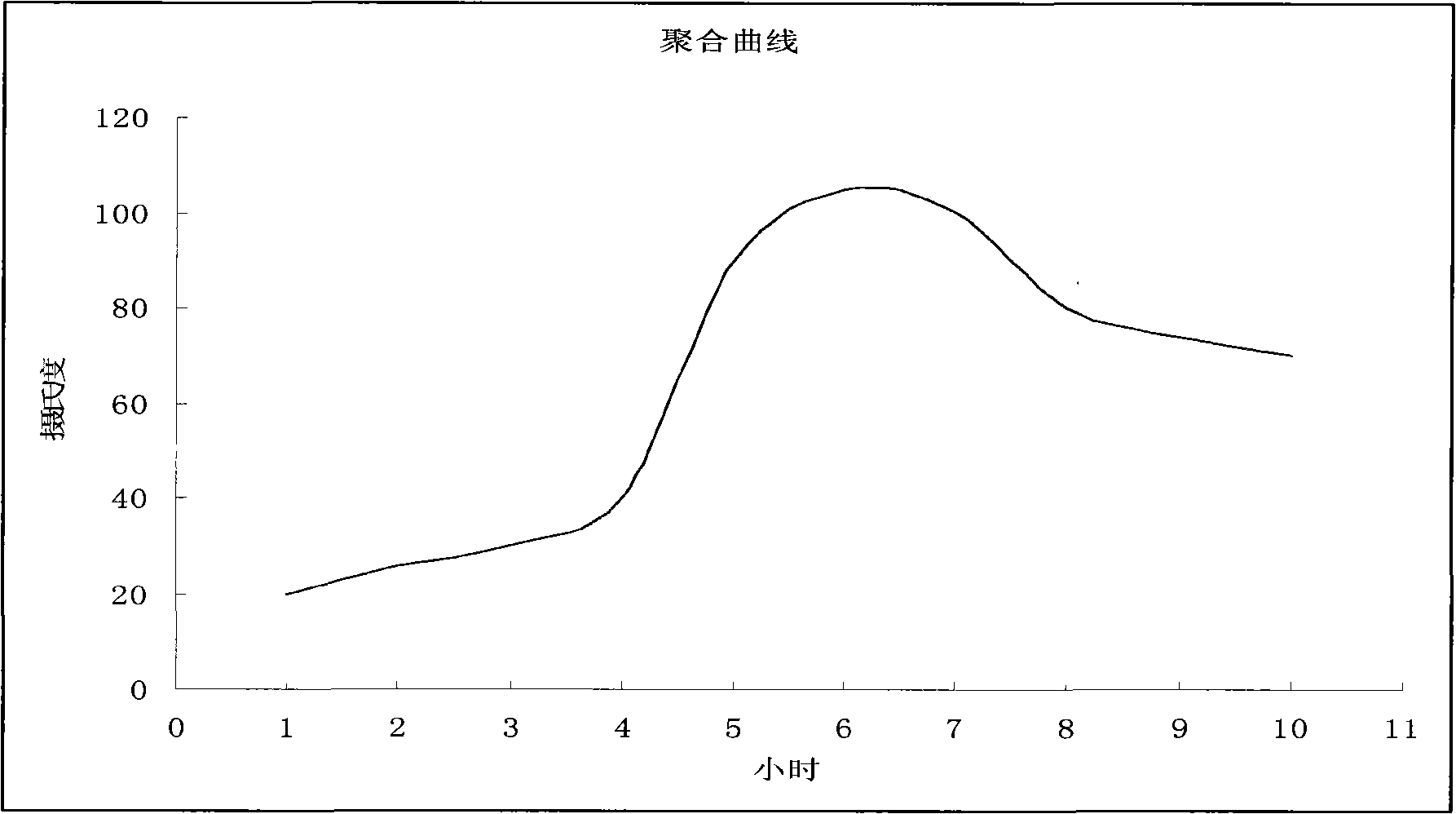

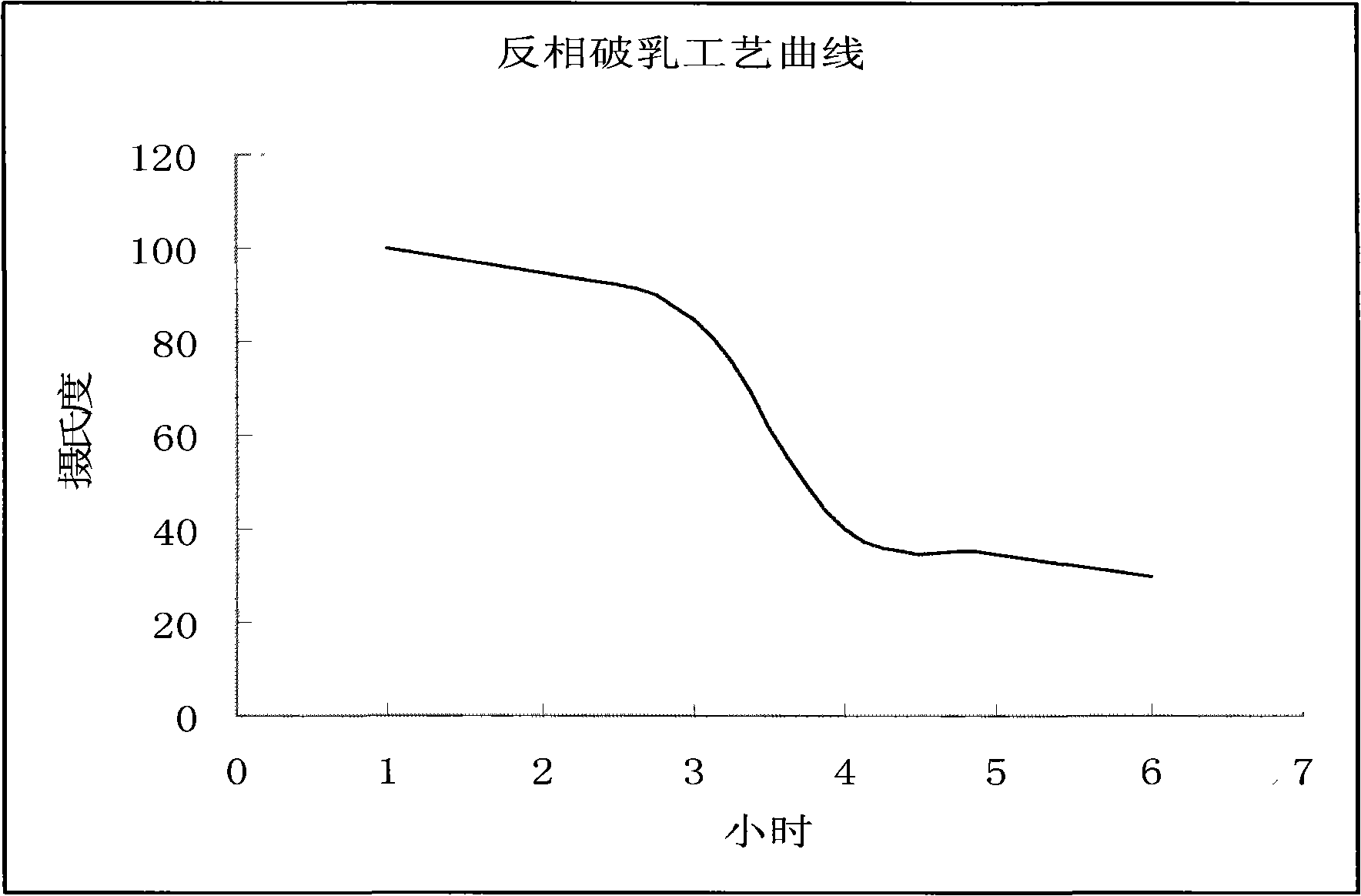

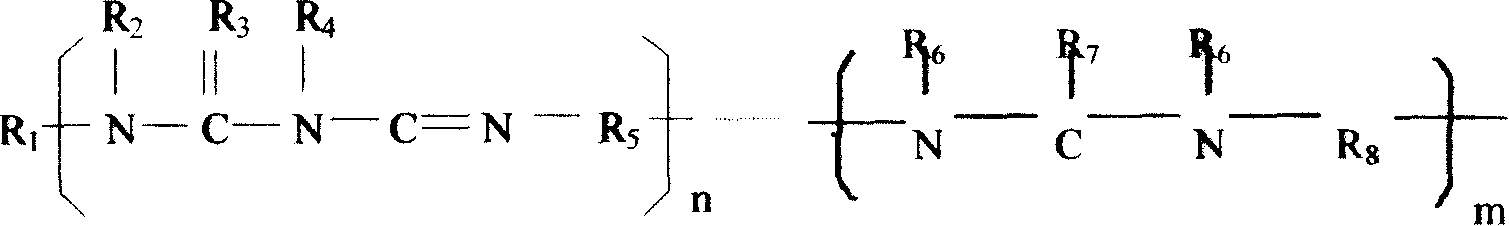

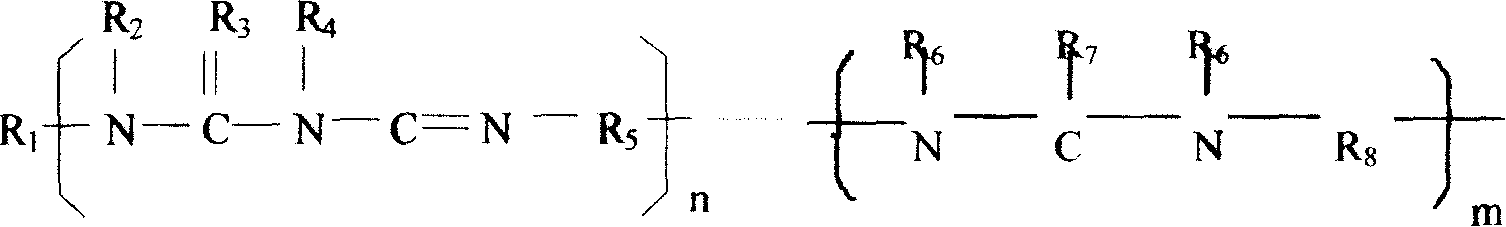

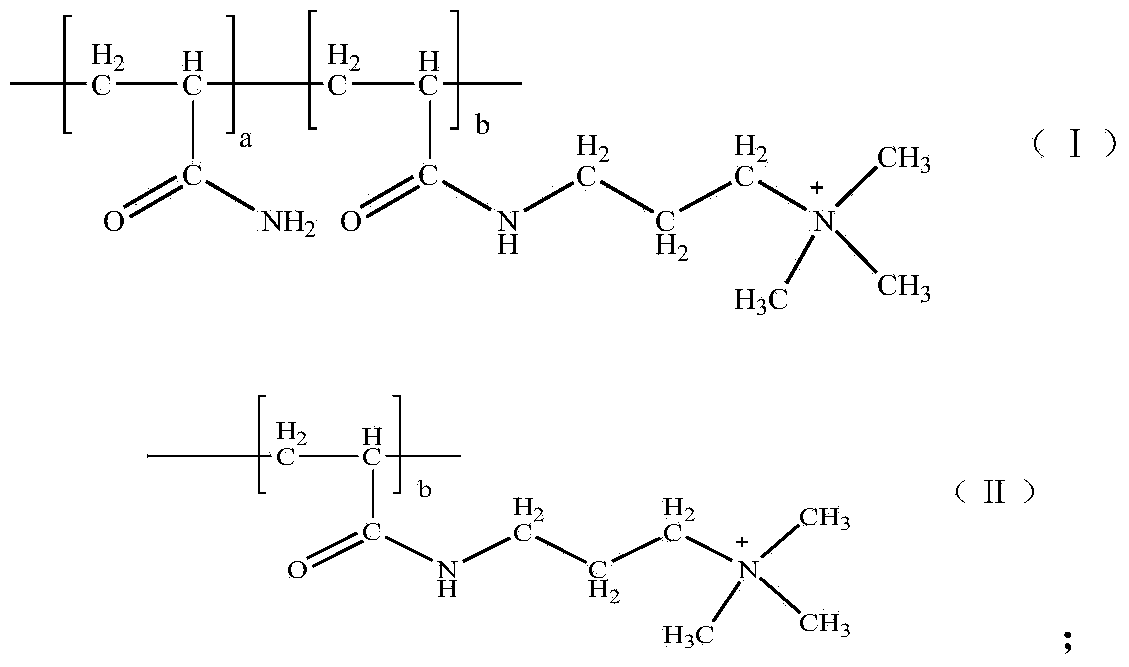

Cationic polymer as well as preparation method and application thereof

ActiveCN103450430AHigh cationic degreeHigh molecular weightFatty/oily/floating substances removal devicesLiquid separationTextile fiberDemulsifier

The invention discloses a cationic polymer as well as a preparation method and application thereof. The cationic polymer is prepared by the following five process steps in sequence: metering and mixing, hydroxymethylation reaction, polycondensation, inhibition reaction and free formaldehyde elimination. The cationic polymer has the advantages of high cationic degree, high molecular weight, long storage life and low formaldehyde content, and can serve as a flocculating agent, a reverse-phase demulsifier, a water reducing agent for concrete or a treating agent of textile fibers.

Owner:GUANGZHOU ZHENQING ENVIRONMENTAL PROTECTION TECH

Terpolymer cationic polyacrylamide

ActiveCN104910321AWide pH range of useHigh molecular weightWater/sewage treatment by flocculation/precipitationFlocculationEngineering

The invention belongs to the technical field of flocculant in sewage treatment technology in environment engineering, and particularly relates to a terpolymer cationic polyacrylamide. The preparation method of the product comprises the following steps: preparation of a cationic monomer E-AM, preparation of a monomer water solution, terpolymerization of AM, E-AM and DAC, and the like. The terpolymer cationic polyacrylamide well embodies the high polymerization activity and favorable flocculation effect of the E-AM monomer and the characteristic that the DAC can be easily used for preparing high-molecular-weight copolymers. Compared with the existing common flocculant product, the terpolymer cationic polyacrylamide has the characteristics of high cation degree, high molecular weight and excellent flocculation property. The actual detection result indicates that the terpolymer cationic polyacrylamide also has the characteristic of high solubility, and thus, is suitable to be used as a flocculant in sewage treatment engineering.

Owner:HENAN HONGKANG ENVIRONMENTAL PROTECTION TECH

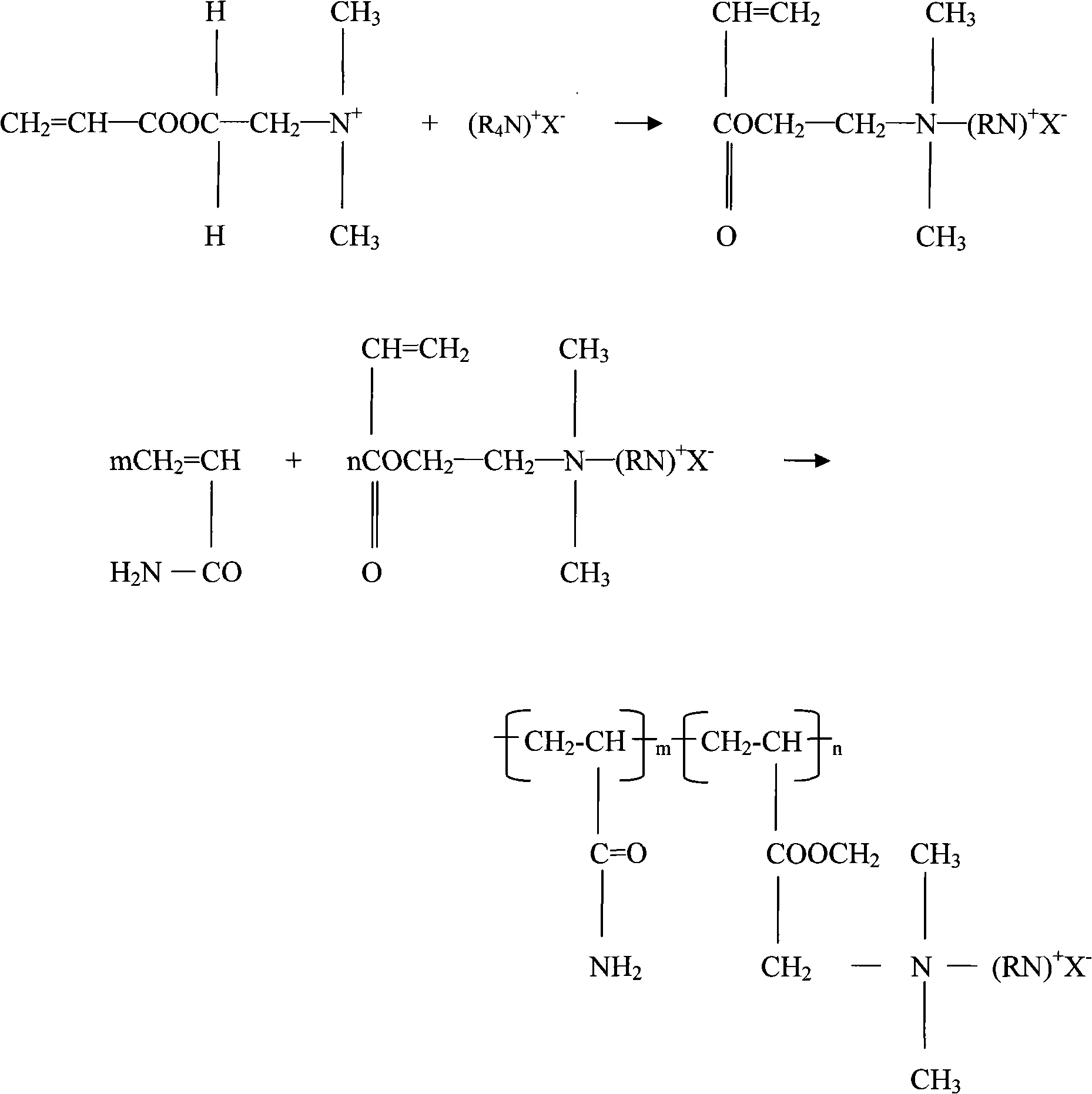

Liquid organic high polymer coagulant and preparation method thereof

InactiveCN101538343AHigh solid contentHigh molecular weightWater/sewage treatment by flocculation/precipitationLiquid temperaturePolymer science

The invention relates to a liquid organic high polymer coagulant and a preparation method thereof. A dimethylaminoethyl acrylate is dissolved in distilled water, quaternary ammonium is added to the distilled water according to the mol ratio of 1:5 to 5:1, the mixture is stirred for 3 hours under the temperature of 20-40 DEG C, and the temperature of the mixture is raised to 90 DEG C within 1 hour; then nitrogen is led into the mixture, an acrylamide monomer, emulsible oil and an evocating agent are added to the mixture, the mol ratio of the acrylamide monomer to the dimethylaminoethyl acrylate is 1:8 to 8:1, the obtained mixture is continuously stirred for 2 hours under the temperature of 95-105 DEG C, the temperature of the obtained mixture is lowered to 80 DEG C within 1 hour after reaction is completed, and the obtained mixture is stirred for 2 hours when the temperature is preserved at 70-80 DEG C; miscible liquids of organic oil and a surface active agent are added into the obtained mixture, the temperature of the obtained mixture is raised to 100 DEG C, the obtained mixture is stirred for 1 hour under the temperature of 95-105 DEG C and also stirred for 1 hour under the temperature of 90-95 DEG C, then the obtained mixture is continuously stirred for 1 hour to enable the temperature of liquid inside a reaction kettle to be lowered to 40 DEG C, and finally the obtained mixture is stirred for 2 hours. The invention has the advantages of high solid content, heavy molecular weight, high charging intensity, high cationic degree and short dissolving time.

Owner:DALIAN ECONOMY & TECH DEV ZONE LIJIA CHEM PRODS

Preparation method of cationic nonsoap colophony sizing agent

InactiveCN1807755AHigh cationic degreeImprove retentionWater-repelling agents additionEpoxySurface-active agents

This invention discloses a cationic non-soap rosin sizing agent preparing method, the making steps as follows: fist changing the rosin nature through epoxy chloropropane and Trimethylamine, then using the styrene, acrylate and cationic monomer aggregation to obtain the cationic macromolecular surface-active agents; under the effect of the assistant solvent and cationic macromolecular surface-active agents, the rosin is dealt by dispersing through emulsification, braising out the solvent and colloid dealing to obtain the high cationic non-soap rosin sizing agent. This invention can reduce the append quantity of the vitriol aluminum greatly; realize applying glue under neutral and ebb alkali condition, improve the left rate of the rosin sizing agent and its application effect.

Owner:SHAANXI UNIV OF SCI & TECH

Method for synthesizing cationic polyacrylamide by using ultraviolet initiated template copolymerization method

The invention relates to a method for synthesizing cationic polyacrylamide by using ultraviolet initiated template copolymerization method. The method comprises the following steps of: adding de-ionized water, an anionic polymer, a cationic monomer and an acrylamide monomer sequentially in a reaction device, stirring uniformly until the components are fully dissolved, so as to form a monomer water solution; adding a proper amount of a solubilizer and an initiator into the monomer water solution, stirring uniformly, adjusting pH (potential of hydrogen) value, charging high pure nitrogen into the reaction device in order to exhaust the air; then sealing the reaction device and putting into an ultraviolet reaction device to initiate the polymerization, so as to generate cationic polyacrylamide colloid; and finally, purifying, washing and refining the colloid, drying in a vacuum drying box and then grinding, thereby obtaining an end product. The method has the advantages that the polymerization initiation time is short, relatively few types of assistants are added and the temperature is not needed to control, thus the production technology can be simplified, the energy consumption can be reduced and the cost can be reduced; and the product synthesized according to the method is concentrated in distribution of cationic groups, is high in cationic degree and molecular weight, is high in purity and is non-toxic and harmless.

Owner:SHENZHEN SHENSHUI WATER RESOURCES CONSULTING CO LTD

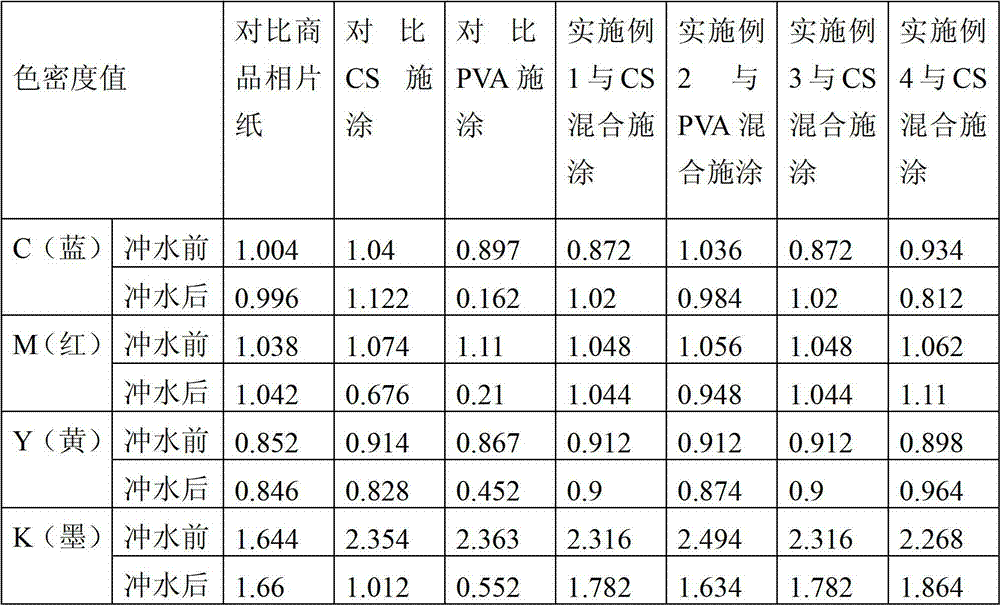

Surface-sizing fixing agent for color ink-jet paper and preparation method and application thereof

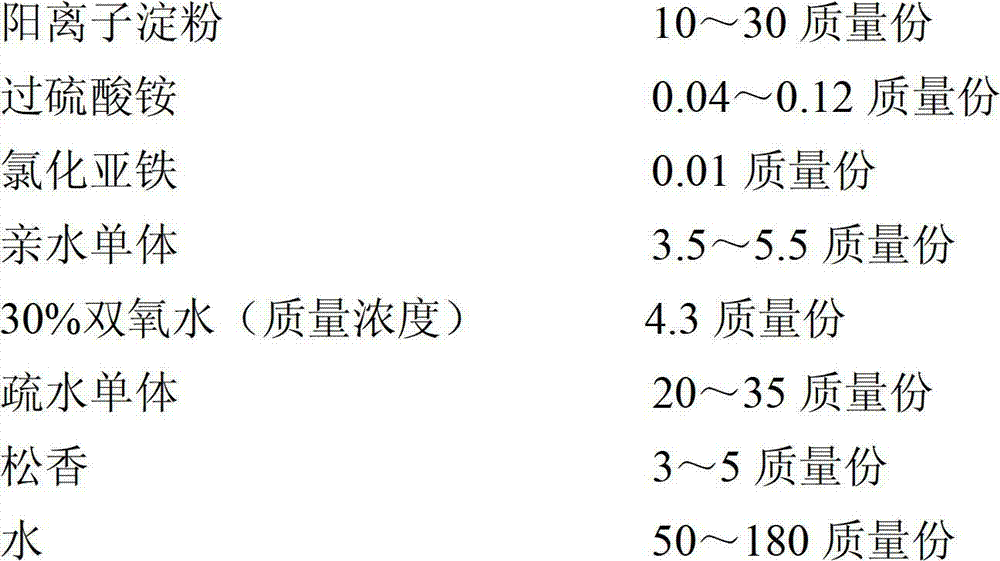

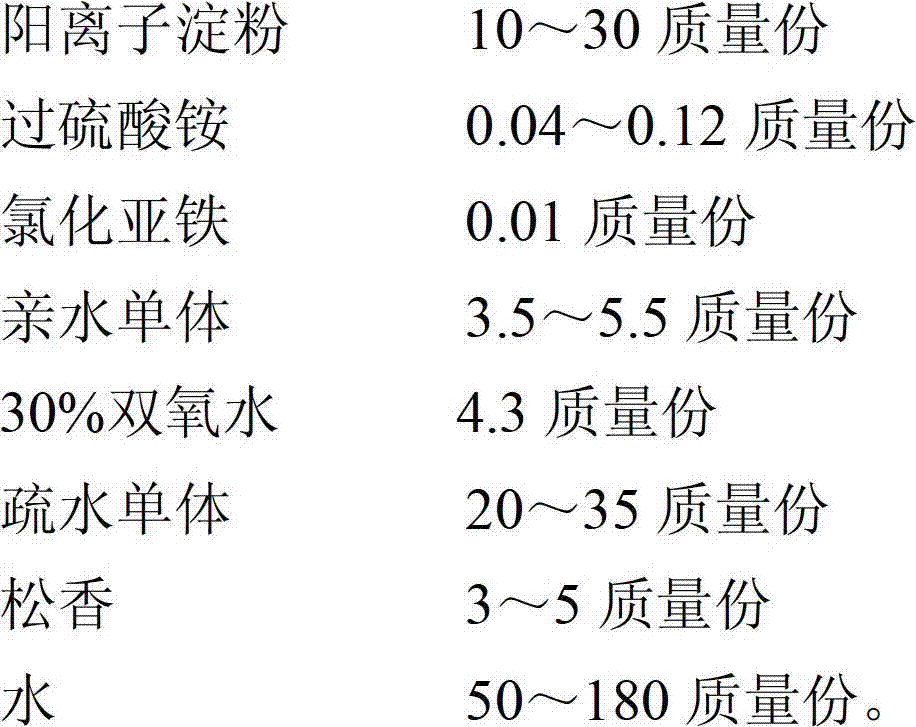

ActiveCN103074805AHigh cationic degreeImprove hydrophobicityNon-fibrous pulp additionHydrophilic monomerWater baths

The invention discloses a surface-sizing fixing agent for color-jet paper and a preparation method and the application thereof, and belongs to the field of preparation technologies of papermaking chemicals. The method comprises the following steps: gelatinizing cationic starch, ammonium persulfate and water under water bath stirring; adding ferrous chloride water solution and hydrophilic monomer solution; dripping hydrogen peroxide diluent for initiation; adding hydrophobic monomer and rosin into a reaction system for monomer pre-emulsification; increasing the temperature to 90-92 DEG C, and dripping hydrogen peroxide diluent for initiation and then reaction for 2-3h; and increasing the temperature to 95-99 DEG C for reaction for 1h, and then naturally cooling to 20-50 DEG C to manufacture the surface-sizing fixing agent for color-jet paper. The prepared surface-sizing fixing agent for color-jet paper is formulated into water solution and then mixed with the cationic starch or polyvinyl alcohol, and meanwhile, an album paper coating cross-linking agent is added for being mixed and applied to improve the surface quality of printing paper, improve the printing quality and particularly greatly improve the water resistance of finished paper.

Owner:FENGKAI JIACHENG PAPER CO LTD

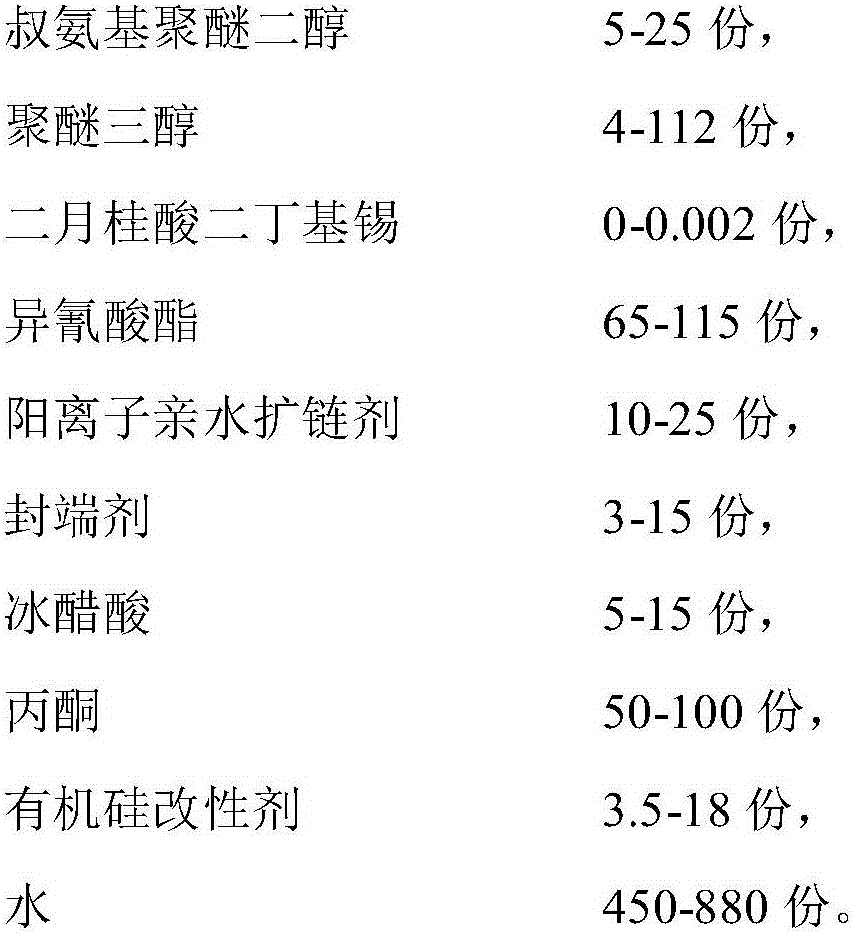

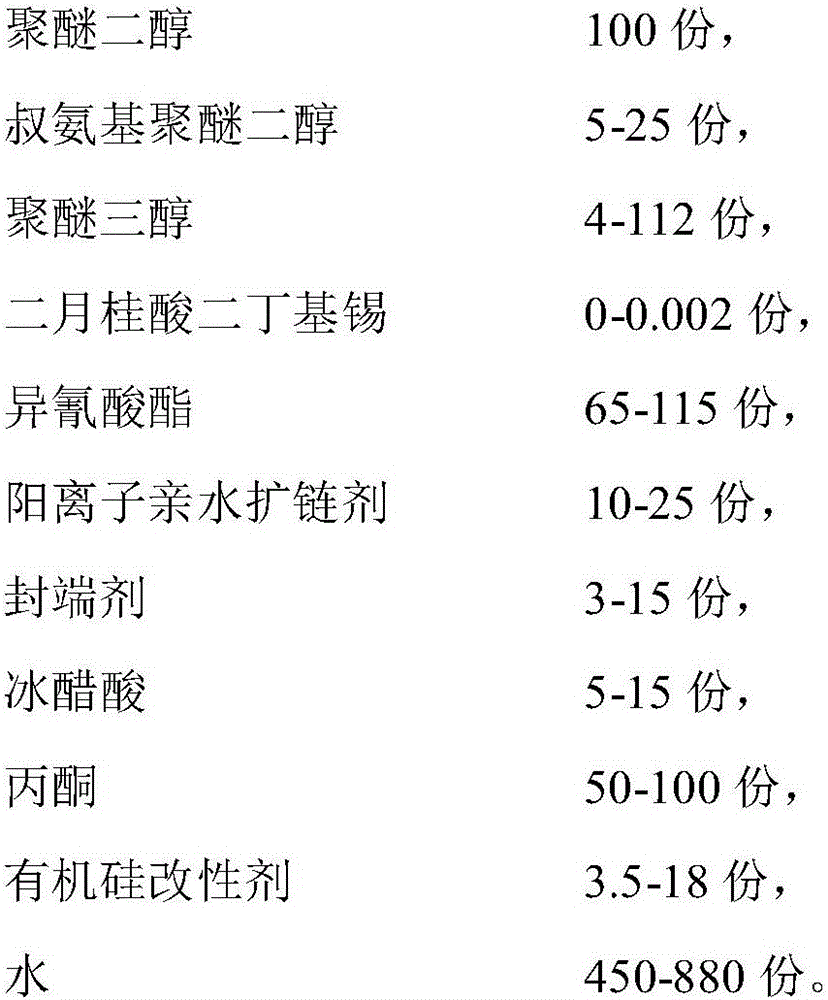

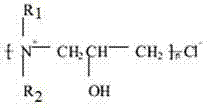

Organosilicon-modified cationic aqueous polyurethane paper wet strength agent and preparation method

InactiveCN106589298ASolve the problem of low cationicity and poor mechanical propertiesHigh cationic degreePaper coatingReinforcing agents additionFiberQuaternary ammonium cation

The invention relates to the technical field of chemistry, and in particular to an organosilicon-modified cationic aqueous polyurethane paper wet strength agent and a preparation method. The organosilicon-modified cationic aqueous polyurethane paper wet strength agent consists of the following materials: polyether diol, tertiary amino polyether diol, polyether triol, dibutyltin dilaurate, isocyanate, cationic hydrophilic chain extender, end-capping agent, glacial acetic acid, acetone, organosilicon modifier and water. The invention introduces tertiary amino groups into both a soft segment structure and a hard segment structure, quaternary ammonium cations are generated after acid neutralization, consequently, the cationic degree is increased, and the organosilicon-modified cationic aqueous polyurethane paper wet strength agent can be better adsorbed on paper fibers with negative charges, and can be quickly and completely retained; by organosilicon modification, crosslinking density is increased, a chemical network structure is formed, and the organosilicon-modified cationic aqueous polyurethane paper wet strength agent which has a high cationic degree and high wet strength can be formed when used on paper; with water as dispersant, the organosilicon-modified cationic aqueous polyurethane paper wet strength agent is nontoxic, pollution-free and highly compatible, and the existence of free formaldehyde and organic halide in conventional wet strength agents are prevented, so the organosilicon-modified cationic aqueous polyurethane paper wet strength agent is environment-friendly and safe.

Owner:ENERGY RESOURCES INST HEBEI ACADEMY OF SCI

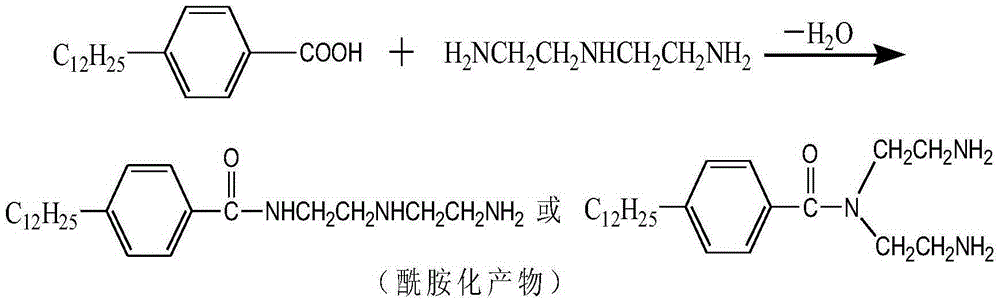

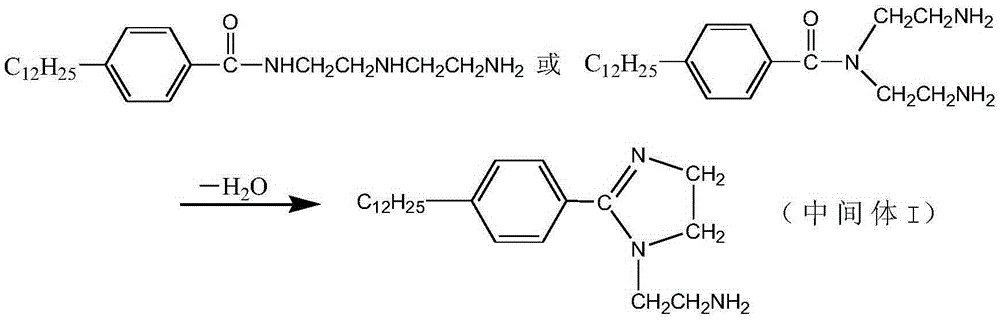

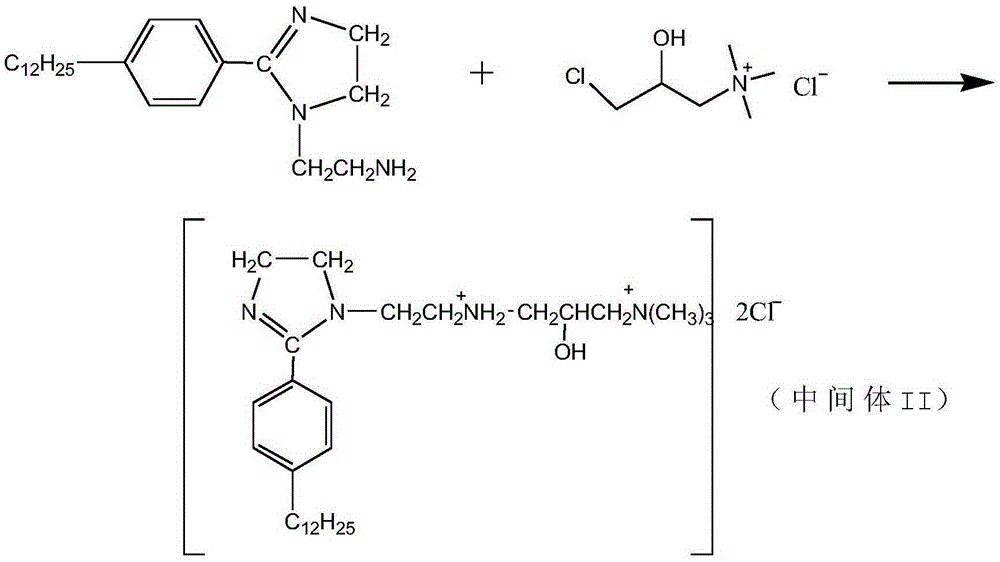

High-cation-degree asphalt emulsifier and application thereof

InactiveCN105295068AHigh cationic degreeIncrease steric hindranceOrganic chemistryBuilding insulationsBenzoic acidDiethylenetriamine

The invention belongs to the field of asphalt emulsifiers and in particular relates to a high-cation-degree asphalt emulsifier and an application thereof. The high-cation-degree asphalt emulsifier has a structural formula shown in the specification. A preparation method of the high-cation-degree asphalt emulsifier comprises the following steps: (1) adding diethylenetriamine into anhydrous dodecyl para toluic acid, heating to 150-160 DEG C, stirring to perform amidation reaction, further heating to 200-220 DEG C to perform dehydration reaction until no distillate is generated, then cooling to 50-70 DEG C, adding a solvent, and stirring for dissolving so as to obtain an solution of an imidazoline cyclic intermediate compound I; (2) then dropwise adding 3-chloro-2-hydroxypropyl trimethyl ammonium chloride aqueous solution into an imidazoline cyclic intermediate compound solution, and then further performing reaction at 70-100 DEG C to obtain an intermediate II; and (3) cooling the intermediate II, and then adding hydrochloric acid to perform acidification reaction to obtain the high-cation-degree asphalt emulsifier. The asphalt emulsifier provided by the invention can be used for preparing emulsified asphalt of which the solid content reaches more than or equal to 75%.

Owner:HAISO TECH +2

Novel decolorizing agent and preparation method thereof

InactiveCN102557217AHigh molecular weightHigh cationic degreeWater/sewage treatment by flocculation/precipitationProcess engineeringEpichlorohydrin

The invention discloses a novel decolorizing agent. The novel decolorizing agent is formed by copolymerizing dicyandiamide formaldehyde polymer and polyepichlorohydrin amine resin. Compared with the conventional dicyandiamide formaldehyde decolorizing agent, the novel decolorizing agent has the advantages that: the molecular weight and the cation degree are greatly improved, so that the decolorizing effect of polymer is improved; and a decolorizing function can be realized by only using the decolorizing agent independently without additional aluminum-based coagulants and iron-based coagulants, so that a coagulation process flow is shortened, a water treatment operation process is simplified, and the treatment cost of dyed wastewater is saved. In addition, the novel decolorizing agent is used as a high-efficient water treatment medicament and can be widely applied to decolorizing treatment of all kinds of dyed wastewater.

Owner:JIANGMEN CITY ZHONGDA ENVIRONMENTAL PROTECTION TECH

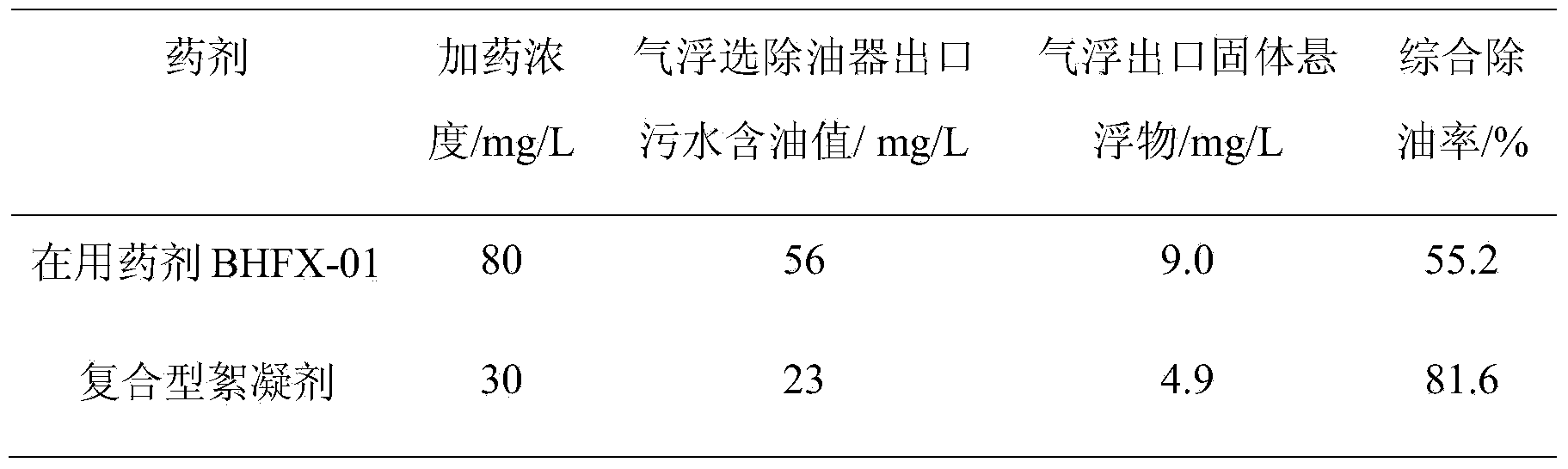

Enhanced disposal method applicable to wastewater of water-based cutting fluids

InactiveCN110104836AEfficient removalImprove biodegradabilityWater/sewage treatment by centrifugal separationFatty/oily/floating substances removal devicesWater basedDecomposition

The invention relates to an enhanced disposal method applicable to wastewater of water-based cutting fluids. The method can effectively achieve removal of organic pollutants and ammonia nitrogen in the wastewater. According to the method, a combined process of physical oil separation, demulsification coagulation, ozone catalysis and flocculation sedimentation is adopted, a cationic demulsificationcoagulant is utilized to fully neutralize the surface charges of emulsified oil droplets, destroy hydration membranes of the emulsified oil droplets, compress an electric double layer, increase the collision probability among the oil droplets and thus accelerate the destabilization and demulsification of emulsified oil, and more free radicals of active hydroxyl are generated in combination with the decomposition rate of ozone under the action of a heterogeneous ternary composite ozone catalyst. In this way, catalyzation of organic pollutants in ozonized water is facilitated, the mineralization rate of organic matter is greatly increased, and the biodegradability of the wastewater is improved significantly.

Owner:SHANGHAI NAT ENG RES CENT FORNANOTECH

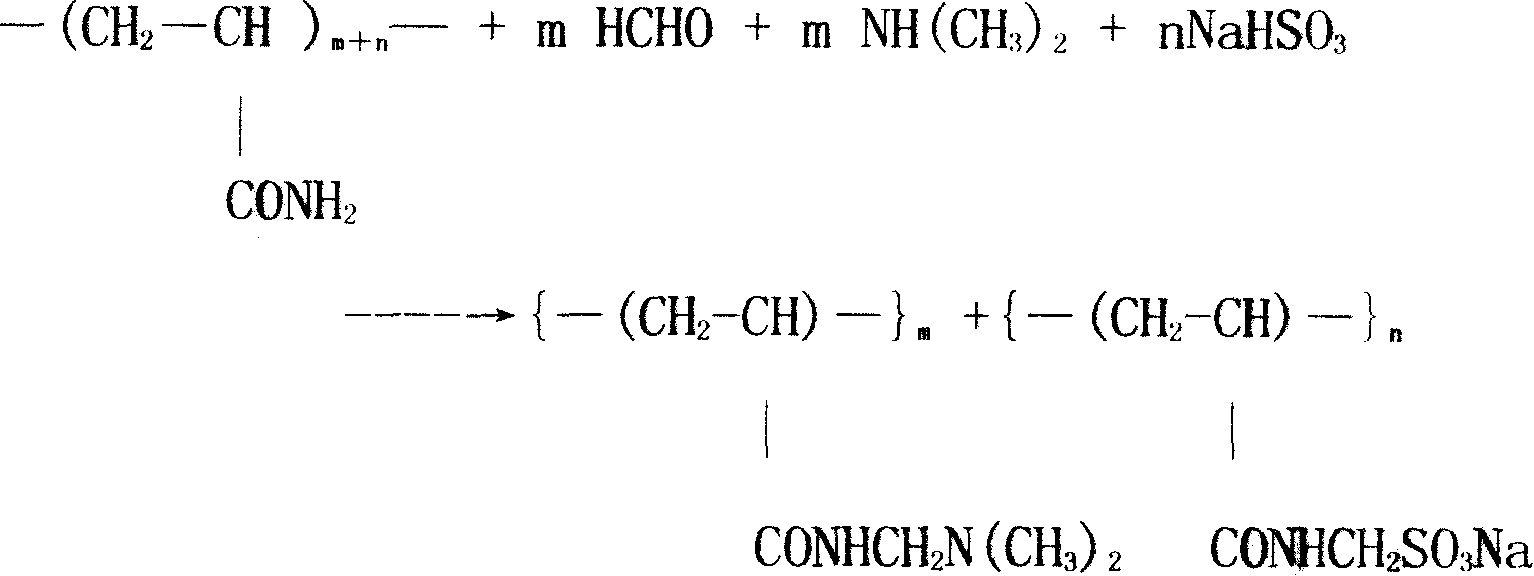

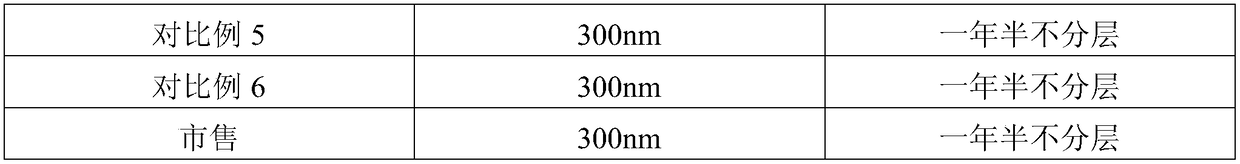

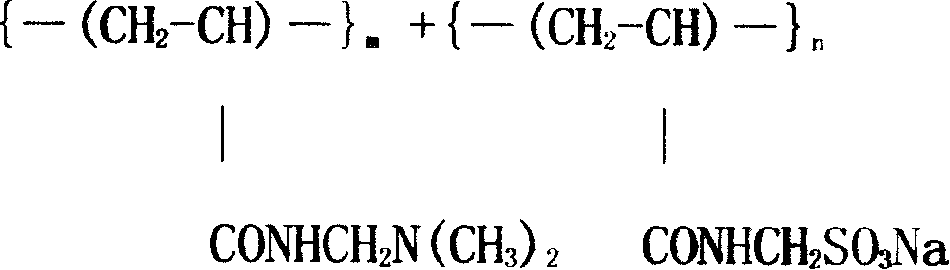

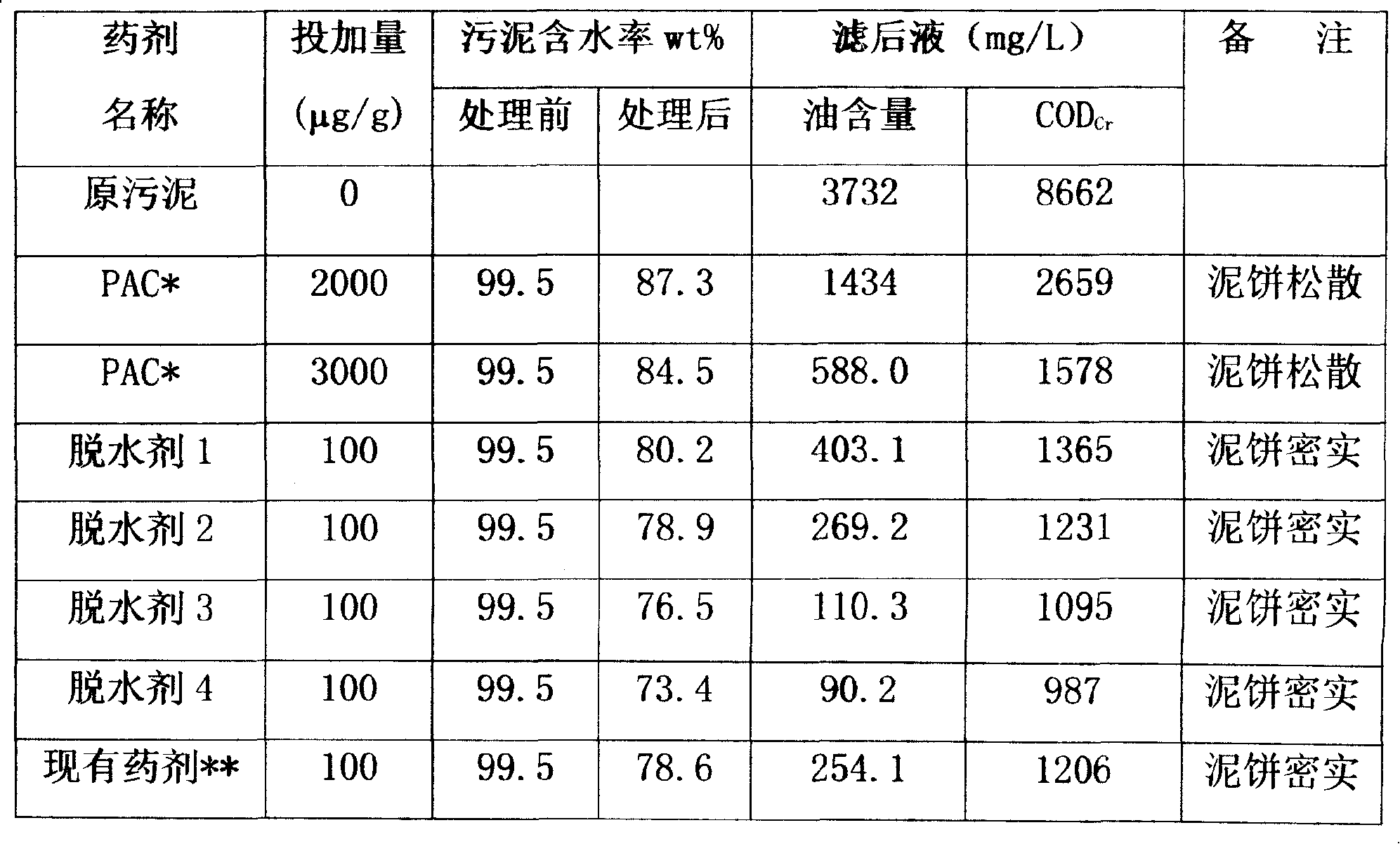

Method for preparing composite sludge dehydrant

ActiveCN101239774ASmooth responseEasy to operateSludge treatment by de-watering/drying/thickeningWater/sewage treatment by flocculation/precipitationChemical industryPetroleum

The present invention relates to a method for preparing a composite sludge dewatering polymer. The polymer is a colloid water solution which takes anion or non-ionic polyacrylamide, formaldehyde, organic amine, sodium bisulfite and fresh water as the raw material and is obtained by the reaction at a certain temperature with a few additive and takes the sulfomethyl polyacrylamide and aminomethyl polyacrylamide as the main component; the composite dewatering agent of the invention is obtained by mixing the colloid water solution and the organic flocculant of the patent 98121074.0 with a volume ratio 5-50:1. The method of the invention has the advantages of simple technique and equipment, stable reaction process, easy operation and short necessary time. The processing effect of the sludge dewatering agent of the invention is better than the existing agent in the condition of the equal agent adding amount; the COD of the processed filtered solution is basically less than 2000mg / L, and the oil content is below 1000mg / L. The method can be applied to the processing of the sewage and sludge in the industries of petroleum, chemical industry and the like.

Owner:CHINA PETROLEUM & CHEM CORP +1

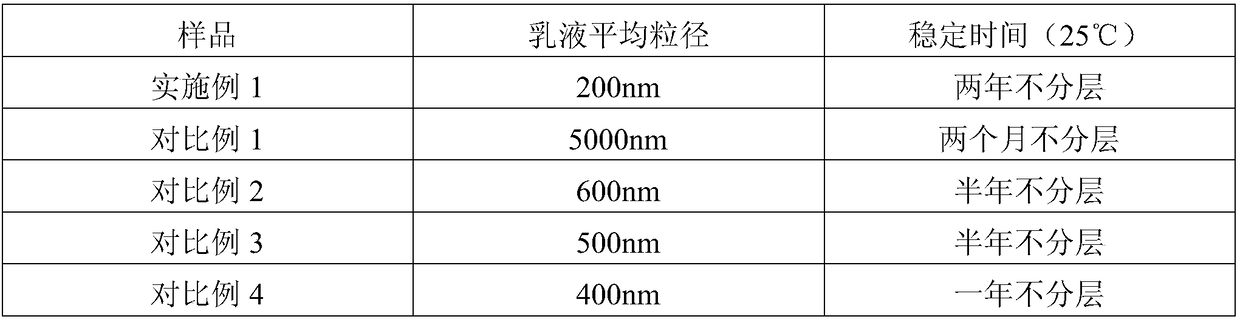

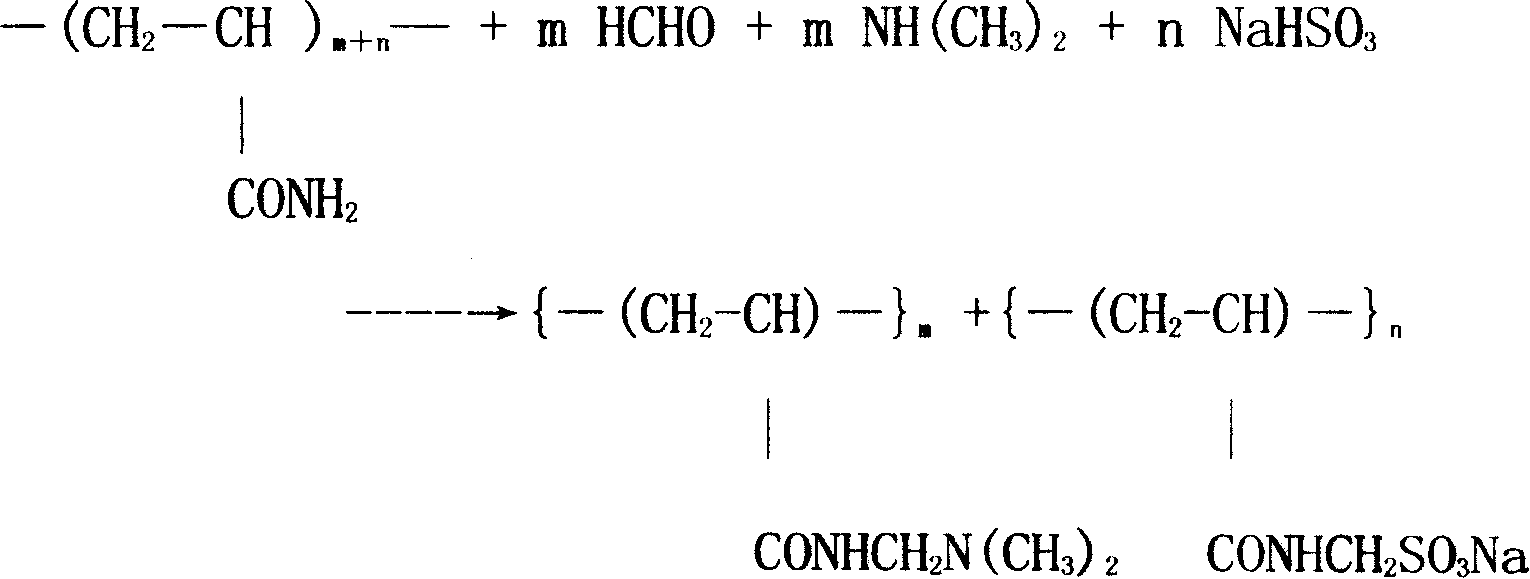

Cationic rosin size emulsifier and preparation method thereof

ActiveCN108396589AAdjust molecular weightAvoid interferenceWater-repelling agents additionAcetic acidEmulsion

The invention provides a cationic rosin size emulsifier and a preparation method thereof. The cationic rosin size emulsifier is prepared from dimethylaminoethyl methacrylate, styrene, chitosan, glacial acetic acid, water, acrylic acid, acrylamide, potassium sodium tartrate and an initiator. The obtained emulsifier has a good stability, can be used to directly emulsify rosin, and has the advantagesof small use amount, good effect and low cost, a rosin size emulsion obtained after emulsification has nanoscale particles and a stable quality, and can be stably stored (at -5 to 50 DEG C) for a long time; and the rosin size emulsion obtained after emulsification is applied to sizing, has the advantages of small use amount of other sizing additives, small use amount of a sizing agent, good effect and low cost, and makes sized paper have certain antibacterial and bactericidal effects and good durability.

Owner:辽宁兴东科技有限公司

Preparation for water soluble high-molecular weight cationic polymer

The invention provides a preparation method of a water-soluble high molecular weight cationic polymer. The method adopts a multi-component composite redox initiation system, adds a variety of additives, and initiates the copolymerization of methacryloyloxyethyltrimethylammonium chloride or acrylamide acryloyloxyethyltrimethylammonium chloride and acrylamide aqueous solution. A water-soluble cationic polymer powder product with an intrinsic viscosity of 13.4-23.4dl / g is prepared, the molar content of METMAC or AETMAC in the polymer is 0.5%-99.5%, and the residual monomer content is ≤0.1wt%. The present invention is characterized in that domestic industrial-grade monomers are directly used as raw materials without refining, and the obtained high molecular weight polymer has a cationic degree of 50-99.5%. The product can be used as clay stabilizer, inverse demulsifier, corrosion inhibitor in petroleum engineering, strengthening agent in papermaking industry, papermaking wastewater treatment agent, water treatment agent in environmental protection, sludge dehydrating agent, etc.

Owner:HAISO TECH

Method for preparing amphiprotic sludge dehydrant

ActiveCN101239775AImprove dehydration effectEasy to makeSludge treatment by de-watering/drying/thickeningChemical industryPetroleum

The present invention relates to a method for preparing the amphoteric polymer which is used for the sludge dewatering. The polymer is a colloid water solution which takes anion or non-ionic polyacrylamide, formaldehyde, organic amine, sodium bisulfite and fresh water as the raw material and is obtained by the reaction at a certain temperature with a few additive and takes the sulfomethyl polyacrylamide and aminomethyl polyacrylamide as the main component. The invention has the advantages of simple technique and equipment, stable reaction process, easy operation and short necessary time. The experiment of dewatering to the sludge of the petroleum refinery shows that the processing effect of the sludge dewatering agent of the invention is better than the existing agent at the condition of same agent adding amount; the COD of the processed filtered solution is less than 2000mg / L, and the oil content is below 1000mg / L. The method can be applied to the processing of the sewage and sludge in the industries of petroleum, chemical industry and the like.

Owner:CHINA PETROLEUM & CHEM CORP +1

Cationic benzene acrylic papermaking surface sizing agent

InactiveCN104674600AImprove adhesionHigh cationic degreeWater-repelling agents additionPaper coatingBenzeneFunctional monomer

The invention relates to a cationic benzene acrylic papermaking surface sizing agent. The cationic benzene acrylic papermaking surface sizing agent is prepared from the following components in percentage by weight: 10-18% of a dispersing agent, 5-10% of an oxidizing agent, 0.01-2% of an initiating agent, 5-10% of a hard monomer, 1-5% of a soft monomer, 0.5-3.5% of a functional monomer, 0.5-1.5% of a cationic monomer, 1-5% of acid, 40-80% of water, 1-3% of a modifying agent and 0.01-0.5% of a crosslinking agent. A preparation method of the cationic benzene acrylic papermaking surface sizing agent concretely comprises the following steps: (1) preparing the initiating agent and water to obtain aqueous solution according to ratio; (2) mixing the dispersing agent with water in ratio, adding the oxidizing agent and the initiating agent aqueous solution accounting for 50% of the total usage amount, heating to the temperature of 80-90 DEG C, carrying out heat preservation reaction; (3) fully mixing the soft monomer, the hard monomer and the functional monomer for later use; and (4) adding the acid and cationic monomer after heat preservation is finished, adding the modifying agent and the crosslinking agent at the same time, and dropwise adding the monomer mixture and the rest initiating agent aqueous solution.

Owner:HAO YU ADDITION AGENT

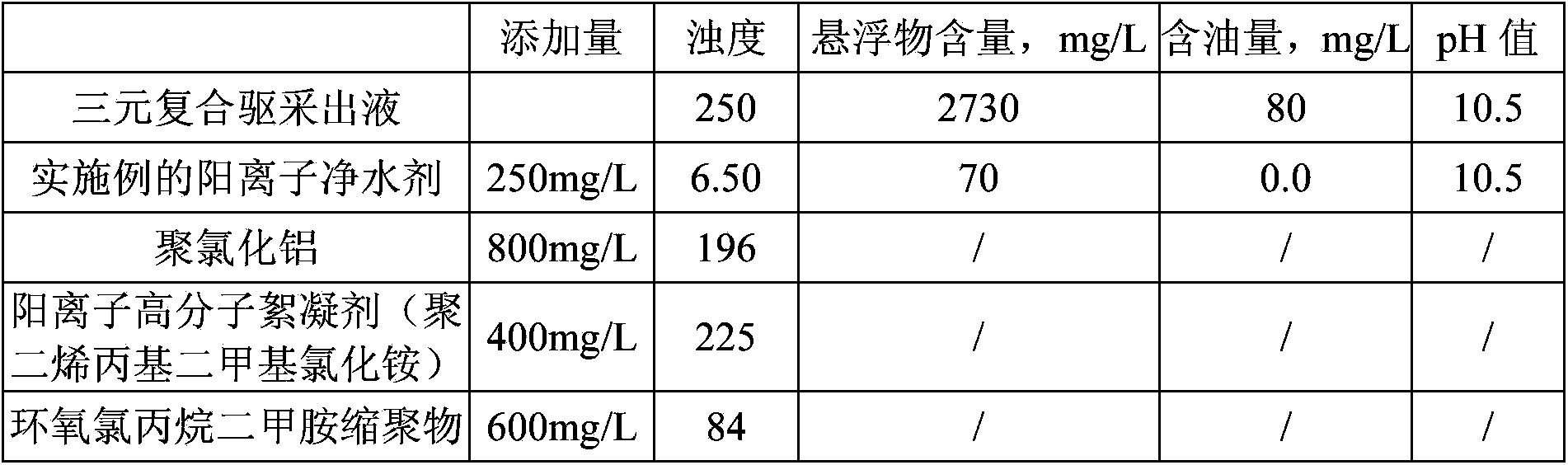

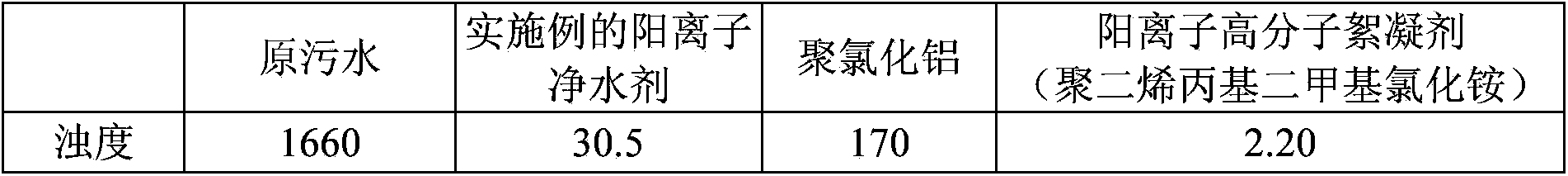

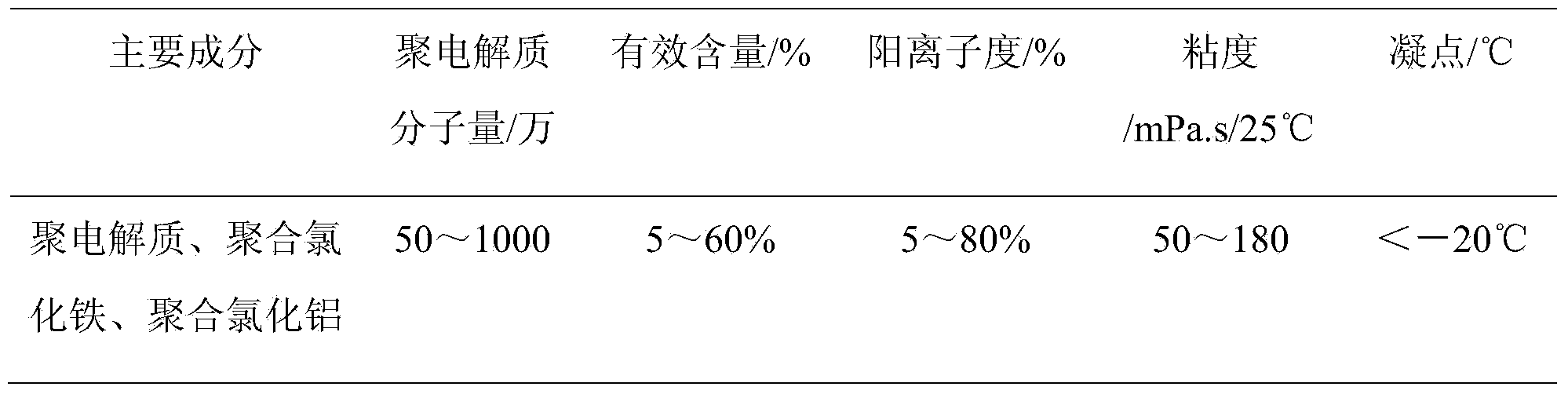

Cationic water purifying agent and application of same in oilfield chemical flooding produced liquid

ActiveCN104071882AGood flocculation effectReduce dosageWater/sewage treatment by flocculation/precipitationFlocculationTetramine

The invention relates to a cationic water purifying agent and application of the same in an oilfield chemical flooding produced liquid. The cationic water purifying agent is prepared through the following steps: mixing dodecylamine, an emulsifier OP-10 and chloropropylene oxide, carrying out dissolving with stirring and then heating to 80 DEG C so as to obtain a mixed solution; adding a mixed liquor of an aqueous hexamethylene tetramine solution and dimethylamine into the mixed solution drop by drop; and after a reaction solution is cooled to 70 DEG C, adding acid to adjust the pH value of the reaction solution to 5, adding a catalyst, maintaining a temperature to be 70 DEG C, carrying out a reaction for 4 h and then cooling to room temperature so as to obtain the cationic water purifying agent. The invention further provides application of the cationic water purifying agent in purifying of an oilfield ternary composite flooding produced liquid. The cationic water purifying agent provided by the invention is a condensed type quaternary ammonium salt high polymer and has the advantages of a good flocculation effect, a small usage amount, low cost and a substantial purifying effect especially on the oilfield ternary composite flooding produced liquid.

Owner:PETROCHINA CO LTD

Composite flocculating agent

ActiveCN103523882AWide molecular weight distributionHigh cationic degreeWater/sewage treatment by flocculation/precipitationPolyelectrolyteMass ratio

The invention discloses a composite flocculating agent. The flocculating agent consists of polyelectrolyte and Lewis acid in mass ratio of (8:1)-(3:1), wherein the composite flocculating agent is prepared by the steps of mixing the polyelectrolyte and the Lewis acid at 20-50 DEG C, then reacting for 0.5-4 hours while stirring at 20-50 DEG C, cooling to room temperature and discharging materials, thus obtaining the composite flocculating agent. The composite flocculating agent is applicable to an offshore oilfield wastewater treatment system, and is capable of solving the problem of difficult wastewater treatment due to output liquid variation on an offshore oilfield as well as overcoming shortcomings of high agent dosage, poor effect and high traffic volume in the prior art. Therefore, the quality of injected water or discharged seawater achieves the standard; the preparation method of the composite flocculating agent is simple, production steps are reduced and the production cost is lowered.

Owner:中海油(天津)油田化工有限公司 +1

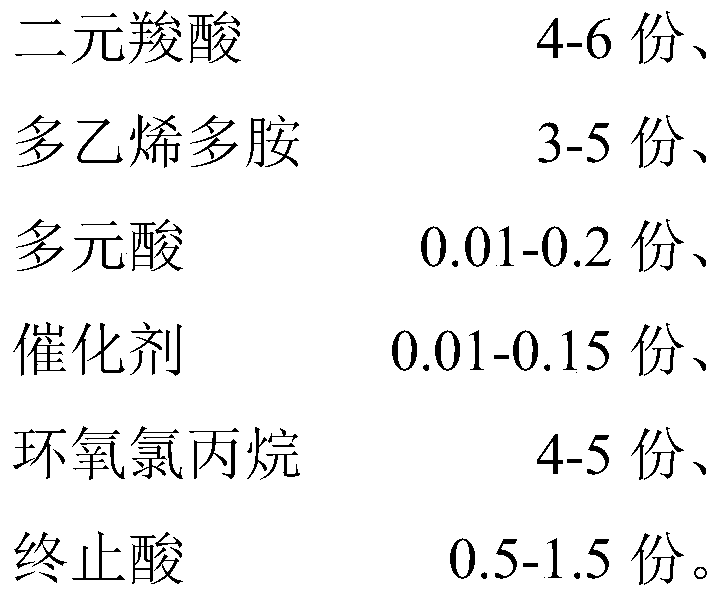

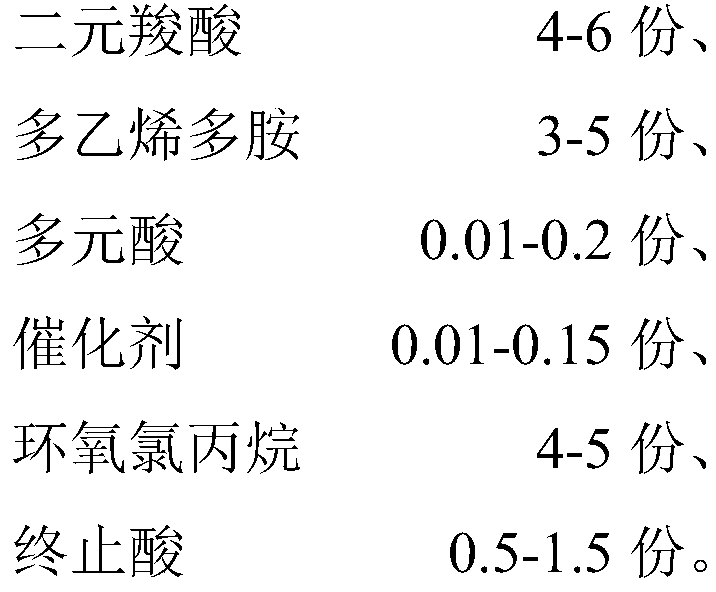

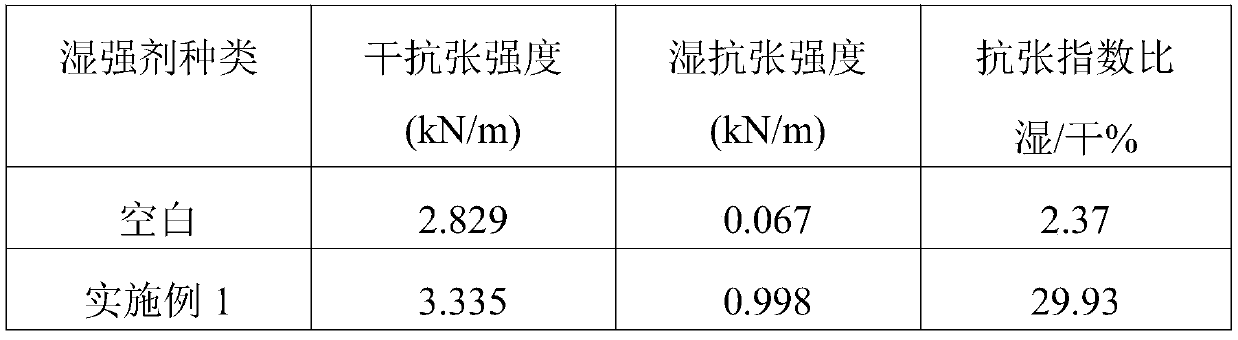

Preparation method and application of branched chain type wet strength agent

ActiveCN111072957AImprove retentionReduce usageReinforcing agents additionPaper/cardboardFiberPolymer science

The invention discloses a preparation method of a branched chain type wet strength agent, which specifically comprises the following steps: adding polybasic acid the weight of which accounts for 0.05-5% of the weight of polyethylene polyamine and which has the functionality of more than or equal to 3 into a polycondensation reaction system of dicarboxylic acid and the polyethylene polyamine for copolymerization, and then adding epoxy chloropropane for modification to obtain the branched chain type wet strength agent. The branched chain type wet strength agent provided by the invention has a highly branched structure and a high cation degree, has a very good retention rate in a use process, and has a use amount less than that of a common wet strength agent. Due to the dendritic structure, the wet strength agent and paper fibers can form a three-dimensional network structure more easily, and the obtained paper has better wet strength and wet strength retention rate.

Owner:SHANGHAI DONGSHENG NEW MATERIALS

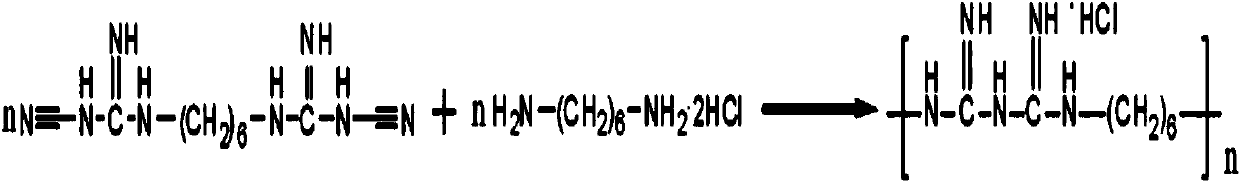

Novel efficient composite guanidyl papermaking bactericide

ActiveCN110074105AImprove effective activityHigh activityBiocidePaper/cardboardPapermakingPotassium hydrogen phthalate

The invention provides a novel efficient composite guanidyl papermaking bactericide, and belongs to the technical field of papermaking bactericide production. The bactericide comprises following components in parts by weight: 10-30 parts of a guanidyl polymer, 5-15 parts of 2-octyl-2H-isothiazol-3-one, 150-450 parts of diethylene glycol, 0.5-1.5 parts of dodecyl dimethyl benzyl ammonium chloride,0.3-1.8 parts of hydroxymethyl cellulose and 0-100 parts of potassium hydrogen phthalate, wherein the guanidyl polymer is polyhexamethylene biguanidine hydrochloride. Polyhexamethylene biguanidine hydrochloride is a broad-spectrum antibacterial product, has killing capacity on Gram-positive bacteria, Gram-negative bacteria, fungi and saccharomycetes and can be used for producing and manufacturingantibacterial paper for health products to replace silver-containing Kuerxin paper, and meanwhile, a polyhexamethylene biguanidine hydrochloride solution also improves physical properties and hygroscopic property of the paper and strength and breathability of the paper stained with water, so that the solution is a papermaking bactericide with excellent performance; the bactericide is one efficientand broad-spectrum composite type TS-302 papermaking bactericide under the synergistic effect of the components.

Owner:甘肃泰升化工科技有限公司

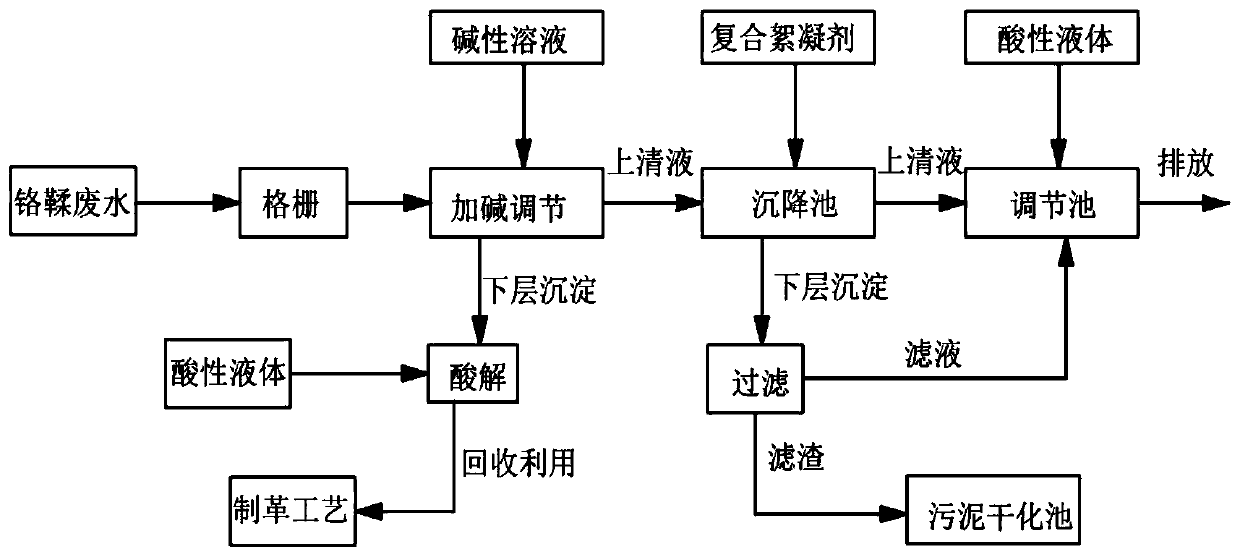

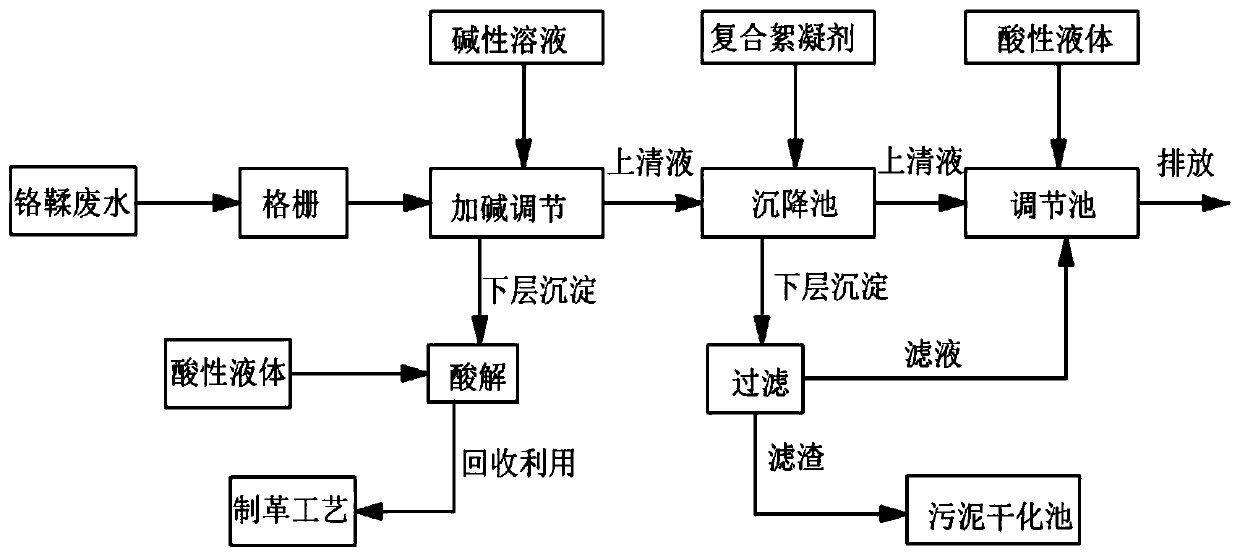

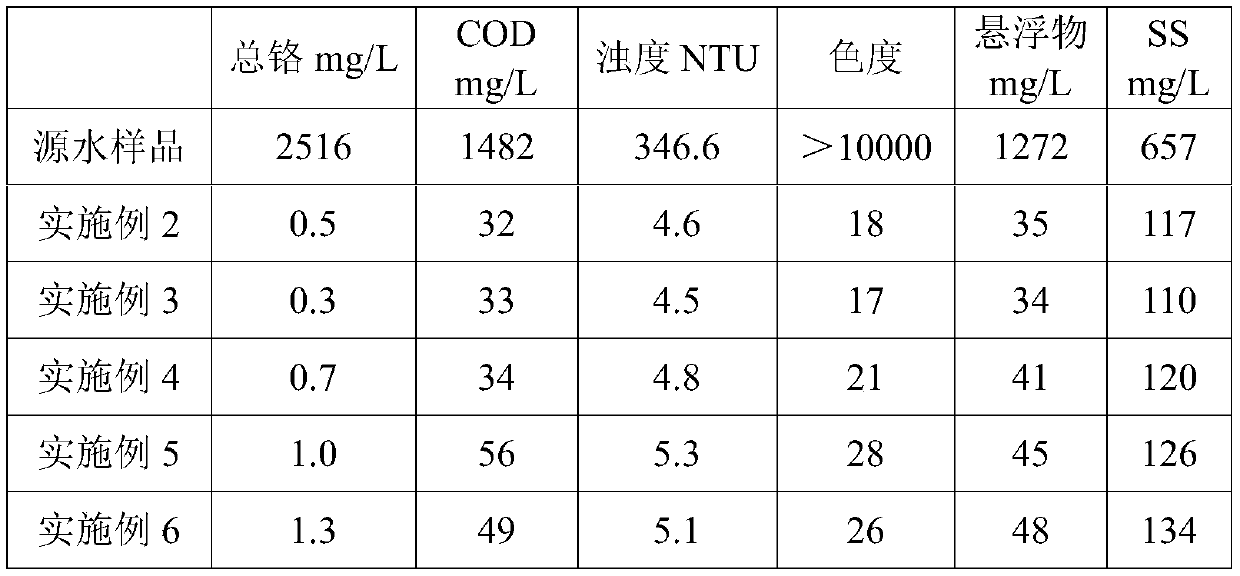

Method for treating chrome tanning wastewater

InactiveCN110002564AHigh cationic degreeHigh intrinsic viscosityOther chemical processesWater contaminantsCross-linkTrapping

The invention provides a method for treating chrome tanning wastewater, and belongs to the technical field of wastewater treatment. The method comprises the steps: performing grid impurity removal, performing adjustment through addition of alkali, performing wastewater sedimentation, and performing adjustment through addition of acid, wherein wastewater sedimentation is performed through a flocculating agent, and the flocculating agent comprises an amphoteric polymer chelating flocculant PDMAMDTC and a chitosan-derived adsorption material; and preparation of the chitosan-derived adsorption material comprises the following steps: dispersing triethylene tetramine and chitosan in an acetic acid solution, then adding a cross-linking agent for a reaction, and then performing washing and drying,and the cross-linking agent contains glutaraldehyde, triethanolamine and 3-mercaptopropionic acid. According to the method for treating the chrome tanning wastewater, a short reaction period of timeis required, the efficiency of decontamination and impurity removal is high, full recycling and utilization of resources are achieved, and the cost of production and treatment is reduced effectively;and the flocculating agent has the advantages of a high degree of reaction completion, low surface energy, high cationic degree, high intrinsic viscosity, large ion adsorption capacity, strong net trapping ability and good performance of flocculation and sedimentation.

Owner:ZHEJIANG OCEAN UNIV

Chemical treatment method for improving red mud settling separation effect

The invention relates to the technical field of red mud settling separation, in particular relates to a chemical treatment method for improving red mud settling separation effect. The treatment methodis characterized by comprising the following steps of: for dissolved red mud with higher iron oxide content, when the content of ferric oxide in the dissolved red mud solid phase is greater than or equal to 20%, a non-ionic settling agent and a synthetic flocculant are combined for treatment; when the content of ferric oxide in the dissolved red mud solid phase is less than 20%, a cationic settling accelerator and a synthetic flocculant are combined for treatment. The chemical treatment method for improving the red mud settling separation effect has the advantages of simple method, high settling efficiency, good settling effect, low treatment cost, improvement of the recovery rate of aluminum oxide and caustic alkali and the like.

Owner:威海汉邦生物环保科技股份有限公司

Spinning technology of blended yarn

The invention discloses a spinning technology of blended yarn. The spinning technology comprises the following steps of 1, modification of cotton fibers; 2, pretreatment of flax fibers; 3, preliminaryprocessing of slivers; 4, drawing and spinning. Compared with the prior art, the spinning technology has the advantages that the modified cotton fibers have a high cationic degree, the adsorption ofthe cotton fibers to dyestuff is greatly improved, and the effect of dyeing cotton yarn is improved; by means of the spinning technology, bamboo fibers, the flax fibers and the cationic cotton fibersare blended to prepare the blended yarn, the prepared yarn integrates the respective advantages of the bamboo fibers, the flax fibers and the cationic cotton fibers, and the obtained blended yarn is high in strength, sizing performance, sizing performance and spinnability, and excellent in moisture absorption and ventilation performance.

Owner:ANHUI ZHAOBAO TEXTILE TECH CO LTD

Method for synthesizing cationic polyacrylamide by using ultraviolet initiated template copolymerization method

The invention relates to a method for synthesizing cationic polyacrylamide by using ultraviolet initiated template copolymerization method. The method comprises the following steps of: adding de-ionized water, an anionic polymer, a cationic monomer and an acrylamide monomer sequentially in a reaction device, stirring uniformly until the components are fully dissolved, so as to form a monomer water solution; adding a proper amount of a solubilizer and an initiator into the monomer water solution, stirring uniformly, adjusting pH (potential of hydrogen) value, charging high pure nitrogen into the reaction device in order to exhaust the air; then sealing the reaction device and putting into an ultraviolet reaction device to initiate the polymerization, so as to generate cationic polyacrylamide colloid; and finally, purifying, washing and refining the colloid, drying in a vacuum drying box and then grinding, thereby obtaining an end product. The method has the advantages that the polymerization initiation time is short, relatively few types of assistants are added and the temperature is not needed to control, thus the production technology can be simplified, the energy consumption can be reduced and the cost can be reduced; and the product synthesized according to the method is concentrated in distribution of cationic groups, is high in cationic degree and molecular weight, is high in purity and is non-toxic and harmless.

Owner:SHENZHEN SHENSHUI WATER RESOURCES CONSULTING CO LTD

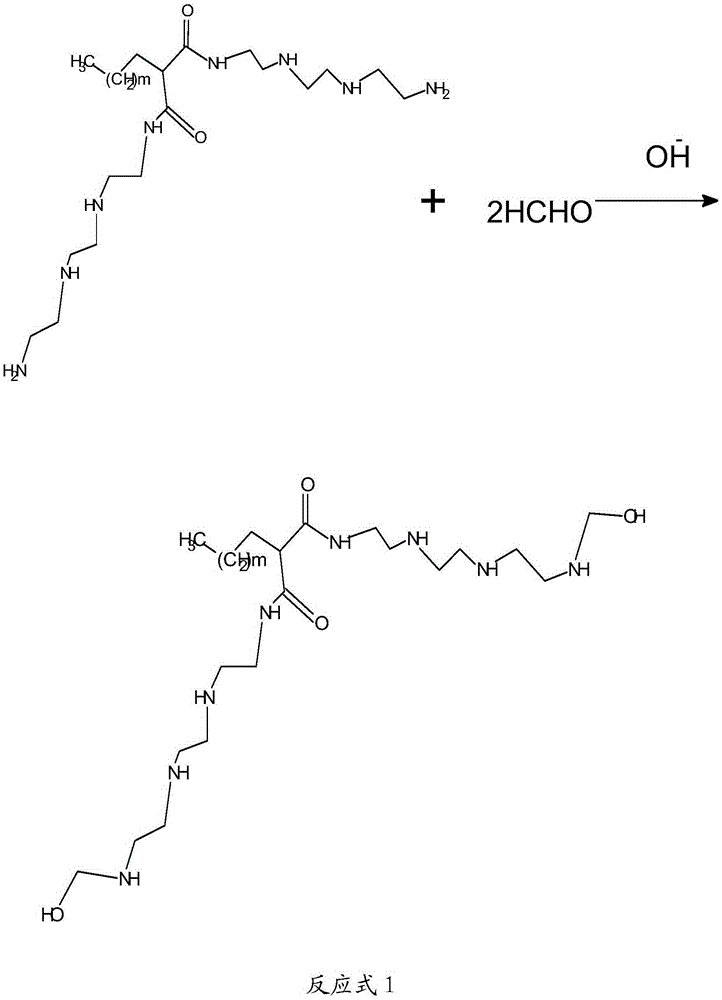

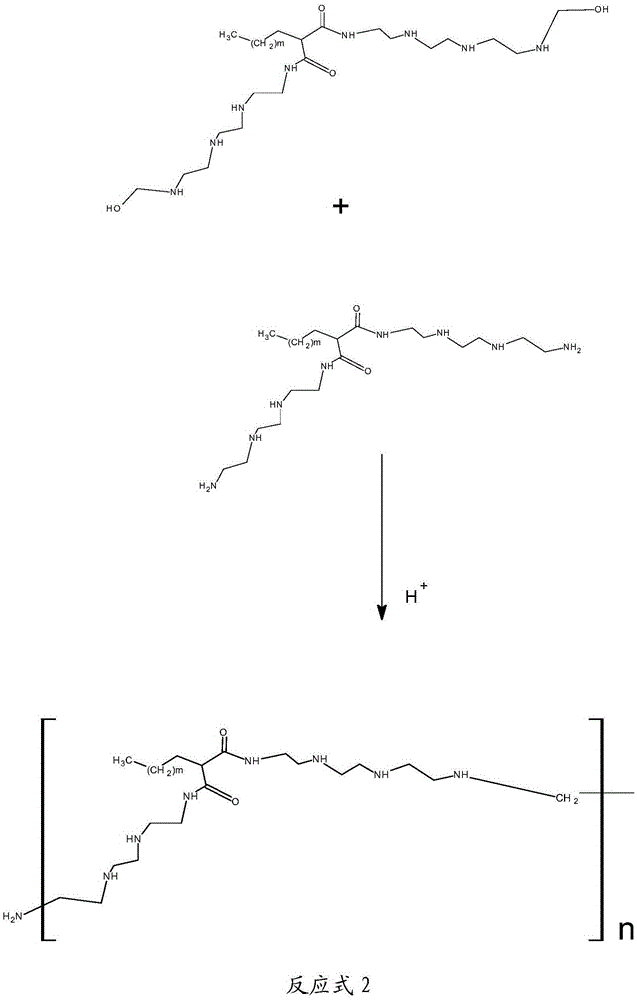

Cationic surfactant and application thereof

ActiveCN105237765AHigh cationic degreeLong storage periodFatty/oily/floating substances removal devicesLiquid separationSURFACTANT BLENDHydroxymethyl

The invention discloses a cationic surfactant which is prepared through the three sequential process steps of metering and mixing, hydroxymethyl reaction and polycondensation reaction. The preparation method specifically comprises the following steps: 400-900 parts by weight of water is added into a reaction kettle, and is heated to a temperature of 55-65 DEG C; the pH value is regulated to 8.5-9.5 with an alkaline substance; 40-120 parts by weight of an alkylamidopolyamine cationic surfactant is added; 70-240 parts by weight of formaldehyde is added; the temperature is increased to 60-85 DEG C, and a reaction is carried out for 40-60min; the pH value is regulated to 2-4 with an acidic substance; the temperature is increased to 85-95 DEG C and a reaction is carried out for 2-4h; and the temperature is maintained and a reaction is carried out for 0.5-1h, such that the cationic surfactant is obtained. The cationic surfactant provided by the invention has the advantages of high cationic degree, large molecular weight, and long storage life. The cationic surfactant has suspension and diffusion property in water, and is miscible with water with any ratio.

Owner:GUANGZHOU ZHENQING ENVIRONMENTAL PROTECTION TECH

Spinning process of multi-fiber blended yarn

InactiveCN108754692AHigh cationic degreeHigh yarn strengthContinuous wound-up machinesDyeing processCardingEngineering

The invention discloses a spinning process of a multi-fiber blended yarn, which comprises the following steps of: (1) cotton fiber modification; (2) selecting a spinning raw material; (3) flower clearing and cotton carding; (4) drawing; (5) spinning. Compared with the prior art, the process has the advantages that the cotton fiber obtained after modification has higher cationic degree, the adsorption of the cotton fiber to the dyestuff is greatly improved, and the dyeing effect of the cotton yarn is improved; the blended yarn obtained by blending the modified cotton fiber, the ramie fiber andthe viscose fiber has the advantages of the three fibers, the blended yarn produced by using vortex spinning has the advantages of less feather, high yarn strength and good strip evenness.

Owner:ANHUI ZHAOBAO TEXTILE TECH CO LTD

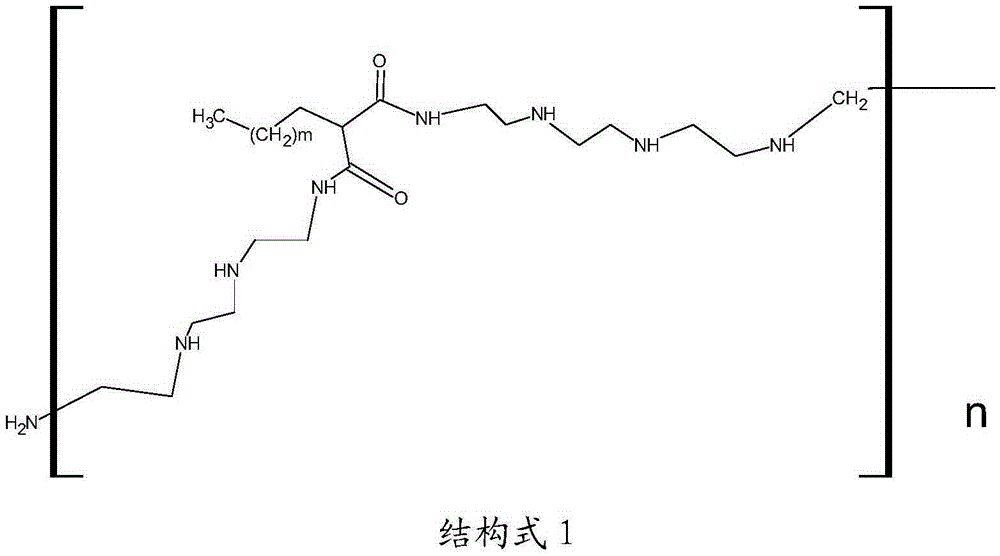

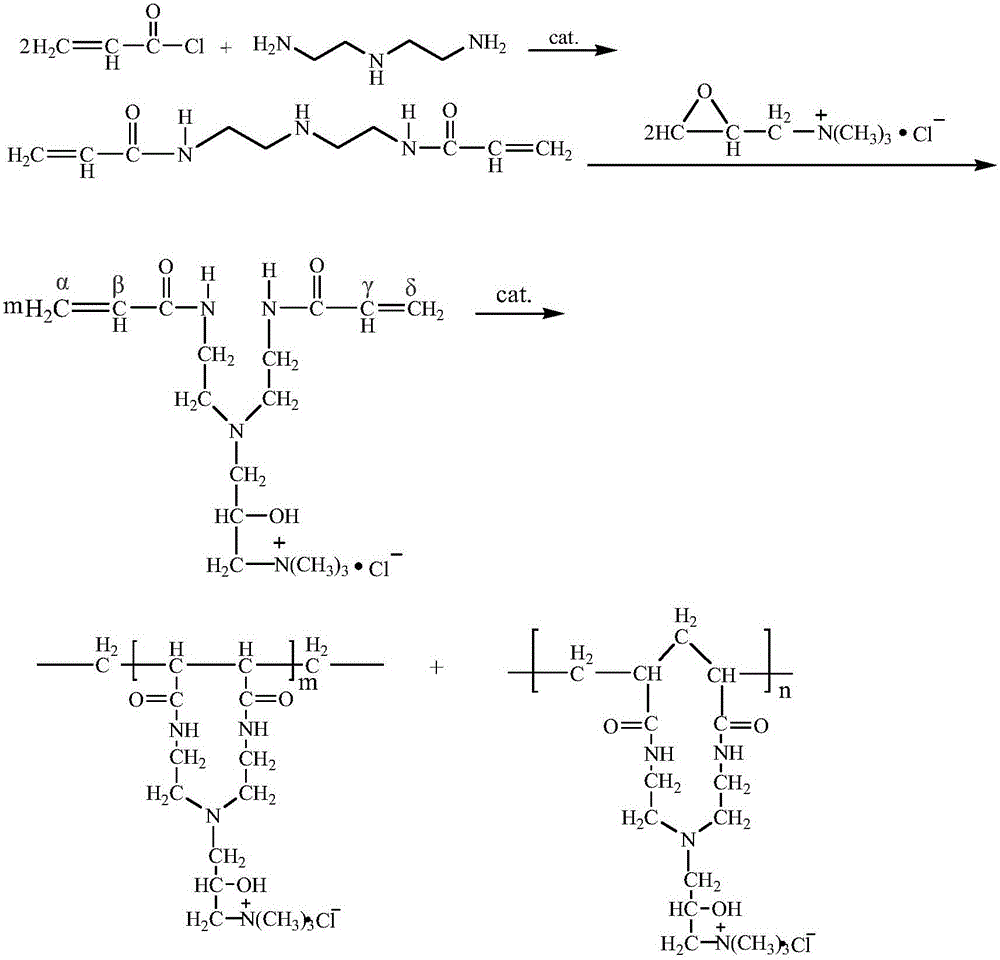

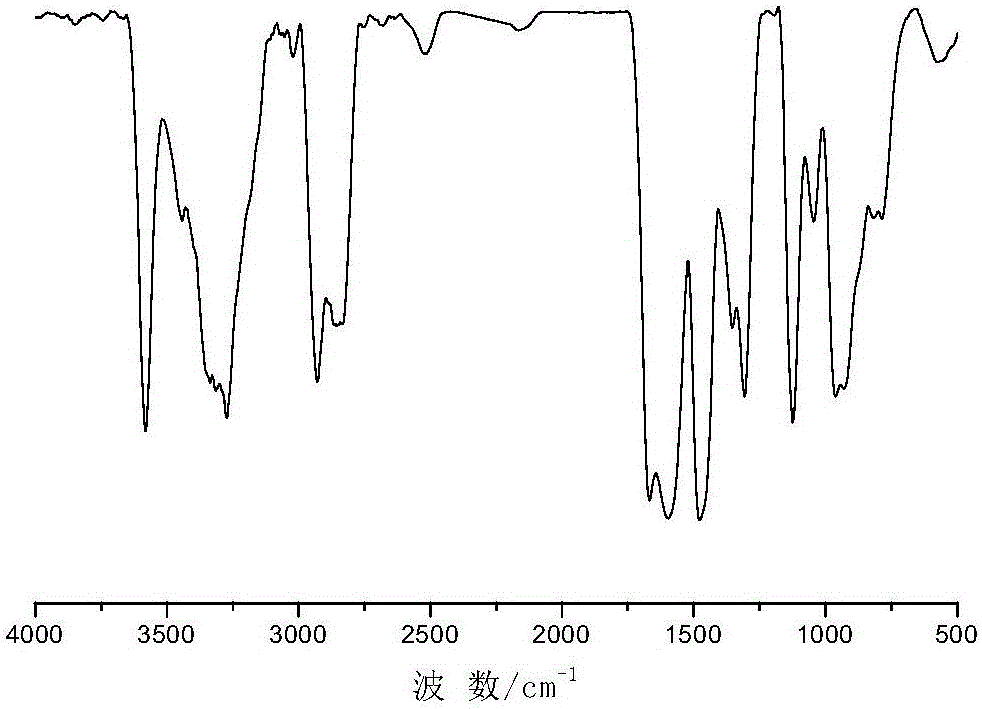

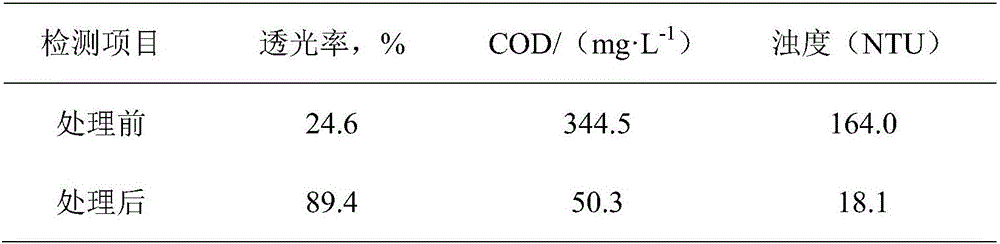

Poly-bisacrylamido cationic compound and preparation method thereof

ActiveCN105820278AHigh cationic degreeGood water solubilityWater/sewage treatment by flocculation/precipitationSolubilityCarbon–oxygen bond

The invention relates to a poly-bisacrylamido cationic compound and a preparation method thereof. The preparation method comprises the following steps: carrying out amidation reaction, chloromethylation reaction, ring-opening reaction and quaterization reaction, preparing two different cationic compounds, and carrying out water solution polymerization to obtain the cationic organic high-molecular polymer. The molecules contain cations, and also contain amido groups, ester groups, carbon-oxygen bonds, large pi bonds and water-soluble hydroxy groups. The cation degree and water solubility of the polymer are greatly enhanced as compared with common cationic compounds. Since the organic matter content in sewage (waste water) is greatly enhanced along with the development of the modern industry and the enhancement of the living standard, the organic matter particle surface is usually negatively charged, and the cationic high-molecular flocculant can perform the electric neutralization and adsorptive bridging functions on particles in water, so that the particles in water are destabilized and flocculated, thereby being beneficial to settling and filter dehydration.

Owner:SHAANXI UNIV OF SCI & TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com