Novel decolorizing agent and preparation method thereof

A decolorizing agent, a new type of technology, applied in the direction of flocculation/sedimentation water/sewage treatment, etc., can solve the problems of small molecular weight, low cationic degree, etc., achieve the effect of simplifying operation procedures, shortening process flow, and saving treatment costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0038] The preparation of embodiment 1 novel decolorizing agent

[0039] 1. Synthesis of component A:

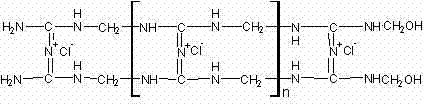

[0040] Add 1.6mol of industrial formaldehyde, 0.3mol of urea, and 1mol of dicyandiamide into a three-necked round-bottomed flask equipped with a serpentine reflux tube, start stirring and heat the system to 50°C, slowly add 0.75mol of ammonium chloride, and the reaction system will automatically heat up React at 85-90°C for 60 minutes, when the temperature of the reaction system drops to 70°C, add the remaining 0.25mol ammonium chloride and react naturally for 30 minutes, then add 0.05mol aluminum trichloride and 0.01mol calcium chloride, and continue the reaction for 30 minutes , that is, to obtain the compound type dicyandiamide formaldehyde condensation polymer of A component.

[0041] 2. Synthesis of component B:

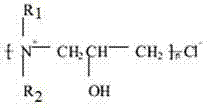

[0042] Add 1.0 mol of epichlorohydrin to the reactor with stirring and heating functions, and evenly add 0.5 mol of diethylenetriamine dropwise under stir...

Embodiment 2

[0045] The preparation of embodiment 2 novel decolorizing agent

[0046] 1. Synthesis of component A:

[0047] Add 1.9mol industrial formaldehyde, 0.5mol urea, and 1mol dicyandiamide to a three-necked round-bottomed flask equipped with a serpentine reflux tube, start stirring and heat the system to 50°C, slowly add 0.9mol ammonium chloride, and the reaction system will automatically heat up React at 85-90°C for 60 minutes, when the temperature of the reaction system drops to 70°C, add the remaining 0.3mol ammonium chloride and react naturally for 30 minutes, then add 0.05mol aluminum trichloride and 0.01mol calcium chloride, and continue the reaction for 30 minutes , that is, to obtain the compound type dicyandiamide formaldehyde condensation polymer of A component.

[0048] 2. Synthesis of component B:

[0049] Add 1.0 mol of epichlorohydrin to the reactor with stirring and heating functions, and evenly add 1.0 mol of diethylenetriamine dropwise under stirring, then dropw...

Embodiment 3

[0052] The preparation of embodiment 3 novel decolorizing agent

[0053] 1. Synthesis of component A:

[0054] Add 2.0mol of industrial formaldehyde, 0.9mol of urea, and 1mol of dicyandiamide into a three-necked round-bottomed flask equipped with a serpentine reflux tube, start stirring and heat the system to 50°C, slowly add 1.125mol of ammonium chloride, and the reaction system will automatically heat up React at 85-90°C for 60 minutes, when the temperature of the reaction system drops to 70°C, add the remaining 0.375mol ammonium chloride and react naturally for 30 minutes, then add 0.05mol aluminum trichloride and 0.01mol calcium chloride, and continue the reaction for 30 minutes , that is, to obtain the compound type dicyandiamide formaldehyde condensation polymer of A component.

[0055] 2. Synthesis of component B:

[0056] Add 1.0 mol of epichlorohydrin to the reactor with stirring and heating functions, and evenly add 0.8 mol of diethylenetriamine dropwise under st...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com